Abstract

The decarbonization of the energy industry is one of the key pillars in the reduction of greenhouse gas emissions in the atmosphere. The energy generation industry is an important driver in the development of nations. Small modular reactors (SMRs) are considered an affordable energy generation technology that can provide clean energy that is comparable to other renewable energy technologies. However, several critical issues are established in the full adoption of and investment in SMRs in developing nations. A state-of-the-art review of the SMRs is proposed, involving key issues on technological, economic, environmental, and socio-political aspects. Methods of aggregating these factors in order to determine a country’s suitability to invest in SMRs have been explored, while also determining specific areas needing improvement.

1. Introduction

Sustainable Development Goals (SDG) of the United Nations number 7 seeks to ensure affordable and clean energy for all. The proposed roadmap aims to phase out coal by 2030 in developed countries that are members of the Organization for Economic Co-operation and Development (OECD). This goal was also extended to developing countries, non-OECD, by 2040 [1]. This phase-out process will nonetheless require support, especially for developing countries. The UN also highlights the fact that about 733 million people lack access to electricity, the majority of whom are in underdeveloped regions [2]. Moreover, SDG 13, which tackles climate change and its impacts on society, highlights the problems of unabated rise in greenhouse gas emissions which is attributed to higher economic activity and sets a target to decrease emissions by 2050. It is uncontestable that many developing countries require a large increase in energy supply to fuel their attainment of high-income status. That growth, when left to the usual fossil-fuel based technologies of energy production, will make the environmental targets set by the UN unachievable. Many different technologies have been developed and invested in in recent years to present an alternative to fossil fuels such as solar, wind, bioenergy, tidal, and hydro, among others. One of the alternative energy sources is nuclear energy.

Recent technological advances in nuclear power engineering can potentially replace fossil-fuel-based power plants as base load providers. While nuclear energy has been harnessed for energy production since the 1950s [3], plants typically built up to now are large in capacity due to large capital investments and long construction times. This is a significant concern especially for a developing country. In addition, the construction of large reactors (LRs) has seen an overall increase in capital costs, especially in recent decades [4]. This makes it more challenging for developing countries to acquire this technology and establish firm foundations for nuclear power plants (NPP). Cooper (2010) identifies an increase in overnight capital cost from USD 1000 kW for NPPs built in the early 1970s to USD 5000 kW–USD 6000 $/kW (all in 2008 dollars) for NPPs built in the early 1990s. Earlier studies have been done that show that this would lead to cost escalations to as high as USD 10,000 kW, as far back as 2009 [5].

On the other hand, recent advances in this field have led to the proposed design and construction of small and medium reactors (SMRs) or small modular reactors. Nuclear power plants with SMRs have an equivalent electric power generation of less than 700 MWe. A modular construction method also renders an advantage, especially in subsequent expansion plans due to economies of scale. This will make repeated production of SMRs less time-consuming and less costly [6].

However, the decision to start a nuclear program for energy purposes is not an easy one to make. The choice of technology is often affected by concerns other than technological factors such as efficiency and availability. Social issues, economic sustainability, and environmental stability also influence decision-makers and the community regarding adoption of NPP. In a webinar organized by the International Atomic Energy Agency (IAEA) on 29 April 2021 on the United Arab Emirates’ agenda leading to the introduction of nuclear energy into its power grid, his excellency Mohamad Al Hammadi, the CEO of Emirates Nuclear Energy Corporation, emphasized that the key element to success of its nuclear program was the long-term energy policy that was envisioned at the time together with its continued government support. Their journey took them 13 years, which were not entirely focused on technological aspects of the program, but included social aspects such as education and social acceptance [7].

Nuclear energy is a concern for many people as witnessed in high-profile incidents such as Three-Mile Island, Chernobyl, and Fukushima. Locatelli et al. (2014) examined the positive contribution of nuclear energy, particularly of small modular reactors (SMRs), to employment. However, the impact of the not-in-my-backyard behavior was noted as a potential hindrance to the widespread deployment of nuclear energy [6]. This attitude brought the issue of the social acceptance of nuclear energy to the fore. It is an important social issue that arises from perceived safety concerns that must be addressed to ensure the technology’s sustainability. Iyer et al. (2014) studied the environmental impact of SMRs and observed that technological preference and institutional inertia in existing regulatory frameworks create path dependencies. Preference for proven technologies also influences decision-making since public information on the country’s technological development along with approval by early adopters encourages investment. On the other hand, a lack of information would create uncertainties over nuclear energy’s performance and long-term viability. Other concerns would include safety, waste disposal, proliferation and terrorism [8]. Glaser et al. (2013) determined proliferation risks of SMRs in relation to its resource requirements. Integrated Pressure Water Reactors (PWRs), due to their lower burnup of fuel in comparison to LRs, would have higher requirements for uranium ore and enrichment services, thus increasing their proliferation risk by about 45% [9]. The question of environmental impact, especially on the locality where the plants will be built, is significant as well. This accountability weighs heavily on the decision-makers, as these decisions will have effects far into the future.

Current reviews on SMRs focus on technological advances being made in relation to problems the industry is trying to solve. These reviews briefly touch on other topics that may be related to these problems. This paper aims to provide a comprehensive review of literature centering on issues that accompany the decision to invest in an SMR, such as those mentioned previously: technical, economic, socio-political and environmental considerations, and ways in which these have been used together to determine a country’s readiness to adopt this technology.

1.1. Small Modular Reactors

According to the IAEA, Small Modular Reactors (SMRs) “are newer generation reactors designed to generate electric power typically up to 300 MW, whose components and systems can be shop fabricated and then transported as modules to the sites for installation as demand arises” [10]. This definition provides the key characteristics of SMRs that set them apart from LRs. Being small, they have much smaller capacities than LRs on a per module basis and in their construction methods. Being modular, SMRs contain all the functions and safety features, built-in, to function as any LR would and are connected to components of typical power-generating equipment and machinery.

On the other hand, the construction of LRs has seen an overall increase in capital costs, especially in recent decades, making it harder for developing countries to acquire this technology and to establish a firm footing in its economic progress. Cooper (2010) points out an increase in overnight capital costs from USD 1000 kW for NPPs built in the early 1970s to USD 5000 kW–USD 6000 $/kW (all in 2008 dollars) for NPPs built in the early 1990s. Studies have been conducted showing that this will lead to a cost escalation to as high as USD 10,000 kW. Lovering et al. (2016) examined this trend by compiling data on nuclear power plants completed up to 2015. The study showed increases of between 50 and 200% in overnight construction costs for the USA, France, West Germany, and Canada, while milder variations of between −17% and 33% were seen for the same costs in Japan, South Korea, and India [4].

While the cost of renewable energy, such as solar PV and wind energy, have gone down considerably in the last decade, they consistently suffer from lower utilization due to a lower load factor. For solar PV, they range from 10 to 25% while wind energy has a range of 21% to 43%. In contrast, thermal and NPPs have an 85% load factor, thus providing a better return for a limited time investment [11]. For this reason, it is not wrong to think that nuclear energy can actually have its space in any country’s energy mix due to the continuous availability of energy supply for as long as the fission chain reaction is active.

1.2. Types of SMRs

IAEA classifies SMRs that it has on record into six different types, as is shown in Figure 1. Land-based water-cooled SMRs are plants that utilize various configurations of light water reactors and heavy water reactors that are seen in large power plants sited on land that are in operation today. Marine-based water-cooled SMRs, on the other hand, are deployed in a marine environment either through a barge-mounted floating power unit or immersible underwater power unit. The first SMR operationalized commercially, KLT-40 S, is deployed in Pevek, Russia for commercial operations of this type. Another type of SMR is the High-temperature Gas cooled SMRs that provide high temperature heat which can be used for electricity generation, industrial applications, and cogeneration. Fast Neutron Spectrum SMRs, on the other hand, are designs that make use of a fast neutron spectrum with different coolant options, including sodium, heavy liquid metal, and helium gas. Molten Salt SMRs, meanwhile, have low-pressure single-phase coolant systems that eliminate the need for large containment, a high temperature system that results in high efficiency, and a flexible fuel cycle. Finally, Micro-sized SMRs are those that generate electrical power of up to 10 MWe [10]. Using the above, one may see the different criteria in which SMRs may be classified, according to power, coolant type, neutron energy, and location.

Figure 1.

SMR classification scheme from the IAEA.

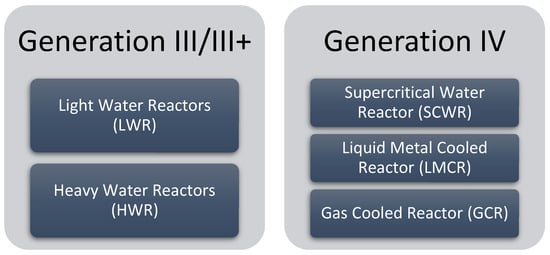

Rowinski et al. [12] provide a slightly different classification scheme of SMRs based on generation, neutron spectrum, and coolant. This scheme is seen in Figure 2. Light Water Reactors (LWRs) are the most common nuclear designs in the world; these use light water or normal water as their primary coolant, and most such designs include an integrated pressurized reactor. A subtype is the pressurized-water reactor (PWR), which uses two coolant loops, one maintained at a high pressure and another at a lower pressure. The high-pressure water flows to a steam generator, where it transfers its thermal energy to the lower pressure water of a secondary system where steam is generated. The steam then drives turbines, which spin an electric generator. Heavy Water Reactors (HWR), on the other hand, use heavy water as a moderator to control the fissile reaction, with the possible use of light water as a coolant with fuel using natural or slightly enriched uranium. This reactor subtype allows for refueling during the reactor operation. The Supercritical Water Reactor (SCWR) is a reactor type that uses steam in supercritical conditions, i.e., above 22.064 MPa, with 647 K as a coolant pumped to the core and then directed to the turbine. This will result in an increase in efficiency and competitiveness of the power station. The Liquid Metal Cooled Reactor (LMCR) is a fast reactor that uses liquid metal as a coolant, without the need for a moderator due to the use of fast spectrum of neutrons. There are two main approaches to the design, loop, and pool concept. Under this type are found the sodium-cooled reactors, lead reactors, and lead bismuth reactors. This technology can be used as a breeder for nuclear fuel, essentially closing the nuclear cycle and lessening the issue surrounding nuclear wastes. Gas Cooled Reactors (GCRs) use gases like helium or carbon dioxide as a coolant with graphite blocks as a moderator; GCRs represent the oldest approach to nuclear energy production.

Figure 2.

Classification scheme by technological generations.

1.2.1. Modularization

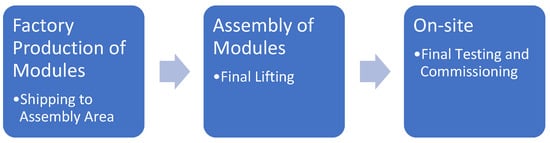

Modularization can be defined as the “process of converting the design and construction of a monolithic or stick-built plant to facilitate factory fabrication of modules for shipment and installation in the field as complete assemblies” [13]. This process provides economic benefits such as ease of production arising from a standard factory environment as opposed to on-site fabrication that requires an investment in on-site fabrication equipment that may possess lesser capabilities/capacities than factory-based ones. This would provide the benefit of faster and cheaper production of these modules. These modules can be assembled on-site in smaller footprints that also allow for easier (and less expensive) logistics options. Modularization also increases the prospects of standardization of modules that would allow for the mass production of these components. The degree of modularization can also be chosen—they can be completely modularized, where all modules are fabricated in factories and assembled into “supermodules” in an assembly area and finally installed as is expressed in Figure 3. Lesser degrees of modularization may involve on-site fabrication of some of the parts and assembled in the assembly area prior to final installation [14].

Figure 3.

Modularization of production processes of a SMR.

However, another form of implementation of modularization in SMRs to achieve savings is through the deployment of smaller reactor vessels that can be interconnected at a later time when the conditions are right. When all SMR units have been connected, the power plant produces power according to the sum total of all operating SMR units. Figure 4 shows a possible scheme of modularization.

Figure 4.

Modularization of an SMR power station/s.

In both cases, there are advantages to construction that are discussed in the succeeding sections.

1.2.2. Co-Siting Economies

While the first module suffers from the diseconomy of scale arising from its lower capacity, it is balanced by the reallocation of fixed costs from this first plant unit to subsequent units due to their production at the same site. Benefits arise from placing two or more SMR units in the same area such as savings from the acquisition of land rights, which would have been spent in the construction of the first unit [14,15]. Co-siting also allows the sharing of costs, such as training of personnel for the same types of plants, spare parts, and upgrades.

1.2.3. Learning and Construction Schedule

Due to modularization, SMRs can also potentially harness learning to reduce significantly the cost of production. Through the experiences and learning obtained during the construction process and the use of tools in delivering a product, efficiency and effectiveness can be improved, which is realized in reduction in costs [16].

Through modularity, it is hoped that SMR manufacturers (and component manufacturers) can reap the gains obtained from having learned to make and made the first components, allowing for a more streamlined and efficient way of fabricating every succeeding component. The concepts of first-of-a-kind (FOAK) and nth-of-a-kind (NOAK) are important, where the FOAK are the products that are produced in the first iteration while NOAK are the iterations that occur much later in the product cycle where learning gains tend to be much smaller. Moreover, the more immature a technology is, the more learning can be gained [17]. Several methods of calculating gains obtained through learning have been devised. Among these methods are those proposed by the NETL [17], Wilton [18], and the Nuclear Energy Agency [19].

Modularization also affords the nuclear power plant an early construction completion and an early start to energy production and sale, due to the smaller-sized modules that can be produced [20]. With an early start, cash inflow may offset the costs of capital that are incurred in the much longer time frame required by a fully-functioning LR. Moreover, the capacities can ramp up together with the growing demand for electricity over time.

1.3. Bibliometric Survey

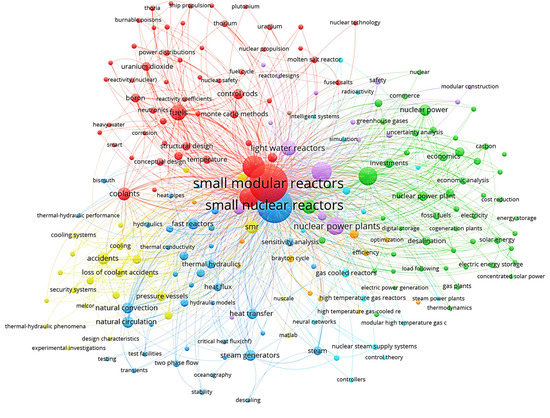

A bibliometric analysis was carried out using VOSViewer. Data on articles and reviews were culled from the SCOPUS database on 10 March 2021 using a combination of keywords related to the subject. A target number of 300 was set to narrow down the themes into which further precision can be achieved. After the VOSViewer map was created, significant branches or thematic areas were identified to further determine the keywords that can be used to filter the literature that must be reviewed to make a comprehensive overview of the topic.

The keywords used to make the initial search in SCOPUS were “SMR” and “Nuclear”. The resulting bibliographic data were used in the VOSViewer application, which resulted in the network map as shown in Figure 5. Four major color groups were observable: the red contained themes related to fuel technology; the yellow referred to issues of safety; the blue nodes tackled issues of heat transfer; and the green nodes were related to issues of the economics of this particular technology.

Figure 5.

Network map for “SMR” and “Nuclear”.

2. Materials and Methods

2.1. Large Reactors

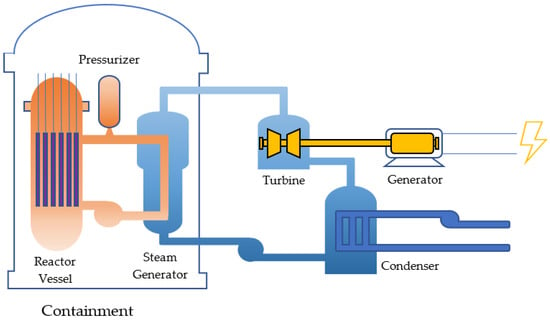

NPPs operate very similarly to fossil-fuel based plants where the main difference lies in the manner in which thermal energy is produced. While in fossil-fuel based plants, energy is released through the combustion of coal, oil, or gas; meanwhile, energy is released through a nuclear fission reaction in a reactor vessel in an NPP. The energy is used to boil water that will be used to produce electricity through a normal Rankine cycle. Figure 6 shows a simplified scheme of electricity production in a nuclear power plant.

Figure 6.

Major components of a nuclear power station.

2.2. Sustainability Triple Bottomline

The Global Reporting Initiative (GRI), through their reporting standards, pushes for a higher level of responsibility of entities for their impacts. These reporting criteria are encapsulated into three main areas: economic, social, and environmental, as seen in Figure 7. These same criteria are contained in the so-called “sustainability triple bottom-line” that was coined by John Elkington in 1994 and which is synonymous with sustainability assessment, 3 E impact assessment (equity, equality, environment), extended impact assessment, and sustainability appraisal methods [21]. Considerations of technologies or projects in these three broad criteria enable a broad-based assessment of its effects from a larger perspective; e.g., a lack of understanding of the harmful effects of coal combustion on the environment may lead to deleterious effects on the health of individuals in the long run (social), or the destruction of infrastructure resulting from climate change.

Figure 7.

Sustainability triple bottom-line framework.

2.2.1. Economics

Through the same database search, keywords relating to economic issues were sought. Primarily for this study, the combination of “SMR” and “Nuclear” and “Economics” was used to survey the literature available on the economics issues surrounding this technology. Typically, the literature would cover issues related to life-cycle costs, which includes the resulting levelized cost of electricity, overnight capital investment costs, and the operating costs. Together with these are the important features of SMRs that make them attractive from an economic perspective, such as modularity, learning, co-siting, and its effects on construction schedules.

2.2.2. Environment

The Scopus database was also searched for literature using the keyword combination “Small Modular Reactors” AND “Nuclear” AND “Environment”, restricted to journal and review articles. This combination of words served to limit the literature to those studies that revolved or touched on the issue of environmental issues related to SMRs.

2.2.3. Socio-Political

Finally, the Scopus database was also searched for literature on social issues that are related to SMRs in order to complete the analysis that would be required by the Sustainability Triple Bottomline. For this search, the keyword combination of “Small Modular Reactors” AND “Nuclear” AND “Social” was used, limited to journal and review articles. Individual articles that were not related to nuclear power generation were removed.

2.3. Metrics in Techno-Economic Modelling

2.3.1. Technology Readiness Levels

In the process of selection of a particular type of technology for an application, the US Department of Energy instituted a Technology Readiness Assessment scheme that determines the “Technology Readiness Level” or maturity of a particular technology. On the other hand, the IAEA also tracks the different stages in the development of SMRs following its own scheme. Table 1 shows a compatibility matrix of the two different schemes as presented by the US DOE and the IAEA. Higher TRL levels translate to a higher readiness for a technology to be adapted for use.

Table 1.

Measures of technology readiness.

2.3.2. Life-Cycle Costs

In this section, terms related to the economics of the construction of nuclear reactors are defined in order to give clarity to the succeeding review.

The capital costs can be distinguished between two types: Capital Expenditure (CAPEX)—also called the overnight cost, or the overnight capital cost (OCC), sums the base construction cost, together with the other owner’s costs and contingencies. It is also called the overnight costs, because the time value of the costs is not considered, i.e., as if the plant had been constructed overnight in an instant [13].

Capital Cost, on the other hand, includes the time value of money or the interest that would have been incurred during construction [23]. Other terms that are defined the same way are the Total Capital Investment Cost (TCIC).

The O & M (Operations and Maintenance) costs sum up the expenses related to the technical, administrative, managerial, and supervisory actions taken to ensure that an item, such as a plant, is in its proper state so that it carries out its functions as needed [24]. These costs are thus called the O & M costs.

The Operating Expenditure (OPEX) is a combination of fixed OPEX that pertains to ensuring that the plant is able to generate energy, and variable OPEX which relates to the costs needed to directly generate a certain amount of energy that can come in the form of labor, fuel, disposal, as well as the consequent decommissioning of the plant [24].

It is worth noting the importance of decommissioning costs, which at this point has been highly neglected in studies. Noguchi indicated the current cost of USD 91 billion of the ongoing decommissioning work on the Fukushima Daiichi Nuclear Power Plant that suffered a meltdown in the aftermath of the earthquake and tsunami in Japan in 2013 [25]. While the aforementioned decommissioning costs are those for a catastrophic accident such as that of Fukushima, decommissioning costs play a minimal role for reactors, as they are spread over the entire 60 year lifetime of the plant [26]. The Nuclear Energy Agency approximates the cost of decommissioning for LRs at $0.01 to $0.16 MWh depending on the discount rate. This is for a plant whose decommissioning cost is equivalent to 15% of the construction cost [11].

Another useful concept that employed in the comparison among various renewable and non-renewable energy technologies is the levelized cost of electricity (LCOE) as obtained from a prospective project. The LCOE compares the overall cost of a project considering its lifetime, the energy produced during the same lifetime, and the discount rate that provides a window to the present value of the costs and the electricity generated. Equations (4) and (5) express this concept, where is the sum of all electricity generated throughout the time period being considered, and as the discount rate.

2.3.3. Environmental Assessment

One of the most important tools used currently to assess the environmental impact of a particular technology or product is the life-cycle assessment (LCA). This technique assesses the environmental impacts, specifically energy use and CO2-equivalent emissions, during each stage of a product’s life from cradle to grave, which includes raw material extraction, construction, operations, decommissioning, and disposal. The LCA methodology can use varying approaches such as end-point modelling, midpoint modelling, or a combination [27].

2.4. Major Components of an SMR

SMRs replicate in many ways the major components found in LRs that power nuclear power stations. These are found at the heart of the station in the reactor vessel where the fuel cores that fuel the chain reaction are located. This chain reaction produces large amounts of heat that is used to generate steam and eventually power a turbine to produce electricity. Note that this is largely similar to any fossil fuel plant where the only major difference is the source of heat which comes from the combustion of the said fossil fuel. Figure 1 shows a schematic diagram of the major components of a nuclear power station. For an SMR whose reactor vessel is modular, parallel connections can be made between these vessels that may combine to power a common turbine and generators that produce power.

3. Comprehensive Review of SMRs

3.1. Technology

In this section, recent developments in relation to the technological implementations of SMRs are reviewed. Schaffrath et al. provide us with an overview of the core design developments of SMRs. Following this summary are technological trends that are attached to the base design of SMRs in order to heighten its attractiveness as a technological alternative to other alternative energy sources.

There are currently 72 ongoing SMR development projects at various stages of completion and intended deployment [10], with Argentina, China, and Russia being the countries at the most advanced stages of development.

Table 2 presents the number of SMR projects at different stages of the project cycle. Only three have been operational, with only one among them for commercial operations. The KLT-40 S entered into full commercial operation in May 2020 and is currently deployed in Pevek, Russia on a floating nuclear power plant.

Table 2.

Status of SMR Projects.

There has been significant progress with regard to SMR basic designs. Schaffrath et al. make note of the trends in SMR designs that facilitate modular construction and of which the major components are small enough to be produced in a production line and transported on-site as a single unit. This eliminates the logistical problem of transporting large components to less populated sites which in many developing nations, would mean less accessibility arising from smaller roads.

With regard to PWRs, integrated designs have been made in order to “modularize” them, at the same time introducing safety improvements by eliminating the need for installation of long lines that carry potential for accidents. Among the components integrated into this type of design are the core, pressurizer, steam generators, and main coolant pumps within the reactor pressure vessel [28].

In terms of core designs, SMR cores will have a fuel cycle of typically two to ten years before the need for refuelling. This need for refuelling would generally imply a shutdown, but due to the modular nature of this design the plant’s operation can continue because of the presence of other operating SMRs. This downtime may be planned and can also minimize the power required to be supplied while these units are being refuelled [28].

Shirvan and Forrest (2016) presented an alternative concept for the construction of an organic simplified nuclear reactor for offshore underwater deployment. Such a reactor would be moderated by graphite, zirconium hydride, and organic coolant. The conceptual design would provide a power density of 40 kW/L and a reduction of the reactor hull size by 40% compared to the PWR designs that can potentially reduce capital costs [29].

On sea-based SMRs, Lee et al. (2015) noted the progress made on the design and construction of ocean nuclear power plants that can take the form of floating power plants, gravity-based structures, and submerged types. The ocean nuclear power plants are notable for the enhanced safety features that they possess against tsunamis or earthquakes and their passive cooling systems that are superior to land-based systems [30]. In addition, Santinello et al. (2016) studied the heat transfer capability of the concept SMR Flexblue, which is a subsea-based nuclear power unit operating up to 100 m deep and several kilometers from the shoreline. Such a design concept provides a certain measure of safety against extreme natural events, such as earthquakes, tsunamis, etc. A 2D CFD was carried out to confirm its heat transfer capacity, but further work has to be done from a 3D approach [31].

Testoni et al. (2021), noted the progress made in the area of microreactors, which are SMRs that have a power output in the range of 1–20 MWe. The advantages of its small size, the simplicity of the plant layout, and the fast on-site installation are balanced by its disadvantages from limited fuel availability, heightened security, and proliferation process. From an economic point of view, microreactors may not compete with power plants but rather with those of similar scale, such as diesel generators and renewable sources in microgrids [32].

Zheng et al. (2018) adopted a market-guided design approach to determine the most appropriate SMR technology considering safety, cost, fuel availability, and profitability. Among the Gen IV reactor concepts, the thorium-based reactor presented the most promise with the advantages offered by thorium. The material is abundant and cheap and offers better proliferation resistance and reduced long-term radiotoxicity from transuranic elements [33]. Tak et al. (2015) studied the potential of an ultra-long cycle on a compact liquid metal-cooled fast reactor, assessing its operational aspect as well as the material performance. The breed and burn strategy allows for a longer core life with just the addition of fertile fuel. Ideal fuels were characterized as being of high thermal conductivity and expansion characteristics, with thorium given special mention. Meanwhile, sodium is identified as a good coolant material [34]. Bromley (2021), carried out lattice physics calculations to determine the reactor physics characteristics of advanced fuel lattices that use hydroxides as coolants and moderated by graphite and other types of metal hydroxides. The calculations showed the suitability of hydroxides as coolants and/or external moderators that can lead to performance improvements for very small and compact SMRs [35].

In order to understand more clearly the behavior of the coupling of multiple SMRs, Dong et al. (2018) developed a software model deployed in Matlab to study the open-loop and closed-loop dynamics of the said plant operation. This model allowed the determination of the dynamics of each unit under different scenarios including that of power stepping and large-range power ramping. This will also allow the future development of operation and control strategies of a nuclear power plant [36].

Hussein (2021) recalled some ideas that can be revisited given the increasing interest in SMRs. On PWRs, since its idea revolved around its compactness, the idea of retrofitting fossil-fueled power plants to take advantage of existing infrastructure and grid connectivity can be revisited. On HTGRs and Molten Salt Reactors, the research behind these have existed since the 1960s and therefore should not have any issues regarding confidence in its technology. On Liquid Metal Cooled Fast reactors, it was recommended that monitoring of cooling flow be made in order to detect any flow blockage, as had happened in older generation reactors [37].

Maccari et al. (2021) used the software code ASTEC, allowing the simulation of the expected main thermal-hydraulic phenomena that drives the accident sequence through nodalization so that the system’s response may be properly evaluated. The code successfully simulated the thermal-hydraulic coupling between containment, the RPV, and passive safety systems, and consequently, the RPV depressurization and core cooling [38].

Trikouros (2011) hypothesized that because there is a variety of reactor designs, the regulatory structure should allow for flexibility (technology-neutral) but with the required degree of safety assurance (risk-informed) [39].

Gao et al. (2021) developed a factorial optimization based SMR siting model in order to deal with complexities associated with optimizing the siting schemes. The model took into account certain risk levels depending on the needs, such as GHG reduction or economics [40].

Safety is an important cornerstone in NPP design, especially when the potential impact in terms of life, property, and damage is high. Core cooling designs have been adopted as design principles in Gen III/III+ reactors in order to enhance the safety features of SMRs. Among them are the reduction of the power density of the cores, and the use of passive cooling features of the RPV exterior to ensure retention of the core melt inside the RPV [28].

Zeliang et al. (2020), reviewed the current state of PWR designs being deployed. Configurations characterized by enhanced safety systems and better reliability are made through simpler designs and reduced number of components that consequently reduces the sources of accident initiators. Among these inherent design characteristics are the use of taller vessels, a larger coolant inventory, lower core power density, and a larger surface to volume ratio. In addition, Hidayatullah et al. (2014) discussed the different expected benefits and possible impediments that SMRs face in its implementation. Among the most important benefits is safety arising from its already wide safety margins. However, changes are needed in terms of adequate emergency planning infrastructure and changes in existing laws and regulations. In terms of technology, efficiency through technology, automation and potential for cogeneration were highlighted as key drivers for its success [41].

Schaffrath et al. also point out that an electrical power output of around 200 MW is low enough to have passive safety features, via free convection, condensation, and evaporation, that allow decay heat to be removed, which can be a key characteristic to avoid severe accidents with core melting [28]. Cooling capacities of such systems can be up to 72 h, although some may even be designed with an infinite heat sink such as air or water [42]. The resulting reduction in power density and increased safety features allows for a reduction in emergency planning zones. SMR designs also allow for partial or total immersion in an underground water wall to increase resilience against pressure waves such as those experienced by the Fukushima power plant [10].

Yin et al. (2018), modelled a severe accident occurring in an SMR to determine the core thermal hydraulic response. Results were obtained on the temperature distribution of the fuel pellets, the fuel cladding, flow rate of the coolant, and hydrogen mass change over time, which will be useful for evaluating the safety feature of SMRs and the residual risks they pose [43].

Carless et al. (2018) estimated the effects of a large lateral surface area-to-volume ratio which is characteristic of SMRs in the radioactivity of areas surrounding it in the event of a loss-of-coolant-accident. The study shows a radioactivity level of 104 ft-3 compared to LRs that are 40–50% higher. This method can be used for developing a regulatory basis for emergency planning zones for iPWRs [44].

Peakman et al. (2018) investigated the safety performance of a molten salt micro-reactor compared to a solid moderator material and conventional solid UO2 fuel. The study showed that the microreactor’s reactivity coefficients were mostly negative, thus exhibiting acceptable safety performance [45].

Fakhraei et al. (2020) highlighted the potential for instability in SMRs, whereby a station blackout may cause instability in the primary system for heat removal. New methods were proposed in utilizing a safety injection tank and using riser valves to guarantee the stable flow and decay heat removal during this coping time in the blackout period [46].

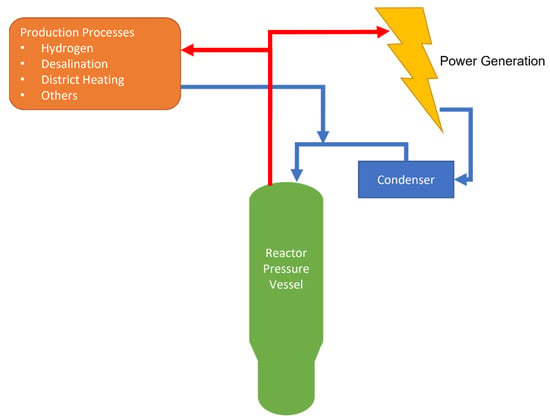

Research has been done as well on SMRs’ potential to overcome its continuous energy generating properties, especially when electricity demand is low through polygeneration. Serra et al. (2009) define polygeneration as the “combined production of two or more energy services and/or manufactured products, seeking to take advantage of the maximum thermodynamic potential (maximum thermodynamic efficiency) of the consumed resources” [47]. To this end, the literature culled in this area examined various ways in which by-products of the production process of nuclear energy can be used in order to generate other types of services that would make this technology more attractive. A basic schematic diagram of how these services can be combined with an SMR is found in Figure 8.

Figure 8.

Schematic diagram of polygeneration with a SMR.

In the whole context of economics, this would add a different revenue stream that would further enhance the value of the technology and set it apart from far simpler renewable energy technologies. SMRs are more suitable for cogeneration than LRs, because it is possible to switch some of the SMRs for the cogeneration, and, consequently, SMRs can run at their full nominal power and maximum conversion efficiency [48]. Through polygeneration, issues related to nuclear energy’s limitation as a base load supplier of electricity may also be addressed.

Ingersoll et al. (2014) carried out parametric studies on designs of a 160 MWt NuScale small modular reactor plant to simultaneously supply electricity and heat for desalination purposes. The result was an eight-module plant model that could produce water at 190,000 m3/day and feed electricity to the main grid between 227–348 MW at an estimated capital cost of USD 1.8 billion [49].

Locatelli et al. (2017) conducted a review to examine the technical and economic feasibility of employing nuclear power plants as load following options, instead of base load providers through cogeneration. It was proposed that desalination, district heating, and the hydrogen production process can be optimized with SMRs in periods of lower electricity demand by dedicating some SMRs in the same plant to electricity production and the rest to the cogenerative process [50].

Locatelli et al. (2018) conducted a techno-economic analysis of using SMRs as a load-following plant by cogeneration with hydrogen production, using AWE, HTGR and SI technologies. The AWE technology would provide a profitable scenario at prices greater than EUR 0.40 Nm3 for hydrogen, while having a low electricity price. HTSE would be profitable at EUR 0.30–0.45 Nm3 while maintaining an efficiency degradation rate of 5–10% per year. SI would be potentially economically feasible at a lower level of EUR 0.30 Nm3 due to its thermal-only requirement [51].

Frick et al. (2019) demonstrated a design of an SMupled with thermal energy storage to allow nuclear power to act as a load follower to respond to the variable power supply demands through the day. The system bypassed steam for ancillary applications that effectively allowed the reactor to operate continuously at 100% capacity [52].

Wang and Yin (2020) developed a combined solar-nuclear system for the production of electricity and desalination of water utilizing a 530 MWth PWR SMR and a concentrated solar power (CSP) system. The resulting system achieved an output of electric power of 258.4 MW and electric efficiency of 35.2% at 900 Wm2 of direct normal irradiance (DNI) [53].

Ghazaie et al. (2020) studied various hybrid desalination schemes coupled to SMRs to determine the best configurations for operation. The study showed that steam from the low-pressure turbine can be extracted to supply the hybrid desalination plants, while a part of the relatively hot water of the SMR condenser is used as feed water for the desalination plant. This setup was seen to decrease the environmental impact due to lesser feedwater requirements and a decreased overall cost of between 6.4% and 7.6% [54].

Using a multi-objective optimization study, Baker et al. (2018) showed that in a hybrid energy system using a 300 MW SMR, a wind generator, a battery, and a reverse osmosis plant, increases in LCOE caused by higher volatility in demand and increases in LCOE may be stabilized by the use of flexible loads. Such flexibility is introduced by such hybrid systems that can offset costs related to its investment [55].

3.2. Economics

A key consideration of the literature about cost is that there has so far only been one nuclear power plant employing SMRs that has entered into commercial operation. Moreover, this unique power plant is operating as a floating SMR. This is coupled with the fact that the majority of SMR projects are in the developmental stages. Therefore, the literature as observed generally seeks to create models and make reasonable estimates of the cost of SMRs, in the absence of real world costs of SMRs, using the aforementioned concepts on modularization, co-siting, and learning, as well as some cost figures that may be inferred from reference nuclear power plants. This area also serves as a highly important component in the comparison among long-term investments in non-fossil fuel energy. It is noted how the costs of other renewable sources of energy have considerably lowered in the last decade, and studies in the area of costs will help newcomer countries decide whether to focus its energies on a particular set of technologies.

An important measure of a technology’s attractiveness is its LCOE. To recap, the LCOE compares the overall cost of a project considering its lifetime, the energy produced during the same lifetime, and the discount rate that provides a window to the present value of the costs and the electricity generated.

Agar et al. (2018) used an analytical hierarchy planning method to assess the rankings provided by nuclear cost experts in determining the most important cost requirement for SMRs. The factors identified in the study were externalities, project financing, plant availability, construction schedule, and direct costs, which showed a marked difference in importance across different cost experts, e.g., utility owner and funding agencies [56].

Lokhov et al. (2013), analyzed the economics and market prospects of SMRs. The study found that SMRs can be availed of with an LCOE of USD 45–80 MWh at a discount rate of 5%; however, markets will require a large scale serial production in factory conditions and a large initial order to maintain its competitiveness [57].

Aydogan et al. (2015) compared the advantages and disadvantages of different types of SMRs then under extensive research and development, putting side by side its different specifications, including its cost. While SMRs lose its economies of scale to standard reactors, they become competitive against nuclear reactors when they take advantage of their modularity, reaching costs equivalent to conventional sources of energy such as natural gas at around $5000 kW [58].

Black et al. (2019) incorporated detailed cost data of a major developer of SMRs using a cost accounting framework to calculate its construction cost and compare it with conventional large scale nuclear power plants. The specific methodology resulted in a cost of $3465 kW for the SMR as opposed to a much more expensive $5587 kW for a large-scale reactor. The detailed cost analysis show also that the reduced capitalized indirect costs prove the importance of reaping the benefits of modularity to achieve a better cost per kW for SMRs [59].

Another way of evaluating the economic attractiveness of a power plant is through its TCIC. To recap, the TCIC is the sum of the overnight capital cost and the interest during construction.

Shropshire (2011) created a model examining the scenarios in which SMRs can be economically viable using a target LCOE of EUR 45 MWh. SMRs would compete well where existing nuclear reactors are being decommissioned, where there is no option to accommodate an LR due to the grid size, or where there are high fuel or carbon cost uncertainties in small distributed markets [60].

Abdulla et al. (2013) examined the different expert assessments on the cost of light water small modular reactors. For a 45 MWe SMR, the cost can range from USD 4000 to 16,300 kWe for a 45 Mwe reactor, and between USD 3200 and 7100 kWe for a 225 MWe reactor with a 2 year earlier delivery than a standard large reactor [61].

Boarin and Ricotti (2014) studied the influence of modularization, co-siting, design savings, and learning effects on the competitiveness of SMRs in comparison with standard LRs using a discounted cashflow analysis, given a specific investment scenario. It confirmed that when multiple units on the same site are deployed, benefits on fixed costs from learning on the construction process and co-siting may be exploited while design modularization and simplification account for the cost reduction of each single SMR unit. Individual SMR costs decrease from EUR 5200 kWe to EUR 4000 kWe as more units are produced and the increased cost of capital e.g., cost of debt = 7% and cost of capital = 15% makes SMRs more attractive than LRs, as they are able to make returns while a portion of the plant is already in operation [15].

Vegel and Quinn (2017) carried out an economic evaluation of SMRs including the direct and indirect costs, scaling factors, and, especially, the regulatory fees as required by the governing regulator of the United States. The flat fee structure for each reactor would dampen the economic attractiveness of SMRs; therefore, a linear scale was proposed in order to cater to the growing need of smaller plant designs [62].

Maronati et al. (2020) employed a cost differential approach to estimate the cost of building a 983 MWe SMR. With a base case of 4090 kWe for a scaled-down standard PWR, a corresponding SMR can cost between 5.84–13.02% less, while scaling the same SMR up to the standard PWR can result in a saving of 11.12–17.89% due to advances in modularity and construction technologies [63].

Lloyd et al. (2021) studied the effects of modularization on the transport and construction costs of SMRs using already-available large PWR nuclear construction cost and schedule data. The study showed that modularization can decrease the construction costs of SMRs by as much as 45% from $9855 kWe to $5470 kWe in comparison to a reference large plant built at $6100 kWe [64].

Authors have also estimated a potential reduction in costs on a percentage basis. Zhang and Sun (2007) examined the economic potential of a modular reactor nuclear power plant as compared to a single-unit large nuclear power plant, assuming the same plant capacity. The study concluded that a 2 × 250 MWth modular plant can have a 5% higher specific cost than an equivalent 458 MWth plant. Costs for the modular plant can be reduced if engineering and construction are managed well to reap the benefits of modularization and mass production [65].

Boldon et al. (2015) assessed the sustainability of a platform for nuclear-renewable energy integration consisting of an SMR plant and wind turbine combined with hydrogen production via electrolysis, using criteria such as cost, environmental impact, and societal implications using a sustainability factor. Modularity could account for up to 40% of savings, plant configuration between 15 and 17%, and NOAK between 1 and 6%, while co-siting is highly dependent on the proportion of costs that are indivisible among multiple units [66].

Ford et al. (2017) compiled data on shipbuilding, nuclear development and decommissioning, transmission cost, material cost, and water withdrawal to estimate the potential cost of floating SMRs. It was found that floating NPPs would cost 1.5–2 times as much as those that are based on land due to the possibly more stringent requirements that may be imposed on them based on a quality perspective [67].

Maronati et al. (2018) used a bottom-up approach to calculate the total capital investment cost of building an SMR, using a part-breakdown structure approach and supply chain data, while varying the degrees of modularity employed in its construction. The methodology showed that with the use of off-site factories to produce modules, the total investment cost can be reduced by up to 23.64%; the use of an assembly area can reduce it by 8.26% and 29.95% lower if both approaches were used, compared to a stick-built construction method [68].

Locatelli et al. (2014) studied the distinct features of small modular reactors and their construction to identify their potential benefits over standard LRs and the conditions that allow them. Through synergistic advantages in learning and construction time offered by modularity, SMRs can offer better internal rates of returns at capacities between one and three GWe with a gap of 1.5–2 years between construction of modules over equivalent LRs [6].

Liman (2018) proposed a methodology to assess the financial feasibility of modular reactors that take into account the right time to construct further additional modules and to shut it down given certain electricity price conditions. The model showed that in the sample case of 10 out of 12 modules of a NuScale reactor that were constructed ahead of the remaining two, there was an NPV of at least EUR 300 m [69].

Mignacca and Locatelli (2020) reviewed the research landscape on the economics of SMRs, which is considered to be what is hindering its development. The review points out that there is a lack of a standard approach in the economic evaluation of SMRs for comparison and a more holistic approach considering the costs at a program or strategy level of a country [70].

3.3. Socio-Political

In the same review by Locatelli et al. (2014), the contribution of SMRs to employment was highlighted as a positive effect on society; however, the impact of the not-in-my-backyard behavior was cited as a potential hindrance to the widespread deployment of SMRs [6,71]. From this, the issue of social acceptance of SMRs and nuclear energy is brought to the fore and is an important social issue that arises from the perceived safety concerns that must be addressed to ensure the technology’s sustainability. In addressing this, Upadhyay and Jain (2016) examined the concept of modularity in the context of SMRs, where it is used to mean the construction of simpler and safer reactors that can be factory manufactured, transported, installed, and scaled up as permitted by the economic environment. This would result in improvement in the perception of safety in the construction and performance of SMRs [72]. Budnitz et al. (2018) also highlighted the inherent safety features that SMRs possess, such as having less thermal energy production per reactor (module), easing the need for cooling, especially after an accident or shutdown, and the risk of a core meltdown and release of radioactive material. However, the inherent safety features are not enough to influence countries to invest in this technology due to a lack of a safety culture that is embedded, especially in newcomer countries, making imperative the need for structures that respect the rule of law and for a strengthening of the current international nuclear safety regime that was initiated through the international Convention on Nuclear Safety (CNS) [73].

Aside from social acceptance arising from safety issues, Ramana and Mian (2014) studied the perceived promises of SMRs in solving four essential problems, including social ones, of cost, waste, proliferation, and safety. Through this study, some tradeoffs were observed to be necessary in choosing a particular technology in order to address one or the other problem, depending on what was deemed more essential in that particular country; for example, when integrated PWRs can have increased safety features, smaller sizes and lower fuel burnup, it comes at an increased cost per kW, a larger volume of waste, and increased proliferation risk. Other technologies such as HTGRs and neutron-fast reactors were investigated and observed with the same tradeoffs [74]. Ramana and Agyapong (2016), also cautioned against overreliance on the argument that SMRs are the most attractive nuclear technology for developing countries. The case of Ghana showed that other factors, such as the confluence of internal and external political forces led to its adoption of large nuclear power plants, contrary to the conventional wisdom of adopting SMRs for its development level [75]. Moreover, Sovacool and Ramana (2015) criticized the apparent rhetoric surrounding SMRs that tends to overemphasize the perceived benefits this technology this will bring to the world, thus setting aside the problems that its commercialization brings. Caution was urged in adopting those positions based on the aforementioned rhetoric rather than strategic choices and social practices [76].

Another important social factor looks inwardly to the internal capabilities of the country in adopting SMR technology. Iyer et al. (2014), in evaluating the scenarios in which SMRs can contribute towards climate mitigation targets, saw that SMRs can truly make an impact in this regard but observed that technological preference and institutional inertia that manifests itself in existing regulatory frameworks create path dependencies. Preference for proven technologies also influences decision-making, since public information on technology development and approval on the part of early adopters would encourage investment, while the lack of information would create uncertainties over performance and long-term viability. Other concerns would include safety, waste disposal, proliferation, and terrorism [8].

Prasad et al. (2014) examined the various issues that affect the proliferation issues that SMRs carry with them on the basis of its design: on fissile material inventory, core-life, refueling, burnup, digital instrumentation and controls, underground designs, sealed designs, enrichment, breeders, excess reactivity, fuel element size, coolant opacity, and sea-based nuclear plant designs. The study notes that SMRs will continue to contain critical masses of fissile material that will require stringent safeguard inspections. With designs that foresee up to 30 years of core life, lesser access to the core will enhance safeguards against proliferation. Due to the high burnup of nuclear fuel in SMRs, the reliability of spent nuclear fuel for weapons purposes declines. Digital instruments and control increase the possibilities of greater ease and accuracy of autonomous monitoring. Underground and sealed designs also make SMRs more difficult, costly, and challenging to access. Higher enrichment levels are also required for SMRs, thus making them more subject to proliferation. All in all, the designs may solve issues related to proliferation or exacerbate them, highlighting the need to introduce safeguards into their designs, accompanied with revisions in regulatory regimes [77].

Glaser et al. (2013) determined the proliferation risks of SMRs in relation to their resource requirements using results from neutronics calculations. Integrated PWRs, due to its lower burnup of fuel in comparison to LRs, will have higher requirements for uranium ore and enrichment services, thus increasing its proliferation risk by about 45% [9].

Zhang et al. (2019) employed an SMR site selection model based on a fuzzy approach, considering climatic and social factors. In using such a model, the social factors of population density and municipality distribution were used, considering the proximity of the SMR site to the population or municipality to be closer to the ideal solution [78].

Overall, Hanna et al. (2019) in analyzing the research landscape of four different low-carbon technologies for energy production, pointed out that there is a lack of depth in the field of social issues. It was found that public and stakeholder perceptions are mentioned but not explored in depth, thus needing further study in addressing the aforementioned issue in order to aid the transition into the adoption of this technology [79].

3.4. Environment

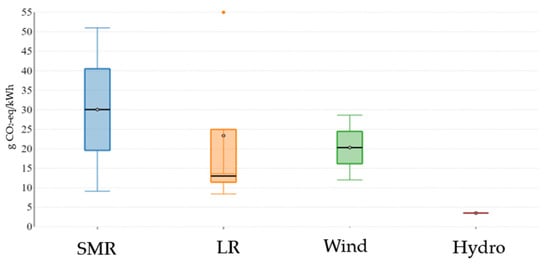

Overall, the search for substitutes for coal and other fossil-fuel based energy is motivated by the long-term effects of these sources of energy on climate change that are usually measured in terms of g CO2 equivalent. Thus, an important criterion for assessing the environmental sustainability of a technology is through this measure.

Boldon et al. (2015) combined several independent studies in order to estimate the global warming potential of SMRs. The study involved scaling a 1000 MWe nuclear plant and obtaining GWP values of 51 g CO2-eq/kWh, 2.3 g SOx/kWh, and 0.08 g NOx/kWh. In the same study, figures for wind energy were also obtained, and 12-g CO2-eq/kWh-wind median value was estimated for a wind farm with 30% availability of land generation with a 20-year lifetime [66].

In a separate study, Carless et al. (2016) compared the GHG emissions of a 300 MWe SMR nuclear plant to a Gen II and a Gen III 1000 MWe nuclear plants through an LCA that combines process chain analysis (PCA) and an economic input output method. The SMR had a 9.1 g CO2-eq/kWh, and the Gen III plant had a 8.4 g CO2-eq/kWh, both of which were better than the Gen II plant at 13.6 g CO2-eq/kWh. Although the SMR measured higher than the Gen III plant, it enjoys other technological advantages such as efficiencies in construction, operation and maintenance, and decommissioning [80].

3.5. Analysis

3.5.1. Technology

Significant progress has been seen in many different areas of the technology aspect of SMRs. The amount of research going on in this field, as well as the number of ongoing projects in different types of SMR technologies show the interest and the progress being made in this area. New variations are being proposed that go beyond the earlier defined classes of SMRs, such as those of subsea-based SMRs and organic SMRs. However, as earlier mentioned, there has only been one SMR in commercial operation; thus, the overall confidence in any given technology cannot be given the “tried-and-tested” mark since even in the technology readiness index, virtually none of them would make it to TRL 9. However, there is no reason to doubt the feasibility of these technologies since they have been spun off from already tried-and-tested technology. Zeliang et al. (2020) confirm that iPWR-type SMRs are based on proven technologies, since they are taken directly from existing commercial PWR reactors [81]. The concepts behind the technologies stand for themselves; what are being developed are detailed design elements that address the necessary requirements for the plant to run, such as cooling, safety, instrumentation, etc.

With good reason, a clear area of research concerns the safety aspects of the SMR. With events that gain popular traction such as grave accidents like the Fukushima Power Plant and the Chernobyl nuclear plant, the issue of safety runs highest among issues in the minds of the public that affect the SMR’s acceptability in their eyes. Thus, the interest in addressing these safety concerns are paramount in order to ensure the commercial success of a specific SMR technology. The previously cited research shows significant effort in this regard has been made: from materials research, disaster-modelling, and plant design.

Another key area found in the literature is the potential for SMRs to be used in tandem with other technologies in order to harness synergies through cogeneration. Several technologies have been tested to work together with SMRs, and those that have emerged as the most promising ones are hydrogen production, water desalination, and district heating. With these possibilities for cogeneration, the SMRs can be used for other purposes, thus maximizing the use of the heat generated, contributing to more revenue streams. Moreover, studies have also shown that with these possibilities of cogeneration, SMRs can be used as a load-follower, rather than just a provider of baseload electricity supply. This means that the SMR can adapt to fluctuations in electricity demand by diverting the heat that would otherwise be used for electricity generation to other productive activities such as those mentioned earlier, i.e., hydrogen production, water desalination, and district heating. SMRs were also studied in connection with the use of other forms of renewable energy such as solar and wind turbines. These studies show that together, they can respond to the demand for a fluctuating electricity supply, with a competitive cost and with a lesser carbon footprint.

3.5.2. Economics

Table 3 presents a summary of the various studies that have been conducted regarding the TCIC of SMRs. Table 4 shows the studies that estimated the reduction in costs of the use of SMRs. Table 5 summarizes the data on estimated LCOE at which SMRs can provide energy. These figures can be used to compare with other technologies, such as wind energy and solar PVs in order to assess its economic suitability.

Table 3.

TCIC cost estimation of various authors.

Table 4.

Estimated percentage reduction in TCIC by various authors.

Table 5.

LCOE estimate of various authors.

The above studies have largely concentrated on one-time capital costs associated with the construction of SMRs using TCIC or LCOE as a methodology. On the other hand, studies relating to opportunistic evaluation of costs depending on changing conditions that can potentially alter it in the future were not performed as often. This risk-based approach that considers the myriad of factors that can affect decision-making in the present can prove advantageous for policy-makers and investors. Techniques such as real options can be utilized to present scenarios that are particular to any given context.

3.5.3. Socio-Political

Table 6 summarizes key socio-political factors identified with SMRs. Among the most important social issues surrounding the installation of SMRs, being a subset of nuclear power plants in general, is the issue of social acceptance, i.e., whether the population where the SMR will be cited are in favor of its installation, at a regional or national level.

Table 6.

Summary of socio-political issues.

This is even more important in light of the recent high-profile accidents that have happened such as those of Fukushima, Three-Mile Island, and Chernobyl. Lei et al. (2013) noted the decrease in public support for the building of nuclear power plants in a region in China by as much as 41%; however, it was concluded that such behavior may differ across different cultures [85]. Other authors have made other observations: Table 7 shows the change in opposition to nuclear power post-Chernobyl in various countries. Despite all these observations, nations have continued to pursue nuclear technology for power.

Table 7.

Changes in opposition to nuclear power in select countries post-Chernobyl.

While Germany has decided to terminate the use of nuclear energy generation by 2022, many countries have decided to continue pursuing the planning and construction of newbuild NPPs, such as China, Finland, France, Hungary, Saudi Arabia, Turkey, United Arab Emirates, United Kingdom, the USA, and Russia [28]. Needless to say, the issue of social acceptance is important since these are associated with mental health problems, trust in public officials, and ultimately, attitudes toward nuclear power generation [82].

It is worthwhile to note as well that in spite of the perceived decrease in public support for nuclear power in China post-Fukushima, Zhan et al. (2021) noted that China still sees nuclear energy playing a big role in its energy development, with SMRs to be deployed by 2025 and synergized with the use of renewable energy by 2030 [86].

The danger of nuclear proliferation and terrorism also was brought to the fore by several authors, indicating the potential of such a technology being used for ends not congruent to the development of society, such as instilling terror through the ease of access to materials that can be used for weapons of mass destruction. Certain types of technology can promote nuclear proliferation.

Internal and external political forces can also be at risk, which can come in the forms of pressure or interest groups from within and without of the country as highlighted by Ramana and Ahmad (2016), in the case of Jordan [83], where apparent pressure from Russia enabled its investment on LRs, contrary to its parallel plan of acquiring SMRs. Together with the above is the institutional inertia that can resist (or promote) the adoption of new technologies such as SMRs. Path dependencies on technologies may restrict the adoption and may also indicate existing regulations that may hinder new technology adoption. Related to institutional inertia is the importance placed on safety by both workers and managers that are translated into codified safety regulations, as well as generally accepted practice or behaviors [73].

Another important social issue is the current development level of a given society or country. Various indicators have been proposed in this area: financial and economic criteria, e.g., GDP, electric grid, technology, and infrastructure [84]. However, other social indicators may also have to be considered in order to evaluate the readiness of a society to adopt technology such as educational level and the appropriate skillsets.

3.5.4. Environmental

The absence of literature related to the environmental impacts of SMRs is notable in this regard. This may be due to the obvious lack of an operating plant that can be a subject for study. For comparison’s sake, we may cite the study of Wang et al. (2019), who conducted a life cycle analysis, including examinations of acidification potential, eutrophication potential, photochemical ozone creation potential, and human toxicity potential of wind energy, nuclear power (large reactor), and hydropower. The study showed that wind power had the highest global warming potential at 28.6 ± 3.2 g CO2-eq/kWh, followed by nuclear power at 12.4 ± 1.5 g CO2-eq/kWh and lastly, hydropower at 3.5 ± 0.4 g CO2-eq/kWh [87]. Boldon et al. (2015) conducted a similar study for wind power and SMRs, noting that they fall within the range for an LR [66]. Moreover, Carless et al. (2016) showed that the GHG emissions of SMRs are similar to those of LRs [80]. Figure 9 shows a graph comparing the results from these different authors. The studies are understandably largely based on projected quantities of materials since there are virtually no SMRs on commercial operations as yet.

Figure 9.

LCA Results according to various authors.

As far as greenhouse gas emissions are concerned, studies have been clearly made with respect to the entire plant in consideration. However, it will be of equal importance what the environmental effects of such modularity can have in either implementations i.e., of modularizing the production process of a single plant, or the modularization of the power producing capacity. In the former case, one can surmise the increased cost of transporting the modular parts of a plant to the assembly area. In the latter case, a nuclear plant with multiple SMRs would possibly have more structural elements incorporated to secure each reactor.

With the ever-increasing concern for environmentally-sustainable technologies, these studies carried out as accurate as possible are important for the decision-making process for newcomer countries to avoid making that trade-off of the environment for development. It is important that before a country makes a decision to choose a certain technology path, in this case SMRs, they know the environmental impact it may have even before embarking on it. This breaks a circular notion that in order for one to know the environmental impact, we need to build the plant first, but to choose what plant to build, we need to know what the environmental effects are. The LCA has to be conducted from the whole plant-design level as early as possible.

The research of Hussein (2020) also suggested the retrofit of coal-fired power plants for SMRs especially for iPWRs. This presents an interesting field of research on environmental impact since many elements of the plants may be re-used. Understandably, the plant’s specification has to be upgraded in order to conform to safety requirements and will have to be considered in any LCA to be conducted in this regard [37].

3.5.5. SMR Features Compared with LRs

All the previous sections have given us important characteristics of an SMR and compare it with an LR. As SMRs have a small power capacity, they have potential to be deployed in remote areas as stand-alone plants and as parts of a small grid which will make LRs economically unfeasible. Due to the advantages afforded by modularization, similar plants can enjoy cheaper manufacturing and construction costs that can arise from learnings from previous production cycles. Modularization also allows for smaller logistical costs, as modules can be transported from factory to site as one single unit. On the other hand, the first unit is expected to be the most expensive. Thanks to the smaller plant capacity and size, the first unit of a series of SMRs can be made available to produce energy, thus reducing the capital needed to construct the plant compared to a similarly sized LR. If capital costs are lower, developing communities will be able to access this technology and hasten their development. From a cost point-of-view, SMRs can be comparable to LRs if enough of them are made to take advantage of the aforementioned learnings.

In terms of technology and designs, design integration in a module allows for compact features, thereby reducing the risk of accidents arising from major plant components. Their smaller size also allows SMRs to be constructed on mobile units such as ships, or to be built underground to minimize exposure to environmental hazards. There will also be considerably lesser logistical issues dues to their size

In terms of socio-political aspects, since both types of plants are nuclear-based, they will both suffer the same public acceptance issues. Both require extensive information and education in order to improve the level of public acceptance. On the other hand, SMRs will seem to suffer security-related issues due to their potential for proliferation coming from their comparatively smaller amount of fuel. However, because of the smaller size of SMRs, where investment may be made by stakeholders “closer-to-home”, there is a democratization of renewable energy development that can insulate one from external political powers.

The literature has also shown that LRs and SMRs have comparatively similar potential environmental impacts, thereby giving a much cleaner alternative to fossil-fuel based plants.

3.5.6. Models of Renewable-Energy Readiness Indices

Having seen the progress in scientific research related to specific issues on SMRs, the question is how they all fit together in giving decision-makers a complete picture of all these issues, together with the advantages and disadvantages of the technology. Some studies have been carried out in combining these elements to determine the readiness of countries to invest in this technology, starting with those related to renewable energy in general. Hawila et al. (2014) assessed the readiness of North African countries to adopt renewable energy technologies. The model adopted factors and sub-factors related to infrastructure, institution and human capital using a multi-criteria decision-making (MCDM) technique coupled with the weighted sum method for the final renewable energy-readiness assessment [88].

Mondal et al. (2015), adopted an approach similar to that of Hawila et al. to study the RE-readiness of the Gulf Cooperation Council countries, incorporating a different set of criteria that were found to be missing in the previous study. A similar MCDM technique was used, employing the equal weights method to assign the weightages to the three pillars of infrastructure, institutions, and human capital. Finally, the weighted sum method is employed to obtain the final RE-readiness index [89].

Black et al. (2015) consolidated 15 criteria to assess each country’s readiness for SMR adoption [84]. Table 8 compares this set of criteria with those employed by the two previous authors. While the study is comprehensive in terms of the technological and economic aspects, these do not consider many socio-political criteria as enumerated in the preceding sections. In addition, local environmental costs and monetary costs with which a country can construct SMR plants are not included in the construction of its index. Black et al. used the AHP method to determine the scores from different countries, using data obtained from public databases. The studies related to energy readiness indices thus far performed have shown that the use of MCDM techniques may be used for this purpose. This shows its flexibility in being used for different sets of criteria.

Table 8.

Criteria for readiness indices for RE/nuclear energy.

4. Challenges and Future Direction

There is a large amount of literature in terms of technology and the economics of SMRs. All these serve to make SMR technology attractive as a means to meet the energy demands and the environmental targets. On the other hand, as highlighted by some authors, there is a need to expand on studies related to the social issues surrounding SMRs and how they affect their feasibility.

On the economic aspects, the use of LCOE and TCIC have been extensively explored with several authors estimating a reduction in costs as more SMRs are installed. However, due to the modular nature of SMRs, consideration of the decisions to proceed with further additions of modules arising from uncertainties in all these factors must be carefully weighed, considered, and presented to decision-makers. These factors may include those that have been discussed, such as technological maturity of new designs, environmental aspects, political situations, public perception, etc. Today’s widespread concern for sustainability issues demand a careful look into the aforementioned issues. Technologies that are not ready to be deployed run the risk of being environmentally catastrophic. In turn, these technologies may not provide what they promise, such as a low carbon footprint, or worse, may fail during operation, requiring contingencies that may be significantly worse than if the SMRs were not deployed in the first place, or that may render the investment financially unsound in the long run. Similarly, a lack of consideration of environmental impact, from cradle-to-grave prior to deployment, may directly contribute to environmental effects such as greenhouse gases and radiation exposure. External political situations have to be weighed as well. An even bigger concern is public perception which can lead to unexpected extreme situations such as psychological impact and social unrest. From a positive point of view, a good public perception of the technology can enable greater participation and thus better implementation of such projects.

A financial model must be constructed that takes into consideration these uncertainties arising from different factors identified. This is especially important for newcomer countries that are more often than not financially challenged and, therefore, need careful consideration of multiple factors. Several options evaluation techniques employed in renewable energy investment can be used to improve the decision-making from an economic point of view. Most papers reviewed have employed a time-value based approach such as the net present value. New techniques such as the real-options approach can be used since it considers varying conditions throughout the life cycle of the plant. Hürlimann (2018) also proposed using explanatory, sequential, and mixed-methods approaches to evaluate investments that take into account quantitative and qualitative findings [90].

From a socio-political perspective, measurements must be made with regard to institutional readiness for nuclear adoption. The presence of institutions such as oversight, safety, education, etc., may increase the probability that further investments in SMRs may be made. These institutions help engender reliability and trust in the technology among the public. Moreover, with strong institutions, foreign investors in energy generation will also see this as a positive environment that will help protect their own investments. While difficult, it is certainly doable to determine what indicators can be used in order to objectively measure these factors. In addition to the aforementioned criteria, among the various socio-political criteria that have been used in studies in this area are the Doing Business Index, Corruption Perceptions Index, and a country’s infrastructure ranking as provided by independent organizations. With a more objective measurement of these factors, better studies may be made that can enhance the use of indices in measuring overall readiness of countries in investing in this technology.