Review on Nano Enhanced PCMs: Insight on nePCM Application in Thermal Management/Storage Systems

Abstract

:1. Introduction

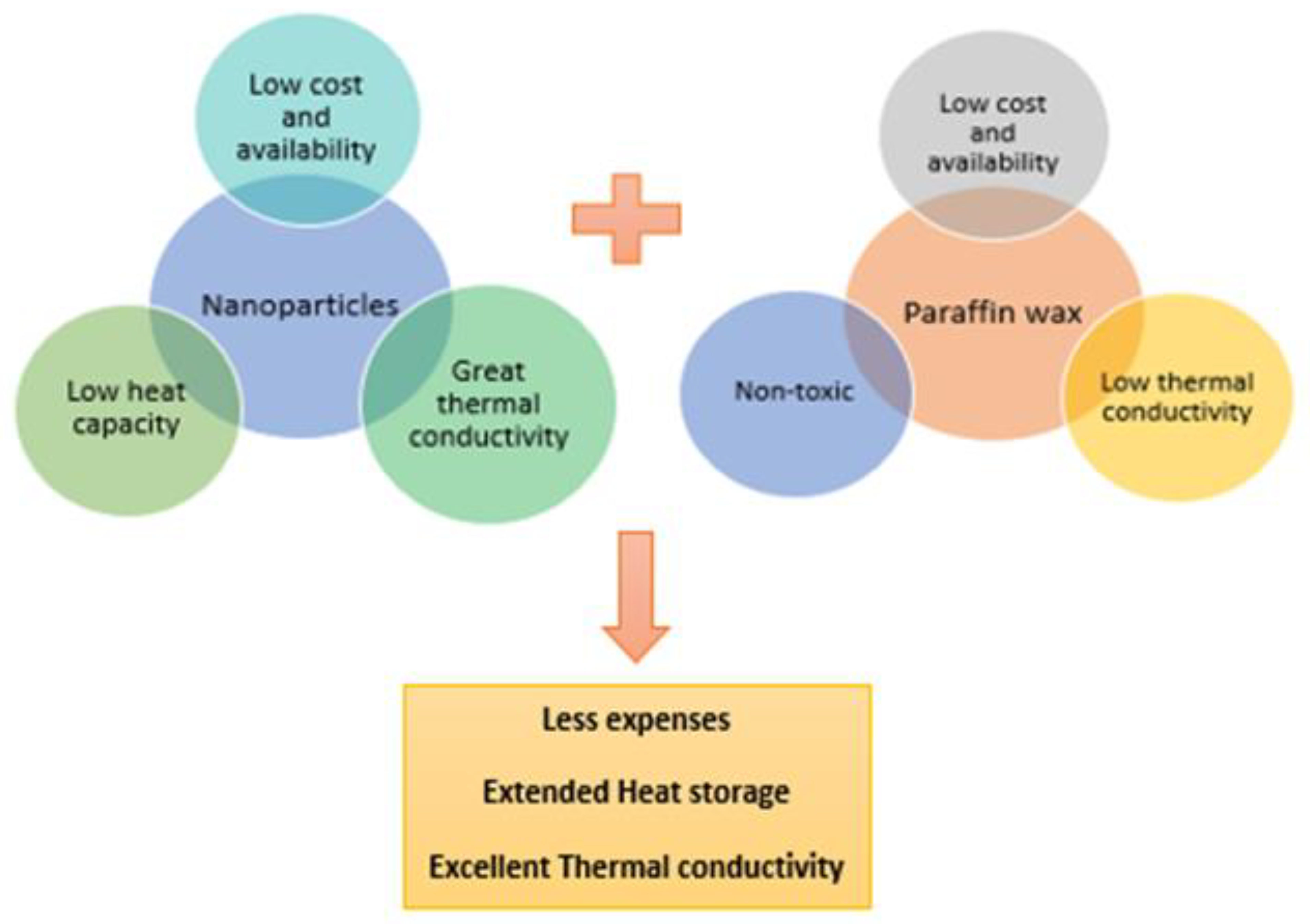

2. Impact of Nanoparticles on PCM’s Physical Behavior

- Density, latent heat, heat capacity, and thermal expansion:

- Thermal conductivity:

- Thermal diffusivity:

- Dynamic viscosity:

2.1. Influence of Thermal Conductivity

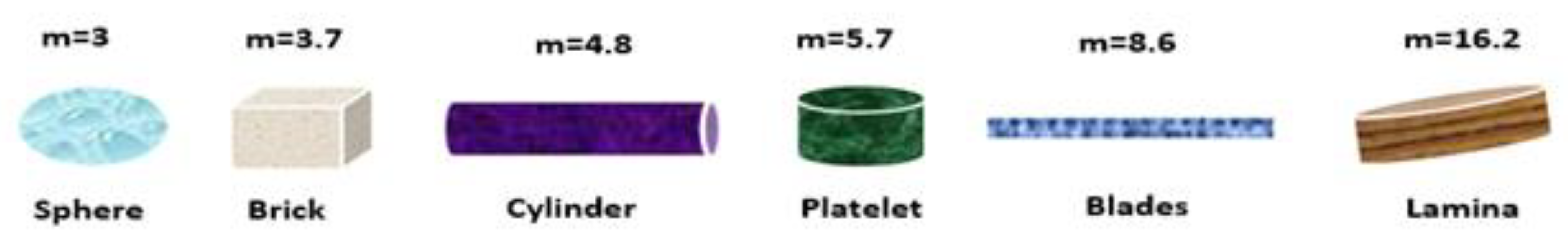

2.2. Influence of Shape Factor

3. Nano-PCM Applications

3.1. Thermal Management

3.2. Thermal Storage

4. Development and Limitations of nePCMs

5. Conclusions

- Nano-enhanced PCMs have a great potential in the electronics cooling field.

- Modern buildings can establish insulation and ventilation process by nePCMs to reduce energy consumption.

- Photovoltaic systems’ electrical efficiency can be fully exploited with nePCMs.

- With nePCMs, further solar energy may be harvested.

- Ecological equilibrium can be achieved by investing in nePCMs.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| PCM | Phase change materials |

| nePCM | Nano-enhanced phase change materials |

| TES | Thermal energy storage |

| PV | Photovoltaic |

| np | Nanoparticle |

| Symbols | |

| k | Thermal conductivity (W m−1 K−1) |

| ρ | Density (kg m−3) |

| Cp | Specific heat (Jkg−1 K−1) |

| µ | Dynamic viscosity (kg m−1 s−1) |

| α | Thermal diffusivity (m2 s−1) |

| β | Thermal expansion (K−1) |

| φ | Volume fraction of the nanoparticle (%) |

| L | Latent heat (kJ/kg) |

| T | Temperature (K) |

| m | Shape factor of nanoparticles |

References

- Bejan, A. The thermodynamic design of heat and mass transfer processes and devices. Int. J. Heat Fluid Flow 1987, 8, 258–276. [Google Scholar] [CrossRef]

- Chen, Z.S.; Li, C.; Wang, G. Common Theoretical Foundation of Thermodynamics and Heat Transfer-Universal Effective Energy Equation for Reversible and Irreversible Processes. K. Cheng Je Wu Li Hsueh Pao/J. Eng. Thermophys. 2017, 38, 1589–1596. [Google Scholar]

- Zhan, N.; Xu, Y.; Wang, D.; Zhou, W.; Lv, H. Research on the Heat Transfer Rules of Natural Convection in a Building with Single Heat Source. Procedia Eng. 2016, 146, 75–82. [Google Scholar] [CrossRef] [Green Version]

- Alam, T.; Kim, M.H. A comprehensive review on single phase heat transfer enhancement techniques in heat exchanger applications. Renew. Sustain. Energy Rev. 2018, 81, 813–839. [Google Scholar] [CrossRef]

- Ji, W.T.; Fan, J.F.; Zhao, C.Y.; Tao, W.Q. A revised performance evaluation method for energy saving effectiveness of heat transfer enhancement techniques. Int. J. Heat Mass Transf. 2019, 138, 1142–1153. [Google Scholar] [CrossRef]

- Lee, D.; Cheng, C.C. Energy savings by energy management systems: A review. Renew. Sustain. Energy Rev. 2016, 56, 760–777. [Google Scholar] [CrossRef]

- Omer, A.M. Energy, environment and sustainable development. Renew. Sustain. Energy Rev. 2008, 12, 2265–2300. [Google Scholar] [CrossRef]

- Nardi, I.; Lucchi, E.; de Rubeis, T.; Ambrosini, D. Quantification of heat energy losses through the building envelope: A state-of-the-art analysis with critical and comprehensive review on infrared thermography. Build. Environ. 2018, 146, 190–205. [Google Scholar] [CrossRef] [Green Version]

- Rodríguez-Soria, B.; Domínguez-Hernández, J.; Pérez-Bella, J.M.; del Coz-Díaz, J.J. Review of international regulations governing the thermal insulation requirements of residential buildings and the harmonization of envelope energy loss. Renew. Sustain. Energy Rev. 2014, 34, 78–90. [Google Scholar] [CrossRef]

- Moore, A.L.; Shi, L. Emerging challenges and materials for thermal management of electronics. Mater. Today 2014, 17, 163–174. [Google Scholar] [CrossRef]

- Ma, Z.; Zhao, D.; She, C.; Yang, Y.; Yang, R. Personal thermal management techniques for thermal comfort and building energy saving. Mater. Today Phys. 2021, 20, 100465. [Google Scholar] [CrossRef]

- Xu, Q.; Liang, L.; She, Y.; Xie, X.; Guo, L. Numerical investigation on thermal hydraulic characteristics of steam jet condensation in subcooled water flow in pipes. Int. J. Heat Mass Transf. 2022, 184, 122277. [Google Scholar] [CrossRef]

- Kumar, D.; Alam, M.; Zou, P.X.W.; Sanjayan, J.G.; Memon, R.A. Comparative analysis of building insulation material properties and performance. Renew. Sustain. Energy Rev. 2020, 131, 110038. [Google Scholar] [CrossRef]

- Gounni, A.; Mabrouk, M.T.; El Wazna, M.; Kheiri, A.; El Alami, M.; El Bouari, A.; Cherkaoui, O. Thermal and economic evaluation of new insulation materials for building envelope based on textile waste. Appl. Therm. Eng. 2019, 149, 475–483. [Google Scholar] [CrossRef]

- Villasmil, W.; Fischer, L.J.; Worlitschek, J. A review and evaluation of thermal insulation materials and methods for thermal energy storage systems. Renew. Sustain. Energy Rev. 2019, 103, 71–84. [Google Scholar] [CrossRef]

- Kim, M.-H.; Kim, D.; Heo, J.; Lee, D.-W. Techno-economic analysis of hybrid renewable energy system with solar district heating for net zero energy community. Energy 2019, 187, 115916. [Google Scholar] [CrossRef]

- Mayer, M.J.; Szilágyi, A.; Gróf, G. Environmental and economic multi-objective optimization of a household level hybrid renewable energy system by genetic algorithm. Appl. Energy 2020, 269, 115058. [Google Scholar] [CrossRef]

- Dhif, K.; Mebarek-Oudina, F.; Chouf, S.; Vaidya, H.; Chamkha, A.J. Thermal Analysis of the Solar Collector Cum Storage System Using a Hybrid-Nanofluids. J. Nanofluids 2021, 10, 616–626. [Google Scholar] [CrossRef]

- Rajashekhar, C.; Mebarek-Oudina, F.; Vaidya, H.; Prasad, K.V.; Manjunatha, G.; Balachandra, H. Mass and heat transport impact on the peristaltic flow of a Ree–Eyring liquid through variable properties for hemodynamic flow. Heat Transf. 2021, 50, 5106–5122. [Google Scholar] [CrossRef]

- Stewart, I.D.; Mills, G. 2—The Energetic Basis. In The Urban Heat Island; Elsevier: Amsterdam, The Netherlands, 2021; pp. 15–47. [Google Scholar]

- Sharma, S.D.; Sagara, K. Latent Heat Storage Materials and Systems: A Review. Int. J. Green Energy 2007, 2, 1–56. [Google Scholar] [CrossRef]

- Raoux, S. Phase Change Materials. Annu. Rev. Mater. Res. 2009, 39, 25–48. [Google Scholar] [CrossRef]

- Sharma, A.; Tyagi, V.V.; Chen, C.R.; Buddhi, D. Review on thermal energy storage with phase change materials and applications. Renew. Sustain. Energy Rev. 2009, 13, 318–345. [Google Scholar] [CrossRef]

- Kuznik, F.; David, D.; Johannes, K.; Roux, J.J. A review on phase change materials integrated in building walls. Renew. Sustain. Energy Rev. 2011, 15, 379–391. [Google Scholar] [CrossRef] [Green Version]

- Skovajsa, J.; Koláček, M.; Zálešák, M. Phase Change Material Based Accumulation Panels in Combination with Renewable Energy Sources and Thermoelectric Cooling. Energies 2017, 10, 152. [Google Scholar] [CrossRef] [Green Version]

- Kolokotsa, D.; Santamouris, M.; Synnefa, A.; Karlessi, T. 3.19—Passive Solar Architecture. In Comprehensive Renewable Energy; Sayigh, A., Ed.; Elsevier: Oxford, UK, 2012; pp. 637–665. [Google Scholar]

- Jesumathy, S.; Udayakumar, M.; Suresh, S. Experimental study of enhanced heat transfer by addition of CuO nanoparticle. Heat Mass Transf. 2012, 48, 965–978. [Google Scholar] [CrossRef]

- Swathykrishnan, B.; Sreelakshmi, C.; Duggal, P.; Tomar, R.K. Application of Phase Change Materials in Buildings. In Proceedings of the 2020 International Conference on Intelligent Engineering and Management (ICIEM), London, UK, 17–19 June 2020; pp. 203–206. [Google Scholar]

- Kushwah, A.; Gaur, M.; Pandit, R. The Role of Phase Change Materials for Lifetime Heating of Buildings in Cold Climatic Conditions. Int. J. Built Environ. Sustain. 2020, 7, 81–96. [Google Scholar] [CrossRef]

- Tariq, S.; Ali, H.; Akram, M.; Janjua, M.; Ahmadlouydarab, M. Nanoparticles enhanced Phase Change Materials (NePCMs)-A Recent Review. Appl. Therm. Eng. 2020, 176, 115305. [Google Scholar] [CrossRef]

- Barreneche, C.; Navarro, H.; Serrano, S.; Cabeza, L.F.; Fernández, A. New Database on Phase Change Materials for Thermal Energy Storage in Buildings to Help PCM Selection. Energy Procedia 2014, 57, 2408–2415. [Google Scholar] [CrossRef] [Green Version]

- Rathore, P.; Shukla, S. Potential of macro encapsulated PCM for thermal energy storage in buildings: A comprehensive review. Constr. Build. Mater. 2019, 225, 723–744. [Google Scholar] [CrossRef]

- Hassan, A.; Laghari, M.S.; Rashid, Y. Micro-Encapsulated Phase Change Materials: A Review of Encapsulation, Safety and Thermal Characteristics. Sustainability 2016, 8, 1046. [Google Scholar] [CrossRef] [Green Version]

- Ayala, E.; Enghardt, M.H.; Horton, M. Cost Effective, Environmentally Safe Tissue Processing Method with Paraffin Oil. J. Histotechnol. 1997, 20, 133–137. [Google Scholar] [CrossRef]

- Soibam, J. Numerical Investigation of a Heat Exchanger using Phase Change Materials (PCMs) for Small-Scale Combustion Appliances. Master’s Thesis, Norwegian University of Science and Technology, Trondheim, Norway, June 2018. [Google Scholar]

- Khalifa, A.J.; Suffer, K.; Shakier, M. A storage domestic solar hot water system with a back layer of phase change material. Exp. Therm. Fluid Sci. 2013, 44, 174–181. [Google Scholar] [CrossRef]

- Pagkalos, C.; Dogkas, G.; Koukou, M.K.; Konstantaras, J.; Lymperis, K.; Vrachopoulos, M.G. Evaluation of water and paraffin PCM as storage media for use in thermal energy storage applications: A numerical approach. Int. J. Thermal Fluids 2020, 1–2, 100006. [Google Scholar] [CrossRef]

- Regin, A.F.; Solanki, S.C.; Saini, J.S. Heat transfer characteristics of thermal energy storage system using PCM capsules: A review. Renew. Sustain. Energy Rev. 2008, 12, 2438–2458. [Google Scholar] [CrossRef]

- Al-Yasiri, Q.; Szabo, M. Performance Assessment of Phase Change Materials Integrated with Building Envelope for Heating Application in Cold Locations. Eur. J. Energy Res. 2021, 1, 7–14. [Google Scholar] [CrossRef]

- Coşanay, H.; Selimefendigil, F.; Öztop, H.F.; Sarı, A. Experimental Analysis of Melting Behavior of Capric Acid (CA)–Stearic Acid (SA) Eutectic Mixture and its 3D Numerical Solution of Natural Convection in a Cup. Arab. J. Sci. Eng. 2022, 47, 15575–15589. [Google Scholar] [CrossRef]

- Al-Najjar, H.M.T.; Mahdi, J.M.; Bokov, D.O.; Khedher, N.B.; Alshammari, N.K.; Catalan Opulencia, M.J.; Fagiry, M.A.; Yaïci, W.; Talebizadehsardari, P. Improving the Melting Duration of a PV/PCM System Integrated with Different Metal Foam Configurations for Thermal Energy Management. Nanomaterials 2022, 12, 423. [Google Scholar] [CrossRef]

- Charvát, P.; Klimeš, L.; Ostrý, M. Numerical and experimental investigation of a PCM-based thermal storage unit for solar air systems. Energy Build. 2014, 68, 488–497. [Google Scholar] [CrossRef]

- Osterman, E.; Butala, V.; Stritih, U. PCM thermal storage system for ‘free’ heating and cooling of buildings. Energy Build. 2015, 106, 125–133. [Google Scholar] [CrossRef]

- Stropnik, R.; Koželj, R.; Zavrl, E.; Stritih, U. Improved thermal energy storage for nearly zero energy buildings with PCM integration. Sol. Energy 2019, 190, 420–426. [Google Scholar] [CrossRef]

- Maranda, S.; Sponagle, B.; Worlitschek, J.; Groulx, D. Experimental Investigation of Thin PCM Packages and Thermal Spreader for Thermal Management of Portable Electronic Devices. Appl. Sci. 2019, 9, 21. [Google Scholar] [CrossRef]

- Arumuru, V.; Rajput, K.; Nandan, R.; Rath, P.; Das, M. A novel synthetic jet based heat sink with PCM filled cylindrical fins for efficient electronic cooling. J. Energy Storage 2023, 58, 106376. [Google Scholar] [CrossRef]

- Devaux, P.; Farid, M.M. Benefits of PCM underfloor heating with PCM wallboards for space heating in winter. Appl. Energy 2017, 191, 593–602. [Google Scholar] [CrossRef]

- Chow, T.-T.; Lyu, Y. Numerical analysis on the advantage of using PCM heat exchanger in liquid-flow window. Appl. Therm. Eng. 2017, 125, 1218–1227. [Google Scholar] [CrossRef]

- Salihi, M.; El Fiti, M.; Harmen, Y.; Chhiti, Y.; Chebak, A.; Alaoui, F.E.M.; Achak, M.; Bentiss, F.; Jama, C. Evaluation of global energy performance of building walls integrating PCM: Numerical study in semi-arid climate in Morocco. Case Stud. Constr. Mater. 2022, 16, e00979. [Google Scholar] [CrossRef]

- Mosavi, A.; Mehdizadeh, H.; Abbasian-Naghneh, S.; Kalbasi, R.; Karimipour, A.; Cheraghian, G. Incorporation of Horizontal Fins into a PCM-Based Heat Sink to Enhance the Safe Operation Time: Applicable in Electronic Device Cooling. Appl. Sci. 2020, 10, 18. [Google Scholar] [CrossRef]

- Nicol, J.F.; Roaf, S. Rethinking thermal comfort. Build. Res. Inf. 2017, 45, 711–716. [Google Scholar] [CrossRef]

- Sorgato, M.J.; Melo, A.P.; Lamberts, R. The effect of window opening ventilation control on residential building energy consumption. Energy Build. 2016, 133, 1–13. [Google Scholar] [CrossRef]

- Rostami, S.; Afrand, M.; Shahsavar, A.; Sheikholeslami, M.; Kalbasi, R.; Aghakhani, S.; Shadloo, M.S.; Oztop, H.F. A review of melting and freezing processes of PCM/nano-PCM and their application in energy storage. Energy 2020, 211, 118698. [Google Scholar] [CrossRef]

- Ji, H.; Sellan, D.P.; Pettes, M.T.; Kong, X.; Ji, J.; Shi, L.; Ruoff, R.S. Enhanced thermal conductivity of phase change materials with ultrathin-graphite foams for thermal energy storage. Energy Environ. Sci. 2014, 7, 1185–1192. [Google Scholar] [CrossRef]

- Jamil, N.; Kaur, J.; Pandey, A.; Shahabuddin, S.; Hassani, S.; Saidur, R.; Ali, R.R.; Sidik, N.A.C.; Naim, M. A Review on Nano Enhanced Phase Change Materials: An Enhancement in Thermal Properties and Specific Heat Capacity. J. Adv. Res. Fluid Mech. Therm. Sci. 2019, 57, 110–120. [Google Scholar]

- Qureshi, Z.; Ali, H.; Khushnood, S. Recent advances on thermal conductivity enhancement of phase change materials for energy storage system: A review. Int. J. Heat Mass Transf. 2018, 127, 838–856. [Google Scholar] [CrossRef]

- Al-Ahmed, A.; Sarı, A.; Mazumder, M.A.J.; Hekimoğlu, G.; Al-Sulaiman, F.A.; Inamuddin. Thermal energy storage and thermal conductivity properties of Octadecanol-MWCNT composite PCMs as promising organic heat storage materials. Sci. Rep. 2020, 10, 9168. [Google Scholar] [CrossRef] [PubMed]

- Safira, L.; Putra, N.; Trisnadewi, T.; Kusrini, E.; Mahlia, T.M.I. Thermal properties of sonicated graphene in coconut oil as a phase change material for energy storage in building applications. Int. J. Low-Carbon Technol. 2020, 15, 629–636. [Google Scholar] [CrossRef]

- Hashempour, S.; Vakili, M.H. Preparation and characterisation of nano enhanced phase change material by adding carbon nano tubes to butyl stearate. J. Exp. Nanosci. 2018, 13, 188–198. [Google Scholar] [CrossRef] [Green Version]

- Said, Z.; Zeyad, H.; Eisa, T.I.; Assad, M.E.H. Nano-Enhanced PCM for Energy Storage. In Proceedings of the 2019 Advances in Science and Engineering Technology International Conferences (ASET), Dubai, United Arab Emirates, 26 March–10 April 2019; pp. 1–6. [Google Scholar]

- Sweidan, A.H.; Heider, Y.; Markert, B. Modeling of PCM-based enhanced latent heat storage systems using a phase-field-porous media approach. Contin. Mech. Thermodyn. 2020, 32, 861–882. [Google Scholar] [CrossRef]

- Raza, J.; Mebarek-Oudina, F.; Ram, P.; Sharma, S. MHD Flow of Non-Newtonian Molybdenum Disulfide Nanofluid in a Converging/Diverging Channel with Rosseland Radiation. Defect Diffus. Forum 2020, 401, 92–106. [Google Scholar] [CrossRef]

- Ruiz-Cabañas, F.; Jové, A.; Prieto, C.; Madina, V.; Fernández, A.; Cabeza, L.F. Materials selection of steam-phase change material (PCM) heat exchanger for thermal energy storage systems in direct steam generation facilities. Sol. Energy Mater. Sol. Cells 2017, 159, 526–535. [Google Scholar] [CrossRef] [Green Version]

- Marzougui, S.; Mebarek-Oudina, F.; Assia, A.; Magherbi, M.; Shah, Z.; Ramesh, K. Entropy Generation on Magneto-Convective Flow of Copper-Water Nanofluid in a Cavity with Chamfers. J. Therm. Anal. Calorim. 2021, 143, 2203–2214. [Google Scholar] [CrossRef]

- Mundra, S.S.; Pardeshi, S.S. Latent heat energy storage system using phase change materials and techniques for their performance improvement: A Review. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1126, 012068. [Google Scholar] [CrossRef]

- Khan, U.; Zaib, A.; Mebarek-Oudina, F. Mixed convective magneto flow of SiO2-MoS2/C2H6O2 hybrid nanoliquids through a vertical stretching/shrinking wedge: Stability analysis. Arab. J. Sci. Eng. 2020, 45, 9061–9073. [Google Scholar] [CrossRef]

- Shafiq, A.; Mebarek-Oudina, F.; Sindhu, T.N.; Rassoul, G. Sensitivity analysis for Walters’ B nanoliquid flow over a radiative Riga surface by RSM. Sci. Iran. 2022, 29, 1236–1249. [Google Scholar] [CrossRef]

- Raza, J.; Mebarek-Oudina, F.; Lund, L.A. The flow of magnetised convective Casson liquid via a porous channel with shrinking and stationary walls. Pramana J. Phys. 2022, 96, 229. [Google Scholar] [CrossRef]

- Singh, R.; Sadeghi, S.; Shabani, B. Thermal Conductivity Enhancement of Phase Change Materials for Low-Temperature Thermal Energy Storage Applications. Energies 2019, 12, 75. [Google Scholar] [CrossRef] [Green Version]

- Marzougui, S.; Mebarek-Oudina, F.; Mchirgui, A.; Magherbi, M. Entropy Generation and Heat transport of Cu-water Nanoliquid in Porous lid-driven Cavity through Magnetic Field. Int. J. Numer. Methods Heat Fluid Flow 2022, 32, 2047–2069. [Google Scholar] [CrossRef]

- Murugan, P.; Ganesh Kumar, P.; Kumaresan, V.; Meikandan, M.; Mohan, K.M.; Velraj, R. Thermal energy storage behaviour of nanoparticle enhanced PCM during freezing and melting. Phase Transit. 2018, 91, 254–270. [Google Scholar]

- Yadav, C.; Sahoo, R.R. Effect of nano-enhanced PCM on the thermal performance of a designed cylindrical thermal energy storage system. Exp. Heat Transf. 2021, 34, 356–375. [Google Scholar] [CrossRef]

- Mebarek-Oudina, F.; Chabani, I. Review on Nano-Fluids Applications and Heat Transfer Enhancement Techniques in Different Enclosures. J. Nanofluids 2022, 11, 155–168. [Google Scholar] [CrossRef]

- Swain, K.; Mebarek-Oudina, F.; Abo-Dahab, S. Influence of MWCNT/Fe3O4 hybrid nanoparticles on an exponentially porous shrinking sheet with chemical reaction and slip boundary conditions. J. Therm. Anal. Calorim. 2022, 147, 1561–1570. [Google Scholar] [CrossRef]

- Wong, K.V.; De Leon, O. Applications of Nanofluids: Current and Future. Adv. Mech. Eng. 2010, 2, 519659. [Google Scholar] [CrossRef] [Green Version]

- Chabani, I.; Mebarek-Oudina, F.; Vaidya, H.; Ismail, A.I. Numerical analysis of magnetic hybrid Nano-fluid natural convective flow in an adjusted porous trapezoidal enclosure. J. Magn. Magn. Mater. 2022, 564, 170142. [Google Scholar] [CrossRef]

- Khan, U.; Mebarek-Oudina, F.; Zaib, A.; Ishak, A.; Abu Bakar, S.; Sherif, E.-S.M.; Baleanu, D. An exact solution of a Casson fluid flow induced by dust particles with hybrid nanofluid over a stretching sheet subject to Lorentz forces. Waves Random Complex Media 2022, 1–14. [Google Scholar] [CrossRef]

- Xuan, Y.; Li, Q. Heat transfer enhancement of nanofluids. Int. J. Heat Fluid Flow 2000, 21, 58–64. [Google Scholar] [CrossRef]

- Reddy, Y.D.; Mebarek-Oudina, F.; Goud, B.S.; Ismail, A.I. Radiation, Velocity and Thermal Slips Effect Toward MHD Boundary Layer Flow Through Heat and Mass Transport of Williamson Nanofluid with Porous Medium. Arab. J. Sci. Eng. 2022, 47, 16355–16369. [Google Scholar] [CrossRef]

- Muneeshwaran, M.; Srinivasan, G.; Muthukumar, P.; Wang, C.C. Role of hybrid-nanofluid in heat transfer enhancement—A review. Int. Commun. Heat Mass Transf. 2021, 125, 105341. [Google Scholar] [CrossRef]

- Borode, A.O.; Ahmed, N.A.; Olubambi, P.A.; Sharifpur, M.; Meyer, J.P. Investigation of the Thermal Conductivity, Viscosity, and Thermal Performance of Graphene Nanoplatelet-Alumina Hybrid Nanofluid in a Differentially Heated Cavity. Front. Energy Res. 2021, 9, 737915. [Google Scholar] [CrossRef]

- Li, X.; Wang, H.; Luo, B. The thermophysical properties and enhanced heat transfer performance of SiC-MWCNTs hybrid nanofluids for car radiator system. Colloids Surf. A Physicochem. Eng. Asp. 2020, 612, 125968. [Google Scholar] [CrossRef]

- Al-Jethelah, M.; Tasnim, S.H.; Mahmud, S.; Dutta, A. Nano-PCM filled energy storage system for solar-thermal applications. Renew. Energy 2018, 126, 137–155. [Google Scholar] [CrossRef]

- Arshad, A.; Jabbal, M.; Yan, Y.; Darkwa, J. The micro-/nano-PCMs for thermal energy storage systems: A state of art review. Int. J. Energy Res. 2019, 43, 5572–5620. [Google Scholar] [CrossRef]

- Arfiansyah, E.; Juwono, A.L. Thermal Modification by High Speed In Situ Mixing for Nanoparticles TiO2 and SDS Surfactant to Paraffin Based PCM Nano Enhanced Composite. Mater. Sci. Forum 2021, 1028, 240–248. [Google Scholar] [CrossRef]

- Angayarkanni, S.A.; Philip, J. Review on thermal properties of nanofluids: Recent developments. Adv. Colloid Interface Sci. 2015, 225, 146–176. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Stetsyuk, V.; Kubiak, K.J.; Yap, Y.F.; Goharzadeh, A.; Chai, J.C. Nanoparticles for convective heat transfer enhancement: Heat transfer coefficient and the effects of particle size and zeta potential. Chem. Eng. Commun. 2019, 206, 761–771. [Google Scholar] [CrossRef] [Green Version]

- Adnan; Khan, U.; Ahmed, N.; Mohyud-Din, S.T.; Alsulami, M.D.; Khan, I. A novel analysis of heat transfer in the nanofluid composed by nanodimaond and silver nanomaterials: Numerical investigation. Sci. Rep. 2022, 12, 1284. [Google Scholar] [CrossRef] [PubMed]

- Chabani, I.; Mebarek-Oudina, F.; Ismail, A.I. MHD Flow of a Hybrid Nano-Fluid in a Triangular Enclosure with Zigzags and an Elliptic Obstacle. Micromachines 2022, 13, 224. [Google Scholar] [CrossRef]

- Mebarek-Oudina, F. Convective heat transfer of Titania nanofluids of different base fluids in cylindrical annulus with discrete heat source. Heat Transf. Asian Res. 2019, 48, 135–147. [Google Scholar] [CrossRef] [Green Version]

- Asogwa, K.K.; Mebarek-Oudina, F.; Animasaun, I.L. Comparative Investigation of Water-Based Al2O3 Nanoparticles Through Water-Based CuO Nanoparticles Over an Exponentially Accelerated Radiative Riga Plate Surface via Heat Transport. Arab. J. Sci. Eng. 2022, 47, 8721–8738. [Google Scholar] [CrossRef]

- Sun, Y.; Yang, D.; Shi, L.; Wu, H.; Cao, Y.; He, Y.; Xie, T. Properties of Nanofluids and Their Applications in Enhanced Oil Recovery: A Comprehensive Review. Energy Fuels 2020, 34, 1202–1218. [Google Scholar] [CrossRef]

- Ali, A.R.I.; Salam, B. A review on nanofluid: Preparation, stability, thermophysical properties, heat transfer characteristics and application. SN Appl. Sci. 2020, 2, 1636. [Google Scholar] [CrossRef]

- Maghrabie, H.M.; Elsaid, K.; Sayed, E.T.; Abdelkareem, M.A.; Wilberforce, T.; Ramadan, M.; Olabi, A.G. Intensification of heat exchanger performance utilizing nanofluids. Int. J. 2021, 10, 100071. [Google Scholar] [CrossRef]

- Nanografi. Available online: https://nanografi.com/ (accessed on 7 January 2023).

- Alibaba. Available online: https://www.alibaba.com/ (accessed on 7 January 2023).

- Mebarek-Oudina, F.; Fares, R.; Choudhari, R. Convection Heat Transfer of MgO-Ag/Water Magneto-Hybrid Nanoliquid Flow into a Special Porous Enclosure. Alger. J. Renew. Energy Sustain. Dev. 2020, 2, 84–95. [Google Scholar] [CrossRef]

- Selimefendigil, F.; Öztop, H.F.; Doranehgard, M.H.; Karimi, N. Phase change dynamics in a cylinder containing hybrid nanofluid and phase change material subjected to a rotating inner disk. J. Energy Storage 2021, 42, 103007. [Google Scholar] [CrossRef]

- Xu, W.; Huang, T.; Huang, S.-M.; Zhuang, Y. Regulation mechanism of magnetic field on non-Newtonian melting and energy storage performance of metal foam composite nano-enhanced phase change materials. Int. J. Heat Mass Transf. 2023, 200, 123501. [Google Scholar] [CrossRef]

- Leong, K.Y.; Abdul Rahman, M.R.; Gurunathan, B.A. Nano-enhanced phase change materials: A review of thermo-physical properties, applications and challenges. J. Energy Storage 2019, 21, 18–31. [Google Scholar] [CrossRef]

- Abdullah, M.Z.; Nasir, F.M.; Abdul Majid, M.F.M. Empirical Viscosity Modeling for SiO2 and Al2O3 Nanofluids Using the Response Surface Method. J. Adv. Res. Fluid Mech. Therm. Sci. 2021, 75, 63–72. [Google Scholar]

- Gagan, S.; Singh, M.; Satbir, S.; Sandhu, H. Experimental Study of Thermal Properties of PCM with addition of Nanoparticles. Indian J. Sci. Technol. 2018, 11, 1–5. [Google Scholar] [CrossRef]

- Sheikholeslami, M. Numerical modeling of nano enhanced PCM solidification in an enclosure with metallic fin. J. Mol. Liq. 2018, 259, 424–438. [Google Scholar] [CrossRef]

- Reddy, K.; Reddy, R.M.; Prasad, B. Experimental Study of Thermal Energy Storage System using Nanofluid. In Techno-Societal, Proceedings of the International Conference on Advanced Technologies for Societal Applications, Pandharpur, India, 20–21 December 2018; Springer: Berlin/Heidelberg, Germany, 2018; pp. 509–514. [Google Scholar]

- Alosious, S.; Sarath, S.R.; Nair, A.R.; Krishnakumar, K. Experimental and numerical study on heat transfer enhancement of flat tube radiator using Al2O3 and CuO nanofluids. Heat Mass Transf. 2017, 53, 3545–3563. [Google Scholar] [CrossRef]

- Faraji, H.; El Alami, M.; Arshad, A.; Faraji, M. Numerical simulation of the melting of a NePCM for cooling of electronic components. Therm. Sci. Eng. Prog. 2021, 21, 100766. [Google Scholar] [CrossRef]

- Li, Z.; Sheikholeslami, M.; Shafee, A.; Haq, R.-u.; Khan, I.; Tlili, I.; Kandasamy, R. Solidification process through a solar energy storage enclosure using various sizes of Al2O3 nanoparticles. J. Mol. Liq. 2019, 275, 941–954. [Google Scholar] [CrossRef]

- Massoudi, M.D.; Ben Hamida, M.B.; Almeshaal, M. Free convection and thermal radiation of nanofluid inside nonagon inclined cavity containing a porous medium influenced by magnetic field with variable direction in the presence of uniform heat generation/absorption. Int. J. Numer. Methods Heat Fluid Flow 2021, 3, 933–958. [Google Scholar] [CrossRef]

- Almeida, F.; Gireesha, B.J.; Venkatesh, P.; Ramesh, G.K. Intrinsic irreversibility of AlO–HO nanofluid Poiseuille flow with variable viscosity and convective cooling. Int. J. Numer. Methods Heat Fluid Flow 2021, 31, 2042–2063. [Google Scholar] [CrossRef]

- Mechai, I.; Abu-Hamdeh, N.H.; Talabany, Z.J.; Ajour, M.N.; Hatamleh, R.I.; Musa, A. Thermal storage examination with Galerkin approach involving mixture of water and nanoparticles. J. Energy Storage 2023, 57, 106281. [Google Scholar] [CrossRef]

- Othman, H.A.; Rguigui, H.; Altoum, S.H.; Elamin, M.A. Nanomaterial efficacy on freezing of PCM with involvement of numerical simulation. J. Mol. Liq. 2022, 362, 119658. [Google Scholar] [CrossRef]

- Li, Z.; Leng, J.; Talabany, Z.J.; Abu-Hamdeh, N.H.; Attar, E.T.; Rothan, Y.A.; Milyani, A.H.; Hussin, A.M. Numerical modeling for phase change within storage system including adaptive grid. J. Energy Storage 2023, 57, 106227. [Google Scholar] [CrossRef]

- Abu-Hamdeh, N.H.; Alghamdi, S.M.; Talabany, Z.J.; Rothan, Y.A.; AlQemlas, T.; Musa, A. Numerical thermal storage analysis within discharging involving nanomaterial. J. Energy Storage 2023, 59, 106530. [Google Scholar] [CrossRef]

- Rothan, Y.A. Modeling for freezing of PCM enhanced with nano-powders within a duct. Eur. Phys. J. Plus 2022, 137, 573. [Google Scholar] [CrossRef]

- Al-Jethelah, M.; Tasnim, S.H.; Mahmud, S.; Dutta, A. Melting of nano-PCM in an enclosed space: Scale analysis and heatline tracking. Int. J. Heat Mass Transf. 2018, 119, 841–859. [Google Scholar] [CrossRef]

- Sheikholeslami, M.; Haq, R.-u.; Shafee, A.; Li, Z. Heat transfer behavior of nanoparticle enhanced PCM solidification through an enclosure with V shaped fins. Int. J. Heat Mass Transf. 2019, 130, 1322–1342. [Google Scholar] [CrossRef]

- Motevali, A.; Rostami, M.H.; Najafi, G.; Yan, W.M. Evaluation and Improvement of PCM Melting in Double Tube Heat Exchangers Using Different Combinations of Nanoparticles and PCM (The Case of Renewable Energy Systems). Sustainability 2021, 13, 10675. [Google Scholar] [CrossRef]

- Nitsas, M.T.; Koronaki, I.P. Thermal Analysis of Pure and Nanoparticle-Enhanced PCM—Application in Concentric Tube Heat Exchanger. Energies 2020, 13, 3841. [Google Scholar] [CrossRef]

- Ghalambaz, M.; Mehryan, S.A.M.; Ayoubloo, K.A.; Hajjar, A.; El Kadri, M.; Younis, O.; Pour, M.S.; Hulme-Smith, C. Thermal Energy Storage and Heat Transfer of Nano-Enhanced Phase Change Material (NePCM) in a Shell and Tube Thermal Energy Storage (TES) Unit with a Partial Layer of Eccentric Copper Foam. Molecules 2021, 26, 1491. [Google Scholar] [CrossRef] [PubMed]

- Bashirpour-Bonab, H. Investigation and optimization of PCM melting with nanoparticle in a multi-tube thermal energy storage system. Case Stud. Therm. Eng. 2021, 28, 101643. [Google Scholar] [CrossRef]

- Buonomo, B.; Ercole, D.; Manca, O.; Nardini, S. Numerical investigation on Nano-PCM in aluminum foam in latent thermal energy storages. Model. Meas. Control. B 2018, 87, 207–212. [Google Scholar] [CrossRef]

- Amidu, M.A.; Ali, M.; Alkaabi, A.K.; Addad, Y. A Critical Assessment of Nanoparticles Enhanced Phase Change Materials (nePCMs) for Latent Heat Energy Storage Applications. SSRN 2022, in press. [Google Scholar] [CrossRef]

- Chibani, A.; Merouani, S. Acceleration of Heat Transfer and Melting Rate of a Phase Change Material by Nanoparticles Addition at Low Concentrations. Int. J. Thermophys. 2021, 42, 66. [Google Scholar] [CrossRef]

- Akhmetov, B.; Navarro, M.E.; Seitov, A.; Kaltayev, A.; Bakenov, Z.; Ding, Y. Numerical study of integrated latent heat thermal energy storage devices using nanoparticle-enhanced phase change materials. Sol. Energy 2019, 194, 724–741. [Google Scholar] [CrossRef]

- Elbahjaoui, R.; El Qarnia, H. Transient behavior analysis of the melting of nanoparticle-enhanced phase change material inside a rectangular latent heat storage unit. Appl. Therm. Eng. 2017, 112, 720–738. [Google Scholar] [CrossRef]

- Hao Kean, T.; Sidik, N.A.C. Thermal Performance Analysis of Nanoparticles Enhanced Phase Change Material (NEPCM) in Cold Thermal Energy Storage (CTES). CFD Lett. 2021, 11, 79–91. [Google Scholar]

- Sharma, S.; Micheli, L.; Chang, W.; Tahir, A.A.; Reddy, K.S.; Mallick, T.K. Nano-enhanced Phase Change Material for thermal management of BICPV. Appl. Energy 2017, 208, 719–733. [Google Scholar] [CrossRef]

- Hussein, F.M.; Faraj, J.J.; Kareem, R.J. Automation, Experimental Investigation of Adding Nano-Particles to PCM for Heating Applications. J. Mech. Eng. Autom. 2018, 8, 32–37. [Google Scholar]

- Santosh, R.; Kumaresan, G.; Paranthaman, V.; Swaminathan, M.R.; Velraj, R. Comparative investigation on heat transfer enhancement of surface-roughened and nano-dispersed phase change material for thermal energy storage. Int. J. Energy Res. 2021, 45, 15992–16005. [Google Scholar] [CrossRef]

- Bashiri Rezaie, A.; Montazer, M. Shape-stable thermo-responsive nano Fe3O4/fatty acids/PET composite phase-change material for thermal energy management and saving applications. Appl. Energy 2020, 262, 114501. [Google Scholar] [CrossRef]

- Chandel, S.S.; Agarwal, T. Review of current state of research on energy storage, toxicity, health hazards and commercialization of phase changing materials. Renew. Sustain. Energy Rev. 2017, 67, 581–596. [Google Scholar] [CrossRef]

- Ghasemi, K.; Tasnim, S.; Mahmud, S. PCM, nano/microencapsulation and slurries: A review of fundamentals, categories, fabrication, numerical models and applications. Sustain. Energy Technol. Assess 2022, 52, 102084. [Google Scholar] [CrossRef]

- Keshteli, A.N.; Sheikholeslami, M. Nanoparticle enhanced PCM applications for intensification of thermal performance in building: A review. J. Mol. Liq. 2019, 274, 516–533. [Google Scholar] [CrossRef]

- Nižetić, S.; Jurčević, M.; Arıcı, M.; Arasu, A.V.; Xie, G. Nano-enhanced phase change materials and fluids in energy applications: A review. Renew. Sustain. Energy Rev. 2020, 129, 109931. [Google Scholar] [CrossRef]

- Williams, J.D.; Peterson, G.P. A Review of Thermal Property Enhancements of Low-Temperature Nano-Enhanced Phase Change Materials. Nanomaterials 2021, 11, 2578. [Google Scholar] [CrossRef]

- Parameshwaran, R.; Kalaiselvam, S. Energy conservative air conditioning system using silver nano-based PCM thermal storage for modern buildings. Energy Build. 2014, 69, 202–212. [Google Scholar] [CrossRef]

- Kant, K.; Anand, A.; Shukla, A.; Sharma, A. Heat transfer study of building integrated photovoltaic (BIPV) with nano-enhanced phase change materials. J. Energy Storage 2020, 30, 101563. [Google Scholar] [CrossRef]

- Nada, S.A.; El-Nagar, D.H.; Hussein, H.M.S. Improving the thermal regulation and efficiency enhancement of PCM-Integrated PV modules using nano particles. Energy Convers. Manag. 2018, 166, 735–743. [Google Scholar] [CrossRef]

- Al-Waeli, A.H.A.; Sopian, K.; Chaichan, M.T.; Kazem, H.A.; Ibrahim, A.; Mat, S.; Ruslan, M.H. Evaluation of the nanofluid and nano-PCM based photovoltaic thermal (PVT) system: An experimental study. Energy Convers. Manag. 2017, 151, 693–708. [Google Scholar] [CrossRef]

- Jilte, R.; Afzal, A.; Panchal, S. A novel battery thermal management system using nano-enhanced phase change materials. Energy 2021, 219, 119564. [Google Scholar] [CrossRef]

- Kumar, R.; Mitra, A.; Srinivas, T. Role of nano-additives in the thermal management of lithium-ion batteries: A review. J. Energy Storage 2022, 48, 104059. [Google Scholar] [CrossRef]

- Alshaer, W.G.; Nada, S.A.; Rady, M.A.; Del Barrio, E.P.; Sommier, A. Thermal management of electronic devices using carbon foam and PCM/nano-composite. Int. J. Therm. Sci. 2015, 89, 79–86. [Google Scholar] [CrossRef]

- Iradukunda, A.-C.; Kasitz, J.; Carlton, H.; Huitink, D.; Deshpande, A.; Luo, F. Concurrent Thermal and Electrical Property Effects of Nano-Enhanced Phase Change Material for High-Voltage Electronics Applications. J. Electron. Packag. 2020, 142, 031109. [Google Scholar] [CrossRef]

- Agrawal, R.; Singh, K.D.P. A review on productivity enhancement of solar still by application of PCM and nano enhanced PCM. In AIP Conference Proceedings; AIP Publishing LLC: Melville, NY, USA, 2021; Volume 2341, p. 030010. [Google Scholar]

- Chen, H.; Li, S.; Wei, P.; Gong, Y.; Nie, P.; Chen, X.; Wang, C. Experimental study on characteristics of a nano-enhanced phase change material slurry for low temperature solar energy collection. Sol. Energy Mater. Sol. Cells 2020, 212, 110513. [Google Scholar] [CrossRef]

- Biswas, K.; Lu, J.; Soroushian, P.; Shrestha, S. Combined experimental and numerical evaluation of a prototype nano-PCM enhanced wallboard. Appl. Energy 2014, 131, 517–529. [Google Scholar] [CrossRef]

- Akeiber, H.; Nejat, P.; Majid, M.Z.A.; Wahid, M.A.; Jomehzadeh, F.; Famileh, I.Z.; Calautit, J.K.; Hughes, B.R.; Zaki, S.A. A review on phase change material (PCM) for sustainable passive cooling in building envelopes. Renew. Sustain. Energy Rev. 2016, 60, 1470–1497. [Google Scholar] [CrossRef]

- Al-Mudhafar, A.H.N.; Hamzah, M.T.; Tarish, A.L. Potential of integrating PCMs in residential building envelope to reduce cooling energy consumption. Case Stud. Therm. Eng. 2021, 27, 101360. [Google Scholar] [CrossRef]

- Wijesuriya, S.; Tabares-Velasco, P.C.; Biswas, K.; Heim, D. Empirical validation and comparison of PCM modeling algorithms commonly used in building energy and hygrothermal software. Build. Environ. 2020, 173, 106750. [Google Scholar] [CrossRef]

- El Qattan, A. Enhancing an Urban Energy Efficiency by Application of PCM and Nano-PCM Materials in Residential Building. In Proceedings of the 12th International Conference on Nano-Technology for Green and Sustainable Construction, Sharm El-Sheikh, Egypt, 27–31 March 2020. [Google Scholar]

- Ma, Z.; Lin, W.; Sohel, M.I. Nano-enhanced phase change materials for improved building performance. Renew. Sustain. Energy Rev. 2016, 58, 1256–1268. [Google Scholar] [CrossRef] [Green Version]

- Li, D.; Wu, Y.; Liu, C.; Zhang, G.; Arıcı, M. Energy investigation of glazed windows containing Nano-PCM in different seasons. Energy Convers. Manag. 2018, 172, 119–128. [Google Scholar] [CrossRef]

- Sayyar, M.; Weerasiri, R.R.; Soroushian, P.; Lu, J. Experimental and numerical study of shape-stable phase-change nanocomposite toward energy-efficient building constructions. Energy Build. 2014, 75, 249–255. [Google Scholar] [CrossRef]

- Al-Waeli, A.H.A.; Kazem, H.A.; Chaichan, M.T.; Sopian, K. Experimental investigation of using nano-PCM/nanofluid on a photovoltaic thermal system (PVT): Technical and economic study. Therm. Sci. Eng. Prog. 2019, 11, 213–230. [Google Scholar] [CrossRef]

- Stalin, P.M.J.; Prasad, K.S.; Kumar, K.P.; Hemadri, G.; Rajesh, M.; Kumar, K.P. Performance improvement of solar PV through the thermal management using a nano-PCM. Mater. Today Proc. 2022, 50, 1553–1558. [Google Scholar] [CrossRef]

- Sopian, K.; Alwaeli, A.H.A.; Al-Shamani, A.N.; Elbreki, A.M. Thermodynamic analysis of new concepts for enhancing cooling of PV panels for grid-connected PV systems. J. Therm. Anal. Calorim. 2019, 136, 147–157. [Google Scholar] [CrossRef]

- Karimi, G.; Azizi, M.; Babapoor, A. Experimental study of a cylindrical lithium ion battery thermal management using phase change material composites. J. Energy Storage 2016, 8, 168–174. [Google Scholar] [CrossRef]

- Krishna, J.; Kishore, P.S.; Solomon, A.B. Heat pipe with nano enhanced-PCM for electronic cooling application. Exp. Therm. Fluid Sci. 2017, 81, 84–92. [Google Scholar] [CrossRef] [Green Version]

- Kumar, A.; Kothari, R.; Sahu, S.K.; Kundalwal, S.I. Thermal performance of heat sink using nano-enhanced phase change material (NePCM) for cooling of electronic components. Microelectron. Reliab. 2021, 121, 114144. [Google Scholar] [CrossRef]

- Faraji, H.; Faraji, M.; El Alami, M.; Hariti, Y.; Arshad, A.; Hader, A.; Benkaddour, A. Cooling of recent microprocessors by the fusion of nano-enhanced phase change materials. Mater. Today Proc. 2020, 30, 865–869. [Google Scholar] [CrossRef]

- Kothari, R.; Vaidya, D.V.; Shelke, V.; Sahu, S.K.; Kundalwal, S.I. Experimental Investigation of Thermal Performance of Nano-Enhanced Phase Change Materials for Thermal Management of Electronic Components. In Proceedings of the ASME Power Conference, Salt Lake City, UT, USA, 15–18 July 2019. [Google Scholar]

- Al-Rashed, A.A.A.A. Thermal management of lithium-ion batteries with simultaneous use of hybrid nanofluid and nano-enhanced phase change material: A numerical study. J. Energy Storage 2022, 46, 103730. [Google Scholar] [CrossRef]

- Murali, G.; Sravya, G.S.N.; Srinath, A.; Jaya, J. An Experimental Investigation on Cooling Performance of Battery Pack by Using Nano-Enhanced Phase Change Material. J. Comput. Theor. Nanosci. 2021, 18, 1213–1220. [Google Scholar] [CrossRef]

- Temel, U.N.; Kilinc, F.; Coskun, S. Thermal Protection Performances of the Macro and/or Nano Enhanced PCM in a Representative Battery Pack. Nanoscale Microscale Thermophys. Eng. 2022, 26, 52–66. [Google Scholar] [CrossRef]

- Abdelrazik, A.S.; Saidur, R.; Al-Sulaiman, F.A. Thermal regulation and performance assessment of a hybrid photovoltaic/thermal system using different combinations of nano-enhanced phase change materials. Sol. Energy Mater. Sol. Cells 2020, 215, 110645. [Google Scholar] [CrossRef]

- Barreneche, C.; Martín, M.; Calvo-de la Rosa, J.; Majó, M.; Fernández, A.I. Own-Synthetize Nanoparticles to Develop Nano-Enhanced Phase Change Materials (NEPCM) to Improve the Energy Efficiency in Buildings. Molecules 2019, 24, 1232. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ashok, V.; Geetha, N.B.; Rajkumar, S.; Pauline, T. Experimental Investigations for Thermal Energy Management by Encapsulation of Nano -Enhanced Bio Phase Change Material in buildings. Energy Sources Part A Recovery Util. Environ. Eff. 2022, 44, 4165–4183. [Google Scholar]

- Martín, M.; Villalba, A.; Fernández, A.I.; Barreneche, C. Development of new nano-enhanced phase change materials (NEPCM) to improve energy efficiency in buildings: Lab-scale characterization. Energy Build. 2019, 192, 75–83. [Google Scholar] [CrossRef]

- Bahrami, L.; Kasaeian, A.; Pourfayaz, F.; Ghafarian, S. Modeling of the effect of nano-enhanced phase change material on the performance of a large-scale wallboard. J. Therm. Eng. 2021, 7, 1857–1871. [Google Scholar] [CrossRef]

- Abdollahi, N.; Rahimi, M. Potential of water natural circulation coupled with nano-enhanced PCM for PV module cooling. Renew. Energy 2020, 147, 302–309. [Google Scholar] [CrossRef]

- Kandeal, A.W.; Algazzar, A.M.; Elkadeem, M.R.; Thakur, A.K.; Abdelaziz, G.B.; El-Said, E.M.S.; Elsaid, A.M.; An, M.; Kandel, R.; Fawzy, H.E.; et al. Nano-enhanced cooling techniques for photovoltaic panels: A systematic review and prospect recommendations. Sol. Energy 2021, 227, 259–272. [Google Scholar] [CrossRef]

- Ergün, A. Energy and exergy analysis of a PV/thermal storage system design integrated with nano-enhanced phase changing material. Int. J. Exergy 2020, 32, 82–101. [Google Scholar] [CrossRef]

- Abdelrazik, A.S.; Al-Sulaiman, F.A.; Saidur, R. Numerical investigation of the effects of the nano-enhanced phase change materials on the thermal and electrical performance of hybrid PV/thermal systems. Energy Convers. Manag. 2020, 205, 112449. [Google Scholar] [CrossRef]

- Daneshazarian, R.; Antoun, S.; Dworkin, S.B. Performance Assessment of Nano-enhanced Phase Change Material for Thermal Storage. Int. J. Heat Mass Transf. 2021, 173, 121256. [Google Scholar] [CrossRef]

- Alomair, M.; Alomair, Y.; Tasnim, S.; Mahmud, S.; Abdullah, H. Analyses of Bio-Based Nano-PCM filled Concentric Cylindrical Energy Storage System in Vertical Orientation. J. Energy Storage 2018, 20, 380–394. [Google Scholar] [CrossRef]

- Das, N.; Kohno, M.; Takata, Y.; Patil, D.V.; Harish, S. Enhanced melting behavior of carbon based phase change nanocomposites in horizontally oriented latent heat thermal energy storage system. Appl. Therm. Eng. 2017, 125, 880–890. [Google Scholar] [CrossRef]

- Harikrishnan, S.; Hussain, S.I.; Devaraju, A.; Sivasamy, P.; Kalaiselvam, S. Improved performance of a newly prepared nano-enhanced phase change material for solar energy storage. J. Mech. Sci. Technol. 2017, 31, 4903–4910. [Google Scholar] [CrossRef]

- Xiong, Q.; Tlili, I.; Dara, R.N.; Shafee, A.; Nguyen-Thoi, T.; Rebey, A.; Haq, R.-U.; Li, Z. Energy storage simulation involving nePCM solidification in appearance of fins. Phys. A Stat. Mech. Its Appl. 2020, 544, 123566. [Google Scholar] [CrossRef]

- Yadav, A.; Shivhare, M.K. Nanoparticle Enhanced PCM for Solar Thermal Energy Storage. In Proceedings of the 2020 Advances in Science and Engineering Technology International Conferences (ASET), Dubai, United Arab Emirates, 4 February–9 April 2020; pp. 1–3. [Google Scholar]

- Sharshir, S.W.; El-Shafai, N.M.; Ibrahim, M.M.; Kandeal, A.W.; El-Sheshtawy, H.S.; Ramadan, M.S.; Rashad, M.; El-Mehasseb, I.M. Effect of copper oxide/cobalt oxide nanocomposite on phase change material for direct/indirect solar energy applications: Experimental investigation. J. Energy Storage 2021, 38, 102526. [Google Scholar] [CrossRef]

- Singh, R.P.; Xu, H.; Kaushik, S.C.; Rakshit, D.; Romagnoli, A. Charging performance evaluation of finned conical thermal storage system encapsulated with nano-enhanced phase change material. Appl. Therm. Eng. 2019, 151, 176–190. [Google Scholar] [CrossRef]

- Mousavi, S.; Siavashi, M.; Heyhat, M.M. Numerical melting performance analysis of a cylindrical thermal energy storage unit using nano-enhanced PCM and multiple horizontal fins. Numer. Heat Transf. Part A Appl. 2019, 75, 560–577. [Google Scholar] [CrossRef]

- Lohrasbi, S.; Miry, S.Z.; Gorji-Bandpy, M.; Ganji, D.D. Performance enhancement of finned heat pipe assisted latent heat thermal energy storage system in the presence of nano-enhanced H2O as phase change material. Int. J. Hydrogen Energy 2017, 42, 6526–6546. [Google Scholar] [CrossRef]

- Selimefendigil, F.; Şirin, C. Experimental investigation of a parabolic greenhouse dryer improved with copper oxide nano-enhanced latent heat thermal energy storage unit. Int. J. Energy Res. 2022, 46, 3647–3662. [Google Scholar] [CrossRef]

- Sharma, R.K.; Ganesan, P.; Tyagi, V.V.; Metselaar, H.S.C.; Sandaran, S.C. Thermal properties and heat storage analysis of palmitic acid-TiO2 composite as nano-enhanced organic phase change material (NEOPCM). Appl. Therm. Eng. 2016, 99, 1254–1262. [Google Scholar] [CrossRef]

- Algarni, S.; Mellouli, S.; Alqahtani, T.; Almutairi, K.; Khan, A.; Anqi, A. Experimental investigation of an evacuated tube solar collector incorporating nano-enhanced PCM as a thermal booster. Appl. Therm. Eng. 2020, 180, 115831. [Google Scholar] [CrossRef]

- Elarem, R.; Alqahtani, T.; Mellouli, S.; Aich, W.; Khedher, N.B.; Kolsi, L.; Jemni, A. Numerical study of an Evacuated Tube Solar Collector incorporating a Nano-PCM as a latent heat storage system. Case Stud. Therm. Eng. 2021, 24, 100859. [Google Scholar] [CrossRef]

- Punniakodi, B.M.S.; Senthil, R. Recent developments in nano-enhanced phase change materials for solar thermal storage. Sol. Energy Mater. Sol. Cells 2022, 238, 111629. [Google Scholar] [CrossRef]

- Yang, R.; Li, D.; Salazar, S.L.; Rao, Z.; Arıcı, M.; Wei, W. Photothermal properties and photothermal conversion performance of nano-enhanced paraffin as a phase change thermal energy storage material. Sol. Energy Mater. Sol. Cells 2021, 219, 110792. [Google Scholar] [CrossRef]

- Khan, M.M.A.; Ibrahim, N.I.; Mahbubul, I.M.; Ali, H.M.; Saidur, R.; Al-Sulaiman, F.A. Evaluation of solar collector designs with integrated latent heat thermal energy storage: A review. Solar Energy 2018, 166, 334–350. [Google Scholar] [CrossRef]

- Khanlari, A.; Tuncer, A.D.; Sözen, A.; Aytaç, İ.; Çiftçi, E.; Variyenli, H.İ. Energy and exergy analysis of a vertical solar air heater with nano-enhanced absorber coating and perforated baffles. Renew. Energy 2022, 187, 586–602. [Google Scholar] [CrossRef]

- Lebedev, V.A.; Amer, A.E. Limitations of using phase change materials for thermal energy storage. IOP Conf. Ser. Earth Environ. Sci. 2019, 378, 012044. [Google Scholar] [CrossRef]

- Rathod, M.K.; Banerjee, J. Thermal stability of phase change materials used in latent heat energy storage systems: A review. Renew. Sustain. Energy Rev. 2013, 18, 246–258. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Castell, A.; Barreneche, C.; Gracia, A.; Fernández, A. Materials used as PCM inthermal energy storage in buildings: A review Renewable and Sustainable. Energy Rev. 2011, 15, 1675–1695. [Google Scholar]

- Naeem, L.A.; Al-Hattab, T.A.; Abdulwahab, M.I. Study of the Performance of Paraffin Wax As a Phase Change Material in Packed Bed Thermal Energy Storage System. Iraqi J. Chem. Pet. Eng. 2018, 17, 25–33. [Google Scholar]

- Sharma, A.; Sharma, S.D.; Buddhi, D.; Sawhney, R.L. Thermal cycle test of urea for latent heat storage applications. Int. J. Energy Res. 2001, 25, 465–468. [Google Scholar] [CrossRef]

- El-Sebaii, A.A.; Al-Amir, S.; Al-Marzouki, F.M.; Faidah, A.S.; Al-Ghamdi, A.A.; Al-Heniti, S. Fast thermal cycling of acetanilide and magnesium chloride hexahydrate for indoor solar cooking. Energy Convers. Manag. 2009, 50, 3104–3111. [Google Scholar] [CrossRef]

- Shukla, A.; Buddhi, D.; Sawhney, R. Thermal cycling test of few selected inorganic and organic phase change materials. Renew. Energy 2008, 33, 2606–2614. [Google Scholar] [CrossRef]

| Authors | Thermal System | Revelations |

|---|---|---|

| Charvát et al. [42] | Numerical and experimental investigation on a unit of heat storage filled with paraffin wax for a solar system |

|

| Osterman et al. [43] | Numerical and experimental analysis in an office envelope embedded with an air-based solar collector and Paraffin thermal storage unit. |

|

| Stropnik et al. [44] | Experimental inquiry on the employment of PCMs in a storage tank. |

|

| Arumuruet al. [45] | Heat sink with cylindrical fins and PCM studied experimentally. |

|

| Maranda et al. [46] | Electronic component with a PCM package experimentally considered. |

|

| Devaux and Farid [47] | Numerical study with Energy-Plus on the incorporation of phase change materials in two huts. |

|

| Chow and Lyu [48] | Double-pipe water–heat exchanger with a PCM layer evaluated with a FORTRAN code. |

|

| Salihi et al. [49] | Simulation with Energy-Plus software of a building with PCMs layers in its walls. |

|

| Mosavi et al. [50] | Computational study on the behavior of paraffin in a heat sink with rectangular fins. |

|

| Authors | Nanoparticles | Findings |

|---|---|---|

| Liu et al. [87] | SiO2, TiO2, and Al2O3 | 45% overall enhancement in thermal efficiency when introducing nanoparticles. |

| Adnan et al. [88] | Ag | Conformity of nanoparticle usage with industrial and engineering sectors. |

| Chabani et al. [89] | Cu, and TiO2 | The great thermal conductivity of nanoparticles promotes enhanced exploitation of thermal configuration. |

| Mebarek-Oudina [90] | TiO2 | Thermal efficiency is directly related to the incremented presence of nanoparticles. |

| Asogwa et al. [91] | Al2O3 and CuO | The type and thermo-physical aspects of the nanoparticles determine theheat absorption rateand circulation. |

| Yongxiang et al. [92] | Fe2O3, ZnO, Ag, and SiO2 | Nanoparticles can alter and increase the thermal conductivity of the base fluid. |

| Ali et al. [93] | MgO, CuO, Al2O3, and TiO2 | Thermo-physical properties of nanoparticles present them as great candidates for heat exchange, cooling and heating systems. |

| Maghrabie et al. [94] | MWCNT and Al2O3 | Nano-fluids can absorb prolonged amounts of heat and thus alter the heat exchanger performance. |

| Thermal Conductivity (W/mK) | |

|---|---|

| CuO | 33 |

| Al2O3 | 17.65 |

| Paraffin | 0.21 |

| Configuration | Findings | References |

|---|---|---|

| Numerical analysis of a 2D square enclosure filled with a solid nano-PCM | The melting process is accelerated when introducing nanoparticles. | [115] |

| Storage system with plain encapsulated paraffin PCM | Solidification and melting duration are lessened for PCM with Al2O3. | [116] |

| Double-tube heat exchanger tested numerically | Including nano-PCMs in heat exchangers boost their thermal efficiency, with a 39% reduction in melting process. | [117] |

| Concentric tube in a heat exchanger with PCMs simulated | Heat storage rate is intensified as nanoparticles are induced. Addition of nanoparticles in PCMs should be controlled to maintain an equilibrium between kinematic viscosity and heat transfer. | [118] |

| Porous thermal system (shell and tube) filled with nano-PCMs numerically modelled | 13% of melting time is gained when suspending several nanoparticles in PCMs. | [119] |

| Computational evaluation of a multi-tube thermal system with nePCM | Up to 22% of energy savings is obtained, owing to the thermal conductivity of nano-enhanced PCMs. | [120] |

| Quantitative inquiry on a parallelepiped tank with nano-PCM | Energy storage rate of the TES is enhanced for the nano-PCM comparing to metal foam. | [121] |

| Numerical examination of a triplex tube heat exchanger | 50% thermal transfer increase through the nano-PCM distribution. | [122] |

| Simulation of a rectangular thermal energy storage system with nano-PCMs | The addition of nanoparticles in PCMs improves thermal transmission and melting rate substantially. | [123] |

| Melting and solidification process of nano-PCM numerically | Alumina nanoparticles enhanced the PCM’s thermal conductivity. | [124] |

| Modelling of the melting of nano-enhanced PCM | Nanoparticle concentration and Rayleigh number are proportional to melting time decrease. | [125] |

| Cavity filled with pure PCM and nePCM managed numerically and experimentally | The exceeding augmentation in nanoparticle volume fraction strengthens the viscosity and thus deteriorates the thermal performance. | [126] |

| BICPV thermo-electrical system with micro-fins, PCM, and nano-PCM experimentally evaluated | Heat transfer coefficient is augmented when combing micro-fins and nano-PCMs. Temperature reduction of 19%, thus boosting the cooling performance. | [127] |

| Experimental investigation on the charging and discharging process in a heat exchanger using water, air, and nano-PCMs | Increasing nanoparticle concentration reduces the charging duration by almost 9%. | [128] |

| Application | Authors | Findings |

|---|---|---|

| Electronic component cooling | Krishna et al. [158] | 25% reduction in the evaporator temperature. NePCM can save up to 53% of the electrical energy supposedly supplied to the fan. |

| Kumar et al. [159] | 15 °C decrease in temperature is reported. | |

| Faraji et al. [160] | Nusselt number is enhanced with nePCM and thus contributes to extended cooling of the microprocessor. | |

| Kothari et al. [161] | Temperatures of electronic elements drop with nePCM. | |

| Cooling of batteries | Al-Rashed [162] | Hybrid nanoparticle suspensions in PCMs enhanced the thermal properties. |

| Murali et al. [163] | Nano-enhanced PCM regulated the temperature distribution under 50 °C. | |

| Temel et al. [164] | Working temperature of the battery cell experiences major decrease through nePCM. | |

| Heyhat et al. [165] | Nanoparticles contributed to managing the working temperature of the battery. | |

| Buildings | Barreneche et al. [166] | Thermo-stability of nePCMs makes them compatible with building performance improvement. |

| Ashok et al. [167] | Thermal comfort is achieved at a low cost in buildings that use nePCMs. | |

| Martín et al. [168] | Nano-enhanced PCMs ensure protracted enhanced thermal effectiveness. | |

| Bahrami et al. [169] | Temperature fluctuations of the envelope are regulated by 52% due to the nePCM. Nano-enhanced PCM reduced the ventilating system consumption by 7%. | |

| PV systems | Abdollahi and Rahimi [170] | Electrical productivity is improved by almost 50% for the nePCM case. |

| Kandeal et al. [171] | Adapting cooling process with nano-enhanced PCMs is a reliable strategy. | |

| Ergün [172] | Upgrading the system with nePCMs delivers 42 W of energy savings and ensures a decreased rate of energy destruction. | |

| Abdelrazik et al. [173] | High thermal and electrical performance are provided by the nePCM owing to the overall temperature regulation in July. |

| Authors | Conception | Results |

|---|---|---|

| Singh et al. [181] | Finned conical TES | Charging time of TES with nePCM is much lower than that of pure PCM. |

| Mousavi et al. [182] | Cylindrical TES | Melting time of nePCM is shorter when adding fins. |

| Lohrasbi et al. [183] | Finned heat pipe TES | Prolonged heat storage is reported for the nePCM case. |

| Selimefendigil and Şirin [184] | Parabolic greenhouse dryer | TES with nePCM lowered the average energy consumption. Nanoparticles contribution reduced the drying time by 58%. |

| Sharma et al. [185] | Heat storage equipment | Nano-enhanced organic PCMs highly enhance the energy storage rate. |

| Algarni et al. [186] | Tube solar collector | Employing nano-enhanced PCMs boosted the thermal efficiency and produced heated water for extended periods. |

| Elarem et al. [187] | Evacuated Tube Solar Collector | Nano-enhanced PCM intensifies and accelerates thermal transmission. |

| Punniakodi and Senthil [188] | Solar thermal storage system | Thermal storage enhancement is directly related to nanoparticle addition to PCMs. |

| Yang et al. [189] | Glass thermal storage envelope | Maximum performance is reached when increasing the nanoparticle volume fraction. |

| Khan et al. [190] | Solar collectors | Strong thermal transfer is associated with high temperature outlet values, which nePCMs assure. |

| Khanlari et al. [191] | Solar air heater | Absorbing coefficient is augmented by presence of nePCMs. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mebarek-Oudina, F.; Chabani, I. Review on Nano Enhanced PCMs: Insight on nePCM Application in Thermal Management/Storage Systems. Energies 2023, 16, 1066. https://doi.org/10.3390/en16031066

Mebarek-Oudina F, Chabani I. Review on Nano Enhanced PCMs: Insight on nePCM Application in Thermal Management/Storage Systems. Energies. 2023; 16(3):1066. https://doi.org/10.3390/en16031066

Chicago/Turabian StyleMebarek-Oudina, Fateh, and Ines Chabani. 2023. "Review on Nano Enhanced PCMs: Insight on nePCM Application in Thermal Management/Storage Systems" Energies 16, no. 3: 1066. https://doi.org/10.3390/en16031066

APA StyleMebarek-Oudina, F., & Chabani, I. (2023). Review on Nano Enhanced PCMs: Insight on nePCM Application in Thermal Management/Storage Systems. Energies, 16(3), 1066. https://doi.org/10.3390/en16031066