The Comprehensive Effects of Nano Additives on Biodiesel Engines—A Review

Abstract

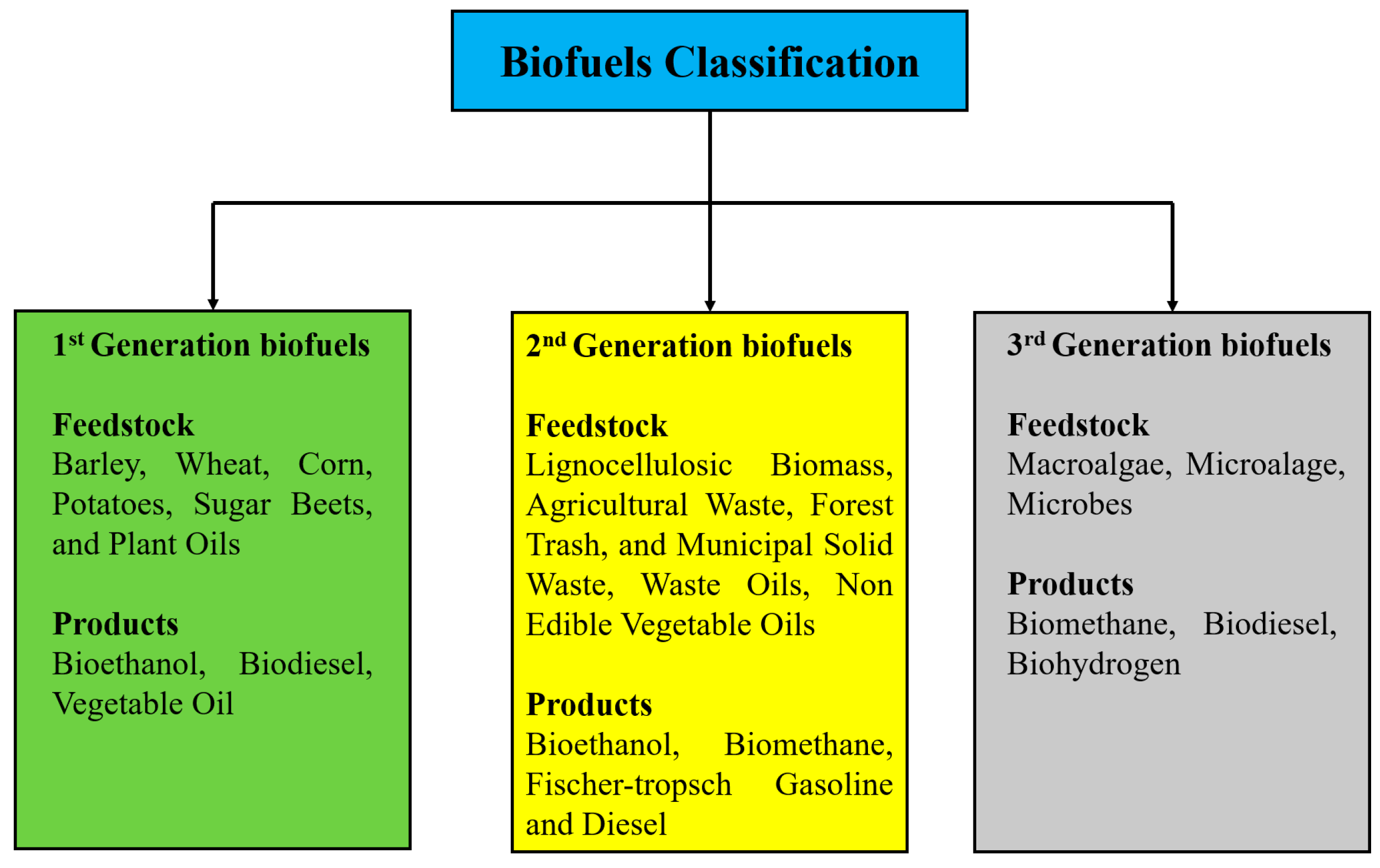

1. Introduction

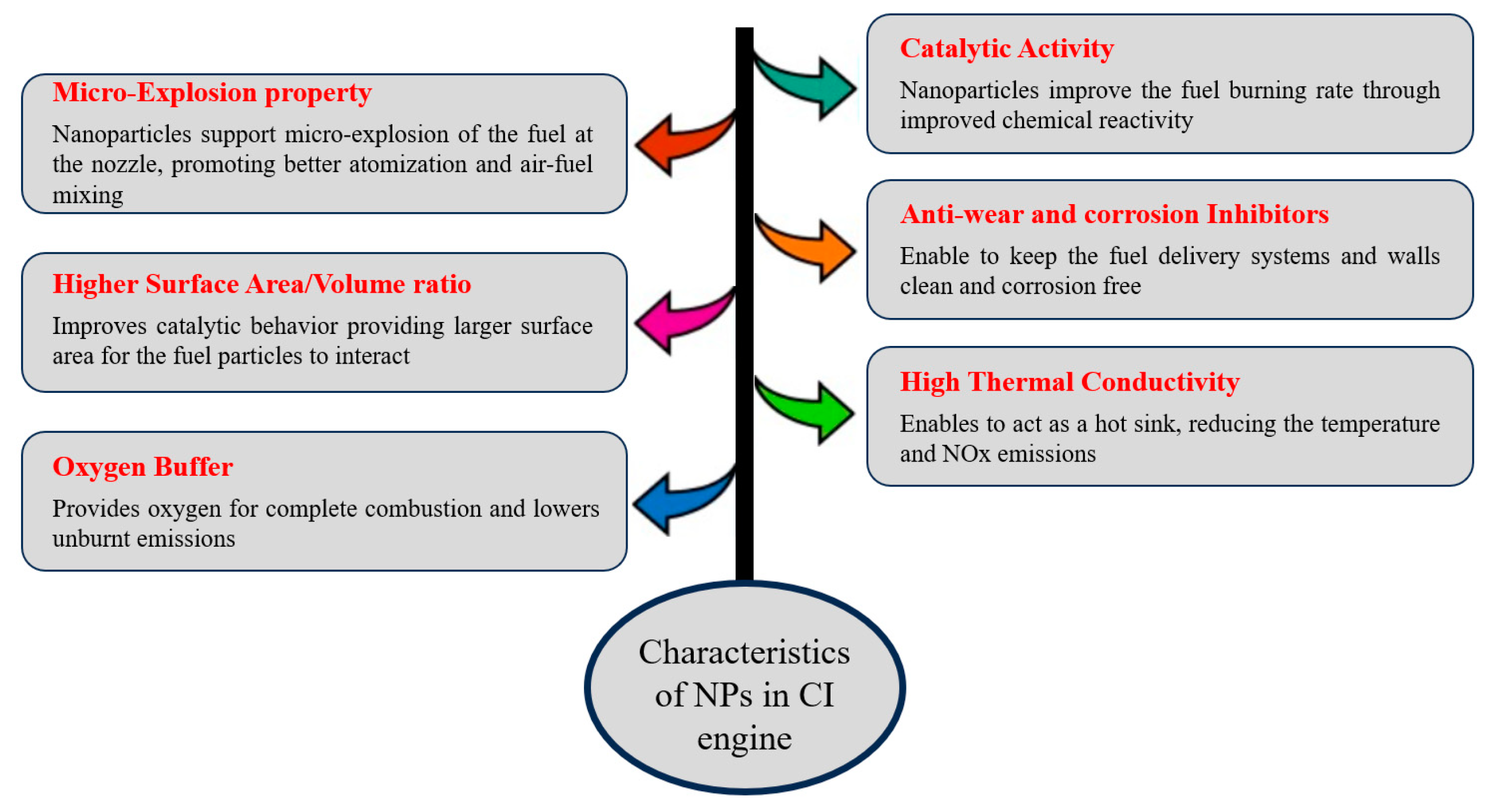

2. The Effect of Nanoparticles on Biodiesel

2.1. The Impact on the Characteristics of Biodiesel

2.2. Application of Nanoparticles in Biodiesel Production

2.3. Preparation of Nanoscale Biofuels

3. Engine Performance

3.1. Cylinder Pressure

3.2. Heat Release Rate (HRR)

3.3. Brake Thermal Efficiency (BTE)

3.4. Brake Specific Fuel Consumption (BSFC)

4. Exhaust Emissions

4.1. Carbon Monoxide (CO)

4.2. Carbon Dioxide (CO2)

4.3. Hydroxide (HC)

4.4. Nitrogen Oxides (NOX)

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ni, P.; Wang, X.; Li, H. A review on regulations, current status, effects and reduction strategies of emissions for marine diesel engines. Fuel 2020, 279, 118477. [Google Scholar] [CrossRef]

- Marmiroli, B.; Venditti, M.; Dotelli, G.; Spessa, E. The transport of goods in the urban environment: A comparative life cycle assessment of electric, compressed natural gas and diesel light-duty vehicles. Appl. Energy 2020, 260, 114236. [Google Scholar]

- Das, A.K.; Sahu, S.K.; Panda, A.K. Current status and prospects of alternate liquid transportation fuels in compression ignition engines: A critical review. Renew. Sustain. Energy Rev. 2022, 161, 112358. [Google Scholar] [CrossRef]

- Inal, O.B.; Zincir, B.; Deniz, C. Investigation on the decarbonization of shipping: An approach to hydrogen and ammonia. Int. J. Hydrogen Energy 2022, 47, 19888–19900. [Google Scholar] [CrossRef]

- Cernat, A.; Pana, C.; Negurescu, N.; Lazaroiu, G.; Nutu, C.; Fuiorescu, D. Hydrogen—An alternative fuel for automotive diesel engines used in transportation. Sustainability 2020, 12, 9321. [Google Scholar] [CrossRef]

- Bashir, M.F.; Bashir, M.A.; Raza, S.A.; Bilan, Y.; Vasa, L. Linking gold prices, fossil fuel costs and energy consumption to assess progress towards sustainable development goals in newly industrialized countries. Geosci. Front. 2024, 15, 101755. [Google Scholar] [CrossRef]

- Cantarero, M.M.V. Of renewable energy, energy democracy, and sustainable development: A roadmap to accelerate the energy transition in developing countries. Energy Res. Soc. Sci. 2020, 70, 101716. [Google Scholar] [CrossRef]

- Esmi, F.; Borugadda, V.B.; Dalai, A.K. Heteropoly acids as supported solid acid catalysts for sustainable biodiesel production using vegetable oils: A review. Catal. Today 2022, 404, 19–34. [Google Scholar] [CrossRef]

- Prabakaran, P.; Karthikeyan, S. Algae biofuel: A futuristic, sustainable, renewable and green fuel for I.C. engines. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Khujamberdiev, R.; Cho, H.M. Exploring the Environmental and Performance Implications of Utilizing Waste Swine Oil Biodiesel in CI Engines. Energies 2024, 17, 551. [Google Scholar] [CrossRef]

- Toldrá-Reig, F.; Mora, L.; Toldrá, F. Developments in the use of lipase transesterification for biodiesel production from animal fat waste. Appl. Sci. 2020, 10, 5085. [Google Scholar]

- Maheshwari, P.; Haider, M.B.; Yusuf, M.; Klemeš, J.J.; Bokhari, A.; Beg, M.; Al-Othman, A.; Kumar, R.; Jaiswal, A.K. A review on latest trends in cleaner biodiesel production: Role of feedstock, production methods, and catalysts. J. Clean. Prod. 2022, 355, 131588. [Google Scholar] [CrossRef]

- Mathew, G.M.; Raina, D.; Narisetty, V.; Kumar, V.; Saran, S.; Pugazhendi, A.; Sindhu, R.; Pandey, A.; Binod, P. Recent advances in biodiesel production: Challenges and solutions. Sci. Total Environ. 2021, 794, 148751. [Google Scholar] [CrossRef]

- Osorio-González, C.S.; Gómez-Falcon, N.; Sandoval-Salas, F.; Saini, R.; Brar, S.K.; Ramírez, A.A. Production of biodiesel from castor oil: A review. Energies 2020, 13, 2467. [Google Scholar] [CrossRef]

- You, X.; Yang, L.; Zhou, X.; Zhang, Y. Sustainability and carbon neutrality trends for microalgae-based wastewater treatment: A review. Environ. Res. 2022, 209, 112860. [Google Scholar] [CrossRef] [PubMed]

- Fu, J.; Li, P.; Lin, Y.; Du, H.; Liu, H.; Zhu, W.; Ren, H. Fight for carbon neutrality with state-of-the-art negative carbon emission technologies. Eco-Environ. Health 2022, 1, 259–279. [Google Scholar] [CrossRef]

- Srivastava, R.K.; Shetti, N.P.; Reddy, K.R.; Kwon, E.E.; Nadagouda, M.N.; Aminabhavi, T.M. Biomass utilization and production of biofuels from carbon neutral materials. Environ. Pollut. 2021, 276, 116731. [Google Scholar] [CrossRef] [PubMed]

- Supriyanto, E.; Sentanuhady, J.; Dwiputra, A.; Permana, A.; Muflikhun, M.A. The recent progress of natural sources and manufacturing process of biodiesel: A review. Sustainability 2021, 13, 5599. [Google Scholar] [CrossRef]

- Singh, D.; Sharma, D.; Soni, S.L.; Sharma, S.; Sharma, P.K.; Jhalani, A. A review on feedstocks, production processes, and yield for different generations of biodiesel. Fuel 2020, 262, 116553. [Google Scholar] [CrossRef]

- Khujamberdiev, R.; Cho, H. Impact of Biodiesel Blending on Emission Characteristics of One-Cylinder Engine Using Waste Swine Oil. Energies 2023, 16, 5489. [Google Scholar] [CrossRef]

- Mandari, V.; Devarai, S.K. Biodiesel Production Using Homogeneous, Heterogeneous, and Enzyme Catalysts via Transesterification and Esterification Reactions: A Critical Review. BioEnergy Res. 2022, 15, 935–961. [Google Scholar] [CrossRef]

- Ferrero, G.O.; Faba, E.M.S.; Rickert, A.A.; Eimer, G.A. Alternatives to rethink tomorrow: Biodiesel production from residual and non-edible oils using biocatalyst technology. Renew. Energy 2020, 150, 128–135. [Google Scholar] [CrossRef]

- Bashir, M.A.; Wu, S.; Zhu, J.; Krosuri, A.; Khan, M.U.; Aka, R.J.N. Recent development of advanced processing technologies for biodiesel production: A critical review. Fuel Process. Technol. 2022, 227, 107120. [Google Scholar] [CrossRef]

- Sia, C.B.; Kansedo, J.; Tan, Y.H.; Lee, K.T. Evaluation on biodiesel cold flow properties, oxidative stability and enhancement strategies: A review. Biocatal. Agric. Biotechnol. 2020, 24, 101514. [Google Scholar] [CrossRef]

- Adekunle, A.S.; Oyekunle, J.A.O.; Oduwale, A.I.; Owootomo, Y.; Obisesan, O.R.; Elugoke, S.E.; Durodola, S.S.; Akintunde, S.B.; Oluwafemi, O.S. Biodiesel potential of used vegetable oils transesterified with biological catalysts. Energy Rep. 2020, 6, 2861–2871. [Google Scholar] [CrossRef]

- Sreeharsha, R.V.; Dubey, N.; Mohan, S.V. Orienting biodiesel production towards sustainability and circularity by tailoring the feedstock and processes. J. Clean. Prod. 2023, 414, 137526. [Google Scholar] [CrossRef]

- Jin, C.; Wei, J.; Chen, B.; Li, X.; Ying, D.; Gong, L.; Fang, W. Effect of nanoparticles on diesel engines driven by biodiesel and its blends: A review of 10 years of research. Energy Convers. Manag. 2023, 291, 117276. [Google Scholar] [CrossRef]

- Udayakumar, M.; Sivaganesan, S.; Sivamani, S. Performance and emissions of lemon peel oil biodiesel powered single cylinder direct injection diesel engine loaded with ceria nanoparticles additives and stabilized zirconia coating. Mater. Today Proc. 2022, 66 Pt 4, 1994–2000. [Google Scholar] [CrossRef]

- Ooi, J.B.; Chan, X.L.; Jaliliantabar, F.; Tan, B.T.; Wang, X.; Song, C.P.; Chiong, M.-C.; Hung, Y.M. Experimental study of quaternary blends with diesel/palm-oil biodiesel/ethanol/diethyl ether for optimum performance and emissions in a light-duty diesel engine using response surface methodology. Energy 2024, 301, 131782. [Google Scholar] [CrossRef]

- Jain, A.; Bora, B.J.; Kumar, R.; Sharma, P.; Barik, D.; Balasubramanian, D.; Ramegowda, R.; JS, F.J.; Varuvel, E.G.; Le, D.T.N.; et al. Impact of the operational parameters of a dual fuel engine operating on a blend of Water Hyacinth biodiesel and Mesua ferrea biodiesel with hydrogen–A clean development mechanism. Int. J. Hydrogen Energy 2024, 66, 689–702. [Google Scholar] [CrossRef]

- Muninathan, K.; Ramanan, M.V.; Monish, N.; Baskar, G. Economic analysis and TOPSIS approach to optimize the CI engine characteristics using span 80 mixed carbon nanotubes emulsified Sapindus trifoliatus (soapnut) biodiesel by artificial neural network prediction model. Appl. Energy 2024, 355, 122309. [Google Scholar] [CrossRef]

- Ahmad, A.; Yadav, A.K.; Singh, A.; Singh, D.K. A machine learning-response surface optimization approach to enhance the performance of diesel engine using novel blends of Aloe vera biodiesel with MWCNT nanoparticles and hydrogen. Process Saf. Environ. Prot. 2024, 186, 738–755. [Google Scholar] [CrossRef]

- Garugubilli, R.; Prasad, V.V.S.; Sagari, J. Experimental investigation on diesel engine operating with CuO nanoparticles dispersed Azadirachta indica biodiesel. Int. J. Thermofluids 2024, 22, 100641. [Google Scholar] [CrossRef]

- Haq, M.U.; Jafry, A.T.; Ali, M.; Ajab, H.; Abbas, N.; Sajjad, U.; Hamid, K. Influence of nano additives on Diesel-Biodiesel fuel blends in diesel engine: A spray, performance, and emissions study. Energy Convers. Manag. X 2024, 23, 100574. [Google Scholar]

- Ganesh, D.; Gowrishankar, G. Effect of nano-fuel additive on emission reduction in a biodiesel fuelled CI engine. In Proceedings of the 2011 International Conference on Electrical and Control Engineering, Yichang, China, 16–18 September 2011; IEEE: New York, NY, USA, 2011; pp. 3453–3459. [Google Scholar]

- Puchakayala, H.C.; Viswanathan, A.; Abrar, I.; Rajamohan, N. Maximizing the potential of biodiesel through nanoparticle assistance: A review of key factors affecting performance and emissions. Sustain. Energy Technol. Assess. 2023, 60, 103539. [Google Scholar] [CrossRef]

- Hoang, A.T. Combustion behavior, performance and emission characteristics of diesel engine fuelled with biodiesel containing cerium oxide nanoparticles: A review. Fuel Process. Technol. 2021, 218, 106840. [Google Scholar] [CrossRef]

- Soudagar, M.E.M.; Shelare, S.; Marghade, D.; Belkhode, P.; Nur-E-Alam, M.; Kiong, T.S.; Ramesh, S.; Rajabi, A.; Venu, H.; Khan, T.M.Y.; et al. Optimizing IC engine efficiency: A comprehensive review on biodiesel, nanofluid, and the role of artificial intelligence and machine learning. Energy Convers. Manag. 2024, 307, 118337. [Google Scholar] [CrossRef]

- Hosseinzadeh-Bandbafha, H.; Panahi, H.K.S.; Dehhaghi, M.; Orooji, Y.; Shahbeik, H.; Mahian, O.; Karimi-Maleh, H.; Kalam, M.A.; Jouzani, G.S.; Mei, C.; et al. Applications of nanotechnology in biodiesel combustion and post-combustion stages. Renew. Sustain. Energy Rev. 2023, 182, 113414. [Google Scholar] [CrossRef]

- Heidari-Maleni, A.; Gundoshmian, T.M.; Karimi, B.; Jahanbakhshi, A.; Ghobadian, B. A novel fuel based on biocompatible nanoparticles and ethanol-biodiesel blends to improve diesel engines performance and reduce exhaust emissions. Fuel 2020, 276, 118079. [Google Scholar] [CrossRef]

- Mohan, S.; Dinesha, P.; Aiswarya, V. Synergetic influence of hydrogen peroxide emulsification and MWCNT nanoparticles to reduce engine exhaust emissions using B20 biodiesel blend. Int. J. Hydrogen Energy 2022, 47, 21863–21877. [Google Scholar] [CrossRef]

- Wang, J.; Sun, H.; Devanesan, S.; Alsahi, M.S.; Anderson, A.; Daniel, F.; Praveenkumar, T.R. Performance and emission characteristics of safflower oil biodiesel blended with nanoparticles and hydrogen on diesel engines of road and bridge machinery. Fuel 2023, 352, 128946. [Google Scholar] [CrossRef]

- Kunchi, L.R.; Bhatti, S.K.; Lankapalli, S.V.P.; Sagari, J. Effect of multi ferrites nanoparticles added Terminalia bellirica biodiesel on diesel engine: Combustion, performance, and emission studies. Int. J. Thermofluids 2024, 22, 100652. [Google Scholar] [CrossRef]

- Krishnamoorthi, T.; Sampath, S.; Saravanamuthu, M.; Vengadesan, E.; Dillikannan, D. Combined influence of thermal barrier coating and nanoparticle on performance and emissions of DI diesel engine fueled with neat palm oil biodiesel: An experimental, statistical and energy and exergy analysis. Process Saf. Environ. Prot. 2024, 186, 274–288. [Google Scholar] [CrossRef]

- Simhadri, K.; Rao, P.S.; Paswan, M. Improving the combustion and emission performance of a diesel engine with TiO2 nanoparticle blended Mahua biodiesel at different injection pressures. Int. J. Thermofluids 2024, 21, 100563. [Google Scholar] [CrossRef]

- Kari, J.; Vanthala, V.S.P.; Sagari, J. Performance and emission characteristics of a diesel engine fuelled with Mesua ferrea biodiesel with chromium oxide (Cr2O3) nanoparticles: Experimental approach and response surface methodology. Int. J. Thermofluids 2024, 22, 100637. [Google Scholar] [CrossRef]

- Abishek, M.S.; Kachhap, S.; Rajak, U.; Verma, T.N.; Singh, T.S.; Shaik, S.; Cuce, E.; Alwetaishi, M. Alumina and titanium nanoparticles to diesel–Guizotia abyssinica (L.) biodiesel blends on MFVCR engine performance and emissions. Sustain. Energy Technol. Assess. 2024, 61, 103580. [Google Scholar] [CrossRef]

- Lalhriatpuia, S.; Pal, A. Computational optimization of engine performance and emission responses for dual fuel CI engine powered with biogas and Co3O4 nanoparticles doped biodiesel. Fuel 2023, 344, 127892. [Google Scholar] [CrossRef]

- Elwardany, A.E.; Marei, M.N.; Eldrainy, Y.; Ali, R.M.; Ismail, M.; El-kassaby, M.M. Improving performance and emissions characteristics of compression ignition engine: Effect of ferrocene nanoparticles to diesel-biodiesel blend. Fuel 2020, 270, 117574. [Google Scholar] [CrossRef]

- Ağbulut, Ü.; Karagöz, M.; Sarıdemir, S.; Öztürk, A. Impact of various metal-oxide based nanoparticles and biodiesel blends on the combustion, performance, emission, vibration and noise characteristics of a CI engine. Fuel 2020, 270, 11752. [Google Scholar] [CrossRef]

- Opuz, M.; Uyumaz, A.; Babagiray, M.; Solmaz, H.; Calam, A.; Aksoy, F. The effects of metallic fuel addition into canola oil biodiesel on combustion, engine performance and exhaust emissions. J. Energy Inst. 2023, 111, 101390. [Google Scholar] [CrossRef]

- Rastogi, P.M.; Sharma, A.; Kumar, N. Effect of CuO nanoparticles concentration on the performance and emission characteristics of the diesel engine running on jojoba (Simmondsia chinensis) biodiesel. Fuel 2021, 286 Pt 1, 119358. [Google Scholar] [CrossRef]

- Jeyakumar, N.; Balasubramanian, D.; Sankaranarayanan, M.; Karuppasamy, K.; Wae-Hayee, M.; Le, V.V.; Tran, V.D.; Hoang, A.T. Using Pithecellobium Dulce seed-derived biodiesel combined with Groundnut shell nanoparticles for diesel engines as a well-advised approach toward sustainable waste-to-energy management. Fuel 2023, 337, 127164. [Google Scholar] [CrossRef]

- Bitire, S.O.; Jen, T.-C. Modulation of the best conditions for improved engine performance and reduced exhaust emissions using an eco-friendly nano additive in parsley biodiesel blend. Environ. Technol. Innov. 2023, 30, 103062. [Google Scholar] [CrossRef]

- Anbarsooz, M. Combustion characteristics of nanofuels: A comprehensive review on diesel/biodiesel-based nanofuels. Fuel 2023, 337, 126834. [Google Scholar] [CrossRef]

- Ağbulut, Ü.; Sarıdemir, S. A general view to converting fossil fuels to cleaner energy source by adding nanoparticles. Int. J. Ambient Energy 2019, 42, 1569–1574. [Google Scholar] [CrossRef]

- Leung, D.Y.C.; Wu, X.; Leung, M.K.H. A review on biodiesel production using catalyzed transesterification. Appl. Energy 2020, 87, 1083–1095. [Google Scholar] [CrossRef]

- Deng, X.; Fang, Z.; Liu, Y.-H.; Yu, C.-L. Production of biodiesel from Jatropha oil catalyzed by nanosized solid basic catalyst. Energy 2021, 36, 777–784. [Google Scholar] [CrossRef]

- Mardhiah, H.H.; Ong, H.C.; Masjuki, H.H.; Lim, S.; Lee, H.V. A review on latest developments and future prospects of heterogeneous catalyst in biodiesel production from non-edible oils. Renew. Sustain. Energy Rev. 2017, 67, 1225–1236. [Google Scholar] [CrossRef]

- Bet-Moushoul, E.; Farhadi, K.; Mansourpanah, Y.; Nikbakht, A.M.; Molaei, R.; Forough, M. Application of CaO-based/Au nanoparticles as heterogeneous nanocatalysts in biodiesel production. Fuel 2016, 164, 119–127. [Google Scholar] [CrossRef]

- Jume, B.H.; Gabris, M.A.; Nodeh, H.R.; Rezania, S.; Cho, J. Biodiesel production from waste cooking oil using a novel heterogeneous catalyst based on graphene oxide doped metal oxide nanoparticles. Renew. Energy 2020, 162, 2182–2189. [Google Scholar] [CrossRef]

- Tangy, A.; Pulidindi, I.N.; Pulidindi, I.N.; Pulidindi, I.N. Strontium Oxide Nanoparticles for Biodiesel Production: Fundamental Insights and Recent Progress. Energy Fuels 2021, 35, 187–200. [Google Scholar] [CrossRef]

- Miri, K.; Riam, A.-M.; Aharon, G. Optimization of bio-diesel production from soybean and wastes of cooked oil: Combining dielectric microwave irradiation and a SrO catalyst. Bioresour. Technol. 2011, 102, 1073–1078. [Google Scholar]

- Maleki, B.; Talesh, S.S.A. Optimization of ZnO incorporation to αFe2O3 nanoparticles as an efficient catalyst for biodiesel production in a sonoreactor: Application on the CI engine. Renew. Energy 2022, 182, 43–59. [Google Scholar] [CrossRef]

- Changmai, B.; Rano, R.; Vanlalveni, C.; Rokhum, S.L. A novel Citrus sinensis peel ash coated magnetic nanoparticles as an easily recoverable solid catalyst for biodiesel production. Fuel 2021, 286 Pt 2, 119447. [Google Scholar] [CrossRef]

- Rashid, A.B. Utilization of Nanotechnology and Nanomaterials in Biodiesel Production and Property Enhancement. J. Nanomater. 2023, 1, 7054045. [Google Scholar] [CrossRef]

- Mofijur, M.; Ahmed, S.F.; Ahmed, B.; Mehnaz, T.; Mehejabin, F.; Shome, S.; Almomani, F.; Chowdhury, A.A.; Kalam, M.A.; Badruddin, I.A.; et al. Impact of nanoparticle-based fuel additives on biodiesel combustion: An analysis of fuel properties, engine performance, emissions, and combustion characteristics. Energy Convers. Manag. X 2024, 21, 100515. [Google Scholar] [CrossRef]

- Gaur, J.; Kumar, S.; Pal, M.; Kaur, H.; Batoo, K.M.; Momoh, J.O. Current trends: Zinc oxide nanoparticles preparation via chemical and green method for the photocatalytic degradation of various organic dyes. Hybrid Adv. 2024, 5, 100128. [Google Scholar] [CrossRef]

- Almanzalawy, M.S.; Elkady, M.F.; Sanad, A.; Yousef, M.; Elwardany, A.E. Combined effects of ferric oxide nanoparticles and C2–C4 alcohols with diesel/biodiesel blend on diesel engine operating characteristics. Alex. Eng. J. 2024, 103, 38–50. [Google Scholar] [CrossRef]

- de Almeida Campos, L.A.; Neto, A.F.S.; Noronha, M.C.S.; de Lima, M.F.; Cavalcanti, I.M.F.; Santos-Magalhães, N.S. Zein nanoparticles for drug delivery: Preparation methods and biological applications. Int. J. Pharm. 2023, 635, 122754. [Google Scholar] [CrossRef]

- Booramurthy, V.K.; Kasimani, R.; Subramanian, D.; Pandian, S. Production of biodiesel from tannery waste using a stable and recyclable nano-catalyst: An optimization and kinetic study. Fuel 2020, 260, 116373. [Google Scholar] [CrossRef]

- Shchegolkov, A.V.; Shchegolkov, A.V. Synthesis of Carbon Nanotubes Using Microwave Radiation: Technology, Properties, and Structure. Russ. J. Gen. Chem. 2022, 92, 1168–1172. [Google Scholar] [CrossRef]

- Mukherjee, S.; Paria, S. Preparation and Stability of Nanofluids-A Review. IOSR J. Mech. Civ. Eng. 2013, 9, 63–69. [Google Scholar] [CrossRef]

- Jin, C.; Wei, J. The combined effect of water and nanoparticles on diesel engine powered by biodiesel and its blends with diesel: A review. Fuel 2023, 343, 127940. [Google Scholar] [CrossRef]

- Modi, V.; Rampure, P.B.; Babbar, A.; Kumar, R.; Nagaral, M.; Bhowmik, A.; Kumar, R.; Pandey, S.; Hasnain, S.M.M.; Ali, M.M.; et al. Nanoparticle-enhanced biodiesel blends: A comprehensive review on improving engine performance and emissions. Mater. Sci. Energy Technol. 2024, 7, 257–273. [Google Scholar] [CrossRef]

- Devaraj, A.; Nagappan, M.; Yogaraj, D.; Prakash, O.; Rao, Y.A.; Sharma, A. Influence of nano-additives on engine behaviour using diesel-biodiesel blend. Mater. Today Proc. 2022, 62 Pt 4, 2266–2270. [Google Scholar] [CrossRef]

- Soudagar, M.E.M.; Nik-Ghazali, N.-N.; Kalam, M.A.; Badruddin, I.A.; Banapurmath, N.R.; Akram, N. The effect of nano-additives in diesel-biodiesel fuel blends: A comprehensive review on stability, engine performance and emission characteristics. Energy Convers. Manag. 2018, 178, 146–177. [Google Scholar] [CrossRef]

- Mohanrajhu, N.; Sekar, S.; Jayabal, R.; Sureshkumar, R. Screening nano additives for favorable NOx/smoke emissions trade-off in a CRDI diesel engine fueled by industry leather waste fat biodiesel blend. Process Saf. Environ. Prot. 2024, 187, 332–342. [Google Scholar] [CrossRef]

- Lamore, M.T.; Zeleke, D.S.; Kassa, B.Y. A comparative study on the effect of nano-additives on performance and emission characteristics of CI engine run on castor biodiesel blended fuel. Energy Convers. Manag. X 2023, 20, 100493. [Google Scholar]

- Bitire, S.O.; Jen, T.-C. An optimization study on a biosynthesized nano-particle and its effect on the performance-emission characteristics of a diesel engine fueled with parsley biodiesel blend. Energy Rep. 2023, 9, 2185–2200. [Google Scholar] [CrossRef]

- Tomar, M.; Kumar, N. Effect of multi-walled carbon nanotubes and alumina nano-additives in a light duty diesel engine fuelled with schleichera oleosa biodiesel blends. Sustain. Energy Technol. Assess. 2020, 42, 100833. [Google Scholar] [CrossRef]

- Venu, H.; Appavu, P. Al2O3 nano additives blended Polanga biodiesel as a potential alternative fuel for existing unmodified DI diesel engine. Fuel 2020, 279, 118518. [Google Scholar] [CrossRef]

- Murugesan, A.; Avinash, A.; Gunasekaran, E.J.; Murugaganesan, A. Multivariate analysis of nano additives on biodiesel fuelled engine characteristics. Fuel 2020, 275, 117922. [Google Scholar] [CrossRef]

- Prabu, A. Nanoparticles as additive in biodiesel on the working characteristics of a DI diesel engine. Ain Shams Eng. J. 2018, 9, 2343–2349. [Google Scholar] [CrossRef]

- Gad, M.S.; Jayaraj, S. A comparative study on the effect of nano-additives on the performance and emissions of a diesel engine run on Jatropha biodiesel. Fuel 2020, 267, 117168. [Google Scholar] [CrossRef]

- Gavhane, R.S.; Kate, A.M.; Soudagar, M.E.M.; Wakchaure, V.D.; Balgude, S.; Rizwanul Fattah, I.M.; Nik-Ghazali, N.N.; Fayaz, H.; Khan, T.Y.; Mujtaba, M.A.; et al. Influence of silica nano-additives on performance and emission characteristics of Soybean biodiesel fuelled diesel engine. Energies 2021, 14, 1489. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, J.; Zhang, Z.; Zhang, B.; Hu, J.; Zhong, W.; Ye, Y. A comprehensive review of stability enhancement strategies for metal nanoparticle additions to diesel/biodiesel and their methods of reducing pollutant. Process Saf. Environ. Prot. 2024, 183, 1258–1282. [Google Scholar] [CrossRef]

- Fan, L.; Cheng, F.; Zhang, T.; Liu, G.; Yuan, J.; Mao, P. Visible-light photoredox-promoted desilylative allylation of α-silylamines: An efficient route to synthesis of homoallylic amines. Tetrahedron Lett. 2021, 81, 153357. [Google Scholar] [CrossRef]

- Afzal, A.; Nawfal, I.; Mahbubul, I.M.; Kumbar, S.S. An overview on the effect of ultrasonication duration on different properties of nanofluids. J. Therm. Anal. Calorim. 2019, 135, 393–418. [Google Scholar] [CrossRef]

- Kumar, V.; Choudhary, A.K. Prediction of the Performance and emission characteristics of diesel engine using diphenylamine Antioxidant and ceria nanoparticle additives with biodiesel based on machine learning. Energy 2024, 301, 131746. [Google Scholar] [CrossRef]

- El-Adawy, M. Effects of diesel-biodiesel fuel blends doped with zinc oxide nanoparticles on performance and combustion attributes of a diesel engine. Alex. Eng. J. 2023, 80, 269–281. [Google Scholar] [CrossRef]

- Manimaran, S.; Selvakumaran, T.; Alharbi, S.A.; Karthikeyan, L.; Dhanalakshmi, K. Enhancing diesel engine performance and emissions control: The role of RuO2 nanoparticles and ammonia additives with microalgae blends. Fuel 2024, 368, 131662. [Google Scholar] [CrossRef]

- Channappagoudra, M. Effect of copper oxide nanoadditive on diesel engine performance operated with dairy scum biodiesel. Int. J. Ambient Energy 2018, 42, 530–539. [Google Scholar] [CrossRef]

- Jain, A.; Bora, B.J.; Kumar, R.; Sharma, P.; Medhi, B.J.; Farooque, A.A.; Tirth, V.; Senthilkumar, N.; Peyyala, P.K. Impact of titanium dioxide (TiO2) nanoparticles addition in Eichhornia Crassipes biodiesel used to fuel compression ignition engine at variable injection pressure. Case Stud. Therm. Eng. 2023, 49, 103295. [Google Scholar] [CrossRef]

- Sathish, T.; Ağbulut, Ü.; Kumari, V.; Rathinasabapathi, G.; Karthikumar, K.; Jyothi, N.R.; Kandavalli, S.R.; Muni, T.V.; Saravanan, R. Energy recovery from waste animal fats and detailed testing on combustion, performance, and emission analysis of IC engine fueled with their blends enriched with metal oxide nanoparticles. Energy 2023, 284, 129287. [Google Scholar] [CrossRef]

- Brindahdevi, K.; Kim, P.T.; Kumar, M.V.; Govindasamy, C.; Anderson, A.; Gavurová, B. Enhancing emission control and analyzing the performance and combustion attributes of vehicular engines with spirulina microalgae diesel Ce2O3 nanoparticles blends. Environ. Res. 2023, 239 Pt 2, 117370. [Google Scholar] [CrossRef]

- Jegan, C.D.; Selvakumaran, T.; Karthe, M.; Hemachandu, P.; Gopinathan, R.; Sathish, T.; Ağbulut, Ü. Influences of various metal oxide-based nanosized particles-added algae biodiesel on engine characteristics. Energy 2023, 284, 128633. [Google Scholar] [CrossRef]

- Rajpoot, A.S.; Choudhary, T.; Chelladurai, H.; Rajak, U.; Sahu, M.K. Comparison of the effect of CeO2 and CuO2 nanoparticles on performance and emission of a diesel engine fueled with Neochloris oleoabundans algae biodiesel. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Jaikumar, S.; Srinivas, V.; Rajasekhar, M. Influence of dispersant added nanoparticle additives with diesel-biodiesel blend on direct injection compression ignition engine: Combustion, engine performance, and exhaust emissions approach. Energy 2021, 224, 120197. [Google Scholar] [CrossRef]

- Kannan, G.R.; Karvembu, R.; Anand, R. Effect of metal-based additive on performance emission and combustion characteristics of diesel engine fuelled with biodiesel. Appl. Energy 2011, 88, 3694–3703. [Google Scholar] [CrossRef]

- Rajpoot, A.S.; Chelladurai, H.; Choudhary, A.K.; Ambade, B.; Choudhary, T. Thermal and environmental assessment of Botryococcus braunii green biodiesel with nanoparticles using energy-exergy-emission-sustainability (3ES) analysis in a diesel engine. Sustain. Energy Technol. Assess. 2023, 60, 103473. [Google Scholar] [CrossRef]

- Kumar, S.; Dinesha, P.; Rosen, M.A. Effect of injection pressure on the combustion, performance and emission characteristics of a biodiesel engine with cerium oxide nanoparticle additive. Energy 2019, 185, 1163–1173. [Google Scholar] [CrossRef]

- Soudagar, M.E.M.; Nik-Ghazali, N.-N.; Kalam, M.A.; Badruddin, I.A.; Banapurmath, N.R.; Khan, T.M.Y.; Bashir, M.N.; Akram, N.; Farade, R.; Afzal, A. The effects of graphene oxide nanoparticle additive stably dispersed in dairy scum oil biodiesel-diesel fuel blend on CI engine: Performance, emission and combustion characteristics. Fuel 2019, 257, 116015. [Google Scholar] [CrossRef]

- Singh, A.K.; Pali, H.S.; Khan, M.M. Response surface optimization approach to enhance the performance of diesel engine using ternary blends of biobutanol and biodiesel doped with ZnO nanoparticles. Energy Convers. Manag. 2024, 300, 117899. [Google Scholar] [CrossRef]

- Meenakshi, V.; Devi, P.B.; Al Obaid, S. Exploring the relationship between fuel injection pressure and nanoparticle additives on the combustion, performance and emission characteristics of diesel engine fueled with animal waste-based blends. Fuel 2024, 372, 132065. [Google Scholar] [CrossRef]

- Liang, X.; Ji, H.; Ali, E.; Marzouki, R. Ultrasonic-assisted biodiesel generation from waste chicken fat utilizing a novel and reusable Ce-doped Fe2O3 nanocatalyst: Optimization by CCD, kinetics, and nano-additive on emissions and performance of a diesel engine. Process Saf. Environ. Prot. 2024, 184, 834–853. [Google Scholar] [CrossRef]

- Chetia, B.; Debbarma, S.; Das, B. An experimental investigation of hydrogen-enriched and nanoparticle blended waste cooking biodiesel on diesel engine. Int. J. Hydrogen Energy 2024, 49 Pt B, 23–37. [Google Scholar] [CrossRef]

- Maleki, B.; Venkatesh, Y.K.; Esmaeili, H.; Haddadi, M.; Prakash, R.M.; Balakrishna, G.R. Novel Co3O4 decorated with rGO nanocatalyst to boost microwave-assisted biodiesel production and as nano-additive to enhance the performance-emission characteristics of diesel engine. Energy 2024, 289, 129944. [Google Scholar] [CrossRef]

- Birhanu, T.T.; Zeleke, D.S. Evaluating the effect of diethyl ether and moringa oleifera antioxidant additives on the performance and emission characteristics of jatropha biodiesel-diesel blended fuel on CI engine—An experimental investigation. Heliyon 2024, 10, e31436. [Google Scholar] [CrossRef]

- Uslu, S.; Maki, D.F.; Salam Khaleel Al-Gburi, A. Investigation of nanoparticle (Fe3O4) addition to 3rd generation biodiesel (spirulina microalgae)/diesel mixture as an innovative fuel according to different engine variables: An RSM optimization. Energy Convers. Manag. 2024, 310, 118481. [Google Scholar] [CrossRef]

- Sathish, T.; Ağbulut, Ü.; Ubaidullah, M.; Saravanan, R.; Giri, J.; Shaikh, S.F. Waste to fuel: A detailed combustion, performance, and emission characteristics of a CI engine fuelled with sustainable fish waste management augmentation with alcohols and nanoparticles. Energy 2024, 299, 131412. [Google Scholar] [CrossRef]

- Mujtaba, M.A.; Kalam, M.A.; Masjuki, H.H.; Gul, M.; Soudagar, M.E.M.; Ong, H.C.; Ahmed, W.; Atabani, A.E.; Razzaq, L.; Yusoff, M. Comparative study of nanoparticles and alcoholic fuel additives-biodiesel-diesel blend for performance and emission improvements. Fuel 2020, 279, 118434. [Google Scholar] [CrossRef]

- Ooi, J.B.; Kau, C.C.; Manoharan, D.N.; Wang, X.; Tran, M.-V.; Hung, Y.M. Effects of multi-walled carbon nanotubes on the combustion, performance, and emission characteristics of a single-cylinder diesel engine fueled with palm-oil biodiesel-diesel blend. Energy 2023, 281, 128350. [Google Scholar] [CrossRef]

- Manimaran, S.; Athimoolam, A.; Albeshr, M.F.; Praveenkumar, T.R.; Beata, G. Effects of nano-additives and ammonia on performance and emission characteristics of diesel engine fueled with Aleurites moluccanus. Fuel 2024, 363, 130787. [Google Scholar] [CrossRef]

- Kumar, S.S.; Rajan, K.; Mohanavel, V.; Ravichandran, M.; Rajendran, P.; Rashedi, A.; Sharma, A.; Khan, S.A.; Afzal, A. Combustion, performance, and emission behaviors of biodiesel fueled diesel engine with the impact of alumina nanoparticle as an additive. Sustainability 2021, 13, 12103. [Google Scholar] [CrossRef]

- Bitire, S.O.; Jen, T.-C. The role of a novel green synthesized nanoparticles added parsley biodiesel blend on the performance-emission characteristics of a diesel engine. S. Afr. J. Chem. Eng. 2022, 41, 161–175. [Google Scholar] [CrossRef]

- Örs, I.; Sarıkoç, S.; Atabani, A.E.; Ünalan, S.; Akansu, S.O. The effects on performance, combustion and emission characteristics of DICI engine fuelled with TiO2 nanoparticles addition in diesel/biodiesel/n-butanol blends. Fuel 2018, 234, 177–188. [Google Scholar] [CrossRef]

- Allami, H.A.; Nayebzadeh, H. The assessment of the engine performance and emissions of a diesel engine fueled by biodiesel produced using different types of catalyst. Fuel 2021, 305, 121525. [Google Scholar] [CrossRef]

- Soudagar, M.E.M.; Nik-Ghazali, N.N.; Kalam, M.A.; Badruddin, I.A.; Banapurmath, N.R.; Ali, M.A.B.; Kamangar, S.; Cho, H.M.; Akram, N. An investigation on the influence of aluminium oxide nano-additive and honge oil methyl ester on engine performance, combustion and emission characteristics. Renew. Energy 2020, 146, 2291–2307. [Google Scholar] [CrossRef]

- Khan, O.; Khan, M.Z.; Bhatt, B.K.; Alam, M.T.; Tripathi, M. Multi-objective optimization of diesel engine performance, vibration and emission parameters employing blends of biodiesel, hydrogen and cerium oxide nanoparticles with the aid of response surface methodology approach. Int. J. Hydrogen Energy 2023, 48, 21513–21529. [Google Scholar] [CrossRef]

- Heidari-Maleni, A.; Mesri-Gundoshmian, T.; Jahanbakhshi, A.; Karimi, B.; Ghobadian, B. Novel environmentally friendly fuel: The effect of adding graphene quantum dot (GQD) nanoparticles with ethanol-biodiesel blends on the performance and emission characteristics of a diesel engine. NanoImpact 2021, 21, 100294. [Google Scholar] [CrossRef]

- Kumar, S.; Dinesha, P.; Bran, I. Influence of nanoparticles on the performance and emission characteristics of a biodiesel fuelled engine: An experimental analysis. Energy 2017, 140 Pt 1, 98–105. [Google Scholar] [CrossRef]

- Venu, H.; Madhavan, V. Effect of Al2O3 nanoparticles in biodiesel-diesel-ethanol blends at various injection strategies: Performance, combustion and emission characteristics. Fuel 2016, 186, 176–189. [Google Scholar] [CrossRef]

| Biofuel Type | Blend Type | Density (kg/m3) | Kinematic Viscosity (cSt) | Calorific Value (MJ/kg) | Cetane Number | Flash Point (°C) | Ref. |

|---|---|---|---|---|---|---|---|

| Terminalia bellirica biodiesel | B20 (20% biodiesel + 100% diesel) | 872.6 | 4.22 | 40.319 | 62 | 142 | [43] |

| +50 ppm BZnFMO | 875.3 | 4.28 | 40.858 | 62 | 140 | ||

| +75 ppm BZnFMO | 877.7 | 4.32 | 41.065 | 62 | 138 | ||

| Palm oil biodiesel | B100 | 883.3 | 4.3 | 39.6 | 52 | 140 | [44] |

| +45 ppm CeO2 | 891 | 4.41 | 40.95 | 57 | 122 | ||

| Mahua oil biodiesel | B20 | 850 | 2.62 | 41.114 | / | 43 | [45] |

| +25 ppm TiO2 | 852 | 2.7 | 41.168 | / | 40 | ||

| +100 ppm TiO2 | 858 | 2.74 | 41.283 | / | 41 | ||

| Mesua ferrea biodiesel | B20 | 872 | 3.5 | 39.66 | 58 | 152 | [46] |

| +60 ppm Cr2O3 | 876 | 3.61 | 40.34 | 60 | 147 | ||

| +100 ppm Cr2O3 | 882 | 3.73 | 40.93 | 61 | 138 | ||

| Guizotia abyssinica (L.) biodiesel | B10 | 820.1 | 3.21 | 43.0 | 46 | 75 | [47] |

| +100 ppm AI2O3 | 834 | 2.91 | 45.0 | 53 | 79 | ||

| +100 ppm TiO2 | 844 | 2.98 | 44.3 | 52 | 81 | ||

| Raw linseed oil biodiesel | B20 | 834.2 | 3.36 | 40.03 | 49 | 107 | [48] |

| +50 ppm Co3O4 | 836 | 3.46 | 43.16 | 49.7 | 109 | ||

| +100 ppm Co3O4 | 838 | 3.56 | 43.27 | 50.4 | 110 | ||

| Waste frying oil biodiesel | B30 | 852 | 4.9 | 45.29 | / | 76 | [49] |

| +300 ppm ferrocene | 853 | 4.85 | / | / | 76 | ||

| Waste frying oil biodiesel | B10 | 844.6 | 3.17 | 41.89 | 51.147 | >100 | [50] |

| +100 ppm TiO2 | 844.7 | 3.19 | 42.73 | 52.134 | >100 | ||

| +100 ppm AI2O3 | 844.7 | 3.19 | 43.05 | 51.983 | >100 | ||

| +100 ppm SiO2 | 844.7 | 3.19 | 42.89 | 51.676 | >100 | ||

| Canola oil biodiesel | B20 | 839.25 | 3.214 | / | / | 80 | [51] |

| +50 ppm quantum dots | 840.43 | 3.236 | / | / | 77 | ||

| +100 ppm quantum dots | 840.36 | 3.23 | / | / | 77 | ||

| Jojoba biodiesel | B20 | 845.36 | 3.59 | 41.93 | / | 71 | [52] |

| +25 ppm CuO | 858.15 | 3.68 | 41.22 | / | 66 | ||

| +75 ppm CuO | 871.17 | 3.87 | 41.66 | / | 63 | ||

| Pithecellobium Dulce seed-derived biodiesel | B20 | 838 | 3.22 | 41.9 | 55 | 65 | [53] |

| +100 ppm Groundnut shell nanoparticle | 840 | 3.20 | 42.1 | 54 | 64 | ||

| parsley biodiesel | B20 | 901 | 4.01 | 40.24 | 54.2 | 108 | [54] |

| +50 ppm SiO2 | 907 | 4.08 | 41.38 | 57.2 | 120 | ||

| +100 ppm SiO2 | 918 | 4.14 | 42.53 | 62.8 | 127 |

| Fuel Type | BTE | BSFC | HRR | CP | Ref. |

|---|---|---|---|---|---|

| B30 + 100 ppm DPA | ↑ 2.42% than B30 | ↓ 2.54% than B30 | / | / | [90] |

| B30 + 50 ppm DPA + 50 ppm CeO2 | ↑ 5.74% than B30 | ↓ 6.35% than B30 | / | / | |

| B0 + 50 ppm ZnO | ↑ 4.34% than B0 | ↓ 5.6% than B0 | 24.9 J/deg | ↑ 1.82% than B0 | [91] |

| B20 + 50 ppm ZnO | ↑ 3.28% than B20 | ↓ 6.44% than B20 | 23.88 J/deg | ↑ 0.46% than B20 | |

| B40 + 50 ppm ZnO | / | ↓ 2.5% than B40 | 22.46 J/deg | / | |

| B20 + 50 ppm RuO2 | ↑ 12.5% | ↓ 5.55% than B20 | / | / | [92] |

| B20 + 100 ppm RuO2 | ↑ 18.75% | ↓ 6.7% than B20 | / | / | |

| B20 | 30.55% | 0.3 kg/kWh | 60.78 J/deg | 51.19 bar | [93] |

| B20 + 25 ppm CuO | 30.75% | 0.3 kg/kWh | 61.01 J/deg | 53.34 bar | |

| B20 + 50 ppm CuO | 30.86% | 0.297 kg/kWh | 63.67 J/deg | 53.99 bar | |

| B20 + 75 ppm CuO | 31.26% | 0.295 kg/kWh | 65.37 J/deg | 53.24 bar | |

| B100 | 24.11% | / | / | / | [94] |

| B100 + 50 ppm TiO2 | 24.99% | / | / | ↑ 2.21% than Diesel mode | |

| B100 + 100 ppm TiO2 | 25.77% | / | ↑ 1.5% than Diesel mode | ↑ 5.17% than Diesel mode | |

| B100 + 150 ppm TiO2 | 26.98% | / | ↑ 4.27% than Diesel mode | ↑ 6.62% than Diesel mode | |

| B20 | 29% | 0.29 g/kWh | 77.3 J/deg | 72.8 bar | [95] |

| B20 + 50 ppm ZnO | 31% | 0.25 g/kWh | 77.9 J/deg | 73.4 bar | |

| B20 + 100 ppm ZnO | 33.1% | 0.22 g/kWh | 78.7 J/deg | 75 bar | |

| B20 + 50 ppm Ce2O3 | ↑ 2.6% than B20 | ↓ 5.9% than B20 | ↑ 1.2% than B20 | ↑ 3.6% than B20 | [96] |

| B40 + 50 ppm Ce2O3 | ↑ 1.1% than B40 | ↓ 3.7% than B40 | / | ↑ 1.3% than B40 | |

| B25 | ↑ 13.9% than diesel | ↓ 14.75% than diesel | ↑ 5.7% than diesel | ↑ 3.12% than diesel | [97] |

| B25 + 150 ppm CeO2 | ↑ 68.23% than diesel | ↓ 41.23% than diesel | ↑ 9.8% than diesel | ↑ 5.72% than diesel | |

| B25 + 150 ppm SiO2 | ↑ 49.73% than diesel | ↓ 33.41% than diesel | ↑ 12.6% than diesel | ↑ 18.8% than diesel | |

| B25 + 150 ppm TiO2 | ↑ 32.4% than diesel | ↓ 25.62% than diesel | ↑ 20.2% than diesel | ↑ 23.4% than diesel |

| Fuel Type | CO | HC | CO2 | NOX | Ref. |

|---|---|---|---|---|---|

| B30 + 100 ppm TiO2 | ↓ 12.46% than B30 | ↓ 8.63% than B30 | / | ↑ 1.84% than B30 | [112] |

| B30 + 100 ppm CNT | ↓ 8.5% than B30 | / | / | ↓ 3.92% than B30 | |

| Diesel | 0.064 g/kWh | 45 g/kWh | / | 870 ppm | [92] |

| B20 | 0.06 g/kWh | 40 g/kWh | / | 900 ppm | |

| B20 + 50 ppm RuO2 | 0.054 g/kWh | 38 g/kWh | / | 920 ppm | |

| B20 + 100 ppm RuO2 | 0.05 g/kWh | 34g/kWh | / | 920 ppm | |

| B20 | ↓ 11.12% than diesel | ↓ 5.18% than diesel | / | / | [52] |

| B20 + 25 ppm CuO | ↓ 12.87% than diesel | ↓ 9.39% than diesel | ↑ 1.7% than B20 | ↑ 0.4% than B20 | |

| B20 + 50 ppm CuO | ↓ 13.15% than diesel | ↓ 12.17% than diesel | ↑ 3.4% than B20 | ↑ 0.7% than B20 | |

| B20 + 75 ppm CuO | ↓ 11.5% than diesel | ↓ 7.45% than diesel | ↑ 5.16% than B20 | ↑ 1.8% than B20 | |

| EBD | ↓ 27.36% than diesel | ↓ 11.67% than diesel | ↓ 16.99% than diesel | ↓ 6.86% than diesel | [94] |

| EBD + 50 ppm TiO2 | ↓ 35.85% than diesel | ↓ 24.56% than diesel | ↓ 12.57% than diesel | ↑ 3.05% than diesel | |

| EBD + 100 ppm TiO2 | ↓ 34.9% than diesel | ↓ 27.91% than diesel | ↓ 8.01% than diesel | ↑ 5.55% than diesel | |

| EBD + 150 ppm TiO2 | ↓ 41.19% than diesel | ↓ 31.8% than diesel | ↑ 2.35% than diesel | ↑ 8.06% than diesel | |

| Diesel | / | 0.5 g/kWh | / | 5.02 g/kWh | [95] |

| B20 | / | 0.33 g/kWh | / | 4.52 g/kWh | |

| B20 + 50 ppm ZnO | / | 0.31 g/kWh | / | 3.67 g/kWh | |

| B20 + 100 ppm ZnO | / | 0.29 g/kWh | / | 3.66 g/kWh | |

| B20 + 25 ppm MWCNTs | ↓ 19% than B20 | ↓ 11% than B20 | / | ↑ 21% than B20 | [113] |

| B20 + 50 ppm MWCNTs | ↓ 24.1% than B20 | ↓ 14.8% than B20 | / | ↑ 39.5% than B20 | |

| B20 + 100 ppm MWCNTs | ↓ 7.5% than B20 | ↓ 4.7% than B20 | / | ↑ 13.5% than B20 | |

| Diesel | / | 450 ppm | [114] | ||

| B20 | / | 496 ppm | |||

| B20 + 25 ppm TiO2 | ↓ 3.1% than B20 | ↓ 8.1% than B20 | 452 ppm | ||

| B30 | / | 452 ppm | |||

| B30 + 25 ppm TiO2 | ↓ 5.6% than B30 | ↓ 9.1% than B30 | 426 ppm | ||

| Diesel | 9.1 g/kWh | / | 11.68 g/kWh | 6.2 g/kWh | [97] |

| B25 | 10.8 g/kWh | ↓ 6.23% than diesel | 14.28 g/kWh | / | |

| B25 + 150 ppm CeO2 | 13.2 g/kWh | ↓ 14.3% than diesel | 18.18 g/kWh | 6.09 g/kWh | |

| B25 + 150 ppm SiO2 | 9.5 g/kWh | ↓ 29.25% than diesel | 18.9 g/kWh | 4.29 g/kWh | |

| B25 + 150 ppm TiO2 | 9.1 g/kWh | ↓ 31.89% than diesel | / | 2.87 g/kWh |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, F.; Cho, H.M. The Comprehensive Effects of Nano Additives on Biodiesel Engines—A Review. Energies 2024, 17, 4126. https://doi.org/10.3390/en17164126

Zheng F, Cho HM. The Comprehensive Effects of Nano Additives on Biodiesel Engines—A Review. Energies. 2024; 17(16):4126. https://doi.org/10.3390/en17164126

Chicago/Turabian StyleZheng, Fangyuan, and Haeng Muk Cho. 2024. "The Comprehensive Effects of Nano Additives on Biodiesel Engines—A Review" Energies 17, no. 16: 4126. https://doi.org/10.3390/en17164126

APA StyleZheng, F., & Cho, H. M. (2024). The Comprehensive Effects of Nano Additives on Biodiesel Engines—A Review. Energies, 17(16), 4126. https://doi.org/10.3390/en17164126