Numerical Simulation Study on the Dynamics of Bluff-Body Flames under Oxygen-Lean Conditions

Abstract

:1. Introduction

2. Numerical Method Computational and Mathematical Model

2.1. Numerical Method

2.2. Numerical Configuration and Simulated Case

2.2.1. Model Structure

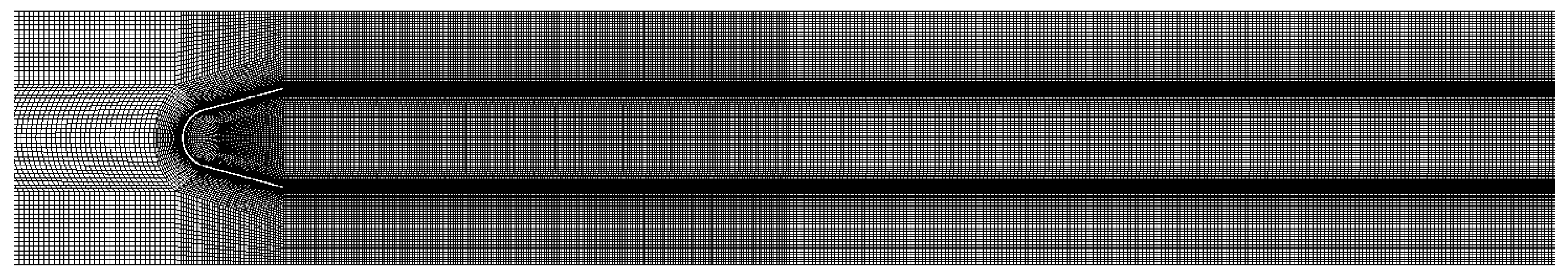

2.2.2. Meshing

2.2.3. Computational Domain and Boundary Conditions

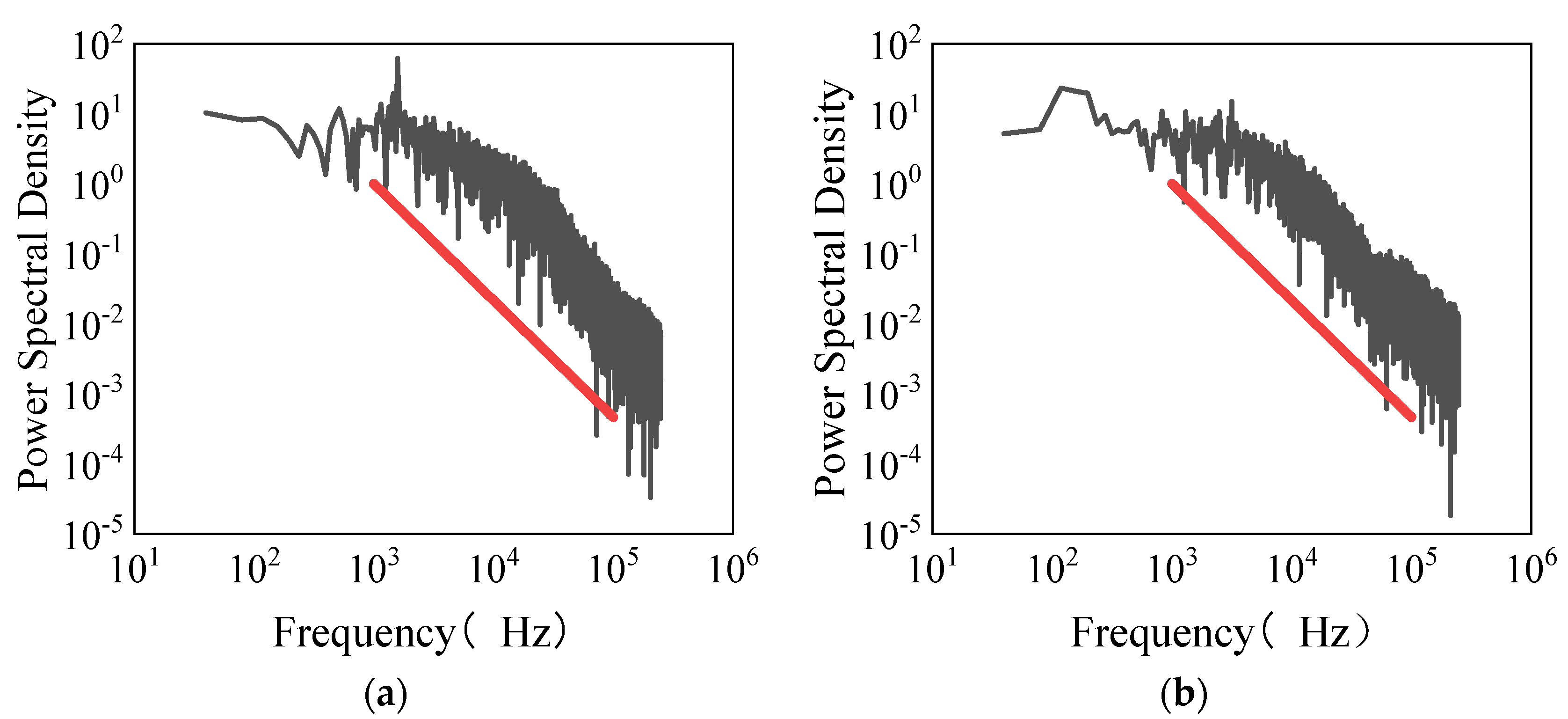

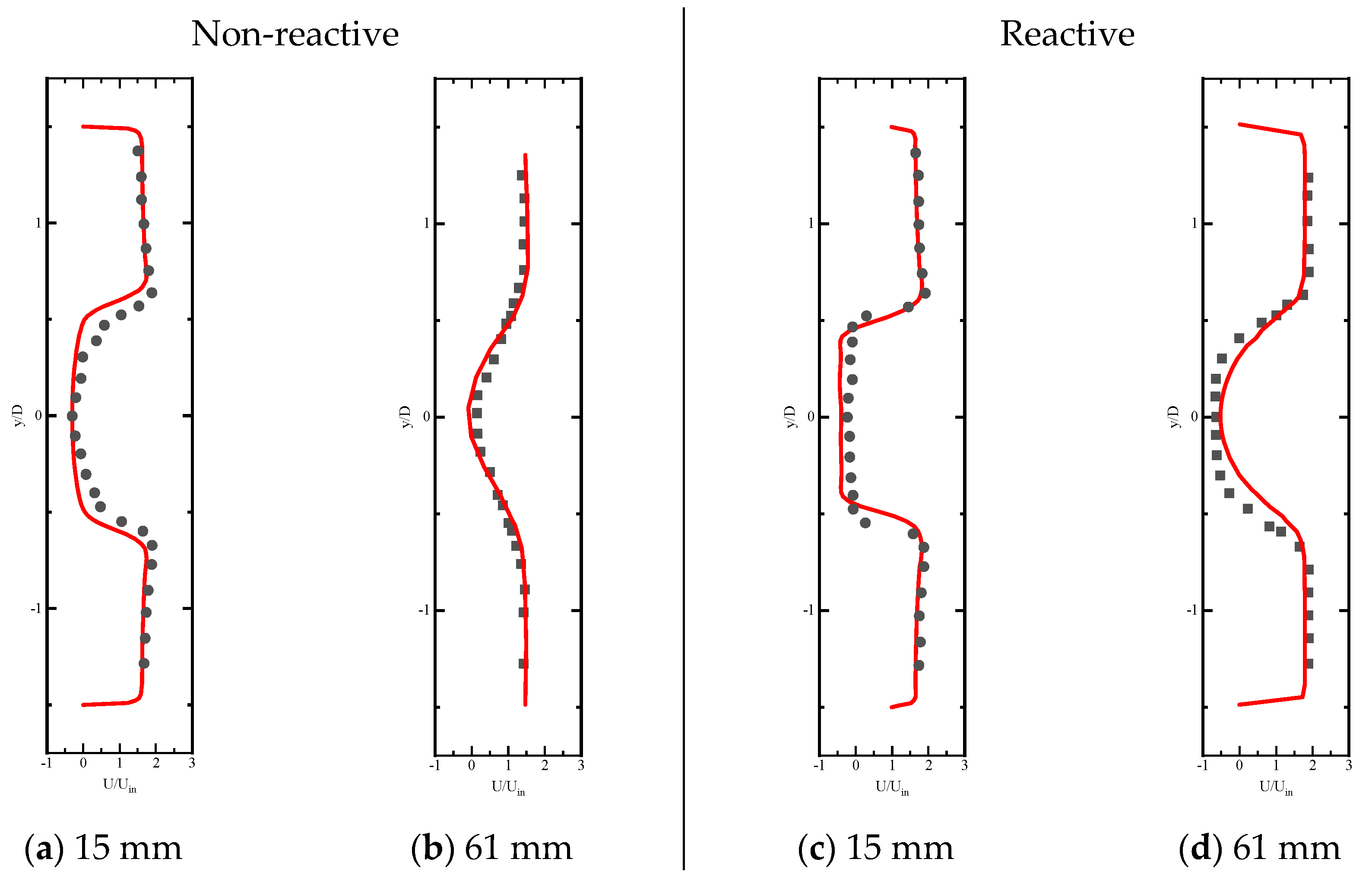

2.3. Model Verification

3. Results and Discussion

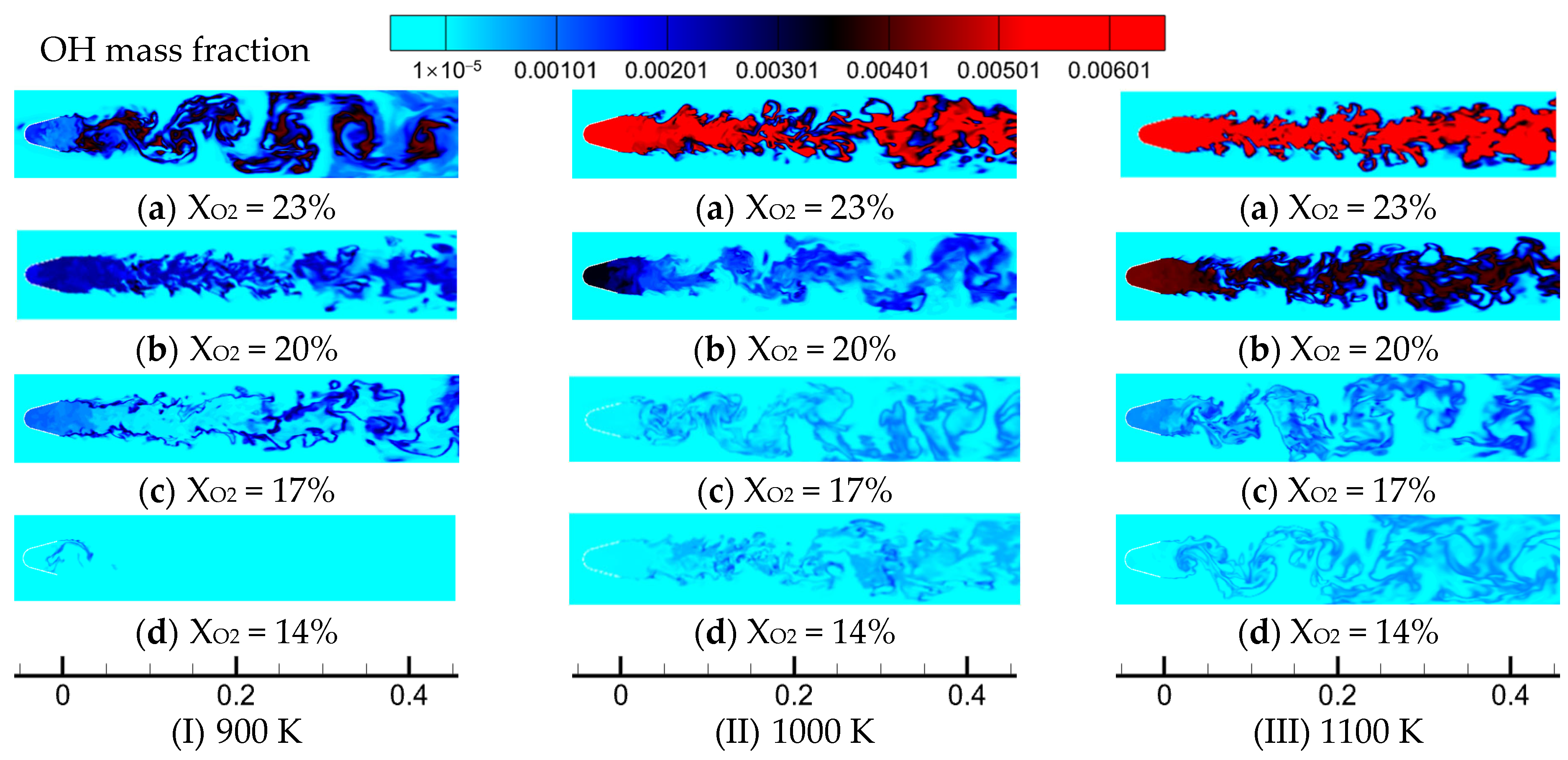

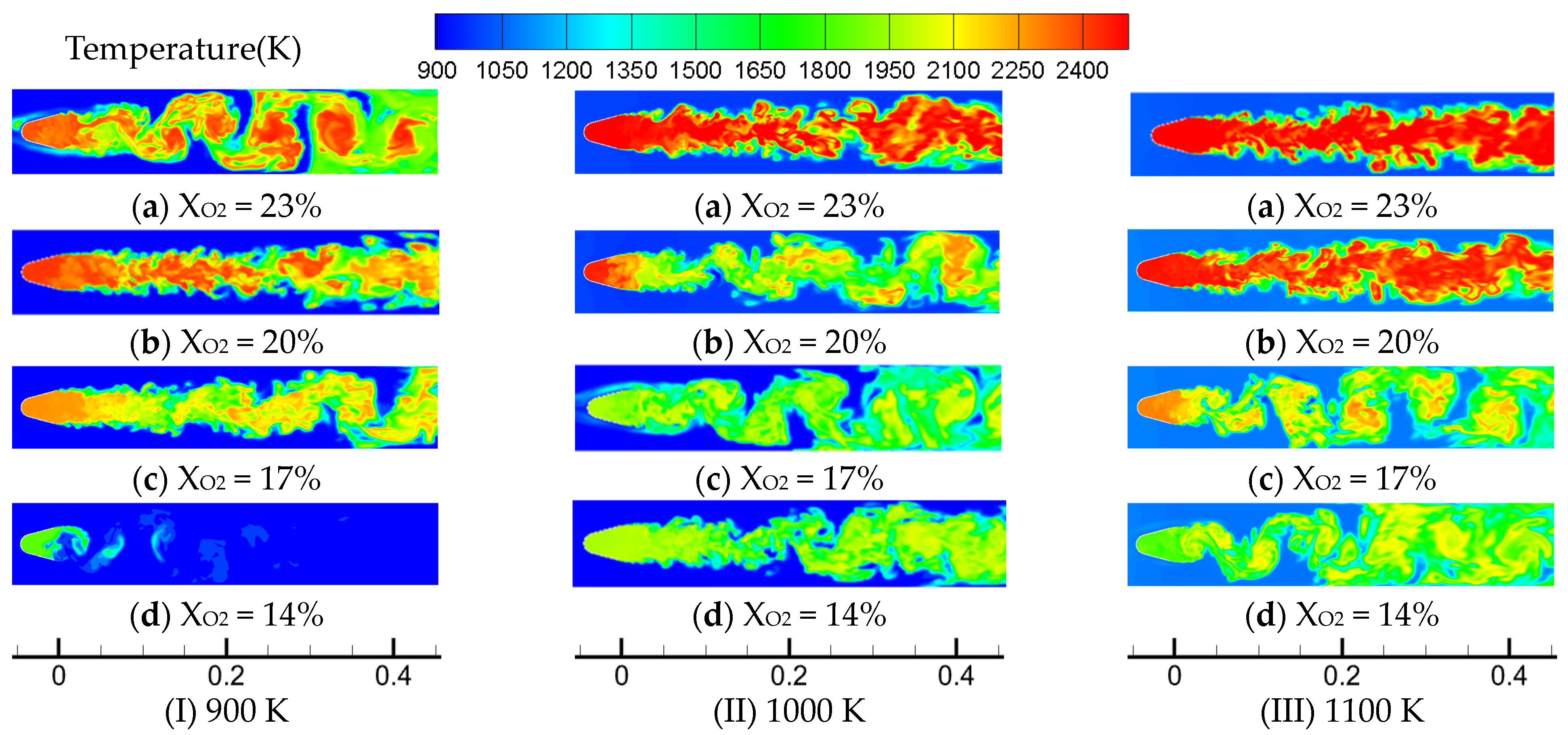

3.1. Effect of Oxygen Content on Dynamic Combustion Characteristics under Various Temperatures

3.1.1. Vortex Structure

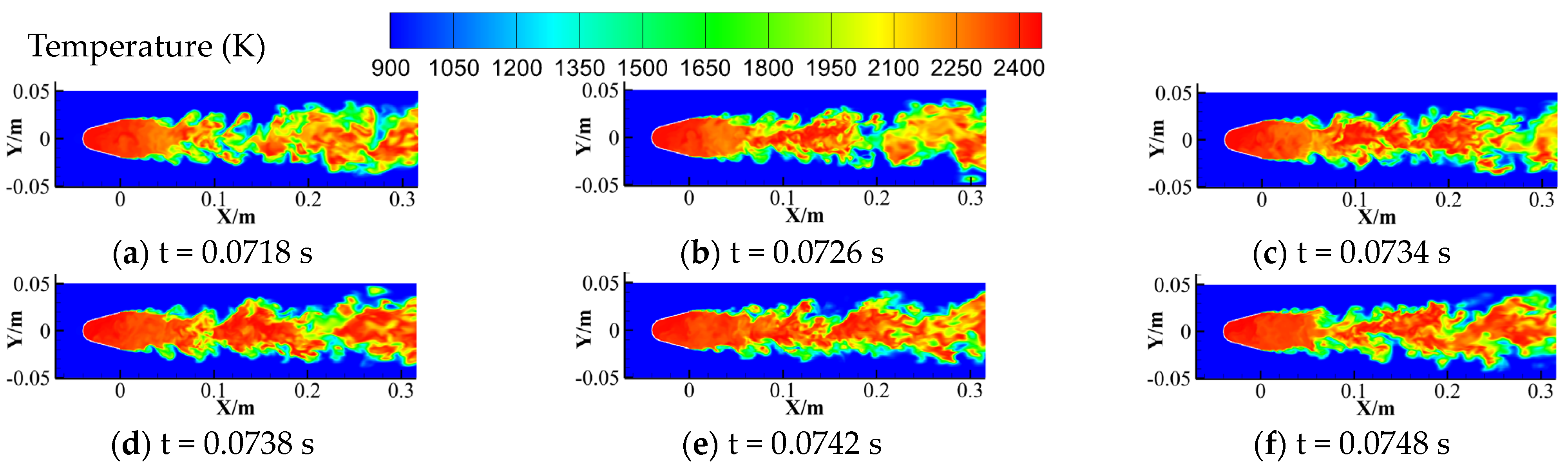

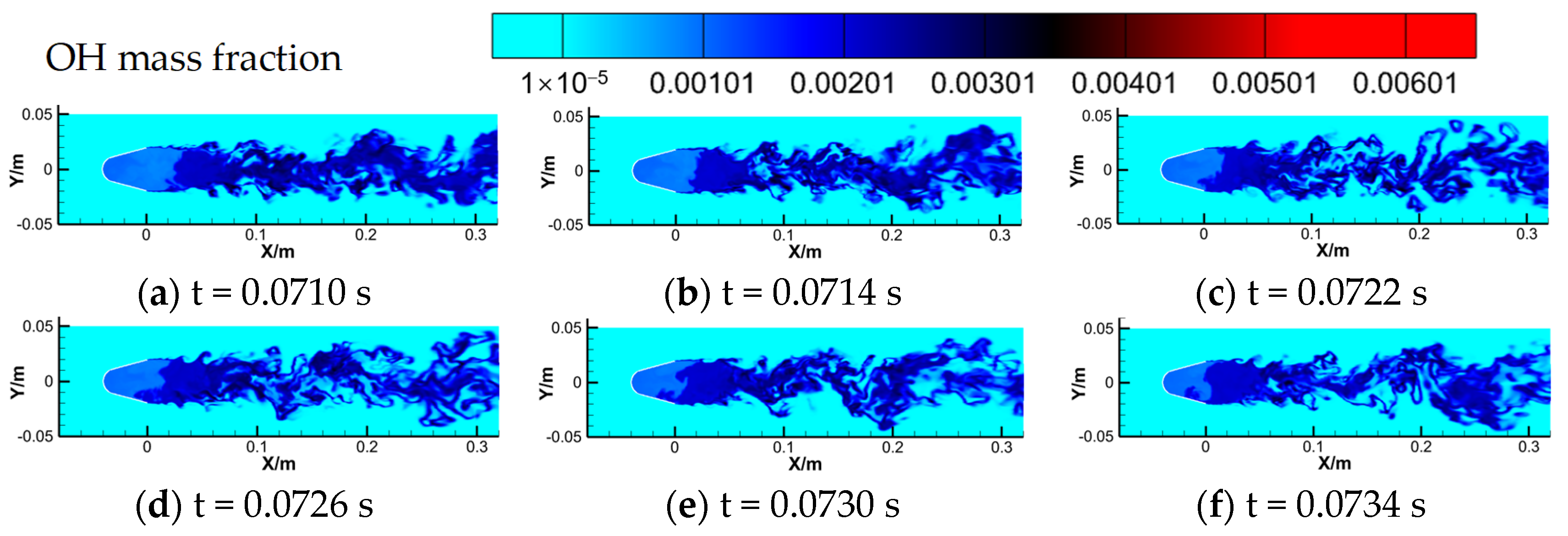

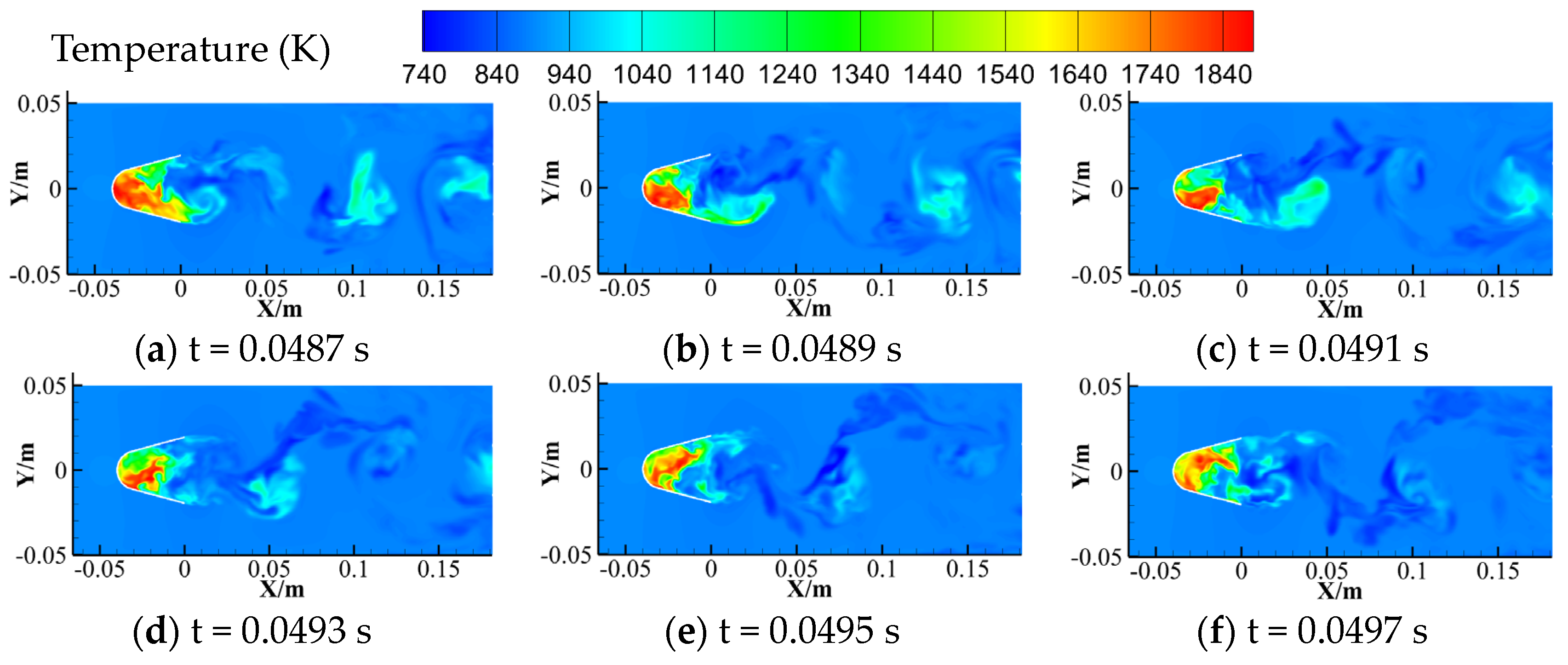

3.1.2. Flame Structure

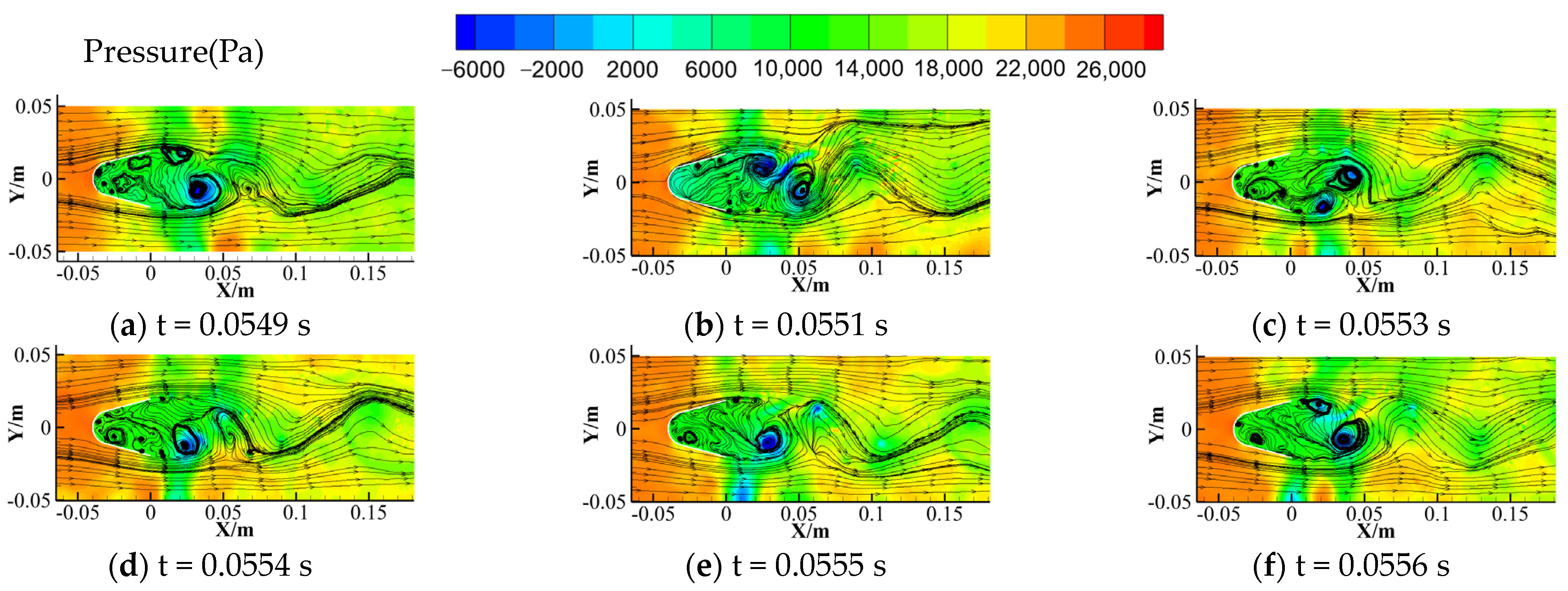

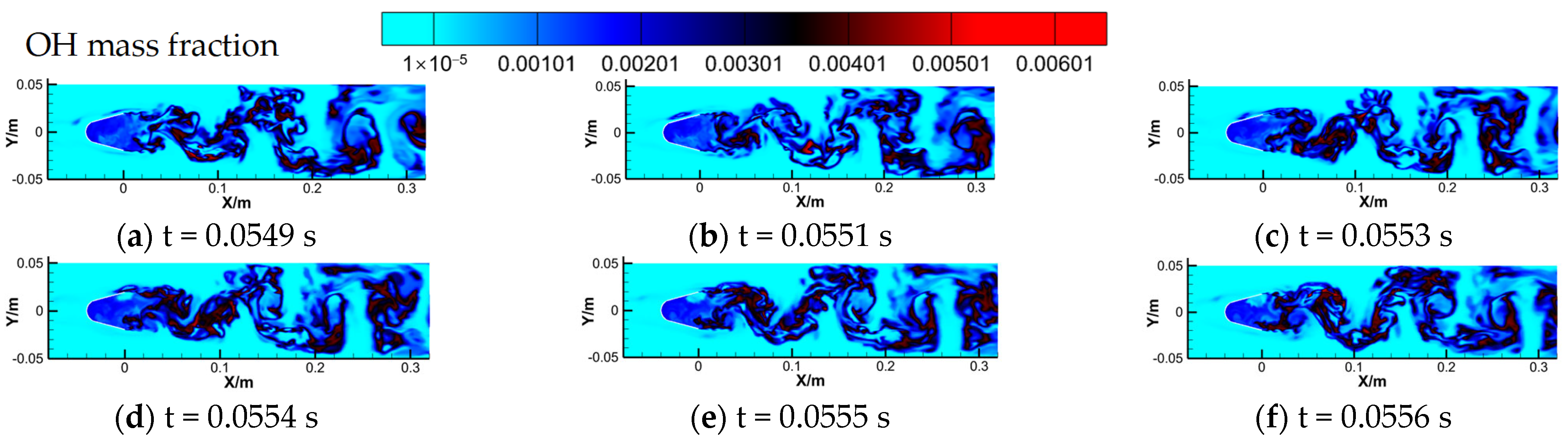

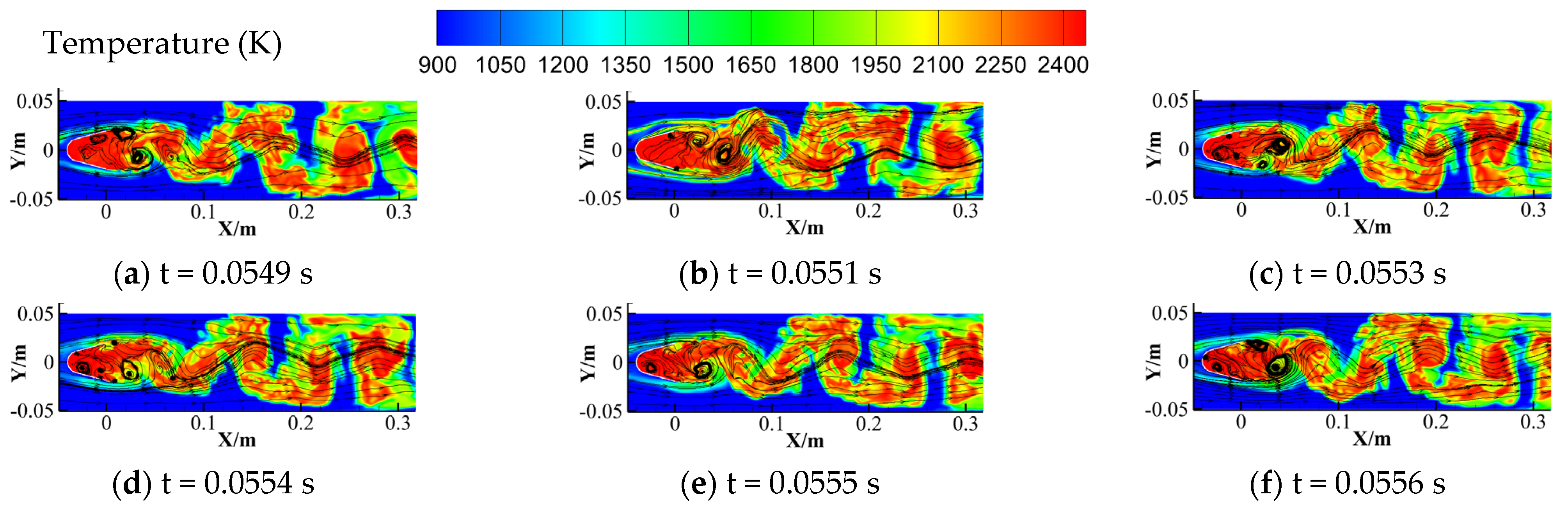

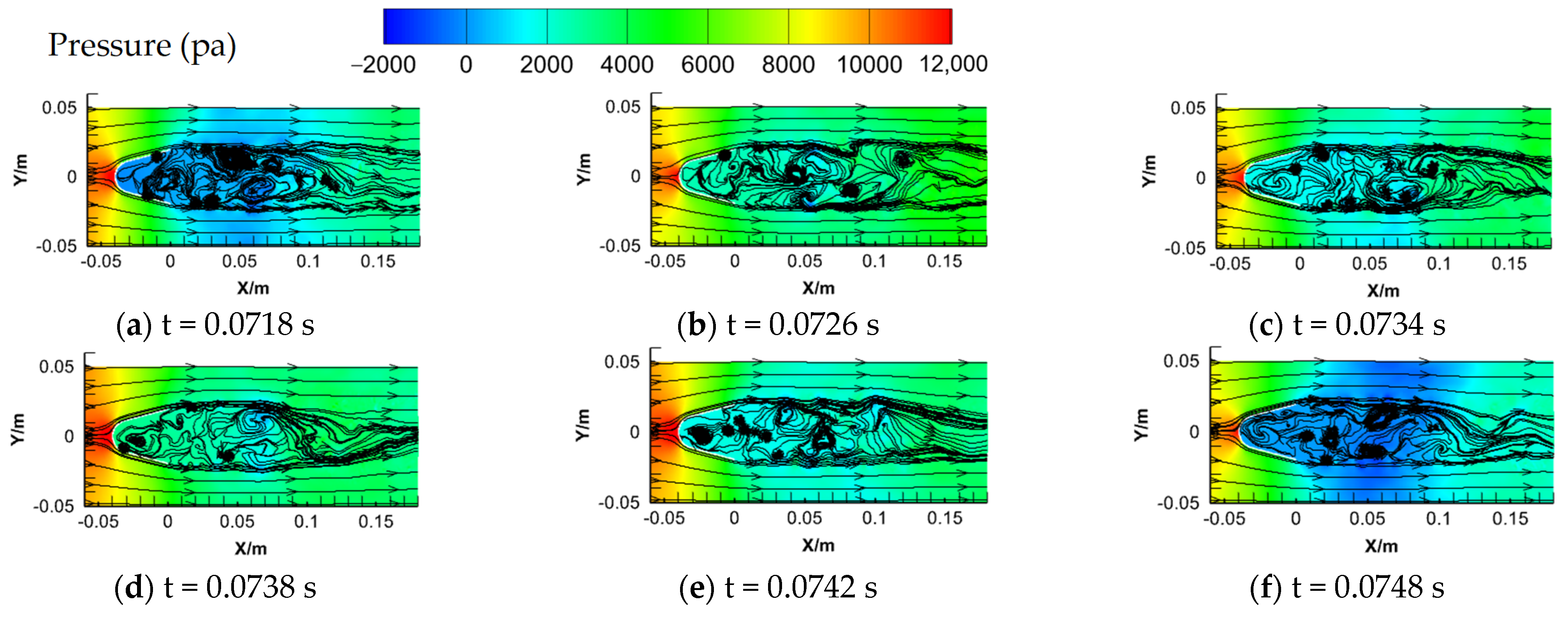

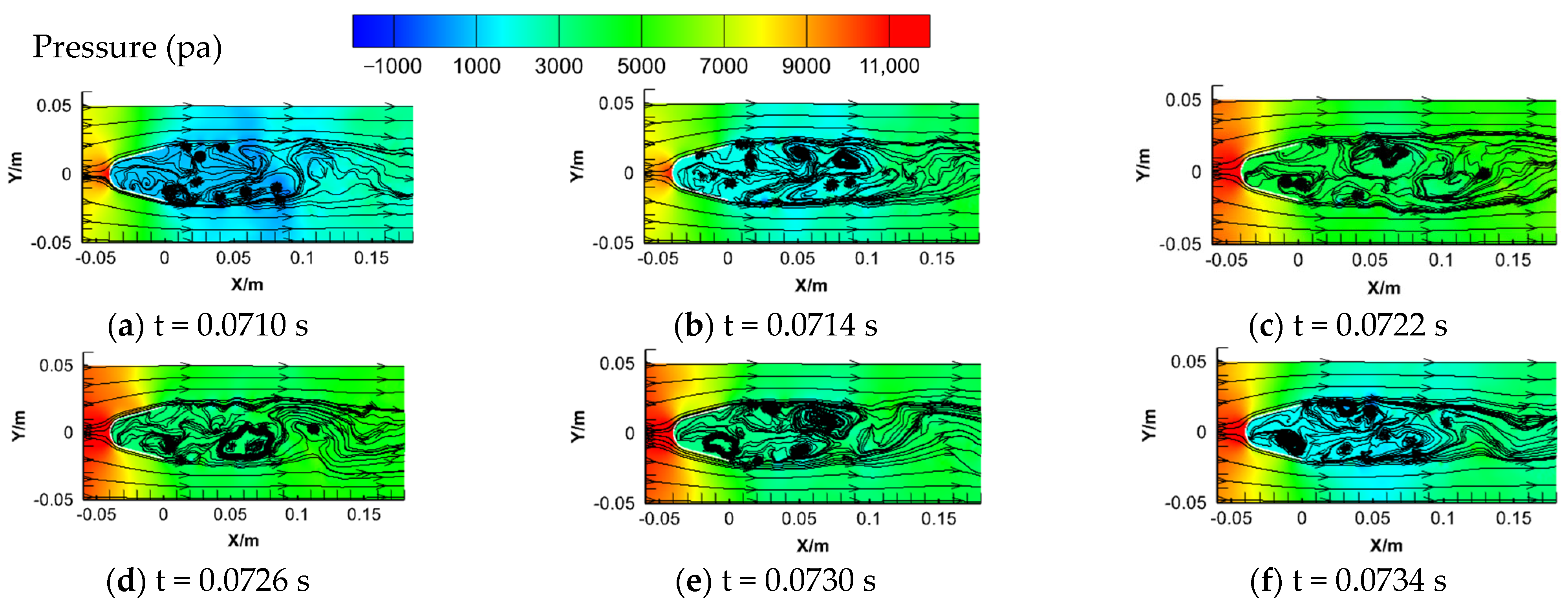

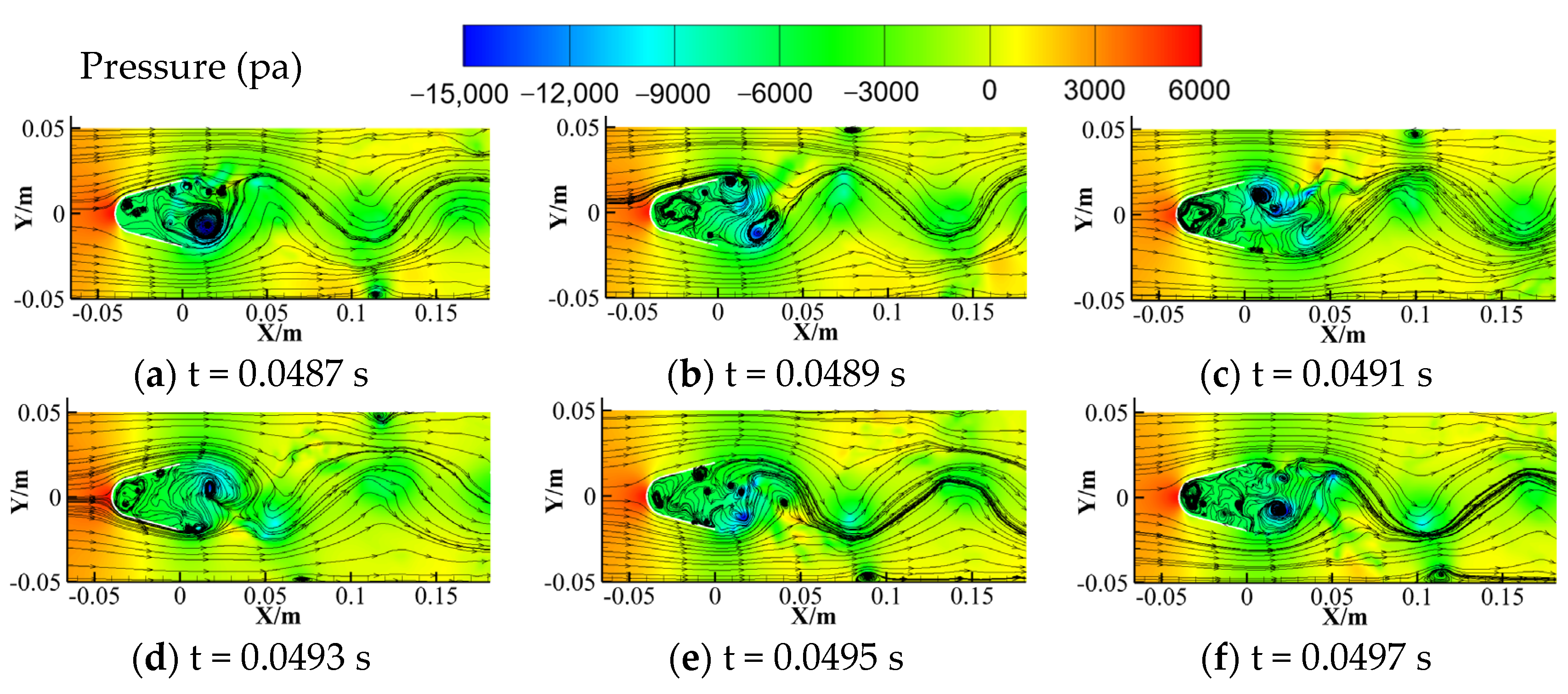

3.2. Effect of Oxygen Content on Instantaneous Reaction-Flow Field

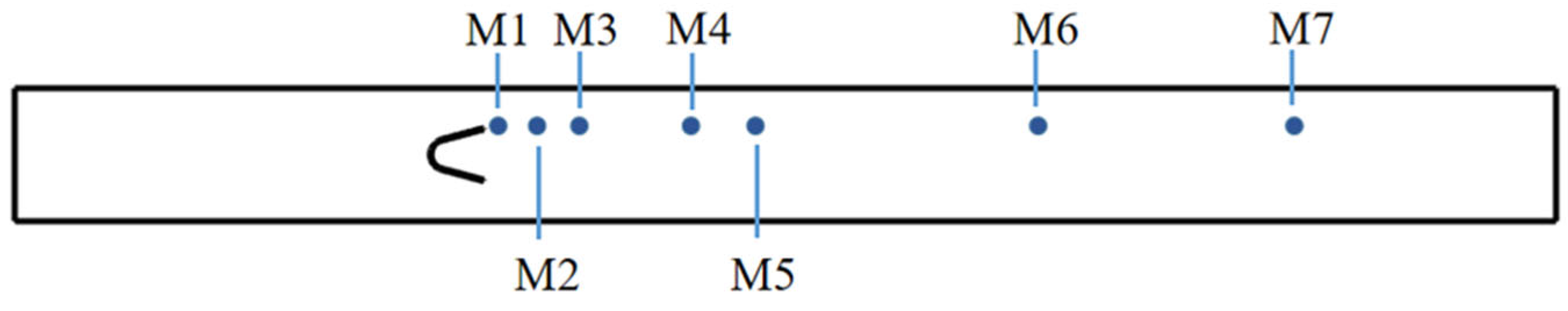

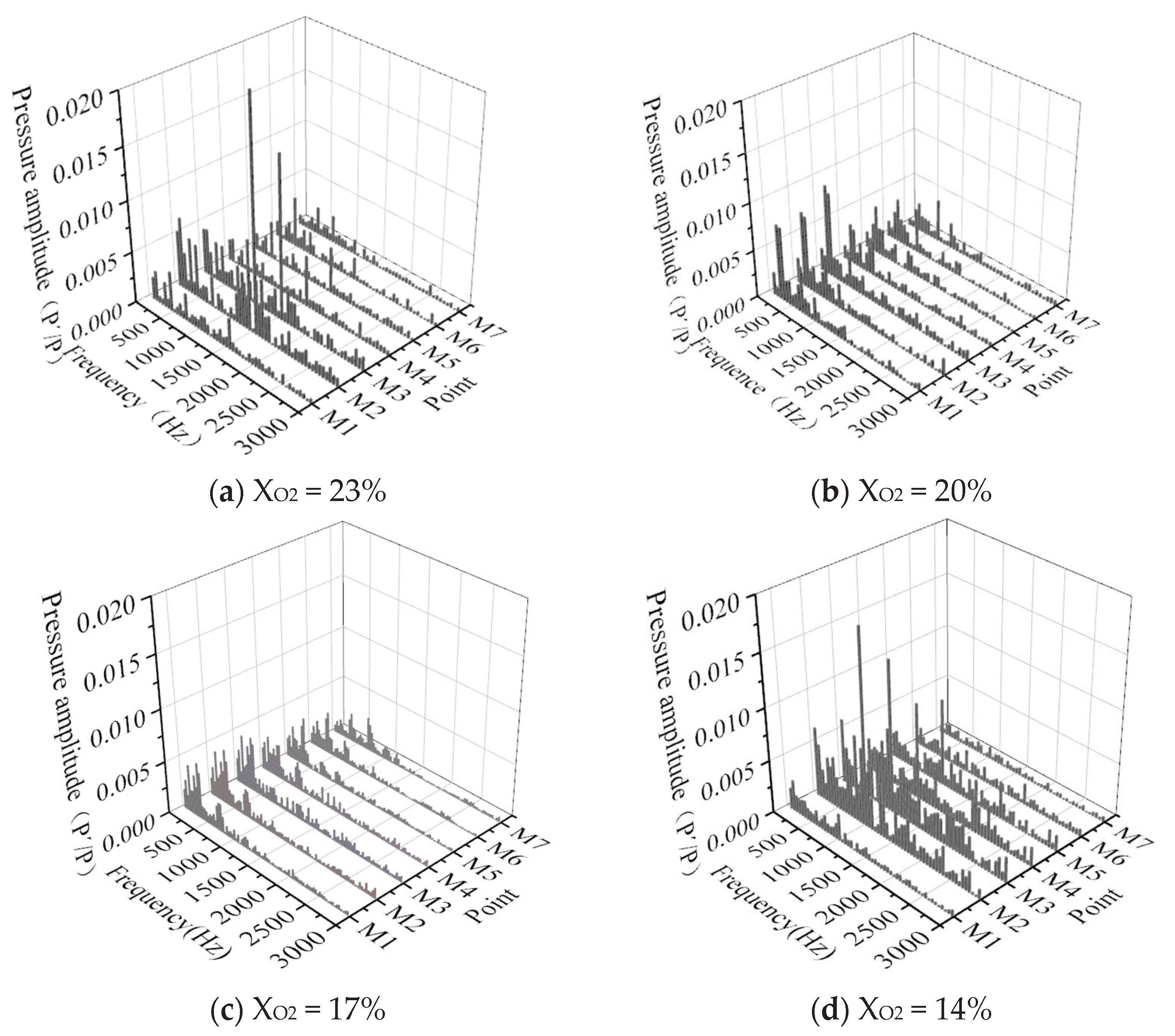

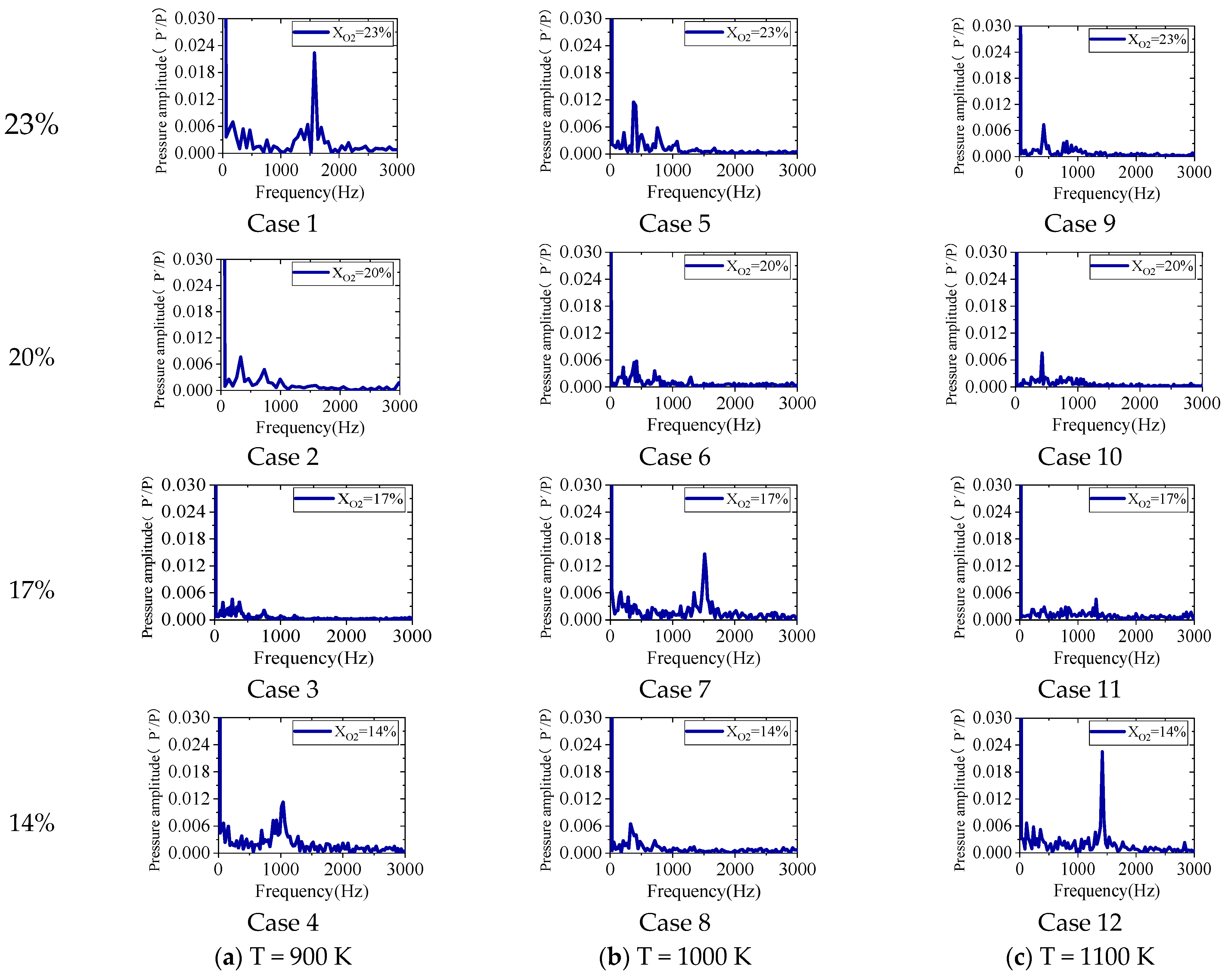

3.3. Spectral Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yang, M.; Tian, Y.; Guo, M.; Le, J.; Zhang, H.; Zhang, C. Optimized design of aero-engine high temperature rise combustion chamber based on “kriging-NSGA-II”. J. Braz. Soc. Mech. Sci. Eng. 2023, 45, 59. [Google Scholar] [CrossRef]

- Li, J.; Chen, J.; Jin, W.; Yuan, L.; Hu, G. The design and performance of a RP-3 fueled high temperature rise combustor based on RQL staged combustion. Energy 2020, 209, 118480. [Google Scholar] [CrossRef]

- Zhang, R.; Huang, X.; Fan, W.; Bai, N. Influence of injection mode on the combustion characteristics of slight temperature rise combustion in gas turbine combustor with cavity. Energy 2019, 179, 603–617. [Google Scholar] [CrossRef]

- Zhou, L.; Zhong, L.; Liu, Z.; Wei, H. Toward highly-efficient combustion of ammonia–hydrogen engine: Prechamber turbulent jet ignition. Fuel 2023, 352, 129009. [Google Scholar] [CrossRef]

- Sun, Z.; Cui, M.; Ye, C.; Yang, S.; Li, X.; Hung, D.; Xu, M. Split injection flash boiling spray for high efficiency and low emissions in a GDI engine under lean combustion condition. Proc. Combust. Inst. 2021, 38, 5769–5779. [Google Scholar] [CrossRef]

- Cohen, J.; Anderson, T. Experimental Investigation of Near-Blowout Instabilities in a Lean, Premixed Step Combustor. In Proceedings of the 34th Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 15–18 January 1996; p. 819. [Google Scholar]

- Lieuwen, T.C.; Yang, V. Combustion Instabilities in Gas Turbine Engines: Operational Experience, Fundamental Mechanisms, and Modeling; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2005. [Google Scholar]

- Riahi, Z.; Bounaouara, H.; Hraiech, I.; Mergheni, M.A.; Sautet, J.-C.; Nasrallah, S.B. Combustion with mixed enrichment of oxygen and hydrogen in lean regime. Int. J. Hydrogen Energy 2017, 42, 8870–8880. [Google Scholar] [CrossRef]

- Malbois, P.; Salaün, E.; Rossow, B.; Cabot, G.; Bouheraoua, L.; Richard, S.; Renou, B.; Grisch, F. Quantitative measurements of fuel distribution and flame structure in a lean-premixed aero-engine injection system by kerosene/OH-PLIF measurements under high-pressure conditions. Proc. Combust. Inst. 2019, 37, 5215–5222. [Google Scholar] [CrossRef]

- Weigand, P.; Meier, W.; Duan, X.R.; Stricker, W.; Aigner, M. Investigations of swirl flames in a gas turbine model combustor: I. Flow field, structures, temperature, and species distributions. Combust. Flame 2006, 144, 205–224. [Google Scholar] [CrossRef]

- Bonciolini, G.; Ebi, D.; Doll, U.; Weilenmann, M.; Noiray, N. Effect of wall thermal inertia upon transient thermoacoustic dynamics of a swirl-stabilized flame. Proc. Combust. Inst. 2019, 37, 5351–5358. [Google Scholar] [CrossRef]

- Vignat, G.; Durox, D.; Prieur, K.; Candel, S. An experimental study into the effect of injector pressure loss on self-sustained combustion instabilities in a swirled spray burner. Proc. Combust. Inst. 2019, 37, 5205–5213. [Google Scholar] [CrossRef]

- Soundararajan, P.R.; Vignat, G.; Durox, D.; Renaud, A.; Candel, S. Effect of Different Fuels on Combustion Instabilities in an Annular Combustor; Turbo Expo: Power for Land, Sea, and Air; American Society of Mechanical Engineers: New York, NY, USA, 2020; p. V04BT04A046. [Google Scholar]

- Gao, T.; Liang, J.; Sun, M.; Zhong, Z. Dynamic combustion characteristics in a rectangular supersonic combustor with single-side expansion. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2017, 231, 1862–1872. [Google Scholar] [CrossRef]

- Kang, J.; Sung, H.-G. Kerosene/GOx dynamic combustion characteristics in a mixing layer under supercritical conditions using the LES-FPV approach. Fuel 2017, 203, 579–590. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, J.; Yang, T.; Ma, Y. Bluff-Body Flames in Hot and Diluted Environments. In Proceedings of the ASME Power Conference, Lake Buena Vista, FL, USA, 24–28 June 2018; American Society of Mechanical Engineers: New York, NY, USA, 2018; p. V001T01A002. [Google Scholar]

- Roy, R.N.; Sreedhara, S. A numerical study on the influence of airstream dilution and jet velocity on NO emission characteristics of CH4 and DME bluff-body flames. Fuel 2015, 142, 73–80. [Google Scholar] [CrossRef]

- Wang, G.; Si, J.; Xu, M.; Mi, J. MILD combustion versus conventional bluff-body flame of a premixed CH4/air jet in hot coflow. Energy 2019, 187, 115934. [Google Scholar] [CrossRef]

- Kumar, P.; Mishra, D. Characterization of bluff-body stabilized LPG jet diffusion flame with N2 dilution. Energy Convers. Manag. 2008, 49, 2698–2703. [Google Scholar] [CrossRef]

- Mishra, D.; Kumar, P. Effects of N2 gas on preheated laminar LPG jet diffusion flame. Energy Convers. Manag. 2010, 51, 2144–2149. [Google Scholar] [CrossRef]

- Hosseini, S.E.; Wahid, M.A. Investigation of bluff-body micro-flameless combustion. Energy Convers. Manag. 2014, 88, 120–128. [Google Scholar] [CrossRef]

- Noor, M.; Wandel, A.P.; Yusaf, T. Numerical study of oxygen dilution and temperature distribution of biogas combustion in Bluff-body MILD burner. In Proceedings of the 7th Australian Combustion Symposium (ACS 2013), Perth, Australia, 6–8 November 2013; University of Western Australia: Crawley, Australia, 2013; pp. 299–303. [Google Scholar]

- Erickson, R.; Soteriou, M. The influence of reactant temperature on the dynamics of bluff body stabilized premixed flames. Combust. Flame 2011, 158, 2441–2457. [Google Scholar] [CrossRef]

- Erickson, R.; Soteriou, M.; Mehta, P. The influence of temperature ratio on the dynamics of bluff body stabilized flames. In Proceedings of the 44th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 9–12 January 2006; p. 753. [Google Scholar]

- Shanbhogue, S.J.; Husain, S.; Lieuwen, T. Lean blowoff of bluff body stabilized flames: Scaling and dynamics. Prog. Energy Combust. Sci. 2009, 35, 98–120. [Google Scholar] [CrossRef]

- Emerson, B.; O’Connor, J.; Juniper, M.; Lieuwen, T. Density ratio effects on reacting bluff-body flow field characteristics. J. Fluid Mech. 2012, 706, 219–250. [Google Scholar] [CrossRef]

- Emerson, B.; Lundrigan, J.; O’Connor, J.; Noble, D.; Lieuwen, T. Dependence of the bluff body wake structure on flame temperature ratio. In Proceedings of the 49th AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 4–7 January 2011; p. 597. [Google Scholar]

- Wang, B.-C.; Bergstrom, D.J. A dynamic nonlinear subgrid-scale stress model. Phys. Fluids 2005, 17, 035109. [Google Scholar] [CrossRef]

- Xu, L.; Zhang, Y.; Tang, Q.; Johansson, B.; Yao, M.; Bai, X.-S. LES/FGM investigation of ignition and flame structure in a gasoline partially premixed combustion engine. Proc. Combust. Inst. 2023, 39, 4851–4860. [Google Scholar] [CrossRef]

- Kundu, K.; Penko, P.; VanOverbeke, T. A practical kinetic mechanism for computing combustion in gas turbine engines. In Proceedings of the 35th Joint Propulsion Conference and Exhibit, Los Angeles, CA, USA, 20–24 June 1999; p. 2218. [Google Scholar]

- Roach, J.; Fisher, T.; Frankel, S.; Sekar, B.; Kiel, B. Cfd predictions of damköhler number fields for reduced order modeling of v-gutter flame stability. In Proceedings of the 46th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 7–10 January 2008; p. 509. [Google Scholar]

- Liu, X. Study on Low Emission Combustion Chamber Design and Premixed Combustion Characteristics. Ph.D. Thesis, Harbin Engineering University, Harbin, China, 2017. [Google Scholar]

- Wu, H.; Ma, P.C.; Lv, Y.; Ihme, M. MVP-Workshop Contribution: Modeling of Volvo bluff body flame experiment. In Proceedings of the 55th AIAA Aerospace Sciences Meeting, Grapevine, TX, USA, 9–13 January 2017; p. 1573. [Google Scholar]

- Santosh Kumar, T.; Alemela, P.; Kok, J.B. Dynamics of Flame Stabilized by Triangular Bluff Body in Partially Premixed Methane-Air Combustion. In Turbo Expo: Power for Land, Sea, and Air; American Society of Mechanical Engineers: New York, NY, USA, 2011; pp. 1017–1026. [Google Scholar]

- Putnam, A.A.; Dennis, W.R. Organ-pipe oscillations in a flame-filled tube. Symp. (Int.) Combust. 1953, 4, 566–575. [Google Scholar] [CrossRef]

- Zinn, B.T.; Powell, E.A. Nonlinear combustion instability in liquid-propellant rocket engines. Symp. (Int.) Combust. 1971, 13, 491–503. [Google Scholar] [CrossRef]

- Schadow, K.; Gutmark, E. Combustion instability related to vortex shedding in dump combustors and their passive control. Prog. Energy Combust. Sci. 1992, 18, 117–132. [Google Scholar] [CrossRef]

| No. | Reactions | A | n | Ea |

|---|---|---|---|---|

| 1 | C12H23 + N2=>12CH + 11H + N2 | 5.50 × 1010 | 0.00 | 3.00 × 104 |

| FORD/C12H23 0.8/ | ||||

| FORD/N2 0.8/ | ||||

| 2 | N2 + CO + HO2=>CO2 + OH + N2 | 3.50 × 1013 | 0.00 | 2.29 × 104 |

| FORD/N2 0.1/ | ||||

| FORD/CO 1.0/ | ||||

| FORD/HO2 1.0/ | ||||

| 3 | H2 + 2O=>O2 + H2 | 1.00 × 1018 | 0.00 | 0.00 |

| FORD/H2 1.0/ | ||||

| FORD/O 2.0/ | ||||

| 4 | H2 + OH<=>H2O + H | 1.17 × 1011 | 1.30 | 3.62 × 103 |

| 5 | H2 + O<=>H + OH | 2.50 × 1015 | 0.00 | 6.00 × 103 |

| 6 | H + O2<=>O + OH | 4.00 × 1014 | 0.00 | 1.80 × 104 |

| 7 | H2 + 2H<=>2H2 | 4.00 × 1020 | −1.00 | 0.00 |

| 8 | H + O2<=>HO2 | 1.00 × 1015 | −0.87 | 0.00 |

| 9 | H + HO2<=>H2 + O2 | 1.50 × 1014 | 0.00 | 0.00 |

| 10 | O + HO2<=>OH + O2 | 2.50 × 1013 | 0.00 | 0.00 |

| 11 | CO + OH<=>CO2 + H | 1.51 × 107 | 1.30 | −7.58 × 102 |

| 12 | 2CH + N2<=>C2H2 + N2 | 1.00 × 1018 | 0.00 | −7.58 × 102 |

| 13 | C2H2 + O2<=>2CO + H2 | 3.00 × 1016 | 0.00 | 1.90 × 102 |

| 14 | CH + O<=>CO + H | 1.00 × 1012 | 0.70 | 0.00 |

| 15 | CH + OH<=>CO + H2 | 1.00 × 1013 | 0.00 | 0.00 |

| Pressure/MPa | Temperature/K | Mach Number | Oil-to-Gas Ratio | Oxygen Content/% | |

|---|---|---|---|---|---|

| Case1 | 0.1 | 900 | 0.2 | 0.03 | 14–23 |

| Case2 | 0.1 | 1000 | 0.2 | 0.03 | 14–23 |

| Case3 | 0.1 | 1100 | 0.2 | 0.03 | 14–23 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, F.; Zhao, M.; Qin, S.; Wang, Z.; Xie, Y.; Zheng, H.; Liu, X.; Zhang, F. Numerical Simulation Study on the Dynamics of Bluff-Body Flames under Oxygen-Lean Conditions. Energies 2024, 17, 142. https://doi.org/10.3390/en17010142

Deng F, Zhao M, Qin S, Wang Z, Xie Y, Zheng H, Liu X, Zhang F. Numerical Simulation Study on the Dynamics of Bluff-Body Flames under Oxygen-Lean Conditions. Energies. 2024; 17(1):142. https://doi.org/10.3390/en17010142

Chicago/Turabian StyleDeng, Fuquan, Minwei Zhao, Shunchuang Qin, Zhaokun Wang, Yongliang Xie, Hongtao Zheng, Xiao Liu, and Feng Zhang. 2024. "Numerical Simulation Study on the Dynamics of Bluff-Body Flames under Oxygen-Lean Conditions" Energies 17, no. 1: 142. https://doi.org/10.3390/en17010142

APA StyleDeng, F., Zhao, M., Qin, S., Wang, Z., Xie, Y., Zheng, H., Liu, X., & Zhang, F. (2024). Numerical Simulation Study on the Dynamics of Bluff-Body Flames under Oxygen-Lean Conditions. Energies, 17(1), 142. https://doi.org/10.3390/en17010142