A Wellbore Pressure Control Method for Two-Layer Coal Seam Gas Coproduction Wells

Abstract

:1. Introduction

2. Methods

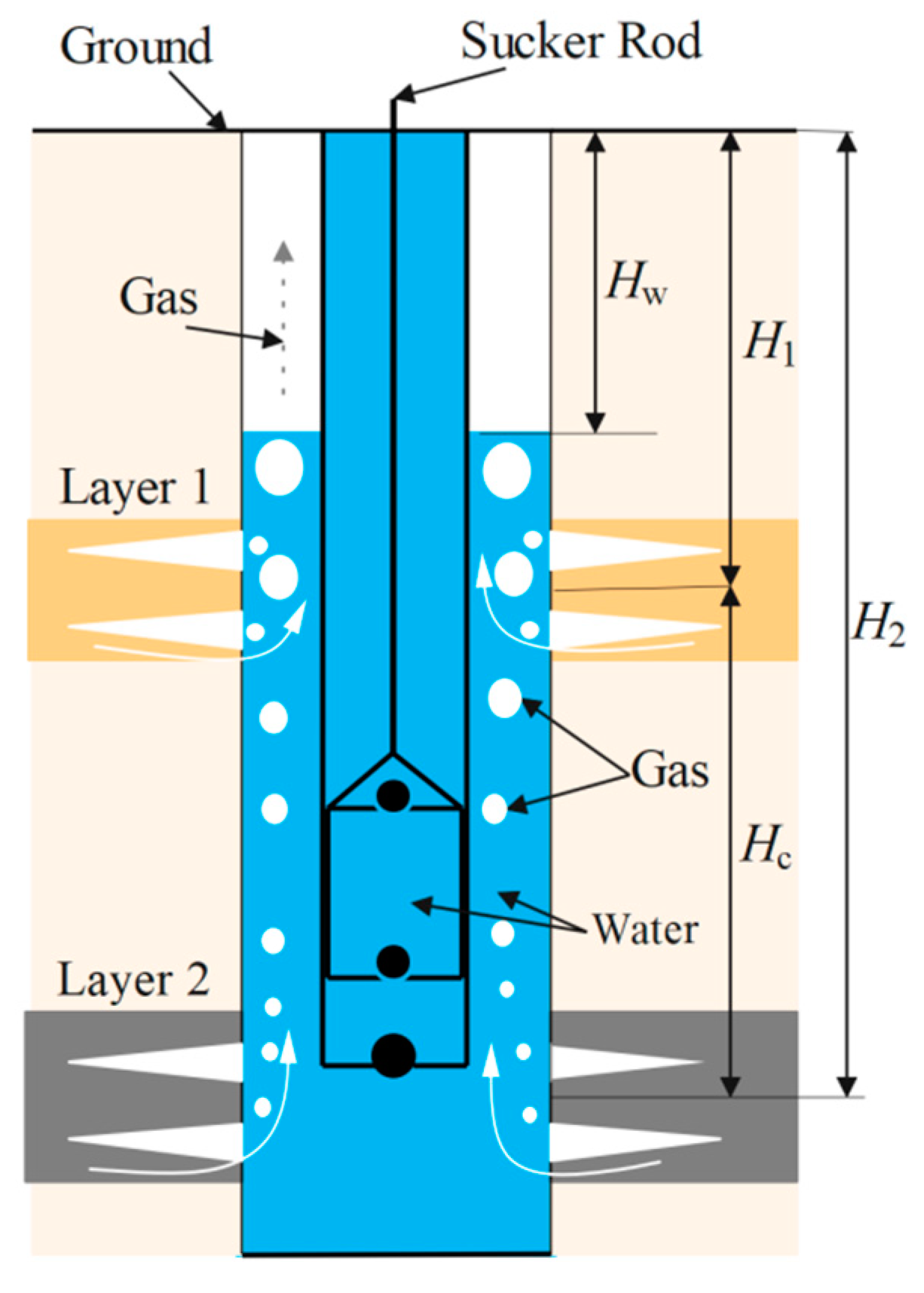

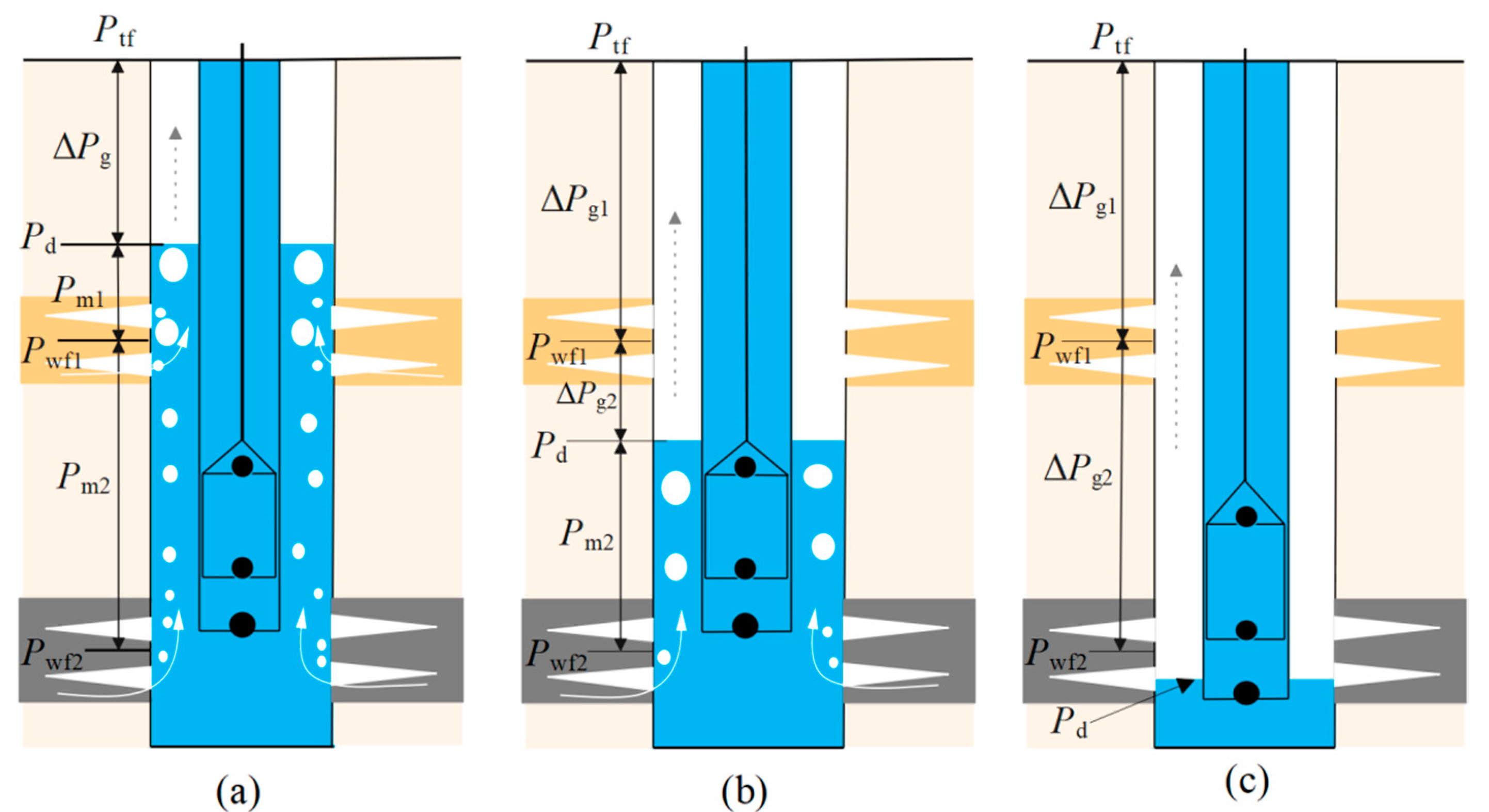

2.1. Production Output and Wellbore Pressure Distribution

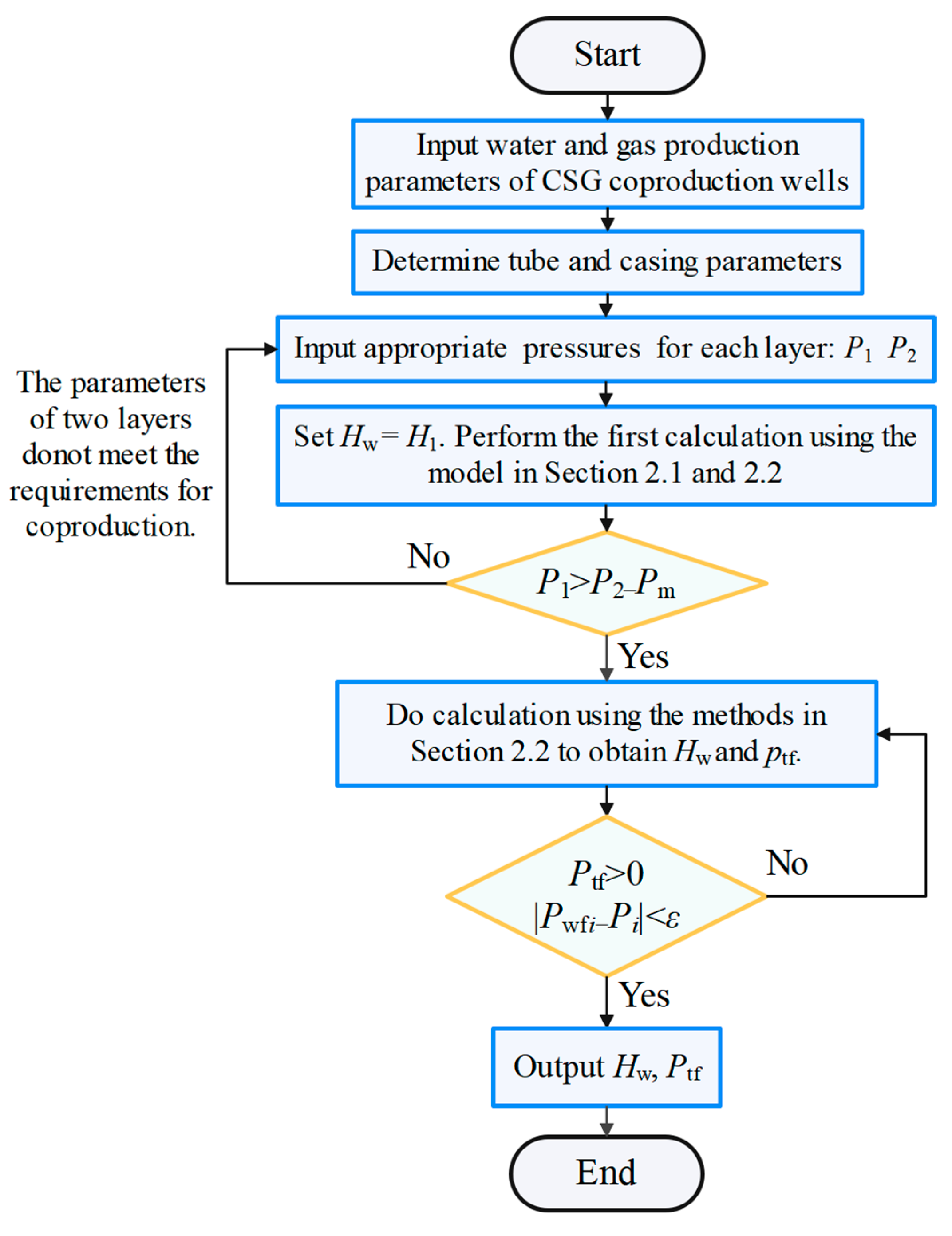

2.2. Calculation for Pressure Distribution in the Wellbore

2.2.1. Single-Phase Gas Flow

2.2.2. Gas–Liquid Two-Phase Flow

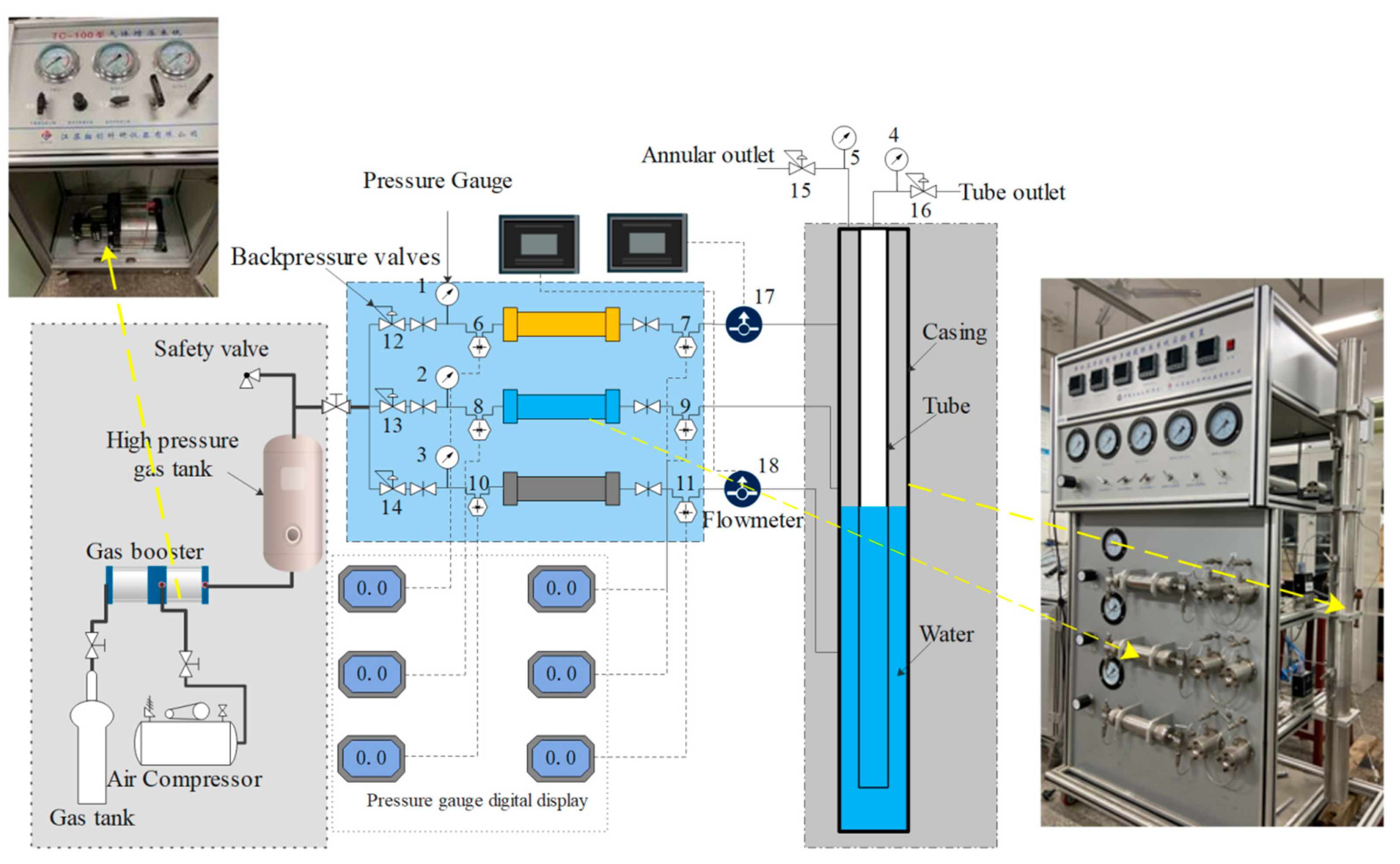

3. Experiments

3.1. Device and Method of Experiment

3.2. Materials for Experiments and Processing

4. Results and Discussion

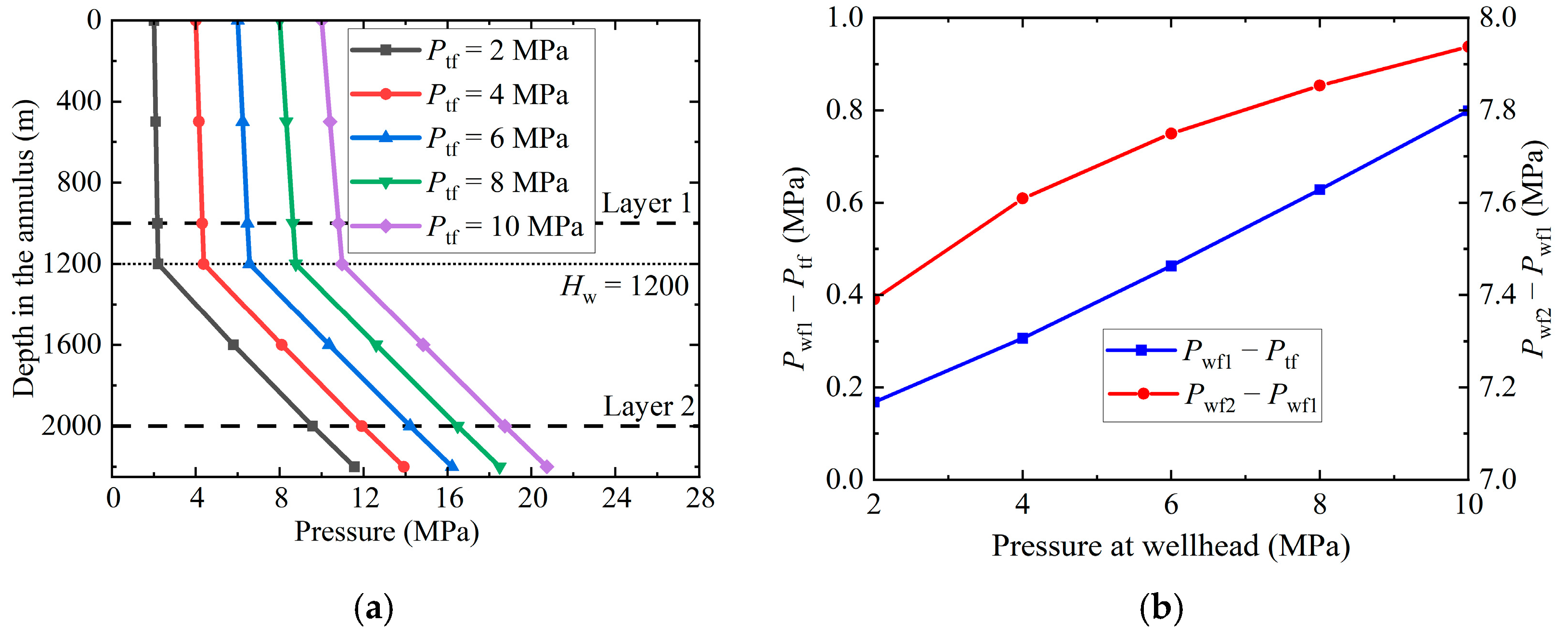

4.1. Pressure at the Wellhead

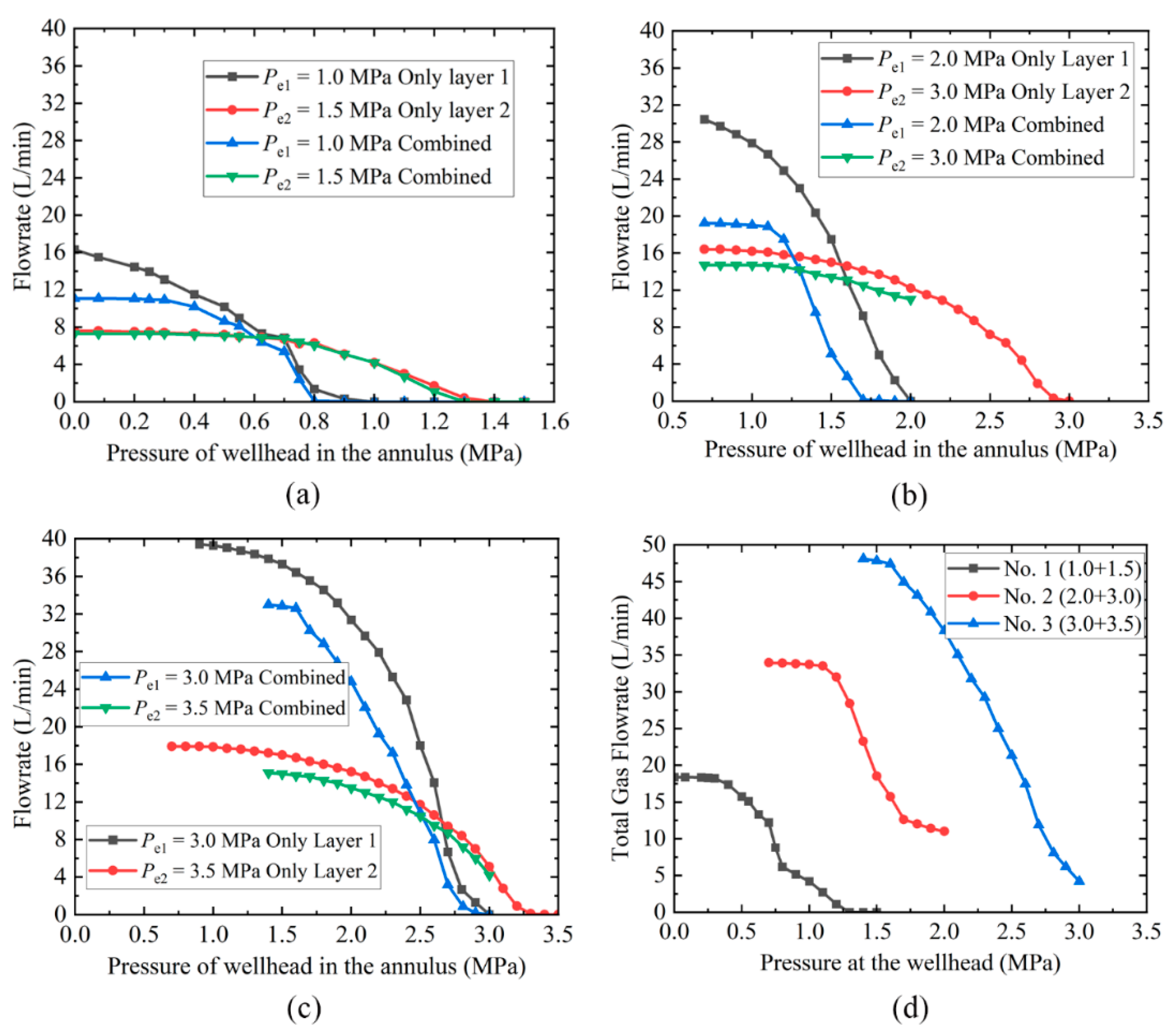

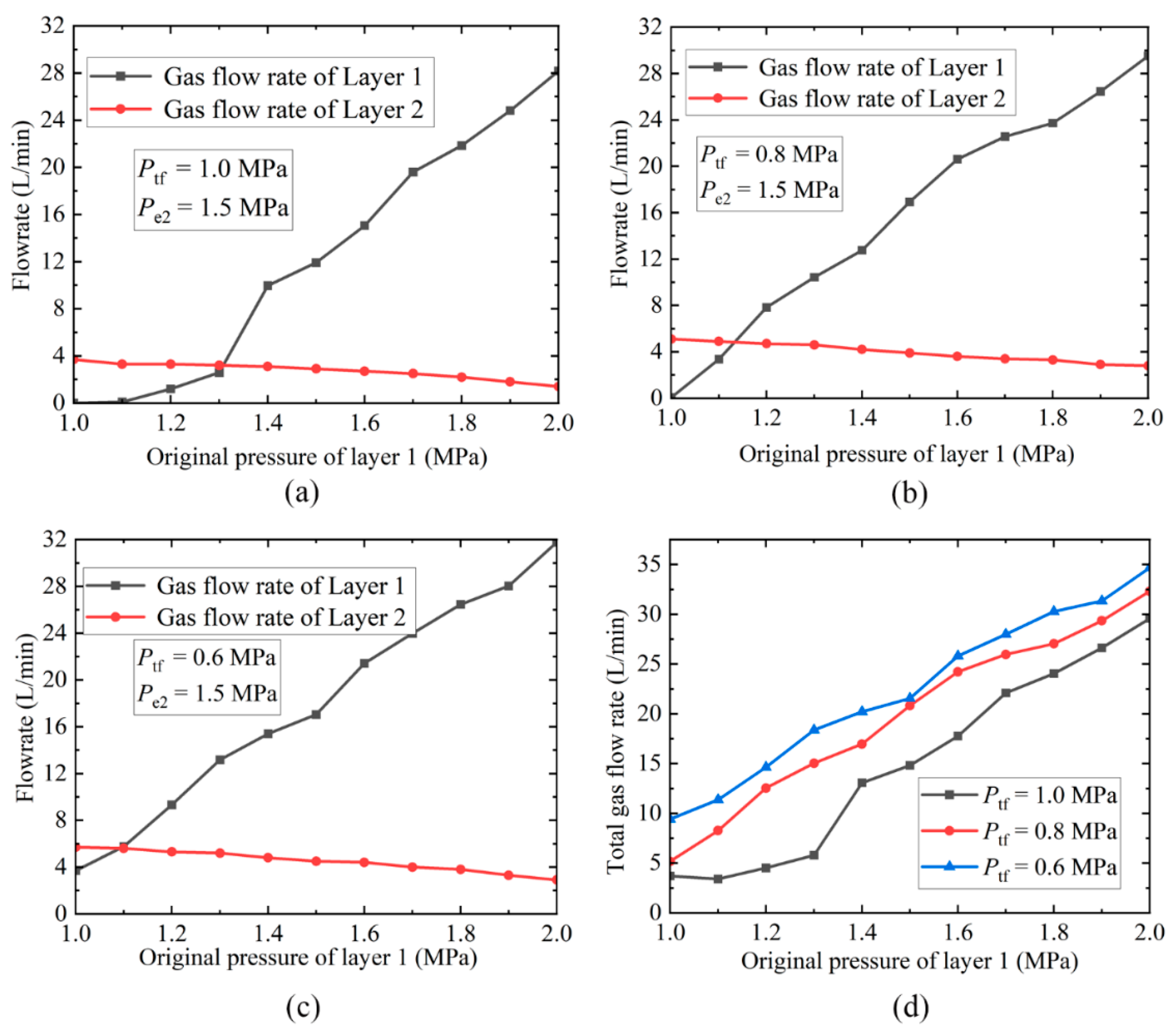

4.2. Output of Layer 1

4.3. Output of Layer 2

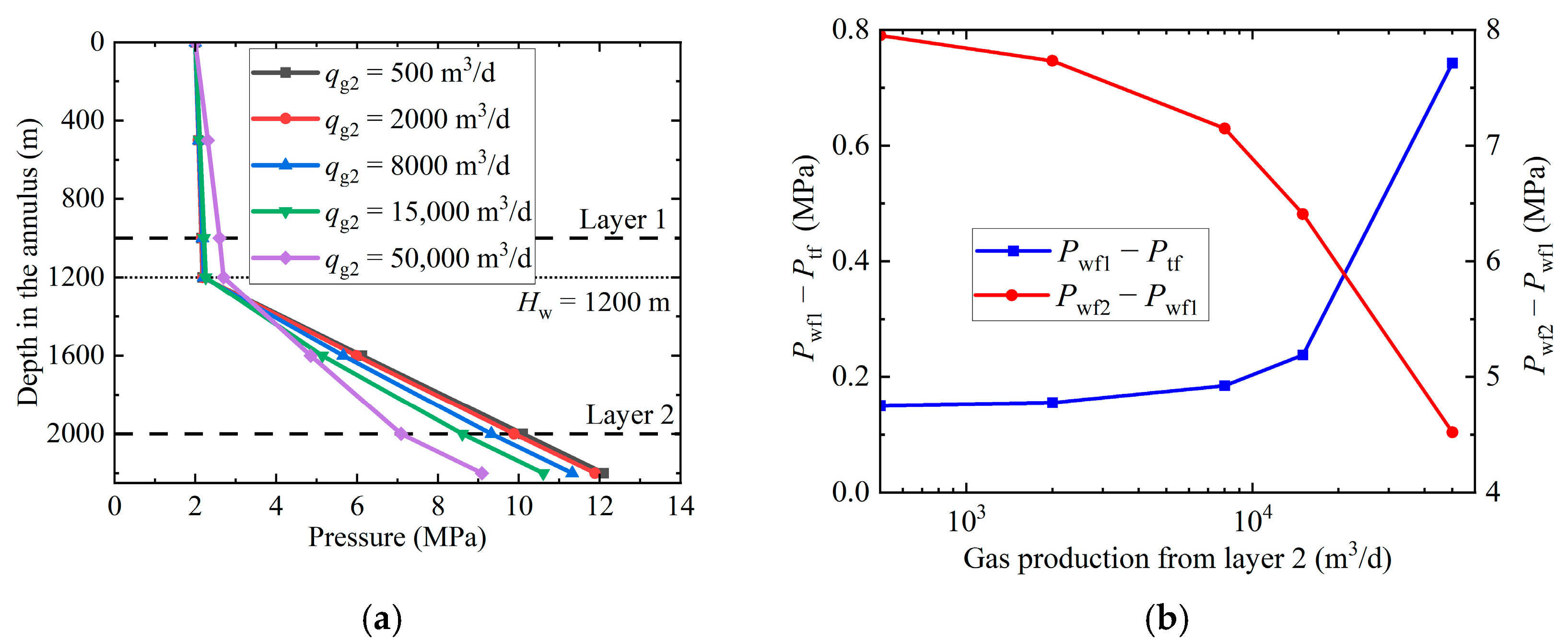

4.4. Dynamic Fluid Level

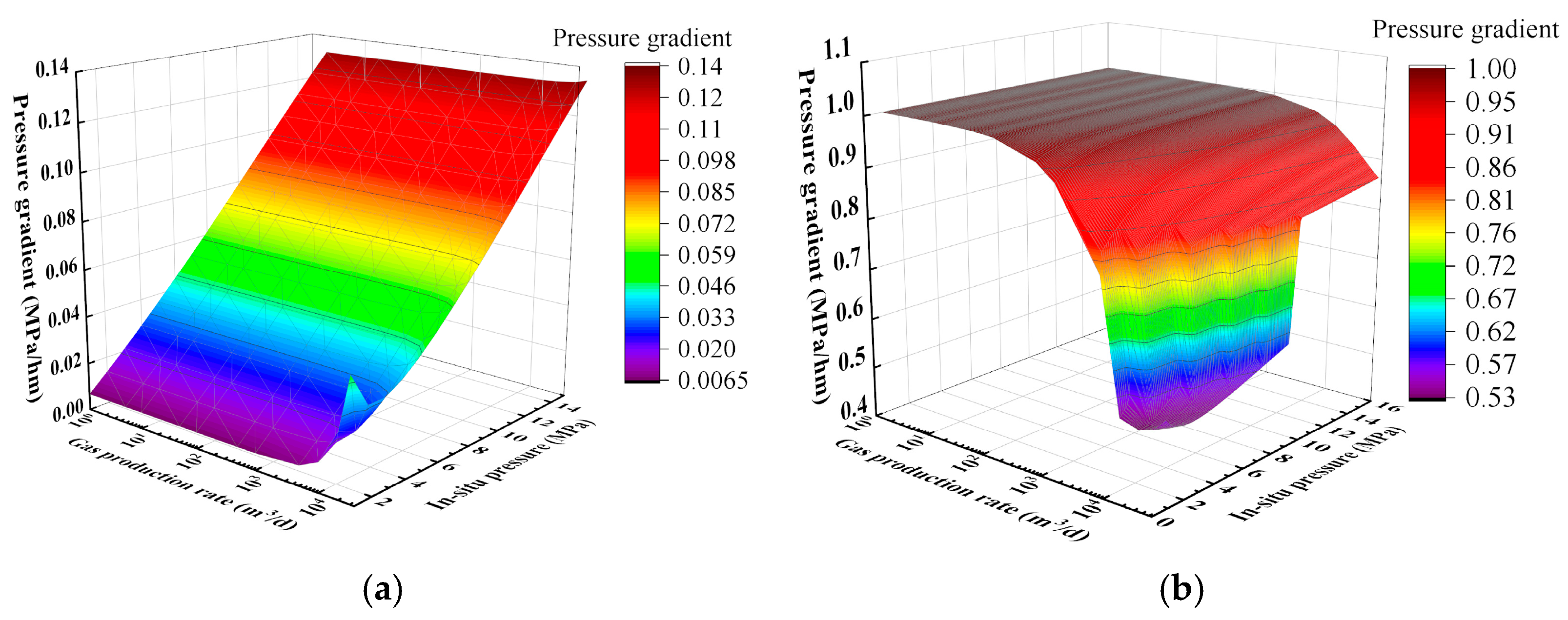

4.5. Pressure Gradient

5. Conclusions

- (1)

- Based on the wellbore pressure distribution law of CSG coproduction wells, a production parameter control method is established to effectively inhibit interlayer interference in the wellbore. A calculation method for the key parameter control requirements of the coproduction well is established, which provides a basis for the proper parameter regulation of the coproduction wells with an artificial drainage system.

- (2)

- For a given CSG coproduction well, the main factors affecting its wellbore pressure distribution are wellhead pressure, depth of the dynamic fluid surface, and the output of layer 1 and layer 2. Among them, the effect of wellhead pressure on the production pressure of the producing layers is the most obvious, but the effect of wellhead pressure on the interlayer pressure difference is small. An increase in wellhead pressure will directly result in an increase in pressure at both layers’ depths. Also, a decrease in wellhead pressure can lead to a decrease in pressure at both layers’ depths.

- (3)

- Changes in layer 1 output primarily affect the difference between the wellhead pressure and the pressure at the depth of layer 1. It has little effect on the difference between the pressures at the depths of layers 1 and 2. On the other hand, changes in the output of layer 2 affect the production pressure at both layer 1 and layer 2 depths. Therefore, when the dynamic fluid level is located between the two layers, a reasonable dynamic change of the pressure difference between the two layers can be realized by adjusting the depth of the dynamic fluid level. Thus, the interlayer interference in the wellbore can be effectively suppressed.

- (4)

- Fifteen sets of experiments on the effect of production pressure on coproduction were conducted using a set of two-layer coproduction test devices. The experimental results found that the gas production from the coproduction would be lower than the sum of the gas production from the two separate layers. However, by adjusting the wellhead pressure and dynamic fluid level parameters, it is able to make the gas production from the coproduction greater than the single layer production. Moreover, when the wellhead pressure of the combined production is lower than 50% of the low-pressure production layer, the gas production of the coproduction will not increase significantly.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sander, R.; Pan, Z.; Connell, L.D. Laboratory Measurement of Low Permeability Unconventional Gas Reservoir Rocks: A Review of Experimental Methods. J. Nat. Gas Sci. Eng. 2017, 37, 248–279. [Google Scholar] [CrossRef]

- Clarkson, C.R. Production Data Analysis of Unconventional Gas Wells: Review of Theory and Best Practices. Int. J. Coal Geol. 2013, 109–110, 101–146. [Google Scholar] [CrossRef]

- Hamawand, I.; Yusaf, T.; Hamawand, S.G. Coal Seam Gas and Associated Water: A Review Paper. Renew. Sustain. Energy Rev. 2013, 22, 550–560. [Google Scholar] [CrossRef]

- Liu, J.; Sang, S.; Zhou, Z.; Caiqin, B.; Jun, J.; Yansheng, S. Practice and Understanding of Multi-Layer Drainage of CBM Wells in Liupanshui Area. Coal Geol. Explor. 2020, 48, 93–99. [Google Scholar] [CrossRef]

- Zhang, Z.; Qin, Y.; Fu, X.; Yang, Z.; Guo, C. Multi-Layer Superposed Coalbed Methane System in Southern Qinshui Basin, Shanxi Province, China. J. Earth Sci. 2015, 26, 391–398. [Google Scholar] [CrossRef]

- Xu, H.; Tang, D.; Tang, S.; Wenzhong, Z.; Songhang, Z.; Shu, T.; Feng, W. Coal Reservoir Characteristics and Prospective Areas for Jurissic CBM Exploitation in Western Ordos Basin. Coal Geol. Explor. 2010, 38, 26–32. [Google Scholar] [CrossRef]

- Li, G.; Zhang, H. The Geological Model of Coalbed Methane(CBM) Reservoir in the Eastern Ordos Basin. Nat. Gas Geosci. 2015, 26, 160–167. [Google Scholar] [CrossRef]

- Fetisov, V.; Ilyushin, Y.V.; Vasiliev, G.G.; Leonovich, I.A.; Müller, J.; Riazi, M.; Mohammadi, A.H. Development of the Automated Temperature Control System of the Main Gas Pipeline. Sci. Rep. 2023, 13, 3092. [Google Scholar] [CrossRef]

- Meyer, A.G.; Lindenmaier, R.; Heerah, S.; Benedict, K.B.; Kort, E.A.; Peischl, J.; Dubey, M.K. Using Multiscale Ethane/Methane Observations to Attribute Coal Mine Vent Emissions in the San Juan Basin from 2013 to 2021. JGR Atmos. 2022, 127, e2022JD037092. [Google Scholar] [CrossRef]

- Pétron, G.; Miller, B.; Vaughn, B.; Thorley, E.; Kofler, J.; Mielke-Maday, I.; Sherwood, O.; Dlugokencky, E.; Hall, B.; Schwietzke, S.; et al. Investigating Large Methane Enhancements in the U.S. San Juan Basin. Elem. Sci. Anthr. 2020, 8, 038. [Google Scholar] [CrossRef]

- Karacan, C.Ö. Single-Well Production History Matching and Geostatistical Modeling as Proxy to Multi-Well Reservoir Simulation for Evaluating Dynamic Reservoir Properties of Coal Seams. Int. J. Coal Geol. 2021, 241, 103766. [Google Scholar] [CrossRef]

- Karacan, C.Ö. Production History Matching to Determine Reservoir Properties of Important Coal Groups in the Upper Pottsville Formation, Brookwood and Oak Grove Fields, Black Warrior Basin, Alabama. J. Nat. Gas Sci. Eng. 2013, 10, 51–67. [Google Scholar] [CrossRef]

- Adsul, T.; Ghosh, S.; Kumar, S.; Tiwari, B.; Dutta, S.; Varma, A.K. Biogeochemical Controls on Methane Generation: A Review on Indian Coal Resources. Minerals 2023, 13, 695. [Google Scholar] [CrossRef]

- Zhang, J.; Yip, C.; Xia, C.; Liang, Y. Evaluation of Methane Release from Coals from the San Juan Basin and Powder River Basin. Fuel 2019, 244, 388–394. [Google Scholar] [CrossRef]

- Humez, P.; Mayer, B.; Nightingale, M.; Becker, V.; Kingston, A.; Taylor, S.; Bayegnak, G.; Millot, R.; Kloppmann, W. Redox Controls on Methane Formation, Migration and Fate in Shallow Aquifers. Hydrol. Earth Syst. Sci. 2016, 20, 2759–2777. [Google Scholar] [CrossRef]

- Clarkson, C.R.; Behmanesh, H.; Chorney, L. Production-Data and Pressure-Transient Analysis of Horseshoe Canyon Coalbed-Methane Wells, Part II: Accounting for Dynamic Skin. J. Can. Pet. Technol. 2013, 52, 41–53. [Google Scholar] [CrossRef]

- Pearce, J.K.; Hofmann, H.; Baublys, K.; Golding, S.D.; Rodger, I.; Hayes, P. Sources and Concentrations of Methane, Ethane, and CO2 in Deep Aquifers of the Surat Basin, Great Artesian Basin. Int. J. Coal Geol. 2023, 265, 104162. [Google Scholar] [CrossRef]

- Cui, Z.; Su, P.; Liu, L.; Li, M.; Wang, J. Quantitative Characterization, Exploration Zone Classification and Favorable Area Selection of Low-Rank Coal Seam Gas in Surat Block in Surat Basin, Australia. China Pet. Explor. 2022, 35, 108–118. [Google Scholar] [CrossRef]

- Wang, C.; Jia, C.; Peng, X.; Zhu, S.-Y.; Liu, F. A New Well Structure and Methane Recovery Enhancement Method in Two Coal Seams. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 42, 1977–1988. [Google Scholar] [CrossRef]

- Zhang, L.; Shi, J.; Zhang, Q.; Qiao, X.; Xin, C.; Shi, L.; Wang, H. Experimental study on the nuclear magnetic resonance of shale in the southeastern Ordos Basin. J. China Coal Soc. 2018, 43, 2876–2885. [Google Scholar] [CrossRef]

- Zhang, P.; Wang, X.; Zhang, Y.; Wang, C.; Zheng, L.; Gan, M.; Liao, Y. Calculation Model of Bottom Hole Flowing Pressure of Double-Layer Combined Production in Coalbed Methane Wells. Int. J. Energy Res. 2023, 2023, 7506870. [Google Scholar] [CrossRef]

- Meng, S.; Li, Y.; Wang, J.; Gu, G.; Wang, Z.; Xu, X. Co-Production Feasibility ofThree Gases in Coal Measures: Discussion Based on Field Test Well. J. China Coal Soc. 2018, 43, 168–174. [Google Scholar] [CrossRef]

- Guo, C.; Qin, Y.; Sun, X.; Wang, S.; Xia, Y.; Ma, D.; Bian, H.; Shi, Q.; Chen, Y.; Bao, Y.; et al. Physical Simulation and Compatibility Evaluation of Multi-Seam CBM Co-Production: Implications for the Development of Stacked CBM Systems. J. Pet. Sci. Eng. 2021, 204, 108702. [Google Scholar] [CrossRef]

- Wang, Z.; Qin, Y.; Li, T.; Zhang, X. A Numerical Investigation of Gas Flow Behavior in Two-Layered Coal Seams Considering Interlayer Interference and Heterogeneity. Int. J. Min. Sci. Technol. 2021, 31, 699–716. [Google Scholar] [CrossRef]

- Jia, L.; Peng, S.; Xu, J.; Yan, F. Interlayer Interference during Coalbed Methane Coproduction in Multilayer Superimposed Gas-Bearing System by 3D Monitoring of Reservoir Pressure: An Experimental Study. Fuel 2021, 304, 121472. [Google Scholar] [CrossRef]

- Liang, B.; Shi, Y.; Sun, W.; Fang, S.; Jia, L.; Zhao, H. Experiment on influence of inter layer spacing on combined desorption of double-layer coalbed methane reservoir. J. China Univ. Min. Technol. 2020, 49, 54–61+68. [Google Scholar] [CrossRef]

- Wang, Z.; Qin, Y. Physical Experiments of CBM Coproduction: A Case Study in Laochang District, Yunnan Province, China. Fuel 2019, 239, 964–981. [Google Scholar] [CrossRef]

- Jiang, W.; Wu, C.; Wang, Q.; Xiao, Z.; Liu, Y. Interlayer Interference Mechanism of Multi-Seam Drainage in a CBM Well: An Example from Zhucang Syncline. Int. J. Min. Sci. Technol. 2016, 26, 1101–1108. [Google Scholar] [CrossRef]

- Oleg, K.; Andrey, S.; Sergey, S.; Vladimir, I.; Helmut, M. High Productive Longwall Mining of Multiple Gassy Seams: Best Practice and Recommendations. Acta Montan. Slovaca 2022, 27, 152–162. [Google Scholar] [CrossRef]

- Andrey, A.S.; Pavel, N.D.; Vyacheslav, Y.A.; Sergey, A.S. Improvement of Technological Schemes of Mining of Coal Seams Prone to Spontaneous Combustion and Rock Bumps. J. Min. Inst. 2023, 1–13. [Google Scholar]

- Chen, Y.; Luo, J.; Hu, X.; Yang, Y.; Wei, C.; Yan, H. A New Model for Evaluating the Compatibility of Multi-Coal Seams and Its Application for Coalbed Methane Recovery. Fuel 2022, 317, 123464. [Google Scholar] [CrossRef]

- Sadatomi, M.; Sato, Y.; Saruwatari, S. Two-Phase Flow in Vertical Noncircular Channels. Int. J. Multiph. Flow 1982, 8, 641–655. [Google Scholar] [CrossRef]

- Hasan, A.R.; Kabir, C.S. Predicting Multiphase Flow Behavior in a Deviated Well. SPE Prod. Eng. 1988, 3, 474–482. [Google Scholar] [CrossRef]

- Kelessidis, V.C.; Dukler, A.E. Modeling Flow Pattern Transitions for Upward Gas-Liquid Flow in Vertical Concentric and Eccentric Annuli. Int. J. Multiph. Flow 1989, 15, 173–191. [Google Scholar] [CrossRef]

- Papadimitriou, D.A.; Shoham, O. A Mechanistic Model for Predicting Annulus Bottomhole Pressures in Pumping Wells. In Proceedings of the SPE Production Operations Symposium, SPE, Oklahoma City, Oklahoma, 7 April 1991; p. SPE-21669-MS. [Google Scholar]

- Antonio, C.V.M.; Time, R.W. An Experimental and Theoretical Investigation of Upward Two-Phase Flow in Annuli. SPE J. 2002, 7, 325–336. [Google Scholar] [CrossRef]

- An, H.-J.; Langlinais, J.P.; Scott, S.L. Effects of Density and Viscosity in Vertical Zero Net Liquid Flow. J. Energy Resour. Technol. 2000, 122, 49–55. [Google Scholar] [CrossRef]

- Qin, Y.; Moore, T.A.; Shen, J.; Yang, Z.; Shen, Y.; Wang, G. Resources and Geology of Coalbed Methane in China: A Review. Int. Geol. Rev. 2018, 60, 777–812. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, Z.; Qin, Y.; Wu, C.; Yi, T.; Li, Y.; Tang, J.; Chen, J. Optimization Methods of Production Layer Combination for Coalbed Methane Development in Multi-Coal Seams. Pet. Explor. Dev. 2018, 45, 312–320. [Google Scholar] [CrossRef]

- Ilyushin, Y.V. Development of a Process Control System for the Production of High-Paraffin Oil. Energies 2022, 15, 6462. [Google Scholar] [CrossRef]

- Li, Q.; Xu, J.; Shu, L.; Yan, F.; Pang, B.; Peng, S. Exploration of the Induced Fluid-Disturbance Effect in CBM Co-Production in a Superimposed Pressure System. Energy 2023, 265, 126347. [Google Scholar] [CrossRef]

- Yang, Z.; Li, Y.; Qin, Y.; Sun, H.; Zhang, P.; Zhang, Z.; Wu, C.; Li, C.; Chen, C. Development Unit Division and Favorable Area Evaluation for Joint Mining Coalbed Methane. Pet. Explor. Dev. 2019, 46, 583–593. [Google Scholar] [CrossRef]

- Meng, S.; Li, Y.; Wu, X.; Xu, Y.; Guo, H. Productivity Equation and Influencing Factors of Co-Producing Coalbed Methane and Tight Gas. J. China Coal Soc. 2018, 43, 1709–1715. [Google Scholar] [CrossRef]

- Jin, Z.; Yang, C.; Zhang, S. Gas Production Engineering, 1st ed.; Petroleum Industry Press: Beijing, China, 2004; ISBN 978-7-5021-4902-4. [Google Scholar]

- Liu, X.; Liu, C.; Liu, G. Dynamic Behavior of Coalbed Methane Flow along the Annulus of Single-Phase Production. Int. J. Coal Sci. Technol. 2019, 6, 547–555. [Google Scholar] [CrossRef]

- Standing, M.B.; Katz, D.L. Density of Natural Gases. Trans. AIME 1942, 146, 140–149. [Google Scholar] [CrossRef]

- Dranchuk, P.M.; Abou-Kassem, H. Calculation of Z Factors For Natural Gases Using Equations of State. J. Can. Pet. Technol. 1975, 14, PETSOC-75-03-03. [Google Scholar] [CrossRef]

- Cullender, M.H.; Smith, R.V. Practical Solution of Gas-Flow Equations for Wells and Pipelines with Large Temperature Gradients. Trans. AIME 1956, 207, 281–287. [Google Scholar] [CrossRef]

- Hasan, A.R.; Kabir, C.S.; Rahman, R. Predicting Liquid Gradient in a Pumping-Well Annulus. SPE Prod. Eng. 1988, 3, 113–120. [Google Scholar] [CrossRef]

- Sun, B. Multiphase Flow in Oil and Gas Engineering, 1st ed.; China University of Petroleum Press: Dongying, China, 2013; ISBN 978-7-5636-4225-0. [Google Scholar]

| No. | Pr1 | Pr2 | Ptf | No. | Pr1 | Pr2 | Ptf |

|---|---|---|---|---|---|---|---|

| MPa | MPa | MPa | MPa | MPa | MPa | ||

| 1 | 1.0 | 1.5 | 0~1.5 | 9 | 1.0~2.0 | 1.5 | 0.6 |

| 2 | 2.0 | 3.0 | 0.7~2.0 | 10 | 1.0 | - | 0~1.0 |

| 3 | 3.0 | 3.5 | 1.4~3.0 | 11 | - | 1.5 | 0~1.5 |

| 4 | 2.0 | 2.0~3.5 | 1.8 | 12 | 2.0 | - | 0.7~2.0 |

| 5 | 2.0 | 2.0~3.5 | 1.5 | 13 | - | 3.0 | 0.7~3.0 |

| 6 | 2.0 | 2.0~3.5 | 1.2 | 14 | 3.0 | - | 0.9~3.0 |

| 7 | 1.0~2.0 | 1.5 | 1.0 | 15 | - | 3.5 | 0.7~3.5 |

| 8 | 1.0~2.0 | 1.5 | 0.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, H.; Qi, Y.; Hu, H.; Zhang, F.; Jing, C.; Zhao, J. A Wellbore Pressure Control Method for Two-Layer Coal Seam Gas Coproduction Wells. Energies 2023, 16, 7148. https://doi.org/10.3390/en16207148

Zhu H, Qi Y, Hu H, Zhang F, Jing C, Zhao J. A Wellbore Pressure Control Method for Two-Layer Coal Seam Gas Coproduction Wells. Energies. 2023; 16(20):7148. https://doi.org/10.3390/en16207148

Chicago/Turabian StyleZhu, Hongying, Yaoguang Qi, Hao Hu, Fenna Zhang, Chuankai Jing, and Junwei Zhao. 2023. "A Wellbore Pressure Control Method for Two-Layer Coal Seam Gas Coproduction Wells" Energies 16, no. 20: 7148. https://doi.org/10.3390/en16207148

APA StyleZhu, H., Qi, Y., Hu, H., Zhang, F., Jing, C., & Zhao, J. (2023). A Wellbore Pressure Control Method for Two-Layer Coal Seam Gas Coproduction Wells. Energies, 16(20), 7148. https://doi.org/10.3390/en16207148