Abstract

Gasoline engines employing the spatially distributed auto-ignition combustion mode, known as controlled auto-ignition (CAI), are a prospective technology for significantly improving engine efficiency and reducing emissions. This review paper provides an overview of developments in various gasoline CAI technologies and discusses their attendant strengths and weaknesses. Hybrid propulsion systems powered by high-efficiency gasoline CAI engines can provide a low-carbon pathway for mobility sector decarbonisation. Therefore, this paper focuses on the challenges and opportunities of CAI implementation, especially for electrified powertrains. Different control actuators that can extend the CAI operating range are discussed, and opportunities for synergistic operation between thermal and electric components of hybridised powertrains are identified. Such synergies can remove impediments in the way of CAI system adoption and can, thus, support CAI adoption and maximise efficiency gains from its implementation. The prospects of supporting CAI combustion for different powertrain electrification levels, hybrid architectures, engine size, and energy management systems are discussed. Load levelling offered by electrified powertrains through CAI-favouring energy management strategies has the potential to substantially relax the operating point requirements for CAI-based thermal propulsion units and to remove the need for expensive actuators. The highly flexible spark-assisted partially premixed compression ignition hybrid mode (SACI-PPCI) emerges as a promising CAI strategy for conventional powertrains, and the moderately flexible spark-assisted compression ignition (SACI) configuration can be a cost-effective thermal propulsion mode for electrified powertrains.

1. Introduction

The global transportation system accounts for about 16% of the world’s greenhouse gas emissions. Around half of these originate from road passenger vehicles, which are, at present, mostly powered by internal combustion engines running on fossil fuels [1]. Moreover, harmful pollutants from combustion, particularly NOx, particulate matter, unburned hydrocarbons, and CO, deteriorate local air quality and have adverse health impacts [1]. To decarbonise the road transport sector, an estimated 3–4% reduction in CO2 emissions is needed every year between now and 2030 [2], thus necessitating transformative technological innovations. Some potential transportation decarbonisation pathways include powertrain electrification [3], fuel cell-powered vehicles [4], and internal combustion engines operating on net-carbon neutral fuels, such as renewable hydrogen [5], e-fuels [6] or biofuels [7].

Decarbonisation via complete powertrain electrification, i.e., replacing internal combustion engine vehicles with battery electric vehicles (BEV), is limited by the need to decarbonise the power generation system, to expand and improve recharging infrastructure, and to improve battery technology to make it more energy-dense and economical [8,9]. Traditionally fuelled partially electrified vehicles, i.e., hybrid electric vehicles (HEV), can help bridge this gap and make timely, cost-effective, and impactful contributions to climate change mitigation efforts, as they have relatively high technology readiness levels and benefit from an existing refuelling infrastructure [10,11].

HEVs can offer significant system-level efficiency improvements resulting from the high energy conversion efficiency of the electric components, thermal propulsion unit (TPU) operation at high efficiency points, and waste energy recuperation. These improvements, which directly correlate to CO2 emission reductions, can be over 50%, on a tank-to-wheel basis, relative to contemporary spark-ignition (SI) engines [10]. Depending on the carbon intensity of the electricity grid, the relative greenhouse gas emissions of HEVs can be superior, comparable, or inferior to those of BEVs [1,10,11]. There is, however, an increasing consensus developing that, as electricity generation and battery production become less carbon-intense, BEVs will have a significantly lower CO2 footprint compared to fossil fuel-powered internal combustion engine vehicles [1]. Until then, distributing the total available battery storage capacity as smaller batteries across many mild or parallel HEVs instead of concentrating it as larger batteries in fewer BEVs or plug-in hybrids can be a more effective decarbonisation pathway [1,10].

The emission reduction potential of HEVs can be bolstered by improving the fuel conversion efficiency of their TPUs and by reducing the associated pollutant emissions. Multiple avenues for TPU efficiency improvement are being actively researched, including ultra-lean combustion [12,13], fuel chemistry improvements [10], over-expanded cycles and flexible valve trains [14,15,16], waste heat recovery [17], alternative cycles [18], and advanced combustion concepts [19,20]. Novel TPU designs, such as micro-gas turbines [21] and free piston linear generators [22] are also being developed.

This paper discusses advances in TPUs employing the advanced combustion concept of controlled auto-ignition (CAI) [19], with special emphasis on its potential to improve HEV system efficiencies by exploiting synergies between CAI and powertrain electrification. CAI is a thermodynamically efficient combustion mode. It is distinct from the conventional combustion modes of spark and compression ignition because of the mixture preparation and ignition strategies employed. CAI technologies have been actively researched for over two decades (initially mostly for diesel engines [23,24,25,26]) and can play an important role in transport decarbonisation. The discussion in the paper focuses on gasoline CAI TPU advancement because approximately 80% of the global light-duty vehicle fleet is powered by gasoline, and diesel vehicles have seen a decline in popularity in many automotive markets in the post ‘dieselgate’ era [1].

Broad reviews of CAI can be found in the literature [27,28], as well as reviews on gasoline direct injection (GDI) engines [29,30]. Comprehensive surveys of engine technology [31] and powertrain configuration [32] evolution for HEVs are also available [33]. The current review lies at the intersection of such compendiums and contributes the following to the automotive sector decarbonisation discourse:

- Refreshes and re-contextualises the benefits and challenges of CAI for the current mobility landscape where powertrain electrification is becoming increasingly common.

- Offers a consistent and up-to-date characterisation for various CAI embodiments.

- Discusses opportunities for addressing CAI control challenges and improving system efficiency in CAI TPU-based HEVs through the co-development of thermal and electrical components.

CAI is defined in general terms, and associated advantages and challenges are discussed in Section 2, followed by a discussion of various CAI embodiments (Section 3) and engine control options (Section 4). Opportunities for complementary CAI and hybrid propulsion system (HPS) development and operation are discussed in Section 5.

2. Controlled Auto-Ignition

As the name suggests, CAI utilises auto-ignition (AI) as the principal energy release pathway during combustion. The other pathway commonly used in internal combustion engines is positive ignition, most commonly spark ignition (SI). In CAI, the cylinder contents are relatively well-mixed, and if the post-compression pressure and temperature are sufficiently high, near-simultaneous AI is initiated at multiple points across the cylinder. This is different from traditional compression ignition (CI) ‘diesel’ combustion, where auto-ignition is spatially restricted to the vaporised fuel-air cloud around the fuel injector. Moreover, in CAI, AI is triggered not only by the compression of the trapped cylinder charge, but thermal assistance (e.g., via intake air heating or combustion product entrapment) is also needed to make the well-mixed, diluted, and lean cylinder mixture cross the self-ignition temperature threshold. CAI has thus been described as the ‘flameless’ and ‘volumetric’ energy release from the spontaneous combustion of lean and diluted, homogenous, air-fuel mixtures [34].

The onset of AI during CAI in the cylinder is governed by the chemical kinetics of the local fuel-air-residual-gas parcels and their respective pressure and time histories. This can lead to control challenges and has necessitated the development of multiple mixture preparation strategies. These strategies help tailor the AI behaviour of cylinder contents to realise efficient, clean, stable, and moderately aggressive energy release. In most practical CAI systems, a certain level of heterogeneity (in temperature, fuel, or residual gas distribution) is purposefully introduced in the trapped mixture to control AI and the ensuing heat release behaviour. However, the combusting mixtures are still reasonably well-mixed compared to those in conventional compression ignition engines, which are highly stratified. Hence, only the initial stage of conventional compression ignition combustion (the pre-mixed combustion stage) is achieved through the AI of a well-mixed fuel-air mixture. The latter stage is controlled (not kinetically) by mixing. Moreover, conventional compression ignition combustion is locally rich.

2.1. The Thermodynamic Case for Gasoline CAI

CAI-based energy release can offer thermal efficiency advantages through the efficient utilisation of the expansion stroke and relatively low combustion temperatures resulting from diluted and/or lean combustion. Because of the latter attribute, CAI has also been referred to as ‘low temperature combustion’ in the literature [34,35]. Both diluted (dilution via residual gases) and lean (dilution via air) combustion offer thermal efficiency benefits. The multi-site initiation of combustion in CAI can help improve engine stability and combustion efficiency by increasing the likelihood of successful and repeatable combustion. There are also associated (net favourable) effects on engine-out emissions resulting from the cylinder composition, mixedness levels, and energy release phasing.

Lean, diluted combustion presents a high thermodynamic efficiency pathway because it minimises the total in-cylinder process irreversibility and thus provides a net efficiency gain, resulting from [34]:

- A decrease in heat transfer losses because of lower temperatures of cylinder contents [+].

- An increase in specific heat ratio of the combusting mixture, which allows for more useful work to be harvested per unit expansion of the expanding gases [+].

- A decrease in the useful energy (exergy) lost with exhaust gases [+].

- An increase in combustion irreversibility because of lower combustion temperatures. For practical combustion systems, these losses range between 20 and 25% (up to 32% according to [35]) and are difficult to ‘engineer our way out of’ [−].

These thermodynamic benefits can be reduced in engines employing flame-propagation-based (deflagrative) combustion (i.e., SI engines) because the reduction in combustion temperatures slows down flame propagation. This results in the poor utilisation of the expansion stroke (thermal efficiency reduction) and makes combustion more unstable (combustion efficiency and engine stability deterioration). To counter reductions in flame propagation speed in lean SI engines, combustion chambers and air paths are designed to enhance in-cylinder turbulence levels, often at the expense of gas-exchange efficiency [36]. Simultaneous fast and low-temperature heat release is realised in CAI engines through the multi-site AI combustion of well-mixed lean and diluted mixtures, whereby combustion is slow locally because of leaning and dilution, but because energy release is distributed across the entire cylinder, accumulated heat release is sufficiently fast. This reduces the need for high turbulence levels and permits the design of ports and valves with high flow efficiency.

When gasoline is used in CAI, another potential advantage arises from its AI chemistry. These relatively high octane number (ON) and low cetane number (CN) fuels (research ON > 60 and CN < 30 [37]) have longer chemical ignition delays compared to those of diesel, thus permitting more time for the preparation of auto-ignitable mixtures by allowing the fuel to vaporise more thoroughly and mix with air and residual gases. Gasoline fuels are also more volatile than diesel fuels (boiling range 20–160 °C vs. 160–380 °C, respectively [38]), which facilitates the preparation of a well-mixed vaporised fuel-air mixture. Hence, there is a need for very high pressure fuel injectors to promote premixed combustion, as is the case for diesel engines, that can be reduced [39].

Gasoline CAI, therefore, has the potential to improve engine efficiency by:

- Allowing thermodynamically efficient dilute and/or lean combustion;

- Improving combustion efficiency through multi-site AI;

- Reducing in-cylinder turbulence requirements to allow the design of efficient air flow passages;

- Using a volatile, low-reactivity fuel to ease the formation of a vaporised fuel-air mixture.

2.2. Effects on Emissions

In addition to thermal efficiency improvements, CAI engines can also have net-favourable effects on pollutant emissions. The exact effects depend on the CAI strategy employed and the operating point of the engine. The effects on various pollutant emissions are listed below, with the arrows within parentheses indicating the general direction of expected change in engine-out emissions compared to conventional engines. Clearly, subsequent clean-up with aftertreatment substantially reduces vehicle-out emissions.

2.2.1. NOx (↓)

Thermal NOx production is likely reduced significantly in CAI engines because of lower combustion temperatures and reduced oxygen availability caused by diluted and lean operation. Moreover, because of the parallel energy release from multiple ignition sites across the cylinder, NOx is not generated from the compressive heating of initially burned gases, as happens in SI and CI engines. A reduction of 97% in NOx emissions was reported by Oakley et al. [40] for a CAI strategy relative to SI operation in the same engine.

2.2.2. Soot, Smoke, Particulate Matter (↓,↑)

Particulate emissions are likely to be reduced to near zero because of the high levels of pre-mixing present in most CAI engines, which results in locally lean combustion. Local fuel-air equivalence ratios less than 0.5 are considered sufficiently lean for preventing soot formation [37]. CAI strategies employing direct injection (DI) can, however, witness an increase in cylinder-out particulate matter (PM) emissions resulting from pool fires and diffusive combustion of the injected fuel [30]. The two are, respectively, caused by fuel impingement on combustion chamber walls and overlapping fuel injection and heat release events, which is indicative of insufficient fuel-air mixing. Therefore, combustion chambers have to be designed and fuel injection events controlled appropriately to keep PM emissions low. The heat capacity and dilution effects of exhaust-gas recirculation can also cause an increase in PM emissions by limiting the temperatures and amount of oxygen needed for soot oxidation, respectively. Very high EGR levels can counter these effects by lowering combustion temperatures below the soot-formation threshold [41].

2.2.3. Hydrocarbons (↑)

Major determinants of engine-out hydrocarbon (HC) emissions are the fuel-air equivalence ratio of the trapped mixture (rich combustion leads to higher unburned hydrocarbons), engine stability (at unstable engine operating points, HC emissions increase), fuel entrapment in crevice regions, and the oxidation of crevice-released fuel during expansion.

The overall lean nature of CAI should reduce HC emissions because of the availability of excess air for fuel oxidation, and the multi-site nature of CAI combustion should lower unburned HC emissions at traditionally unstable operating points by improving combustion efficiency. However, fuel trapped in cylinder crevices during the main combustion event can cause an increase in cylinder-out HC emissions. This is because: (i) more fuel is trapped in the cylinder crevices, and (ii) relatively less crevice-released fuel is oxidised during expansion. More fuel is trapped in the crevices because the low CN fuels used in gasoline CAI have longer ignition delays and are present in the cylinder for a longer period before combustion [37]. The likelihood of the oxidation of crevice-released fuel during the expansion stroke is lower in CAI engines because of the relatively low combustion and expansion temperatures [42].

2.2.4. CO (↑)

Factors that determine engine-out CO levels are similar to those for HC, as both are products of incomplete combustion. For the same scenarios as for high HC emissions, CO emissions can increase if the fuel is partially oxidised. The oxidation of CO to CO2 requires temperatures that range between 1125 and 1225 °C [19], which might not be available at all operating points during CAI operation, especially at low load-operating points. In Oakley et al. [40], CO emissions from a homogenous CAI engine increased monotonically as the load was reduced. However, at high loads, CO emissions were found to be lower than those from SI operation.

2.2.5. Effects on Aftertreatment Systems

Because of their NOx and PM reduction potential, CAI engines can lower exhaust aftertreatment requirements, especially if engine operation regions that increase CO and HC (e.g., part load operation) can be avoided. Excess engine-out CO or HC emissions can be cleaned using oxidation after-treatment devices. Oxidising partially oxidised chemical species through exhaust aftertreatment is cheaper and easier to manage than simultaneously trying to reduce NOx and oxidise HC and CO using three-way catalysts (TWC), which are needed in current SI engines because all three species are exhausted out of the cylinder at unacceptably high levels [37]. However, if NOx emissions are not reduced sufficiently by in-cylinder combustion management, then TWC for stoichiometric CAI engines and selective catalytic reduction (SCR) for lean CAI engines are needed.

If engine-out PM emissions are high in DI CAI engines, they can be managed using particulate filters. The need for such filters is likely to arise only at low loads where temperatures are not high enough for soot oxidation.

One challenge for CAI combustion is that the relatively low exhaust temperatures reduce the conversion efficiency of exhaust aftertreatment devices, which typically require temperatures higher than 250 °C [1]. Although the reduction in engine-out emissions reduces the dependence on aftertreatment devices, lean (‘diesel-like’) aftertreatment might be required, which could increase system cost and complexity [43,44].

2.3. An Overview of CAI Challenges

Research on various CAI modes has been ongoing since at least 1979 [45,46] and recently CAI engines have witnessed some commercial success [47,48]. The biggest impediment to their adoption has been the difficulty in reliably controlling the onset and phasing of combustion across a sufficiently wide operating range. Failure to optimally and adequately control combustion can lead to unacceptably high pressure-rise rates (PRR) or high levels of combustion instability, in addition to having adverse effects on thermal efficiency and emissions [49]. Some of the phenomena that serve as barriers to acceptable CAI engine operation at the edges of the speed and load operating map are summarised below.

Low Load Limit (Lean/Instability Limit): At low loads, combustion temperatures decrease because of low peak and mean effective pressures, which causes a decrease in residual gas temperatures. The low trapped mixture temperatures retard or stop AI, which, respectively, leads to partial-burn or misfires. Moreover, in turbocharged engines, at low loads, the exhaust gas might not have adequate energy to sufficiently boost cylinder pressure to achieve AI.

High Load Limit (Ringing Limit): As more fuel is added to meet increasing torque requirements at high loads, the pressure-rise rates and peak pressure can become excessively high, leading to unacceptably loud combustion and mechanical damage. This is known as the ringing limit and serves as a high load boundary. A number of metrics have been used to index combustion intensity in CAI engines, e.g., PRR (bar/°CA [49] or bar/sec [50]), ringing intensity (MW/m2 [51]), and calculated or measured combustion noise [52]. Comparisons of various combustion intensity metrics have been conducted by Ghandhi et al. [52] and Eng [50]. A limit of 3 bar/°CA was found to be an often-used PRR limit [49,53,54].

To moderate energy release at high loads, dilution levels are increased. There are, however, limits to the extent of dilution imposed by the amount of fuel that can be combusted, which is directly coupled to the engine’s power output. This acts as a second high-load limit, where failure manifests as a misfire or a partial fire [55].

Low Speed Limit: At low speeds, combustion temperatures and, consequently, residual gas and trapped mixture temperatures decrease because of increased heat transfer. This, as is conducted at low loads, reduces the mixture’s auto-ignitability and can cause combustion stability problems. For turbocharged engines, turbo-lag can also act as a limiting factor at low speeds, where sufficient exhaust flow might not be available to drive the turbine.

High Speed Limit: At high speeds, hot combustion gases needed for controllably triggering AI might not be retained in sufficient quantities for some valve timing-based internal EGR (iEGR) strategies. Another consequence of these iEGR strategies can be the limiting of fresh air being drawn in, as they may necessitate a reduction in maximum valve lifts (e.g., a negative valve overlap strategy). Moreover, at higher speeds, cylinder content temperatures might increase because of decreased heat transfer, which could lower ignition delays and lead to uncontrolled AI.

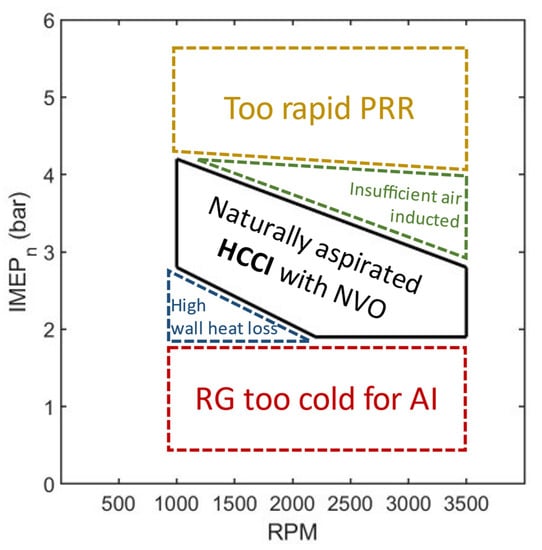

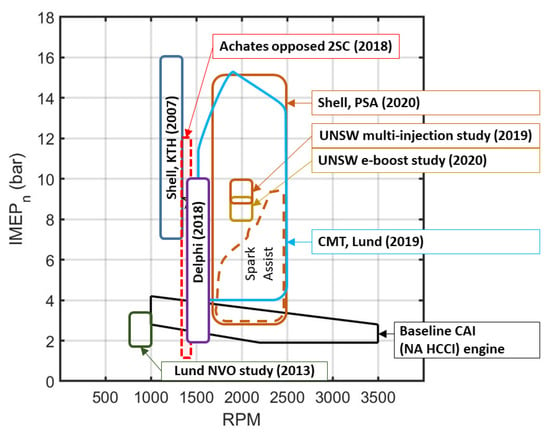

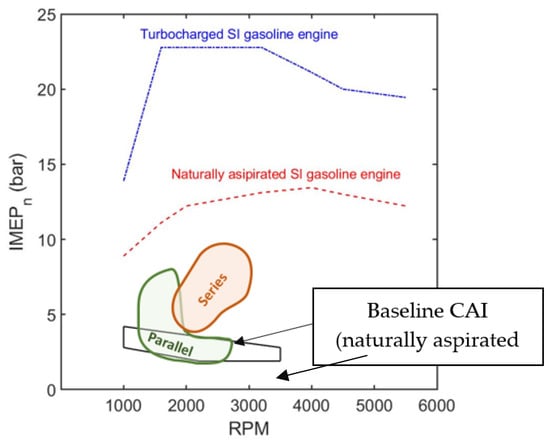

All of the CAI limiting effects listed above are summarised in Figure 1. The CAI operating map shown was adapted from Fu et al. [49] and was used as a baseline CAI engine throughout the paper. It represents a naturally aspirated, gasoline port fuel-injected, four-stroke, automotive engine that employs the CAI strategy of homogeneous charge compression-ignition (HCCI) and has a negative valve overlap (NVO) for trapping hot residual gases. A summary of the general discussion on the opportunities and challenges of CAI presented in the preceding sections is provided in Table 1.

Figure 1.

Limits to the HCCI operation of the baseline CAI engine. BMEP has been converted to net IMEP by assuming 90% mechanical efficiency (RG: residual gas).

Table 1.

Comparison of CAI and conventional engine combustion technologies.

3. CAI Characterisation and Development

The pursuit of the potential benefits of CAI whilst simultaneously avoiding the accompanying challenges has led to the development of numerous CAI realisation strategies.

Two-stroke gasoline engine researchers were the first to study CAI [45,46,56,57]. They were interested in it as a means to stabilise low load performance. The inherently high fraction of hot residual gases that are trapped after scavenging in two-stroke engines were exploited to initiate multi-site CAI. Thus, improving the quality of combustion and reducing HC emissions, which were exceptionally high for the port fuel-injected (PFI) or carburetted engines. Even though two-stroke CAI achieved some commercial success [58], the cost of managing exhaust HC emissions via combustion and thermal efficiency improvements was too high compared to using valved, four-stroke engines that did not suffer from the gas-exchange problems inherent to the two-stroke architecture. Two-stroke engines have witnessed a resurgence in interest in recent times because of their potential to extend the high-load CAI operating limit [18,59,60,61,62].

Diesel engine researchers investigated CAI as a means to reduce engine-out NOx and soot emissions by breaking the so-called ‘NOx-soot trade-off’ [23,24,25,26]. They hoped to avoid diffusion combustion while retaining the high efficiency of CI engines. Diesel CAI was an active research area at the turn of the century, but it has seen a downturn in the post-dieselgate era because of the general disfavour exhibited towards diesel engines by the automotive market. Some of the most promising gasoline CAI technologies have their roots in diesel CAI research.

Gasoline four-stroke engine researchers are interested in CAI as a means of achieving diesel-like efficiencies and lowering NOx emissions, while retaining the low PM emissions of traditional SI engines [60,63,64,65]. A secondary motivation is to stabilise engine combustion at low loads to mitigate cyclic variability by replacing deflagrative combustion with more robust multi-site AI. A tertiary motivation is the desire to reduce costs, relative to diesel engines, by using cheaper, low-pressure fuel injectors and cost-effective aftertreatment devices [37].

A characterisation of various CAI strategies and a discussion on their relative strengths and weaknesses is presented next.

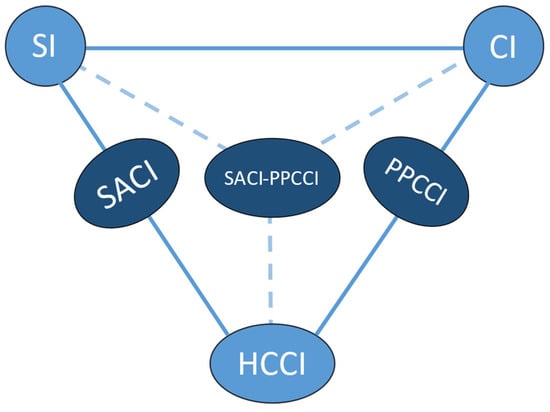

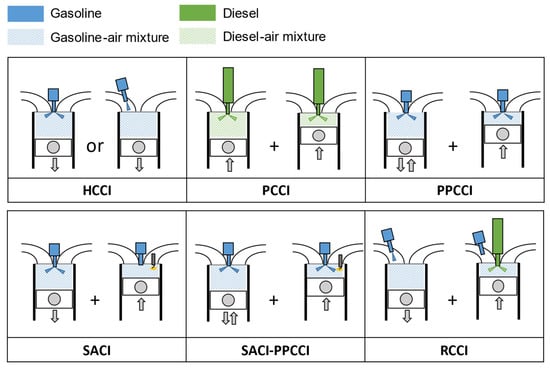

3.1. Strategy 1: Homogeneous Charge Compression Ignition (HCCI)

This is the original ‘best of both worlds’ CAI engine concept that is a true hybrid between a conventional DI CI diesel engine and a pre-mixed SI gasoline engine. In fact, most of the discussion presented so far for CAI is directly applicable to HCCI. The use of HCCI was avoided so as not to couple CAI to just one implementation mode. Figure 2 compares various gasoline CAI modes (that are discussed below) to standard SI and CI combustion. HCCI’s placement signifies the optimum fusion of CI and SI concepts and is thus designated as a third combustion mode.

In HCCI, a diluted, lean, or stoichiometric, fully premixed (homogeneous) fuel-air-residual gas mixture is made to combust via AI by making the cylinder’s thermodynamic conditions conducive for spontaneous, self-sustaining combustion. Since the composition of the mixture is homogenous, ignition begins at multiple sites distributed uniformly across the combustion chamber. The resulting energy release is volumetric and takes place at a near-constant volume around the top dead centre (TDC). The thoroughly mixed fuel and air, which is usually in excess of stoichiometric, prevent PM production, and the low combustion temperatures thwart thermal NOx generation.

3.1.1. Mixture Preparation

Four-stroke cycle-based gasoline HCCI engines achieve homogeneous mixing via PFI [53,64,65] or DI during the intake stroke [60,63]. Recent trends have leaned towards intake stroke DI because of improved mixing and better mixture preparation control.

Preparing a homogenous mixture is more difficult using diesel because of its poor vaporisation characteristics. Early diesel engine HCCI research explored homogeneous fuel-air mixture preparation via PFI to allow greater time for air-fuel mixing [66,67]. Later research efforts have preferred DI during compression and expansion strokes because of improved fuel vaporisation and combustion control.

Two-stroke cycle HCCI engines have traditionally achieved homogeneity between fuel and fresh air from the direct metering of fuel into the air stream, which was then churned in the crankcase before being pushed into the combustion chamber. Newer two-stroke CAI engines use DI [59,62].

Figure 2.

Various CAI modes and their connection to standard SI and CI combustion. Adapted from [68].

3.1.2. HCCI Limits

The two most-significant hurdles that have limited the adoption of HCCI engines result from its most prized feature, its combustion mode. The two hurdles are: (i) a lack of ignition and combustion phasing control, and (ii) very rapid combustion at high loads. To overcome these hurdles, multiple solutions have been proposed that try to retain as much of the efficiency and emission benefits of the best-case scenario technology. These are the CI-suffixed CAI strategies shown in Figure 2 and are discussed next. The use of the suffix CI (instead of AI) is likely an artefact of the historical efforts to deploy pre-mixed, auto-ignited combustion in CI (diesel) engines. These strategies drift from the HCCI vertex of the combustion mode triangle towards SI or CI as they attempt to address the shortcomings of HCCI by borrowing combustion management tactics from either/both of the conventional combustion modes. In one form or another, all of these strategies try to:

- Help control the onset of combustion by providing ignition triggers to reduce the reliance on chemical kinetics and make combustion take place stably with low variability;

- Introduce stratification in the mixture to have the mixture be ‘pre-mixed enough’ [64] instead of being perfectly mixed to spread out energy release and moderate pressure-rise rates.

3.2. Strategy 2a: Premixed Charge Compression Ignition (PCCI)

Premixed charge compression ignition (PCCI) [1,23] or premixed compression ignition (PCI) [24,26], is a diesel engine strategy that came out of the challenges associated with creating homogenous fuel-air mixtures in diesel engines and the need to control and moderate HCCI combustion. In this approach, premixed rather than homogeneous cylinder gas mixtures are created by injecting fuel directly into the cylinder typically during the compression stroke at relatively advanced timings (e.g., 60°CA bTDC in [23]). This provides more time for mixing relative to diesel combustion to avoid very rich pockets, while still having relatively rich strata available to initiate AI [24,26]. The fuel-air stratification reduces the reliance on chemical kinetics for combustion initiation, and the existence of an air-fuel ratio distribution across the cylinder moderates the energy release rates. Additionally, the premixed nature of background cylinder contents reduces soot emissions; and if appropriate levels of dilution via EGR are used, NOx emissions can also be kept low.

In the literature, diesel engines with early compression stroke injection have sometimes [25,69] been referred to as HCCI engines, but here, they are referred to as premixed to be consistent with the mixture preparation process requirements for DI HCCI engines defined earlier, i.e., injection during the intake stroke. Moreover, as there are non-negligible heterogeneities in the combusting mixture’s composition even with the relatively advanced injection, PCCI is considered a more apt characterisation.

Fuel Injection

Most premixed CAI strategies [25,69] (including gasoline strategies discussed under strategy 2b [39,70]) employ multiple fuel injections as they allow for increased control over combustion timing and phasing. With multiple injections, the initial injections help prepare a lean, premixed background charge that is ignited by a relatively rich, combustion-triggering injection pulse close to TDC when cylinder gases are compressed and have higher temperatures. By splitting the fuel admission, energy release is spread across a wider crank angle window to avoid very rapid PRR, thus allowing more fuel to be added at higher loads without breaching PRR thresholds. The timing of the initial injection event is important. Early injection during the compression stroke when the cylinder gas density is relatively low results in higher jet penetration, which increases the likelihood of fuel adhering to combustion chamber walls [23]. This, in turn, can cause an increase in PM emissions. Therefore, designing appropriate injectors [24] and combustion chambers [26] to reduce wall wetting and/or using suitable split-injection strategies to deliver fuel in multiple, smaller jet parcels are important strategies.

The timing and duration of the AI triggering injection pulse is also important, as it determines the gap or overlap between the fuel injection and heat release events, i.e., the ignition dwell. It is preferrable to have ignition dwell, which is often taken to be an index of the extent of diffusive combustion and PM emissions [37,69], be positive. With split injection strategies, the final pulse can be shortened by metering most of the required fuel through earlier injections to maintain a positive dwell. High injection pressures can also help maintain the desired ignition dwell by injecting the required amount of fuel in a shorter period [37]. There can be accompanying fuel mixing benefits from high-pressure injection. Very high pressures can, however, cause excessive mixing, whereby the local equivalence ratios can become too lean to support combustion, and the long penetration lengths of high-pressure jets can cause an increase in PM emissions through increased wall impingement. Injection timings can have different effects on emissions depending on the specific engine combustion chamber design and injection event details. Some general trends summarised from Bobi et al. [27] are as follows: advancing injection timing causes an increase in HC CO emissions because of increased wall wetting and crevice entrapment, and it lowers NOx and PM emissions because of reduced combustion temperatures.

High levels of EGR have been used in PCCI engines to reduce mixture reactivity and delay the start of heat release after injection [71,72]. High EGR diesel combustion can be considered analogous to using a low reactivity fuel, such as gasoline, in diesel engines, as both EGR and gasoline reduce the mixture’s auto-ignitability. This is the basis of strategy 2b.

Another way to moderate PRR is to retard combustion phasing, but in HCCI combustion, retarded combustion has been found to be very unstable, both in diesel [73] and gasoline engines [53]. A late injection event in multistage injection PCCI can help stabilise retarded combustion by providing relatively rich pockets to anchor combustion across consecutive cycles. PCCI has sometimes been realised by very late (post-TDC) injection to have long ignition dwell and to promote thorough fuel-air mixing [71,74].

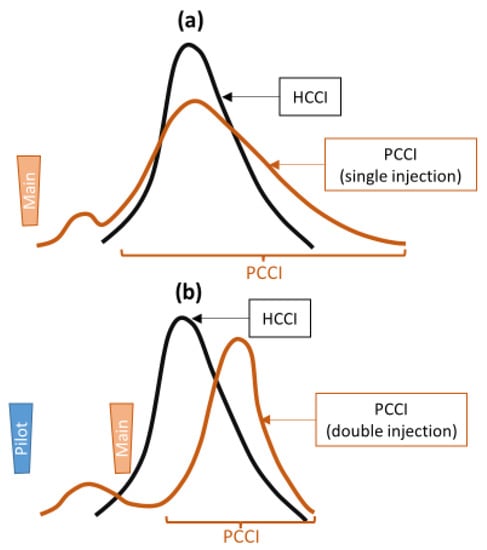

Figure 3 shows qualitative heat release rate (HRR) curves comparing HCCI and PCCI combustion. The top PCCI curve is for a case when diesel is injected in a single event, and the bottom one is for a two stage (pilot-main) injection strategy. Notice the relatively mild HRR with the PCCI strategies and the ability to control combustion phasing and distribute energy release using multiple injections. The initial crests in both the PCCI curves are caused by low temperature (T < 725 °C) oxidation (so-called ‘cool flame’ or low temperature heat release) reactions that occur readily in diesel-like fuels [42]. Such fuels exhibit two-stage AI chemistry, i.e., some chain branching reactions start at low temperatures, during which a part of the fuel reforms to lower hydrocarbons in advance of the main heat release event. In the PCCI cases, fuel injected during the compression stroke can undergo such reformation to release some of the fuel’s energy. Up to 10% of the total heat release can take place through such reactions [19]. Low-temperature heat release is generally not observed in gasoline engines running on high-octane-number gasoline fuels under typical intake conditions [20]. PCCI combustion can thus be considered a two-stage process, comprising a low temperature heat release stage followed by a main heat release stage. The main heat release event can be further split into two events, a premixed phase followed by a late mixing controlled combustion phase [27].

Figure 3.

Qualitative rate of heat release plots for (a) single and (b) double injection PCCI compared to HCCI. Based on HRR curves in [25,26,27,69].

3.3. Strategy 2b: Partially Premixed Charge Compression Ignition (PPCCI)

PCCI attempted to temper diesel HCCI to make it more manageable and controllable. Diesel, however, is an inherently poor fuel choice for HCCI combustion. Its high autoignition propensity (high CN) makes it susceptible to premature AI during fuel-air mixing processes at typical diesel engine compression ratios. According to Kalghatgi et al. [37], a compression ratio of 10:1 would be needed to allow injected diesel sufficient time to mix with air to form a well-mixed mixture. Conducting this so would, however, remove one of the biggest thermodynamic advantages that diesel engines possess and thus lower their efficiency. Hence, a low CN fuel, such as gasoline, can be a more-appropriate choice for moderating HCCI. This is the basis of the PCCI concept adaptation for gasoline engines, which is referred to as partially premixed auto-ignition (PPAI) [69] or partially premixed compression ignition (PPCI) [39]. In this paper, it is referred to as partially premixed charge compression ignition (PPCCI) to have consistent terminology with its diesel precursor (PCCI). Kalghatgi and Johansson described PPCCI combustion as the burning ‘of a stratified fuel cloud with a mixture of diffusion and premixed flames together with some bulk autoignition’ [37].

PPCCI can be realised in engines with compression ratios typical of diesel engines if thermal assistance is available (e.g., as intake air heating or charge heating via iEGR) to promote the AI of gasoline. Without any thermal AI assistance, gasoline fuels would require compression ratios in the range of 18–20:1 for AI. PPCCI engine compression ratios range from 16 to 18:1 [39,41,68,75]. Compared to diesel engines, PPCCI engines require relatively low fuel injection pressures because of gasoline’s volatile nature, which reduces the need for atomisation to vaporise fuel, and the relatively greater time available for mixing.

In PPCCI, similar to PCCI, heterogeneity is purposefully introduced in the cylinder mixture to create a non-uniform equivalence ratio distribution to moderate and stabilise combustion. From the surveyed literature, this is always performed using multiple direct injections [41,68,69,75,76,77,78]. The first fuel injection typically takes place during the intake or early compression stroke (e.g., 150–170°CA bTDC [69,75]) but can take place later too (e.g., 26–31°CA bTDC [70]). According to Kalghatgi et al. [37], for high-ON fuels, such as gasoline, injection at 60°CA bTDC is sufficient to form homogenous mixtures for combustion. The first PPCCI injection is followed by additional injections (typically 1–3), with the last one phased around TDC to serve as an AI trigger (e.g., 16–0°CA bTDC [75]).

The intermediate injection(s), if present, create(s) a lean stratified charge, and the last injection generates a rich cloud that ignites relatively easily (shorter ignition delay). The triggering fuel injection yields a relatively rich mixture, e.g., the third injection in Liu et al. [41] prepared a fuel-air equivalence ratio 0.49 mixture, compared to 0.24 and 0.2 for the second and first injections, respectively. The proportion of fuel mass injected during the pilot and main injection events also affects engine efficiency and emissions and combustion noise [75]. Thus, injection parameters have to be selected to realise appropriate levels of fuel stratification in a globally lean mixture to optimally control ignition and combustion progression. Dempsey et al. [77] compared the relative performance of a PPCCI engine across a range of stratification levels.

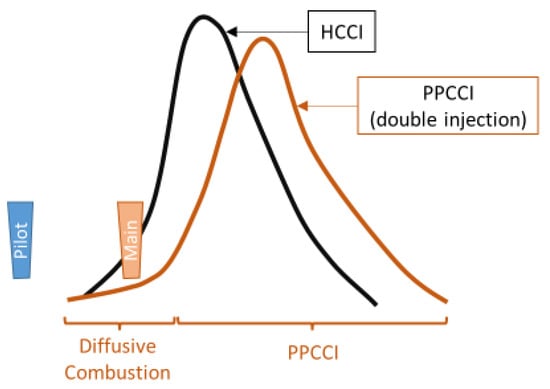

Figure 4 shows a qualitative comparison of heat release traces between HCCI and two-stage-injection PPCCI. The initial rise in the PPCCI trace is because of the diffusive combustion of the ignition-triggering injection, which is followed by a rapid rise when the background lean mixture auto-ignites. The HRR, and consequently the PRR, for PPCCI is lower than that for HCCI, thus allowing for more fuel to be injected and extending the high load limit. Moreover, no observable low-temperature heat release from the compression of the early injected fuel is present [69]. The lack of early heat release allows for the injection of large quantities of gasoline during compression without concerns about premature AI. Note, however, that such reactions can occur in gasoline CAI engines under certain in-cylinder thermal and chemical conditions [79].

Figure 4.

Qualitative HRR plots for HCCI and double injection PPCCI. Based on HRR curves in [41,69].

Recently, a new variant of PPCCI that incorporates diffusive combustion in addition to AI has been demonstrated by Sellnau and co-workers to extend the high load limit in a heavy duty engine to as high as 23 bar BMEP [79,80,81]. The strategy, referred to as ‘PPCI-diffusion’ has a late compression pilot injection (30–40°CA bTDC), which triggers an AI stage, followed by a second injection close to TDC, which initiates a diffusive combustion stage. A similar two-stage (AI + diffusion) gasoline combustion strategy was used by Hanson et al. [59] in a two-stroke opposed-piston PPCCI engine at high load points. High diesel-like injectors with injection pressures ranging between 1000 and 2000 bar were used in both the PPCCI-diffusion combustion engines.

PPCCI Limits

While PPCCI enables the extension of high load limits, there are still limits to this extension, as at very high loads, PRR becomes prohibitively high. Therefore, EGR is also used to moderate energy release rates; to counter the effects of excessive dilution, PPCCI engines are generally supercharged to further extend the high load limit [68,69]. Recent PPCCI work has also used ‘e-boost’ for operating the engine at high loads [41].

Since PPCCI engines do not have a spark plug, they cannot switch to conventional SI operation at high loads, which would be analogous to PCCI engines reverting to conventional CI at very high loads, where PRR could not be moderated using EGR, boost, and multiple injections [25,26,71,72,74]. This is one of the motivations behind the development of spark-assisted compression ignition engines (strategies 3 and 4). PPCCI engines can potentially switch to a different ‘conventional’ combustion strategies, namely diffusive (CI) combustion at the highest loads [59,79].

In PPCCI engines, low load operation can be a challenge because of gasoline’s poor AI characteristics and the relatively low temperatures at low loads. A few approaches that can enable stable low-load operation in PPCCI engines are:

- Using variable valve actuation techniques, such as exhaust rebreathing [39] or negative valve overlap [76], to raise cylinder temperatures by trapping or recycling hot combustion products (iEGR) to promote AI.

- Using a spark or a glow plug to assist with the combustion of the stratified mixture created by a late injection event [68]. This is different from spark-assisted compression ignition because ignition phasing is controlled by the late injection event and not the spark discharge.

- Avoiding low load operation by deactivating cylinders in multi-cylinder engines, e.g., in Cracknell et al. [68] one of the four cylinders was deactivated at low loads, and up to a 33% improvement in fuel consumption was reported.

The benefit of the latter two approaches is that they do not require expensive variable valve actuation systems and can be implemented using standard engine devices.

Figure 5 presents a speed-load map of various PPCCI studies surveyed and compares them to the baseline CAI engine from Figure 1. It can be seen that the high load limit was extended significantly with net IMEP, as high as 16 bar for a four-stroke engine [69] and 12 bar for a two-stroke engine [59], which is equivalent to 24 bar for four-stroke engines if the power enhancement from the doubling of the firing frequency is assumed to be twofold. Practically, specific power improvement realised in two-stroke engines ranges between 20 and 60% [82]. A tabulated summary of the various studies from Figure 5 is provided in the Appendix A (Table A1).

Figure 5.

Operating regions of various PPCCI engines surveyed (Table A1). BMEP has been converted to net IMEP by assuming 90% mechanical efficiency.

3.4. Strategy 3: Spark Assisted Compression Ignition (SACI)

Another CAI strategy that was developed to address the shortcomings of HCCI combustion is spark-assisted compression ignition (SACI) [63,65], which is also referred to as spark-controlled compression ignition (SPCCI) [47,48] or spark-ignited compression ignition [53]. In it, combustion is triggered in a well-mixed CAI (i.e., HCCI) engine via spark discharge, and the subsequent energy release is moderated by retarding combustion phasing and employing EGR and supercharging as needed.

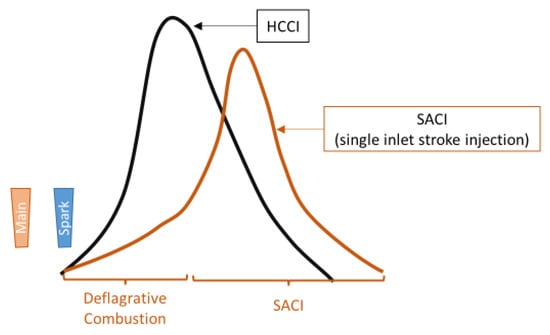

The sequencing of combustion in SACI engines is as follows: a near-homogeneous mixture is prepared by early (generally during the intake stroke) direct fuel injection. A spark discharge event around firing TDC triggers deflagrative combustion. The advancing flame causes the temperature of the cylinder charge to rise through compression heating, which lowers the mixture’s ignition delay and eventually triggers AI. Thus, a two-stage combustion process is realised, comprising an initial slow deflagrative stage, in which some of the fuel’s energy is released, and a second AI stage that rapidly burns the remaining fuel present as a lean, homogenous fuel-air-residual gas mixture. The first stage is similar to normal combustion progression in GDI SI engines, whereas the second stage is similar to abnormal SI combustion caused by end-gas AI (i.e., knocking). Instead of being avoided, end-gas AI is purposefully initiated and managed by creating favourable conditions for its onset, e.g., higher compression ratios and warmer in-cylinder conditions. Figure 6 presents a qualitative comparison of SACI and HCCI combustion using fabricated HRR profiles. The lower HRR for SACI demonstrates its combustion-moderating influence. SACI heat release is slow at the start during deflagrative combustion and becomes faster during the main AI stage. Since both PPCCI (Figure 4) and SACI are attempts at reigning in the aggression of HCCI combustion, there are similarities between their HRR profiles.

Figure 6.

Qualitative HRR plots for SACI and HCCI. Based on HRR curves in [53,63].

The phasing of SACI combustion is controlled by: (i) spark timing, (ii) the speed of flame-propagating combustion and the fraction of energy released through it, and (iii) the ensuing AI, the nature of which is determined by the composition and thermodynamic state of the post-deflagration mixture. Of these determinants, the principal is the spark timing. Having the correct mixture state, composition, and in-cylinder flows at the time of spark firing is thus critically important. Instabilities in initial flame propagation and early kernel growth at the dilute and lean conditions typical of HCCI combustion are major sources of cyclic variability in SACI combustion [65,83]. This is particularly problematic at low loads where the mixture temperatures are low and cause the further slowing down of flame initiation processes [65]. Olesky et al. [63] found that, for constant combustion phasing, AI stage reactions started at around 765 °C, irrespective of the spark timing.

The nature (speed and proportion) of the deflagration combustion stage can be tailored by controlling the temperature and composition of the cylinder mixture and, through that, the onset of spark-assisted AI. The flame propagating stage can be made longer at higher loads to avoid excessive PRR, e.g., by increasing external EGR (eEGR), decreasing iEGR, or decreasing intake air temperature or pressure. In Olesky et al. [63], 18 to 34% of the total energy release was made to take place via SI by adjusting the ratio of iEGR to eEGR. In Xie et al. [65], iEGR was reduced by decreasing positive valve overlap, which resulted in heat release becoming similar to that of SI combustion.

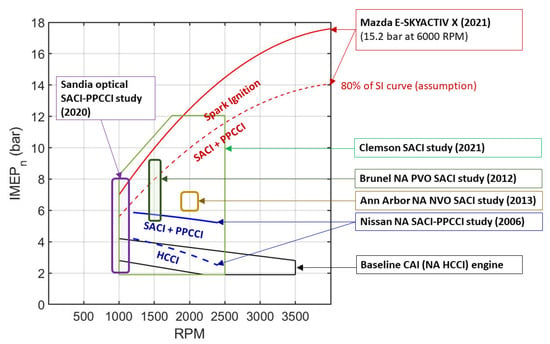

Since SACI engines are equipped with a spark plug, they can transition to conventional SI operation in regions where CAI is not feasible by making appropriate adjustments in the mixture preparation and gas exchange processes, e.g., switching to an overexpanded (Miller-type) cycle, mixture enleanment, and/or increasing EGR to avoid SI knock [84]. Operating range coverage examples from SACI engine studies are shown in Figure 8.

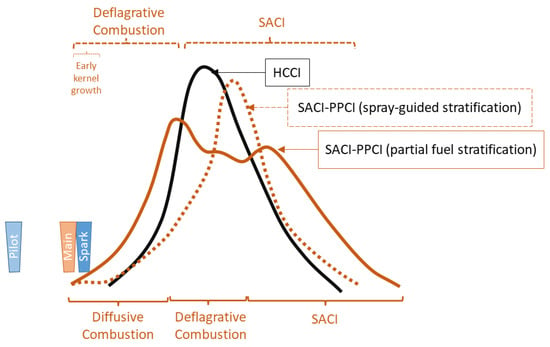

3.5. Strategy 4: SACI-PPCCI Hybrid

As the name suggests, this strategy is a combination of strategies 2b and 3 and is thus placed in between the two in Figure 2. It is categorised separately because it utilises moderating influences from both of its constituent CAI strategies, stratification via multiple DI events from PPCCI and deflagrative combustion from SACI. In the literature, however, it is more commonly referred to as SACI implementation [30,47,53]. Strategies such as SACI-PPCCI hybrid are reminders that various means of characterising CAI strategies are merely tools to facilitate structured discussions on the topic and are not constraints to CAI implementation.

In the SACI-PPCCI hybrid strategy, a late second injection event takes place shortly before (or at the same time as) spark firing in an SACI engine [83]. The additional injection introduces localised stratification around the spark plug with a homogenous background charge. This is conducted to have locally rich strata to make SI more stable and to accelerate flame propagation [53,85]. The stabilisation provided by the second injection makes operation at more retarded spark timings possible, where typically lean and diluted HCCI mixtures experience very unstable combustion [53,73]. Retarding combustion phasing by decreasing iEGR without additional support from fuel stratification reduced combustion stability in Olesky et al. [63]. SACI-PPCCI hybrid engines can have more than two injections, e.g., Hu et al. [85] employed 1–3 early injections around 300°CA bTDC to form the background well-mixed mixture.

Flame imaging experiments by Hu et al. [85] found that the pre-spark injected fuel in a ‘partially fuel stratified’ engine acted as a locally rich diffusively burning ‘super igniter’. The injector was located such that the fuel jets straddled the spark plug electrode. The resulting energy release was three orders of magnitude higher than that from a standard spark discharge. The following deflagrative stage burned a well-mixed lean mixture, and the final AI stage consumed the remaining very lean end-gas. The resulting HRR profile for such SACI-PPCCI combustion (qualitatively illustrated in Figure 7) is a combination of PPCCI and SACI profiles and has three stages: a diffusive PPCCI stage, a deflagrative SACI stage that has lower HRR than the preceding diffusive stage, and a stronger late AI stage. The nature of the first combustion stage can vary depending on the spatial and temporal distribution of the stratified fuel mixture around the spark plug. Flame imaging results from Reuss et al. [83], in which fuel injection jets were targeted just below the spark plug gap and stratification was achieved using spray-guidance (instead of wall or flow guidance [29]), did not reveal a diffusive combustion stage. Combustion progressed, as qualitatively illustrated in Figure 7, in the following stages: early kernel growth, flame propagation, and AI. Depending on the nature of fuel stratification, SACI-PPCCI HRR profiles can resemble one of the profiles shown in Figure 7 or be a combination of the two. Reuss et al. [83] also provided useful HRR and flame area-based ‘engineering metrics’ that can be used to index SACI combustion progression.

Figure 7.

Qualitative HRR plots for SACI-PCCI combustion. Based on HRR curves in [83,85].

SACI-PPCCI provides flexibility in tailoring energy release profiles by controlling fuel injection and spark discharge events that determine the fraction of each of the three combustion stages. CA50 was found to correlate strongly and linearly with spark timing, demonstrating that spark timing is a strong overall combustion phase controller [85].

As discussed for PCCI and PPCCI, late fuel injections can cause diffusion combustion, which can increase NOx and PM emissions. Higher than expected, yet still low, NOx emissions observed in Yoshizawa et al. [53] were attributed to the combustion of the relatively rich stratified mixture around the spark plug.

Operating Strategies

Because of the flexibility in tailoring combustion strategies, the engine operation of SACI-PPCCI can be switched between SI, SACI, SACI-PPCCI, HCCI, and PPCCI as needed to cover the desired operating region. Moderated HCCI strategies (SACI, PPCCI, or SACI-PPCCI) can be used at high loads to manage PRR, and HCCI can be used at low loads to benefit from its thermal and combustion efficiency advantages. If CAI is not possible at low loads, conventional SI operation can be used, and if PRR is excessive at very high loads, CAI combustion can be switched to SI with accompanying adjustments in mixture preparation and gas-exchange settings. An example of a commercial SACI-PPCCI engine is presented next.

Mazda’s SKYACTIV X [47] engine and the e-SKYACTIV X [48] variant for mild hybrid applications are the first class of four-stroke gasoline CAI engines to reach the market. They are GDI SI engines with high compression ratios (16:1 and 15:1, respectively) and use a split fuel-injection strategy to realise SACI-PPCCI CAI. The pilot injection takes place during the intake stroke, and the main injection occurs during the compressions stroke. The fuel is injected at the moderately high pressure of 500 bar, and the engines run very lean with an air-fuel ratio of 40:1 in CAI mode [30]. The engines also use turbulence in the form of strong swirl and tumble flows to help vaporise the injected fuel and to optimally direct it around the spark plug. A clutched supercharger is used to boost the engine as needed and is disengaged when natural aspiration is desired. A variable valve timing system creates positive valve overlap to help scavenge hot exhaust gases or operate the engine on an over-expanded cycle by early intake valve closing as needed. The SKYACTIV X engine covers most (80%) of its operating range under CAI operation and switches to conventional stoichiometric SI operation at very high loads. This is probably because the PRR moderation provided by spark assist is not sufficient at the highest load points. The engines operate in SI mode during cold start and warm up periods as well, likely due to cylinder contents being too cold to achieve stable AI. A resulting fuel economy improvement of up to 30% has been reported. The rated torque and power for Mazda e-SKYACTIV X translate to a BMEP of 13.7 bar at 6000 RPM and 15 bar at 4000 RPM [48]. The engine’s operating envelope is compared to that of the baseline CAI engine and other SACI studies surveyed in Figure 8. A summary of the referenced studies is provided in Table A2 in Appendix A. A joint reading of both highlights that:

Figure 8.

Operating regions of various SACI and SACI-PPCCI engines surveyed (Table A2). BMEP was converted to net IMEP by assuming 90% mechanical efficiency.

- SACI alone cannot adequately extend the CAI operating envelope. Assistance is needed from PPCCI to provide stable, lean combustion across a wide operating range.

- SACI-PPCCI hybrid engines allow for using relatively high compression ratios because of the availability of two ignition control knobs (spark discharge and fuel stratification) that can provide effective PRR moderation.

- HCCI can serve as a stable low- to medium-load combustion mode, and operation can be switched to SI operation at very high loads and cold engine conditions.

- Adjusting iEGR to the eEGR ratio using various valve overlap strategies is an effective way of stabilising SACI operation and extending its load limits.

- Greater in-cylinder flow control and turbulence, relative to non-SI CAI engines, might be needed to stabilise and accelerate combustion during the deflagrative stage.

3.6. Strategy 5: Gasoline Compression Ignition (GCI) [Redundant]

In the literature, the term gasoline compression ignition (GCI) [37,41,53,59,77] or gasoline direct injected compression ignition (GDCI) [39,68] is used as well to refer to gasoline CAI. It is more commonly used to refer to gasoline PPCCI engines [1,39,41,68,77], but it has been used for gasoline SACI engines as well [53]. A reasonable case for the use of the term for both the gasoline CAI strategies can be made, but its use in the PPCCI context seems more appropriate, as the technology is a direct offshoot of diesel engines and is often implemented directly in diesel engines. Additionally, there is no spark plug in the cylinder, and the prime initiator of AI is compression. For this reason, PPCCI engines typically have higher compression ratios than SACI engines. PPCCI-SACI hybrid engines have compression ratios between the two (around 15:1). Because of the relative vagueness of the term, the use of ‘GCI’ is avoided in this paper.

3.7. Strategy 6: Reactivity Controlled Compression Ignition (RCCI)

Reactivity controlled compression ignition (RCCI) combustion is a CAI strategy in which two fuels—a high-reactivity (high-CN) and a low-reactivity (low-CN) fuel—are used [86,87]. Generally, the high reactivity fuel is diesel, and the low reactivity fuel is gasoline. Appropriate amounts of each are metered to tailor the reactivity of the combusting mixture to obtain desired energy release profiles. Natural gas can also be used as a low-reactivity fuel [88]. Because the scope of the present work is focused on single gasoline fuel-based systems, RCCI is discussed very briefly below.

In RCCI, typically, a homogenous mixture is formed in the cylinder by the port fuel injection of gasoline. The mixture is then compressed, and because of its low reactivity, it does not auto-ignite during compression. AI is triggered around TDC in a conventional CI combustion-like fashion by the injection of diesel into the hot compressed mixture of gasoline and air. The diesel combustion triggers the AI of the homogenised gasoline mixture that combusts rapidly in a premixed combustion event. The amount of low- and high-CN fuels admitted, along with the high CN fuel’s injection timing, can be varied for various speed and load conditions to achieve stable combustion with low NOx and soot emissions. The challenge with this approach is that it requires two fuels, which increases the system cost and level of complexity. Octane-on-demand technologies [1] can potentially remove the need for carrying two separate fuels.

In a recently proposed RCCI variant ‘intelligent charge compression ignition’, the low-CN fuel is directly injected into the cylinder instead of being injected into the intake port. This offers better control over the low-CN–high-CN fuel stratification [89]. Another RCCI variant being developed, especially for electrified powertrains, is the ‘dual-mode dual-fuel’ concept, in which the relative proportion of the two fuels and diffusive and premixed combustion stages are adjusted to cover a wide operating map [90].

Graphical and tabulated summary comparisons of the various CAI concepts discussed here are presented in Figure 9 and Table 2, respectively. They highlight differences in fuel injection strategies and mixture formation.

Figure 9.

An overview of mixture preparation processes in various CAI technologies. Adapted from [1].

Table 2.

Comparison of various engine combustion systems.

4. Controlling CAI Combustion

One of the biggest challenges for CAI engine development has been combustion control. In actual engines, a host of control parameters have to be simultaneously adjusted to control CAI across the desired operating range [91]. This entails precisely controlling the chemical composition and the thermodynamic state of the cylinder contents to initiate combustion, manage heat release, and ensure adequate chemical energy availability and stable combustion, all within emissions and drivability constraints while trying to maximise efficiency. A list of potential CAI control actuators that can be used, together or in isolation, to meet these combustion control requirements is presented below.

4.1. Exhaust Gas Recirculation

Combustion products can be recirculated or retained to moderate or accelerate combustion. Different EGR effects can have competing influences on combustion. Zhao [19] characterised these effects as follows:

- Charge heating—combustion products by virtue of their temperature can increase the temperature of the cylinder gases.

- Dilution effect—combustion products reduce the amount of oxygen in the trapped mixture by replacing air.

- Heat capacity effect—combustion products contain CO2 and H2O, which have relatively high heat capacities compared to that of O2. Hence, the trapped mixture’s heat capacity can increase, and its ratio of specific heat can decrease.

- Chemical effect—partially oxidised products of combustion, e.g., CO, HC, or NO can participate in chemical reactions in the trapped mixture.

For CAI combustion, charge heating, dilution, and heat capacity effects are of primary concern. Charge heating can increase the chances of AI and make deflagrative combustion faster, whereas excessive dilution can hamper combustion by starving it of oxygen. The heat capacity effect can reduce compression temperatures and pressure to thwart AI. iEGR is primarily used to exploit the charge heating effect, whereas eEGR can be tailored via an eEGR cooling system to exploit charge heating, dilution, or heat capacity effects.

Because of these competing effects, EGR on one hand is used to extend the lower operating limit by increasing charge temperature to ensure stable AI, and on the other hand, it is used to extend the high load limit by lowering charge temperature (heat capacity effect) to allow for the admission of additional fuel. An unintended consequence of the foregoing is that the dilution effect makes combustion unviable at higher loads because of insufficient oxygen availability, leading to misfires or partial fires [55]. EGR can also be needed as a charge heater to extend the high load limit if the trapped gas temperatures are not high enough for realising AI.

Depending on the net effects of combustion product retention or recirculation, the effects on emissions could be positive or negative. NOx emissions can decrease because of lower temperatures. PM emissions can increase if insufficient oxygen is available for soot oxidation unless temperatures are lowered below the soot-formation threshold.

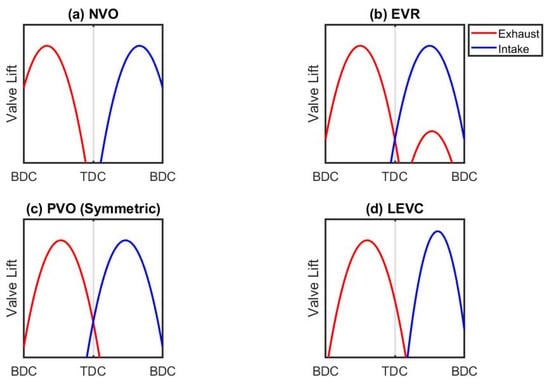

iEGR Strategies via Variable Valve Actuation

Valve timing, duration, and lift adjustments, i.e., variable valve actuation, can be used to control the amount of trapped residual gases. Variable valve actuation systems can offer different levels of flexibility, ranging from variable valve timing (VVT) to continuous variable valve lift (CVVL) systems [92]. Owing to the tremendous potential of improving engine efficiency (10–12% according to [54]) and emissions by flexibly controlling engine breathing, many major automotive companies have tried to develop such systems, e.g., BMW ‘valvetronic’ [93,94], Lotus ‘active valve train’ [95], Toyota ‘valvematic’ [96], Nissan ‘variable valve event and lift’ [97], and Fiat/Schaeffler ‘Multi/UniAir’ [98]. Despite some of these technologies having made their way into production engines (e.g., [98,99]) their cost and concerns over reliability and accuracy have restricted their widescale adoption [98].

Many of the surveyed CAI studies used iEGR via valve opening and closing control to support CAI (see Table A1 and Table A2). The valve actuation approaches used by these studies are summarised below, and a graphical comparison is presented in Figure 10.

Figure 10.

Comparison of (a) negative valve opening, (b) exhaust valve reopening, (c) positive valve overlap, and (d) late exhaust valve closing valve lift profiles.

- Negative Valve Overlap (NVO): Exhaust valves are closed before TDC, often accompanied by a late opening of the intake valves, to retain more combustion products than would have been retained with exhaust valve closure at/after TDC (Figure 10a). The residual gases are recompressed during the latter part of the exhaust stroke, which increases their temperature and can offer AI benefits NVO periods ranging between 60 and 220°CA were used in Borgqvist et al. [76] and between 114 and 136°CA in Xie et al. [65]. Some of the fuel’s energy can be released during the NVO period by injecting the fuel during or before it if the cylinder conditions are conducive for low-temperature heat release [76,100]. With NVO strategies, a pumping loss penalty is incurred because of recompression. These losses increase at higher loads because of higher expansion pressures [65]. Therefore, NVO might be preferable only at lower loads, where it provides hotter iEGR and greater thermal stratification [54].

- Exhaust Rebreathing via Exhaust Valve Reopening (EVR): To reduce pumping losses incurred because of NVO, recompression can be avoided by having a second exhaust valve opening event, typically during the intake stroke (Figure 10b). Some exhaust gases from the exhaust port would thus be readmitted into the cylinder and heat the fresh charge. Because of the recirculation of the exhaust gases, the charge heating potential of EVR iEGR is lower than that of NVO iEGR. Sellnau et al. [39] used exhaust rebreathing to extend their PPCCI engine’s low load performance and also to elevate exhaust temperatures to improve aftertreatment system efficiency.

- Exhaust Rebreathing via Positive Valve Overlap (PVO): In this approach, intake and exhaust valves are opened simultaneously beyond the overlap periods typical of automotive engines (Figure 10c). Adequate iEGR for CAI can be retained through this approach if intake and exhaust valve timings, about or on one side of TDC, are selected smartly [65]. Pumping losses are lower than for NVO with this rebreathing method as well, which makes it promising for high-load CAI operation. Xie et al. [65] realised CAI using PVO in an SACI engine. SACI engines typically require relatively less thermal assistance for AI because of the availability of a positive ignition source in the form of a spark.

- Exhaust Rebreathing via Late Exhaust Valve Closing (LEVC): In this exhaust rebreathing strategy, exhaust valves close after TDC, and some exhaust gases are rebreathed from the exhaust port during the expansion stroke (Figure 10d) [54]. This method produces relatively high levels of thermal stratification but not as high as NVO. It also has lower pumping losses than NVO.

Another strategy that has sometimes been used to adjust iEGR levels is engine exhaust throttling using a back pressure valve [39,101]. Increasing exhaust back-pressure traps more iEGR and thus supports CAI.

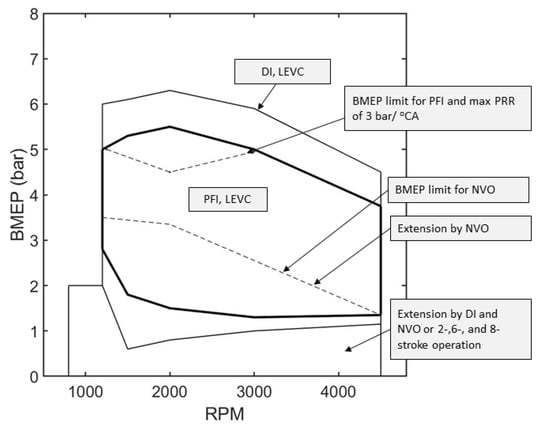

4.2. Cycle Type

A potential way of extending the high load limit is by distributing energy release over multiple revolutions of the crankshaft instead of concentrating it all in one dedicated ‘power stroke’ taking place every other revolution. The most promising, and arguably the most researched, means of conducting this is by operating a two-stroke cycle, whereby the firing frequency would be doubled relative to four-stroke cycles [46], thus lowering the mean effective pressure requirements. Two-stroke engines also have the advantage of retaining high quantities of residual gases (iEGR), which can be beneficial in promoting CAI [102]. CAI operation has been utilised in two-stroke engines with various scavenging configurations. Examples include ported cross-scavenged, ported loop-scavenged, poppet-valved loop-scavenged, uniflow-scavenged with intake ports and exhaust poppet valves, and ported uniflow-scavenged designs [46,49]. To avoid significantly redesigning the valve-in-head architecture of automotive engines, the poppet-valved, loop-scavenged two-stroke cycle engine is an enticing option. Two-stroke cycle operation can be realised in a flexible four-stroke engine by changing valve timings via the CVVL module and adjusting spark and fuel injection timings accordingly. Switching from two- to four-stroke cycles can be achieved during engine operation to leverage the benefits of both cycles at appropriate operating points [54,61]. Lang et al. [54] successfully realised CAI across a wide operating map in a gasoline, dual-injection (PFI + DI) engine equipped with an electromechanical CVVL system (Figure 11).

Figure 11.

The extension of CAI operation through iEGR management and cycle switching using a CVVL system. Adapted from [54].

Other cycle options that could be investigated are six- and eight-stroke cycles that have two consecutive firing strokes followed by gas exchange or redundant strokes [54].

4.3. Low Load Avoidance

Another strategy to help control CAI can be to restrict engine operation to moderate- and high-load operating points, where AI is easier to achieve and CAI combustion is more stable. Moreover, for throttled engines, this would avoid operation at points with the worst pumping losses. Possible ways of avoiding low-load operation are:

- Cylinder deactivation at low loads to force the active cylinders to operate at higher pressures and temperatures (i.e., at higher loads) [68]. Engine cylinders can be deactivated by closing valves [54], stopping fuel injection and spark plug firing [1]. In a CVVL-capable engine study, additional 6–10%-point fuel consumption benefits were realised through cylinder deactivation [54].

- Load levelling via powertrain electrification to shield the engine from low-load operation and transient changes in driving power demand by providing propulsion (entirely or partly) via the electric traction motor. This is discussed in more detail in Section 5.

4.4. Boosting

An effective way to counter the EGR dilution-imposed limit on fuel addition at high loads is through boosting, whereby intake pressure is increased using a compressor. Hence, more air is forced into the cylinder, allowing for more fuel to be burned and higher torques to be generated.

Boosting can be achieved through exhaust-driven turbochargers, mechanical superchargers that withdraw some work from the engine’s crankshaft, or electric superchargers that have an electric motor driving the compressor. Electric superchargers, also known as e-boost systems, can promptly respond to the engine’s aspiration needs and are not limited by turbo lag at low loads and speeds [41,103]. With the availability of high-voltage circuits in electrified powertrains, e-boost systems can be adopted more widely.

4.5. Fuel Injection

As discussed for the various partially premixed CAI embodiments, fuel injection strategies can play a pivotal role in moderating combustion via fuel stratification and allowing stable, retarded combustion to extend the high load limit. Locally rich mixtures can also help achieve stable combustion at low loads. Some fuel injection design considerations for CAI engines are injector location (port and/or in-cylinder, position and angle relative to spark plug in SACI variants); number of injection events and their timing, duration, and injected fuel quantity; injection pressure, injector design, and number of injectors [77]. Injection details of some of the surveyed gasoline CAI studies are provided in Appendix A.

4.6. Ignition Assistance

As discussed for SACI engines, ignition aids (positive ignition devices) can be used in CAI engines to control ignition timing and combustion phasing, which can help moderate heat release and stabilise combustion to extend low- and high-load operations, respectively. The most common ignition aid is the spark plug. Some other ignition assistance devices are glow plugs [76], pre-combustion chambers (PCC), plasma ignition, and laser ignition [85]. None of the CAI studies surveyed used PCCs or any of the unconventional positive ignition devices, but because of their ability to stabilise combustion and promote efficient energy release, PCCs might warrant consideration for some SACI strategies. In some respects, PCCs and CAI are similar because both aim to promote fast combustion in lean and dilute engines by having multiple ignition sites. Depending on the CAI strategy, employing a PCC in a CAI engine might introduce redundancy. A recent commercial (non-CAI) application of PCC, albeit in a supercar, is in Maserati’s Nettuno engine [104]. Mahle’s dedicated hybrid engine [105] uses their PCC, the ‘Mahle Jet Ignition’ system [106].

4.7. Charge Heating

Intake air heating can be employed to facilitate the AI of low-reactivity fuels, such as gasoline. This can be accomplished by recycling exhaust heat using an appropriate thermal management system or through electric heaters. There could be new electric heating possibilities available because of the electrification of powertrains. Direct intake air heating instead of using iEGR can help avoid associated pumping losses. Sellnau et al. [39] used a 2.3 kW electric heater upstream of the intake valves. Air heating would, however, reduce the engine’s volumetric efficiency and consequently the output power. In the surveyed CAI studies, intake air was heated to temperatures between 60 and 180 °C [85,107]. A near 1:1 negative correlation was reported between combustion phasing (indexed by CA50) and intake air temperature for HCCI engines by Kalghatgi et al. [37], i.e., every 1 °C increase in intake temperature advanced CA50 by 1°CA. For PPCCI engines, the correlation also depends on injection timing and, for SACI engines, on spark timing [85]. The CAI stage heat release increased significantly in the SACI-PPCCI engine studied by Hu et al. [85] when the intake air temperature was increased from 30 to 60 °C. Cinar et al. [108] reported the significant advancement and strengthening of CAI in an HCCI engine when air temperature was increased to 120 °C.

For operating points where AI is to be discouraged, e.g., at high loads, intake air temperature can be lowered to increase ignition delays. This can be useful in SACI engines with high compression ratios to avoid knocking under SI operation at high loads.

4.8. Engine Cooling

As CAI can be controlled by managing cylinder temperatures to encourage or discourage AI, the engine cooling system can serve as a slow speed AI control actuator. If the system is adjusted to remove less heat from the cylinders, then the cylinder contents will become hotter and AI will become easier. The opposite (removing more heat) would make AI less likely. Such an approach would have similarities to ‘low heat rejection’ combustion concepts [109].

4.9. Compression Ratio

Another CAI control actuator can be the geometric compression ratio, which traditionally has been a fixed parameter because of the complexities associated with varying it during engine operation. If, however, reliable and cost-effective means of changing the compression ratio can be developed, then the need for controlling non-compression-based AI enablers can be reduced. Hence, CAI operating limits can be extended, including for cold start conditions, and engines can be made fuel-flexible. Compression ratios can be varied at different operating points based on the trapped mixture’s reactivity. Some of the means of varying compression ratios are free pistons [18], variable length connecting rods [110], multi-link crankshaft rotation mechanisms [111], and dual (split)-piston mechanisms [112]. The performance of variable compression ratio-capable CAI engines has been the subject of multiple studies [18,113,114,115,116].

4.10. Altering Mixture Reactivity

The scope of the current paper emphasises CAI for gasoline-fuelled engines; therefore, the potential benefits of altering charge reactivity by introducing non-standard species have not been explored in detail.

According to the literature, the ideal gasoline CAI fuel should have a research octane number (RON) between 70 and 80 [37,75]. This is considered a good compromise between the need for a high-reactivity fuel at low loads where cylinder conditions are difficult for AI and the need for a low-reactivity fuel at high loads where high temperature and pressure might initiate AI prematurely. Some strategies that have been discussed in the reviewed literature to chemically adjust the mixture’s auto-ignitability are:

- Introducing a high reactivity fuel in a low-reactivity fuel mixture to promote AI when desired. This is the RCCI approach.

- Using high-ON fuels, such as ethanol, to prolong ignition delay and thus allow operation at high compression ratios. Christensen et al. [107] realised stable CAI, albeit at relatively low loads, using ethanol in an engine with a very high compression ratio of 21:1.

- Introducing radical producing species, such as ozone, in the intake air [117] or partially reforming the injected fuel via low-temperature heat release [100] to lower AI temperature.

- Fuel blending, e.g., 80% gasoline with 20% diesel to form ‘dieseline’ that has lower ON than gasoline [37] or mixing n-heptane and iso-octane via separate injectors in intake ports to control fuel ON for HCCI operation [118], or blending hydrogen and methane [119].

- Using low ON fuels, such as naphtha (RON 60–85 [30]) to achieve AI at low compression ratios and mixture temperatures. Such fuels can also offer a reduction in CO2 on a well-to-wheel basis, as they need less processing [68].

If engine operation is limited to moderate and high load points via low-load avoidance, then optimal RON would be higher than 70. Thus, market gasoline fuels that typically have a RON greater than 70 might offer natural advantages for HPS CAI operation.

A summary of the control actuators listed above is presented in Table 3. The table also identifies whether the effects of adjusting a given control parameter can help extend operational limits of a naturally aspirated HCCI engine. Moreover, the response rates of various means of adjusting the control parameter have been characterised (in a slightly arbitrary and subjective manner) as either being ‘fast’, ‘intermediate’, or ‘slow’.

Table 3.

CAI control parameters, their effects and benefits, and implementation options. LL, LS, and HL, respectively, identify if the effect can help extend low-load, low-speed, or high-load HCCI engine limits. ‘Interm.’ is short for intermediate.

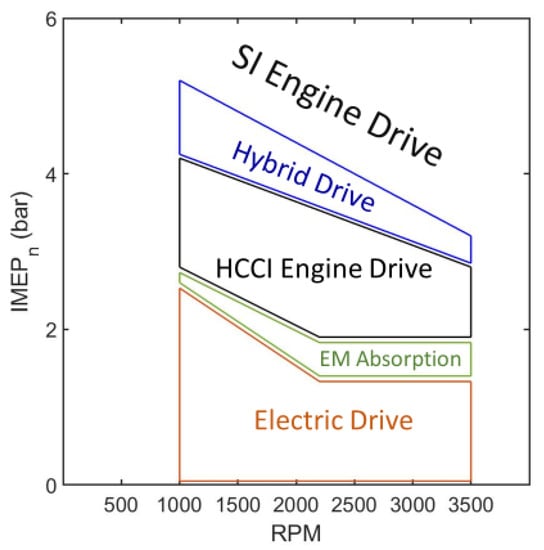

5. Opportunities for CAI-Based HPS