Abstract

Several countries are focusing their efforts on diversifying electricity generation to promote the transition towards a sustainable low-carbon energy system through the strategic development of the value chains related to renewable energy industries. In this way, the development of a national industry that helps to ensure a clean and affordable electricity supply and that also generates important socio-economic benefits, has gained relevance worldwide. This article proposes a methodology and economic model that considers technological progress and economies of scale to analyze a potential upstream development and integration of the value chain of the photovoltaic industry in Mexico. The results show that the upstream development of a national photovoltaic industry is financially viable and sustainable, and with which the national demand for photovoltaic technology could be satisfied by 76% and imports reduced by 47%, both compared to a reference scenario. This enables the generation of more than 447,000 jobs and an added value of more than 12,000 M USD. This would increase the national value content to 89% by 2040 and contribute to the national goal of generating 35% of its electricity through clean energy technologies, fulfilling the commitment established in its nationally determined contributions. Furthermore, it would enable the transition towards a sustainable energy future in Mexico.

1. Introduction

A value chain integrates all the activities that are required to produce goods, from their conception and production (involving both the physical transformation and the services used) to their consumption and final disposal [1,2]. The linkage between these activities can vary in number and degree of sophistication according to the degree of transformation required by the goods, adding value as each of the stages progresses [3]. However, this concept only involves the direct participants of the value chain and focuses on seeking the improvement of the products and processes used to compete successfully in markets [4,5,6]. This fails to consider those other benefits that can favor the fulfillment of social, economic and environmental objectives, offering a more effective and sustainable way to create wealth, jobs and prosperity [7,8]. By considering these benefits, the participation of the government in the development of value chains is facilitated, turning it into an engine for innovation, investment and economic growth, through the creation or consolidation of new sectors, which promote the diversification of the productive structure, especially those of a strategic nature, depending on national priorities [9]. This can be achieved through policies and initiatives that facilitate or regulate the development of national industries and products, such as specific programs for the creation of industries considered strategic for national development; direct support for the creation and improvement of physical infrastructure and social infrastructure (institutions); the development of national technological capacity; commercial and competition policies; and programs to support labor-intensive industries [10,11,12]. Likewise, the government can contribute to the development of new industries of strategic nature by participating within the value chain as a producer, through government-owned companies that compete for a market share or as a buyer, through public tenders or direct assignments, which may be determined by particular or strategic requirements for the government, such as economic, social or environmental [13]. Related to the above, research on value chains has evolved towards a broader understanding, by including the potential of the government to adapt industrial development policies and direct them towards a structural transformation that provides a sustainable and low-carbon economy [14,15,16], or the promotion of innovation, knowledge dissemination and adaptation to the Fourth Industrial Revolution [17,18,19], thereby creating a new basis for incorporating development objectives more systematically into value chain interventions. This is especially true in developing countries, where taking industrial policy as the basis for interventions to support the development of value chains has the potential to make them more effective in terms of improving added economic value and social benefits [13]. An example of the above are the industries related to technologies for the use of renewable energies, which have the capacity to offer broad socioeconomic benefits [20,21,22], especially the photovoltaic (PV) industry, which enjoys a constantly expanding market mainly thanks to price reductions derived from technological innovation [23,24,25] and to the minimization of capital costs [26]. This is the main reason why most of the energy systems transition scenarios around the world show that PV technology will be one of the main pillars of energy supply in the future [23,24,25]. However, in addition to the socioeconomic benefits that these technologies can generate, several countries, such as the United States of America [27], China [28], Japan [29] or those belonging to the European Union [30], are increasingly focusing their efforts on diversifying electricity generation, using, among others, PV technology, with the aim of achieving energy security [31]. This is mainly due to geopolitical risks caused by the limited availability of cheap fossil resources that can meet the growing demand and guarantee access to energy services in a reliable and affordable way. In addition to the fact that this energy security strategy is based on the use of renewable resources, it seeks to reduce greenhouse gas emissions and decarbonize energy use; thus trying to ensure that energy security objectives are consistent with the objectives of environmental protection and of sustainable development [32,33,34]. Therefore, the development of a national PV industry that helps to ensure a supply of clean and affordable electricity and that also generates positive socio-economic effects has great relevance worldwide [24,35,36].

From this perspective, the development of the value chains of the renewable energy industries, including photovoltaics, seems to take a “strategic” approach, especially when it comes to ensuring the supply of critical raw materials or essential material resources for these industries, that are economically important for the manufacture of the technologies involved in the decarbonization of the power sector [37,38]. This is even more so the case for those developing countries with abundant renewable resources and endowed with these critical raw materials, [39,40] which gives them a leading role in the energy transition and the fight against climate change [28,41], while allowing them to improve their energy security [37,38]. The latter is relevant, since even though renewable resources are not subject to the same degree of geopolitical influences as fossil fuels [42], the massive deployment of renewable energy technologies in developing countries seeking an energy transition could pose a potential risk to their energy security, if there is an interruption in the supply of these critical raw materials, which could lead to a high level of uncertainty and a high price increase [40].

In this sense, the PV industry has already offered a good example of these risks during the 2000s, when it suffered a shortage of its main raw material, polysilicon (Poly-Si), as a result of the high demand for PV technology, making it a critical material for this industry and causing its price to increase up to 1200% in a period of three years [43]. At present, these risks increase when we learn about the current regional concentration of Poly-Si and the oligopolistic structure of the manufacture of this material and its market, which has China as its main actor [44].

In the national context, Mexico is a country with a declining oil production, with proven and limited reserves for only nine years at the current rate of consumption [45], which puts its energy security at risk [46,47].

Therefore, the development and integration of a national PV industry that promotes the diversification of the energy matrix through the use of the abundant solar resource that the country has, using PV technology to improve the availability and accessibility of energy, promoting the transition towards a low-carbon energy system while promoting economic growth and ensuring access to inputs and critical components for this industry, seems to be essential to contribute to national energy security and the fight against climate change.

Faced with this problem, the contribution of this article is to propose a methodology and an economic model that integrates technological progress and economies of scale, to evaluate a financially sustainable development and integration of the upstream value chain of the PV industry in Mexico (VCPVIM). For this purpose, the methodology and economic model are presented highlighting the joint impact of technological progress and economies of scale in the costs reduction of the PV industry value chain; at the end of Section 3, we show that several works present similar or conventional methodologies and models, but do not consider or represent both factors that impact the manufacturing cost of a PV device, in our case, technological progress and economies of scale. In this article, it is also shown that with the proposed methodology and economic model, a gradual development of the upstream VCPVIM is obtained that progressively contributes to meeting the future PV demand for electricity generation in Mexico, and sets up the generation of important socioeconomic benefits, collaborating to improve national energy security and the transition towards a sustainable energy future in Mexico.

2. Energy Security and the PV Industry

Energy security is one of the main objectives to be achieved in several countries around the world, and which, together with sustainability, constitute the pillars of any present energy policy. However, to achieve them it is essential to provide access to adequate, reliable and affordable energy supplies that keep economies running and increase the well-being of the population, increasing the challenge. Therefore, a clear conceptualization of energy security is essential. However, its meaning can be broad and may differ according to individual and geopolitical perspectives in which it occurs. According to [48,49,50], energy security has predominantly meant the production, trade and access to fossil energy resources, in an uninterrupted manner, that satisfies the demand for these resources in a reliable, affordable and resilient way to price volatility; elements that have been considered essential for the functioning of economies and human systems. However, over time, this definition has been supplemented by adding characteristics that involve economic development and its balance with the environment and sustainability, linking them with obtaining socio-economic benefits. In line with this, [51,52,53] state that energy security is made up of: the availability and accessibility of energy supply sources; diversification of energy sources; the resilience of supply chains to disruptions; the affordability of acquiring resources and the development of energy infrastructure; integration into stable global markets and access to information on markets and prospects; and environmental sustainability that implies the use of energy resources to meet the needs of the present in an environmentally responsible way without compromising the ability of future generations to meet their own needs. However, despite the multiple definitions that can be given to energy security, dependence on a small group of energy sources increases the potential for economic and social disruption, and more if the countries that produce and export them limit or manipulate the supply of these energy sources. In addition, when access is not limited, fluctuations in the prices of these fossil resources can generate uncertainty in the markets that depend on these resources. Even without considering the effects of price volatility, economies that depend on a limited portfolio of fossil energy resources have less energy security, compared to those that enjoy an abundance of these energy resources [42]. Faced with this situation, the diversification of electricity generation is an area in which several countries are increasingly focusing to improve their national energy security [30,33,34], driven primarily by increased demand for electricity and the need to reduce greenhouse gas (GHG) emissions. Therefore, the use of renewable energies has been proposed as a means to diversify the energy matrix for the generation of electricity [54,55], as a way to improve energy security. The principles behind these recommendations are that renewable energy sources are generated locally, have low operating costs and in the case of solar energy, as well as for other renewable energy sources, the marginal cost of the energy resource is equal to or close to zero [24,56,57]. In this way, the cost of renewable energy depends mainly on capital and installation costs, since its fixed and variable operating costs are low or non-existent [26,35]. Therefore, it can be assumed that renewable resources are not subject to the same degree of cost variations due to geopolitical influences as fossil fuels are [42], and can lead to the conclusion that renewable energy sources have a low risk for energy security. However, this may not be valid during all stages of its development, particularly during its expansion [58]. Globalization and protection of the upstream value chain, factors identified for fossil energy sources, can also be applied to technologies that take advantage of renewable energy sources. In other words, politics and markets cannot disturb solar energy, unlike the supply of natural gas or oil and its derivatives. However, as seen in the previous section, the use of solar energy requires the use of PV technology which totally depends on access to Poly-Si, which, being present in each of the steps of the chain of rising value of the PV industry, makes it a critical material for this industry [40]. Furthermore, its cost depends on global supply chains, which can take actions that, directly or indirectly, influence global access to this material, since its production is concentrated in a small number of countries, predominantly China, as shown in Table 1.

Table 1.

Main Poly-Si producers in 2019.

Therefore, Poly-Si and the value chain of the PV industry could be considered as “strategic” for national energy security, especially if it is treated from the perspective of the regional concentration of resources and the implications of their geopolitical management [37]; such was the case more than a decade ago in this industry and is currently happening with lithium in some Latin American countries [39].

As with fossil resources, this concentration of critical materials for renewable industries may be beneficial for some countries, but not for those countries that, despite having abundant renewable resources, do not have guaranteed massive access to the technologies they take advantage of these resources for the generation of electricity, resulting in a potential risk to its energy security as there is very low or no availability of these critical materials.

As the PV industry has become competitive by massively deploying one of the world’s leading energy transition technologies, several governments have taken action and worked to substantially promote the national development of this industry [59,60] through the implementation of green industrial policies, which aim to increase the competitiveness of renewable energy sources against fossil fuels and promote sectoral growth policies to develop the ascending value chain of the PV industry at the national level [61,62], through local content requirements [63] and national incentives such as preferential access to financing [64].

At the national level for Mexico, energy security is also an issue of vital importance, viewing it as one of the three elements necessary to achieve a comprehensive energy system, and considering it as the ability to maintain an energy surplus that provides the certainty to continue with the development of productive activities [65]. However, Mexico has ceased to be a net energy exporter country, losing self-sufficiency. The national energy independence indicator decreased more than 50% in 15 years, going from a level of above 1.4 in 2003 to 0.7 in 2018 [46,47]. Therefore, the country must generate alternatives that improve national energy security. In this sense, at the government level, they have proposed, among other activities, to expand the participation of clean energies and optimize the operation and expansion of the related infrastructure; also to strengthen support activities, the generation of knowledge, training, financing and the supply of primary inputs for value chains [66,67].

Considering the above, an important motivation of this article was to analyze the viability of developing and locally integrating the upstream value chain of the PV industry in Mexico, which can improve the availability and accessibility of PV technology, ensuring access to the inputs and key components of this industry, providing affordability of resources and thus contributing to the improvement of national energy security, making it a strategic industry for the country.

3. PV Industry Value Chain Development in Mexico

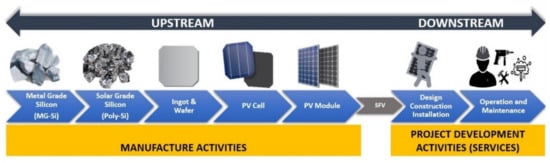

As mentioned, a value chain comprises a series of activities and processes necessary for the elaboration of a product that satisfies a specific need. Based on this concept, it can be said that the value chain of the PV industry is responsible for satisfying the need for electricity generation by manufacturing, installing, and operating the technology that transforms solar radiation into electrical energy. Typically, this value chain can be divided into two sections (Figure 1): upstream, which includes all those activities that involve a process of transformation of raw materials and manufacturing; and downstream, which includes all the activities necessary for the installation and operation of a PV system, until its final disposal [35,68,69].

Figure 1.

Activities of the PV industry value chain. Source: own elaboration.

On the upstream side, the activities of this value chain begin with the elaboration of metal grade silicon (MG-Si) through carbothermic reduction of SiO2 [70,71,72], followed by the elaboration of polysilicon 9N (Poly-Si) or solar grade silicon after the purification of MG-Si by chemical vapor deposition (CVD), known as the Siemens process [73,74] (the “grade” of Poly-Si is specifically related to its degree of purity, being 99.999999999% pure (9N) for solar applications and 99.99999999999 (11N) for electronic applications, specifically for the development of integrated circuits and microprocessors). Subsequently, Poly-Si ingots are manufactured through the Czochralski (Cz) method, where a pure silicon seed crystal is immersed in a crucible containing molten Poly-Si and subsequently extracted by slowly rotating it, finally creating a rod ingot, which is cut into square wafers of 244 cm2 (Ingot link) [73,74]. This is followed by the manufacture of PV cells (CFV), where the upper part of the wafer is textured and coated with an anti-reflective layer to improve light capture while a dielectric passivation layer is added to the lower part to produce additional electrical current and increase the cell’s ability to capture sunlight, as well as prevent overheating. Next, silver paste contacts and a layer of aluminum paste are added to the top and rear of the cell, respectively, to convert the wafer into a functional CFV [73,75]. Finally, the assembly of the PV modules (MFV) is carried out, where the CFVs are interconnected in a matrix of 60 or 72 cells, encapsulated between a glass sheet and sheets of thermoplastic encapsulants, and wrapped in an aluminum frame; lastly, the terminals of the CFV matrix are connected to a junction-box to have an MFV capable of generating electricity [73].

In general terms, the upstream value chain of the PV industry worldwide has continued to develop, thanks to the momentum generated by new policies that promote the incorporation of renewable energies into the energy matrix to mitigate climate change [24,30]. In this way, PV technology has been consolidating itself as the leading technology in electricity generation, passing the barrier of 100 GW of new PV installations interconnected and not connected to the grid in 2018. Worldwide, the accumulated installed capacity reached 627 GW in 2019, meaning an increase of 22% in respect to the installed capacity in 2018 [76]. Said growth derives from the rise of the markets of emerging countries such as India and Mexico, which added 10.8 GW and 3.6 GW, respectively, and the small, but continuous increases in Europe (8.4 GW) and China (44.3 GW), despite the slowdown in their PV market [77,78]. However, the growth of the global PV market continues to be driven by a limited number of countries [76,79] as new markets begin to emerge, where distributed generation (DG) has been central to this change. For example, in Australia, one in five households generated part of their electricity with solar energy and it is estimated that DG in this country increased by 22% in 2018 [80]. In India, PV energy grew by 60% during the same year [81], while in Latin America, DG has begun to experience significant growth, particularly in Brazil, where accumulated distributed capacity exceeded 0.5 GW in 2018. By the end of 2018, at least 32 countries already had a cumulative national installed capacity of 1 GW or more [76]. However, for most countries, there is still a need for support schemes for PV solar energy, as well as regulatory frameworks and promotion policies [79,82].

In summary, and in line with the current trend, the use of photovoltaic solar energy is expected to continue to be the protagonist of the global energy transition, led by expectations of further price and cost reductions in the near future [69].

Regarding Mexico, the development and research of the PV industry had its beginnings in the 70 s when, as a result of the oil crisis, the Center for Research and Advanced Studies (CINVESTAV, for its acronym in Spanish) obtained financing to build a plant for the manufacture of CFV and MFV. However, as a consequence of the economic crisis in 1982, the plant closed its operations and in this way the country canceled its participation in the ascending value chain of the PV industry [83]. This situation continued for more than 15 years, until 2003, when a plant for the assembly of MFV was installed again in the country [84]. Currently, Mexico only participates within the last link of the ascending part of the value chain of the PV industry, with a total of nine companies that are dedicated to the assembly of MFV that together have an installed production capacity of almost 1.18 GW (Table 2).

Table 2.

PV module assembly companies in Mexico in 2018.

On the other hand, when PV technology was identified as part of a social policy in the 1980s, the downstream side of the PV industry continued to develop in Mexico over three decades, increasing the participation of PV technology in the country [87,88,89]. In 2013, based on the constitutional reform implemented on the Mexican energy sector, in addition to the social niche, initiatives were developed that led to an opening of the power sector and the creation of a power market, giving the private sector the opportunity to participate in power generation and in such a market. This energy policy sought, through efficient energy and economic diversification, to attract investments to the national power sector, promoting openness and commercial competitiveness with the outside [66]. This resulted in that, in recent years, the demand of the PV industry notably increased, rising from an installed capacity of 66 MW in 2013 (before reform) to more than 6000 MW today (after reform), which notably developed this part of the value chain in Mexico.

By the end of 2021, Mexico had 93 PV power plants (Table 3), and 270,506 PV solar roofs installed throughout the country; together this adds up to an accumulated installed capacity of 8062 MW, meaning direct investments of 8550 million dollars and the generation of more than 64,000 jobs [90,91]. In terms of power generation, said installed capacity is equivalent to 20,589 GWh, representing 6.4% of total power generation of the country. This has contributed, together with other clean energy technologies, to the power sector emissions reduction. As shown in Figure 2, the total emissions from the power sector have decreased steadily since 2016, lowering from 172 MtCO2e to 139 MtCO2e by 2021. This was mainly due to the displacement of carbo electric and thermal power plants [92,93].

Table 3.

PV generation power plants in Mexico, 2021.

Figure 2.

Evolution of PV solar energy share in the generation matrix and of GHG emissions by type of technology, 2012–2021. Source: own elaboration with information from [92,93].

According to [91], it is estimated that distributed generation (DG) could increase its installed capacity at an average annual rate of 17%, while [94] estimates that power generation can increase at an average annual rate of 3.4%. Under these conditions, it is projected that PV power generation could increase its share to 8.4% (considering centralized and distributed generation). This can significantly contribute to Mexico’s goal of generating 35% of its electricity through clean energy technologies, and fulfilling the commitment established in its nationally determined contributions.

The foregoing demonstrates that both the generation of socioeconomic benefits and the fulfillment of national goals regarding climate change have the potential to become important drivers for the development of an integrated value chain of the national photovoltaic industry. This is also considering that Mexico has a solid and resilient national supply chain for the development of critical infrastructure for this industry, highlighting the importance of further analysis.

In this sense, the development of a photovoltaic industry in Mexico and its respective value chain, has been evaluated in various studies; considering the upstream and downstream value chain together [95,96,97]; or separately, the upstream side [98] and the downstream side [99]. However, none of the aforementioned studies jointly evaluate the development and integration of the value chain of the PV industry in Mexico, and the potential socioeconomic benefits derived from it. For example, those studies that evaluate both sides of the value chain do not broadly show the economic benefits derived from the development of the PV industry The study that considers only the upstream side, assesses the competitiveness of the integration of a national upstream value chain based on a tariff scenario, but not the socioeconomic benefits of such integration; while the study that considers only the downstream side, assesses the socioeconomic and macroeconomic benefits based on a scenario of increased capacity of installed PV electricity generation, but does not consider the development and integration of the value chain of the PV industry within the country. In summary, none of the reviewed studies extensively evaluate an upward integration of the value chain of the PV industry in Mexico. In this sense, and given the current situation of the PV industry in the world, in which other countries analyze the upward integration of the value chain of this industry [41,61,100], this article proposes a technical-financial model that considers technological progress and economies of scale to analyze, from a broader perspective, the development and integration of an ascending VCPVIM; determining manufacturing costs, sales prices, national content, the associated potential socioeconomic benefits and the link of said development with the fulfillment of the nationally determined contributions.

4. Materials and Methods

The methodology and the technical-financial model proposed in this article simulates the development of an upstream VCPVIM that involves production capacity increases and the progressive integration of the upstream links for the period 2018–2040. This study was carried out through the following steps:

- First, the year 2018 was established as the reference year, since the year had sufficient information to represent the current structure and production capacity of the PV industry upstream value chain in Mexico.

- Second, through a bottom-up cost model, the total manufacturing cost for the VCPVIM, the minimum sale price or minimum sustainable price (MSP) and the national content proportion were estimated for the reference year.

- Third, through a techno-economic analysis that considers technological progress and economies of scale, the total manufacturing cost for the VCPVIM, the minimum sale price or minimum sustainable price (MSP) and the national content proportion were estimated for the base and alternative scenarios.

- Finally, the socioeconomic and environmental benefits were estimated and evaluated for each scenario, focusing on job generation, added value and the link of the development of the VCPVIM with the fulfillment of the nationally determined contributions.

This was based on the construction of two scenarios: a base scenario that simulates an increase of production capacity, based on the current structure of the upstream PV value chain within the country and on its historical growth, considering that the use of imported materials and supplies dominates this scenario; and an alternative scenario that simulates, for the same period, a complete integration of the upstream processes of the PV industry value chain based on monocrystalline silicon, considering the greatest possible contribution of homeland inputs and materials.

4.1. Scenarios Construction

4.1.1. Reference Year

According to [85,101] the current structure of the VCPVIM is based only on the assembly process of MFV, with a production capacity of 1.18 GW/year, while the installed capacity for PV power generation is 5377 MW and 916 MW, for centralized generation (CG) and distributed generation (DG), respectively [91,94].

The manufacturing cost was estimated through a bottom-up cost model (Equation (1)) that considers the technical and economic variables from Table 4. Meanwhile the sale price, described as the minimum price at which a manufacturer can financially support the manufacture and sale of a good, was estimated in line to the cost proportion of manufacture of an MFV over its MSP, which is on average 87% [73]. Finally, the national content proportion (Equation (10)) was estimated, also from the information in Table 4.

Table 4.

Technical and economic variables to determine the proportion of national content and the cost of assembling a photovoltaic module in Mexico for the reference year.

4.1.2. Base Scenario

The Base Scenario was constructed considering that the structure of the upstream value chain of the PV industry in Mexico and in its national proportion content was the same as that mentioned for the reference year. This remained constant during the period 2018–2040, increasing its production capacity throughout the period, to partially cover the national demand for PV technology for electricity generation, which is estimated to grow at an average annual rate of 12.4% (considering GC and DG) [91,94,109]. Based on this information, the demand for PV technology was determined.

According to Table 5, it is estimated that the production capacity of the VCPVIM in the present scenario will grow at an average annual rate of 4.6%, which is assumed to be constant during the study period. To satisfy the national demand for PV technology, the difference between VCPVIM production capacity and such demand will be covered by imports. Likewise, if there are production surpluses, these will be added to the production capacity of the following year, with the aim of reducing imports throughout the study period.

Table 5.

Historical data on MFV manufacturing capacity in Mexico.

To estimate the manufacturing costs of the present scenario, annual manufacturing costs were calculated (Equation (1)) and adjusted according to technological progress and the increases in the VCPVIM production capacity throughout the study period, as shown in Equation (2). In line with international trends, such an increase will be in the order of 1 GW [100]. Meanwhile the MSP was calculated using the same cost proportion as in the reference year, and assumed to be constant for the entire period. To ensure the financial sustainability of the VCPVIM, the increases in production capacity will depend on the profits generated. Therefore, such profits are retained and reinvested once they reach a value equal to or greater than the investment required to increase VCPVIM production capacity, based on investment costs (capex) necessary to increase manufacturing capacity. For this, it is considered that the entire production is sold.

Finally, the socioeconomic benefits associated to this scenario were determined by evaluating their impact on added value and employment, through an input-output matrix analysis (Equations (11) and (12)) based on the information by the National Institute of Statistics and Geography (INEGI, by its acronym in Spanish) [110], including those industries that have a direct relationship with the manufacturing processes in accordance with the structure considered for the VCPVIM in the present scenario.

4.1.3. Alternative Scenario

The Alternative Scenario was constructed assuming that the upstream side of the VCPVIM is fully integrated by the year 2040, considering the following links: (i) metal grade silicon (MG-Si), (ii) polysilicon (Poly-Si), (iii) silicon ingot and wafers (Ingot), (iv) photovoltaic cells (CFV) and (v) photovoltaic modules (MFV).

As in the base scenario, it was assumed that the VCPVIM increases its production capacity to meet the national demand for PV technology. Thus, the upstream integration of the VCPVIM, as well as the increases in manufacturing capacity, can be carried out and self-financed, and the same procedure described in the base scenario is carried out. Considering also that the entire production is sold, the shortfalls to satisfy the national demand for MFV are covered with imports and production surpluses are used to reduce imports.

The manufacturing costs for this scenario were calculated using Equation (1) and adjusted with Equation (2). The adjustment in the manufacturing cost when carried out progressively will depend on the year in which both the integration and the increase in manufacturing capacity are carried out. Unlike the baseline scenario, the MSP was calculated annually as manufacturing costs change due to technological progress and capacity increases, as shown in Equation (5). Once manufacturing costs and the MSP were calculated, the proportion of national content was estimated as the VCPVIM progresses, considering a greater supply of homeland materials (Equation (10)). Finally, the socioeconomic benefits associated to this scenario were determined by Equations (11) and (12).

4.2. Calculations

4.2.1. Cost Model

The cost model was used to assume the construction, expansion, and operation of a hypothetical integrated PV industry upstream value chain in Mexico. The manufacturing of the final good of each link (), as well as the total manufacturing cost for the entire VCPVIM is expressed in US dollars per watt (USD/W) (the data and results related to costs and prices are expressed in constant dollars of 2013), and determined by the following equation:

where denotes the total manufacturing cost of the entire PV industry upstream value chain in Mexico; denotes the type of cost (materials, O&M, labor, electricity, etc.) considered to produce the products of the link i; and denotes the number of links considered for the upstream PV industry value chain: (1) MG-Si; (2) Poly-Si; (3) Ingot; (4) PV cells and (5) PV modules.

For the years following the reference year, the manufacturing cost was adjusted by a cost reduction factor (f) that it derives from the reductions generated by technological progress and the integration of links, as well as increases in production capacity [111,112,113], as shown in Equation (2):

where:

where:

where denotes the number of years (22 years) of the analysis period; denotes the year of the period in which the integration of one or more links to the VCPVIM is carried out; denotes the proportion of the reduction factor corresponding to the year in which the integration of one or more links to the VCPVIM is carried out; denotes the link of the value chain of the PV industry; denotes the number of links considered for the value chain of the photovoltaic industry; denotes the production cost of link of the VCPVIM; denotes the total manufacturing cost of the final good of the VCPVIM (the MFV). The same calculation was performed for both the Base Scenario and the Alternative Scenario. For the Base scenario, was determined from the price experience curve for MFV, considering that a reduction in the manufacturing cost generates an equivalent reduction in the sale price. In the present study, a LR of 23% was conservatively assumed. For the Alternative Scenario, was calculated from simulating the manufacturing cost of a fully upstream integration of the VCPVIM for the reference year (2018) and for the last year of the study period (2040), in line with the information regarding the technological progress of the PV industry [69,114]. With the information obtained from these simulations, we estimated that the derived from technological progress for the VCPVIM was 0.355 for the period 2018–2040 (See Table S1 of the Supplementary Materials).

In addition:

where denotes the manufacturing capacity in the year where the increase applies; denotes the manufacturing capacity in the reference year; denotes the scaling factor, with 0.376; which is obtained from the LR value considered through the relationship LR = (1 − PR) = (1 − 2-b) [111,115] and denotes the number of years (22 years) of the analysis period. The investment costs (capex) necessary to increase manufacturing capacity, as well as for the upstream integration of the value chain of the PV industry, for the reference and final years, are shown in Table S2 of the Supplementary Materials. According to [26,116,117], it is estimated that capex for equipment decreases at an annual average rate of 7.4%, while capex for facilities increases at a rate of 2.4% annual average. The value of is also progressive and depends on the increase of the VCPVIM manufacturing capacity and on the year where such increase applies.

4.2.2. Sustainable Minimum Price Model (MSP)

The MSP model estimates the minimum price at which a manufacturer can financially support the manufacture and sale of a good by simulating a discounted cash flow (CFp) for the operation of the hypothetical VCPVIM [81,101,102]. It is given by the following Equation:

With:

where denotes the number of years (22 years) of the analysis period; denotes the number of links considered for the value chain of the photovoltaic industry; i denotes the link of the VCPVIM; w denotes the discount rate that equals the weighted average cost of capital (WACC), specific for each link i and according to the subsector s of the industry to which it belongs (see, Table S3 of the Supplementary Materials) [74,118,119]; where denotes the income (net sales) of link i. Revenues result from the product of the MSP for the plant’s production capacity; denotes the manufacturing cost of the final good of link i in period p, includes costs of materials and supplies, O&M costs (4% for equipment and 3% for facilities, both of the initial investment) and labor costs; denotes an income tax (30%); denotes the depreciation cost of link i (Table S3); denotes the investment cost for link i; denotes the change in net working capital (NWC) requirements for link i, established as the difference between the three-month algebraic sum of current assets and liabilities for the current year compared to the previous year [120].

4.2.3. National Content Proportion Model

The proportion of local content is defined as the percentage that represents the value of the national direct materials and labor used in the manufacture of a good, over the total cost of production of the final good [121,122,123]. According to this definition, the proportion of national content in the value chain of the PV industry developed in Mexico () was calculated using the following equation:

where denotes the proportion of national content in the final good of link i of the of the VCPVIM, with:

where denotes the proportion of the value of national materials used to manufacture the final good of the link i of the VCPVIM; denotes the manufacturing cost of the final good of link i; denotes the total cost of the national labor used to manufacture the final good of the link i. With:

where denotes the value of the imported materials used to manufacture the final good of the link i of the VCPVIM; denotes the number of imported materials used to manufacture the final good of the link i of the VCPVIM. From the foregoing, it is understood that as the value of imported materials is replaced along the VCPVIM, the proportion of national content in the final good approaches 1.

4.2.4. Socioeconomic Benefits Model

The quantification of the economic and social impact, associated with the development of a value chain of the PV industry in Mexico, in terms of added value and job creation was carried out through an input-output model [124], using a 262 × 262 symmetric matrix with information from [110]. With this matrix, the exogenous effects of a new investment on the added value (∆VA) and employment (∆E) in each of the sectors of the national economy were determined, obtaining the added value multipliers (MVA) and employment (ME), as shown in the following equations:

where denotes the increase in the added value of sector j derived from the integration and/or capacity increase in link i of VCPVIM; denotes the multiplier of the added value of sector j; denotes the increase in the number of employees in sector j derived from the integration and/or capacity increase in link i of VCPVIM; denotes the employment multiplier of sector j; denotes the investments destined to the construction and equipping of the facilities necessary for the integration and/or capacity increase of link i to the VCPVIM; and denotes the number of years of the analysis period.

5. Results

Based on national prospects [91,94], the use of PV technology for electricity generation could increase its share from 1.3% in 2018 to 21.8% by 2040, considering both CG and DG. Meanwhile, the use of conventional technologies based on fossil fuels for electricity generation could reduce its participation from 73.7% to 52.8%, ceasing to emit around 854 MtCO2e of GHG emissions through the 22 years of the analyzed period. With this, it would be possible to improve national energy security and meet the goal of generating electricity through clean energies by 35% in 2024 [125] and reaching 46.2% by 2040. It would also be possible to keep the commitment established in the nationally determined contributions to reduce emissions in this sector by 31% in 2030 [126], where PV energy would contribute to reducing such emissions by 14.7%. However, to achieve this goal there must be an accumulated installed capacity of PV power of 82,299 MW by 2040 (Table 6).

Table 6.

Installed capacity, electricity generation and GHG emissions based on national perspectives, 2018–2040.

5.1. Baseline Scenario

According to the historical data (Table 7), it is estimated that the MFV assembly capacity of the VCPVIM in the Baseline Scenario (BS) will grow at an average annual rate of 4.6%. Based on this growth, it is determined that the upstream structure of the VCPVIM in this scenario will reach a production capacity of 3180 MW/year by 2040, with an accumulated production capacity of 38,186 MW. Thus, 46.4% of the accumulated national demand for MFV could be covered to meet national goals, while the remaining 53.6% will be covered through imports. Table 5 shows the annual evolution of VCPVIM production capacity and its surpluses, as well as imports in relation to the national demand for PV technology.

Table 7.

Evolution of the VCPVIM production capacity, costs, and prices in the Baseline Scenario, 2018–2040.

In relation to the assembly costs and sales prices of the present scenario, the cost of assembling an MFV in Mexico decreased by 52% during the analyzed period, going from 0.217 USD/W in 2018 to 0.105 USD/W in 2040. Such a reduction is mainly because the cost of the CFV decreases from 0.094 to 0.045 USD/W. With respect to the MSP, this decreases from 0.249 USD/W to 0.120 USD/W by 2040. Considering the above, to satisfy the national demand for PV technology for electricity generation in the present scenario, a cumulative total of 13,330 M USD must be invested throughout the study period; where 59% corresponds to the total sales of VCPVIM production, and 41% corresponds to the total value of imports of PV technology (MFV) (Table 7).

Regarding the proportion of national content (PCN), this remains constant in relation to the reference year, because the present scenario does not consider the incorporation of more links. It is estimated that this has a value of 0.08, considering that the labor is totally of national origin and 0.06 if only the use of materials is considered, as shown in Table 8. This is because of the lack of national materials in the assembly of the MFV, since it is considered that the only national input is the “packaging” (Section S2, Table S5 in Supplementary Materials).

Table 8.

Proportion of national content of the VCPVIM in the reference year.

Finally, to increase the VCPVIM production capacity from 1.18 GW to 3.18 GW, according to the present scenario, a total investment of 149.2 M USD is needed (Table S11 of Section S2 in Supplementary Materials). From which a direct added value of 756.5 M USD and an indirect added value of 810.7 M USD can be generated, as well as approximately 1025 direct jobs and 43,681 indirect jobs throughout the entire period. Most of both the indirect value added (80%) and the indirect jobs generated (78%) correspond to the construction industry sector, derived from increases in the VCPVIM production capacity, as shown in Table 9.

Table 9.

Total socioeconomic benefits of the VCPVIM in the Baseline Scenario.

5.2. Alternative Scenario

According to the results obtained, this scenario shows that a development and complete integration of the upstream links of the value chain of the PV industry in Mexico is possible and economically viable. In terms of cumulative production, Table 10 shows that a fully integrated VCPVIM could satisfy 76% of the national demand of PV technology by producing a cumulative total of 62,186 MW by 2040, producing 1.6 times higher than the cumulative production of the BS. Imports of this technology are 47% lower in this Alternative Scenario (AS) in relation to BS, reducing from 42,113 MW to 23,412 MW.

Table 10.

Evolution of the VCPVIM production capacity, costs, and prices in the Alternative Scenario.

Continuing with the development of the AS, Table 11 shows that the manufacturing cost is reduced by 49.3% towards 2040 with respect to the reference year, lowering from 0.217 to 0.110 USD/W. This is derived from both the complete integration of the VCPVIM (35.5%) and the increases in production capacity (13.8%) throughout the period, indicating that the influence of technological progress is greater on reducing costs than on economies of scale.

Table 11.

Manufacturing costs and MSP in the Alternative Scenario, 2018–2040.

Likewise, Figure 3 presents the evolution of the decrease in manufacturing costs in the AS, where manufacturing PV technology results in a higher cost compared to the BS, averaging a difference of 24% between the years 2018 and 2025. However, once the MFV, CFV and Ingot links are integrated, which together represent more than 80% of the total manufacturing cost, and added to the increases in production capacity, the difference between these costs decreases to finally reach 5% when the VCPVIM is fully integrated by 2040. This is reflected in the MSP estimated for this AS, which is reduced by 46% with respect to the price of the reference year, lowering from 0.249 to 0.135 USD/W.

Figure 3.

Evolution in the development of the Alternative Scenario and its impact on the decrease in manufacturing costs in relation to the Baseline Scenario, 2018–2040. Source: own elaboration.

Regarding the PCN, Table 12 shows that it increases, in terms of the use of materials and supplies of national origin for the manufacture of each of the final products of each link of the VCPVIM, as its upstream integration progresses throughout the AS. Since the Ingot and MG-Si links are the only links that use materials and supplies considered as imported in their manufacturing processes towards the end of the analyzed period, these links do not reach a 100% proportion in the use of materials or supplies of national origin. Materials and supplies considered imported can be seen in Table S5 of Section S2 in Supplementary Materials.

Table 12.

Proportion of materials and supplies of national origin in the manufacture of the final products of each link of the VCPVIM in the Alternative Scenario.

Likewise, Table 13 indicates the final PCN in terms of the integration of the VCPVIM links. The PCN increases by more than 80% with respect to the reference year once the VCPVIM is fully integrated towards the last year of the study period. The MFV link is the one that most contributes to the increase of the PCN.

Table 13.

Proportion of national content of each link of the VCPVIM in the Alternative Scenario.

In relation to socioeconomic benefits, with the development of this scenario, a total of 10,364 direct jobs and 447,222 indirect jobs can be generated, where, similar to the BS, the sector that benefits the most from the development of the VCPVIM is the construction industry, since this sector represents 83% of indirect jobs (Table 12). However, it must be remembered that these jobs are not permanent, as they are generated only while new facilities are being built by increasing production capacity and integrating links. In terms of permanent jobs, the present scenario generates 10.2 times more jobs than the BS. At the same time, it can generate a direct added value of 3194.2 M USD and an indirect value of 8967.7 M USD (Table 14), the total being 7.8 times added value than BS. In terms of total accumulated production capacity, for every one MW produced, seven jobs are generated and an added value greater than 149,000 USD. The total investment needed to carry out this Alternative Scenario is about 1715 M USD, which is 11.5 times more than the BS (see Section S2, Tables S11 and S12).

Table 14.

Total socioeconomic benefits of the development and integration of the VCPVIM in the Alternative Scenario by 2040.

Finally, Table 15 shows the jobs and added value generated in each link of the VCPVIM, as this is integrated throughout the development of the EA. Both the added value and the number of jobs increase with the integration of links to the VCPVIM, with the CFV manufacturing link being the one that generates the most jobs and added value, followed by the link for the manufacture of Poly-Si. Together, these two links represent approximately 61% and 54% of the total generation of jobs and of the total added value generated, respectively, by 2040. This emphasizes the importance of having those links of a strategic nature that ensure the supply of the main inputs for the development of a value chain of the national PV industry.

Table 15.

Job creation and added value evolution in terms of the integration of VCPVIM links in the Alternative Scenario, 2018–2040.

6. Conclusions

In this study, we presented a methodology and an economic model that considered the impact of the progress of PV technology and economies of scale to simulate and evaluate the feasibility of a possible development and upstream integration of a value chain of the PV industry in Mexico (VCPVIM), and its potential generation of socioeconomic benefits for the country by the year 2040.

Our analysis showed that such development and integration of the VCPVIM can be self-financing and economically viable, enabling the generation of more than 447,000 jobs (20,318 jobs/year on average over the 22 years of the analyzed period). This figure is in line with the number of jobs that were annually generated during 2019 in the PV industry of other countries, such as China (2 million), USA (36,000) and India (38,760) [127]. In addition, an added value greater than 12,000 M USD, allows to gradually increase the value of national content of the VCPVIM, reaching 89% by 2040. It also satisfies 76% of the national demand for PV technology for said year, through which it is possible to contribute to the fulfillment of the national goals of clean energy and mitigation of GHG emissions; as well as to improve national energy security by using renewable energy resources, and ensure inputs and key components for this industry. All this, through an investment of more than 1700 M USD over the period 2018–2040. In addition, it also shows that it is possible to increase production capacities, not only to meet national demand, but to open other markets and release production to other countries. This avoids cuts in the supply of photovoltaic technology, especially in Central and South America, which would benefit the global supply chain.

However, to promote such innovation, diversification, and better insertion of value chains in specific sectors, all in the context of an open economy, the market and the public and private sectors must complement each other and cooperate constructively within an institutional framework that guarantees transparency and efficiency. Given that the implementation of industrial policies necessarily occurs from an intimate interaction between these two actors, the capacities of both and the type of relationship they establish will largely determine the results of these policies. Under this perspective, if the government has a genuine vision of development, and has the appropriate institutional framework, it can build broad formal and informal agreements with a common long-term vision with the private sector, focused on promoting a profound productive transformation, strengthening in this way the formation of human capital, the technological appropriation, and the strategic development of certain sectors of the economy.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/en16042072/s1, Table S1: Change in technical and economic variables derived from technological progress considering a complete integration of the VCPVIM in the year 2018 and 2040; Table S2: Capex per link of the value chain of the PV industry for the years 2018 and 2040; Table S3. Discount rate and number of periods per link to prepare the cash flow; Table S4: Total socioeconomic benefits of the VCPVIM in the Base Scenario; Table S5: Manufacturing costs derived from the upstream integration of VCPVIM in the Alternative Scenario; Table S6: Total socioeconomic benefits by subsector in the Alternative Scenario for the MFV link; Table S7: Total socioeconomic benefits by subsector in the Alternative Scenario for the CFV link; Table S8: Total socioeconomic benefits by subsector in the Alternative Scenario for the Ingot link; Table S9: Total socioeconomic benefits by subsector in the Alternative Scenario for the Poly-Si link; Table S10: Total socioeconomic benefits by subsector in the Alternative Scenario for the MG-Si link; Table S11: Cash flow for the Baseline Scenario, 2018–2040; Table S12: Cash flow for the Alternative Scenario, 2018–2040; Figure S1: Evolution of the share of PV energy on electricity generation, 2018–2040; Figure S2: Avoided emissions evolution derived from the increase in the share of clean energies on electricity generation, 2018–2040; Figure S3: Cumulative capacity evolution of PV generation plants, 2018–2040.

Author Contributions

Conceptualization, J.M.I.-S.; methodology, J.M.I.-S., M.O.B.-E., Á.d.l.V.-N. and A.M.-A.; software, M.O.B.-E.; validation, J.M.I.-S., M.O.B.-E., Á.d.l.V.-N. and A.M.-A.; formal analysis, J.M.I.-S. and M.O.B.-E.; investigation, M.O.B.-E. and J.M.I.-S.; resources, J.M.I.-S.; data curation, M.O.B.-E.; writing—original draft preparation, M.O.B.-E. and J.M.I.-S.; writing—review and editing, J.M.I.-S., M.O.B.-E., Á.d.l.V.-N. and A.M.-A.; visualization, M.O.B.-E.; supervision, J.M.I.-S., Á.d.l.V.-N. and A.M.-A.; project administration, J.M.I.-S.; funding acquisition, J.M.I.-S. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the SENER-CONACYT Sustainability Energy 2017 by the Call [291239] through the scholarship of the Doctorate Program [001484].

Data Availability Statement

Not applicable.

Acknowledgments

The authors thank María de Jesús Pérez Orozco and Genice Kirat Grande Acosta for the technical support granted.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| AS | Alternative Scenario |

| BS | Baseline Scenario |

| CINVESTAV | Spanish acronym for Center for Research and Advanced Studies |

| CFV | PV cells |

| CG | Centralized Generation |

| CVD | Chemical Vapor Deposition |

| Cz | Czochralski |

| DG | Distributed Generation |

| GHG | Greenhouse Gases |

| GW | Giga Watt |

| GWh | Giga Watt Hour |

| MFV | PV modules |

| MG-Si | Magnesium Silicide |

| MSP | Minimum Sustainable Price |

| MtCO2e | Million Tons of Carbon Dioxide Equivalent |

| MUSD | Million US Dollar |

| MW | Megawatt |

| O&M | Operations and maintenance |

| PCN | Proportion of national content |

| PCNB | Proportion of national content in the final good of the link |

| PCNM | Proportion of the value of national materials used to manufacture the final good of the link |

| Poly-Si | Polycrystalline silicon |

| PV | Photovoltaic |

| USD | US Dollar |

| VCPVIM | Value Chain of the PV Industry in Mexico |

| W | Watt |

References

- Porter, M. Competitive Strategy: The Core Concepts. In Competitive Advantage: Creating and Sustaining Superior Performance; The Free Press. A Division of Macmillan, Inc.: New York, NY, USA, 1985; p. 32. ISBN 0-02-925090-0. [Google Scholar]

- Kaplinsky, R.; Morris, M. A Handbook for Value Chain Research; University of Sussex, Institute of Development Studies: Brighton, UK, 2002; p. 113. [Google Scholar]

- Food and Agriculture Organization of the United Nations (FAO). Guidelines for Value Chain Analysis. Available online: https://www.fao.org/3/bq787e/bq787e.pdf (accessed on 9 December 2022).

- Helmsing, B.; Vellema, S. Value Chains Governance and Inclusive Endogenous Development: Towards a Knowledge Agenda; Development Policy Review Network (DPRN): Amsterdam, The Netherlands, 2011; p. 63. [Google Scholar]

- Bijman, J.; Ton, G. Producer Organisations and Value Chains. Capacit. Org. 2008, 34, 16. [Google Scholar]

- United States Agency for International Development (USAID). A Synthesis of Practical Lessons from Value Chain Projects in Conflict-Affected Environments, Report Value Chain Development in Conflict Affected Environments Project; USAID: Washington, DC, USA, 2008; p. 42.

- Bolwig, S. Integrating Poverty and Environmental Concerns into Value-Chain Analysis: A Conceptual Framework. Dev. Policy Rev. 2010, 28, 173–194. [Google Scholar] [CrossRef]

- Department for International Development (DFID). Private Sector Development Strategy Prosperity for All: Making Markets Work; DFID: London, UK, 2008; p. 52.

- Grossmann, H.; Bagwitz, D.; Elges, R.; Kruk, G.; Lange, R. Sustainable Economic Development in Conflict-Affected Environments: A Guidebook. Available online: https://reliefweb.int/report/world/sustainable-economic-development-conflict-affected-environments-guidebook (accessed on 9 December 2022).

- Chang, H. Industrial Policy: Can We Go beyond an Unproductive Confrontation? In Proceedings of the Annual World Bank Conference on Development Economics 2010, Global, Seoul, Republic of Korea, 22–24 June 2009; p. 27. [Google Scholar]

- Comisión Económica para América Latina y el Caribe (CEPAL). Theory and Practice of Industrial Policy. Evidence from the Latin American Experience; CEPAL: Santiago de Chile, Chile, 2009; p. 51. [Google Scholar]

- Lim, G.; Teo, J.K. Climbing the Economic Ladder: The Role of Outward Foreign Direct Investment. J. Asian Public Policy 2018, 12, 312–329. [Google Scholar] [CrossRef]

- Horner, R.; Alford, M. The Roles of the State in Global Value Chains: An Update and Emerging Agenda; GDI Working Paper 2019-036; The University of Manchester: Manchester, UK, 2019; p. 26. [Google Scholar]

- Altenburg, T.; Assmann, C. Green Industrial Policy: Concept, Policies, Country Experiences; UN Environment; German Development Institute/Deutsches Institut für Entwicklungspolitk (DIE): Geneva, Switzerland; Bonn, Germany, 2017; p. 240. [Google Scholar]

- United Nations Industrial Development Organization (UNIDO). Industrial Development Report 2018. Demand for Manufacturing: Driving Inclusive and Sustainable Industrial Development; UNIDO: Vienna, Austria, 2017; p. 274. ISBN 978-92-1-106455-1. [Google Scholar]

- Fay, M.; Hallegatte, S.; Vogt-Schilb, A.; Rozenberg, J.; Narloch, U.; Kerr, T.M. Decarbonizing Development: Three Steps to a Zero-Carbon Future. Climate Change and Development; World Bank Publications: Washington, DC, USA, 2015; ISBN 1-4648-0606-3. [Google Scholar]

- Srai, J.S.; Harrington, T.S.; Tiwari, M.K. Characteristics of Redistributed Manufacturing Systems: A Comparative Study of Emerging Industry Supply Networks. Int. J. Prod. Res. 2016, 54, 6936–6955. [Google Scholar] [CrossRef]

- Hsu, J.; Chuang, Y.P. International Technology Spillovers and Innovation: Evidence from Taiwanese High-Tech Firms. J. Int. Trade Econ. Dev. 2014, 23, 387–401. [Google Scholar] [CrossRef]

- Schwab, K. The Fourth Industrial Revolution. Economía 2016, XVI, 194–197. [Google Scholar]

- Borbonus, S. Generating Socio-Economic Values from Renewable Energies; Institute for Advanced Sustainability Studies (IASS): Postdam, Germany, 2017; p. 32. [Google Scholar]

- Zawaydeh, S. Economic, Environmental and Social Impacts of Development of Energy from Sustainable Resources—Case Study; World Energy Engineering Congress: Orlando, FL, USA, 2015; p. 21. [Google Scholar]

- International Renewable Energy Agency (IRENA). The Socio-Economic Benefits of Solar and Wind Energy; IRENA: Abu Dhabi, United Arab Emirates, 2014; p. 108. [Google Scholar]

- International Energy Agency (IEA). Renewables 2020. Analysis and Forecast to 2025; IEA: Paris, France, 2020; p. 172. [Google Scholar]

- International Renewable Energy Agency (IRENA). Global Energy Transformation: A Roadmap to 2050; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2019; p. 52. ISBN 978-92-9260-121-8. [Google Scholar]

- Wang, X.; Barnett, A. The Evolving Value of Photovoltaic Module Efficiency. Appl. Sci. 2019, 9, 1227. [Google Scholar] [CrossRef]

- Powell, D.M.; Fu, R.; Horowitz, K.; Basore, P.A.; Woodhouse, M.; Buonassisi, T. The Capital Intensity of Photovoltaics Manufacturing: Barrier to Scale and Opportunity for Innovation. Energy Environ. Sci. 2015, 8, 3395–3408. [Google Scholar] [CrossRef]

- Okioga, I.T.; Wu, J.; Sireli, Y.; Hendren, H. Renewable Energy Policy Formulation for Electricity Generation in the United States. Energy Strategy Rev. 2018, 22, 365–384. [Google Scholar] [CrossRef]

- Zou, H.; Du, H.; Ren, J.; Sovacool, B.K.; Zhang, Y.; Mao, G. Market Dynamics, Innovation, and Transition in China’s Solar Photovoltaic (PV) Industry: A Critical Review. Renew. Sustain. Energy Rev. 2017, 69, 197–206. [Google Scholar] [CrossRef]

- Ayoo, C. Towards Energy Security for the Twenty-First Century. In Energy Policy; Taner, T., Ed.; Intechopen: London, UK, 2020; p. 26. ISBN 978-1-78923-874-7. [Google Scholar]

- European Commission. A Clean Planet for All. A European Long-Term Strategic Vision for a Prosperous, Modern, Competitive and Climate Neutral Economy; European Commission: Brussels, Belgium, 2018; p. 25. [Google Scholar]

- Hache, E. Do Renewable Energies Improve Energy Security in the Long Run? Int. Econ. 2018, 156, 127–135. [Google Scholar] [CrossRef]

- International Renewable Energy Agency (IRENA). NDCs in 2020: Advancing Renewables in the Power Sector and Beyond; IRENA: Abu Dhabi, United Arab Emirates, 2019; p. 40. ISBN 978-92-9260-168-3. [Google Scholar]

- García-Gusano, D.; Iribarren, D. Prospective Energy Security Scenarios in Spain: The Future Role of Renewable Power Generation Technologies and Climate Change Implications. Renew. Energy 2018, 126, 202–209. [Google Scholar] [CrossRef]

- Wang, B.; Wang, Q.; Wei, Y.M.; Li, Z.P. Role of Renewable Energy in China’s Energy Security and Climate Change Mitigation: An Index Decomposition Analysis. Renew. Sustain. Energy Rev. 2018, 90, 187–194. [Google Scholar] [CrossRef]

- International Renewable Energy Agency (IRENA). Future of Solar Photovoltaic: Deployment, Investment, Technology, Grid Integration and Socio-Economic Aspects (A Global Energy Transformation: Paper); International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2019; p. 73. ISBN 978-92-9260-156-0. [Google Scholar]

- International Renewable Energy Agency (IRENA). Renewable Energy and Jobs: Annual Review 2019; IRENA: Abu Dhabi, United Arab Emirates, 2019; p. 40. [Google Scholar]

- Brown, M.; Wang, Y.; Sovacool, B.; D’Agostino, A. Forty Years of Energy Security Trends: A Comparative Assessment of 22 Industrialized Countries. Energy Res. Soc. Sci. 2014, 4, 64–77. [Google Scholar] [CrossRef]

- Silberglitt, R.S.; Bartis, J.T.; Chow, B.G.; An, D.L.; Brady, K. Critical Materials: Present Danger to U.S. Manufacturing; Rand Corporation: Santa Monica, CA, USA, 2013; ISBN 0-8330-7927-1. [Google Scholar]

- Lunde Seefeldt, J. Lessons from the Lithium Triangle: Considering Policy Explanations for the Variation in Lithium Industry Development in the “Lithium Triangle” Countries of Chile, Argentina, and Bolivia. Polit. Policy 2020, 48, 727–765. [Google Scholar] [CrossRef]

- European Commission. Report on Critical Raw Materials and the Circular Economy; Publications Office of the European Union: Brussels, Belgium, 2018; p. 78. ISBN 978-92-79-94626-4. [Google Scholar]

- Solar Energy Industries Association (SEIA). The Solar+ Decade & American Renewable Energy Manufacturing. 100 GW by 2030; Solar Energy Industries Association: Washington, DC, USA, 2020; p. 10. [Google Scholar]

- Shum, R.Y. Heliopolitics: The International Political Economy of Solar Supply Chains. Energy Strateg. Rev. 2019, 26, 100390. [Google Scholar] [CrossRef]

- Greentech InDetail. Polysilicon: Supply, Demand & Implications for the PV Industry; Greentech Media Inc.: Boston, MA, USA, 2008; p. 134. [Google Scholar]

- Bernreuter, J. Polysilicon Manufacturers: How the Ranking of the Top Ten Producers Has Been Whirled around Since 2004. Available online: https://www.bernreuter.com/polysilicon/manufacturers/ (accessed on 12 December 2022).

- Comisión Nacional de Hidrocarburos (CNH). Análisis de Reservas de Hidrocarburos 1P, 2P, 3P. Available online: https://www.gob.mx/cms/uploads/attachment/file/460767/Analisis_de_Reservas_1P_2P_3P_2019._vf-cnh-web.pdf (accessed on 12 December 2022).

- Secretaría de Energía (SENER). Balance Nacional de Energía 2018; SENER: Mexico City, Mexico, 2019; p. 125.

- de la Vega-Navarro, A. Énergies Fossiles et Énergies Renouvelables: La Place Du Mexique Dans l’ Intégration et La Transition Énergétique En Amérique Du Nord; Centre d’études et de recherches internationales, Université de Montréal: Montreal, QC, Canadá, 2017; p. 52. [Google Scholar]

- Winzer, C. Conceptualizing Energy Security. Energy Policy 2012, 46, 36–48. [Google Scholar] [CrossRef]

- Valentine, S.V. Emerging Symbiosis: Renewable Energy and Energy Security. Renew. Sustain. Energy Rev. 2011, 15, 4572–4578. [Google Scholar] [CrossRef]

- Jun, E.; Kim, W.; Chang, H. The Analysis of Security Cost for Different Energy Sources. Appl. Energy 2009, 86, 1894–1901. [Google Scholar] [CrossRef]

- Yergin, D. Ensuring Energy Security. Foreign Aff. 2006, 85, 69–82. [Google Scholar] [CrossRef]

- Intharak, N.; Julay, J.; Nakanishi, S.; Matsumoto, T.; Sahid, E.; Aquino, A. A Quest for Energy Security in the 21st Century; Asia Pacific Energy Research Centre: Tokyo, Japan, 2007; p. 113. [Google Scholar]

- Badea, A.; Rocco, S.; Tarantola, S.; Bolado, R. Composite Indicators for Security of Energy Supply Using Ordered Weighted Averaging. Reliab. Eng. Syst. Saf. 2011, 96, 651–662. [Google Scholar] [CrossRef]

- Grande-Acosta, G.; Islas-Samperio, J. Towards a Low-Carbon Electric Power System in Mexico. Energy Sustain. Dev. 2017, 37, 99–109. [Google Scholar] [CrossRef]

- García-Gusano, D.; Iribarren, D.; Garraín, D. Prospective Analysis of Energy Security: A Practical Life-Cycle Approach Focused on Renewable Power Generation and Oriented towards Policy-Makers. Appl. Energy 2017, 190, 891–901. [Google Scholar] [CrossRef]

- Sandor, D.; Fulton, S.; Engel-Cox, J.; Peck, C.; Peterson, S. System Dynamics of Polysilicon for Solar Photovoltaics: A Framework for Investigating the Energy Security of Renewable Energy Supply Chains. Sustainability 2018, 10, 160. [Google Scholar] [CrossRef]

- International Renewable Energy Agency (IRENA). REN 21. Renewables 2017 Global Status Report; IRENA: Paris, France, 2017; p. 302. ISBN 978-3-9818107-6-9. [Google Scholar]

- Johansson, B. Security Aspects of Future Renewable Energy Systems-A Short Overview. Energy 2013, 61, 598–605. [Google Scholar] [CrossRef]

- Klitkou, A.; Coenen, L. The Emergence of the Norwegian Solar Photovoltaic Industry in a Regional Perspective. Eur. Plan. Stud. 2013, 21, 1796–1819. [Google Scholar] [CrossRef]

- Dewald, D.; Truffer, B. Market Formation in Technological Innovation Systems—Diffusion of Photovoltaic Applications in Germany. Ind. Innov. 2011, 18, 285–300. [Google Scholar] [CrossRef]

- Gallagher, J.; Lopez, C.; Mah, J.; McGarrigle, A.; McGarrigle, P.; Olien, L. Alberta’s Solar PV Value Chain Opportunities; Solas Energy Consulting Inc.: Calgary, AB, Canada, 2018; p. 63. [Google Scholar]

- Sustainable Energy Authority of Ireland (SEAI). Ireland’s Solar Value Chain Opportunity; SEAI: Dublin, Ireland, 2017; p. 78. [Google Scholar]

- Johnson, O. Promoting Green Industrial Development through Local Content Requirements: India’s National Solar Mission. Clim. Policy 2016, 16, 178–195. [Google Scholar] [CrossRef]

- Meckling, J.; Hughes, L. Protecting Solar: Global Supply Chains and Business Power. New Polit. Econ. 2018, 23, 88–104. [Google Scholar] [CrossRef]

- Secretaría de Energía (SENER). Estrategia Nacional de Energía 2013–2027; SENER: Mexico City, México, 2013; p. 74.

- Diario Oficial de la Federación (DOF). Ley de La Industria Eléctrica. Available online: https://www.dof.gob.mx/nota_detalle.php?codigo=5355986&fecha=11/08/2014#gsc.tab=0 (accessed on 12 December 2022).

- Diario Oficial de la Federación (DOF). Ley de Hidrocarburos. Available online: https://www.dof.gob.mx/nota_detalle.php?codigo=5355989&fecha=11/08/2014#gsc.tab=0 (accessed on 12 December 2022).

- International Energy Agency (IEA). Solar PV Module Manufacturing and Demand 2014–2020. Available online: https://www.iea.org/data-and-statistics/charts/solar-pv-module-manufacturing-and-demand-2014-2020 (accessed on 12 December 2022).

- VDMA Photovoltaic Equipment. International Technology Roadmap for Photovoltaic (ITRPV)–2019 Results; VDMA: Frankfurt am Main, Germany, 2020; p. 88. [Google Scholar]

- Oliveira, V.D.D. Tapping of Metallurgical Silicon Furnaces–A Brief Comparison between Continuous and Discontinuous Processes; Furnace Tapping Conference 2018; Southern African Institute of Mining and Metallurgy: Kruger Park, South Africa, 2018; p. 13. [Google Scholar]

- Xakalashe, B.S.; Tangstad, M. Silicon Processing: From Quartz to Crystalline Silicon Solar Cells. In Proceedings of the Southern African Pyrometallurgy 2011 International Conference, Johannesburg, South African, 6–9 March 2011; p. 18. [Google Scholar]

- Myrvågnes, V. Analyses and Characterization of Fossil Carbonaceous Materials for Silicon Production. Ph.D. Thesis, Norwegian University of Science and Technology Faculty of Natural Sciences and Technology Department of Materials Science and Engineering, Torgarden, Norway, 2008; p. 248. [Google Scholar]

- National Renewable Energy Laboratory (NREL). Crystalline Silicon Photovoltaic Module Manufacturing Costs and Sustainable Pricing: 1H 2018 Benchmark and Cost Reduction Roadmap; NREL: Washington, DC, USA, 2020; p. 58.

- Fu, R.; James, T.L.; Woodhouse, M. Economic Measurements of Polysilicon for the Photovoltaic Industry: Market Competition and Manufacturing Competitiveness. IEEE J. Photovolt. 2015, 5, 515–524. [Google Scholar] [CrossRef]

- Kumar, A.; Bieri, M.; Reindl, T.; Aberle, A.G. Economic Viability Analysis of Silicon Solar Cell Manufacturing: Al-BSF versus PERC. Energy Procedia 2017, 130, 43–49. [Google Scholar] [CrossRef]

- REN21. Renewables 2020 Global Status Report; REN21 Secretariat: Paris, France, 2020; p. 367. ISBN 978-3-948393-00-7. [Google Scholar]

- Hannen, P. China Shakes PV World. Available online: https://www.pv-magazine.com/2018/06/05/china-shakes-pv-world/ (accessed on 10 November 2021).

- Shaw, V. China Releases New Provisions for PV Development in 2018. PV Magazine, 1 June 2018. Available online: https://www.pv-magazine.com/2018/06/01/china-releases-new-provisions-for-pv-development-in-2018/ (accessed on 12 November 2021).

- International Energy Agency (IEA PVPS). Trends in Photovoltaic Applications 2019; IEA PVPS: Rheine, Germany, 2019; p. 98. [Google Scholar]

- Clean Energy Council (CEC). Clean Energy Australia Report 2019. Clean Energy Council: Melbourne, Asutralia, 2019; p. 82. [Google Scholar]

- MERCOM. Clean Energy Insights, India’s Rooftop Solar Market–Where Is It Now and Where Is It Going? Available online: https://mercomindia.com/rooftop-solar-where-its-going-intersolar/ (accessed on 10 December 2021).

- SolarPowerEurope SolarPower Europe’s Global Market Outlook 2019–2023. Available online: https://www.solarpowereurope.org/insights/webinars/global-market-outlook-solar-2019-2023 (accessed on 26 February 2022).

- Centro de Investigación y de Estudios Avanzados del Instituto Politécnico Nacional (CINVESTAV). Historia Del Departamento de Ingeniería Eléctrica. Available online: https://ie.cinvestav.mx/conoce-ie/historia (accessed on 12 October 2020).

- Iniciativa Climática México (ICM). Instituto Nacional de Eletricidad y Energías Limpial (INEEL). Cadena de Valor de La Generación Distribuida Fotovoltaica En México; ICM, INEEL: Mexico City, México, 2019; p. 131.

- Bellini, E. Nadie Dijo Fácil: Industria En América Latina. Available online: https://www.pv-magazine-latam.com/2018/09/12/nadie-dijo-facil-industria-en-america-latina/ (accessed on 12 December 2022).

- Secretaría de Economía. Registro de Proveedores de La Industria Eléctrica. Available online: http://www.proveedores-energia.economia.gob.mx/regprov/#/busquedaPublica/electrica (accessed on 13 August 2018).

- Islas-Samperio, J.M.; Grande-Acosta, G.K.; Carrasco-González, F.; Valenzuela, J.M. La Era Fotovoltaica En México, 1st ed.; Reflexio, Academia y Comunicación, S. de R.L. y C.V.: Mexico City, México, 2020; ISBN 978-607-97089-2-4. [Google Scholar]

- Sánchez-Juárez, A.; Martínez-Escobar, D.; de la Luz Santos Magdaleno, R.; Ortega-Cruz, J.; Sánchez-Pérez, P.A. Aplicaciones Fotovoltaicas de La Energía Solar En Los Sectores Residencial, Servicio e Industrial, 1st ed.; Mazón, J.T., Ed.; Consejo Nacional de Ciencia y Tecnología (CONACYT): Mexico City, Mexico, 2017; p. 316. ISBN 978-5-230-41732-3.

- Auditoria Superior de la Federación (ASF). Informe Del Resultado de La Fiscalización Superior de La Cuenta Pública 2011. Available online: https://www.asf.gob.mx/uploads/55_Informes_de_auditoria/Mensaje_IRCP_2011.pdf (accessed on 12 December 2022).

- Asociación Mexicana de Energía Solar (ASOLMEX). Centrales Solares. Available online: https://asolmex.org/centrales-solares/ (accessed on 12 November 2020).

- Comisión Reguladora de Energía (CRE). Contratos Interconexión de Pequeña y Mediana Escala/Generación Distribuida Solicitudes de Interconexión de Centrales Eléctricas Con Capacidad Menor a 0.5 MW; CRE: Mexico City, México, 2022; p. 8.

- Instituto Nacional de Ecología y Cambio Climático (INECC). Inventario Nacional de Emisiones de Gases y Compuestos de Efecto Invernadero (INEGYCEI), 1990–2020; INECC: Mexico City, México, 2022.

- Secretaría de Energía (SENER). Balance Nacional de Energía 2017; SENER: Mexico City, México, 2018; p. 129.

- Secretaría de Energía (SENER). Programa de Desarrollo Del Sistema Eléctrico Nacional (PRODESEN) 2019–2033. Available online: https://www.gob.mx/sener/articulos/prodesen-2019-2033-221654 (accessed on 12 December 2022).

- Secretería de Energía (SENER). Mapa de Ruta Tecnológica Para La Industria Solar Fotovoltaica; SENER: Mexico City, México, 2017; p. 72.

- Instituto Mexicano del Petróleo (IMP). Reporte de Inteligencia Tecnológica-Energía Solar Fotovoltaica; IMP: Mexico City, México, 2017; p. 84.

- Instituto Mexicano del Petróleo (IMP). Cartera de Necesidades de Innovación y Desarrollo Tecnológico: Energía Solar Fotovoltaica; Towards Energy Security for the Twenty-First Century; IMP: Mexico City, México, 2017; p. 39.