Heat-Transfer Mechanisms in a Solar Cooking Pot with Thermal Energy Storage

Abstract

1. Introduction

2. Materials and Methods

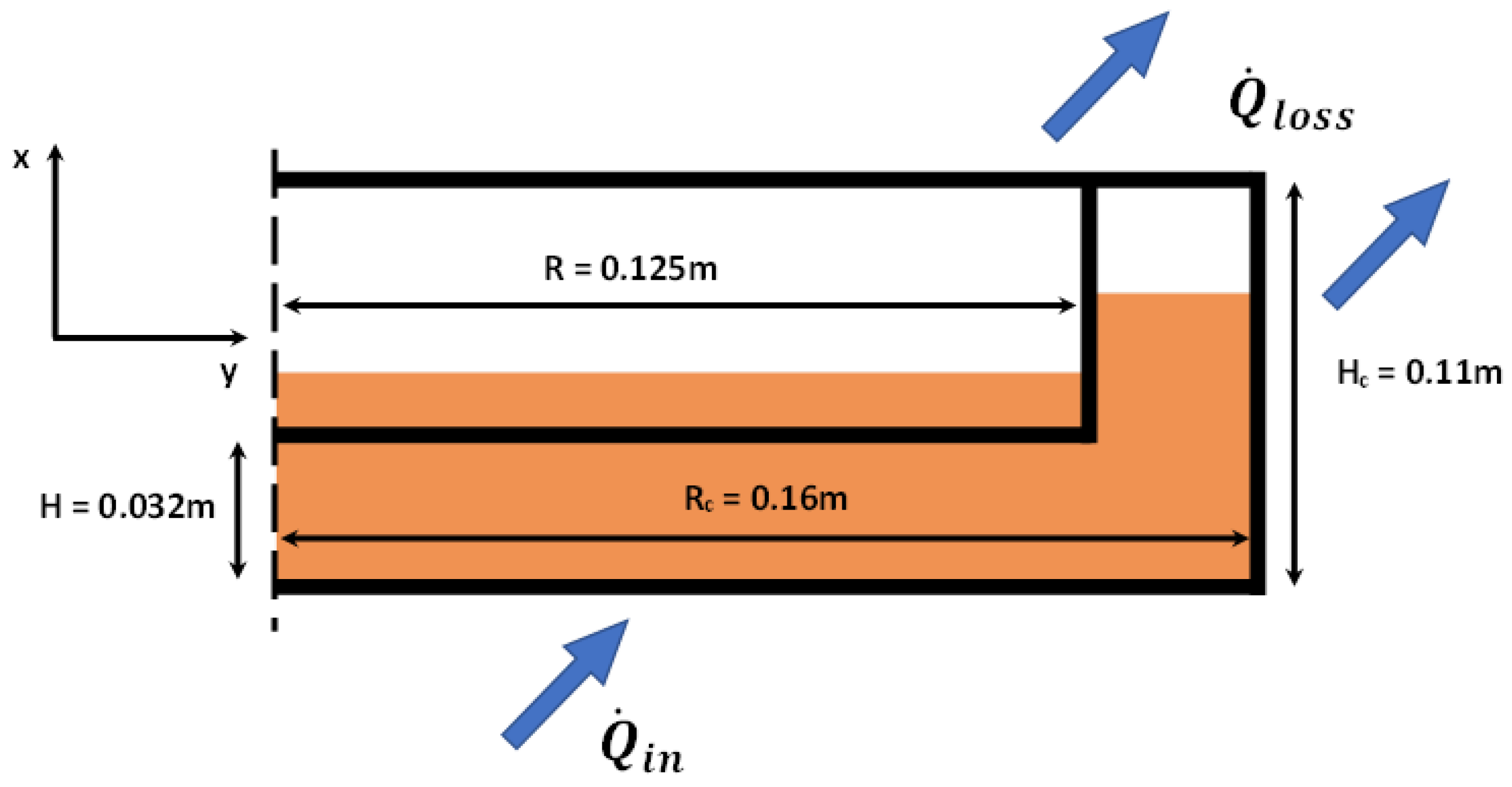

2.1. Experimental Setup

2.2. Numerical Setup

3. Results and Discussion

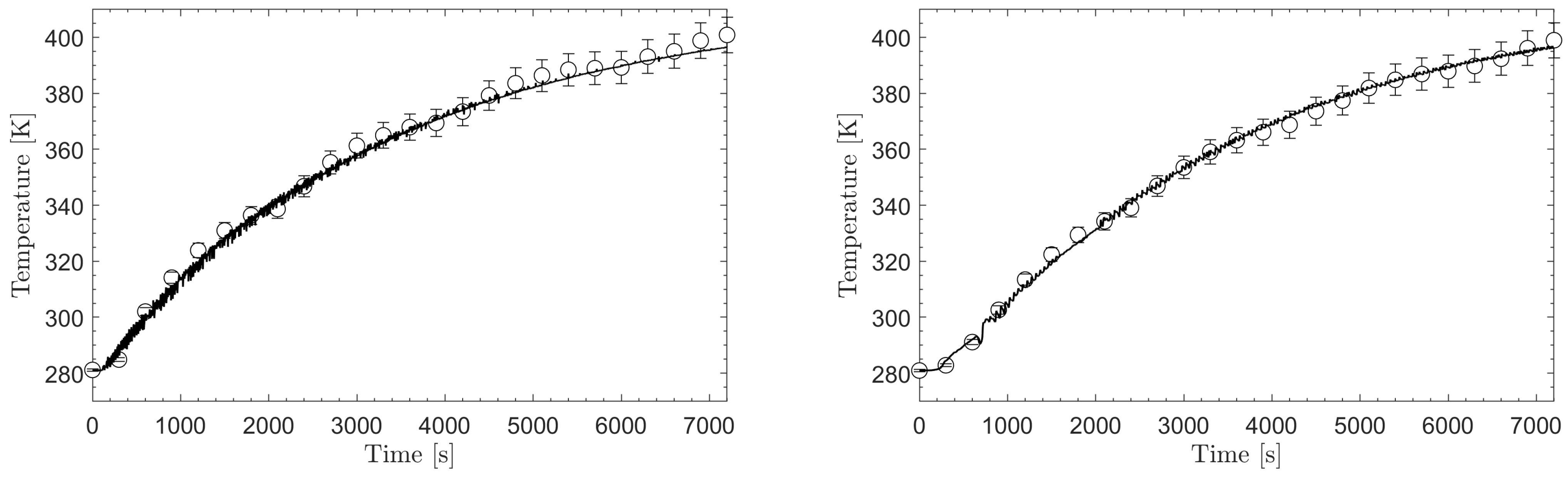

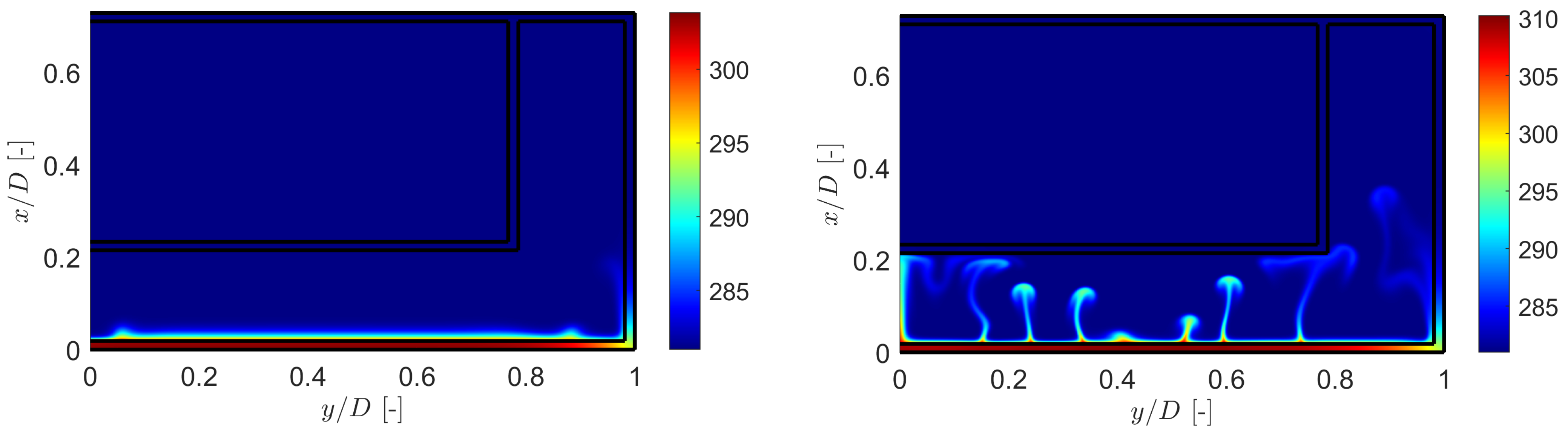

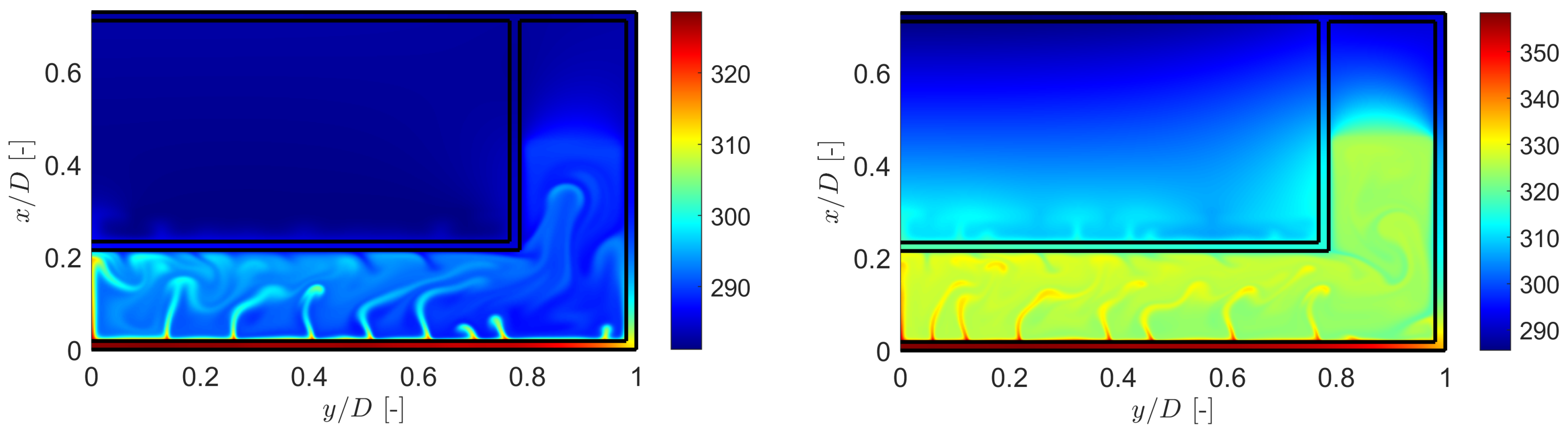

3.1. Temperature Evolution in Time

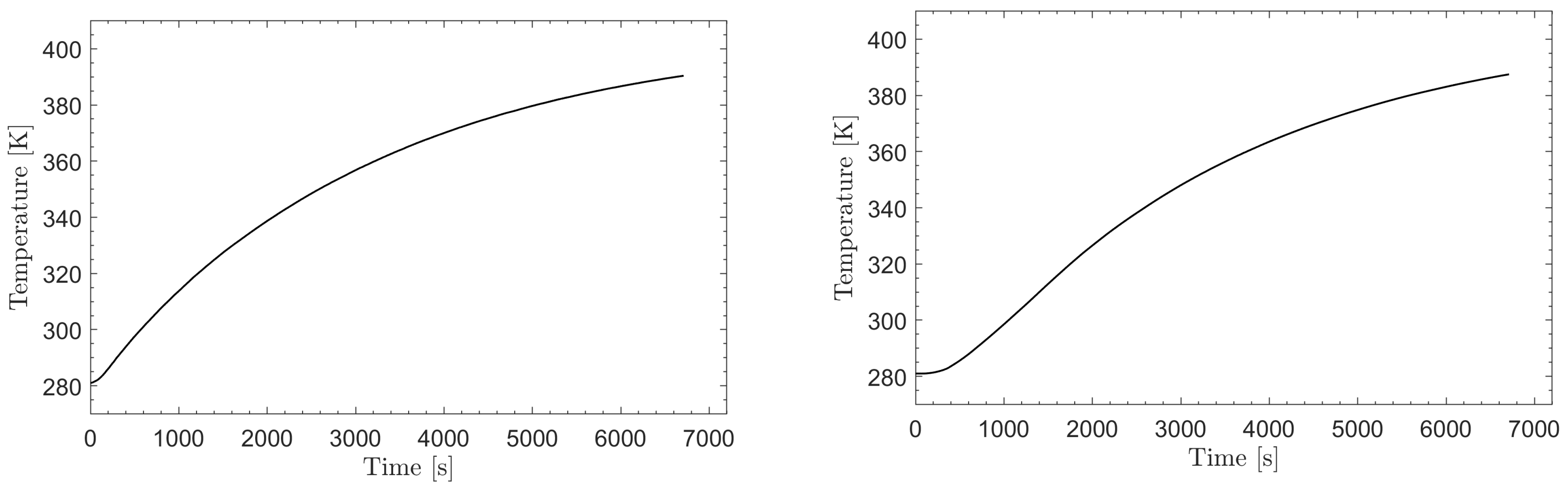

3.2. Average Temperature Evolution in the TES and Pot

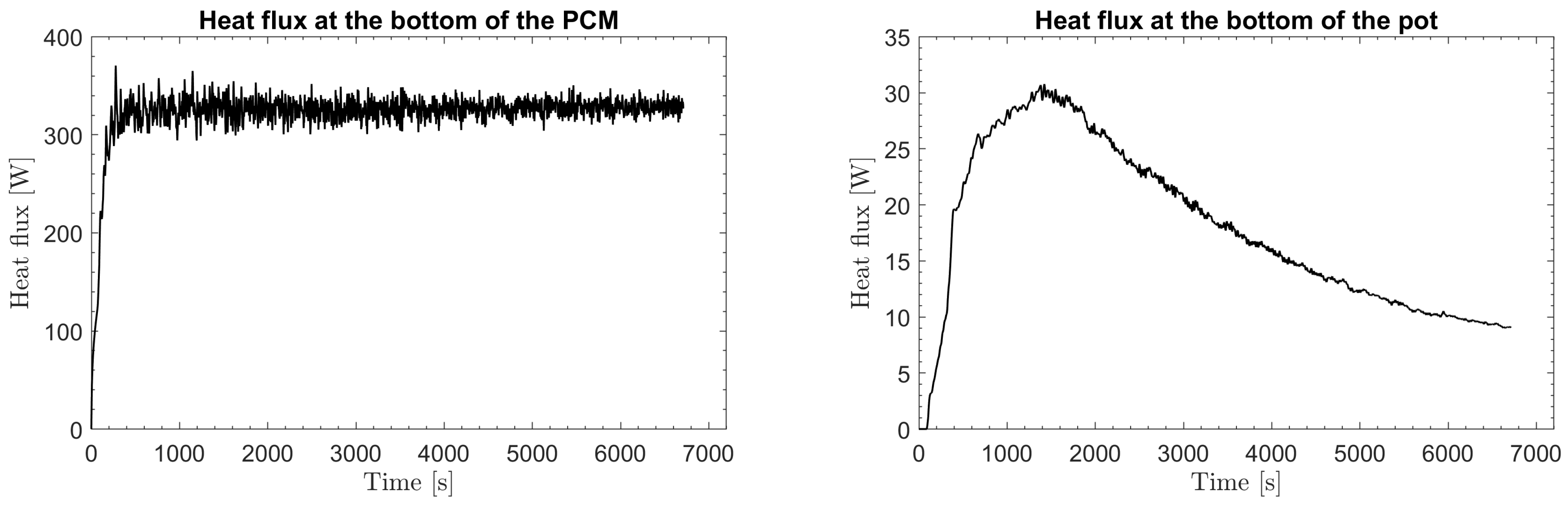

3.3. Transient Heat Transfer Phenomena

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| TES | Thermal energy storage |

| CFD | Computational fluid dynamics |

| PCM | Phase-changing material |

References

- Aramesh, M.; Ghalebani, M.; Kasaeian, A.; Zamani, H.; Lorenzini, G.; Mahian, O.; Wongwises, S. A review of recent advances in solar cooking technology. Renew. Energy 2019, 140, 419–435. [Google Scholar] [CrossRef]

- Herez, A.; Ramadan, M.; Khaled, M. Review on solar cooker systems: Economic and environmental study for different Lebanese scenarios. Renew. Sustain. Energy Rev. 2018, 81, 421–432. [Google Scholar] [CrossRef]

- Arunachala, U.C.; Kundapur, A. Cost-effective solar cookers: A global review. Sol. Energy 2020, 207, 903–916. [Google Scholar] [CrossRef]

- Cuce, E.; Cuce, P.M. A comprehensive review on solar cookers. Appl. Energy 2013, 102, 1399–1421. [Google Scholar] [CrossRef]

- Yettou, F.; Azoui, B.; Malek, A.; Gama, A.; Panwar, N.L. Solar cooker realisations in actual use: An overview. Renew. Sustain. Energy Rev. 2014, 37, 288–306. [Google Scholar] [CrossRef]

- Ahmed, S.M.M.; Rahmatullah, M.; Al-Amin, M.R.; Ahammed, S.; Ahmed, F.; Saleque, A.M.; Rahman, M.A. Design, construction and testing of parabolic solar cooker for rural households and refugee camp. Sol. Energy 2020, 205, 230–240. [Google Scholar] [CrossRef]

- Mohod, A.G.; Khandetod, Y.P.; Sengar, S. Eco-friendly utilisation of parabolic concentrating solar cooker for extraction of cashew nut shell oil and household cooking. Int. J. Sustain. Energy 2010, 29, 125–132. [Google Scholar] [CrossRef]

- Omara, A.A.M.; Abuelnuor, A.A.; Mohammed, H.A.; Habibi, D.; Younis, O. Improving solar cooker performance using phase change materials: A comprehensive review. Sol. Energy 2020, 207, 539–563. [Google Scholar] [CrossRef]

- Nkhonjera, L.; Bello-Ochende, T.; John, G.; King’ondua, C.K. A review of thermal energy storage designs, heat storage materials and cooking performance of solar cookers with heat storage. Renew. Sustain. Energy Rev. 2017, 75, 157–167. [Google Scholar] [CrossRef]

- Samylingam, L.; Aslfattahi, N.; Saidur, R.; Yahya, S.M.; Afzal, A.; Arifutzzaman, A.; Tan, K.H.; Kadirgama, K. Thermal and energy performance improvement of hybrid PV/T system by using olein palm oil with MXene as a new class of heat transfer fluid. Sol. Energy Mater. Sol. Cells 2020, 218, 110754. [Google Scholar] [CrossRef]

- Benoudina, B.; El Hadi Attia, M.; Driss, Z.; Afzal, A.; Muthu Manokar, A.; Sathyamurthy, R. Enhancing the solar still output using micro/nano-particles of aluminum oxide at different concentrations: An experimental study, energy, exergy and economic analysis. Sustain. Mater. Technol. 2021, 29, e00291. [Google Scholar] [CrossRef]

- Lecuona, A.; Nogueira, J.-I.; Ventas, R.; Rodríguez-Hidalgo, M.; Legrand, M. Solar cooker of the portable parabolic type incorporating heat storage based on PCM. Appl. Energy 2013, 111, 1136–1146. [Google Scholar] [CrossRef]

- Chaudhary, A.; Kumar, A.; Yadav, A. Experimental investigation of a solar cooker based on parabolic dish collector with phase change thermal storage unit in Indian climatic conditions. J. Renew. Sustain. Energy 2013, 5, 023107. [Google Scholar] [CrossRef]

- Rekha, S.M.S.; Sukchai, S. Design of Phase Change Material Based Domestic Solar Cooking System for Both Indoor and Outdoor Cooking Applications. J. Sol. Energy Eng. 2018, 140, 041010. [Google Scholar] [CrossRef]

- Bhave, A.G.; Thakare, K.A. Development of a solar thermal storage cum cooking device using salt hydrate. Sol. Energy 2018, 171, 784–789. [Google Scholar] [CrossRef]

- Yadav, V.; Kumar, Y.; Agrawal, H.; Yadav, A. Thermal performance evaluation of solar cooker with latent and sensible heat storage unit for evening cooking. Aust. J. Mech. Eng. 2017, 15, 93–102. [Google Scholar] [CrossRef]

- Choudhari, K.S.; Shende, M. Solar cooker using PCM material. J. Basic Appl. Eng. Res. 2015, 2, 1449–1453. [Google Scholar]

- Senthil, R.; Cheralathan, M. Enhancement of the thermal energy storage capacity of a parabolic dish concentrated solar receiver using phase change materials. J. Energy Storage 2019, 25, 100841. [Google Scholar] [CrossRef]

- Keith, A.; Brown, N.J.; Zhou, J.L. The feasibility of a collapsible parabolic solar cooker incorporating phase change materials. Renew. Energy Focus 2019, 30, 58–70. [Google Scholar] [CrossRef]

- Bhave, A.G.; Kale, C.K. Development of a thermal storage type solar cooker for high temperature cooking using solar salt. Sol. Energy Mater. Sol. Cells 2020, 208, 110394. [Google Scholar] [CrossRef]

- Coccia, G.; Aquilanti, A.; Tomassetti, S.; Comodi, G.; Nicola, G. Design, realisation, and tests of a portable solar box cooker coupled with an erythritol-based PCM thermal energy storage. Sol. Energy 2020, 201, 530–540. [Google Scholar] [CrossRef]

- Mawire, A.; Lentswe, K.; Owusu, P.; Shobo, A.; Darkwa, J.; Calautit, J.; Worall, M. Performance comparison of two solar cooking storage pots combined with wonderbag slow cookers for off-sunshine cooking. Sol. Energy 2020, 208, 1166–1180. [Google Scholar] [CrossRef]

- Wollele, M.B.; Hassen, A.A. Design and experimental investigation of solar cooker with thermal energy storage. Aims Energy 2019, 7, 957–970. [Google Scholar] [CrossRef]

- Vigneswaran, V.S.; Kumaresan, G.; Sudhakar, P.; Santosh, R. Performance evaluation of solar box cooker assisted with latent heat energy storage system for cooking application. IOP Conf. Ser. Earth Environ. Sci. 2017, 67, 012017. [Google Scholar] [CrossRef]

- Kumaresan, G.; Raju, G.; Iniyan, S.; Velraj, R. CFD analysis of flow and geometric parameter for a double walled solar cooking unit. Appl. Math. Model. 2015, 39, 137–146. [Google Scholar]

- Abreha, B.G.; Mahanta, P.; Trivedi, G. Numerical modeling and simulation of thermal energy storage for solar cooking using Comsol multiphysics software. Aip Conf. Proc. 2019, 2091, 020004. [Google Scholar]

- Joshi, J.B.; Pandit, A.B.; Patel, S.B.; Singhal, R.S. Development of Efficient Designs of Cooking Systems. II. Computational Fluid Dynamics and Optimization. Ind. Eng. Chem. Res. 2012, 51, 1897–1922. [Google Scholar] [CrossRef]

- Mbodji, N.; Hajji, A. Modeling, testing, and parametric analysis of a parabolic solar cooking system with heat storage for indoor cooking. Energy Sustain. Soc. 2017, 7, 32. [Google Scholar] [CrossRef]

- Hoffmann, J.-F.; Vaitilingom, G.; Henry, J.-F.; Chirtoc, M.; Olives, R.; Goetz, V.; Py, V. Temperature dependence of thermophysical and rheological properties of seven vegetable oils in view of their use as heat transfer fluids in concentrated solar plants. Sol. Energy Mater. Sol. Cells 2018, 178, 129–138. [Google Scholar] [CrossRef]

- SunFire Solutions. Available online: https://www.sunfire.co.za/ (accessed on 16 February 2023).

- Mawire, A.; Ramokali, M.; Mothupi, M. A solar thermal experiment with parabolic dish solar cookers for developing countries. Eur. J. Phys. 2020, 41, 055104. [Google Scholar] [CrossRef]

- Tegenaw, P.D.; Lentswe, K.; Mawire, A.; Owusu, P.; Vanierschot, M. A Thermal Model of a Solar Cooker with Thermal Energy Storage using Computational Fluid Dynamics. In Proceedings of the ISES Solar World Congres, Virtual, 25–29 October 2021. [Google Scholar]

- Hirt, C.W.; Nichols, B.D. Volume of fluid (VOF) method for the dynamics of free boundaries. J. Comput. Phys. 1981, 39, 201–225. [Google Scholar] [CrossRef]

- Fasina, O.O.; Colley, Z. Viscosity and Specific Heat of Vegetable Oils as a Function of Temperature: 35 °C to 180 °C. Int. J. Food Prop. 2008, 11, 738–746. [Google Scholar] [CrossRef]

- Domanski, R.; El-Sebaii, A.A.; Jaworski, M. Cooking during off-sunshine hours using PCMs as storage media. Energy 1995, 20, 607–616. [Google Scholar] [CrossRef]

| [s] | [K] | b [s] | |

|---|---|---|---|

| TES | 51.5 | 404.8 | 3.22 × 10 |

| POT | 310.8 | 421.9 | 2.33 × 10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vanierschot, M.; Mawire, A. Heat-Transfer Mechanisms in a Solar Cooking Pot with Thermal Energy Storage. Energies 2023, 16, 3005. https://doi.org/10.3390/en16073005

Vanierschot M, Mawire A. Heat-Transfer Mechanisms in a Solar Cooking Pot with Thermal Energy Storage. Energies. 2023; 16(7):3005. https://doi.org/10.3390/en16073005

Chicago/Turabian StyleVanierschot, Maarten, and Ashmore Mawire. 2023. "Heat-Transfer Mechanisms in a Solar Cooking Pot with Thermal Energy Storage" Energies 16, no. 7: 3005. https://doi.org/10.3390/en16073005

APA StyleVanierschot, M., & Mawire, A. (2023). Heat-Transfer Mechanisms in a Solar Cooking Pot with Thermal Energy Storage. Energies, 16(7), 3005. https://doi.org/10.3390/en16073005