Energy is the crucial factor for the sustainability of our society. The energy sector earns five trillion dollars every year, producing 3000 gigawatts annually [

1]. Unfortunately, 80% of global final energy consumption is still from fossil fuels, which results in the pollution of the environment and important climate disturbances [

2]. The burning of hydrocarbons is the main source of the most important greenhouse gas—carbon dioxide. The total emissions of CO

2 in 2021 amounted to 41,062,896,000.00 Mg [

3]. This is why decarbonization is one of the major concerns for the future. Fighting climate change by reducing greenhouse gas emissions is one of the basic United Nations’ Sustainable Development Goals. More than 100 countries have pledged to achieve carbon neutrality. In Europe, Norway will become carbon neutral by 2030, Finland and Sweden by 2045, and the European Union as a whole community by 2050, with the same goal for Great Britain. In Asia, both the Republic of Korea and China will achieve this goal by 2050 [

4].

The most important part of achieving carbon neutrality is by supporting renewable sources of energy. This is another of the UN’s Sustainable Development Goals. It has very strong support globally. Over the last few years, especially in the context of solar and wind energy, every year there has been a new record. Even in 2020, which involved full lockdowns and a global pandemic, records were achieved. In 2020, the global wind capacity was 774 GW (12.5% more than in 2019) and the global PV solar capacity was 760 GW (18% more than in 2019) [

5]. In 2021, as much as 94 GW of new wind power plants and 175 GW of solar plant energy were created—a new record for the year [

6].

An important alternative is nuclear power. However, there is uncertainty concerning its safety, especially after the Fukushima disaster. The world’s largest nuclear power plant, Kashiwazaki-Kariwa, is also located in Japan, with a capacity of 7965 MW. During the tsunami of 2011, the facility was not affected; nevertheless, it shut down and more money was spent on better safety installations. The plant is still not in operation and its future is unknown [

8]. However, nuclear power has been successful in many other regions, in France in Europe, in China and South Korea in Asia, and in the USA and Canada in America [

9].

Another solution which is very promising is the use of hydrogen. In our opinion, this may be the fuel of the future, but still there are many problems that need to be solved. This paper presents the advantages and problems connected with the production of energy from hydrogen, the current legislation concerning hydrogen in the European Union, and a local case study from Poland, a country that belongs to this community.

1.1. Hydrogen as an Energetic Alternative

Hydrogen is the most common element in our environment, so there is no danger that its resources may be depleted. Huge resources are available in water, hydrocarbons (including biogas and methane), and also in organic matter. It is true that during a combustion reaction or a transformation within hydrogen-based electrochemical devices, no additional substances harmful to the environment are formed apart from neutral water. Hydrogen forms more compounds than any other element [

10]. Hydrogen is also similar to alkali metals and halogens. It forms not only oxides, but also sulfides and halides. On a weight basis, hydrogen can deliver three times more energy than gasoline. What is more, when burning hydrogen, the amount of pollutants emitted into the atmosphere will be lower than that in the case of gasoline [

11].

On the other hand, there are different ways of producing hydrogen, with varying and sometimes serious environmental consequences. Among these production technologies, thermochemical, photochemical, photocatalytic [

12,

13], photoelectrochemical, and biocatalytic processes may be distinguished [

14].

The choice of hydrogen production methods depends, to a large extent, on the available resources and existing energy systems in individual countries, as well as on the pursued political goals, i.e., decarbonization and supporting economic growth, etc.

Different countries use a variety of terminology, adopting different assumptions and attitudes towards certain technologies. First of all, hydrogen has many different categorizations [

15]. Increasingly, the multiplication of different shades of hydrogen has overcomplicated this discussion. There have been attempts to settle the color debate, with the aim of establishing clear definitions for the carbon content, technology, and sources of electricity that create them.

At the same time, in addition to color, more and more attention is being paid to carbon intensity or carbon equivalence. The intensity of carbon dioxide emissions—expressed as the Mgs of CO

2 per Mg of H

2 produced—is a technology-neutral criterion for assessing the hydrogen footprint [

16]. There are four basic kinds of hydrogen: brown, grey, blue, and green (see

Table 1).

Gray hydrogen can be commercially produced on the base of fossil fuels in different ways:

- -

steam and/or oxygen hydrocarbon reforming, steam methane reformer (SMR),

- -

ATR: the autothermal reforming of natural gas,

- -

or through a partial oxidation of coal or heavy oil [

18].

In all three cases, syngas (containing H and CO) is produced. The CO may be removed through a water displacement reaction in a gas exchange reaction. Through this, more hydrogen can be obtained, as can more CO

2. The present yearly production of gray hydrogen is 70 Mt (and 830 Mt of CO

2) [

19]. At the same time, this is the cheapest technology.

Brown hydrogen—in this technology, coal is used and hydrogen is produced through coal gasification. This process is in use in many different industries. It is based on the conversion of carbon-rich substrates into hydrogen and is connected with important carbon dioxide emissions. The global production of brown hydrogen is around 79 Mt annually, but this also comes with emissions of 830 Mt of carbon dioxide—the highest amount for all kinds of hydrogen production [

20].

Blue hydrogen technology is similar to that of gray hydrogen, but with blue hydrogen, some of the carbon dioxide released through the steam methane reformer process is captured. For the blue hydrogen facilities that are currently operating on a commercial basis, carbon capture occurs only in the steam methane reformer process and there is currently no attempt to capture the carbon dioxide resulting from the combustion of natural gas, which is used to provide heat and high pressure for process purposes. Carbon capture storage (CSS) requires energy, which is often provided by electrical power generated by the burning of additional natural gases [

21].

Finally, with regard to green hydrogen, this is the technology chosen for our study, which is also strongly supported by the European Union and is presented in the next paragraph.

1.2. Green Hydrogen

Green hydrogen is produced via the process of water electrolysis, using only electricity from renewable energy sources. The electrolysis process can split water into hydrogen and oxygen molecules [

22]. Electrolysis requires both water and electricity. About 9 L of water are needed to produce 1 kg of H

2, producing 8 kg of oxygen as a by-product, which can be used on a smaller scale in healthcare or on a larger scale for industrial purposes [

23,

24]. If all of today’s hydrogen production, which is around 70 Mt of H

2, was to be produced by electrolysis, this would result in a water requirement of 617 million cubic meters, which is equivalent to 1.3% of the global energy sector’s water use today, or roughly twice as much as the current water consumption for the hydrogen produced from a steam methane reformer.

Water electrolysis methods can be divided into three main types:

alkaline,

membrane (PEM—proton exchange membrane and AEM—anion exchange membrane),

based on cells with solid oxides (SOE—solid oxide electrolyzer).

Table 2 summarizes the parameters of these typical water electrolysis methods.

Alkaline electrolysis systems are most often compared to other water electrolysis methods due to them having the longest presence in the market. Electrolysis based on solid oxide (SOE) systems is the most efficient in terms of its use of electricity, but it is still under development. Corrosion, seals, thermal cycling, and chromium migration are the main challenges facing this SOE technology [

25].

Proton exchange membrane (PEM) electrolysis systems are more efficient than alkaline electrolyzers. Their corrosion and sealing problems are not as problematic as those in SOE cells, but the cost of membrane cells is still higher compared to alkaline cell systems [

25].

Alkaline cell systems have the lowest capital cost and lowest efficiency, but the cost of the electricity used for their electrolysis is the highest [

25].

Green hydrogen is considered to be a clean solution, since it is based on renewable energy [

26]. However, due to its technological maturity level, it is also the most expensive solution. Therefore, the challenge is to efficiently produce hydrogen as a fuel when extracting it from the environment in the cheap way and without additional emissions of pollutants, such as carbon dioxide. The main obstacle in this case is the cost of production; however, it is still possible to introduce green hydrogen into the real world. The price is supposed to fall with further technological development and growing production, and financial incentives may lead to the economic efficiency of such an investment.

As of now, the country that has been most successful in introducing these hydrogen technologies is China—it is the largest user and producer of hydrogen in the world, with more than 24 million Mg of coal-based hydrogen per year. In the five-year plan for the years 2021–2025, hydrogen is one of the main industries of the future for this country [

27].

The European Union wants to follow this path, but there, green hydrogen is in focus.

However, among the most important factors regarding hydrogen production is not only technology, but also policy.

1.3. Policy Supporting Hydrogen Production in the European Union

Until 2017, only one country, Japan, had a national hydrogen strategy. Currently, over 30 countries have developed or are preparing hydrogen strategies, which indicates a growing interest in the development of clean, green energy solutions.

The development of the hydrogen market in Europe is connected to the implementation of the European Union’s current climate policy.

It is worth mentioning the EU’s AFID—Alternative Fuels Infrastructure Directive of 22 October 2014. It obliges the member states to create an appropriate number of hydrogen fueling stations by the end of 2025. However, this number is not given precisely and is ultimately intended to result directly from the policy adopted by each member state [

28].

The widest approach was presented in the document of the European Commission entitled the European Green Deal. Its main goal is the climate neutrality of the EU by 2050. The main goal is to achieve climate neutrality by 2050 [

29]. The directions of changes for individual sectors of the economy are as follows:

the decarbonization of the gas sector by introducing low-emission gases such as hydrogen,

support for clean technologies in industry, including clean hydrogen and energy storage,

the decarbonization of transport (air, road, rail, and water), i.e., by introducing alternative, sustainable transport fuels [

29].

In 2020, a hydrogen strategy for a climate-neutral Europe was issued [

30]. It may be summarized in five points:

investment support,

support production and demand,

creating a hydrogen market and infrastructure,

research and cooperation,

international cooperation.

This was enhanced in 2021 as the “Hydrogen and gas markets decarbonisation package proposal”. It was connected with the Regulation of the European Parliament and of the Council on the internal markets for renewable and natural gases and hydrogen [

31], and the Directive of the European Parliament and the Council on the common rules for the internal markets and natural gases and hydrogen [

32]. According to this package:

In May 2022, a new plan called “REPowerEU” was introduced, in order to rapidly reduce the dependence on Russian fossil fuels and fast forward the green transition. The community assumed a cut-down of two thirds of Russian gas import by the end of 2022, and all imports should be stopped by 2027.

There are three pillars of this plan:

a demand reduction (energy savings and a better energy efficiency),

a diversification of the suppliers for conventional (fossil) fuel imports and a further reduction in greenhouse gas emissions,

an acceleration of the transition to renewable energy sources: 45% of energy from renewables in 2030 [

33].

The strategy also includes many more detailed goals, like doubling the EU’s production of biomethane and investments into hydrogen technologies, especially ports and storage facilities. For example, in the Mediterranean and North Sea, major hydrogen corridors will be developed [

34].

Delivering the REPowerEU objectives requires an additional investment of EUR 210 billion between now and 2027 [

33].

Despite these ambitious goals, in 2022, the overall hydrogen consumption in the EU was only about 2% of the energy market [

34]. It was used mainly for the production of different kinds of plastics and fertilizers. Unfortunately, 96% of this production was based on natural gas, which meant important emissions of carbon dioxide. However, this will change. The European Commission has proposed the production of 10 million Mg of renewable hydrogen by 2030 and the importing of 10 million Mg by 2030. What is more, the EU strategy assumes a phased approach to the full development, production, and dissemination of green hydrogen; 40 GW of green hydrogen based on electrolysis is planned to be installed by 2030. During the transitional period, the EC enables the production of hydrogen using, e.g., fossil fuels combined with carbon capture and storage (CCS) technology. Gradually, renewable hydrogen will become cost competitive in relation to other types of hydrogen. After 2050, only green-emission-free hydrogen will be allowed in the EU. The costs associated with the comprehensive development of green hydrogen are around EUR 180–EUR 470 billion [

29].

All countries in the EU, including Poland—the country where the case study installation is located—must also implement this European energy and climate policy. However, they also have their own legislation.

In the case of Poland, new directions for the energy sector were introduced by the Energy Policy of Poland until 2040 [

35], which was adopted in 2021 by the Council of Ministers (2021). This document takes into account the objectives announced by the European Commission in 2019 and the principles of the European Green Deal.

The climate neutrality of Poland will require an energy transformation, which needs the building of a zero-emission energy system.

It is important to assume that the energy transformation process will involve the emergence of new participating industries in the transformation of the energy sector, a vital part of which is the development of low-emission transport [

35].

The PEP2040 strategy also relates to hydrogen in the following ways:

a fuel alternative to crude oil for transport,

a tool for industry decarbonization,

support for increasing the share of renewable energy sources,

support for the decarbonization of the gas sector by 2030 [

35].

For the transport and distribution of the produced quantities of hydrogen, the existing gas infrastructure may be used. By 2030, the Polish gas network will be able to transport a mixture containing approximately 10% of biomethane or green hydrogen [

35].

A domestic hydrogen production of over 1 million Mg annually places Poland in third place in Europe, but this is not hydrogen produced using renewable energy sources, so it cannot be included in the energy transformation leading to climate neutrality [

35].

The general objective included in the PSW project is therefore to transform the Polish hydrogen industry in order to achieve climate neutrality and further economic development.

This is a strategic challenge for the authorities and the national economy, which requires a comprehensive approach that takes into account the entire value chain and solves a wide range of problems. In all cases, green hydrogen is intended to minimize the use of fossil fuels, thus reducing the greenhouse gas emissions into the atmosphere [

35].

1.4. Research Problem of the Study

Apart from the legislation and infrastructure problems, there are a lack of data on the environmental impact in relation to the hydrogen production in Poland, especially in the case of new and developing technologies. Previous studies related to hydrogen production have focused mostly on mature hydrogen production technologies [

36], including electrolysis [

37]. There has only been one paper (preprint) published on the life cycle assessment of an AEM electrolyzer [

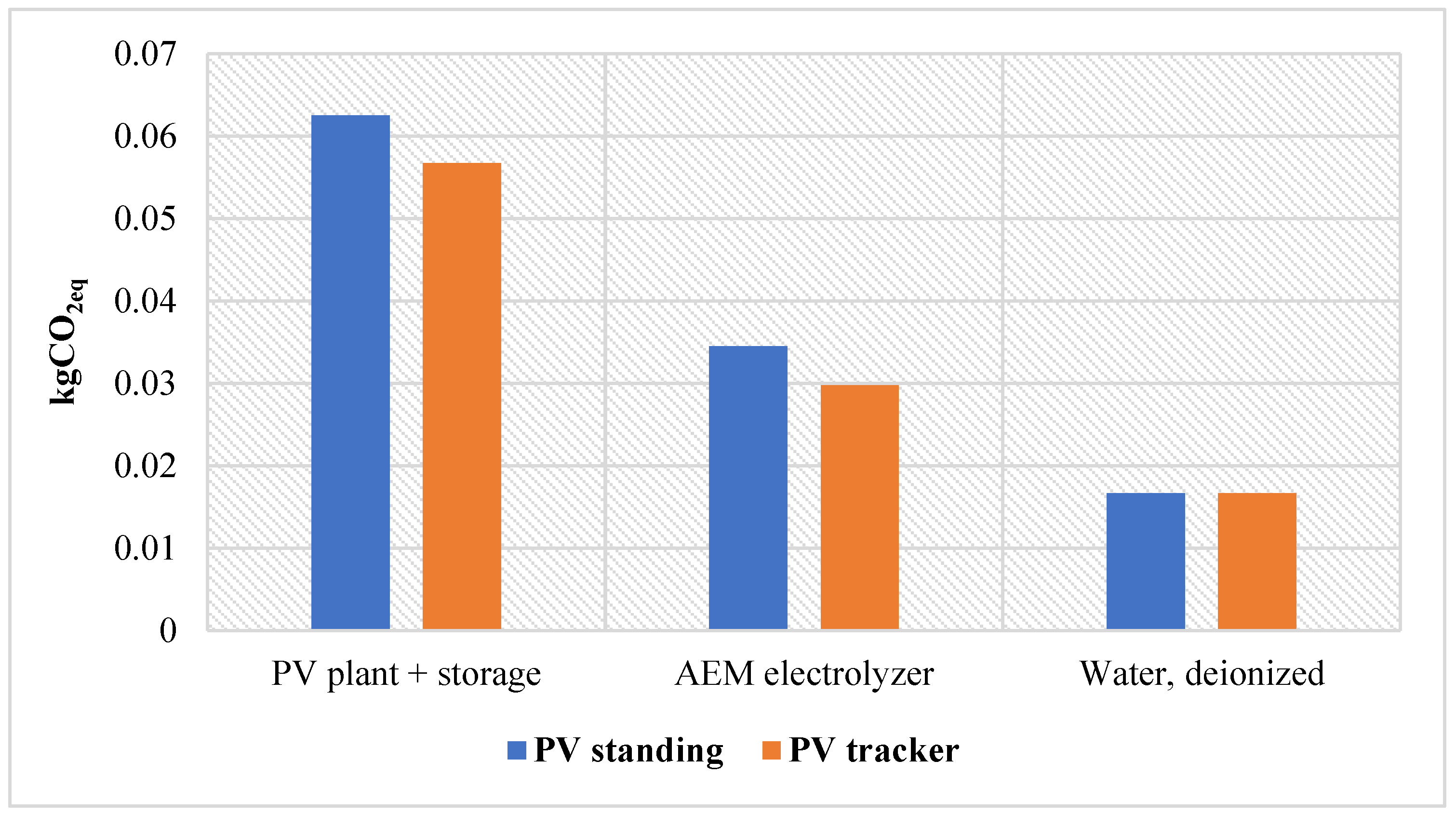

38]; however, it does not cover the full pathway of hydrogen production, focusing on the optimization of its construction. Therefore, the aim of this study is calculation of the carbon footprint of a green hydrogen plant on the basis of a life cycle assessment, including the concept of a solar-to-hydrogen plant with AEM electrolyzers operating under temperate climate conditions.

The object of this study is the concept of a green hydrogen plant with 5 MW peak power located in Zarzecze, in the southern part of the country. This is going to be one of the first green hydrogen plants in Poland. The novelty of this study is connected to the application of the newly developed anion exchange membrane (AEM) technology for electrolysis. Therefore, the results of the life cycle assessment presented in the article are the primary raw data results connected to this issue and can be used for further studies estimating green hydrogen potential, as well as the carbon dioxide emissions related to the solar-to-hydrogen pathway.