A Novel Geothermal Wellbore Model Based on the Drift-Flux Approach

Abstract

1. Introduction

2. Model Formulation

- The gas–liquid mixture flows one-dimensionally along the wellbore;

- We disregard the axial heat conduction within the wellbore;

- We disregard the impact of drill cuttings;

- We consider the impact of the casing and cement sheath on heat transfer;

- We consider the slip relationship between the gas and liquid phases.

2.1. Conservation Equations for Gas–Liquid Two-Phase Flow

2.2. Constitutive Equations

2.2.1. Mixture Equation

2.2.2. Wellbore Friction

2.2.3. Formation–Wellbore Heat Exchange

2.2.4. Slip Model

2.3. Supplementary Equations

2.3.1. Density Equation

2.3.2. Viscosity Equation

3. Numerical Methods

- Initialize the pressure and temperature: First, set the initial pressure and temperature values, then divide the wellbore into grids.

- Calculate the velocity and phase fractions: Use the mass conservation equation and momentum conservation equation to determine the fluid velocities and phase fractions. This step involves calculating the movement properties of the fluids within the wellbore.

- Calculate the temperature: Apply the energy conservation equation to compute the temperature, considering the heat conduction within the wellbore fluids.

- Newton–Raphson iteration: Since the discretized equations form a nonlinear system, use the Newton–Raphson iteration method. Based on the current values of velocity, phase fractions, temperature, and pressure, compute the Jacobian matrix and iterate to solve the nonlinear equations.

- Error and convergence check: Compare the calculated residuals with the convergence criteria. If the error is less than the threshold of 10−6, the solution is considered converged, and the loop can end.

- Update the solution and continue the loop: If the solution has not converged, update the velocity, phase fractions, temperature, and pressure values based on the Newton–Raphson iteration results and error assessment. Then, return to step 1 to continue the iteration process.

- Advance to the next time step: Once the simulation converges, proceed to the next time step and continue simulating the wellbore conditions at the next moment.

3.1. Discretization of Equations

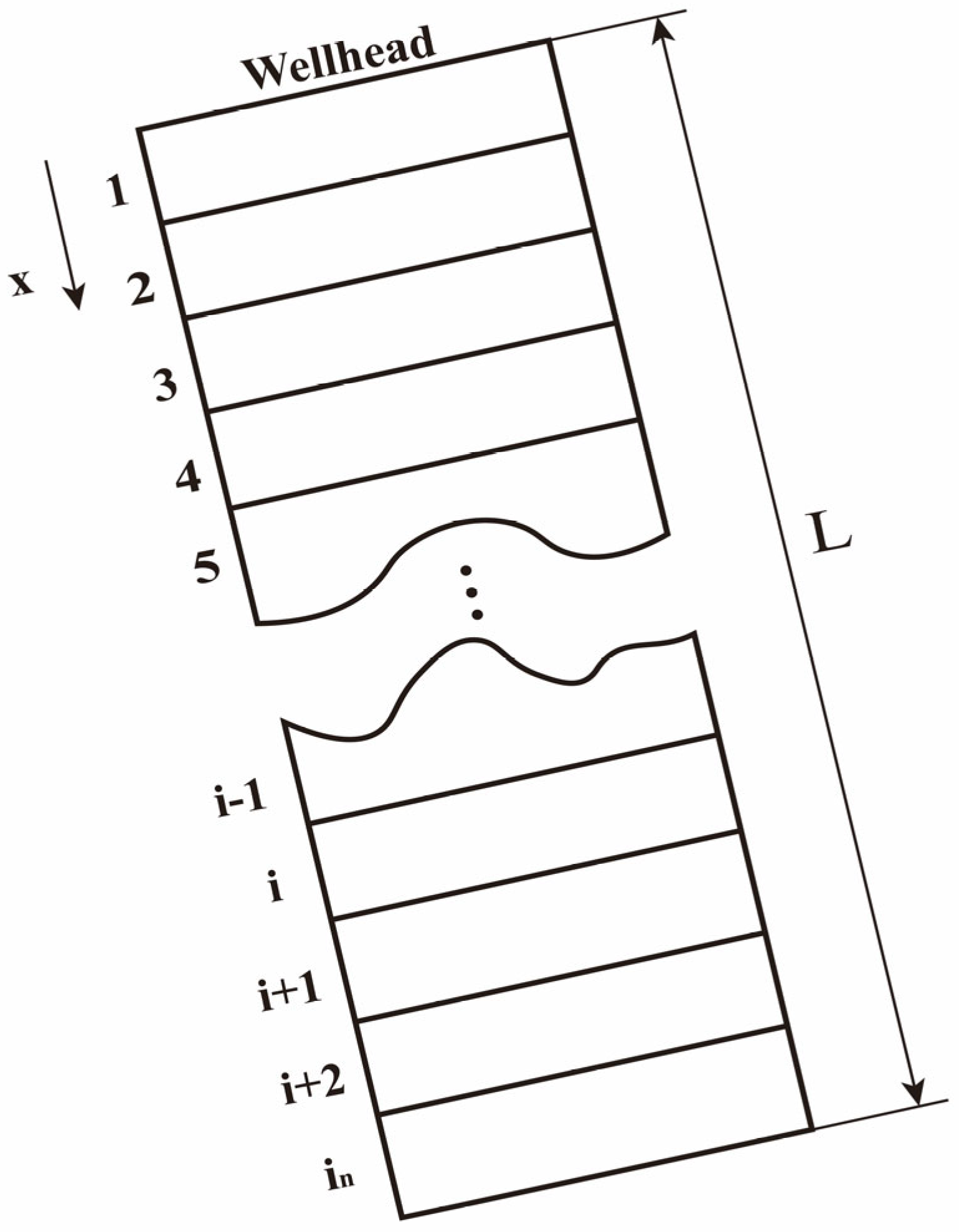

3.1.1. Grid Division

3.1.2. Mass Conservation Equation

3.1.3. Momentum Conservation Equation

3.1.4. Energy Conservation Equation

3.2. Boundary Conditions

3.2.1. At the Wellhead

3.2.2. At the Bottom Hole

3.3. Newton–Raphson Iteration

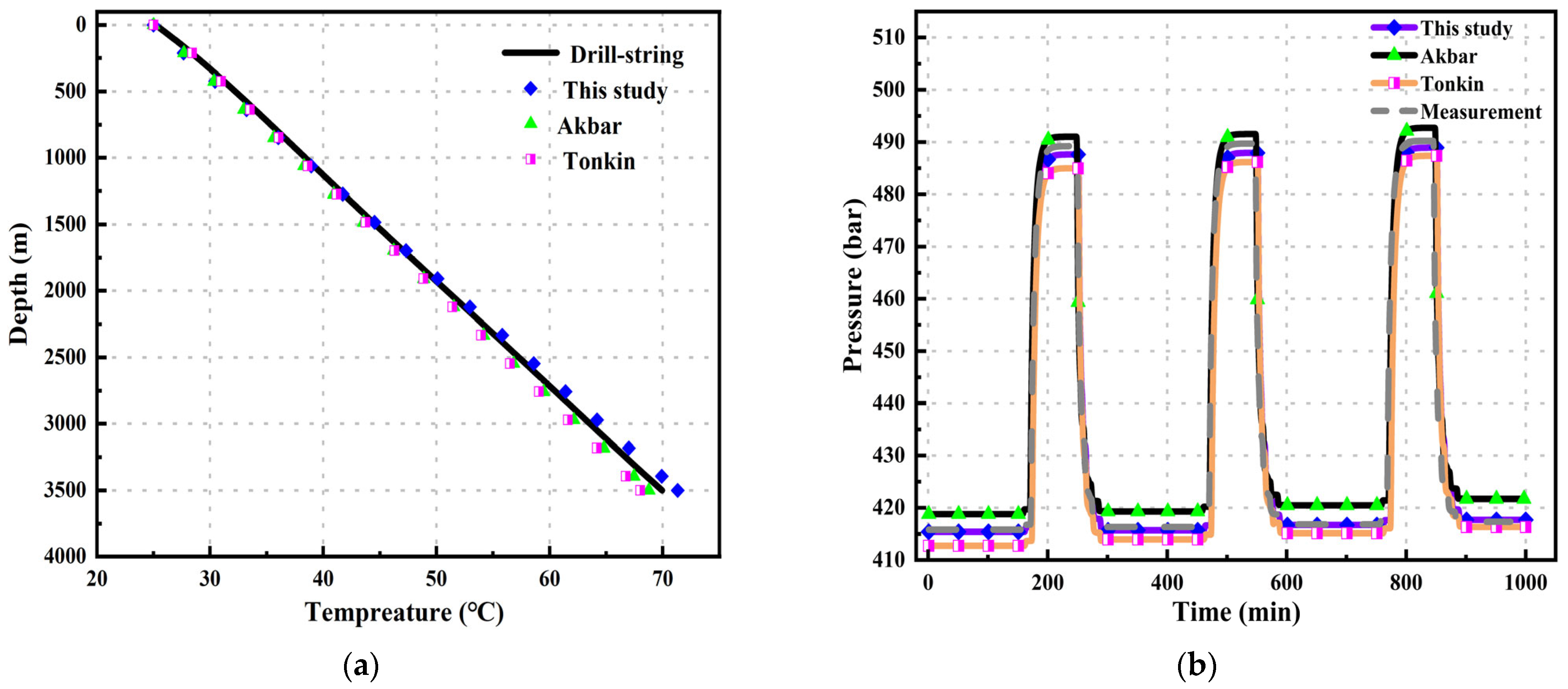

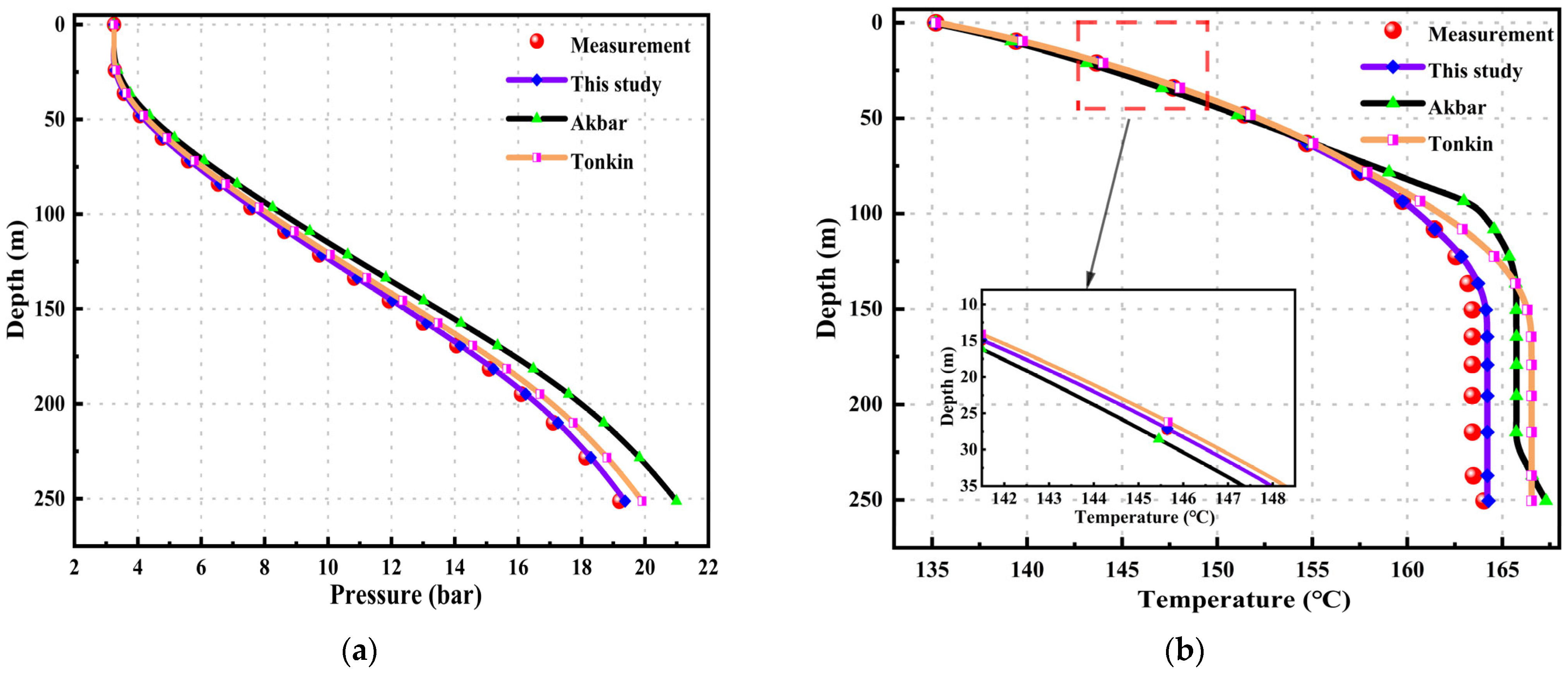

4. Model Verification and Analysis

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| C0 | profile coefficient |

| D | wellbore diameter, mm |

| e | specific internal energy, J/kg |

| f | wellbore friction coefficient |

| h | specific enthalpy, J/kg |

| kf | formation thermal conductivity |

| Ku | critical Kutateladze number |

| P | wellbore pressure, Pa |

| Q | energy change value, W/m2 |

| ri | wellbore radius, mm |

| Δr | difference between the wellbore radius and the drill pipe radius, mm |

| Re | Reynolds number |

| Tei | unaffected formation temperature, °C |

| Tf | fluid temperature inside the drill string, °C |

| Ta | fluid temperature in the annulus, °C |

| TD | temperature function |

| Ut | heat transfer coefficient |

| v | velocity, m/s |

| vm | mixture velocity, m/s |

| vd | drift velocity, m/s |

| vc | characteristic velocity, m/s |

| vsgf | critical velocity value, m/s |

| ρ | phase density, kg/m3 |

| α | volume fraction |

| ρm | mixture density, kg/m3 |

| ξ | wellbore roughness |

| μm | viscosity of the gas–liquid mixture, mm2/s |

References

- Bjornsson, G.; Bodvarsson, G.S. A Multi-Feedzone Wellbore Simulator. Geotherm. Resour. Counc. Trans. 1987, 11, 503–507. [Google Scholar]

- Tian, S.; Finger, J.T. Advanced Geothermal Wellbore Hydraulics Model. J. Energy Resour. Technol. 2000, 122, 142–146. [Google Scholar] [CrossRef]

- Khasani, D.K.; Itoi, R. Numerical study of the effects of CO2 gas in geothermal water on the fluid-flow characteristics in production wells. Eng. Appl. Comput. Fluid Mech. 2021, 15, 111–129. [Google Scholar] [CrossRef]

- Gao, X.; Wang, Z.-Y.; Qiao, Y.-W.; Li, T.-L.; Zhang, Y. Effects of seepage flow patterns with different wellbore layout on the heat transfer and power generation performance of enhanced geothermal system. Renew. Energy 2024, 223, 120065. [Google Scholar] [CrossRef]

- Saeid, S.; Al-Khoury, R.; Barends, F. An efficient computational model for deep low-enthalpy geothermal systems. Comput. Geosci. 2013, 51, 400–409. [Google Scholar] [CrossRef]

- Saeid, S.; Al-Khoury, R.; Nick, H.M.; Hicks, M.A. A prototype design model for deep low-enthalpy hydrothermal systems. Renew. Energy 2015, 77, 408–422. [Google Scholar] [CrossRef]

- Brown, C.S.; Falcone, G. Investigating heat transmission in a wellbore for Low-Temperature, Open-Loop geothermal systems. Therm. Sci. Eng. Prog. 2024, 48, 102352. [Google Scholar] [CrossRef]

- Zuber, N.; Findlay, J. Average volumetric concentration in two-phase flow systems. J. Heat Transf. 1965, 87, 453–468. [Google Scholar] [CrossRef]

- Hasan, A.R.; Kabir, C.S. Modeling two-phase fluid and heat flows in geothermal wells. J. Pet. Sci. Eng. 2010, 71, 77–86. [Google Scholar] [CrossRef]

- Pan, L.; Oldenburg, C.M. T2Well—An integrated wellbore–reservoir simulator. Comput. Geosci. 2014, 65, 46–55. [Google Scholar] [CrossRef]

- Akbar, S.; Fathianpour, N.; Al-Khoury, R. A finite element model for high enthalpy two-phase flow in geothermal wellbores. Renew. Energy 2016, 94, 223–236. [Google Scholar] [CrossRef]

- Tonkin, R.A.; O’Sullivan, M.J.; O’Sullivan, J.P. A review of mathematical models for geothermal wellbore simulation. Geothermics 2021, 97, 102255. [Google Scholar] [CrossRef]

- Tonkin, R.A.; O’Sullivan, J.; Gravatt, M.; O’Sullivan, M. A transient geothermal wellbore simulator. Geothermics 2023, 110, 102653. [Google Scholar] [CrossRef]

- Shi, H.; Holmes, J.A.; Durlofsky, L.J.; Aziz, K.; Diaz, L.R.; Alkaya, B.; Oddie, G. Drift-flux modeling of two-phase flow in wellbores. SPE J. 2005, 10, 24–33. [Google Scholar] [CrossRef]

- Lei, H.-W.; Xie, Y.-C.; Li, J.; Hou, X.-W. Modeling of two-phase flow of high temperature geothermal production wells in the Yangbajing geothermal field, Tibet. Front. Earth Sci. 2023, 11, 1019328. [Google Scholar] [CrossRef]

- Xu, Z.-M.; Song, X.-Z.; Li, G.-S.; Wu, K.; Pang, Z.-Y.; Zhu, Z.-P. Development of a transient non-isothermal two-phase flow model for gas kick simulation in HTHP deep well drilling. Appl. Therm. Eng. 2018, 141, 1055–1069. [Google Scholar] [CrossRef]

- Hajidavalloo, E.; Daneh-Dezfuli, A.; Falavand Jozaei, A. Effect of temperature variation on the accurate prediction of bottom-hole pressure in well drilling. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 1–21. [Google Scholar] [CrossRef]

- Hasan, A.R.; Kabir, C.S. Wellbore heat-transfer modeling and applications. J. Pet. Technol. 2012, 86–87, 127–136. [Google Scholar] [CrossRef]

- Orkiszewski, J. Predicting Two-Phase Pressure Drops in Vertical Pipe. J. Pet. Technol. 1967, 19, 829–838. [Google Scholar] [CrossRef]

- Rouhani, S.Z.; Axelsson, E. Calculation of void volume fraction in the subcooled and quality boiling regions. Int. J. Heat Mass Transf. 1970, 13, 383–393. [Google Scholar] [CrossRef]

- Pan, L.; Oldenburg, C.M.; Wu, Y.-S.; Pruess, K. T2Well/ECO2N Version 1.0: Multiphase and Non-Isothermal Model for Coupled Wellbore-Reservoir Flow of Carbon Dioxide and Variable Salinity Water; Report LBNL-4291E; Earth Sciences Division, Lawrence Berkeley Laboratory, University of California: Berkeley, CA, USA, 2011. [Google Scholar]

- Hibiki, T.; Tsukamoto, N. Drift-flux model for upward dispersed two-phase flows in vertical medium-to-large round tubes. Prog. Nucl. Energy 2023, 158, 104611. [Google Scholar] [CrossRef]

- Barati, H.; Hibiki, T.; Schlegel, J.P.; Tsukamoto, N. Two-group drift-flux model for dispersed gas-liquid flow in large-diameter pipes. Int. J. Heat Mass Transf. 2024, 218, 124766. [Google Scholar] [CrossRef]

- Hibiki, T.; Ishii, M. One-dimensional drift-flux model and constitutive equations for relative motion between phases in various two-phase flow regimes. Int. J. Heat Mass Transf. 2003, 46, 4935–4948. [Google Scholar] [CrossRef]

- Bhagwat, S.M.; Ghajar, A.J. A flow pattern independent drift flux model based void fraction correlation for a wide range of gas–liquid two phase flow. Int. J. Multiph. Flow 2013, 59, 186–205. [Google Scholar] [CrossRef]

- Liu, Y.-X.; Upchurch, E.R.; Ozbayoglu, E.M. Experimental and Theoretical Studies on Taylor Bubbles Rising in Stagnant Non-Newtonian Fluids in Inclined Non-Concentric Annuli. Int. J. Multiph. Flow 2022, 147, 103912. [Google Scholar] [CrossRef]

- Harmathy, T.Z. Velocity of large drops and bubbles in media of infinite or restricted extent. AIChE J. 1960, 6, 281–288. [Google Scholar] [CrossRef]

- Fjelde, K.K.; Karlsen, K.H. High-resolution hybrid primitive–conservative upwind schemes for the drift flux model. Comput. Fluids 2002, 31, 335–367. [Google Scholar] [CrossRef]

- Lee, A.L.; Gonzalez, M.H.; Eakin, B.E. The Viscosity of Natural Gases. J. Pet. Technol. 1966, 18, 997–1000. [Google Scholar] [CrossRef]

- Chen, X.; Wang, S.-W.; He, M.; Xu, M.-B. A comprehensive prediction model of drilling wellbore temperature variation mechanism under deepwater high temperature and high pressure. Ocean Eng. 2024, 296, 117063. [Google Scholar] [CrossRef]

- Meng, L.-D.; Zhang, X.-L.; Jin, Y.-J.; Yan, K.; Li, S. Numerical simulation of fracture temperature field distribution during oil and gas reservoir hydraulic fracturing based on unsteady wellbore temperature field model. Geophysics 2024, 89, M1–M15. [Google Scholar] [CrossRef]

- Lou, W.-Q.; Sun, D.-L.; Sun, X.-H.; Li, F.-P.; Liu, Y.-X.; Guan, L.-C.; Sun, B.-J.; Wang, Z.-Y. High-precision nonisothermal transient wellbore drift flow model suitable for the full flow pattern domain and full dip range. Pet. Sci. 2023, 20, 424–446. [Google Scholar] [CrossRef]

- Liu, Y.-X.; Upchurch, E.R.; Ozbayoglu, E.M.; Baldino, S.; Wang, J.-Z.; Zheng, D.-Z. Design and Calculation of Process Parameters in Bullheading andPressurized Mud Cap Drilling. In Proceedings of the IADC/SPE International Drilling Conference and Exhibition, Stavanger, Norway, 7–9 March 2023. [Google Scholar]

- Liu, W.-Z.; Zeng, Q.-D.; Yao, J. Poroelastoplastic Modeling of Complex Hydraulic-Fracture Development in Deep Shale Formations. SPE J. 2021, 26, 2626–2650. [Google Scholar] [CrossRef]

- He, Y.-T.; Yang, Z.-Z.; Jiang, Y.-F.; Li, X.-G.; Zhang, Y.-Q.; Song, R. A full three-dimensional fracture propagation model for supercritical carbon dioxide fracturing. Energy Sci. Eng. 2020, 8, 2894–2906. [Google Scholar] [CrossRef]

- Yue, P.; Yang, H.-G.; He, C.-J.; Yu, G.-M.; Sheng, J.-J.; Guo, Z.-L.; Guo, C.-Q.; Chen, X.-F. Theoretical Approach for the Calculation of the Pressure Drop in a Multibranch Horizontal Well with Variable Mass Transfer. ACS Omega 2020, 45, 29209–29221. [Google Scholar] [CrossRef]

- Garg, S.K.; Pritchett, J.W.; Alexander, J.H. Development of New Geothermal Wellbore Holdup Correlations Using Flowing Well; Idaho National Lab. (INL): Idaho Falls, ID, USA, 2004. [Google Scholar] [CrossRef]

- Zolfagharroshan, M.; Khamehchi, E. A rigorous approach to scale formation and deposition modelling in geothermal wellbores. Geothermics 2020, 87, 101841. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Depth (m) | 3500 |

| Wellbore diameter (mm) | 222 |

| Drillpipe ID (mm) | 119 |

| Drillpipe OD (mm) | 159 |

| Gas injection rate (m3/s) | 0.263 |

| Surface temperature (°C) | 25 |

| Bottom-hole temperature (°C) | 71.1 |

| Casing ID (mm) | 306 |

| Casing OD (mm) | 350 |

| Mud density (kg/m3) | 1066.45 |

| Parameter | Value |

|---|---|

| Depth (m) | 248.4 |

| Vertical depth (m) | 248.4 |

| Angle with vertical (degrees) | 0 |

| 0–159.7 m internal diameter (mm) | 102 |

| 159.7–248.4 m internal diameter (mm) | 99 |

| Depth (m) | 248.4 |

| Surface temperature (°C) | 22 |

| Bottom-hole temperature (°C) | 163.5 |

| Parameter | Value |

|---|---|

| Depth (m) | 2377 |

| Production casing depth (m) | 1250 |

| Wellbore diameter (mm) | 244.5 |

| Slotted liner depth (m) | 2371 |

| Slotted liner size (mm) | 177.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, Y.; Li, W.; Zhang, J.; Lei, J.; Xu, X.; Bian, L. A Novel Geothermal Wellbore Model Based on the Drift-Flux Approach. Energies 2024, 17, 3569. https://doi.org/10.3390/en17143569

Yuan Y, Li W, Zhang J, Lei J, Xu X, Bian L. A Novel Geothermal Wellbore Model Based on the Drift-Flux Approach. Energies. 2024; 17(14):3569. https://doi.org/10.3390/en17143569

Chicago/Turabian StyleYuan, Yin, Weiqing Li, Jiawen Zhang, Junkai Lei, Xianghong Xu, and Lihan Bian. 2024. "A Novel Geothermal Wellbore Model Based on the Drift-Flux Approach" Energies 17, no. 14: 3569. https://doi.org/10.3390/en17143569

APA StyleYuan, Y., Li, W., Zhang, J., Lei, J., Xu, X., & Bian, L. (2024). A Novel Geothermal Wellbore Model Based on the Drift-Flux Approach. Energies, 17(14), 3569. https://doi.org/10.3390/en17143569