Abstract

Transport costs are strongly influenced by fuel prices and fuel consumption in transport, i.e., energy efficiency. The aim of the article is to present the problem of energy efficiency in freight transport with the use of Heavy Duty Vehicles (HDV). The authors presented the factors of energy efficiency in road transport, energy efficiency of the road vehicles, the share of fuel costs in the total costs of transport companies and the relationship between the increase in fuel prices and the increase in transport rates. Research methods include, apart from literature analysis, interviews conducted in Polish transport companies in 2022 and the analysis of data collected by the authors on the transport services market over the last 20 years. The increase in rates over the last 20 years, until 2021, largely coincided with the increase in fuel prices, while in 2022, for the first time in this period, the increase in fuel prices was greater than the increase in rates. However, the prices for transport services increased with the increase in energy consumption costs, not with changes in fuel prices. The cost of energy consumption depends on the efficiency of its use, which is constantly increasing, although to a small extent. Research shows that the efficiency of fuel consumption in high-tonnage transport changes at a rate of 0.8–1% per year while the proportion of fuel costs in Polish transport companies transporting goods by road in the last 20 years oscillates between 29% and 46%. There was also an increase in the freight rates on this market, in most cases by over 30%. Despite this, however, the profitability of some companies deteriorated. A large increase in transport rates, compensating for the increase in fuel prices, applies mainly to transport companies whose strategy is to compete with the quality of services, and when high-value loads are transported, while a small increase in transport rates, which does not compensate for the increase in fuel prices, applies mainly to companies whose strategy is to compete on the price of transport services and when low-value cargo is being transported. The results of research on the market in Poland conducted by the authors of the article agrees with the results and opinions of other authors and researchers from other countries. The authors also agree with the view that the possibilities of increasing the efficiency of energy consumption in road transport by the carriers themselves are limited. The road transport market, especially in Poland, is highly competitive, which results in high efficiency of transport processes. However, this efficiency is largely affected by factors beyond the control of these companies (technological factors, infrastructure and energy sources). It seems that the involvement of the state is necessary. The research carried out by the authors of the article also confirmed the existing relationships between the weight of the transported cargo and energy consumption identified by other authors.

1. Introduction

Transport costs have a very large, usually the largest, share in logistics costs. Transport costs are strongly influenced by fuel prices on the one hand, and fuel consumption in transport, i.e., energy efficiency, on the other. Fuel costs account for a large proportion of the total cost of a transportation company. For example, they typically account for around 32–33 per cent of the running costs of trucks (38 to 44 tonnes GVW) in the UK [1]. The results obtained by the authors of the article on the Polish market are similar—they amount to 30–40% (average 36%). They will be presented later in the article.

Energy consumption in transport companies depends on various factors, both technical and organizational. Technical progress in transport, including road transport, is very high, which may result in increased energy efficiency. However, the energy prices have a large impact on the profitability of companies. The problem of energy consumption is all the more important, especially since transport is considered to be the sector with the greatest potential for energy savings [2].

The aim of the article is to present the problem of energy efficiency in freight transport, with particular emphasis on road transport, which in Europe has the largest share in freight transport, with the use of Heavy Duty Vehicles.

In this article the energy efficiency is measured by the amount of energy used in the transport process or the amount of fuel consumed by one vehicle per km.

This issue is very important because energy consumption in transport affects the costs of transport companies, and thus the costs of their customers, as well as the external costs of transport. There is a conflict of interests between entrepreneurs and their environment. Companies often make decisions unfavorable for the environment, e.g., frequent deliveries in small quantities, the use of transport with higher external costs. On the other hand, increasing the efficiency of business processes, including logistics, and within them, transport, should also lead to a reduction in the negative impact of these processes on the natural environment. Better efficiency of these processes results in a reduction in the consumption of production resources (raw materials, materials, energy).

The authors of the article were inspired to take up this topic by two phenomena that had a very large impact on the efficiency of logistics processes: the COVID-19 pandemic and the energy crisis. During this period, freight rates increased significantly—most in sea transport, then in rail and air transport, and the least in road transport. The intention of the authors was to investigate the reasons for the increase in these rates. For this purpose, data on the increase in rates and costs of transport companies were analyzed. Interviews and transport efficiency calculations were carried out. Attention was focused on transport using Heavy Duty Vehicles.

The authors identified the following research gap, which they tried to fill: how the efficiency of consumption of energy by the HDV has changed in recent years in Poland and how this change was related to the prices and profitability of transport companies. The authors analyzed changes in fuel prices and prices of services as well as the profitability of transport companies over the last 20 years. They also examined the impact of factors in the environment of companies, i.e., primarily the energy crisis in 2022.

It seems that so far, no studies of this type have been conducted, not only in Poland, but also in the world. The authors used data from the Polish transport companies. However, the resulting conclusions may reflect general patterns in transport also in other countries.

The authors formulated the following research questions:

- What are the factors of energy efficiency in road transport?

- What is the share of fuel costs in the total costs of Polish transport companies?

- What is the energy efficiency of vehicles and is this efficiency is improving?

- Does the increase in fuel prices link to the increase in transport rates?

- Does an increase in fuel prices result in a deterioration in the profitability of transport companies, or is this increase compensated for by an increase in prices for transport services?

- What determines the possibility of raising transport rates to compensate for the increase in fuel prices?

The article consists of two main parts. The first part is an analysis of the literature. The second part is a presentation of our own research, preceded by a discussion of the research methodology.

In order to present the state of knowledge regarding the efficiency of energy consumption in road freight transport and to identify the research gap, the authors conducted an analysis of the literature (publications, reports, analyses) and divided them into the following parts:

- (a)

- Factors of energy efficiency in transport

- (b)

- Changes in energy efficiency in transport

Results of the research concerning the above issues, with particular emphasis on road freight transport, are discussed below. Sources of information on this subject are included in Table 1.

- (a)

- Factors of energy efficiency in transport

Various factors influence the energy consumption of different types of freight transport. They can be divided into direct and indirect factors [3]. Direct factors (logistics, technical and operational) are related to the use of the vehicle (train, truck), and indirect factors are related to the construction and maintenance of infrastructure and the production of energy and means of transport and vehicle maintenance [4]. Logistics factors include, for example, the use of the vehicle’s payload. Technical factors that affect both energy consumption in combustion and electric engines are vehicle weight, payload, engine type and efficiency, fuel type and aerodynamics [5,6]. Operational factors relate to the way the vehicle is used (speed and driving dynamics), but also to the characteristics of the infrastructure [7,8,9,10].

In terms of technical factors, for example, studies in Finland have shown variations of 5–15% in the fuel efficiency of different trucks [11]. Driving resistance is also an important factor (aerodynamic friction, rolling friction, energy dissipated by braking) [12]. Research conducted over the last few decades has shown that companies can use a wide range of measures to reduce fuel consumption in transport. In recent years, in the literature, a large role in saving fuel is attributed to the human factor [13]. However, technical factors are of course very important.

Table 1.

Literature sources used in the article.

Table 1.

Literature sources used in the article.

| Problems Presented in the Literature | Sources |

|---|---|

| Factors influencing energy consumption in transport | [1,2,3,4,14] |

| Operational factors | [5,6] |

| Technical factors 5–6, 11, 12 | [11,12] |

| Energy consumption in stages of supply chain | [15,16,17,18,19,20] |

| Efficiency of transportation processes | [21,22,23,24,25,26,27] |

| Energy efficiency in modes of transport | [28,29,30,31,32,33,34,35,36,37,38,39,40,41] |

| Technological factors | [42,43,44,45,46,47,48,49,50,51] |

| Human factors | [13,52] |

| Necessity of system approach | [53,54,55,56,57,58,59,60] |

| Coordination of processes in supply chains | [61,62,63,64,65,66,67,68,69,70,71] |

| Changes in energy efficiency in transport | [72,73,74] |

| Prospects of the increase in energy efficiency | [75,76,77] |

| Studies and models of energy efficiency | [77,78,79,80] |

| Data-consumption of petrol in road transport | [81,82,83,84,85,86,87] |

| Changes of freight rates in road transport | [87,88,89] |

Factors affecting energy consumption in transport can also be divided into company-dependent and company-independent factors. The influence of factors beyond the control of transport companies is significant. For example, fleet fuel efficiency can be around 10 percent lower in winter than in summer, mainly because more energy is used to heat vehicles [14]. However, factors dependent on transport companies are also important, including strategic ones, for example, the choice of the market on which the company operates (in terms of geography, type of transported cargo and their transportability).

Rizet et al. [15] analyzed the energy consumption and CO2 emissions of supply chains across a range of products in Belgium, France and the UK. They found that energy efficiency and emissions are influenced by producers (vehicle design), logisticians and forwarders (selection of the method of transport for shipment), energy producers (type of fuel-biofuels, electricity), carriers, operators (optimization of the distribution network and drivers (efficient driving). Shippers can also have an impact by choosing a source of supply [16].

Energy efficiency is also differentiated at different stages of both the transport process and, more broadly, the logistics process. There is low efficiency on the last mile, which is due to the fact that these are deliveries with small loads that have to be made in a short time [17,18]. Vehicle capacity is often not fully utilized [19]. Energy consumption in the last mile is greatest [15].

According to the conducted research, the way of loading trucks and the way of arranging goods and their movement (e.g., transporting clothes folded or on hangers) is of key importance for energy efficiency in transport. The properties of the transported goods and the provisions of labor laws also have an impact [20]. However, the lack of good cooperation with customers and suppliers (imposed delivery and collection dates, last-minute changes to orders, large numbers of returns and lack of good information flow) also has a negative impact, which means that transport or logistics companies are under constant pressure of time, which has a negative impact on the efficiency of their processes. At this point, the authors want to comment that it is for the benefit of customers of transport companies that the possibility of increasing the efficiency of transport processes should be sought. Between the social (environmental) interest and the interest of transport companies, there is usually a convergence of goals, i.e., increasing the efficiency of transport processes leads to a reduction in external costs of transport, unless transport companies achieve higher profitability by providing services (at a high price) that are characterized by low utilization of transport capacity (e.g., frequent deliveries, in small quantities in JIT).

Significant factors of efficiency, including energy efficiency and impact on the natural environment (CO2 emissions) are the scale of operation and the degree of use of production resources (capacity, mileage) [21]. Achieving the benefits resulting from the scale of operation requires not only the use of means of transport with a higher load capacity, but also the good use of the transport capacity. In transport, energy consumption depends on the efficiency of transport processes, and this depends to a large extent on the use of the load capacity and mileage of vehicles, the weight of transported loads, the average load during journeys with a load, the share of empty runs and the average energy consumption of the vehicle [22,23,24,25,26,27].

One of the factors of energy efficiency is the chosen mode of transport. Traditionally, it is believed that the energy consumption is greatest in air and car transport. Air transport is about 100 times less energy efficient per load weight than electric rail and 19 times less efficient than a truck [28,29]. Shipping, on the other hand, is traditionally regarded as “the most environmentally friendly means of transport” [30]. Its relative environmental advantage is due to its low energy consumption; for example, a container ship with a capacity of 3700 TEU3 uses only 0.026 kW to cover one tonne per kilometer, as opposed to 0.067 kW for diesel-powered rail transport, 0.18 kW for a truck and 2 kW for a Boeing 747–400 air freight [31].

Not only the choice of the mode of transport is important here, but also the vehicle and its use. In rail transport, the range of variability of fuel consumption per tonne of transported cargo is from 1 to 17 and even more [32]. In contrast, a long-distance (international) truck with a load factor of 100% uses less energy than a train with a load factor of 35% operating domestically [3]. This proves the importance of the efficiency of transport processes, which is influenced by the proper management of these processes.

Greater efficiency of processes in rail transport can be achieved due to the higher capacity of trains (e.g., replacing two-axle wagons with bogie wagons) and the use of more powerful locomotives that can pull heavier goods (PowerHaul locomotives). Double stacking as used in North America is an efficient way to carry more volume over a given train length, but is not a realistic option in Europe due to the more limited loading gauge. Instead, measures are being explored to increase the length of trains, often requiring changes to signaling systems, passing and terminals.

Also in road transport, the payload of vehicles is an important efficiency factor. Large trucks are usually several times more energy efficient than vans [34]. Lenzen (1999) estimated that the energy consumed by vans was 9 and 23 times greater than that used by rigid articulated trucks in terms of energy consumption per tonne-kilometer [35].

Even more efficient, also from the energy point of view, are the so-called Large and Heavy Vehicles. For example, the use of vehicles with a total weight of 60 t and 68 t increased the energy efficiency of the systems by 18.0% and 20.5%, respectively [36].

A specific problem in transport is the use of vehicle mileage. In the EU, the number of empty truck journeys varies greatly from country to country, ranging from 44 percent of journeys (Eire) to 15 percent (Denmark) with a total average of around 24 percent in 2010 [37]. The level of empty trips is usually inversely related to the distance, because the longer the trip, the greater possibility to find a backload. This agrees with the conclusions of the research of the authors of this article. Better mileage utilization translates into rates for transport services, which are usually lower on longer routes per tonne-kilometer. It explains why the highest energy efficiency (9.9 MJ/100 t/km) in road transport occurs in international transport [38], so on longer journeys. However, it also depends on various factors-primarily the possibility of obtaining return cargo from a given location. Some locations, even if it is a large urban agglomeration, may not have an industrial character, which makes it difficult to obtain return cargo.

The problem of capacity utilization is particularly acute in final distribution, not only due to lower vehicle capacities or shorter routes, but also because products of different dimensions and different transport susceptibility are often transported together. Therefore, the efficiency of their use is supported by solutions that allow them to be used to transport various loads [39,40].

The performance of smaller vehicles, especially in the city, is usually lower than that of large trucks, not only due to the lower load capacity or the degree of loading by the transported goods, but also due to the various applications of these vehicles (transport of tools, equipment and parts, place to work inside vehicle). As a result, the payload utilization of the vans can be very low [41]. In order to increase the efficiency of vans, manufacturers are trying to increase their payload by increasing the length of the wheelbase.

The use of battery-powered electric vehicles and hybrid electric vehicles reduces energy consumption and the costs of this consumption [42,43]. Small vehicles (tricycles and vans) and electric fleets are used for last-mile deliveries in cities [44]. Benefits include reduced vehicle-kilometers, emission savings and reduced parking occupancy [45].

Petrol-powered vehicles have the highest greenhouse gas emissions. Hybrid vehicles and diesel engines (compression ignition) are more efficient, thanks to which they not only consume less fuel but also emit less CO2 [46].

However, according to an assessment [47], any low-emission solution for freight vehicles and AF (Alternative Fuel) can have positive and negative elements, and none of these solutions can be considered consistently beneficial in all aspects of private profitability, service level, environmental, safety and social impact.

It was also estimated that energy efficiency could be significantly improved in rail transport [48], maritime [49] and air [50] due to changes in the construction of vehicles, technological progress, the use of, for example, fuel cells, solar panels and sails. However, as the authors indicate, potentially greater savings may result from improvements in the operation, loading and maintenance of freight vehicles throughout their life cycle than from technical progress in the design of new vehicles [51]. One of the most cost-effective measures in the road freight transport sector is driver training [52]. Railway companies such as Deutsch Bahn have also improved their fuel efficiency with similar driver programs.

The results of the conducted research suggest that low energy efficiency is influenced not only by technical factors, but also by other factors such as lack of flexibility and limited information exchange, as well as oversupply of logistics services, incorrect pricing and sales campaigns [53]. Therefore, in order to radically reduce energy consumption in transport, technological progress alone is not enough [21]. It is necessary to look at logistics processes in a holistic–systemic way [54,55].

The potential to increase energy efficiency in maritime transport is estimated at 10% to 20%, depending on the size and type of ship [56]. One of the most important elements of the supply chain in this branch of transport is considered to be the reduced speed of the ship, which in turn allows for the increased efficiency of operations performed in ports [57]. However, it is not only the speed itself that is important (which should be optimal), but maintaining this speed at a constant level [58].

Reducing speed due to increased port capacity is one of the measures that can contribute to a significant reduction in emissions at limited cost. According to analyses conducted by Çağatay et al. [59] ports have great potential to achieve further energy efficiency.

Systemic aspects appearing in transport chains, and looking more broadly in supply chains, also play a very important role in this problem. Efficiency of transport processes as the impact on the efficiency of transport users. Higher efficiency of port operations translates into lower costs of logistics processes (e.g., inventories) for cargo owners [60].

At this point, another comment by the authors of the article: this problem can of course refer to all modes of transport—if the processes at the beginning and end of the transport process are well organized, then goods can be transported at an optimal speed from the point of view of energy consumption. What is more, if a transport company cooperates with its customers, it has information about transport needs in advance and can optimize the process—e.g., send goods earlier and store them in its intermediate–reloading terminal.

This efficiency is supported by the harmonization and coordination of processes in supply chains at all stages. It is therefore not only about cooperation between service providers of logistics services [61,62] but also with the users of these services (management of packaging, procurement, storage and transport, information exchange) [63,64,65]. Energy efficiency is also influenced by the final consumer (last mile deliveries) [66,67].

If we take into account different emission levels in different locations, we are dealing with a kind of trade-off relation. Choosing a local supplier may bring apparent savings in the form of lower energy consumption in transport, if it is less energy efficient than another located at a greater distance [68].

To sum up these considerations, according to the literature, the main factors of energy efficiency in transport are as follows: vehicle characteristics (e.g., vehicle design, vehicle size and weight, engine, friction), vehicle use (e.g., speed and driving dynamics), type of fuel, properties of transported goods, condition of infrastructure, mode of transport, logistic considerations, e.g., use of vehicle capacity, choice of transport method, distribution network, choice of supply source and cooperation with suppliers and recipients, all of which affects the efficiency of transport processes. Some of these factors are fully independent of the transport company (e.g., the condition of the infrastructure), some factors are partially dependent (vehicle characteristics, capacity utilization, cooperation with contractors). The factor that depends on the company is first of all way the vehicles are used and the management of the transport process.

- (b)

- Changes in energy efficiency in transport

The profitability of transport companies is strongly influenced by the energy efficiency of vehicles and fuel prices. These prices have been rising relatively moderately over the past 20 years. The situation in the fuel market has changed radically and unfavorably for transport companies in 2021 (in Poland—increase by 60%) and in 2022 (by 13.5%) [69]. Fuel costs in road transport generally account for 30–40% of overall costs, which, with usually low margins, is a serious problem in the event of an increase in prices. However, in order to properly assess the impact of these prices, the energy efficiency of vehicles would have to be taken into account.

Efficiency in road transport has increased significantly over the last century. This increase could still be noticed at the beginning of the 21st century. It is estimated that fuel economy in truck transport in the case of the heaviest sets—tractor + semi-trailer— has improved over the last 30 years from about 50 L/100 km to 30–35 L/100 km, and engine power has doubled from 180 kW to 360 kW [70]. Overall fuel consumption is expected to decrease to around 25 L/100 km in the future. There has been an improvement in fuel efficiency due to the installation of turbochargers and improved ignition due to higher fuel injection pressure, thanks to which it is possible to reduce engine weight and increase payload. Significant contributions to vehicle efficiency are to be made by electric and hybrid engines. Other solutions include aerodynamic improvements and alternative fuels. Diesel engines have become increasingly popular. They are characterized by greater fuel efficiency. Diesel vehicles are estimated to have a fuel economy advantage of around 20 to 40 percent over gasoline vehicles [71].

According to some studies, in the 40 years to 2007, the average fuel efficiency of trucks was improving at a rate of about 0.8–1% per year [72,73]. Between 1980 and 2000, fuel consumption fell by 40%, which is largely due to technologies that monitor fuel consumption. In the early 1990s, energy efficiency factors were, for example, the introduction of aero-dynamic profiles and drag-reducing panels, resulting in aerodynamic improvements of up to 40% and a reduction in fuel consumption of around 20% compared to previous generations of trucks [74].

Major improvements were made in the 1970s and 1980s. While there has been a dynamic increase in the load capacity of trucks (in some countries the so-called “LHV”—Longer and Heavier vehicles are allowed), since 1990 the dynamics of reducing fuel consumption and increasing productivity have decreased. This is partly due to the gradual reduction in improvements resulting from the refinement of existing vehicle technology, but mainly due to the need to comply with tightening emission controls [54]. In 2007, it was estimated that if these controls were not in place, the average fuel efficiency of trucks could be around 7–10 percent higher [72]. However, research in the early 2000s suggested that a range of ‘low emission’ technologies could be implemented in new trucks in the short to medium term [74].

According to some estimates, the efficiency of trucks was to increase by 15% to 2020 [75]. According to the conducted research, an increasing number of transport operators now offer more sustainable transport solutions, which was supposed to give them a competitive advantage in the future. It is also worth paying attention to the statement of McKinnon (2003) quoted by the authors of this publication: “Measures that bring economic and environmental benefits generally enjoy the greatest support and are the easiest to implement” [76]. It seems, therefore, that this confirms the thesis that business and environmental goals can be convergent, which may lead to another conclusion that the search for ways to increase energy efficiency and reduce external costs should be focused on the search for such measures.

For years, very interesting studies have been carried out on the energy efficiency of various transport solutions. Various models have been developed to calculate this efficiency. Both the results of these studies and the results of calculations that can be carried out using these models confirm the “classic” regularities related to the efficiency of transport processes, including energy efficiency.

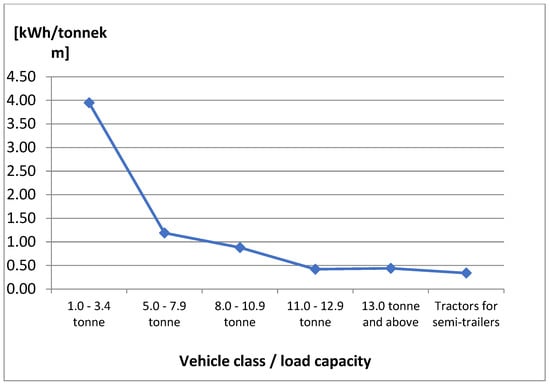

Table 2 and Figure 1 present the results of the studies conducted in the frame of the “Save-Project”, concerning the energy consumption of various vehicles in the Nordic countries in the 1990s [77]. They also confirm the existence of economies of scale in road transport and in terms of fuel consumption. Larger vehicles are more energy efficient. This is influenced not only by the load capacity of these vehicles, but also by their use—larger vehicles are better utilized, which is due to the fact that they are usually used for various tasks. Smaller ones are often used for final distribution and in built-up areas. The larger ones are for transport in rural areas and larger quantities of loads. Although the results of these studies are very interesting and valuable, it is still difficult to fully assess energy efficiency, because they would have to be compared for similar levels of use of these vehicles. This does not change the fact that the results of these studies confirm that there is a positive correlation between the size of the vehicle and the efficiency of the transport process. Although the Norwegian market is completely different from the Polish one, the geographical conditions are also different and the research was conducted so many years ago, it is clear that some general patterns regarding the impact of vehicle load capacity on their efficiency have not changed.

Table 2.

Energy efficiency in Norwegian domestic goods transport on road, 1993–1995.

Figure 1.

Energy efficiency in Norwegian domestic goods transport on road, 1993–1995 (load factor) [77].

Data confirming this relationship can be found in the studies of other authors. An exemplary combination of fuel consumption and vehicle load capacity is presented in Table 3. Increasing the net load capacity by 22%, when changing a small van to a medium truck, results in a decrease in the fuel consumption per tonne by −18.9%, i.e., less than proportionally. The decrease in fuel consumption is even smaller at –15.9%, if instead of lighter vehicles, heavier ones are used (38.6% payload increase). The savings are therefore less than proportional to the increase in payload. The results of these calculations show that the differences in energy efficiency are relatively smaller between medium and large vehicles, what means, that small vehicles are the least energy efficient.

Table 3.

Summary of the typical size, weight and fuel efficiency attributes of vans.

A useful tool for this assessment may be models such as the model developed under the EcoTransIT project, in which using a mathematical formula, it is possible to calculate the energy consumption of vehicles with different load capacity and different degree of loading [79]. This model can therefore be used to assess the effectiveness of the organization of transport processes. Their efficiency depends on two basic factors—typical for transport activity—the degree of vehicle loading and the degree of mileage utilization (share of loaded mileage).

The model developed by Rizet [23] suggests that doubling the load factor of a “truck” from 50 to 100 percent reduces fuel consumption per 100 tonne-kilometers from 2.1 to 1.2 L. This means the saving would be 42.9%. According to the EcoTransIT World methodology, it would be 50%, so the results seem similar.

Other databases are also used to calculate energy consumption and carbon emissions. For example, Kalenoja et al. [80] calculated levels for transport connections using the Eco-TransIT database and the Lipasto database. Sea and road connections from Finland to Italy were analyzed, assuming that the average load utilization ratios for sea were 87–94%, and for road, 90%. These assumptions were based on data collected in the surveyed companies. In addition, the energy consumption of material handling, terminal operations and in the production process were taken into account.

The calculations showed that the energy-efficient transport chain is the one using three modes of transport—sea, rail and road, and the most energy and carbon dioxide emissions are generated by the chain in which only sea and road transport are used. However, the location of production processes should also be taken into account, which is related to their energy efficiency and whether raw materials or processed products are transported.

The authors also emphasize that the obtained results apply to the variant of using small ships with a capacity of 4100 and 5350 t. With larger ships, energy savings were greater.

Summing up these considerations, the authors would like to point out that there are studies on energy efficiency factors in transport, improvement of fuel efficiency of trucks, dynamics of fuel consumption and increase in productivity in transport, models for assessing energy efficiency of various transport solutions, correlation between vehicle size and payload and the efficiency of the transport process. However, there is a lack of broader research presenting changes in the cost of fuel consumption in transport companies and the relationship between the increase in fuel prices and the increase in transport rates. This topic is presented below by the authors, based on their own research.

2. Materials and Methods

In Section 3, the authors present the results of their research conducted for many years, concerning the efficiency of logistics processes, including transport.

The main method of obtaining data from the transport services market was by interviewing employees and managers of companies. The advantage of this method, compared to survey methods, is the ability to collect not only quantitative but, above all, qualitative data, that is, data on the relationship between certain factors, forecasts, opinions, etc. The disadvantage of this method, however, is its high time-consuming nature.

Apart from this important method was the mathematical method and simulation method using the spreadsheet Excel.

The third method was the comparative analysis—for comparing the results of the study performed by the authors of this article with the results of the studies from the literature. Section 3.1 presents an analysis of studies on fuel consumption over 20 years in Europe in high-tonnage freight transport. The results of these studies were analyzed and compared with the results of studies on the Polish transport market.

Section 3.2 presents the results of interviews conducted in 2022 with Polish transportation and forwarding companies that offer services with the use of road transport. These companies differ greatly in terms of the type of services, markets in which they operate and the cargo transported. One of them also has a branch in Germany.

Section 3.3 shows the impact of the weight of the transported cargo on fuel consumption and the results of the simulation carried out by the authors. The methods of data analysis were a mathematical method (calculations made by the authors using an Excel spreadsheet) and comparative analysis—comparing the results obtained using the mathematical method with results obtained other researchers.

Section 3.4 is an analysis of data that have been obtained for over 20 years from Polish transport and forwarding companies from the road transport sector, regarding changes in fuel costs in transport companies and rates for transport services. These are data on transport using most common technology of 16.5 m road sets (road tractor + semi-trailer) with a maximum gross weight of 40 tons—universal (loads that do not require special transport conditions). The authors collected data from transport and forwarding companies during numerous interviews with employees of these companies. The interview method allowed not only to collect numerical data, but also to learn the causes of certain phenomena in the opinion of the respondents.

3. Results

3.1. Fuel Consumption in High-Tonnage Freight Transport in the EU and Poland

The analysis presented in this section has been conducted using data available in the literature and the data collected by the authors of this paper.

The result of the energy crisis in 1973 was the growth of the efficiency of the use of oil—after 15 years after the consumption of oil per dollar of GDP fell by 70–75%, thanks to the improvement of the energy efficiency of the road vehicles [81] One can ask question, whether the present energy crisis will have similar effects?

The efficiency of fuel consumption in the truck transport is increasing, but there are large discrepancies between the results of various studies on this subject.

According to research conducted by the International Council on Clean Transportation in 2015, a typical European long-haul vehicle consumed 33.1 L/100 km and a 12-tonne truck consumed 21.4 L/100 km [82]. According to these authors, available efficiency-enhancing technologies would reduce fuel consumption by 27% in long-haul transport, and the projected annual reduction in 2015–2025 was to amount to 3.1%. These forecasts are therefore more optimistic than in the studies cited earlier in this article.

According to studies by other authors from the same year, such a vehicle was supposed to consume more, i.e., 34.5 L/100 km on long-distance routes. For local transport, this efficiency was to be even higher, as much as 40.7 L/100 km [83]. Furthermore, the authors are skeptical about progress in energy efficiency, claiming that fuel efficiency has stabilized and is no longer expected to increase.

Comparing fuel efficiency is actually very difficult. For example, according to research by the Institute for Internal Combustion Engines and Thermodynamics of the Graz University of Technology (TU Graz) from 2018, the best-in-class truck tractor consumed 29.9 L/100 km, while a typical set used 32.6 L/100 km, so 9% more [84].

If we accept the theses of the authors of the above studies that the efficiency of fuel use will increase by more than 3%, then in 2022 vehicles should consume 27 L/100 km. In fact, such standards have been discussed in the transport environment for years, even before the outbreak of the COVID-19 pandemic. Is it so?

For example, Rachel Muncrief compared a 2002 Euro III DAF XF95.430 truck to a 2017 Euro VI DAF XF440 model and commented on the research results of Lastauto Omnibus (German trucking magazine) as follows:

“The fuel consumption results achieved were 41.9 L/100 km for the 2002 truck and 35.6 L/100 km for the 2017 truck—a nice 15% reduction in fuel consumption. But Lastauto had tested a 2002 Euro III DAF XF95.430 in 2003, and that time the results were 34.6 L/100 km, a far cry from 41.9 L/100 km. Based on that result, the difference between the 2002 and 2017 trucks would have been a one-liter per kilometer increase in fuel consumption—that is, essentially no change at all in fuel efficiency over fifteen years, and if anything a change in the wrong direction”.[85]

The explanation may lie in the following statement of the authors of the study quoted here: “well-known but not yet widely commercialized technologies can achieve a 43% fuel consumption reduction in long haul operation by 2030. This would require an average annual reduction from 2015 to 2030 of 3.6%, reducing the fuel consumption of new tractor-trailers to 18.9 L/100 km by 2030” [83].

This is probably the answer to the question of why there are such large discrepancies between the results of studies, including those conducted by the authors of this article. It is necessary to ask the question—are we talking about vehicles actually operated by transport companies? First of all, these differences result from many different factors—the weight of the transported cargo, route, distance, congestion, driving style, type of fuel, class of the vehicle and its age.

Table 4 presents the data collected by the authors on the transport services market in 2001 on the fuel consumption of various road trains. Consumption varied markedly from brand to brand. The vehicles consumed up to 40 L/100 km. The average from the data in the table is almost 38 L/100 km. If we compare this with the results from recent years, it can be said that progress has been made, as modern vehicles consume slightly more than 30 L/100 km.

Table 4.

Fuel consumption—tractors with semi-trailers in Poland, 2001.

The results of research on fuel consumption by modern vehicles are presented in the next Section 3.2.

3.2. Interviews with Transport Companies in Poland

This section presents the results of research conducted by the authors using interviews on the effectiveness of the functioning of transport companies, which were conducted by the authors in 2022.

Below are presented case studies of the Polish transport, forwarding and logistics companies, developed on this basis.

The first company is a transport and forwarding company—operating on the Polish and German market and dealing with the distribution of goods of commercial and production companies. The company serves regular customers with whom fixed-term contracts are signed, which is a very important element of the strategy and which undoubtedly has a significant impact on the efficiency of logistics processes and the profitability of the company. It competes with quality and transport capacity. Quality is ensured by fairly new equipment: tractors and semi-trailers not older than 3–5 years and qualified and experienced drivers. The main goods that the company transports are wood, glass, packaging and paper in rolls. The profitability, depending on the client, ranges from 30–50%, which is presented in Table 5. This is a very good result, significantly exceeding the average profitability of transport companies operating on the Polish market.

Table 5.

Fuel consumption depending on load weight (example–company 1).

As can be seen from the data presented in Table 5, there is a strong relationship between the type of cargo transported and fuel consumption. For light loads, consumption is actually less than 30 L/100 km. When the payload is fully used (25 t net), it is just 30 L/100 km. Such consumption has been the norm in the road transport for years.

The consumption of petrol is not correlated with the profitability, although fuel costs are a significant item in the company’s total costs.

Table 6 shows the results for two sample routes operated by this company. The financial results are very good, despite the fact that deliveries are combined, which means that the goods are not transported between two points, but distributed with one vehicle to many different points, which of course also affects fuel consumption (braking and starting). Despite this, however, profitability is surprisingly high.

Table 6.

Impact of pandemic on costs and rentability.

It is all the more surprising if we compare the increases in fuel prices and the increases in rates during the COVID-19 pandemic. The price of fuel increased by over 80%, and the freight rates increased by only 30–35% (Table 6 and Table 7). So how does the company manage to achieve such good profitability? Has the efficiency of transport processes increased?

Table 7.

Changes in fuel prices and transport rates.

The Polish branch of the company achieved lower profitability than the German branches, mainly due to lower rates, but also slightly worse utilization of the annual mileage (approx. 90%). The branch in Germany, thanks to higher rates and, even for this market, above-average efficiency of delivery processes (almost 100% mileage utilization), also achieved above-average profits and high profitability. In both branches, however, the impact of the pandemic on profitability was mitigated, as the increase in fuel prices was offset to some extent by the increase in freight rates.

Another surveyed company is a forwarding and transport company, which could even be described as a logistics operator. It serves other markets and provides other services than the previously described company. It carries the so-called “general cargo”, i.e., small batches of cargo internationally and on regular routes, which are consolidated in the company’s own warehouses. In addition to means of transport of various capacities, the company also has its own infrastructure.

It is a company that stands out in the field of ecodriving (ZF-Transics telematics system for Poland). The company largely uses the scoring system for drivers in this area, offered under the name TX-Eco.

Below are comments from one of the company’s managers on the current conditions:

- There has been no increase in fuel efficiency in recent years.

- Road sets (40 tons of GVW) consume 30–30.5 L/100 km.

- In the summer months, fuel consumption drops to around 27 L for some vehicles.

- Consumption increases significantly in winter, because the loads are rather heavy, routes are in Scandinavia and cars often consume a lot of energy during parking.

According to the company’s manager, fuel consumption, in addition to the driver’s driving style, depends on:

- specific vehicle;

- topography;

- cargo weight;

- weather conditions.

When it comes to driving style, there are the following factors:

- total number of brake applications per 100 km/on a given route;

- number of emergency brakes;

- number of stops;

- the number of kilometers driven without pressing the accelerator pedal;

- the number of kilometers driven with your foot on the brake pedal;

- idle time, etc.

Much depends on the driver—on the same route, a given driver can have over a thousand brakes, and another two. For this reason, the company uses an incentive system—the points earned by the driver affect his salary–bonus.

In addition to the increase in fuel prices, other costs have also increased. For example, an ordinary tractor, which not so long ago cost EUR 85,000, currently costs up to EUR 160,000.

There are also indicated differences in fuel consumption depending on the brand (ceteris paribus). In opinion of this manager Scania, Mercedes and the new MAN deserve recognition. Higher wear is recorded by Volvo m-ki vehicles.

As far as rates are concerned, their increase exceeds 30% and even reaches 50%, which may be explained by the relatively difficult market (high requirements as to the quality of services and large unbalances of cargo flows to and from Scandinavia, which has a large impact on the rates). On the market of consolidated groupage shipments, rates are usually higher and companies that can effectively manage their processes to achieve high profits.

The third company has yet another operating model. Similar to the one described above, it also carries groupage and partial loads in domestic relations. It does not utilize the network for consolidating cargo, but it consolidates shipments. The company does not see an improvement in the fuel efficiency of their vehicles, but rather an increase of 0.5–1 L more. He cites the use of Adblue as the cause. The share of fuel costs varies, as in the case of other companies, from 30 to over 40%.

The fourth is a transport company serving the food market on short and long-distance routes (domestic and international transport):

- international transport on longer routes;

- domestic transport on shorter routes.

The company recently experienced a 70% increase in overhead costs. What is interesting and surprising in the case of this particular company, was that customers did not compensate for this increase by increases in their rates. Rates increased from EUR 1/km to EUR 1.08/km, which is very little and does not allow for satisfying profitability, so the company wants to wait out difficult times for now.

As a commentary on the information and opinions expressed by the managers of the interviewed companies, it is worth analyzing the data on fuel consumption collected by the authors of the article in previous years. Table 8 presents data on fuel consumption by various heavy goods vehicles in Poland in 2011, i.e., from over 10 years ago. The average consumption was lower than the average calculated for 2001 (see Table 4)—i.e., 35.5 L/100 km [86]. Analyzing these data, it can be concluded that an improvement of energy efficiency is taking place, although it is affected by many different factors—age of the vehicle, its make, routes on which the vehicle is driven, topography, load weight and driver’s skills (especially with the principles of ecodriving). Therefore, in order to properly assess whether there has been an improvement in productivity over the past years, detailed research would be needed.

Table 8.

Transport rates—2011 for a tractor with a semitrailer.

3.3. Influence of Load Weight on Fuel Consumption

The data obtained from the surveyed companies were compared with the results of calculations carried out using the EcoTransIT World model. The results are shown in Figure 2. Seemingly, there are significant discrepancies between these results obtained from company 1, especially with increasingly heavier loads or with increasing capacity utilization. However, if the aforementioned specificity of the company’s operation is taken into account, it may be that the results are actually similar. The Eco model deals with a direct transport between two points and this company delivers up to several points on a given route. The fuel consumption is therefore higher in this case, and the fuel consumption during braking and starting is the greater the heavier the vehicle with the load.

Figure 2.

Energy consumption in HDV depending on the load capacity.

Convergent with the results of calculations using this model are the results of research conducted by Polish scientists. Energy consumption according to Eco when driving an empty vehicle is 8.5 MJ/km and when 100% full it is 14.40 MJ/km. Similar results were obtained by Polish engineers who studied the fuel consumption of such vehicles [87]:

- At 0% occupancy, on average—8.6 MJ/km (6.48 in the city, 10.9 outside the city);

- With 100% filling of the vehicle, on average—14.52 MJ/km (10.9 in the city, 18.13 outside the city).

Taking into account the location of the transport is very important—the increase in fuel consumption in the city was 67%, and outside the city it was 45%.

Cargo weight is an important factor in fuel consumption, but it is not a proportional increase. For example, increasing the load of a high-tonnage vehicle (40 tons GVW) from 50% to 100% increases energy efficiency by 37%.

Large vehicles are very efficient. With 100% utilization of the payload, energy consumption in vehicles >26–40 t is 66% lower per tonne of load than in small vehicles of >3.5–7.5 t.

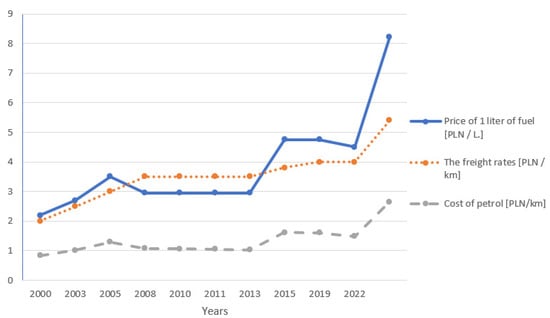

3.4. Analysis of Changes in Prices of Services and Fuels in the Polish Market of Road Freight Transport

Data on the profitability of transport services have been collected by the authors for over 20 years (since the beginning of the 21st century) and the results of calculations on the basis of these data are presented in Table 9 and Figure 3.

Table 9.

Changes of costs and freight rates in road transport in Poland with the use of HDV in years 2000–2022.

Figure 3.

Changes of costs of petrol and freight rates in road transport (HDV) in Poland (2000–2022).

The share of fuel costs in Polish transport companies transporting goods by road oscillates between 29% and 46% and rentability very often very low—a few percent up to 10%. Much lower, in fact, than rentability of the German division of the first interviewed company (see Section 3.2). This has not changed even during the recent increase in fuel prices. Contrary to other modes of transport, freight rates in this market increased by only 30%, while, for example, in the market of intercontinental container transport, they increased by over 700%. These results are consistent with data from other authors presented earlier in this article.

In the analysis, the authors first assumed that fuel consumption in 2000 was 38 L/100 km (see Table 3). It was also assumed that the efficiency of its consumption changed by 0.8–1% according to the assumptions of IEA [74]. It seems that these assumptions are correct, because in 2022 the consumption is 30 L/100 km, which is exactly as much as reported by the surveyed companies (see previous sections). What is more, according to this methodology in 2011, this should be 35.67 L/100 km, so the same amount of average consumption—35.67 L/100 km this year, according to the data collected by the authors from the Polish market (see Table 9).

As shown in Figure 3, the increase in rates over the last 20 years coincided with the increase in fuel consumption costs. This means that customers compensated for this increase by an increase in the prices paid for the service, which was a certain regularity in this market. This was the case when the Viatoll system was introduced in Poland—some customers increased their rates to the extent that the tolls for using the roads covered by the system increased. It was the same recently, when fuel prices rose sharply. However, this is not a general rule, because not all customers of transport companies apply such compensation. In the authors’ opinion, a large increase in rates applies mainly to companies whose strategy is not to reduce costs, but to ensure high quality, and thus also high quality of transport services. An important factor is, of course, the value of transported goods—in the case of high-value cargo, the share of transport costs, even after such drastic increases that the market experienced this year, is still small.

Figure 3 also shows that in 2022 the situation changed unfavorably for transport companies. For the first time in 20 years, the increase in transport rates has not kept pace with the increase in fuel prices, which obviously has a negative impact on their financial situation. According to the analysis of the European Road Freight Rates Benchmark, the European indicator of contract freight road rates reached a record 121 points in Q2 2022. The European spot road freight rate index also reached a record high of 134 points [88]. For example, on the most favorable route for Polish carriers between Warsaw and Duisburg, the rate amounted to EUR 1451 on average (EUR 1.34/km), increasing by as much as 37 percent. per year [89].

The increase in fuel prices is not the only problem for transport companies. In the case of companies that also provide warehouse processes, the increase in energy prices also resulted in an increase in storage costs (e.g., lighting or heating of the warehouse). Other costs, such as vehicle prices, have also increased significantly. The response to such drastic increases in the costs of operating companies should be an increase in the efficiency of fuel use. Analyzing the studies cited in this article (articles, reports) one can come to the conclusion that indeed energy efficiency is constantly (albeit slowly) improving.

4. Discussion

In order to properly assess changes in energy efficiency in transport, in-depth research should be carried out, taking into account the actual fuel consumption of various types of vehicles, the various types of loads, the various conditions (road class, road conditions, speed), and the way a driver drives a vehicle. Only such a broad analysis that meets the condition of comparability of data allows the assessment of the degree of efficiency improvement and its factors. However, the increase is certainly small, as it seems.

Therefore the question still remains, what are the reasons for this state of affairs? Why do companies not look for solutions that will increase energy efficiency to a greater extent? The share of fuel consumption costs in road transport companies is very high, even in those that operate the largest road vehicles, which are the most efficient in relation to vehicles with less payload. Transport companies should, as it might seem, be motivated to look for pro-efficiency solutions. This is certainly the case—Polish transport and forwarding companies try to use their resources as efficiently as possible—both in terms of time and load capacity. The last parameter in Polish transport is particularly impressive—Polish carriers achieve over 90% utilization of the mileage in both direction, which means that there is a very small proportion of empty runs. It should be noted, however, that this applies to universal technology and long-distance transport. Margins are usually very low, so there is an incentive (actually a necessity) to make production resources more productive.

If vehicles with a fuel consumption standard below 30 L/100 km are already available, are carriers interested in buying them? And if not, why? Are the costs of their purchase and operation so high that they are unprofitable?

These are questions that can only be answered through extensive research.

For now, the conclusion that can be drawn is that the increase in fuel consumption costs is compensated for by customers by the increase in rates. Such a situation takes place especially when loads of high value and low transport susceptibility are transported, meaning that, firstly, the share of transport costs in the value of the goods is small, and secondly, that such customers are more interested in the quality of services than in reducing costs of transport. However, in the era of the current economic crisis, inflation, rising energy prices and falling demand for transport services, will there not be pressure to reduce transport costs by looking for innovative solutions? Will new solutions be introduced, such as hydrogen drive?

5. Conclusions

Based on data from Polish companies in the road transport sector regarding changes in fuel prices and rates for transport services obtained by the authors over more than 20 years, and based on interviews with company managers, the authors formulated the following conclusions:

The improvement in fuel efficiency in Polish transport companies is very similar to the annual rate of 0.8–1% identified by previous researchers in other countries.

In Polish transport companies transporting goods by road, the share of fuel costs in the last 20 years oscillated between 29% and 46%.

Fuel prices in Poland in 2020–2021 increased by 60.9% compared to 2019 and by 13.5% in 2022.

In 2022 there was also an increase in rates in this market; they increased in most cases by more than 30% (in some cases even up to 50%).

The increase in rates over the last 20 years, until 2021, largely coincided with the increase in fuel prices.

In 2022, for the first time during this period, the increase in fuel prices was greater than the increase in rates.

However, if fuel consumption and its greater efficiency are taken into account, it turns out that the growth rate of fuel consumption costs coincides with the growth rate of transport services prices, which means that customers of transport companies compensated for the increase in costs by increasing freight rates.

Despite this, however, there was a deterioration in the profitability of some companies; a large increase in transport rates compensating for the increase in fuel prices applies mainly to transport companies whose strategy is to compete with the quality of services and when high-value loads are transported. A small increase in transport rates, which does not compensate for the increase in fuel prices, applies mainly to companies whose strategy is to compete on the price of transport services and when low-value cargo is transported. Other operating costs of transport companies also increased significantly, e.g., vehicle prices, and in the case of companies that also carry out warehouse processes, the increase in energy prices also resulted in an increase in storage costs.

From interviews with managers, their opinion is there has been no reduction in fuel consumption recently; however, based on the comparison of data from 20 years, it can be seen that fuel consumption is lower, and therefore energy efficiency is improved, many factors affecting energy efficiency are beyond the company’s control (e.g., infrastructure).

The reaction of companies to the increase in fuel prices should be not only to increase transport rates (which will not cover the increased fuel costs in every case, but will increase energy efficiency). Some factors are independent of the transport company (e.g., the condition of road infrastructure); however, there are those that are influenced by the company such as vehicle characteristics and their use (driving speed and dynamics), as well as, to some extent, logistical considerations (e.g., use of the vehicle’s load capacity).

Energy efficiency in road freight transport is improving steadily, but at a slow pace. This raises the question of what the causes are. Road freight transport is highly efficient in Europe. In general, large trucks carry a large amount of cargo per year, their payload is very well utilized and empty runs form a low proportion. Polish companies from logistics industry can effectively manage and organize their transportation processes. Very often the utilization of round-trip mileage is over 90%. On the other hand, with very low freight rates for services, it cannot be different. Such good results are also very important for social reasons. Better efficiency of transport processes means fewer transports, lower costs of these processes, lower energy consumption and lower external costs of transport.

Certainly, to a large extent, the reason for the high efficiency of transport processes is the high competitiveness of this mode of transport. Market mechanisms force pro-efficiency measures in this transport sector, which also explains the very high share of road transport in Europe and Poland. On the one hand, this raises concerns about the impact of such a structure of the transport system on external costs. On the other hand, poor use of means of transport, even in the most ecological modes, also does not lead to the implementation of a sustainable development policy. Well-used large trucks (often blamed for generating high social costs) consume less energy and can be greener than means of transport in other modes. This problem is pointed out by the authors of the publications cited in this article [33] and the authors of this article for years [90].

Freight rates in this market are closely related to energy consumption costs. In the transport services market in Poland, transport users force their carriers to lower transport rates, which makes their profitability very low. However, in periods of increased operating costs, transport companies are forced to raise the price and customers have to accept it. The proof of such a correlation was the situation right after the opening of the EU market to Polish companies. As expected before the accession, costs of transport fell sharply due to better use of the means of transport (more orders, less empty runs), but so did the freight rates. It can therefore be concluded that the increase in the efficiency of processes (e.g., by reducing energy consumption) benefits not carriers but their customers, and indirectly the economy and society.

Employees of transport companies (especially those who have only been working for a few years) do not always notice the increase in energy efficiency in road transport. However, the efficiency of road transport is undoubtedly improving, which is evident from the data presented in this article over the last 20 years. This is confirmed by the authors cited in this article and by data on external costs of transport published in various publications over the years. These costs, according to the authors of various studies, are becoming lower, which is due to, among other things, with less energy consumption [91,92].

In road transport, economies of scale can also be achieved, which translates into benefits not only for companies, but also lower social costs. Road vehicles are efficient not only because of their higher payload and good use of it, but also over longer distances. In the context of the aforementioned competition between the modes of transport, a certain paradox can be mentioned here. The benefits of “mass” modes of transport are revealed on longer routes, but also on longer routes, road transport becomes more efficient (fewer empty runs).

Therefore, a solution should be found that takes into account the real possibilities of implementing a sustainable development policy. Since it is not possible (or even should not be) to reduce the share of road transport, efforts should be made to increase its efficiency, also in terms of energy. The only question is how? And therefore, another question—have we not already reached the limits of this efficiency? Free market mechanisms enforce pro-efficiency activities, but apparently there are limitations here.

Therefore, external factors, independent of carriers, are important factors of energy efficiency. Such a thesis is formulated by the transport environment, whose representatives are lobbying for greater involvement of the state in the development of transport. Although the statement that the transport company has only a small percentage of its impact on its financial results seems to be a gross exaggeration, it should be admitted that the representatives of the transport industry are right that they do not have a full impact on the efficiency of their processes.

Carriers in Poland are no longer reducing their energy consumption to a large extent. What is more, they do not buy vehicles that consume less fuel. The question is why? Are they too expensive or are such vehicles really not put into operation? The surveyed companies did not confirm that such vehicles were available for sale.

What operators can do for their part is to increase the degree of integration in supply chains and improve cooperation between carriers, forwarders and their customers. However, companies cooperate because it actually brings benefits, which is verified by difficult periods of economic activity (e.g., the global economic crisis that began in 2008).

If we have actually reached the “limits of efficiency”, then the conclusion is that alternative solutions should be sought—new technologies and new energy sources (hydrogen?). What is probably needed here is state involvement in the development of these new technologies. If carriers could influence a reduction in energy consumption, they would certainly have found effective solutions by now. Apparently, they are out of their reach. Therefore, the state should finance research into new technologies that may result in reduced energy consumption.

One of the authors of this article participated in an expert opinion commissioned by the Polish Ministry of Infrastructure. The purpose was to examine whether the amendment of the Council Directive 96/53/EC of 25 July 1996, planned by the European Commission, and the admission of these vehicles in international transport would be beneficial for Poland. The results showed great benefits from the operation of such vehicles, also from the point of view of social costs (lower external costs of transport, fewer accidents, less congestion) [93]. Despite this, the Ministry of Infrastructure did not decide to change the regulations, and in Poland only 45’ sea containers were allowed for road transport. It seems that this was decided only by political factors (opposition from the railway community, which is afraid of competition from road carriers). However, the topic regularly returns not only in scientific publications. Representatives of the transport and logistics industry discuss this topic with politicians.

Research carried out by the authors of the article also confirmed the existing relationships between the weight of the transported cargo and energy consumption identified by other authors. Vehicles with a large load capacity are much more energy efficient than smaller ones, e.g., delivery vans, provided; however, this load capacity is very well used.

Finally, increasing the load capacity of road vehicles is only a partial solution to the problem of energy consumption in transport. It seems that alternative energy sources should be sought (e.g., the use of hydrogen energy).

Author Contributions

Conceptualization, D.M. and B.M.; methodology, D.M. and B.M.; software, D.M.; validation, formal analysis, investigation, resources, data curation, writing—original draft preparation, writing—review and editing D.M. and B.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- DFF International Ltd. RHA Cost Tables 2011; Road Haulage Association: Weybridge, UK, 2011. [Google Scholar]

- Pimentel, D.; Pleasant, A.; Barron, J.; Gaudioso, J.; Pollock, N.; Chae, E.; Kim, Y.; Lassiter, A.; Schiavoni, C.; Jackson, A. US energy conservation and efficiency: Benefits and costs. Environ. Dev. Sustain. 2004, 6, 279–305. [Google Scholar] [CrossRef]

- García-Álvarez, A.; Pérez-Martínez, P.J.; González-Franco, I. Energy Consumption and Carbon Dioxide Emissions in Rail and Road Freight Transport in Spain: A Case Study of Car Carriers and Bulk Petrochemicals. J. Intell. Transp. Syst. 2013, 17, 233–244. [Google Scholar] [CrossRef]

- Van Wee, B.; Janse, P.; Van Den Brink, R. Comparing energy use and environmental performance of land transport modes. Transp. Rev. 2005, 25, 3–24. [Google Scholar]

- Advenier, P.; Boisson, P.; Delarue, C.; Douaud, A.; Girard, C.; Legendre, M. Energy consumption and CO2 emissions of road transportation: Comparative analysis of technologies and fuels. Energy Environ. 2002, 13, 631–646. [Google Scholar] [CrossRef]

- Koopman, G.J. Long-term challenges for inland transport in the European Union: 1997–2010. Consequences for transport fuel economy and use. Energy Policy 1997, 25, 1151–1161. [Google Scholar] [CrossRef]

- Espinosa-Aranda, J.L.; García-Rodenas, R. A discrete event-based simulation model for real-time traffic management in railways. J. Intell. Transp. Syst. 2012, 16, 94–107. [Google Scholar] [CrossRef]

- Burgess, S.C.; Choi, J.M.J. A parametric study of the energy demands of car transportation: A case study of two competing commuter routes in the UK. Transp. Res. Part D 2003, 8, 21–36. [Google Scholar] [CrossRef]

- Ng, S.T.; Cheu, R.L.; Lee, D.H. Simulation evaluation of the benefits of real-time traffic information to trucks during incidents. J. Intell. Transp. Syst. 2006, 10, 89–99. [Google Scholar] [CrossRef]

- Cuddihy, J.; Kennedy, C.; Byer, P. Energy use in Canada: Environmental impacts and opportunities in relationship to infrastructure systems. Can. J. Civ. Eng. 2005, 32, 1–15. [Google Scholar] [CrossRef]

- Nylund, N.; Erkkila, K. HDV Fuel Efficiency: Methodology, vehicle performance and potential for fuel savings. In Proceedings of the International Energy Agency Workshop 2007, Paris, France, 21–22 June 2007. [Google Scholar]

- Guzzella, L.; Sciarretta, A. Vehicle Propulsion Systems, 2nd ed.; Springer: Zürich, Switzerland, 2007; ISBN 9783540746911. [Google Scholar]

- McKinnon, A. Increasing Fuel Efficiency in the Road Freight Sector in Green Logistics, 3rd ed.; McKinnon, A.C., Browne, M., Piecyk, M., Whiteing, A., Eds.; Kogan Page: London, UK, 2015. [Google Scholar]

- Coyle, M. Basic Steps to Improving Vehicle Fuel Efficiency, Transport and Logistics Research Unit; University of Huddersfield: Huddersfield, UK, 1998. [Google Scholar]

- Rizet, C.; Browne, M.; Cornelis, E.; Leonardi, J. Assessing carbon footprint and energy efficiency in competing supply chains: Review—Case studies and benchmarking. Transp. Res. Part D Transp. Environ. 2012, 17, 293–300. [Google Scholar] [CrossRef]

- Doherty, S.; Hoyle, S. Supply Chain Decarbonization—The Role of Logistics and Transport in Reducing Supply Chain Emissions; World Economic Forum: Geneva, Switzerland, 2009. [Google Scholar]

- McKinnon, A. Freight transport deceleration: Its possible contribution to the decarbonisation of logistics. Transp. Rev. 2016, 36, 419–436. [Google Scholar] [CrossRef]

- Perboli, G.; Musso, S.; Rosano, M.; Tadei, R.; Godel, M. Synchro-modality and slow steaming: New business perspectives in freight transportation. Sustainability 2017, 9, 1843. [Google Scholar] [CrossRef]

- Brown, J.R.; Guiffrida, A.L. Carbon emissions comparison of last mile delivery versus customer pickup. Int. J. Log. Res. Appl. 2014, 17, 503–521. [Google Scholar] [CrossRef]

- Wehner, J. Energy Efficiency in Logistics: An Interactive Approach to Capacity Utilisation. Sustainability 2018, 10, 1727. [Google Scholar] [CrossRef]

- Leonardi, J.; Baumgartner, M. CO2 efficiency in road freight transportation: Status quo, measures and potential. Transp. Res. Part D 2004, 9, 451–464. [Google Scholar] [CrossRef]

- McKinnon, A.; Ge, Y. The potential for reducing empty running by trucks: A retrospective analysis. Int. J. Phys. Distrib. Log. Manag. 2006, 36, 391–410. [Google Scholar] [CrossRef]

- Rizet, C.; Cruz, C.; Mbacke, M. Reducing freight transport CO2 emissions by increasing the load factor. Proced. Soc. Behav. Sci. 2012, 48, 184–195. [Google Scholar] [CrossRef]

- Rogerson, S.; Santén, V. Shippers’ opportunities to increase load factor: Managing imbalances between required and available capacity. Int. J. Log. Res. Appl. 2017, 20, 581–603. [Google Scholar] [CrossRef]

- Piecyk, M.I.; McKinnon, A.C. Forecasting the carbon footprint of road freight transport in 2020. Int. J. Prod. Econ. 2010, 128, 31–42. [Google Scholar] [CrossRef]

- Liimatainen, H.; Pöllänen, M. Trends of energy efficiency in finnish road freight transport 1995–2009 and forecast to 2016. Energy Policy 2010, 38, 7676–7686. [Google Scholar] [CrossRef]

- McKinnon, A.; Ge, Y. Use of a synchronised vehicle audit to determine opportunities for improving transport efficiency in a supply chain. Int. J. Log. Res. Appl. 2004, 7, 219–238. [Google Scholar] [CrossRef]

- Perez-Martınez, P.J. Freight transport, energy use and emission trends in Spain. Transp. Res. Rec. 2010, 2191, 16–22. [Google Scholar] [CrossRef]

- Niedzballa, H.A.; Schmitt, D. Comparison of the specific energy demand of aeroplanes and other vehicle systems. Aircr. Des. 2001, 4, 163–178. [Google Scholar] [CrossRef]

- Bode, S.; Isensee, J.; Krause, K.; Michaelowa, A. Climate policy: Analysis of ecological, technical and economic implications for international maritime transport. Int. J. Marit. Econ. 2002, 4, 164–184. [Google Scholar] [CrossRef]

- McKinnon, A.; Allen, J.; Woodburn, A. Development of greener vehicles, aircraft and ships. In Green Logistics: Improving the Environmental Sustainability of Logistics, 3rd ed.; McKinnon, A., Browne, M., Whiteing, A., Piecyk, M., Eds.; Chartered Institute of Logistics and Transport: London, UK, 2012. [Google Scholar]

- Garcıa Alvarez, A. Energıa y Emisiones en el Transporte por Ferrocarril; Fundacion de los Ferrocarriles Espanoles: Madrid, Spain, 2011. [Google Scholar]

- ECMT. Cutting Transport CO2 Emissions—What Progress? OECD: Paris, France, 2007; p. 264. [Google Scholar]

- TRENS. Calculation of Indicators of Environmental Pressure Caused by Transport, Main Report; European Commission, Office for Official Publications of the European Communities: Luxembourg City, Luxembourg, 2003. [Google Scholar]

- Lenzen, M. Total requirements of energy and greenhouse gases for Australian transport. Transp. Res. Part D 1999, 4, 265–290. [Google Scholar] [CrossRef]

- Palander, T.; Haavikko, H.; Kortelainen, E.; Kärhä, K. Comparison of Energy Efficiency Indicators of Road Transportation for Modeling Environmental Sustainability in “Green” Circular Industry. Sustainability 2020, 12, 2740. [Google Scholar] [CrossRef]

- De Angelis, L. A Fall in Average Vehicle Loads: Average Loads, Distances and Empty Running in Road Freight Transport—2010 Statistics in Focus; Eurostat: Luxembourg City, Luxembourg, 2011. [Google Scholar]

- Khan Ankur, A.; Kraus, S.; Grube, T.; Castro, R.; Stolten, D. A Versatile Model for Estimating the Fuel Consumption of a Wide Range of Transport Modes. Energies 2022, 15, 2232. [Google Scholar] [CrossRef]

- University of St Gallen. The Transport Optimization Report; ECR Europe: Brussels, Belgium, 2000. [Google Scholar]

- Fernie, J.; Sparks, L.; McKinnon, A.C. Retail logistics in the UK: Past, present and future. Int. J. Retail. Distrib. Manag. 2010, 38, 894–914. [Google Scholar] [CrossRef]

- DfT. Delivering a Sustainable Transport System: The Logistics Perspective; DfT: London, UK, 2008. [Google Scholar]

- Allen, J.; Browne, M.; Cherrett, T. Investigating relationships between road freight transport, facility location, logistics management and urban form. J. Transp. Geogr. 2012, 24, 45–57. [Google Scholar] [CrossRef]

- Gao, Z.; Lin, Z.; Franzese, O. Energy Consumption and Cost Savings of Truck Electrification for Heavy-Duty Vehicle Applications. Transp. Res. Rec. 2017, 2628, 99–109. [Google Scholar] [CrossRef]

- Leonardi, J.; Cullinane, S.; Edwards, J. Alternative fuels and freight vehicles status, costs and benefits, and growth. In Green Logistics: Improving the Environmental Sustainability of Logistics; Kogan Page: London, UK, 2014. [Google Scholar]

- Browne, M.; Allen, J.; Leonardi, J. Evaluating the use of an urban consolidation centre and electric vehicles in central London. IATSS Res. 2011, 35, 1–6. [Google Scholar] [CrossRef]

- Department for Transport. Transport Energy Model Report Moving Britain Ahead; Department for Transport: London, UK, 2018.

- Baker, H.; Cornwell, R.; Koehler, E.; Patterson, J.; Powell, N. Review of Low Carbon Technologies for Heavy Duty Vehicles; Annex; Department for Transport: London, UK, 2009.

- Rail Safety and Standards Board (RSSB). The Case for Rail 2007: The First Sustainable Development Review of the Mainline Railways of Great Britain; RSSB: London, UK, 2007. [Google Scholar]