1. Introduction

Decarbonization of buildings is of paramount significance in the European Union (EU) environmental policy, considering that buildings in the EU consume 40% of the total energy and emit 36% of the greenhouse gases [

1]. The Energy Performance of Buildings Directive (EPBD) 2010/31/EU urges member states to decarbonize the building sector through the integration of local renewable energy sources (RES), among other measures. Meanwhile, the EU Renovation Wave aims at the renovation of the public and private building stock, along with the increase of the share of local RES in heating and cooling [

2]. Moreover, the revised Renewable Energy Directive (EU) 2023/2413 included the target for an average annual increase in the share of renewables in heating and cooling by 0.8% and 1.1% during the years 2021–2025 and 2026–2030 [

3]. Owing to its abundance, solar energy is at the core of the EU solar energy strategy [

4] and Strategic Energy Technology (SET) Plan [

5], which aim at supporting photovoltaics (PV), solar heating, as well as solar thermal (including concentrated solar power (CSP)) technologies in buildings.

Compared to commercially established PV-driven systems, solar thermal trigeneration systems for the production of heating, cooling and electricity have a series of advantages. Firstly, they are associated with higher overall conversion efficiencies of solar radiation; thus they can yield more final energy per unit of utilized area [

6]. Secondly, thermal energy storage (TES) is less expensive than electrical energy storage through batteries [

7]. Furthermore, through solar thermal trigeneration systems, it is easier to produce at the same time electricity, heating and cooling [

8,

9], compared to the use of PVs with heat pumps, which typically have a single operating mode at a given time. Finally, solar thermal trigeneration systems can be hybridized with alternative heat sources such as geothermal, waste heat and biomass [

8,

9] and are thus more relevant in the context of sector coupling.

Solar thermal systems can be based on different types of collectors, the most prominent being flat plate, evacuated tube and parabolic trough collectors (PTCs). The main advantage of concentrating PTCs is their capability of operating at higher temperatures that range from around 150 °C to 400 °C [

6,

10,

11], which enables higher conversion efficiencies into electricity and cooling as well as improved energy densities and hence flexibility if coupled with high-temperature sensible TES systems.

The most commonly investigated type of solar thermal trigeneration system driven by PTCs is based on an Organic Rankine Cycle (ORC) that is coupled with a thermally activated chiller. Overall, different technologies of thermally activated chillers have been proposed along with various ways of integrating them with ORCs. The most widely considered options are based on absorption chillers [

8,

10] as well as ejector cooling cycles (ECCs) [

9,

12,

13] in various configurations. In general, thermal cooling based on ejector has advantages over absorption chillers such as lower capital expenses and operation and maintenance costs, less complicated design and more flexibility in the choice of the working fluid, even though their coefficient of performance (COP) is lower than absorption chillers [

7]. Another advantage of the combination of ORC with ECC is that some parts of the configuration can be common (generator, condenser, pump, etc.). Finally, this combination has the possibility of producing cooling and electricity as well as heating from low temperature sources [

7]. Most studies on such solar thermal trigeneration systems based on integrated ORCs with ECCs (ORC-ECCs) primarily focus on the analysis and optimization of the ORC-ECC system itself, without considering the demand side, i.e., the building. As a result, the impact that the properties of the building have on the performance and the optimal size of the system are not thoroughly analyzed.

Taking into account the energy demands of the building is also very significant in the context of the EPBD Directive 2010/31/EU, which introduced the concept of cost-optimal levels of energy consumption, which refers to the implementation of energy efficiency (EE) or RES measures that would lead to a reduction of the energy consumption but also to the minimization of the global cost (GC) in the lifetime of the building. The methodological steps for building cost-optimality assessments are provided in the supplementary Directive 244/2012/EU [

14] and its accompanying guidelines [

15]. Apart from its implementation by the EU member states for the revision of their minimum energy performance requirements [

16], the methodology has been also widely used to calculate the optimal sizing of individual elements for EE (for example, thickness of insulation) or RES measures in buildings [

17,

18,

19,

20]. An analysis based on this methodology was conducted for the evaluation of the implementation of different combinations of EE and RES interventions in the case of residential [

21] and office buildings [

22] in Greece considering various combinations of insulation, energy systems, integration of solar energy, etc., in different climate zones (CZs).

Concerning the application of the cost-optimal methodology, it can be concluded that it offers the possibility to assess not only the optimal combination of a package of measures but also the optimal implementation of individual measures in a specific building type. Although much research has been done in employing the cost-optimality methodology, most of the studies focus on single-purpose energy measures such as thermal insulation, PVs and heat pumps. Moreover, most studies on cost-optimality focus on either residential or office buildings. Nevertheless, regarding non-residential buildings, differences exist between the different building types, such as the operation schedule and the energy loads, which may affect the cost-optimal implementation of energy measures. The ongoing encouraging research findings on trigeneration implementation in terms of energy performance and the lack of extensive application of the cost-optimality methodology for all tertiary-sector building types under different climatic conditions raise the research interest on the investigation of the cost-optimal sizing of such combinatorial systems in a wider spectrum of building types and CZs.

Triggered by the above conclusion, the current study investigates the cost-optimal integration of a solar trigeneration system consisting of PTCs, TES and ORC-ECC in two tertiary sector buildings with different operation schedules and energy loads, namely a hospital building and an office building. An extensive cost-optimality assessment of different design scenarios of the trigeneration system is conducted, for the assessment of the optimal size of the trigeneration system in each building. Based on that, conclusions regarding the optimal implementation of solar trigeneration in buildings are extracted. Moreover, the impact of the operation schedule and energy demands of the two examined building types on the performance of the trigeneration system is investigated. The environmental impact of the integration of the trigeneration system is studied through the detailed calculation of GHG emissions. Moreover, through the calculation of investment KPIs, the economic viability of the integration of the technology in buildings is investigated, and insights regarding the requirements for an acceptable economic performance are provided and discussed. Finally, the effect of the different CZs is studied by simulating the operation and estimating the cost-optimal scenario in two different CZs in Greece. To achieve the objectives of the study, initially, reference office and hospital buildings were defined by elaborating building-features’ data of the Greek building stock, followed by the calculation of their energy loads in the two CZs based on dynamic energy simulations. A model for the simulation of the operation of the trigeneration system was then created, which allowed the calculation of the system’s performance under different values of its design parameters, and several alternative design scenarios for the trigeneration system were established for each building. For each scenario, the system’s techno-economic and environmental performance was calculated by utilizing the results from the building and the trigeneration system’s simulation and by including all relevant costs.

3. Results

In this section, initially, the simulation results from the buildings simulation are presented for the two examined buildings in the two CZs, along with the results from the trigeneration system’s simulation for a specific design scenario, to demonstrate the results from both simulation models and the differences between the examined buildings. Then, a sensitivity analysis of the design parameters of the trigeneration system for the two buildings is presented, which leads to conclusions regarding the effect of each design parameter on the performance of the system. After that, the results from the cost-optimality assessment for the two buildings are presented. Based on the latter, an investigation of the economic viability focused on the office building is presented.

3.1. Building and Trigeneration System Simulation Results

The results from the dynamic BEM regarding the buildings’ loads, developed using EnergyPlus, which were retrieved in the form of loads per end use on an hourly basis for a whole year for the office and the hospital building, are presented in

Figure 3 and

Figure 4, respectively. These results were then fed into the trigeneration system’s simulation model. The peak and average heating and cooling loads for the two buildings in the two CZs are presented in

Table 5. Both buildings have heating and cooling loads in the winter and in the summer, respectively, and lighting and devices loads all over the year. As expected, in both buildings, the heating loads are higher in CZ C and the cooling loads are higher in CZ B. The demands in the hospital building are almost continuous, due to the operation schedule of the building, while there are only a few hours in the winter and in the summer when no heating and no cooling demand exists, respectively. In addition, the demand for DHW is constant throughout the year. On the other hand, the demands of the office building are intermittent due to the intermittent operation schedule. Finally, the demands in the hospital building are much higher than in the office building, as expected due to its larger size and continuous operation schedule. This is also confirmed in

Table 6 and

Table 7, where the annual values of several energy indicators and of CO

2,eq emissions, respectively, are presented for the two buildings. In terms of normalized values, the normalized energy demand per each end use in the hospital is higher than the office, which is expected due to its continuous operation. As a result, the PEC and the CO

2,eq emissions are higher for the case of the hospital. Finally, for both buildings, both the PEC and the emissions are slightly higher in Zone C.

Following the feeding of the simulated buildings’ loads in the physical model of the trigeneration system, the performance of the system is computed for various design parameters’ values. Indicatively, to better understand the introduced simulation procedure and the consequent computed indicators, the modeling results for a specific design, i.e., PTC aperture area of 300 m

2, an ORC size equal to 20% of the peak PTC thermal output (i.e., 31 kW and 29 kW in CZ B and CZ C, respectively) and a TES capacity capable of 13h of discharge (i.e., 400 kWh and 380 kWh in CZ B and CZ C, respectively), are presented in

Figure 5 and

Table 8. Considering the ORC-ECC efficiencies and COP (see

Table 2), the trigeneration system has a nominal heating capacity of 27 kW and 25 kW in CZ B and CZ C, respectively. The cooling capacity in the summer is equal to 3.1 kW and 2.9 kW in CZ B and CZ C, respectively, while it is higher in the spring and autumn due to the higher COP (see

Table 2). Moreover, the minimum heating capacity (i.e., 75% of the nominal) is 20.25 kW and 18.75 kW in CZ B and CZ C, respectively, while the minimum cooling capacity is the same as the nominal.

Figure 5 depicts the outputs from the trigeneration system in each building. In the case of the office building, both the heating and the cooling output are intermittent, following the demand of the building. Electricity is produced during the hours with no heating or cooling demand, if there is available thermal energy, as well as during the hours when the system operates in CHP mode. On the contrary, in the case of the hospital, the heating and cooling output is almost continuous during the winter and the summer months, respectively, due to the building’s continuous heating demand, while during spring and autumn, there are several hours when there is no demand for heating or cooling. In these hours, DHW is produced, as its demand is continuous throughout the year. As a result, the system never operates in electricity-only mode. Finally, it can be observed that the heating capacity (27 kW) is close to the average heating load of the office building, while it is much lower than the average heating load of the hospital building (see

Table 5).

The difference in the operation of the trigeneration system in the two buildings can be also deducted from

Table 8, where annual results describing the operation of the trigeneration system in the examined buildings and CZs are presented. It is observed that the distribution of the heat produced by the collectors is different in the two buildings, based on their demands. Solar heat is mainly utilized for heating and cooling in the case of the hospital building, as the produced heating and cooling is higher than the office building. Thus, in the latter, more electricity is produced. As for DHW production in the hospital building, it is lower than heating since heating is prioritized over DHW. The demand coverage in the case of the hospital is lower, due to the building’s high loads compared to the trigeneration system’s heating and cooling capacity. Nevertheless, the latter results in a complete utilization of the heating and cooling produced by the trigeneration system. In the case of the office, the minimum heating output (20.25 kW) is higher than the heating load at some hours (see

Figure 3). At these hours, the produced heat is higher than the heating demand of the building, and thus the surplus heat is dumped. The cooling output is generally lower than the respective building’s loads, and therefore the utilization of the cooling output is high. Concerning differences due to location,

Table 8 dictates that the annual production of solar heat is lower in the case of CZ C, due to the lower availability of DNI. Moreover, in both buildings, more heating and less cooling are produced by the trigeneration system in CZ C, as expected, while the production of DHW in the hospital building in CZ B is higher. The electricity production is similar in both CZs.

Concerning the impacts at the building level, the results are presented in

Table 9. As expected, the reduction of oil consumption is higher in the case of the hospital, as the trigeneration system produces more heating, as well as DHW, while the electricity consumption reduction is higher in the case of the office building. The reduction of both the PEC and the emissions is higher in the case of the hospital building. This shows that the implementation of the same system has a higher impact on the PEC and emissions reduction in the case of the hospital. Regarding the differences between the CZs, the PEC and emissions reduction are similar, even though there are differences in the reduction of oil and electricity.

Finally, the economic assessment of the trigeneration system in the examined buildings is presented in

Table 10. The GC is calculated based on Equation (11). The annual cash flow in the case of the hospital is higher than that of the office, due to the higher reduction in oil costs. Moreover, based on the NPV, IRR and discounted PBP, the integration of the system in the office building is a non-viable investment, contrary to the hospital building, for which the indicators suggest a viable investment.

Overall, it can be concluded that the implementation of the same trigeneration system has a higher impact on the PEC and emissions reduction and a higher economic performance in the case of the hospital. Two factors leading to that result can be identified:

As for cooling, the operation in cooling-only mode has the lowest performance. As a result, the hospital building’s almost constant cooling demand during summer leads to a worse performance compared to the office, where the system operates in cooling mode only during the operation schedule of the building. However, this is counterbalanced by the better performance in the winter.

3.2. Sensitivity Analysis of the Design Parameters

In this section, indicative results from the two buildings that demonstrate the differences between the examined scenarios and the impact of the design parameters on the system’s performance are presented. The results correspond to indicative PTC sizes for the two buildings. In

Figure 6,

Figure 7,

Figure 8 and

Figure 9, the variation of energy, environmental and economic indicators for different ORC and TES sizes is presented, for a PTC size of 300 m

2 for the office and 7200 m

2 for the hospital building, both in CZ B.

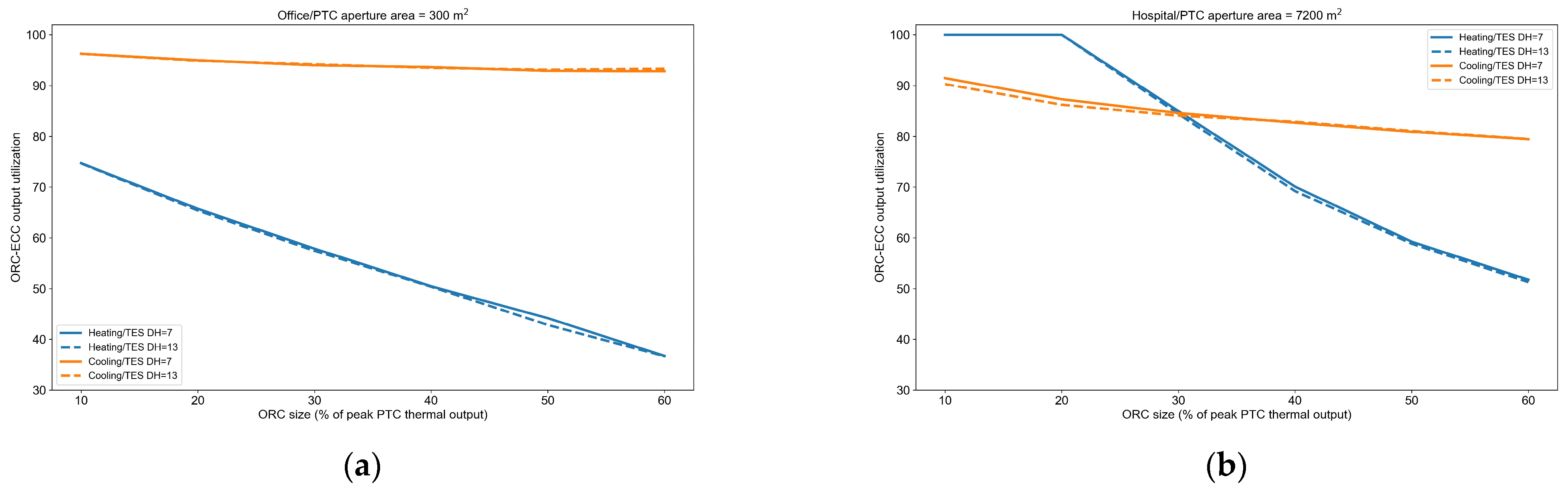

In

Figure 6, the variation of the PEC and the GC of the building for increasing ORC size is presented, for two different sizes of the TES. For smaller ORC sizes, the increase in the size leads to a decrease in both the PEC and the GC, as the trigeneration system produces more output, leading to the minimum GC. A further increase in the ORC size results in a further decrease of the PEC, while the GC increases, as the higher CAPEX cannot be counterbalanced by the additional benefit. Finally, a further increase in the ORC size results in an increase of both the GC and the PEC, suggesting a decrease in the energy production from the system. This is related to the cut-off threshold of the ORC-ECC, which, as the ORC size increases, results in fewer hours of operation and lower utilization of the solar heat, as explained above. The lower utilization of the ORC-ECC outputs for an increasing ORC size can be also verified from

Figure 7, where the utilization of the ORC-ECC outputs for an increasing ORC size is presented. The impact is lower in the utilization of cooling since the cooling output is much lower than the cooling demand due to the low COP. As for the TES capacity, its increase results in more beneficial values of PEC and GC for lower ORC sizes, as more heat can be stored, while for larger ORC sizes, the increase of the TES capacity is not beneficial. Moreover, the TES size has a low impact on the outputs’ utilization.

Regarding the NPV (

Figure 8), in the case of the office building, only negative values are obtained, while positive values appear for the hospital. The optimal NPV is achieved for medium ORC sizes, while the increase of the TES capacity leads to higher NPV values. Moreover, as expected, for each TES size, the optimal NPV value occurs for the same ORC size as the one for the optimal GC. Finally, the CO

2,eq emissions reduction (

Figure 9) is inversely proportional to the PEC reduction, as expected, and is higher for higher TES capacity. A maximum of around 14% and 16% emission reduction is observed for the office and the hospital building, respectively.

From the above, it can be concluded that the increase in the ORC size is beneficial only up to a certain point, while the increase in the TES size leads to more beneficial PEC and GC values at lower ORC sizes.

In

Figure 10, the GC-PEC plots for the two buildings are presented for indicative consecutive values of the examined PTC sizes. For a specific PTC size, the variation of the GC and PEC that was presented in

Figure 6 can be observed. Furthermore, as the PTC size increases, higher reduction of the PEC can be achieved as more solar heat is available. In the case of the office, this leads to a higher GC. In the case of the hospital, the medium PTC size presented (7200 m

2) shows lower GC values than the other sizes. This difference between the buildings is related to the building loads.

3.3. Cost-Optimality Assessment

In the following sections, the cost-optimality assessment results are presented for the two examined buildings. The results are presented mainly in the form of the GC-PEC plot, which allows the identification of the cost-optimal scenario and its respective PEC level. In these plots, the scenarios with a negative NPV are marked with a red circle. Also, to better demonstrate the effect of a different PTC size, a line is depicted in the plots, which shows the scenarios with the minimum GC for each examined PTC size. Finally, the cost-optimal scenario is marked with yellow.

3.3.1. Office Building

The GC-PEC plots for the office building in the two CZs are presented in

Figure 11. The optimal scenario in both CZs is observed for the lowest examined PTC size, as expected. Moreover, in all examined scenarios, the NPV is negative, suggesting a non-viable investment. Regarding the comparison between the CZs, in CZ C the points are shifted towards higher PEC and GC values, due to the higher PEC of the building in CZ C. Other than that, the variation of the points is similar in the two CZs. In addition, in

Figure 12, the GC and PEC, which correspond to the line frontiers of cost minima of

Figure 11, together with the NPV are presented for CZ B. As the PTC size increases, the GC and the PEC vary inversely, while the NPV decreases, remaining negative in all scenarios. This suggests that the increase of the PTC size is not beneficial in the case of the office, as for larger sizes the additional energy cost reduction is not enough to counterbalance the higher CAPEX.

The design characteristics of the cost-optimal scenarios in the two CZs are presented in

Table 12, while the trigeneration system performance in these design scenarios is presented in

Table 13. The cost-optimal PTC size, ORC size as a percentage of the peak PTC thermal output and TES discharge hours are the same in the two CZs. As for the trigeneration system’s performance, the produced heating and cooling is balanced in CZ B, while more heating is produced in CZ C, due to the higher heating load. Overall, the reduction of PEC and emissions is around 10–11% in both CZs. The economic indicators are not acceptable in both cases, while their values are slightly better in CZ C. Finally, the utilization of the outputs from the trigeneration system is higher in the case of cooling compared to heating. This is because the ORC size, and thus the heating capacity of the system, is higher than the building’s heating loads at some hours (see

Figure 3). The latter confirms the observation made in

Figure 12 regarding the higher GC and lower NPV at higher PTC sizes. More specifically, higher PTC size entails higher ORC and heating capacity, which in turn results in lower utilization of the heat from the ORC. This leads to lower economic performance.

3.3.2. Hospital Building

The GC-PEC plots for the hospital building in the two CZs are presented in

Figure 13. In this case, many scenarios present a positive NPV. Comparing performances between the CZs, similar conclusions as in the case of the office can be drawn, while the variation of the points in the plot is similar in the two CZs. Moreover, in

Figure 14, the GC and PEC and the NPV of the scenario with the minimum GC for each examined PTC field aperture area are presented. As the PTC size increases, the GC initially decreases, reaching its optimal value for a PTC size of 7200 m

2. After this point, the GC increases, as the additional energy cost reduction is not enough to counterbalance the impact of the CAPEX on the GC. The NPV has an inverse variation, reaching its optimal value at the same PTC size, while it remains positive in all cases. On the other hand, the PEC constantly decreases as the PTC size increases, as more solar heat is produced from the trigeneration system. The above findings suggest that a larger PTC field is beneficial for the hospital up to a certain point, as the higher PEC reduction can result in a reduction of the GC.

The design parameters’ values of the cost-optimal scenarios in the two CZs are presented in

Table 14, while the trigeneration system’s performance indicators in these scenarios are presented in

Table 15. The optimal PTC size is higher in the case of CZ B, while the annual thermal energy produced from the collectors is similar. The cost-optimal ORC size as a percentage of the peak PTC thermal output and the TES discharge hours are the same in the two CZs. As for the trigeneration system’s performance, the distribution of heating and cooling is different, with more heating and electricity produced in CZ C and more cooling and DHW in CZ B. However, the reduction of PEC and emissions is similar, around 14% and 16%, respectively, in both CZs. Also, the economic indicators are acceptable and slightly better in CZ B. Finally, in contrast to the office building case, the utilization of both outputs from the trigeneration system is high.

3.3.3. Cost-Optimal Design Compared to the Building Energy Demand

To further analyze the cost-optimal design, in

Table 16, the heating and cooling capacity at the cost-optimal scenario is compared to the building’s maximum and average loads (see

Table 5), while the building’s demand coverage from the trigeneration system is presented in

Table 17. In the case of the hospital, the heating load corresponds to the sum of the heating and DHW load of the building. The cost-optimal heating and cooling capacity in terms of a percentage of the maximum buildings’ loads in the examined buildings and CZs is equal to 8–19% of the maximum heating load and 1–3% of the maximum cooling load of the building. Also, in both buildings, the system’s heating capacity is similar to the average heating load of the building (see

Table 5). Moreover, the heating demand coverage is higher in the buildings in CZ B (see

Table 17). Meanwhile, the cooling demand coverage is higher in the hospital building and electricity demand coverage is higher in the office building. However, in all cases, the demand coverage in the cost-optimal scenario is limited to a rather low value.

Overall, it can be concluded that despite the differences between the buildings, the heating and cooling capacity in terms of a percentage of the maximum buildings’ loads and the heating demand coverage are similar in the examined buildings and CZs.

3.4. Economic Viability in the Office Building

As presented in the previous sections, the economic indicators in the case of the office building suggest a non-viable investment, even in the cost-optimal scenario. Two parameters that could improve the viability are identified, namely the utilization of the produced heat, which could be higher, and the CAPEX, whose reduction would improve the economic indicators. The influence that those parameters could have on the economic viability is investigated below.

3.4.1. Higher Utilization of Produced Heat

As presented in the cost-optimal results of the office building, the utilization of the heat produced by the ORC is lower than 100% in both CZs (see

Table 13). To investigate the influence of higher heat utilization, the calculation of the economic indicators of the cost-optimal scenarios in CZ B and CZ C was repeated, considering a full utilization of the heat produced by the ORC. More specifically, the surplus of heat was considered to be utilized, resulting in an additional income. The economic indicators are presented in

Table 18. The effect of the full utilization of the surplus heat is important, as an additional annual income of 400–600 EUR resulted in an improvement of the economic indicators compared to those in

Table 13. However, the economic indicators’ values still suggest a non-viable investment.

3.4.2. CAPEX Reduction

The non-beneficial economic indicators in the case of the office occurred mainly because of the high CAPEX, which is not compensated by the cost reductions achieved after the implementation of the system. Thus, reductions in the CAPEX could lead to a viable investment. To investigate that, the CAPEX value that would lead to NPV equal to zero was calculated for the cost-optimal scenario. The results are presented in

Table 19. Based on the results, the minimum reduction of the CAPEX to achieve economic viability is around 58–61%.

4. Discussion

In the cost-optimal scenarios, the ORC size as a percentage of the peak PTC thermal output and the TES discharge hours were found to be the same in all buildings and CZs, despite the differences between the buildings and CZs. This was expected based on the results presented in

Figure 6 and

Figure 8, which show that a smaller ORC size and a large TES size result in more beneficial economic indicators in both buildings. Nevertheless, the cost-optimal PTC size and absolute ORC and TES size were different. The increase in the PTC area was not beneficial for the office (see

Figure 12), while an increase up to a certain point was beneficial for the hospital (see

Figure 14). The latter was also affected by the lower cost per kW of the ORC-ECC at higher ORC sizes (see

Table 4). Moreover, in both examined buildings and both CZs, the heating and cooling capacities were found to be a fraction of the maximum loads of the building (see

Table 16). Also, in both buildings, the trigeneration system covered part of the building’s demand (see

Table 17). Regarding heating, this is expected because, in the winter, the availability of solar energy is low in some hours, also depending on the region. Thus, a large system would be required to cover the whole demand. Regarding cooling, the low COP of the ECC would also require a large system to cover the whole cooling demand, which would not be viable. From the above, it can be concluded that in the cost-optimal scenario, the proposed system covers part of the building’s demand, thus reducing the energy consumption, cost and emissions, but does not fully replace the building’s heating and cooling system. Due to that fact, the proposed trigeneration system requires auxiliary heating and cooling systems, something that is also mentioned in other studies regarding solar trigeneration systems [

9,

64]. In addition, even though the cost-optimal scenario was different in the two buildings, the heating and cooling capacity as a percentage of the buildings’ loads was similar, at 8–19% for heating and 1–3% for cooling (see

Table 16). Also, in both buildings, even though the absolute reduction of PEC and emissions was different, the percentage of reduction was similar at around 10–14% and 10–16% for PEC and emissions reduction, respectively (see

Table 13 and

Table 15). The PEC and GC at the cost-optimal scenario of the office building (see

Table 12) are higher than those reported in the Greek official national report on the minimum energy performance requirements for office buildings [

28] and in a relevant study on office buildings in Greece [

22], where values as low as 114.4 kWh/m

2 and 358.35 EUR/m

2 for the PEC and GC, respectively, are mentioned at the cost-optimal scenario for the office building in CZ B [

28]. However, these more cost-efficient results are obtained by combinations of several EE and RES measures and not regarding a single intervention as obtained in this study. Overall, despite the differences between the two building types, the cost-optimal system size corresponds to a similar percentage of the building’s loads, while the expected relative reduction of PEC and emissions is also similar.

Regarding the operation of the trigeneration system, two parameters were found to be different between the two buildings, i.e., the operating mode of the ORC-ECC system and the degree of utilization of the heat produced by the ORC. Both affected the cost-optimal scenario and the profitability of the trigeneration system. The operating mode of the ORC-ECC was found to be related to the building’s operation schedule. In the hospital building, CHP operation occurs more often than in the office in the winter, due to the almost continuous heating demand and the continuous DHW demand that stem from the continuous schedule. This resulted in better energy and economic performance, as CHP mode was found to have the best performance among the ORC-ECC operating modes (see

Table 11). The more frequent operation in cooling-only mode in the hospital compared to the office had a negative effect, as cooling-only was found to have the lowest performance. However, overall, the positive effect of the operation in CHP mode dominated, resulting in acceptable economic performance in the hospital, contrary to the office. From that, it can be concluded that the building schedule affects the performance of the system, with a continuous schedule being more beneficial.

The second parameter, i.e., the utilization of the heat produced by the ORC, was found to be related to the scale of the heating loads of the building in comparison to the size of the trigeneration system, which depends on the building’s size. In the office, at the minimum examined PTC aperture area, the utilization of the produced heat was lower than 100% (see

Figure 7), due to the building’s heating loads being lower than the minimum trigeneration system’s heating output for some hours. At higher PTC sizes, the heating capacity is higher, and thus the heat utilization is lower, which negatively affects the economic performance. The heat utilization could be improved with a PTC size lower than the minimum examined, which is, however, not realistic. On the other hand, in the hospital, at PTC sizes larger than the minimum size, the heat utilization was almost complete (see

Figure 7), due to the building’s high loads. That resulted in acceptable economic indicators at larger PTC sizes. Overall, considering the minimum PTC size, it can be concluded that the integration of the proposed system in buildings with higher loads would be more beneficial. Furthermore, regarding the effect of the two parameters, it was shown that even if the surplus heat were fully utilized, the economic indicators would remain unacceptable, even though they would be improved (see

Table 18). Thus, the negative effect of the intermittent operation schedule of the office would not be counterbalanced. Finally, it must be mentioned that, as for the cooling loads, their scale is not as important, since due to the low COP of cooling, the trigeneration system’s minimum cooling capacity was found to be lower than the cooling demand for most of the hours.

From the economic assessment, it was found that the hospital building is a suitable facility for integrating the proposed trigeneration system in terms of economic performance, mainly due to its continuous operation schedule and high demand for heating and cooling. Viable economic performance has also been reported in the literature for solar trigeneration systems [

64]. Based on that, buildings with high and continuous heating and cooling demands, such as year-round hotels, would be the most suitable candidates along with hospitals. Moreover, residential buildings with high loads, such as multi-family houses, or district heating applications could be suitable, due to their continuous demand. On the other hand, in the office building, less beneficial economic indicators were calculated compared to those obtained by the cost-optimality survey for combinations of various EE and RES technologies in office buildings in Greece [

22,

28]. It was found that a reduction of the CAPEX is required in the case of the office building to achieve acceptable investment indicators, due to its intermittent operation and lower demands. Such reductions could be expected in the future, as the involved technologies become more widespread and mature and benefit from economies of scale [

65]. However, in the current environment, some form of financial support is required. This support could be provided in the form of subsidies that would decrease the CAPEX. In addition, subsidies are a common measure of promoting the deployment of new technologies, as proposed in ref. [

66]. Moreover, public buildings generally constitute a suitable category of buildings for implementing new energy technologies due to the exemplary role that public buildings should have in the demonstration of new technologies, according to the EU directives [

66,

67]. Thus, they could be eligible to receive subsidies to implement the proposed trigeneration system. Therefore, public offices, education buildings, sports halls, medical facilities and multi-purpose buildings could be considered suitable demonstration buildings, as the implementation of the system in these buildings could become viable through subsidies.

Based on the results from this study, it can be expected that in larger-scale building applications, the cost-optimal design would lead to a larger system as well as to a similar percentage of PEC and emissions reduction. Regarding the economic performance, a higher performance could be expected in larger applications. PTC systems are usually implemented in large-scale applications [

10], since they can benefit from economies of scale that exist for larger plants and have lower specific costs, as well as higher efficiency [

52,

57,

65]. In addition, the lower specific cost of the ORC and integration cost at larger sizes (see Equations (13) and (14)) would have a beneficial effect on the economic performance of the system.

The implementation of the proposed system requires the consideration of several, technical challenges The issue of area availability is important, especially in the case of the hospital building, in which the cost-optimal system consists of a PTC field with a substantial aperture area, while an even larger area would be required to install the whole system, considering the spaces between the PTCs rows and space required for the TES and ORC-ECC equipment. Thus, the area availability requirements could pose a challenge in the deployment of the system, especially in buildings located in urban areas. Moreover, even if the required area is available, alternative uses of this space could be considered by the buildings’ managers. The installation of the PTC field on the rooftop of the examined building could be investigated. However, in this case, issues such as the available rooftop area, wind protection and the securing of integrity of the bearing structure should be addressed and may result in additional costs. Furthermore, the integration of the trigeneration system into the building’s heating and cooling distribution network is site-specific, requires additional equipment (pipes, heat exchangers, pumps, etc.) and could be challenging. Finally, factors such as the availability of suitable commercial expanders, the higher cost of piping, valves and vessels and the flammability of the ORC-ECC working fluid can be limiting factors, especially in the case that the implementation of a high-temperature ORC-ECC system in a building is considered.

Finally, as for the limitations of the study, both the buildings’ heating, cooling and electricity loads and the thermal power production from the PTC field were calculated from simulations based on typical meteorological weather data rather than utilizing actual measurements from both the buildings and from an existing PTC system. The latter could provide more realistic results regarding the energy and economic performance of the system. Moreover, in the calculations, the off-design operation of the trigeneration system, e.g., the part-load operation of the ORC-ECC’s pump or expander, was not considered. Thus, regarding future work, a pilot implementation of the proposed system in a building would provide measurements, allow a more realistic calculation of the system’s performance and reveal the most important technical challenges of the system’s implementation. Moreover, regarding the ORC-ECC, the techno-economic performance of a trigeneration system with a high-temperature ORC-ECC, which would better exploit the high temperature of the PTC field and could achieve a higher thermal efficiency and COP, should be investigated. It must be mentioned that the methodology that was described and implemented in this study could be replicated for the case of different regions, by considering the weather data, typical building characteristics and economic environment of the region. Therefore, an investigation of the system’s techno-economic performance in different regions, as well as for different building types, e.g., hotels, multi-family houses or district heating applications, would allow the assessment of the potential of the proposed system to contribute to the decarbonization of the building sector. Finally, the methodology that was presented in this study could be implemented for the assessment of the techno-economic performance of other novel energy technologies.

5. Conclusions

In this study, the 244/2012/EU regulation’s cost-optimal methodology was implemented for the assessment of a solar trigeneration system consisting of PTCs, TES and ORC-ECC in tertiary sector buildings in Greece. The chosen building types were an office and a hospital, due to the differences in their operation schedule. For each building type, a reference building was established based on features that are mostly encountered in the Greek building stock, while its energy loads and demand were calculated on an hourly basis by means of a dynamic energy simulation. Moreover, a model for the simulation of the trigeneration system’s operation and performance was developed. By varying the system’s design parameters, different design scenarios were defined and indicators related to the energy, environmental and economic performance of the system at each scenario were calculated, leading to the identification of the cost-optimal scenario at each building. The assessment was conducted for two CZs that are the most populated by the considered building types in Greece.

The dynamic energy simulation of the buildings revealed that the hospital building has higher PEC, CO2,eq emissions and energy loads compared to the office, due to its continuous operation schedule and larger size. A key finding from the study was that these two characteristics are decisive in the profitability of the implementation of the system in each building. As for the operation schedule, the continuous heating demand of the hospital resulted in longer operation of the ORC-ECC in CHP mode, which was found to be the most efficient mode, contrary to the office where the system operated in CHP mode only during its operation schedule. Also, the higher heating loads of the hospital resulted in higher utilization of the heat produced by the ORC, contrary to the office, where an amount of surplus heat was dumped. As for cooling, due to the low COP of the ORC-ECC in cooling mode, the utilization of the produced cooling was high in both buildings.

Furthermore, significant findings occurred regarding the cost-optimal size of the trigeneration system and the PEC and emissions reduction. As for the cost-optimal scenario, in the investigated size range, an ORC size corresponding to 20% of the peak PTC thermal output was found to be optimal. As for the TES capacity, 13 h of discharge was found to be optimal in all examined buildings and CZs. Finally, the cost-optimal PTC size was found within the examined range, being the minimum examined size, i.e., 300 m2 for the office, as the increase of the size was not beneficial. In the hospital, the cost-optimal PTC aperture area was equal to 7200 m2 in CZ B and 8400 m2 in CZ C. Despite the differences in the cost-optimal scenario, the heating and cooling capacity as a percentage of the building’s peak heating and cooling load was found to be similar in both buildings, being 8–19% for the heating capacity and 1–3% for the cooling capacity. The coverage of the heating demand in the two buildings ranged from 18 to 36%, while the cooling demand coverage, which was higher in the hospital, remained below 16% in all examined cases. As a result, the existence of auxiliary heating and cooling systems is necessary. Furthermore, the integration of the trigeneration system in the office reduced the PEC by 62.88–65.17 MWh and the CO2,eq emissions by 10.41–10.78 tn, depending on the CZ. The respective reduction in the hospital was higher, being 2529.07–2775.97 MWh for the PEC and 540.34–600.23 tn for the CO2,eq emissions. Nevertheless, the relative reduction of these indicators was similar in the two buildings, with the PEC reduction being around 10% in the office and 14% in the hospital and the CO2,eq reduction being 10% in the office and 16% in the hospital. In addition, the different weather conditions in CZ B and C resulted in different heating and cooling loads, which resulted in a different cost-optimal scenario in the hospital. However, the energy, environmental and economic indicators were similar between the examined CZs.

Finally, the economic performance of the system in the hospital building was found to be acceptable, with a discounted PBP of around 15 years. On the contrary, for the office, the economic indicators suggested a non-viable investment. Therefore, subsidies of at least 58–61% of the CAPEX would be necessary for implementing the suggested system in an office.

Overall, the main implication of the results of this study is that the implementation of the examined solar trigeneration system can contribute to the decarbonization of buildings, due to its potential for decreasing emissions and PEC, as well as energy costs. Provided that the necessary investment financing is available, the presented calculations suggest that the proposed system would be indeed a viable investment for building decarbonization purposes. Meanwhile, maintaining the conventional heating and cooling systems of the building as auxiliary systems remains necessary.