Abstract

The constant development of electronic devices and components allows for older systems (which have been well received) with electronic control of combustion processes in municipal thermal energy to be improved to new levels, with significant economic and ecological effects. This article presents details of the development of an improved natural gas combustion quality control system in the modernized DKVR 6.5-13 steam boiler. This paper presents the results of comparative tests of this boiler obtained for various variants of the system operation. It has been proven that maximum boiler efficiency indicators and minimum toxicity of exhaust gases discharged into the atmosphere can be achieved by using a proposed control system. The system uses the regulated residual chemical underburning method, based on simultaneous control of the oxygen and carbon dioxide content in the exhaust gases. As a result of the use of the proposed method, an increase in boiler efficiency was achieved by 1.5–2.1% compared with standard automatic regulation and an increase by 0.3–0.8% compared with regulation based only on the oxygen content in the exhaust gases. These results were achieved by reducing the excess air coefficient. In addition, nitrogen oxide emissions were reduced by 25–30%, which, with a justified safe carbon monoxide content in exhaust gases of up to 250 ppm, reduced the exhaust gas toxicity index to 20%.

1. Introduction

Traditionally, municipal thermal energy boilers have been classified as heat generators of low and medium power. A characteristic feature of their work is frequently changing thermal loads within a wide range of power regulation from 50 to 100% [1]. Low thermal loads and frequent transient operating modes result in reduced fuel consumption efficiency and increased emissions of harmful substances into the atmosphere [2,3,4,5,6]. Ecological problems are exacerbated by the fact that such heat sources are often located in residential buildings that have relatively low chimneys [7,8,9]. In such conditions, high efficiency and eco-friendliness of fuel combustion can only be ensured by automatic regulation of the combustion process based on immediate shaping of signal instructions and fast-acting actuating devices. Such a control system must operate based on full current information about the parameters characterizing the combustion process.

Currently, a number of solutions are available on the European and global markets for the control, management and optimization of fuel combustion processes in power and industrial heating boilers [10]. The most promising direction is considered to be the use of the Programmable Logic Controller (PLC) and Supervisory Control and Data Acquisition (SCADA) technique based on the Proportional Integral Derivative (PID) feedback loop mechanism [11]. The fundamental ways for solving problems relating to the design of devices for constructing automated boiler control systems are described in [12]. The review of the most important parts of a broader analysis using an example of the water level control system is described in [13,14]. The various boiler control and automation techniques are discussed in [15], which concludes that the newer technique of PLC- and SCADA-based boiler automation is an effective system that overcomes the drawbacks of other control methods.

A comparable analysis of the design and implementation of a boiler automation system using PLC is described in [16]. In [17,18,19,20,21], the authors present SCADA and PLC assistance in controlling crucial parameters using PID control. Modeling an automated management system of technological processes in public energetics is also discussed and described in [22,23,24].

The modernization of a boiler unit automation system at an acting power station that led to a decrease in fuel consumption by 1% and a reduction in nitrogen oxide and carbon monoxide emission by 3% is discussed in [25]. A very interesting solution for automating the control of the combustion process using GSM technology is presented in work [26]. An innovative approach that focuses on the automation of boiler processes in a thermal power plant using IoT is proposed in [27,28]. Based on the analysis of the current literature data regarding the implemented control methods, it can be concluded that most of them are intended for use in power boilers.

A characteristic feature of the operation of such boilers is the maintenance of a stable performance that allows the use of regulation according to the constant oxygen content in the exhaust gases. This method does not work for boilers with variable operating modes, especially at low loads. This is caused by incomplete combustion and corresponding chemical heat losses with the exhaust gases. The method of constant “fuel–air” ratio, widely used in thermal power boilers, reduces the efficiency of the boilers at low loads due to the increasing excess of air and the corresponding physical heat losses with the exhaust gases. The common issue in the analyzed literature is fuel consumption efficiency. Ecological issues are less frequently and separately considered, usually with a small effect on reducing emissions of harmful substances [25].

The authors of this article propose the simultaneous consideration of the issue of the efficient and ecological operation of boilers, defining it as “fuel combustion quality” [1,29,30]. The combustion process in municipal thermal power boilers is very complex, consisting of a large number of input, output and interference signals. Moreover, the operation of such boilers is unstable due to constantly changing loads. The random change in the calorific value of gas or the temperature of gas and air is also important. All the above issues cause frequent and irregular changes in fuel combustion parameters. In these conditions, it is crucial to maintain the combustion process within the optimal range with minimal reaction time to changes and disturbances. To achieve this goal, a method of dynamic control of the combustion process is proposed to ensure the maximum possible efficiency of the boiler, taking into account environmental protection conditions. This method is based on controlling the “fuel–air” ratio based on current information about the oxygen and carbon monoxide content in the exhaust gases [31,32,33].

The original solution in this work was the use of an integrated AGAVA 6432.20 controller performing the functions of four previous system regulators, i.e., boiler capacity, air flow pressure regulator, vacuum regulator in the furnace and water level regulator in the upper boiler drum. Original data were obtained, indicating the high energy and environmental effect of using the developed system.

During the research, standard methods for testing steam boilers were used using certified instruments and devices to ensure the reliability and comparability of the results obtained.

2. Problem Analysis

The authors have many years of experience in designing systems for dynamic control of fuel combustion quality in low and medium power boilers. The Fakel-2000 system was previously implemented in the boiler plant presented in this work [29,32,33]. A feature of this dynamic control system is the continuous maintenance of the boiler in optimal operating conditions in terms of economic and ecological fuel combustion. The system allows for monitoring control changes of parameters such as gas calorific value, fuel and air temperature, atmospheric conditions and the technical condition of the boiler and burners.

At a given moment, the boiler operated with the maximum possible efficiency, also taking into account the atmosphere protection requirements [34,35]. However, over time, there was a need to improve the system, which had been developed on technical solutions from 20 years ago. Due to significant progress in technical and technological development, microprocessor controllers, programmable controllers, exhaust gas composition analyzers and virtually all other elements of the system required modernization. Moreover, in the meantime, the boiler itself was subjected to technical modernization, where it was equipped with electromagnetic gas valves, frequency-controlled blower and exhaust fan drives and a number of other boiler accessories.

According to the initial assumptions, the existing control logic was also modified. This was indicated by the possibility of combining separate control functions in one advanced controller, the significantly shorter response time of new electronic devices and the operation of actuators and actuators. This would lead to narrowing the ranges of automatic regulation of the combustion process and, consequently, to achieving a greater economic and ecological effect.

3. Experimental Object

Investigations were performed in a boiler plant belonging to the Techpribor company (St. Petersburg, Russian). The boiler plant is the source of heat supply for the plant for HVAC (Heating, Ventilation, Air Conditioning) and technological purposes. The direct object of the investigations was the DKVR-6.5-13 GM No. 3 steam boiler (Reg. No. 288466). The boiler had a vertical water tube structure, with two longitudinal drums and a convection bundle with a corridor arrangement of pipes. The boiler had gravity circulation and was additionally equipped with a cast iron economizer to heat the feed water. The boiler produced saturated steam, which was then used in exchangers. The boiler parameters were collected and are presented in Table 1.

Table 1.

Parameters of boiler unit DKVR-6.5-13 No. 3 (according to manufacturer’s data).

The boiler had an individual blowing and exhaust installation, the parameters of which are presented in Table 2. Behind the exhaust fan, exhaust gases were discharged into the atmosphere through the common chimney of the boiler plant.

Table 2.

Parameters of draught blower equipment.

The boiler was equipped with two short-flame GMG-4M gas fuel burners located symmetrically on the front wall of the boiler. The use of liquid fuel was an emergency solution. Burner parameters are presented in Table 3.

Table 3.

Parameters of GMG-4M burners.

The excessive power of the burners (2 × 4.65 MW) in relation to the boiler power (4.6 MW) was dictated by the fact that the boiler was adapted to long-term operation at a load of up to 140% of the design power (i.e., up to 6.5 MW). The burners selected by the manufacturer were the closest to the GMG family of burners (between GMG-1.5M and GMG-5.5/7M). Taking into account the operating conditions of the given boiler plant, it was not expected that the boiler would operate beyond its design power, resulting in unfavorable technical and economic indicators of burner and boiler operations. This fact was an additional incentive to perform investigations.

4. Details of the Technical and Technological Solution

4.1. Modernization of Boiler Equipment

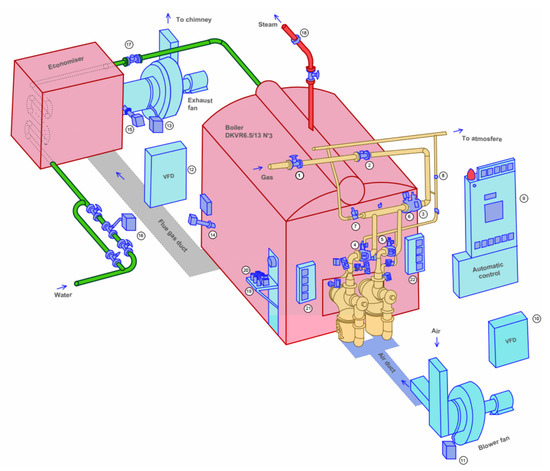

The setup of the boiler unit with modernized equipment and an improved control system is shown in Figure 1. In the gas equipment of modernized boiler no. 3 from the previous devices, the panicles and Dn 250 gate valve (1) remained, through which the boiler was connected to the low-pressure gas supply pipeline. After the gate valve, the following new devices were in-stalled: a turbine gas meter (2) type SG-16MT-650, a main electromagnetic quick-closing valve Dn 100 (3) and two separate electromagnetic quick-closing valves Dn 80 (4, 5) on the gas supply to the GMG-4M burners.

Figure 1.

Modernized DKVR-6.5-13 boiler.

An important element of the modernization to the gas path was the gas flow regulator (6) with an electric drive, controlled automatically from the control cabinet. The section of the supply manifold between the gate valve and the quick-closing valves of the burners was connected to the safety line through a normally open blow-off valve (7). The starting vent line was connected to this line through the ball valve (8).

The flue gas analyzers behind the boiler (14) and behind the boiler unit (15) were replaced with improved models. These elements analyzed the content of oxygen (O2) and chemical combustion products (CO), which was the basis for the proposed method of controlling the efficiency and ecology of fuel combustion. Analyzers determined the efficiency of the boiler and the boiler unit and the occurrence of leaks in the combustion process. The feed water flow regulator actuator (16), which regulated the water level in the boiler, was also replaced.

The blower fan with a blade air flow regulator (11) and the exhaust fan with a blade vacuum regulator in the furnace (13) only required service. Similarly, the following elements were inspected and serviced: the feed water meter (17), the measuring orifice on the steam line (18) and a group of differential pressure gauges (19, 20) used to visually control the boiler operating parameters.

4.2. Modernization of the Control System

The automatic fuel combustion quality control system was completely modernized. First of all, the electric drives of the blowing and exhaust fans were equipped with Variable Frequency Drive (VFD) controllers located in cabinets (10) and (12). This control method provided regulation of the fans’ performance only by changing the number of motor revolutions using a frequency converter, with fully open and non-adjustable mechanical diaphragms (11) and (13). The operation of VFD was much faster and more accurate compared with the mechanical regulation. The mechanical controls remained on board and connected to the control system in case of maintenance on the VFD system. The main control cabinet (9) was completely replaced, and electronic burner control panels (21) and (22) were placed on the front wall of the boiler. The above technical changes were part of the improved Fakel-2010 control technology, as presented in Figure 2.

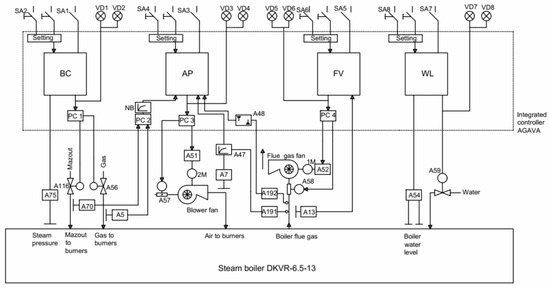

Figure 2.

Block diagram of the fuel combustion quality control system of steam boiler DKVR-6.5-13 (description of elements in the text).

The main element of the Fakel-2010 control system is the integrated AGAVA 6432.20 controller, which performs the functions of the following four previous regulators of the Fakel-2000 system [20]: Boiler Capacity Regulator (BC), Air Pressure Flow Regulator (AP), Furnace Vacuum Regulator (FV) and Water Level Regulator (WLR) in the upper boiler drum (WL).

All control circuits can operate in automatic or manual mode, which is selected by the operator using switches SA1,3,5,7 (automatic or manual). The selected control method is indicated by the VD1-VD8 LEDs. If manual control is selected, settings are made using switches SA2,4,6,8 (more or less) in the settings block.

4.2.1. Boiler Capacity Regulator

The BC regulator controls the thermal power of the boiler by controlling the fuel flow using the A56 (gas) or A116 (fuel) regulator, depending on the signal from the A75 steam pressure sensor. This is related to the mixed use of the boiler for ventilation, heating and production purposes. Moreover, the transmission of information about steam pressure is much faster compared with information from final heat consumers. Therefore, the PID control method is used as the most proven method in boiler control systems.

The type of fuel and the appropriate flow regulator can be selected in the programmable PC1 controller during boiler startup. At the same time, the appropriate pressure sensor (gas or fuel) is selected in the PC2 controller.

4.2.2. Air Pressure Flow Regulator

The AP regulator fulfils the main role in the developed technology for controlling the quality of fuel combustion. Its final task is to precisely regulate the “fuel–air” ratio by changing the efficiency of the blower fan. The main regulation method is to change the speed of the M2 engine using the FVD controller (A51). It is also possible to choose a mechanical regulator with an A57 actuator. The selection is made in the programmable PC3 controller during boiler startup or in the case of maintenance of FVD controllers.

The input signal of the AP regulator is the signal from fuel pressure sensor A5 (gas) or A70 (fuel). At the stage of standard boiler setting, a table of approximate fuel and air pressure ratios is established in the Non-linearity Block (NB) (up to 10 points with linear interpolation between them).

The signal from oxygen content corrector A47 receives signals from air pressure sensor A7 and from the O2 exhaust gas analyzer (A191). According to the optimal oxygen content characteristics programmed (in the device’s memory), the corrector makes precise adjustments to the air pressure in relation to the assumed one in the NB block.

The signal from carbon monoxide content corrector A48 receives a signal from the CO exhaust gas analyzer (A192). According to the authors’ concept of a controlled level of chemical underburn [31], this correction provides for maintaining the CO content in exhaust gases within established ranges. If the upper range is exceeded (“too little air”), the corrector slightly increases the air pressure. If the CO content is lower than the lower range (“too much air”), the air pressure increases accordingly. This additional correction allows to take into account the current conditions of the combustion process, namely fuel calorific value, air and fuel temperature, technical condition of the boiler and additional equipment, etc.

4.2.3. Furnace Vacuum Regulator

The FV regulator is used to maintain a constant value of negative pressure in the boiler furnace, necessary for stable combustion and uniform filling of the furnace with the flame. When using automatic regulation, the controller tries to maintain the vacuum at a constant assumed level, using the PID method. The required correction of the vacuum value is performed by changing the number of revolutions of the M1 exhaust fan motor using the FVD controller (A52).

It is also possible to choose a mechanical flow regulator with an A58 actuator. This selection is made in the PC4 programmable controller during boiler startup or during maintenance of FVD controllers. An ADR type pressure meter (A13) is used as a vacuum sensor in the system, combining the functions of the primary sensor and the converter. The device has an analog current output (4–20 mA) for regulation and two relay (discrete) outputs used in safety automation.

4.2.4. Water Level Regulator

The WL regulator is used to maintain the required water level in the upper boiler drum. The controller provides smooth PID control by receiving a current signal from the A54 drum pressure differential transmitter and acting on feed water flow regulator actuator A59.

5. Methodology

All measurements and chemical analyses were performed in accordance with the methodology of regime setting tests of the GUPTEK State Energy Enterprise in Saint Petersburg [36,37]. The composition and characteristics of the gas fuel were determined on the basis of collected samples tested in a certified laboratory [38,39,40].

The chemical composition of combustion products (oxygen, CO2, CO, nitrogen oxides), their temperatures along the boiler gas route and the excess air coefficients were determined using the MRU Optima 7 flue gas analyzer. The analyzer acquired the values of the dilution coefficient of dry combustion products, which were converted to α. The concentration of carcinogenic substances in the collected exhaust gas samples was checked in a certified laboratory. The measurement results obtained during the research were subjected to statistical processing, the purpose of which was to eliminate results with errors. The results presented in this work are the arithmetic mean of individual results assuming a normal distribution and a confidence interval (p = 0.95). Boiler operation investigations were performed for the entire power control range in operating conditions.

Based on the obtained experimental data, the following issues were developed:

- -

- Characteristics of the “fuel–air” pressure ratio for programming the NB (Non-linearity Block);

- -

- Optimal graph of oxygen content in exhaust gases for programming the A47 controller;

- -

- Optimal content of residual chemical underburn (CO content in exhaust gases), ensuring the maximum value of boiler efficiency.

According to the proposed solution [30,31,32], this value turned out to be close to 225 ppm in the entire range of boiler power regulation. The next important step in the preliminary research was to establish discrete air pressure correction intervals based on the exhaust gas analysis for CO content. This process was intended to program the operating ranges of the A48 controller. The tests showed an incomparably faster response of actuators to signals from transmitters and sensors compared with the previous system (Table 4).

Table 4.

Approximate response time of main control loops.

Such a quick response of the system to the fuel combustion quality parameters made it possible to significantly narrow the discrete correction ranges assumed for the A48 controller as follows: 250 ppm “not enough air” and 200 ppm “too much air”.

6. Experimental Results

Investigations were performed during the period 18 December 2023–22 December 2023 and (after analyzing the results obtained and correcting the research program) during the period 12 January 2024–16 January 2024. The boiler operated on high-methane natural gas, the lower heat of combustion of which was 33.6 MJ/m3. Investigations were performed for actual operating modes of the boiler. The operation of the entire boiler plant allowed the boiler to be kept in a constant operating mode for the required time. According to the proposal of the boiler plant management, it was performed for the following approximate boiler loads (used as standard in the regime card): 100%, 80%, 65% and 50%.

The obtained results were compared for the following variants of the improved fuel combustion quality control system:

- Boiler operation with an improved automatic control system without additional elements to increase economy, with a constant “fuel–air” ratio obtained for the nominal boiler efficiency. This was a reference level for further research [30].

- Boiler operation with the fuel–air ratio non-linearity block (A5-PC2-NB-AP) enabled, without correction of the combustion process according to gas analysis [41,42].

- Boiler operation with correction of the combustion process according to the results of measuring the oxygen content in exhaust gases (A191-A47-AP) [18,43].

- Boiler operation with correction of the combustion process according to the results of measuring the oxygen and carbon monoxide content in exhaust gases according to the authors’ method (A191-A47-AP and A192-A48-AP).

The results of the performed investigations clearly show the effectiveness and efficiency of the implemented method of controlling the quality of fuel combustion. The test results for the above variants of system operation are presented in Table 5.

Table 5.

Results of testing the fuel combustion quality control system.

The table also presents the values of the combustion products’ toxicity, indicator Gsp [mg/m3]. This is a key indicator from the point of view of the proposed combustion method with controlled residual chemical combustion (fourth variant of system operation) [30].

The indicator is based on a comparison of the maximum permissible concentrations of harmful substances in inhaled air TLV-TWA (Threshold Limit Value/Time-Weighted Average) [mg/m3]. From this point of view, nitrogen oxides in the form of NO2 (TLVNO2 = 0.7 mg/m3) are over 30 times more dangerous for humans compared with carbon monoxide (TLVCO = 27 mg/m3) [34]. The mentioned exhaust toxicity index can be determined using the formula presented below:

where CNO2 and CCO are concentrations of nitrogen dioxide and carbon monoxide in exhaust gases [mg/m3] calculated under equal conditions (α = 1.0).

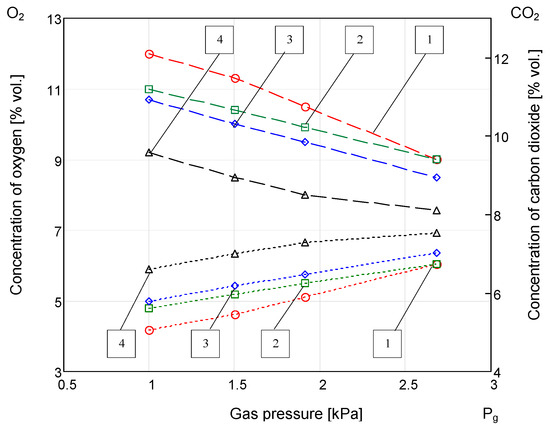

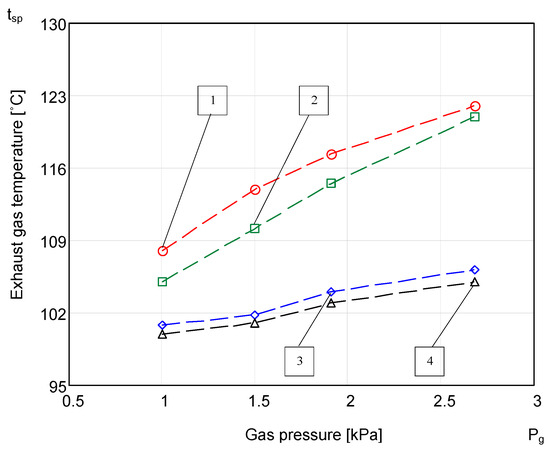

The experimental results (O2, CO2, tsp, α) are presented in Figure 3 and Figure 4. Figure 3 shows the relationship between the concentration of oxygen and carbon dioxide in the exhaust gases depending on the gas pressure upstream of the burners. The analysis included four variants of the system’s operation. The system proposed by the authors of the work, defined as variant 4, ensured the lowest oxygen content in the exhaust gases. Per thousand showed the dependence of the exhaust gas temperature on the gas pressure in front of the burners. The control method proposed by the authors ensured the lowest value of exhaust gas temperature. Both of these achievements contributed to higher fuel efficiency.

Figure 3.

Dependence of O2 (dashed lines) and CO2 (dotted lines) concentration on gas pressure.

Figure 4.

Dependence of exhaust gas temperature on gas pressure.

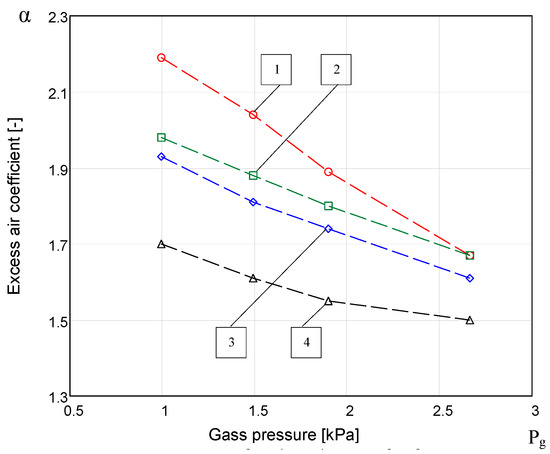

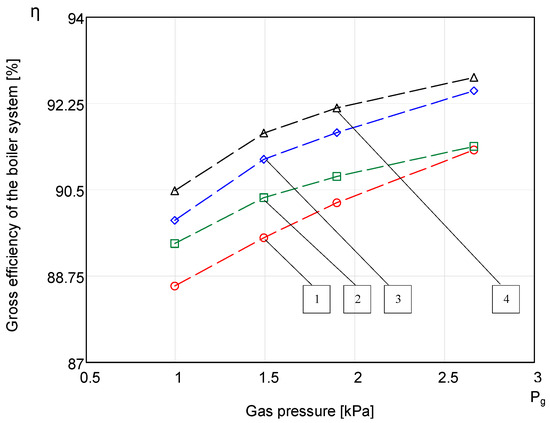

The changes of the calculation values of the boiler efficiency (η) and the exhaust gas toxicity indicator (Gsp) are shown in Figure 5 and Figure 6. In all figures, curves 1–4 correspond to the above options of the control system operation. Based on the obtained results, conclusions were drawn that the improved fuel combustion control system and the modernization of the boiler equipment ensured its efficiency higher than expected by the manufacturer (even without turning on additional fuel saving options). The inclusion of further possible system operating modes (non-linear control of the “fuel–air” ratio, control according to the oxygen content in the exhaust gases and combined control according to the O2 and CO content) ensured increasingly higher boiler efficiency.

Figure 5.

Dependence of air excess coefficient on gas pressure.

Figure 6.

Dependence of gross efficiency of the boiler unit on gas pressure.

With the use of the proposed control system using the regulated residual chemical combustion method based on joint control of the oxygen and carbon monoxide content in the exhaust gases, maximum boiler efficiency indicators and minimum toxicity of exhaust gases discharged into the atmosphere were achieved. Using this method, an increase in boiler efficiency by 1.5–2.1% was achieved compared with regular automatic regulation and an increase in boiler efficiency by 0.3–0.8% compared with regulation based on the oxygen content in the exhaust gases (Figure 6). This result was achieved by reducing the excess air coefficient, lowering the exhaust gas temperature (Figure 4 and Figure 5) and increasing the degree of flame blackness. This ensured a higher intensity of heat transfer in the boiler furnace by radiation and in the pipe bundles by convection.

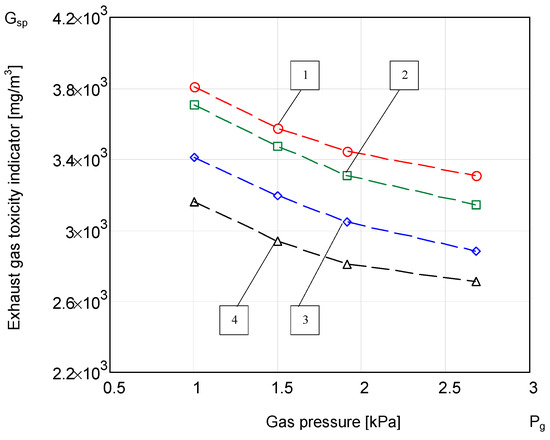

Figure 7 shows the dependence of the exhaust gas toxicity index on the gas pressure in front of the burners. Boiler operation with correction of the combustion process based on the results of measuring the oxygen and carbon monoxide content in exhaust gases ac-cording to the authors’ method ensured its lowest value. Using this type of control, the toxicity of exhaust gases according to the Gsp index was reduced by 15–20% compared with regular automatic regulation and by 6–9% compared with “oxygen” regulation (Figure 7).

Figure 7.

Dependence of exhaust gas toxicity indicator on gas pressure.

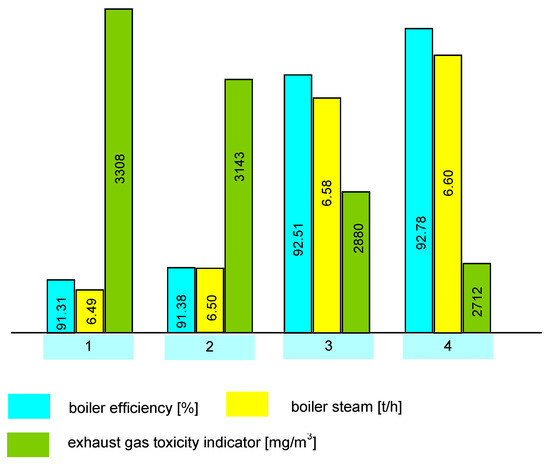

This was the result of a significant reduction in nitrogen oxide emissions by 25–30% (Table 1). The insignificant CO content in the exhaust gases almost did not affect the toxicity index. A comparison of four variants of the control system operation with respect to boiler efficiency, exhaust gas toxicity index and actual boiler steam efficiency at maximum gas pressure is presented in the form of a histogram in Figure 8.

Figure 8.

Comparison of fuel combustion quality indicators at nominal boiler capacity (1–4 options of the control system operation).

The histogram demonstrates the achievement of high results according to the authors’ method for all three basic boiler operation indicators compared with the reference level, i.e., boiler efficiency (92.78% against 91.31%), steam efficiency (6.60 t/h against 6.49 t/h) and exhaust toxicity index (2712 mg/m3 against 3308 mg/m3).

It should be noted that the improved system responds immediately to changes in gas pressure, which is important for saving fuel in transient operating modes. A characteristic operating mode for municipal power boilers is an operation with frequently changing heat loads. This effect cannot be observed in tests, because each test requires the boiler to operate in a constant mode. A reliable characteristic of the long-term efficiency of the boiler, in changing operating modes, is the specific reference fuel consumption (coal equivalent) for the production of a unit of thermal energy (specific reference fuel consumption) [kg of conventional fuel/GJ] [35]. For the investigated boiler, this indicator decreased by approximately 5% during the heating season compared with the previous heating season from 37.26 to 35.40 [kg coal equivalent /GJ]. Due to the impossibility of separating (in the final result) the impact of the boiler modernization and the operation of the improved combustion process control system, a summary result of the achievements is presented.

7. Conclusions

An improved automatic fuel combustion quality control system was developed ac-cording to the authors’ method, which was implemented in the “Fakel-2010” system. The effectiveness of this system was tested under actual boiler operation conditions. Experimental tests of the system were carried out on a functioning DKVR 6.5-13 GM boiler unit installed in an existing boiler plant intended for heat supply of an industrial plant for HVAC and technological purposes. The main type of fuel was natural gas with a calorific value of 33.6 MJ/m3.

New capabilities of elements and devices of electronic control systems for industrial processes were implemented in the improved fuel combustion quality control system. Together with the modernization of the equipment, it was possible to achieve an efficiency value of the boiler (which had been in operation for over 30 years) above the indicators assumed by the manufacturer. A new aspect of the system was the use of non-linear control of the fuel–air ratio. This was particularly important at low boiler power, when its efficiency increased by 0.9% compared with regulation, according to a constant “fuel–air” ratio. The system can be used to control based on the optimal oxygen content in the exhaust gases, which can change dynamically depending on many factors. This allowed obtaining an additional 0.5–1.15% of boiler efficiency in terms of changes in its power.

The authors’ element was the use of control while maintaining an acceptable level of chemical underburn. In addition to increasing the boiler efficiency by another 0.3–0.8%, this method allowed to reduce the toxicity of combustion products by 6–10% compared with “oxygen” control and by 15–20% compared with non-linear air pressure control. An integral result of the use of the new control system was the analysis of specific reference fuel consumption (coal equivalent) for the production of a unit of thermal energy (specific reference fuel consumption) [kg of conventional fuel/GJ]. Compared with the previous heating season, this indicator decreased by 5%. This high result can be explained by the fact that the fast operation of the improved system ensured maximum boiler efficiency, even in transient operating modes.

The authors are aware that the obtained research results are limited to the combustion of gas fuel in municipal power boilers of small and medium power. In their next works, the team plans to expand their research on higher power boilers and boilers operating on pulverized coal or liquid fuel.

Author Contributions

Conceptualization, S.J.-L. and A.S.; Validation, S.J.-L. and A.S.; Investigation, S.J.-L. and A.S.; Data curation, S.J.-L.; Writing—original draft, S.J.-L.; Writing—review & editing, S.J.-L. and A.S.; Visualization, S.J.-L. and Ł.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Acknowledgments

The authors express deep gratitude and appreciation for the cooperation and valuable recommendations to the Research and Production Company Uran-SPb, and personally to Oleg Novikov and Aleksey Okatiev.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Chernousenko, O.Y.; Butovsky, L.S.; Hranovska, O.O.; Moroz, O.S.; Starchenko, O.S. Characteristics of the diffusion-stabalizer burner when combustion of gas at reduced oxygen content in oxidizer. Energy 2021, 32, 231–238. [Google Scholar] [CrossRef]

- Zima, W.; Taler, J.; Grądziel, S.; Trojan, M.; Cebula, A.; Ocłoń, P.; Dzierwa, P.; Taler, D.; Rerak, M.; Majdak, M.; et al. Thermal calculations of a natural circulation power boiler operating under a wide range of loads. Energy 2022, 261, 125357. [Google Scholar] [CrossRef]

- Ciupek, B.; Judt, W.; Gołoś, K.; Urbaniak, R. Analysis of Low-Power Boilers Work on Real Heat Loads: A Case of Poland. Energies 2021, 14, 3101. [Google Scholar] [CrossRef]

- Taler, J.; Trojan, M.; Dzierwa, P.; Kaczmarski, K.; Węglowski, B.; Taler, D.; Zima, W.; Grądziel, S.; Ocłoń, P.; Sobota, T.; et al. The flexible boiler operation in a wide range of load changes with considering the strength and environmental restrictions. Energy 2023, 263, 125745. [Google Scholar] [CrossRef]

- Hernik, B.; Zabłocki, W. Numerical research of combustion with a minimum boiler load. Arch. Thermodyn. 2020, 41, 93–114. [Google Scholar] [CrossRef]

- Duda, P.; Felkowski, Ł. Negative Impact of Thermal Loads on Pressure and Non-Pressure Boiler Parts. Energies 2023, 16, 5768. [Google Scholar] [CrossRef]

- Bajno, D.; Bednarz, Ł.; Grzybowska, A. The Role and Place of Traditional Chimney System Solutions in Environmental Progress and in Reducing Energy Consumption. Energies 2021, 14, 4720. [Google Scholar] [CrossRef]

- Motyl, P.; Król, D.; Poskrobko, S.; Juszczak, M. Numerical Modelling and Experimental Verification of the Low-Emission Biomass Combustion Process in a Domestic Boiler with Flue Gas Flow around the Combustion Chamber. Energies 2020, 13, 5837. [Google Scholar] [CrossRef]

- Kakade, N.; Mani, A.; Bhatkar, C.; Chaudhari, P.; Roshan, R. A Study on Modification of Boiler Chimney against Fouling to Enhance The Efficiency of Boiler. Int. J. Technol. 2023, 13, 22–34. [Google Scholar] [CrossRef]

- Śladewski, Ł.; Wojdan, K.; Świrski, K. New approach to optimizing combustion in power boilers using software inspired by the immune system integrated with an in–furnace temperature monitoring system. J. Power Technol. 2017, 97, 308–313. [Google Scholar]

- Man, C.; Li, J.; Wang, L.; Chi, Y. The fuzzy PID control system for superheated steam temperature of boiler. In Proceedings of the 2011 6th International Forum on Strategic Technology, Harbin, China, 22–24 August 2011; Volume 2, pp. 967–970. [Google Scholar]

- Ryashchenko, I.; Sukhorukov, I. Automation of Power Unit Boiler Equipment during the Introduction of Full-Scale Automated Control Systems. Part II. Therm. Eng. 2009, 56, 482–488. [Google Scholar] [CrossRef]

- Pawlak, M. Performance analysis of power boiler drum water level control systems. Acta Energetica 2016, 4, 81–89. [Google Scholar] [CrossRef]

- Shome, A.; Ashok, S.D. Fuzzy Logic Approach for Boiler Temperature & Water Level Control. Int. J. Sci. Eng. Res. 2012, 3, 1–6. [Google Scholar]

- Dhavale, S.; Salunke, T.H.; Ranaware, S.R.; Sakhare, H.M.; Bodhe, A.S. Effective Boiler Automation System. Int. J. Adv. Res. Electr. Electron. Instrum. Eng. 2016, 5, 84–88. [Google Scholar] [CrossRef]

- Tahsin Labib, S.; Alam, S.U.; Hossain, S.; Patwary, M.I.H.; Ahmed, R.; Islam, M.A. Design and Implementation of Boiler Automation System Using PLC. In Proceedings of the 1st International Conference on Advances in Science, Engineering and Robotics Technology (ICASERT), Dhaka, Bangladesh, 3–5 May 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Behera, C.; Patil, S.M.; Mishra, S.K.; Reddy, G.H.K.; Goswami, A.K. Control and analysis of crucial parameters for an automatic boiler unit in a chemical industry. Int. J. Eng. Sci. Technol. 2022, 14, 94–103. [Google Scholar] [CrossRef]

- Volikov, A.N.; Maslov, Y.V.; Novikov, O.N. Energy-ecological rehabilitation is an economical way to increase enterprise energy efficiency. Sci. Tech. J. Eng. Syst. 2011, 2, 42–49. [Google Scholar]

- Chopade, S.S.; Verma, P.; Verma, P. Simulation of Boiler Control using PLC & SCADA. Int. J. Eng. Adv. Technol. (IJEAT) 2013, 3, 276–279. [Google Scholar]

- Bhowmik, P.K.; Dhar, S.K. Boiler gas burner management system automation using PLC. In Proceedings of the 2012 7th International Conference on Electrical and Computer Engineering, IEEE, Dhaka, Bangladesh, 20–22 December 2012; pp. 925–928. [Google Scholar]

- Jaiswal, A.R.; Jagtap, P.P. Study of PLC and SCADA controlled Thermal Power Plant. Int. Res. J. Eng. Technol. (IRJET) 2016, 3, 267–269. [Google Scholar]

- Bondarev, A.; Sarkisov, S.V.; Pivovarova, I.I.; Bolbyshev, E.V.; Korpusov, A.N. Modeling an automated management system of technological processes in public energetics. J. Phys. Conf. Ser. 2020, 1691, 012002. [Google Scholar] [CrossRef]

- Wang, Y.F.; Wang, M.X.; Liu, Y.; Yin, L.; Zhou, X.R.; Xu, J.F.; Zhang, X.Y. Fuzzy modeling of boiler efficiency in power plants. Inf. Sci. 2012, 542, 391–405. [Google Scholar] [CrossRef]

- Zuberi, M.J.S.; Patel, M.K. Cost-effectiveness analysis of energy efficiency measures in the Swiss chemical and pharmaceutical industry. Int. J. Energy Res. 2019, 43, 313–336. [Google Scholar] [CrossRef]

- Abramovskikh, A.; Ulyanova, U.A.; Lavrinenko, S.V.; Matveeva, A.A.; Malishev, D. Modernisation of boiler unit automation system at acting power station. MATEC Web Conf. 2017, 91, 01002. [Google Scholar] [CrossRef]

- Karuppiah, T.; Sivasankaran, V.; Periasamy, A.R.P.; Muruganand, S. Embedded System Based Industrial Power Plant Boiler Automation Using GSM Technology. Int. J. Adv. Res. Comput. Commun. Eng. 2013, 2, 3321–3325. [Google Scholar]

- Kumar, V.; Kumar, D.; Kumar, I.; Ashok, A. Automation of boiler process at thermal power plant using sensors and IoT. J. Stat. Manag. Syst. 2018, 21, 675–683. [Google Scholar] [CrossRef]

- Shen, S.; Peng, H. Security Technology Analysis of IoT; IOT Workshop, CCIS 312; Springer: Berlin/Heidelberg, Germany, 2012; pp. 401–408. [Google Scholar]

- Szkarowski, A.; Janta-Lipińska, S. Automatyczne sterowanie jakością spalania paliwa stałego w kotłach przemysłowo-grzewczych. Rocz. Ochr. Sr. 2009, 11, 241–257. [Google Scholar]

- Szkarowski, A.; Janta-Lipińska, S. Optymalizacja pracy kotłów metodą sterowanego poziomu niezupełności spalania. Polityka Energetyczna 2009, 12, 129–137. [Google Scholar]

- Szkarowski, A.; Janta-Lipińska, S. Badania energo-ekologicznych wskaźników pracy kotłów przy spalaniu paliwa ze sterowanym resztkowym niedopałem chemicznym. Rocz. Ochr. Sr. 2013, 15, 981–996. [Google Scholar]

- Shkarovskiy, A.; Janta-Lipińska, S. Improving of boiler efficiency by controlling the CO concentration in the furnace cavity. Energy Energy Sav. Ration. Nat. Use 2015, 1, 5–11. [Google Scholar]

- Janta-Lipińska, S.; Shkarovskiy, A. Investigations of advantages of simultaneous combustion of natural gas and mazout in medium power steam boilers. J. Eng. Thermophys. 2020, 29, 331–337. [Google Scholar] [CrossRef]

- Rozporządzenie Ministra Rodziny, Pracy i Polityki Społecznej z dnia 12 Czerwca 2018 r. w Sprawie Najwyższych Dopuszczalnych Stężeń i Natężeń Czynników Szkodliwych dla Zdrowia w Środowisku Pracy; Dziennik Ustaw RP 03.07.2018, poz. 1286; Warszawa, Poland. Available online: https://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU20180001286 (accessed on 14 June 2024).

- Barma, M.C.; Saidur, R.; Rahman, S.M.A.; Allouhi, A.; Akash, B.A.; Sait, S.M. A review on boilers energy use, energy savings, and emissions reductions. Renew. Sustain. Energy Rev. 2017, 79, 970–983. [Google Scholar] [CrossRef]

- Trembovla, W.I. Thermal Engineering Tests of Boiler Plants; Energoatomizdat: Moscow, Russia, 1991. [Google Scholar]

- Ravich, M.B. Fuel and Efficiency of Its Use; Nauka: Moscow, Russia, 1971. [Google Scholar]

- Guidelines for Carrying Out Work on Setting Up and Testing the Boiler Unit. Commodity on Natural Gas and Fuel Oil; Promenergogaz: Leningrad, Russia, 1988.

- Panyusheva, Z.F.; Stolpner, E.B. Technical Control of the Operation of Gasified Boiler Houses; LLP “Pako”: St. Petersburg, Russia, 1994. [Google Scholar]

- Methodology for Carrying Out Routine Adjustment Work on Gas-Using Installations, Boiler Units; CJSC NPF “Uran-SPb”: St. Petersburg, Russia, 2002.

- Ghohberg, J.L. Integrated automatic control of flue gases and increasing the efficiency and environmental friendliness of power boilers. Therm. Power Eng. 1985, 10, 41–44. [Google Scholar]

- Rotach, V. Calculation of the Settings of Microprocessor Control Systems. In Thermal Engineering; MAIK Nauka/Interperiodika Publishing: Moscow, Russia, 1994. [Google Scholar]

- Novikov, O.N.; Okatiev, A.N.; Antonova, N.A. How to increase the efficiency of a boiler room. Ind. Constr. Rev. 2013, 8, 61–63. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).