Laser-Induced Breakdown Spectroscopy Analysis of Sheet Molding Compound Materials

Abstract

1. Introduction

2. Materials and Methods

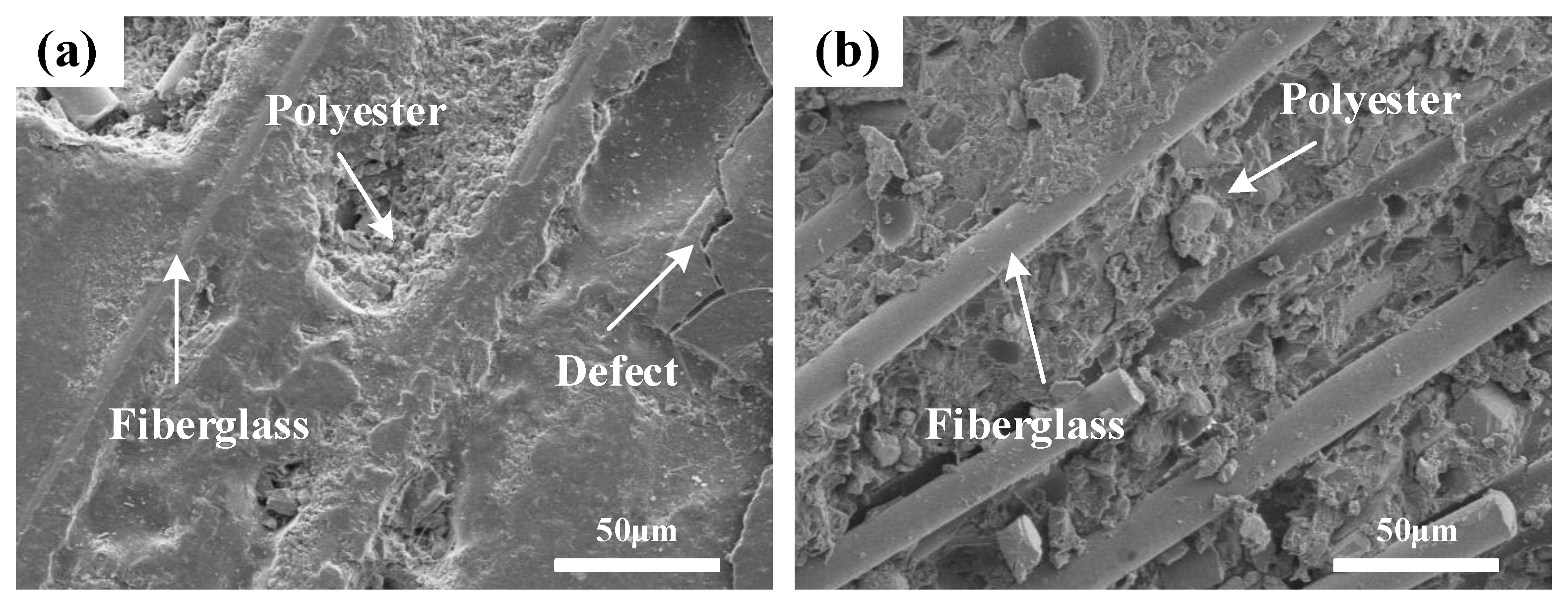

2.1. Materials

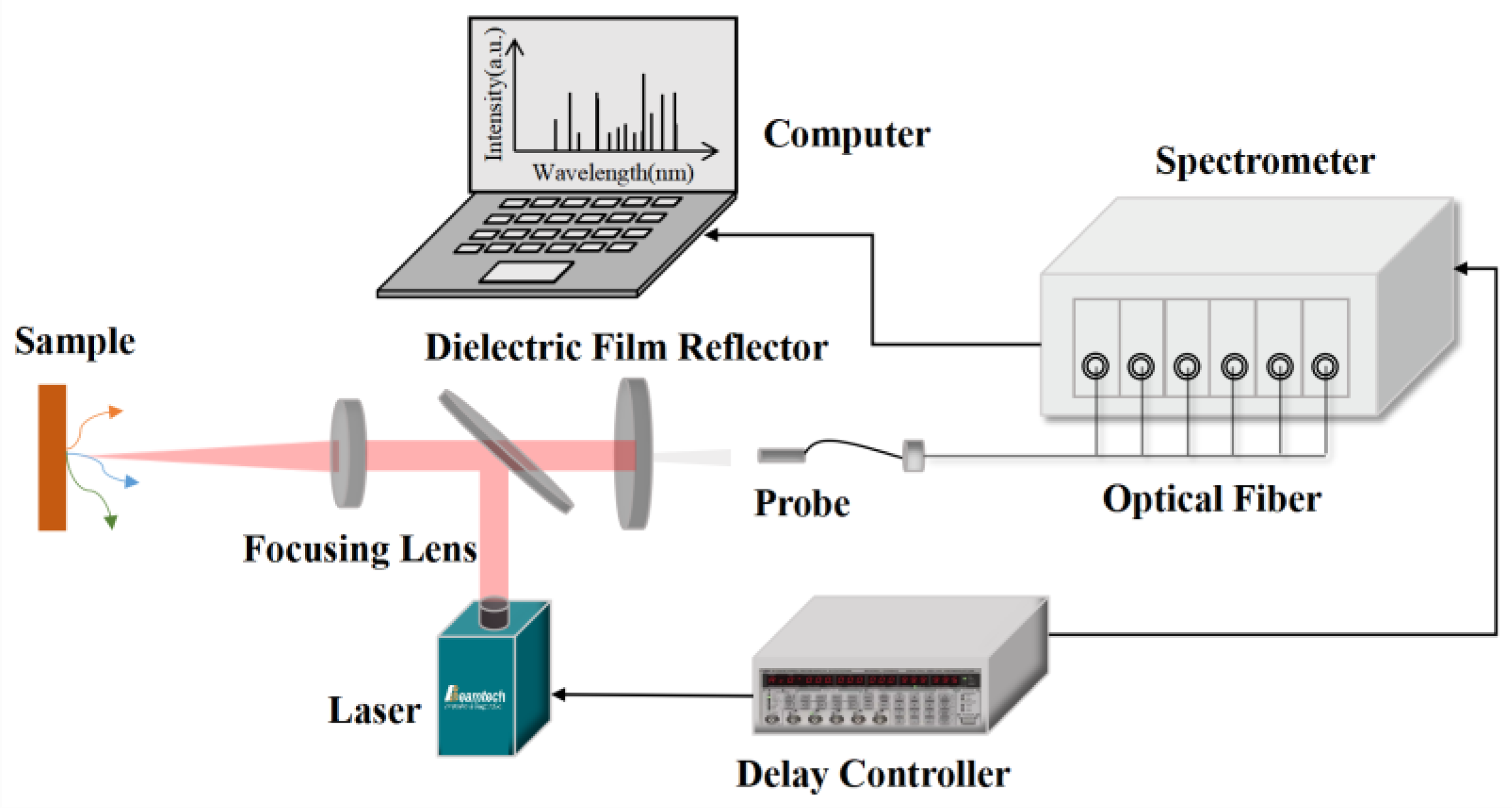

2.2. Equipment

2.3. Data Processing

3. Results and Discussion

3.1. Optimization of LIBS Technical Parameters

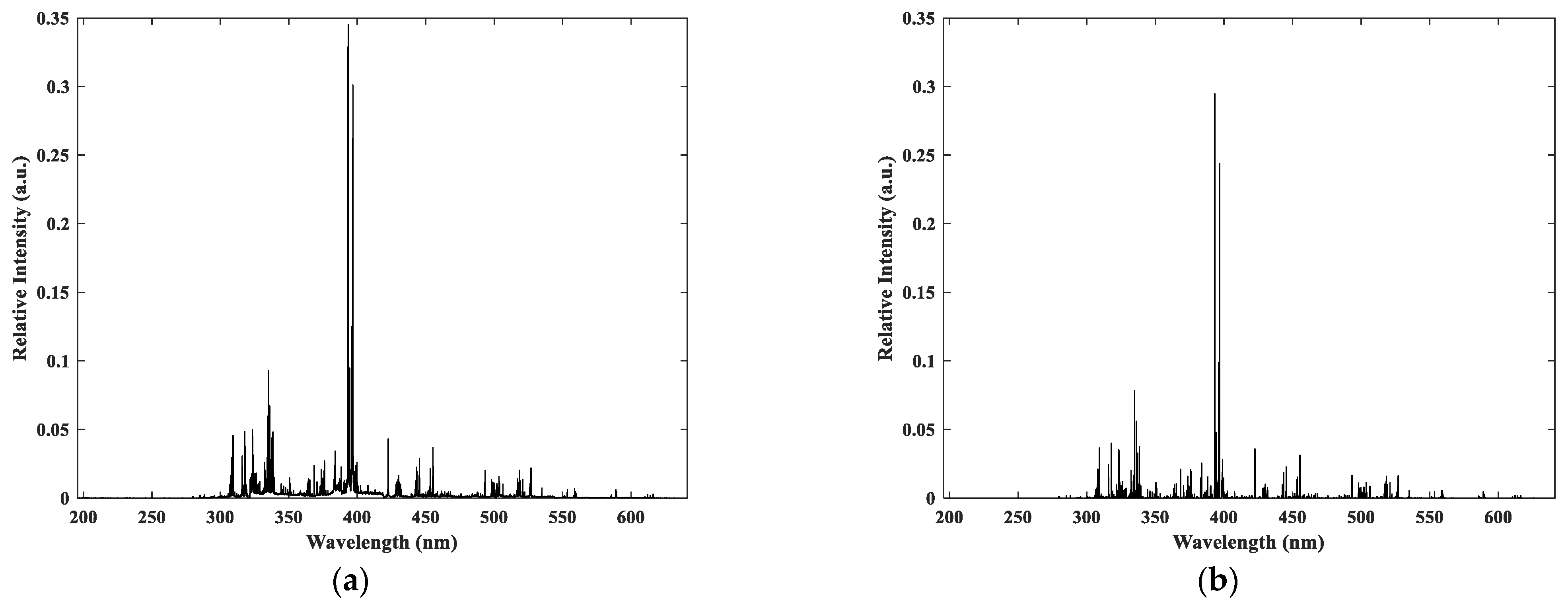

3.1.1. Delay Time

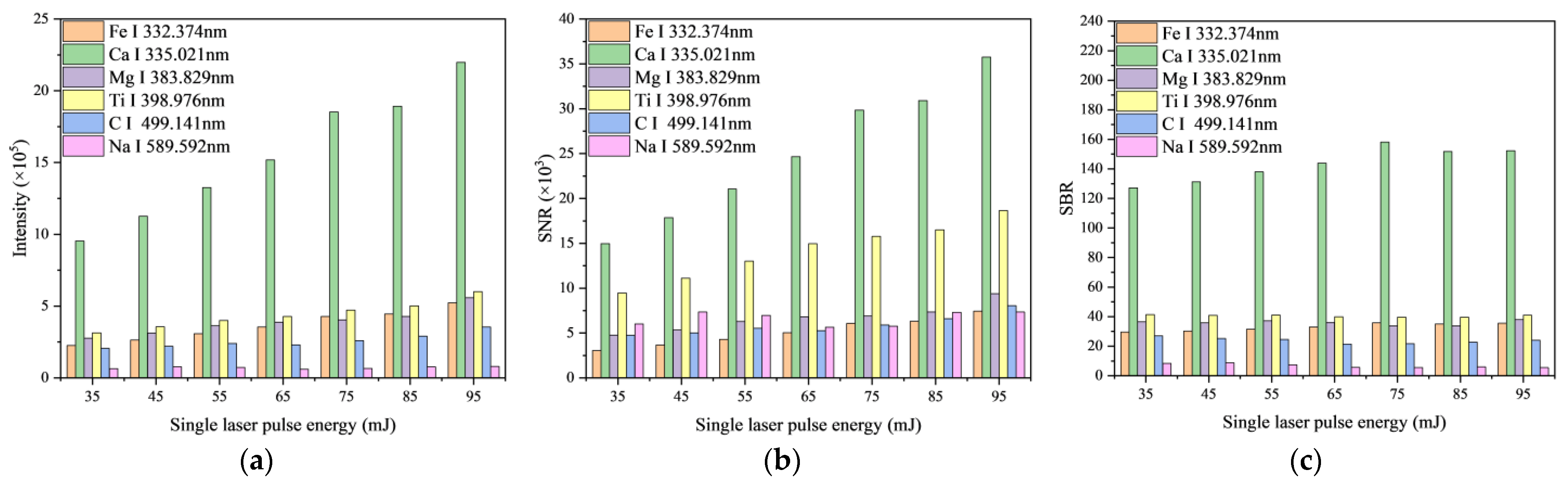

3.1.2. Single Laser Pulse Energy

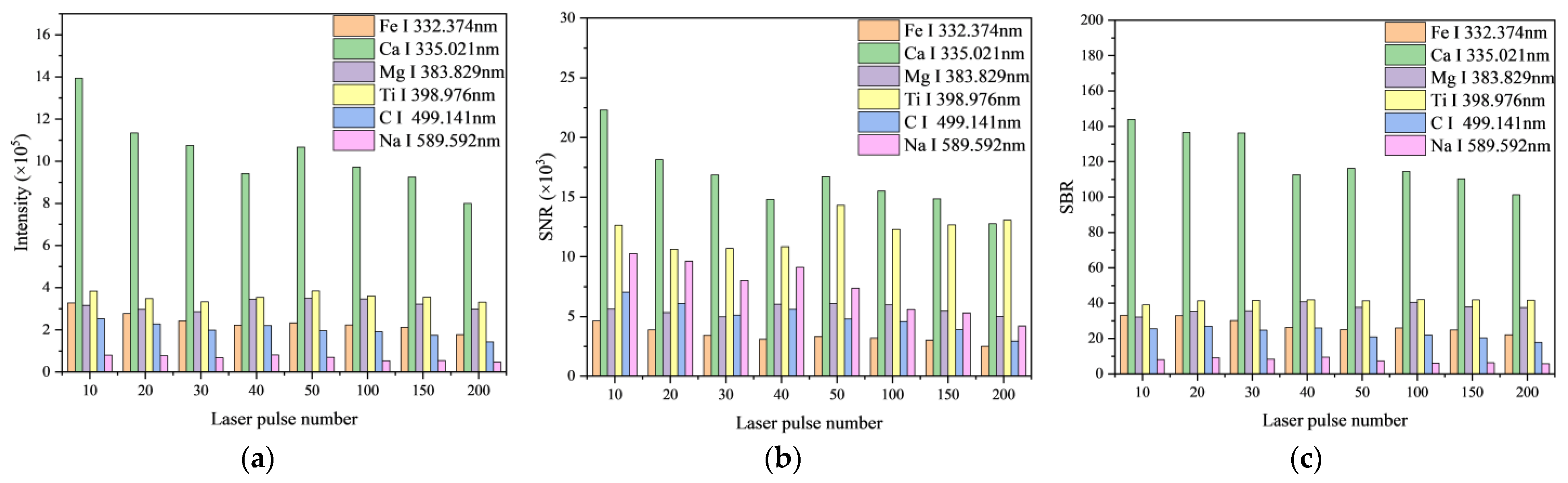

3.1.3. Laser Pulse Number

3.2. Laser Ablation Characteristics of SMC

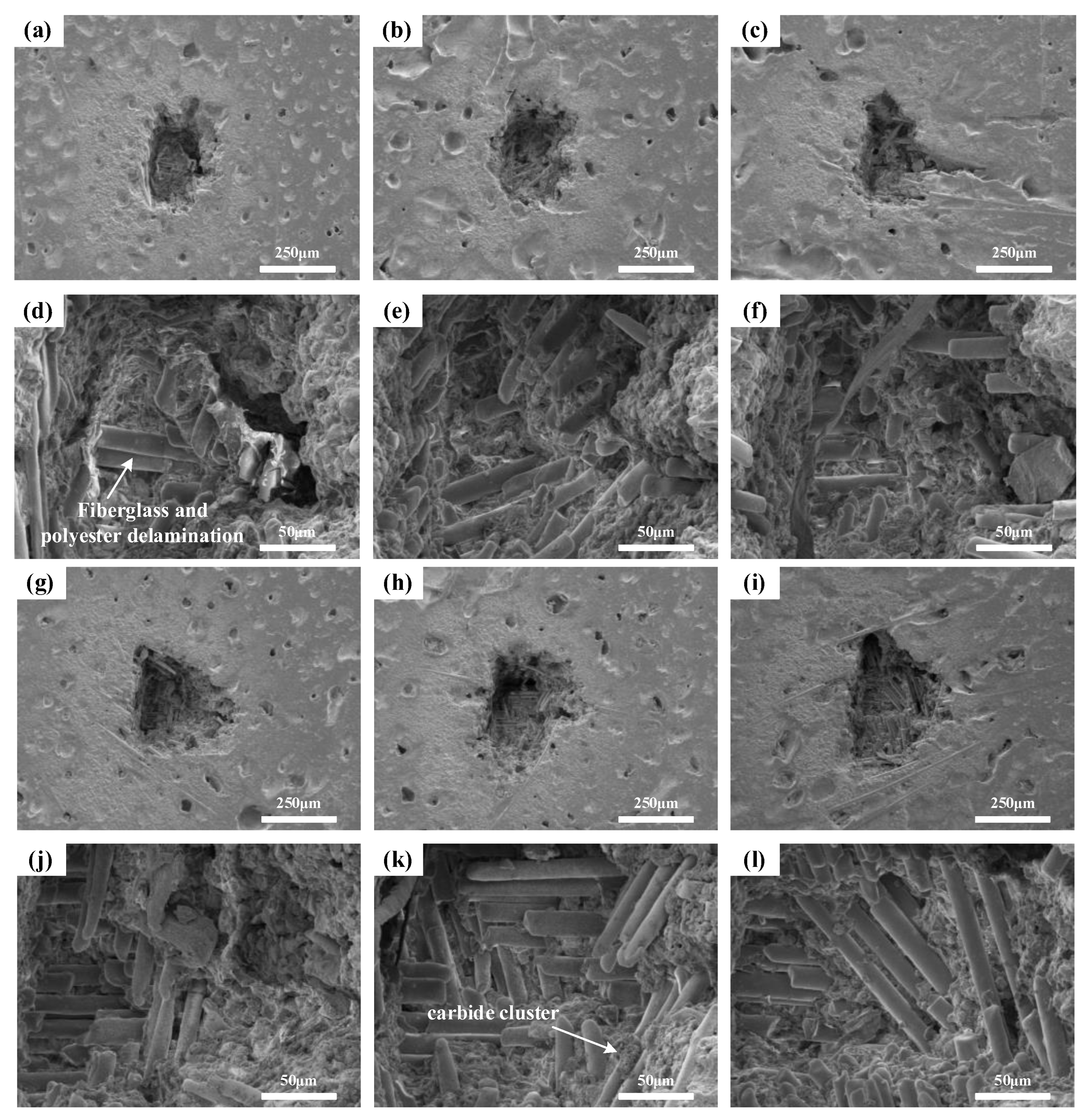

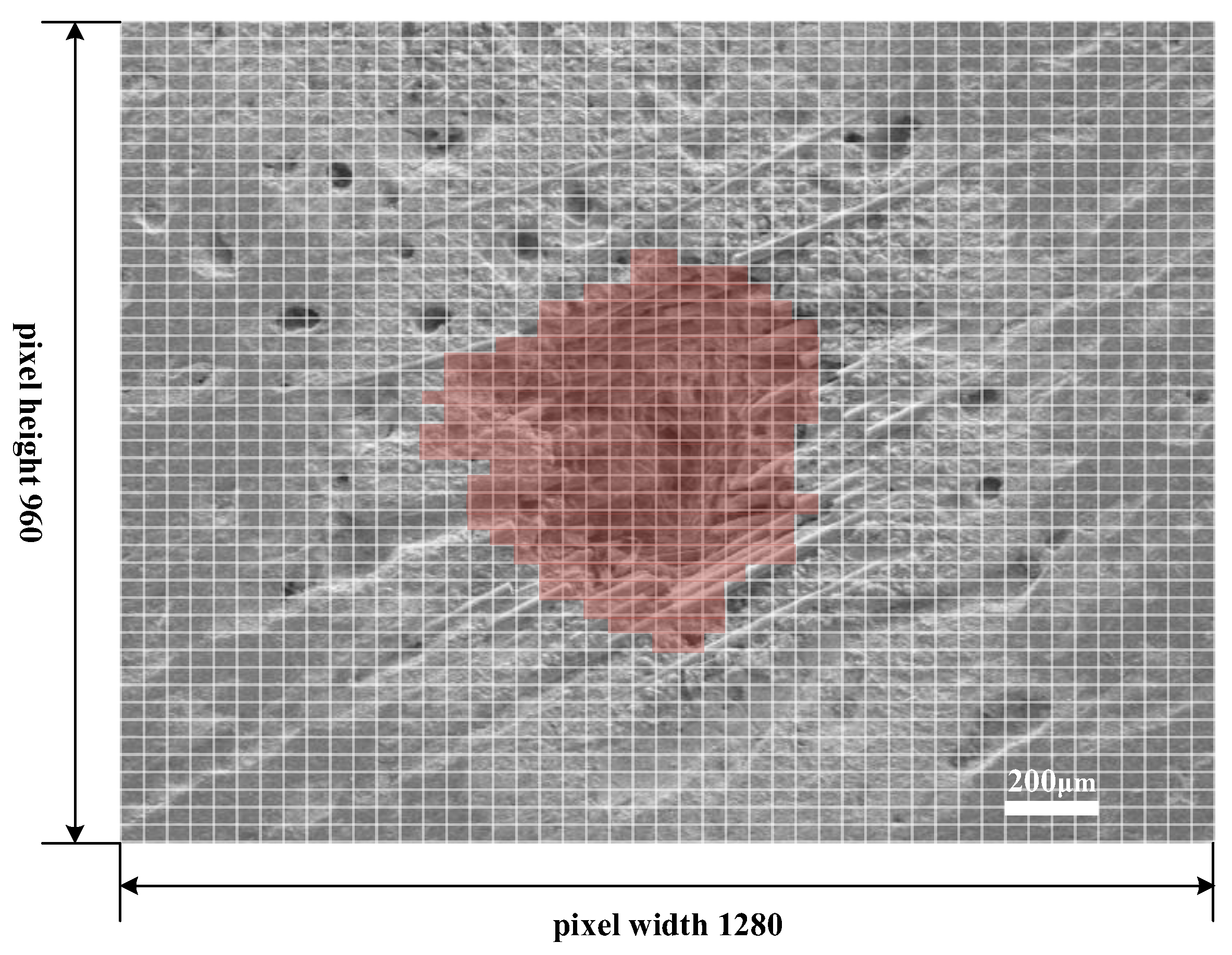

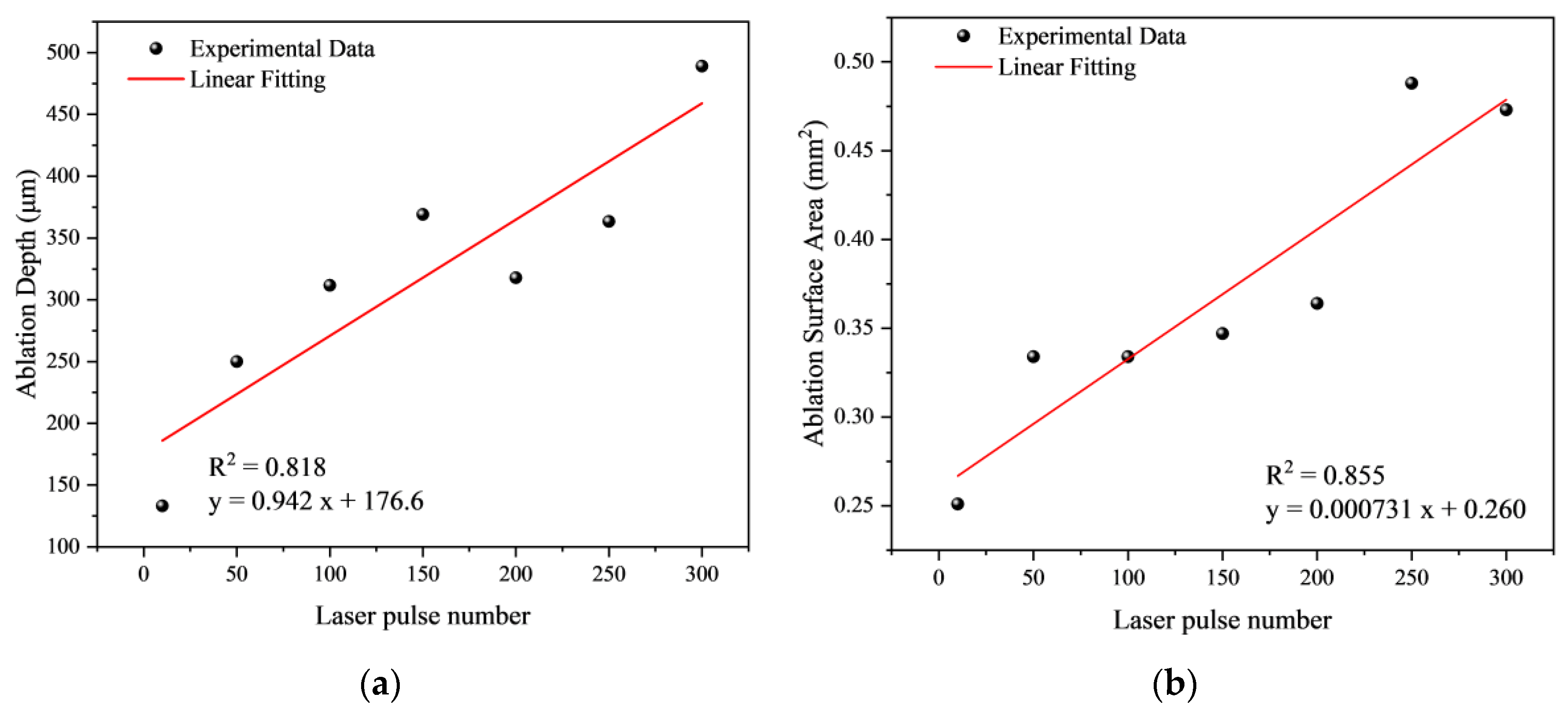

3.2.1. Effect of Laser Pulse Number

3.2.2. Effect of Single Laser Pulse Energy

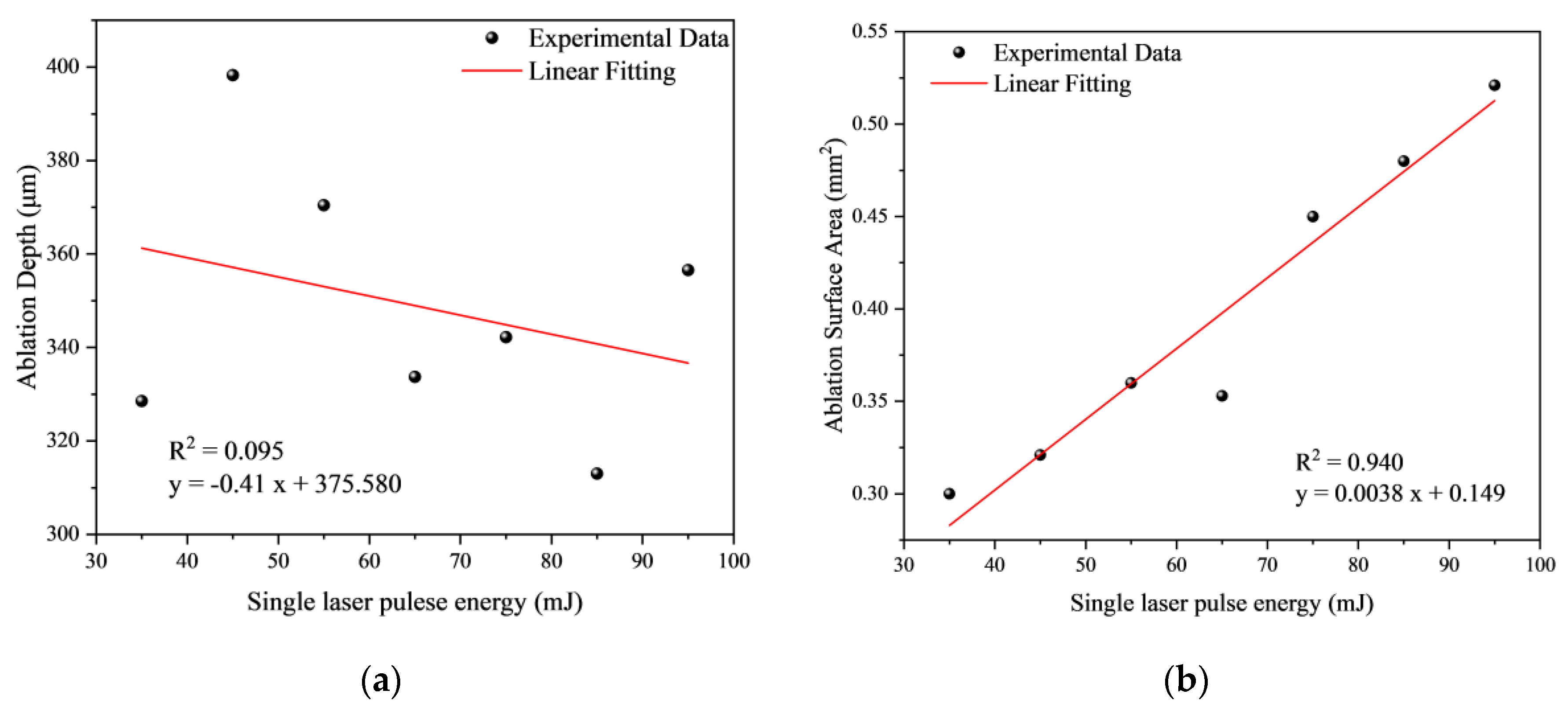

3.2.3. Ablation Characteristics and Laser Parameters Relationship

3.3. LIBS Analysis of the SMC

3.3.1. Element Analysis

3.3.2. Elemental Content Varies with Depth

- -

- The Na content remains relatively constant, with minimal variation as depth changes.

- -

- The content of Ti and Fe elements decreases with increasing depth;

- -

- The Mg and C content initially rises and then falls with depth;

- -

- The Ca element content shows a complex pattern, which decreases initially, then increases, and finally decreases again.

3.3.3. Plasma Parameters

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kearton, B.; Mattley, Y. Laser-Induced Breakdown Spectroscopy Sparking New Applications. Nat. Photonics 2008, 2, 537–540. [Google Scholar] [CrossRef]

- Corsi, M.; Cristoforetti, G.; Hidalgo, M. Effect of Laser-Induced Crater Depth in Laser-Induced Breakdown Spectroscopy Emission Features. Appl. Spectrosc. 2005, 59, 853–860. [Google Scholar] [CrossRef] [PubMed]

- Zheng, J.Y.; Ma, Z.; Gao, L.H. Development of intelligent anti-high power laser materials. Adv. Ceram. 2020, 41, 121–133. [Google Scholar]

- Cao, Z.; Cheng, J.; Han, X. Rapid classification of coal by laser-induced breakdown spectroscopy (LIBS) with K-nearest neighbor (KNN) chemometrics. Instrum. Sci. Technol. 2023, 51, 59–67. [Google Scholar] [CrossRef]

- Guo, H.; Cui, M.; Feng, Z. Classification of Aviation Alloys Using Laser-Induced Breakdown Spectroscopy Based on a WT-PSO-LSSVM Model. Chemosensors 2022, 10, 220. [Google Scholar] [CrossRef]

- Wang, J.; Xue, S.; Zheng, P. Determination of Lead and Copper in Ligusticum wallichii by Laser-Induced Breakdown Spectroscopy. Anal. Lett. 2017, 50, 2000–2011. [Google Scholar] [CrossRef]

- Tiwari, M.; Agrawal, R.; Pathak, A.K. Laser-Induced Breakdown Spectroscopy: An Approach to Detect Adulteration in Turmeric. Spectrosc. Lett. 2013, 46, 155–159. [Google Scholar] [CrossRef]

- Roh, S.B.; Park, S.B.; Oh, S.K. Development of intelligent sorting system realized with the aid of laser-induced breakdown spectroscopy and hybrid preprocessing algorithm-based radial basis function neural networks for recycling black plastic wastes. J. Mater. Cycles Waste Manag. 2018, 20, 1934–1949. [Google Scholar] [CrossRef]

- Ma, S.; Tang, Y.; Ma, Y. Correction: The pH effect on the detection of heavy metals in wastewater by laser-induced breakdown spectroscopy coupled with a phase transformation method. J. Anal. At. Spectrom. 2020, 35, 1499. [Google Scholar] [CrossRef]

- Rehan, I.; Gondal, M.A.; Aldakheel, R.K. Development of laser induced breakdown spectroscopy technique to study irrigation water quality impact on nutrients and toxic elements distribution in cultivated soil. Saudi J. Biol. Sci. 2021, 28, 6876–6883. [Google Scholar] [CrossRef]

- Mehari, F.; Rohde, M.; Kanawade, R. Investigation of the differentiation of ex vivo nerve and fat tissues using laser-induced breakdown spectroscopy (LIBS): Prospects for tissue-specific laser surgery. J. Biophotonics 2016, 9, 1021–1032. [Google Scholar] [CrossRef] [PubMed]

- Nouir, R.; Cherni, I.; Ghalila, H. Early diagnosis of dental pathologies by front face fluorescence (FFF) and laser-induced breakdown spectroscopy (LIBS) with principal component analysis (PCA). Instrum. Sci. Technol. 2022, 50, 465–480. [Google Scholar] [CrossRef]

- Berlo, K.; Xia, W.; Zwillich, F. Laser induced breakdown spectroscopy for the rapid detection of SARS-CoV-2 immune response in plasma. Sci. Rep. 2022, 12, 1614. [Google Scholar] [CrossRef] [PubMed]

- Poggialini, F.; Fiocco, G.; Campanella, B. Stratigraphic analysis of historical wooden samples from ancient bowed string instruments by laser induced breakdown spectroscopy. J. Cult. Herit. 2020, 44, 275–284. [Google Scholar] [CrossRef]

- Siozos, P.; Hausmann, N.; Holst, M. Application of laser-induced breakdown spectroscopy and neural networks on archaeological human bones for the discrimination of distinct individuals. J. Archaeol. Sci.-Rep. 2021, 35, 102769. [Google Scholar] [CrossRef]

- Wang, X.; Hong, X.; Chen, P. Surface Hardness Analysis of Aged Composite Insulators via Laser-Induced Plasma Spectra Characterization. IEEE T. Plasma Sci. 2019, 47, 387–394. [Google Scholar] [CrossRef]

- Wan, N.; Wang, X.; Chen, P. Metal Contamination Distribution Detection in High-Voltage Transmission Line Insulators by Laser-induced Breakdown Spectroscopy (LIBS). Sensors 2018, 18, 2623. [Google Scholar] [CrossRef] [PubMed]

- Zhang, F.; Chen, S.; Wang, T. LIBS characterization of algal fouling on insulators. J. Eng. 2021, 2021, 408–413. [Google Scholar] [CrossRef]

- Sanjana, K.; Babu, M.S.; Sarathi, R. Classification of Polluted Silicone Rubber Insulators by Using LIBS Assisted Machine Learning Techniques. IEEE Access. 2023, 11, 1752–1760. [Google Scholar] [CrossRef]

- Babu, M.S.; Neelmani; Vasa, N.J. Use of LIBS technique for identification of type of pollutant and ESDD level on epoxy-alumina nanocomposites using ANN. Meas. Sci. Technol. 2021, 32, 115201. [Google Scholar] [CrossRef]

- Gondal, M.A.; Shwehdi, M.H.; Khalil, A.A.I. Applications of LIBS for determination of ionic species (NaCl) in electrical cables for investigation of electrical breakdown. Appl. Phys. B 2011, 105, 915–922. [Google Scholar] [CrossRef]

- Neettiyath, A.; Alli, M.B.; Hayden, P. Vacuum ultraviolet laser induced breakdown spectroscopy for detecting sulfur in thermally aged transformer insulation material. Spectrochimi. Acta B 2020, 163, 105730. [Google Scholar] [CrossRef]

- Neettiyath, A.; Vasa, N.J.; Sarathi, R. Life Expectancy Estimation of Thermally Aged Cu Contaminant-Diffused Oil Impregnated Pressboard. IEEE Trans. Dielectr. Electr. Insul. 2021, 28, 637–645. [Google Scholar] [CrossRef]

- Amalanathan, A.J.; Vasa, N.J.; Harid, N. Classification of thermal ageing impact of ester fluid-impregnated pressboard material adopting LIBS. High Volt. 2021, 6, 655–664. [Google Scholar] [CrossRef]

- Yuan, H.; Ye, Z.; Wang, X. Study on spark discharge enhanced laser-induced breakdown spectroscopy of Fe particles in transformer oil. J. Anal. Atom. Spectrom. 2022, 37, 381–389. [Google Scholar] [CrossRef]

- Zhang, S.C.; Wu, L.H.; Sun, X.K. Ultra-low thermal conductivity multilayer composites for insulation in low pressure environments. Adv. Ceram. 2023, 44, 442–450. [Google Scholar]

- NIST Atomic Spectra Database Lines Form. Available online: https://physics.nist.gov/PhysRefData/ASD/lines_form.html (accessed on 6 April 2024).

- Qian, M.; Ren, C.; Wang, D. Stark broadening measurement of the electron density in an atmospheric pressure argon plasma jet with double-power electrodes. J. Appl. Phys. 2010, 107, 063303. [Google Scholar] [CrossRef]

- Stetzler, J.; Tang, S.; Chinni, R.C. Plasma Temperature and Electron Density Determination Using Laser-Induced Breakdown Spectroscopy (LIBS) in Earth’s and Mars’s Atmospheres. Atoms 2020, 8, 50. [Google Scholar] [CrossRef]

- Unnikrishnan, V.K.; Alti, K.; Kartha, V.B. Measurements of plasma temperature and electron density in laser-induced copper plasma by time-resolved spectroscopy of neutral atom and ion emissions. Pramana 2010, 74, 983–993. [Google Scholar] [CrossRef]

- Zhao, X.X.; Luo, W.F.; He, J.F. Measurements of electron number density and plasma temperature using LIBS. In Proceedings of the International Symposium on Optoelectronic Technology and Application 2016, Beijing, China, 9–11 May 2016. [Google Scholar]

- Abdellatif, G.; Imam, H. A study of the laser plasma parameters at different laser wavelengths. Spectrochimi. Acta B 2002, 57, 1155–1165. [Google Scholar] [CrossRef]

- Database for “Stark” Broadening of Isolated Lines of Atoms and Ions in the Impact Approximation. Available online: http://stark-b.obspm.fr/index.php/home (accessed on 6 April 2024).

| Laser Pulse Number | Average Ablation Depth (μm) | Ablation Area (mm2) |

|---|---|---|

| 10 | 133.212 | 0.251 |

| 50 | 250.030 | 0.334 |

| 100 | 311.663 | 0.334 |

| 150 | 369.067 | 0.347 |

| 200 | 317.879 | 0.364 |

| 250 | 363.407 | 0.488 |

| 300 | 489.099 | 0.473 |

| Single Laser Pulse Energy (mJ) | Average Ablation Depth (μm) | Ablation Area (mm2) |

|---|---|---|

| 35 | 328.549 | 0.300 |

| 45 | 398.258 | 0.321 |

| 55 | 370.429 | 0.360 |

| 65 | 333.696 | 0.353 |

| 75 | 342.209 | 0.450 |

| 85 | 313.004 | 0.480 |

| 95 | 356.566 | 0.521 |

| Element | Atomicity | Normalized Mass (%) | Atom (%) |

|---|---|---|---|

| C | 6 | 42.08 | 54.05 |

| O | 8 | 37.05 | 35.73 |

| Na | 11 | 0.30 | 0.20 |

| Mg | 12 | 0.52 | 0.33 |

| Al | 13 | 9.07 | 5.19 |

| Si | 14 | 3.98 | 2.19 |

| S | 16 | 0.07 | 0.03 |

| Cl | 17 | 0.11 | 0.05 |

| K | 19 | 0.19 | 0.08 |

| Ca | 20 | 4.43 | 1.71 |

| Ti | 22 | 0.88 | 0.28 |

| Fe | 26 | 0.31 | 0.08 |

| Pt | 78 | 1.02 | 0.08 |

| Species | Wavelength/nm | Aki/108s−1 | Ek/cm−1 |

|---|---|---|---|

| Fe I | 305.74456 | 0.3130 | 39,625.804 |

| Fe I | 306.64787 | 0.0911 | 54,600.350 |

| Fe I | 307.57194 | 0.3140 | 40,231.336 |

| Fe I | 307.84320 | 0.1520 | 52,512.457 |

| Fe I | 309.15763 | 0.5530 | 40,491.284 |

| Fe I | 318.02231 | 0.4420 | 51,192.273 |

| Fe I | 323.46130 | 0.00115 | 31,322.613 |

| Fe I | 323.94571 | 0.0674 | 50,880.102 |

| Fe I | 332.37362 | 0.2800 | 52,916.295 |

| Fe I | 334.22916 | 0.0942 | 52,857.804 |

| Fe I | 337.20736 | 0.0130 | 47,197.010 |

| Fe I | 338.39788 | 0.0652 | 47,092.712 |

| Fe I | 373.71313 | 0.1410 | 27,166.820 |

| Fe I | 383.71347 | 0.0108 | 47,092.712 |

| Fe I | 388.32797 | 0.1280 | 51,969.101 |

| Fe I | 394.47385 | 0.0130 | 48,289.871 |

| Fe I | 396.11400 | 0.0260 | 48,289.871 |

| Fe I | 398.98569 | 0.0530 | 53,661.079 |

| Fe I | 443.37821 | 0.0262 | 51,604.103 |

| Fe I | 445.43807 | 0.0338 | 45,281.833 |

| Fe I | 527.03560 | 0.0367 | 31,937.325 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, H.; Jian, H.; Zhen, H.; Yu, L.; Chen, H.; Tong, T.; Cui, X.; Wang, X. Laser-Induced Breakdown Spectroscopy Analysis of Sheet Molding Compound Materials. Energies 2024, 17, 2964. https://doi.org/10.3390/en17122964

Shen H, Jian H, Zhen H, Yu L, Chen H, Tong T, Cui X, Wang X. Laser-Induced Breakdown Spectroscopy Analysis of Sheet Molding Compound Materials. Energies. 2024; 17(12):2964. https://doi.org/10.3390/en17122964

Chicago/Turabian StyleShen, Hua, Honglin Jian, Haohan Zhen, Lei Yu, Haibin Chen, Tao Tong, Xuhui Cui, and Xilin Wang. 2024. "Laser-Induced Breakdown Spectroscopy Analysis of Sheet Molding Compound Materials" Energies 17, no. 12: 2964. https://doi.org/10.3390/en17122964

APA StyleShen, H., Jian, H., Zhen, H., Yu, L., Chen, H., Tong, T., Cui, X., & Wang, X. (2024). Laser-Induced Breakdown Spectroscopy Analysis of Sheet Molding Compound Materials. Energies, 17(12), 2964. https://doi.org/10.3390/en17122964