Development of Transpiration-Type Thermoelectric-Power-Generating Material Using Carbon Nanotube Composite Papers with Capillary Action and Heat of Vaporization

Abstract

1. Introduction

2. Experimental Section

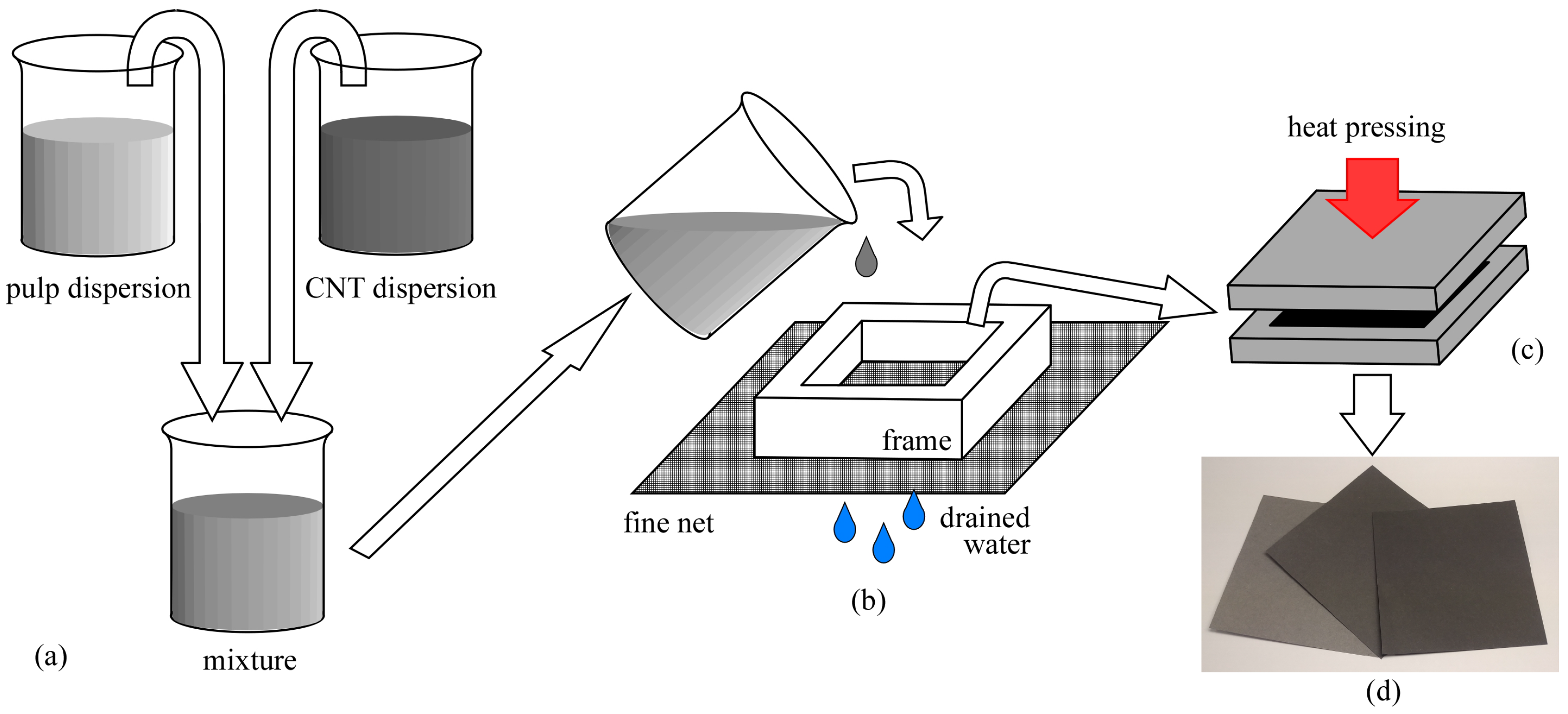

2.1. CNTCP Fabrication Method

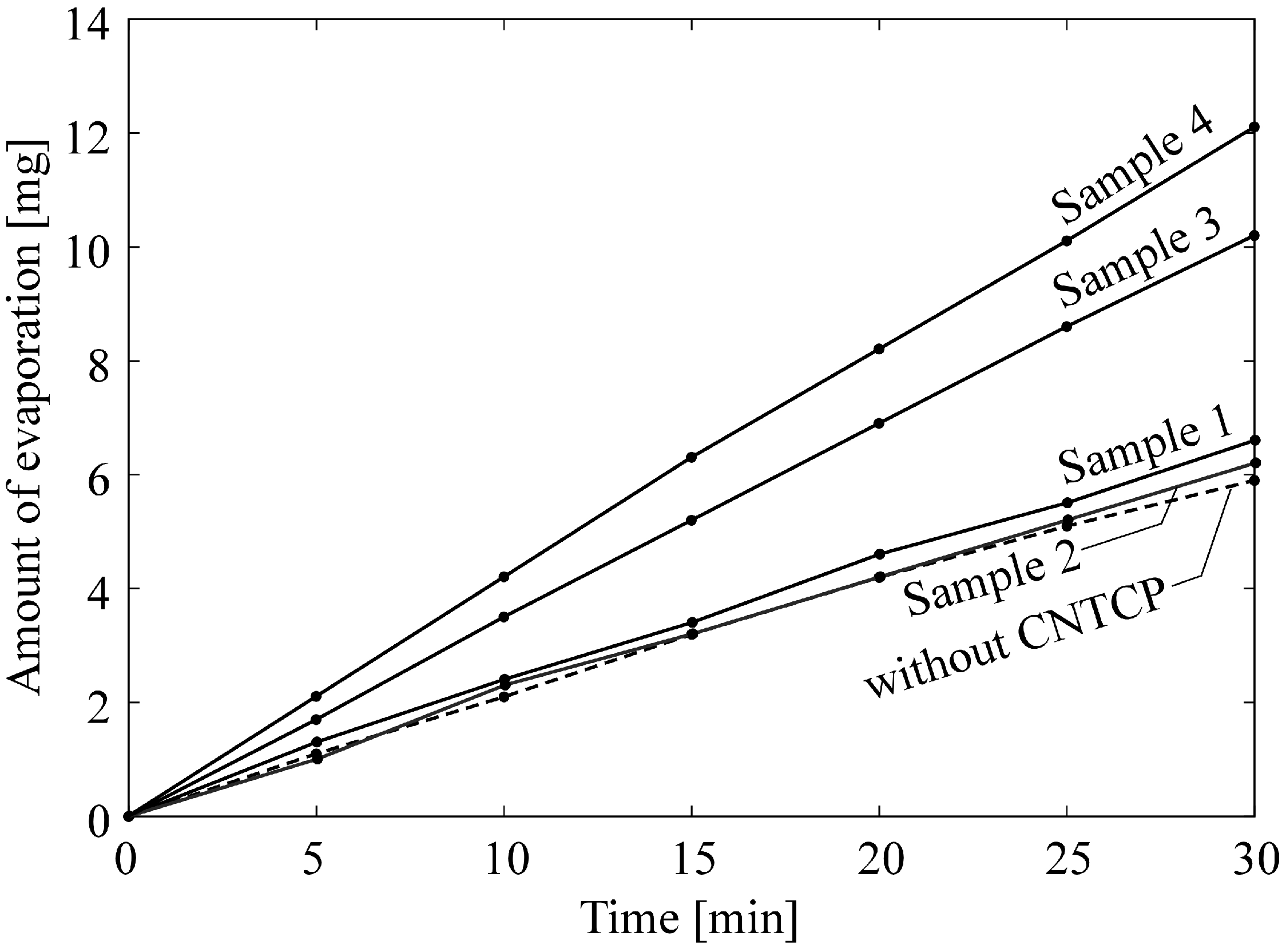

2.2. Evaluation of Liquid Absorption Ability

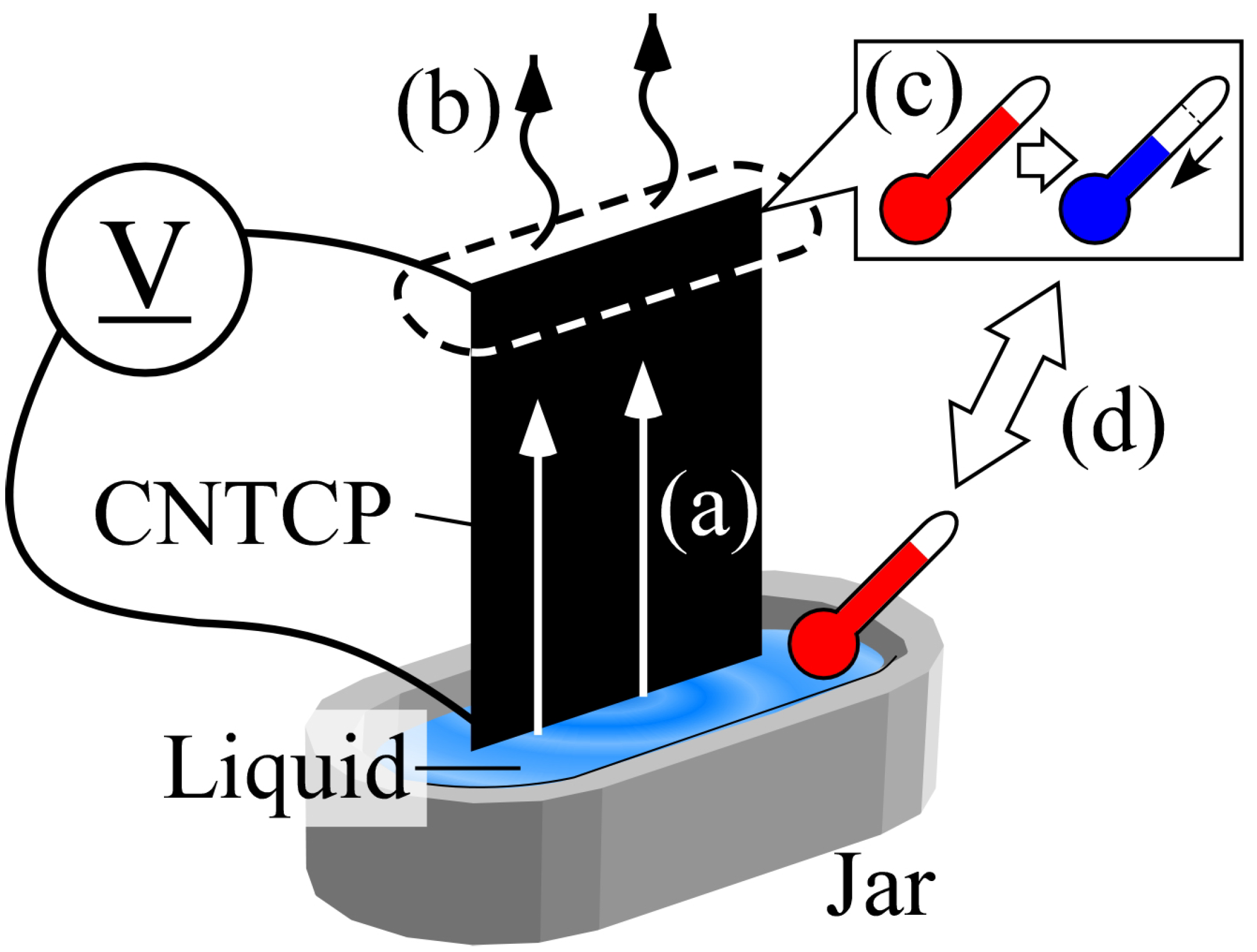

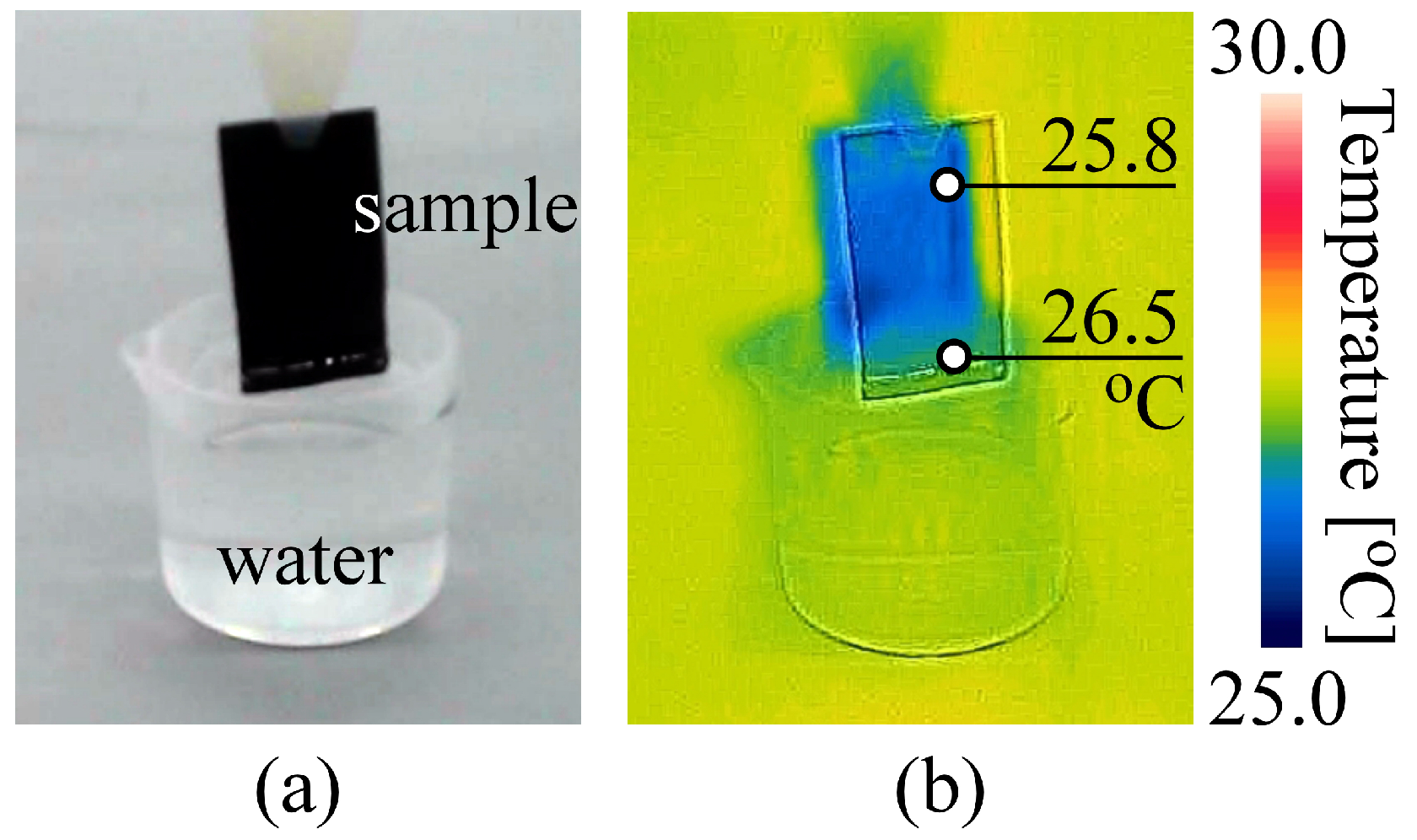

2.3. Measuring Transpiration-Type Thermoelectric Power Generation

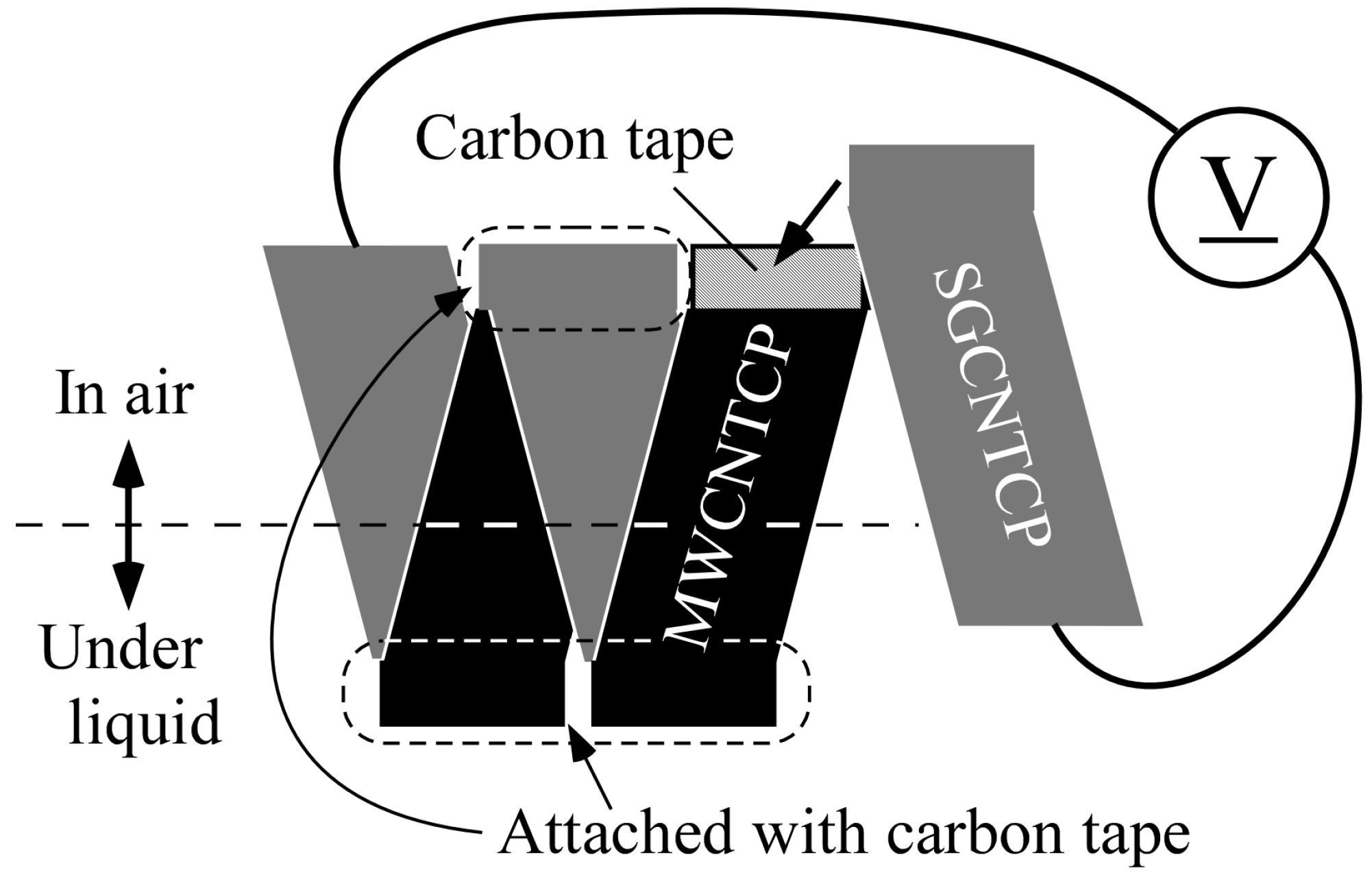

2.4. Examination to Improve Electromotive Force by Using Multiple Sheets

3. Results

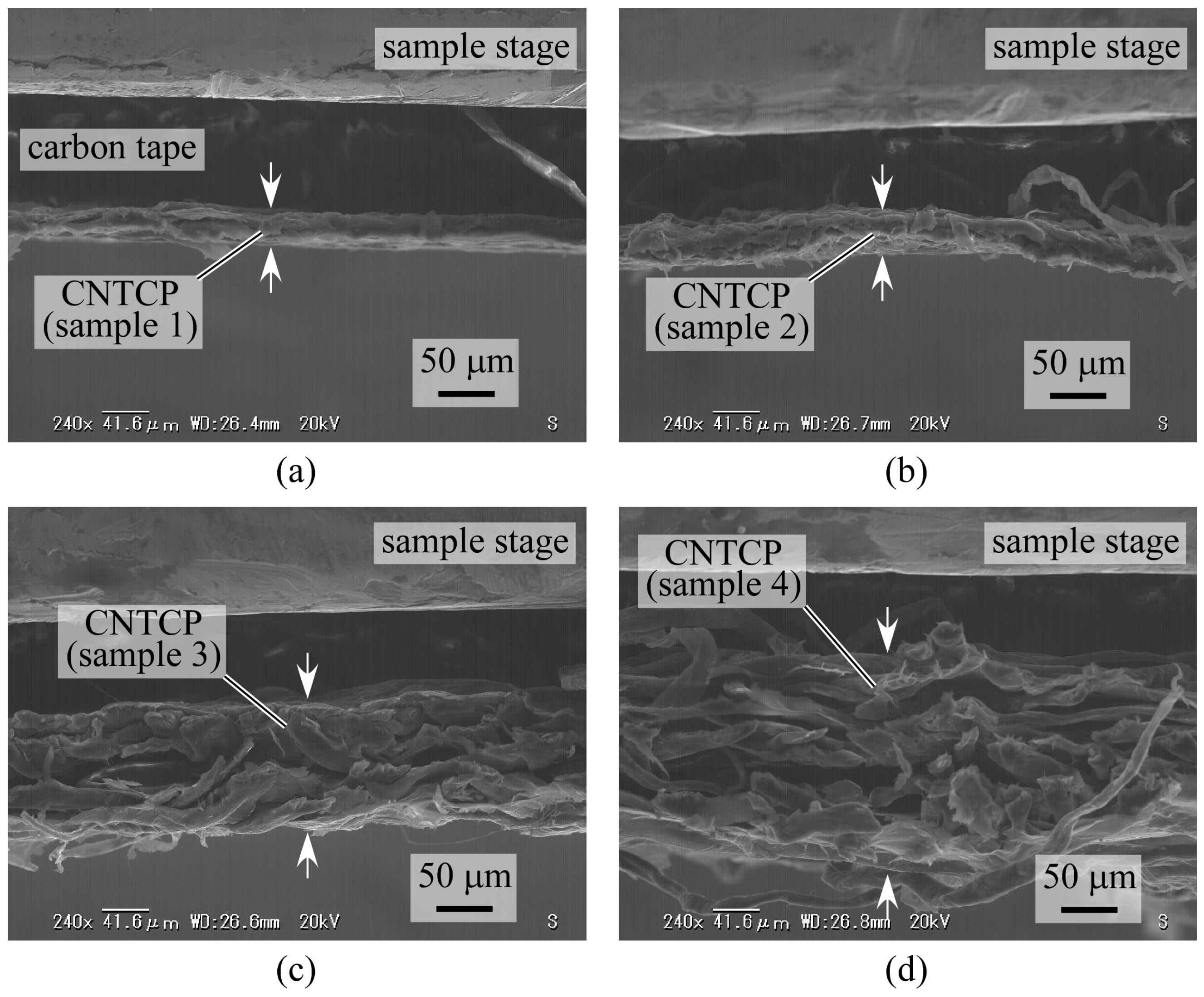

3.1. Absorption Ability of CNTCP

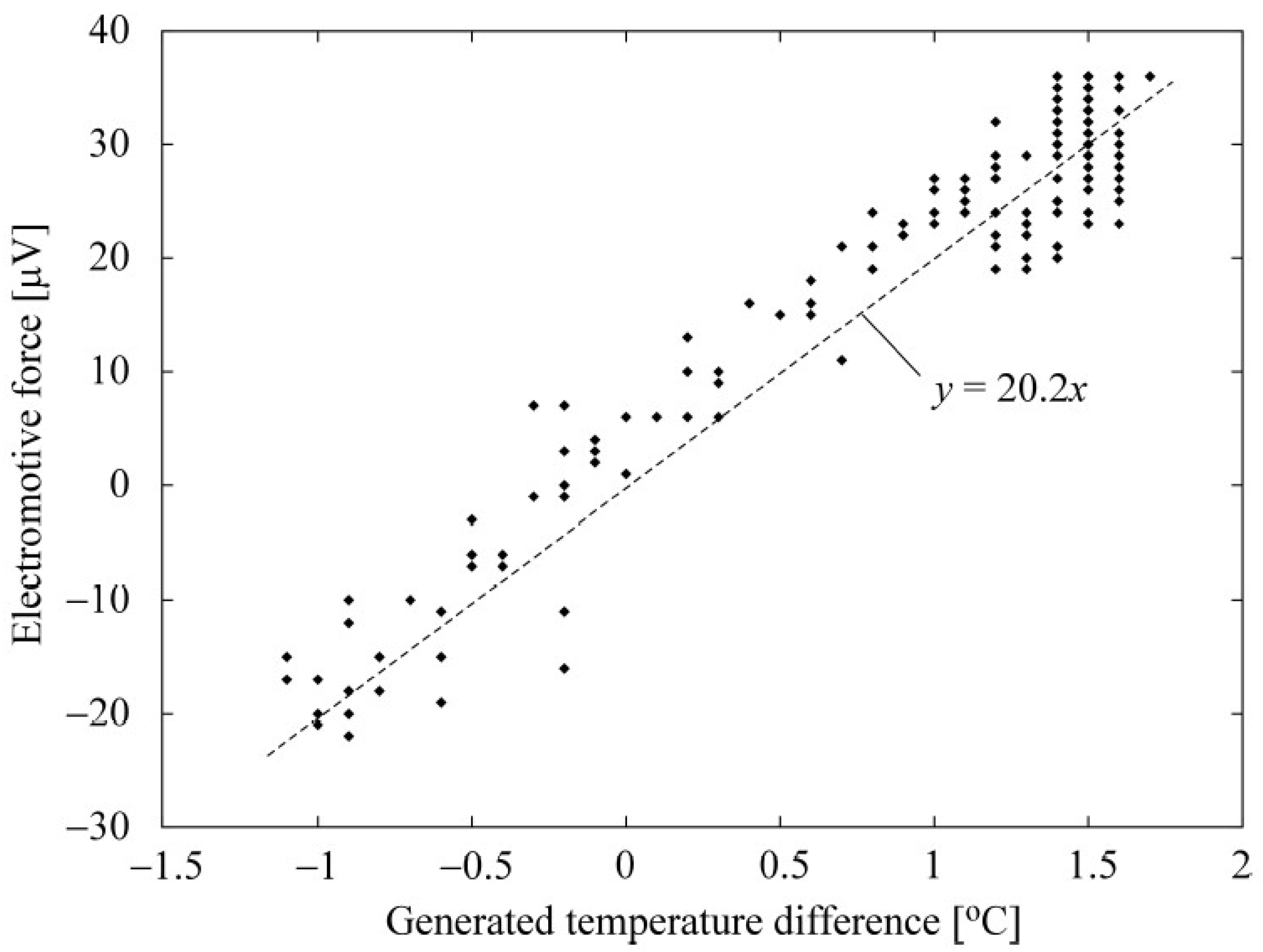

3.2. Evaluation of Transpiration-Type Thermoelectric-Power-Generating Paper

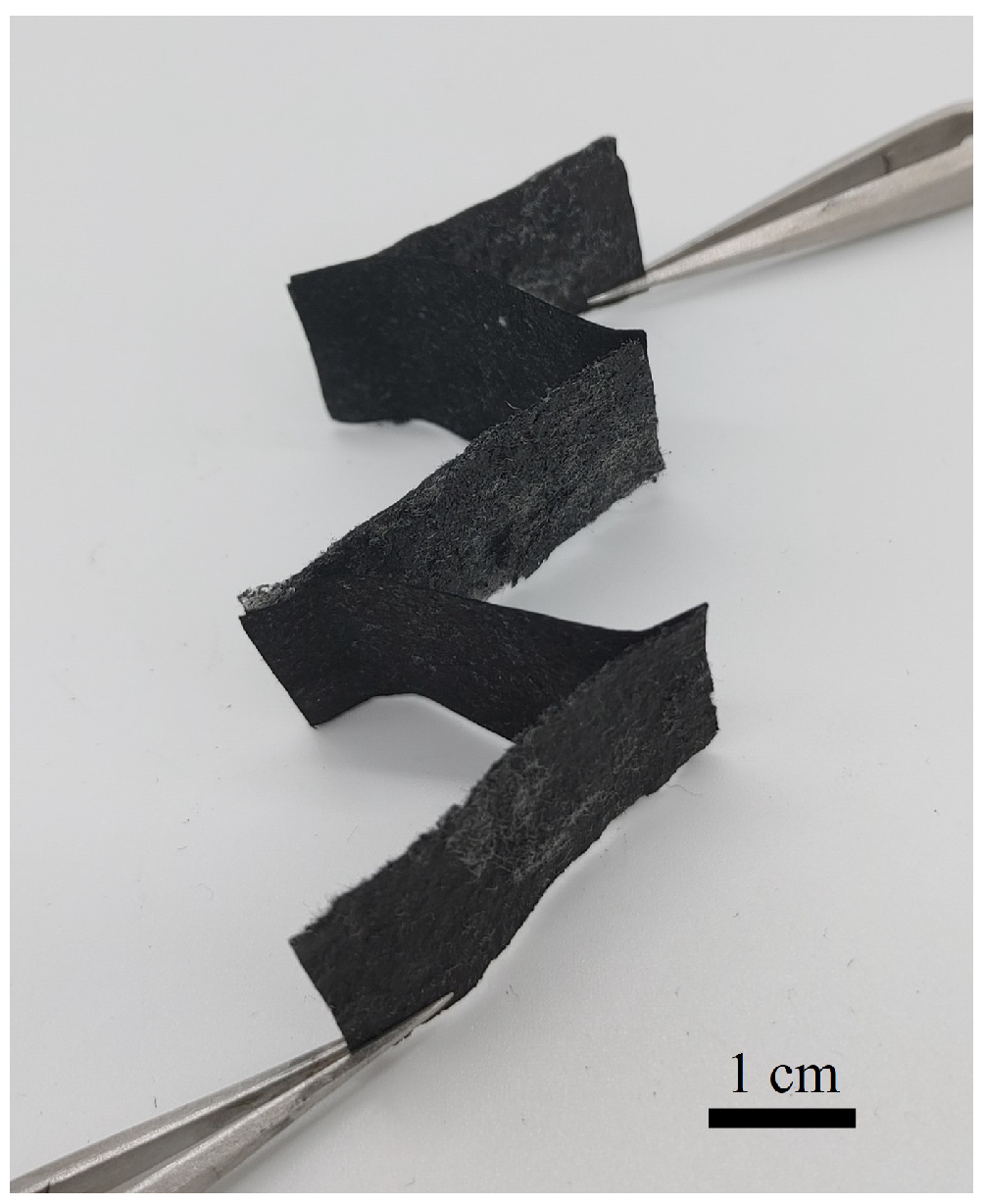

3.3. Multisheet Structure of Thermoelectric-Power-Generating Paper

4. Discussion

4.1. Absorption Ability of CNTCP

4.2. Transpiration-Type Thermoelectric-Power-Generating Paper

4.3. Multisheet Structure

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CNT | carbon nanotube |

| CNTCP | carbon nanotube composite paper |

| SEM | scanning electron microscope |

| SDS | sodium dodecyl sulfate |

| MWCNTCP | CNTCP consisting of multiwalled CNT |

| SGCNTCP | CNTCP consisting of SG101-CNT |

References

- Snyder, G.; Tobere, E. Complex thermoelectric materials. Nat. Mater. 2008, 7, 105–114. [Google Scholar] [CrossRef] [PubMed]

- Caylor, J.; Coonley, K.; Stuart, J.; Colpitts, T.; Venkatasubramanian, R. Enhanced thermoelectric performance in PbTe-based superlattice structures from reduction of lattice thermal conductivity. Appl. Phys. Lett. 2005, 87, 023105. [Google Scholar] [CrossRef]

- Poudel, B.; Hao, Q.; Ma, Y.; Lan, Y.; Minnich, A.; Yu, B.; Yan, X.; Wang, D.; Muto, A.; Vashaee, D.; et al. High-Thermoelectric Performance of Nanostructured Bismuth Antimony Telluride Bulk Alloys. Science 2008, 320, 634–638. [Google Scholar] [CrossRef] [PubMed]

- Okuda, T.; Nakanishi, K.; Miyasaka, S.; Tokura, Y. Large thermoelectric response of metallic perovskites: Sr1−xLaxTiO3 (0 < ∼x < ∼0.1). Phys. Rev. B 2001, 63, 113104. [Google Scholar] [CrossRef]

- Minnich, A.; Dresselhaus, M.; Ren, Z.; Chen, G. Bulk nanostructured thermoelectric materials: Current research and future prospects. Energy Environ. Sci. 2009, 2, 466–479. [Google Scholar] [CrossRef]

- Buge, A.; Supino-Viterbo, V.; Rancurel, G.; Pontes, C. Epileptic phenomena in bismuth toxic encephalopathy. J. Neurol. Neurosurg. Psychiatry 1981, 44, 62–67. [Google Scholar] [CrossRef]

- Taylor, A. Biochemistry of tellurium. Biol. Trace Elem. Res. 1996, 55, 231–239. [Google Scholar] [CrossRef]

- Sundar, S.; Chakravarty, J. Antimony toxicity. Int. J. Environ. Res. Public Health 2010, 7, 4267–4277. [Google Scholar] [CrossRef]

- Oya, T.; Ogino, T. Production of electrically conductive paper by adding carbon nanotubes. Carbon 2008, 46, 169–171. [Google Scholar] [CrossRef]

- Ebbesen, T.; Lezec, H.; Hiura, H.; Bennett, J.; Ghaemi, H.; Thio, T. Electrical conductivity of individual carbon nanotubes. Nature 1996, 382, 54–56. [Google Scholar] [CrossRef]

- Yu, M.F.; Files, B.; Arepalli, S.; Ruoff, R. Tensile Loading of Ropes of Single Wall Carbon Nanotubes and their Mechanical Properties. Phys. Rev. Lett. 2000, 84, 5552–5555. [Google Scholar] [CrossRef] [PubMed]

- Nakai, Y.; Honda, K.; Yanagi, K.; Kataura, H.; Kato, T.; Yamamoto, T.; Maniwa, Y. Giant Seebeck coefficient in semiconducting single-wall carbon nanotube film. Appl. Phys. Express 2014, 7, 025103. [Google Scholar] [CrossRef]

- Liu, J.; Rinzler, A.; Dai, H.; Hafner, J.; Bradley, R.; Boul, P.; Lu, A.; Iverson, T.; Shelimov, K.; Huffman, C.B.; et al. Fullerene Pipes. Science 1998, 280, 1253–1256. [Google Scholar] [CrossRef] [PubMed]

- Blackburn, J.; Ferguson, A.; Cho, C.; Grunlan, J. Carbon-nanotube-based thermoelectric materials and devices. Adv. Mater. 2018, 30, 1704386. [Google Scholar] [CrossRef] [PubMed]

- Ogata, Y.; Iguchi, K.; Oya, T. “Paper dye-sensitized solar cell” based on carbon-nanotube-composite papers. Energies 2020, 13, 57. [Google Scholar] [CrossRef]

- Kou, Y.; Oya, T. Unique dye-sensitized solar cell using carbon nanotube composite papers with gel electrolyte. J. Compos. Sci. 2023, 7, 232. [Google Scholar] [CrossRef]

- Ampo, T.; Oya, T. Development of paper actuator based on carbon-nanotube-composite paper. Molecules 2021, 26, 1463. [Google Scholar] [CrossRef]

- Fugetsu, B.; Sano, E.; Sunada, M.; Sambongi, Y.; Shibuya, T.; Wang, X.; Hiraki, T. Electrical conductivity and electromagnetic interference shielding efficiency of carbon nanotube/cellulose composite paper. Carbon 2008, 46, 1256–1258. [Google Scholar] [CrossRef]

- Imai, M.; Akiyama, K.; Tanaka, T.; Sano, E. Highly strong and conductive carbon nanotube/cellulose composite paper. Compos. Sci. Technol. 2010, 70, 1564–1570. [Google Scholar] [CrossRef]

- Hamana, Y.; Oya, T. Improvement of performance of paper transistor using carbon-nanotube-composite paper and its application to logic circuit. Adv. Sci. Technol. 2014, 95, 32–37. [Google Scholar] [CrossRef]

- Kawata, K.; Oya, T. Development and evaluation of “thermoelectric power-generating paper” using carbon nanotube-composite paper. Jpn. J. Appl. Phys. 2017, 56, 06GE10. [Google Scholar] [CrossRef]

- Miyama, A.; Oya, T. Modification of producing way for “Thermoelectric power generating paper” using carbon-nanotube-composite paper to improve its performance. In Proceedings of the 2019 MRS Fall Meeting & Exhibit, Boston, MA, USA, 1–6 December 2019. EN13.11.21. [Google Scholar]

- Miyama, A.; Oya, T. Improved performance of thermoelectric power generating paper based on carbon nanotube composite papers. Carbon Trends 2022, 7, 100149. [Google Scholar] [CrossRef]

- Gupta, B.; Shah, D.; Mishra, B.; Joshi, P.; Gandhi, V.G.; Fougat, R. Effect of top soil wettability on water evaporation and plant growth. J. Colloid Interface Sci. 2015, 449, 506–513. [Google Scholar] [CrossRef] [PubMed]

- Arkley, R.J. Relationships between plant growth and transpiration. Hilgardia 1963, 34, 559–584. [Google Scholar] [CrossRef][Green Version]

- Graamans, L.; van den Dobbelsteen, A.; Meinen, E.; Stanghellini, C. Plant factories; crop transpiration and energy balance. Agric. Syst. 2017, 153, 138–147. [Google Scholar] [CrossRef]

- Pearcy, R.W.; Schulze, E.D.; Zimmermann, R. Measurement of transpiration and leaf conductance. In Plant Physiological Ecology: Field Methods and Instrumentation; Springer: Dordrecht, The Netherlands, 2000; pp. 137–160. [Google Scholar] [CrossRef]

- Yang, Z.; Sinclair, T.R.; Zhu, M.; Messina, C.D.; Cooper, M.; Hammer, G.L. Temperature effect on transpiration response of maize plants to vapour pressure deficit. Environ. Exp. Bot. 2012, 78, 157–162. [Google Scholar] [CrossRef]

- Haggenmacher, J. The heat of vaporization as a function of pressure and temperature. J. Am. Chem. Soc. 1946, 68, 1633–1634. [Google Scholar] [CrossRef]

- Gates, D.M. Transpiration and Leaf Temperature. Annu. Rev. Plant Physiol. 1968, 19, 211–238. [Google Scholar] [CrossRef]

- Lin, H.; Chen, Y.; Zhang, H.; Fu, P.; Fan, Z. Stronger cooling effects of transpiration and leaf physical traits of plants from a hot dry habitat than from a hot wet habitat. Funct. Ecol. 2017, 31, 2202–2211. [Google Scholar] [CrossRef]

- Gupta, S.; Ram, J.; Singh, H. Comparative Study of Transpiration in Cooling Effect of Tree Species in the Atmosphere. J. Geosci. Environ. Prot. 2018, 6, 151–166. [Google Scholar] [CrossRef]

- Gennes, P.G.; Brochard-Wyart, F.; Quéré, D. Capillarity and Wetting Phenomena: Drops, Bubbles, Pearls, Waves; Springer: New York, NY, USA, 2004. [Google Scholar] [CrossRef]

- Morrow, N.R. Physics and Thermodynamics of Capillary Action in Porous Media. Ind. Eng. Chem. 1970, 62, 32–56. [Google Scholar] [CrossRef]

- Gillespie, T. The capillary rise of a liquid in a vertical strip of filter paper. J. Colloid Sci. 1959, 14, 123–130. [Google Scholar] [CrossRef]

- Mohammadi, S.; Busa, L.S.A.; Maeki, M.; Mohamadi, R.M.; Ishida, A.; Tani, H.; Tokeshi, M. Novel concept of washing for microfluidic paper-based analytical devices based on capillary force of paper substrates. Anal. Bioanal. Chem. 2016, 408, 7559–7563. [Google Scholar] [CrossRef] [PubMed]

- Alexander Böhm and, F.C.; Trieb, C.; Schabel, S.; Biesalski, M. Engineering microfluidic papers: Effect of fiber source and paper sheet properties on capillary-driven fluid flow. Microfluid. Nanofluidics 2014, 16, 789–799. [Google Scholar] [CrossRef]

| Sample No. | Pulp Material | Drying Method |

|---|---|---|

| 1 | Eucalyptus | Heat pressing |

| 2 | Eucalyptus | Oven |

| 3 | Rayon | Heat pressing |

| 4 | Rayon | Oven |

| Numbers of SGCNTCPs | (°C) | (°C) | V (μV) |

|---|---|---|---|

| 3 | 20.4 | 18.8 | 220 |

| 5 | 21.8 | 19.8 | 356 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kamekawa, Y.; Arai, K.; Oya, T. Development of Transpiration-Type Thermoelectric-Power-Generating Material Using Carbon Nanotube Composite Papers with Capillary Action and Heat of Vaporization. Energies 2023, 16, 8032. https://doi.org/10.3390/en16248032

Kamekawa Y, Arai K, Oya T. Development of Transpiration-Type Thermoelectric-Power-Generating Material Using Carbon Nanotube Composite Papers with Capillary Action and Heat of Vaporization. Energies. 2023; 16(24):8032. https://doi.org/10.3390/en16248032

Chicago/Turabian StyleKamekawa, Yudai, Koya Arai, and Takahide Oya. 2023. "Development of Transpiration-Type Thermoelectric-Power-Generating Material Using Carbon Nanotube Composite Papers with Capillary Action and Heat of Vaporization" Energies 16, no. 24: 8032. https://doi.org/10.3390/en16248032

APA StyleKamekawa, Y., Arai, K., & Oya, T. (2023). Development of Transpiration-Type Thermoelectric-Power-Generating Material Using Carbon Nanotube Composite Papers with Capillary Action and Heat of Vaporization. Energies, 16(24), 8032. https://doi.org/10.3390/en16248032