Abstract

Disposable bamboo chopsticks (DBCs) are rarely recycled, and there are not many options for recycling them. Some treatment processes use high technology and complex processes that are not convenient for production at the local level, resulting in practical difficulties in upcycling DBC waste. DBC is lignocellulosic biomass; therefore, DBC has the potential to be recycled and upcycled. The waste management of wood that transforms it into a sustainable material as a biochar with a pyrolysis process accords well with the circular economy model. This research effort aims to upcycle DBC to convert it into biochar with different pyrolysis temperature ranges set at 400 °C (DBC-400), 450 °C (DBC-450), and 500 °C (DBC-500), with a holding time of 60 min. The morphology and essential physicochemical properties of the biochar were analyzed. The research found that all biochar had physicochemical properties and structures appropriate to the agricultural and environmental purposes. Based on the molar ratio of the O/C and H/C, it was indicated that all DBC biochar could persist in the soil for 100 to 1000 years. The DBC-500 had the least hydrophilic surface of biochar, while the DBC-400 had a lower degree of carbonization and aromaticity of biochar. The research concluded that biochar produced at 450 °C had the best properties for supplementary soil and soil treatment, given the cation exchange capacity, specific surface area, average pore diameter, and nutrient content. For future research on the practical application of DBC biochar for agronomical purposes, the results of the properties of DBC biochar with appropriate pyrolysis temperature will lead to the development of a biochar furnace with appropriate technology that is suitable for the local area to be able to produce large amounts of biochar that is effectively DBC. In addition, determining the absorption and release rate of the macronutrients of biochar can predict the frequency of biochar applied in agricultural areas.

1. Introduction

The increase in urban waste is a global crisis caused by enormous resource consumption. Developing countries seem to face severe waste management problems; colossal amounts of waste end up in landfills, which have poorly operated sites and limited capacity, affecting the ecosystem and the quality of life of humans [1,2]. Upcycling and recycling waste are crucial to effective waste management and achieving sustainable consumption and a circular economy, especially in high-consumption situations in urban areas. However, the recycling rate in developing countries is relatively low [3,4]. At the same time, there is also urban waste that has the potential to be imported into the recycling process, such as disposable wooden chopsticks, which are rarely recycled, and for which there are not many options for recycling.

An essential component of Asian cuisine culture is the use of chopsticks, which have been used for thousands of years. Later, disposable wooden chopsticks, mostly made from bamboo, became widely used in many countries in Asia and have continuously expanded and are commonly used throughout the world. China is the largest producer of disposable bamboo chopsticks (DBCs) worldwide, with approximately 80 million pairs per year [5], which are used in China and exported worldwide. There are no records of DBCs production and consumption data in Thailand, but they can be seen daily in street food, trunks, canteens, food deliveries, and restaurants. DBCs as single-use utensils are convenient, cheap, and hygienic; therefore, they are suitable for an urban lifestyle but have a high cost to the environment. The service life of one pair of chopsticks is just one meal, and most end up in a landfill. For this reason, managing DBCs is challenging, especially in Asian countries.

There is an ongoing attempt to study and transform the DBCs wastes using various technologies, such as torrefaction for cofiring with coal [6] and hydrothermal treatment for producing uniform carbon fibers for anodes in Li-ion batteries [7]. The mentioned processes require the use of high technology and complex processes. They are not convenient to use in production at the household or community level. Pyrolysis, a thermal-chemical decomposition process, is an attractive process, corresponding to the circular economy, which converts biomass waste into valuable material [8,9,10]. It has received increasing attention because it is inexpensive, readily available, and not complicated [9,11]. The products of the pyrolysis process are oil, biochar, and syngas, and the proportion of products depends on the pyrolysis condition, such as temperature, heating rate, and residence time [10,12,13]. Fast pyrolysis is the most efficient method of producing biofuels. Li et al. [14] and Huang et al. [15] showed excellent performance from the fast pyrolysis of algae to produce biofuel. The scientific literature reveals that slow pyrolysis is the most effective and appropriate for biochar production [16,17,18], with its yield and simple and robust process, which can apply to small-scale and agricultural production [19,20]. Therefore, the determination of the pyrolysis condition depends on the product required from the process.

One promising and exciting method of upcycling disposable wood waste, from both the perspectives of environmental protection and practical applications, is to convert them to biochar. Biochar is solid carbon-based material produced from biomass through a thermal decomposition process under oxygen-limited conditions [8,9]. Biochar can be produced using various types of feedstocks, including agricultural waste and residues [13,18,21], wood chips and barks [17,19,22], plants [14,23,24,25], animal manure [26,27], urban wastes (i.e., food wastes, green waste) [16,18], and biosolids (i.e., wastewater sludge) [28]. In addition, biochar production can be a waste-to-resource process, making biochar an environmentally friendly material with various uses. It can be carried out on a small scale in a household and on a large scale, such as in the biochar industry [20,29].

Biochar has various applications for agricultural and environmental purposes [10,30,31,32]. Furthermore, satisfactory results have been reported for soil and land resources, plant yields, and plant biomass in the area where biochar is applied [9,11,17,31]. It has been proposed as a peat substitute [33], but, unlike peat, it does not take long to produce. Biochar exhibits a high surface area, a high content of the surface functional group, and pH, which are essential properties for improving the quality of soil resources and soil productivity [31,34,35]. The various types of biochar porosity provide habitats for symbiotic soil microorganisms and a suitable condition for their activities in the soil ecosystem [26,27]. Furthermore, the high porosity of biochar increases water-holding capacity and reduces soil compactness [36,37]. The high content of carbon stability allows biochar to persist in the soil ecosystem over a long period [8,9,20]. Although biochar has been used for many years, biochar research is still essential and ongoing because biochar is a highly diverse material. The properties of biochar change according to the condition of the production process and feedstocks. The efficiency of biochar for each purpose depends on many factors, especially the properties of biochar and the condition of the biochar application.

The most crucial point in the effective function and application of biochar is its unique structural and physicochemical properties [31,36,38,39], which depend on the pyrolysis process [40,41,42]. Its chemical structure is characterized by a high degree of aromaticity and high porosity [43,44,45]. It has been widely observed that the final structural and physicochemical properties of biochar generally vary by the pyrolysis temperature and feedstock types [24,34,46,47]. However, previous work in the literature have stated that the properties of biochar are very diverse and challenging to predict when the feedstock is wood [37,48]. Meanwhile, wood contains varying amounts of lignocellulosic constituents, organic extractives, and inorganic compounds, which are potential sources for biochar production [49,50,51]. The transformation of wood waste into biochar has excellent potential as large-scale carbon sequestration to combat climate change because biochar represents a carbon pool with greater longevity than its source wood, and the benefits of carbon sequestration of biochar are tangible [52,53]. Therefore, selecting the appropriate conditions to produce biochar with the desired properties necessitates understanding the dependent and causative factors, both quantitatively and qualitatively [54,55]. Moreover, it is crucial to characterize the structural and physicochemical properties of biochar before its use. This research is intended to facilitate the upcycling of DBCs to convert them into biochar in the varying temperature ranges of the pyrolysis process. This research focused on investigating the fundamental characteristics of the resulting biochar from DBCs, characteristics which affect its usefulness as a soil amendment and the possibility of upcycling DBCs to produce biochar.

2. Materials and Methods

2.1. Analysis of the Elements and Physicochemical Properties of Disposable Bamboo Chopsticks

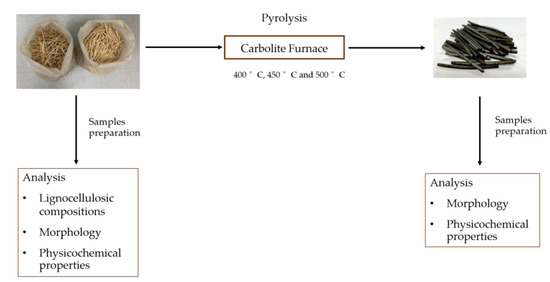

Disposable chopsticks are mainly made from bamboo, with specific properties such as hardness and imperviousness to water. The DBCs waste was cleaned and naturally dried in sunlight for one day before its essential physicochemical properties and morphology characterization were analyzed (Figure 1).

Figure 1.

Feedstock and biochar production.

The lignocellulose in biomass feedstock like bamboo is of significant value in biochar conversion [28,32,56]. The lignocellulosic composition, including cellulose, hemicellulose, and lignin, was analyzed according to the Association of Official and Analytical Chemists International (AOAC) standard based on the AOAC 2016 method [57]. Dry matter and moisture content were determined using an oven drying method that dries at 135 °C for two hours based on the AOAC 930.15 method [58] and the analysis of the ash content according to AOAC 942.05 [57].

Morphology characterization was performed using a Scanning Electron Microscope (SEM) on the SEM machine of model JEOL JSM-6610LV, Oxford X-Max 50, to determine the porosity morphology and characteristics [59]. In addition, energy dispersive X-ray spectroscopy (EDS) is used to analyze qualitative and quantitative elements in feedstock and biochar [37]. The Brunauer-Emmett-Teller (BET) method was used to analyze the specific surface area (SSA). The Barrett-Joyner-Halenda (BJH) method was used for the analysis of the total pore volume (TPV) and the average pore diameter (APD) [59]. An Autosorb-1 surface area and pore size analyzer were used to measure SSA, TPV, and APD.

The elemental composition of carbon (C), hydrogen (H), and nitrogen (N) was analyzed using the Elemental Analyzer (CHN; LECO, Truspec CHN analyzer, Condition: 950, 850 °C, O2 (HP), He (UHP)) [60]. The pH was measured in deionized water and 1 m KCL solution in a 1:10 (w/v) ratio [61]. The cation exchange capacity (CEC) was determined at pH 7 using ammonium acetate extraction [62]. The Kjeldahl method and the distillation apparatus were used to analyze total nitrogen (N) [63]. Total phosphorus (P2O5) was analyzed using the Spectrophotometric molybdovanadophoshate method [63], and the total potassium (K2O) was analyzed using the flame photometric method [63].

2.2. Biochar Production and Its Properties Analysis

According to previous research reports [35], slow pyrolysis can have a higher yield of wood biochar than does intermediate or fast pyrolysis. Cellulose, hemicellulose, and lignin in biomass decompose at temperatures ranging from 200–500 °C [37,64,65]. As the temperature reaches 400 °C, the transformation of biomass to biochar will be practically complete. However, at temperatures of up to 500 °C, it will be possible to remove the tar from biochar, and the carbonization stage will be complete [66,67]. Previous research indicated that pyrolysis at a temperature of ∼500 °C could produce more than 30% of the biochar yield [68,69]. Therefore, DBCs were transformed into biochar using Carbolite Furnace (model; ELF 11/14, CARBOLITE Parsons Lane, Hope Valley England) in different temperature ranges set at 400 °C (DBC-400), 450 °C (DBC-450) and 500 °C (DBC-500), a constant heating rate of 20 °C/min with a residence time of 60 min. The 30 pairs of DBC feedstock were pyrolyzed at each specified pyrolysis temperature. Biochar samples were kept in a desiccator prior to laboratory analysis of their structure and essential properties for soil amendment (Figure 1).

The analysis method for analyzing the physicochemical properties and morphology of DBC biochar follows the standard product definitions and product testing guidelines for biochar used in the soil [70]. The physical and chemical properties and nutrients were analyzed using the same analysis methods as feedstock analysis. Physical and chemical properties, such as SSA, TPV, pH, CEC, and the elements of C, H, and N, were analyzed. The oxygen (O) content was calculated from the difference between the percentages of biomass composition and other components: %C, %H, %N, and ash content when sulfur content is very low [50,71]. Proximate analysis is used to analyze %volatile matter (VM) [72], %ash [73], and %fixed carbon [74] in DBC biochar.

The nutrients in biochar were analyzed, including total N, total P, and total K. The molar ratios of elements that explain the efficiency of biomass to biochar by the pyrolysis process, the stability of biochar, and the period of biochar persistence in the soil were calculated as H/C and O/C ratios [19,75,76], and the C/N ratio was calculated [77,78]. The biochar yield was also calculated for the mass of the feedstock.

2.3. Statistical Analyzes

All statistical analyses were performed with the Social Science Statistical Package (SPSS) software v.28.0.0.0. Data on the physicochemical properties of feedstock and biochar, expressed as mean ± standard deviation (SD), were derived from four replicates. One-way ANOVA: Post hoc multiple comparisons of the Tukey-B test were used to analyze the variant of biochar produced from different pyrolysis temperatures. The analysis of differences in the statistical significance of each data set was at a confidence level of 95%.

3. Results and Discussion

3.1. The Characteristics of Disposable Bamboo Chopsticks

Most generally, DBCs have a variety of sizes; the length is between 18–24 cm, with a diameter range of 4.20–5.00 mm. Most chopsticks popular in restaurants, street food, and canteens are 22 cm or 24 cm in length with an average diameter of 5 mm, weighing approximately 5.60 g/pair. The result showed that the DBCs had 92.08% dry matter, a moisture content of 7.92%, and 0.80% ash content. Analytical results of the lignocellulose content in DBC found that DBCs contain cellulose at 44.12%, hemicellulose at 25.65%, and lignin at 19.20%. The content of lignocellulose in DBC differs from the analysis result of the bamboo by Hernández-Mena et al. [35], who reported that bamboo contains 47.50% cellulose, 15.35% hemicellulose and 26.25% lignin.

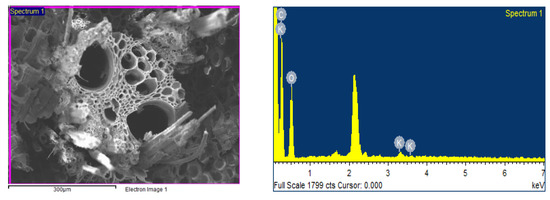

The results of the physical characteristics revealed that the DBCs had an SSA of 0.2774 m2/g and a TPV of 0.00091 cc/g. The pore size was characterized as a mesoporous type (6.583 nm). The SEM and EDS images of the feedstock are shown in Figure 2. The highest element in DBC was the C element with 54.86% weight (wt) and 62.26% atomic, followed by the contents of O (43.73% wt and 37.25% atomic) and K (1.41% wt and 0.49% atomic), respectively.

Figure 2.

SEM and EDS images of the pore structure of disposable bamboo chopsticks.

The elemental analysis of DBC feedstock before transformation into biochar revealed that DBC contained 45.37% C, 6.18% H, 0.34% N, and 48.11% O. The molar ratio of H/C was 1.63, O/C of 0.80, and C/N of 154.52. The analysis showed that DBC had a pH of 3.96, EC of 1470 µS/cm, and CEC of 26.38 cmol/kg. The nutrient content of DBCs is: total N content 0.40% wt, total P2O5 192.63 mg/kg, and total K2O 1646.67 mg/kg.

The properties of DBC are different from the bamboo reported in the literature [35], particularly for C, moisture, and ash. The DBC had a higher C content (45.37%) than bamboo (39%), while having a lower moisture (7.92%) and ash (0.80%) content than bamboo, which had 9.37% moisture and 2.57% ash content.

3.2. Product Yields and Physicochemical Properties of Disposable Bamboo Chopsticks Biochar

The volatile matter, the ash content, the fixed carbon, and the yields of DBC biochar produced from different temperatures are shown in Table 1. Increasing the pyrolysis temperature decreased the volatile content and yields, while an opposite trend was found for the fixed C and ash contents.

Table 1.

Volatile matter, ash, fixed C, yields, pH, and CEC of DBC biochar obtained from different temperatures.

The proximate analysis showed that DBC biochar had volatile matter ranging from 35.99% to 41.87%, and DBC-400 had the highest statistically significant value. Volatile matter mainly contains CO, CO2, H2, CH4, N2, and gaseous carbohydrates; the volatile content is related to hemicellulose and cellulose and the pyrolysis temperature [23]. Increasing temperatures resulted in the further crack of the volatile fractions into low-molecular-weight liquids and gases instead of biochar [18,64]. Ghodake et al. [8] reported several studies where different feedstock types were pyrolyzed at 500 °C, and the VM of different types of biochar varied from 9.94 to 67.90. The ash content of biochar obtained from pyrolysis at different temperatures had similar values at 3.38–3.80%, and all DBC biochar had no statistically significant differences. The biochar yield decreased from 24.08% to 15.82% when the temperature increased from 400 °C to 500 °C. The results indicated that the pyrolysis temperatures significantly influenced it. This was likely due to the fact that most of the lignocellulosic material was decomposed in this temperature range. Studies in the literature have shown that during the pyrolysis process, the primary cracks and secondary decomposition occur at 400–500 °C along with the formation of oxygen functional groups [12,46,67], and the formation of the biochar structure occurs during these temperature ranges with the main precursor, lignin [29,65,67]. The lignin content was reported to be approximately 25% in hardwood and 33% in softwood [56]. The literature reports that bamboo has a lignin content of approximately 21.95–26.76% [12], depending on the age and part of the tree [47]. Chen et al. [28], Qian et al. [32], and Tomczyk et al. [64] reported that biomass feedstock with a high lignin content would likely provide more biochar yield. On the contrary, Adekunle et al. [48] reported results that are not consistent with the above trends.

Increasing the temperature from 400 °C to 500 °C accelerated the degree of carbonization of the DBC biochar; therefore, DBC-500 showed the highest fixed C (52.73%), and the lowest was found in DBC-400 (47.99%). The fixed C content corresponded to the ash content. There were no statistically significant differences in the fixed C content between DBC-450 and DBC-500, but the fixed C content in both biochar showed significant differences from DBC-400. At different pyrolysis temperatures, a general exponential decrease in the yield of DBC biochar and exponential increases in the fixed C content can be observed, which is consistent with the work reported in the literature [10,36,54,71]. The ash content of the DBC biochar produced at 500 °C was lower than the bamboo biochar, which contains 3.9%, according to Hernandez-Mena et al. [35]. The increase in the pyrolysis temperature (400 °C to 500 °C) also reveals the ash content and pH of the DBC biochar. The ash content and pH are a result of the destructive volatilization of lignocellulosic matter in the biochar feedstock [16,51,66] and a concomitant decrease in the acidic functional groups [10,18]. Then the solid phase hydroxides and carbonate phases increase in the ash, thereby increasing the pH value simultaneously [20,37].

Generally, biochar is usually alkaline [8,21,62,77]; however, the DBC feedstock was extremely acidic (pH 3.96), so after undergoing the pyrolysis process, the DBC biochar decreased its acidity, with a pH range of 4.50–5.02, but was still acidic. No statistically significant differences existed between the DBC produced at the different temperatures. However, the DBC biochar produced at 450 °C showed a very strong acidity (4.6); different from the bamboo biochar of strong acidity (5.2) reported by Suthar et al. [11], and significantly different from the moderate alkalinity (8.2) reported by Cruz-Méndez et al. [34]. On the contrary, the pyrolysis temperature significantly affects the decrease in the CEC of DBC biochar and the CEC (53.88% to 49.26 cmol/kg) when the pyrolysis temperature increases from 400 °C to 500 °C. The result is consistent with numerous studies [42,47,62]. The decrease in CEC results from the removal of surface functional groups and the oxidation of aromatic C, which occurs mainly in the temperature range of 300 °C to 400 °C [41,42,68], a determination which was supported by the lower O/C ratio. At a temperature range of 350–650 °C, the chemical bonds in the biomass feedstock are broken and rearranged, forming new functional groups, especially carboxyl and phenol [31]. Banik et al. [43] indicated that the negative surface charge could only come from the carboxylate and phenolate groups. At the pyrolysis temperature at 400 °C, the CEC of DBC biochar (58.93 cmol/kg) is different from bamboo biochar (41.40 mmol/100 g) reported by Suthar et al. [11].

3.3. The Elemental Characteristics of Disposable Bamboo Chopsticks Biochar

The results of the ultimate analysis are presented in Table 2 and show that C content in biochar was the highest value in DBC-500 with 63.47%, which was statistically significantly higher than DBC-400 (60.10%) and DBC-450 (60.68%). The H content was highest in DBC-400 with values of 3.22%, and the lowest was found in DBC-500 with 2.83%. There were no statistically significant differences between DBC-450 and DBC-500 in H and N contents. The highest N content was found in DBC-500, and the lowest value was found in DBC-400. The O content of all biochar ranged from 29.11% to 32.73%, and there was no statistically significant difference between DBC-400 (32.73%) and DBC-450 (32.30%).

Table 2.

Elemental composition and nutrient content of DBC biochar obtained at various pyrolysis temperatures.

The results indicated that increasing the pyrolysis temperatures increased the C content of the DBC biochar, whereas the H and O content decreased. This result is consistent with previous results [25,50,55,71]. The increase in C content was due to high carbonization at high temperatures of high C content in the aromatic structures through volatilization loss of other elements, particularly H and O [36,38,41]. On the other hand, the H and O content decreased due to dehydration reactions and the removal of hydrocarbons, tarry vapors, CO2, and organic surface functional groups during the carbonization process [51]. As pyrolysis increases, O is released at a higher rate than H. As a result, the final biochar product is characterized by a reduced H/C ratio and contains lower O content. All DBC biochar had a C/N ratio of 110–123, which was lower than that of bamboo biochar (C/N ratio of 191 reported by Cruz-Méndez et al. [34] where bamboo was pyrolyzed at 450–550 °C). The C/N ratio of biochar depended on the type of feedstock. The C/N ratio of grape wood biochar was 96.50, and the poultry litter biochar had a C/N ratio of 24.5 when both feedstocks were pyrolyzed at 700 °C [77].

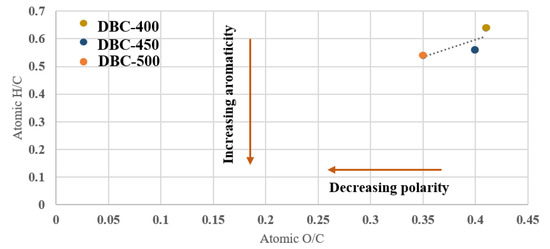

The atomic molar ratios obtained from the ultimate analysis, as presented in Table 2, are commonly used to determine the degree of aromaticity by H/C ratio and the polarity by O/C ratio and have been used for biochar characterization, which varies with the type of biomasses and the pyrolysis temperature [27,49,75]. An increase in the pyrolysis temperature decreases the H/C and O/C ratios, indicating that the structural transformations induce a carbonization process. The results indicated that the H/C and O/C ratios of the DBC biochar decreased with increasing pyrolysis temperature from 400 °C to 500 °C. These results align with those obtained by Li et al. [25] and Ahmad et al. [41]. However, IBI [70] stated that biochar with a H/C ratio lower than 0.7 has more incredible fused aromatic ring structures.

The relationship between C, H, O, and pyrolysis temperature, as shown in the Van-Krevelen diagram (Figure 3), may be helpful in discerning biochar longevity in soil systems [55,73]. As the H/C ratio decreases, the aromaticity of biochar increases [9,43,71], and as the O/C ratio increases, the polarity increases [18,67]. The study results indicated that DBC-400 showed a lower degree of carbonization. At the same time, DBC-500 presented the least hydrophilic surface of biochar with the lowest O/C ratio (0.35), and the highest degree of aromaticity.

Figure 3.

Van-Krevelen diagram of DBC biochar obtained from different pyrolysis temperature.

The result found that the pyrolysis process alters the nutrient content in biochar. Thermal degradation affects total P2O5 and the total K2O but has no significant effect upon total N content. The total N content decreased from 0.53% to 0.47% with increased pyrolysis temperature from 400 °C to 500 °C, suggesting an ignition loss of N during pyrolysis. The maximum content of total K2O (8.26 g/kg) was observed in DBC-450, while the minimum (4.94 g/kg) was found in DBC-400. Increasing the temperature from 400 °C to 500 °C decreased total P2O5 content from 3.33 g/kg to 2.62 g/kg. The nutrient content tends to decrease when the temperature increases due to the loss of volatile compounds (C, H, and O) in the feedstock and the relatively small loss of alkali nutrients in the gaseous phase [11,22,78]. However, K and P vaporize at higher temperatures; therefore, the DBC biochar had a higher total P2O5 and a higher total K2O than the DBC feedstock, and DBC-500 had a lower nutrient content than DBC-450.

3.4. Morphology Characteristics and Physical Properties of DBC Biochar

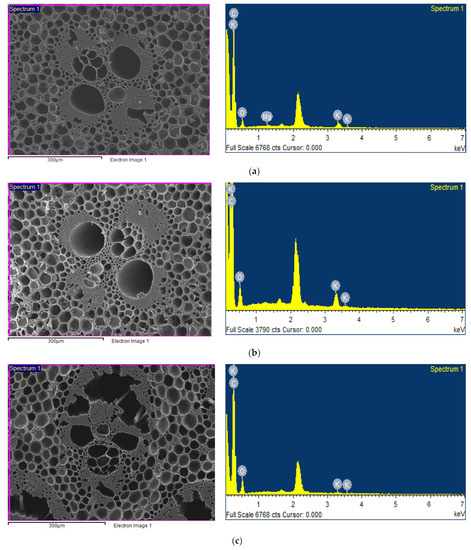

Biochar made from DBC feedstock developed high porosity, and different temperature ranges from 400–500 °C affected the formation of the pores. The BET surface area of DBC biochar obtained from different temperature production processes also varied considerably from 356.521 m2/g to 465.313 m2/g, and the average pore volume ranged from 0.535 cc/g to 1.087 cc/g. Biochar was produced at different temperatures, with an average pore diameter ranging from 9.833 Å to 10.968 Å. Table 3 summarizes the analysis of the physical characteristic and morphology of DBC biochar made at different pyrolysis temperatures.

Table 3.

Electron Microscopy Analysis of DBC biochar.

The pore size of all DBC biochar is classified as micropore type, as in the reported literature on biochar produced from wood at the same temperatures (400–500 °C), such as cotton stalk [23], cotton seed [27], and bamboo [35]. However, some previous studies found that wooden biochar had a mesoporous type, such as Samanea saman (Jacq.) Merr. And Streblus ilicifolius (Vidal) Corner. [19]. The pores of biochar originate from the vascular bundles of feedstocks [7]. Shaaban et al. [37] showed that rubber wood sawdust biochar produced at 500 °C with 60 min of holding time had a small surface area of 2.2 m2/g, a large APV of 11 nm and a TPV of 6.1 × 10−3 cm3/g. Increasing the temperature from 400 °C to 500 °C resulted in sudden jumps in the surface area of DBC biochar of 356.521 m2/g to 465.313 m2/g and the pore volume of 0.535 cc/g to 1.087 cc/g. This trend of results is similar to the literature reports of Domingues et al. [17], Bonelli et al. [21], Cheng et al. [23], and Ferreira et al. [24].

Biochar is made from different feedstocks with different sizes of surface area. Song and Guo [62] reported that poultry litter biochar produced at different pyrolysis temperatures of 300 °C to 600 °C had surface areas of 2.0 m2/g to 3.2 m2/g, while Tag et al. [16] reported that orange pomace biochar and vine pruning obtained from the same pyrolysis condition had surface areas of 1.2 m2/g and 8.1 m2/g, respectively. The results of Shaaban et al. [37] stated that the rubber wood sawdust biochar obtained by pyrolysis at 300 °C to 700 °C had a surface area of 1.399 m2/g to 5.493 m2/g. The surface area of the mentioned biochar is smaller than the surface area of DBC biochar, which is the result of feedstock types. Wood-based biochar had a larger surface area than biochar produced from non-wooden feedstock, such as punning, poultry, sludge, agricultural waste [65]. However, the results by Jindo et al. [65] showed that biochar produced from different types of wood feedstocks at the same pyrolysis temperature provides a different surface area size. The high temperature in the pyrolysis process resulted in ruptures on the surface of biomass and influenced the formation and volatilization of intermediate melts [11,37,68].

In terms of SSA and APV of hardwood biochar, this reduces the relatively large wood-based cellular structures into smaller pores, which increases the SSA and APV [44]. Furthermore, SSA and APV will be created during the release of volatile or water volatilization processes associated with pyrolysis and loss of micro-molecule organic components, both of which can result in the formation of voids within the biochar matrix during their processes [20,54,65]. As a result, the DBC feedstock pyrolysis at 500 °C (DBC-500) resulted in the lowest volatile matter and the highest pore volume. The analysis of the pore structure of DBC biochar obtained from the different pyrolysis temperatures is shown in Figure 4.

Figure 4.

The pore structure of DBC biochar produced from various pyrolysis temperatures analyzed by SEM and EDS image. (a) DBC-400, (b) DBC-450, and (c) DBC-500.

SEM analysis of the three DBC biochar products revealed that the pyrolysis temperature influenced the morphology of the biochar under an identical residence pyrolysis time and the same biomass. The significant elements found in all DBC biochar were C, O, and K, except for Mg, which was presented in DBC-400 with 0.49% wt and 0.26% atomic. The C element was the highest in DBC-500 with 81.60% wt and 85.91% atomic, followed by DBC-450 with 78.57% wt and 84.15% atomic, and DBC-400 with 78.44% wt and 84.39% atomic, respectively. The % weight and % atomic element of K found in DBC biochar were opposite to the % weight of the C element. The DBC-400 had the highest % wt and % atomic element of 3.51% and 1.16%, respectively, followed by DBC-450 (2.92% wt and 0.96% atomic) and DBC-500 (0.96% wt and 3.10% atomic), respectively. The highest % wt and % atomic of the O element (18.51% and 14.89%) were found in the DBC-450, followed by the DBC-400 (17.57% wt and 14.19% atomic) and DBC-500 (17.44% wt and 13.78% atomic), respectively.

3.5. The Potential and Suitability of Biochar Produced from DBC for Application in Agricultural and Environmental Purposes

DBC is made from bamboo as lignocellulosic biomass, which can produce biochar with a high C content of almost 50%, a low moisture content (7.92%), and a low ash content (0.80%). The elemental content of DBC, including C, P, and K, was considered essential as a biochar feedstock applied for soil amendment. The results showed that upcycling the DBC wastes by pyrolysis process at a temperature of 400 °C, 450 °C, and 500 °C provided the product classified as biochar according to IBI and EBC standard with C content, H/C, and O/C ratios. IBI proposed that material classified as biochar should have a C content of more than 10% and a H/C of less than 0.7 [70]. At the same time, the EBC stated that material sufficient to classify as biochar must have a C content greater than 50%, a H/C ratio not exceeding 0.7, and O/C should be lower than 0.4 [60]. Furthermore, the quality of all DBC biochar is classified in class 1, according to the IBI, with more than 60% of C content [70].

Biochar is a versatile material for various applications, and each application demands specific qualities. Biochar has been used for various agricultural and environmental purposes, such as an application for soil amendment, an adsorbent in soil and water treatment, and as carbon sequestration to mitigate climate change [13,30,32,53,54]. However, to effectively use biochar for various purposes, it is necessary to select it with suitable properties for the application. The results indicated that the biochar derived from DBC had various properties depending on the pyrolysis temperature, which makes the overall DBC biochar properties suitable for soil amendment, adsorbent, and carbon sequestration.

When biochar is an absorbent, the properties most needed are high porosity, a large specific surface area, and large surface functional groups for the adsorption mechanism [26,44,50] based on electrostatic interaction, ion exchange, pore filling, and precipitation [26,40]. The porosity of all DBC biochar is classified as microporous, which are the main contributors to the biochar surface area of biochar and are also responsible for efficient adsorbents supported by previous studies [10,27,30,43]. Moreover, previous research works of the literature indicated that wooden biochar provided the greatest SSA and could promote more remarkable changes in soil physical characteristics over other feedstock-based biochar [20,64]. Moreover, Uchimiya et al. [27] indicated that the properties attributable to functional groups at the surface of biochar, including VM, O content, and pH, control the capacity of heavy metal sequestration in the soil.

Suppose that C storage in the soil is a goal. In that case, DBC-500 is the best biochar suitable for this purpose due to the highest C content and the highest degree of aromaticity and condensation represented by the H/C ratio. Furthermore, regarding the stability of biochar in the soil represented by the O/C ratio [76], the result indicated that all DBC biochar is moderately stable with a half-life between 100 to 1000 years (O/C ratio = 0.2–0.6). Therefore, the biochar with the most longevity in the soil would be the DBC-500. However, Schimmelpfennig and Glaser [55] recommended that the biochar suitable for soil amendment and carbon sequestration should have an O/C ratio < 0.4, H/C ratio < 0.6, black carbon > 15%, and a surface area > 100 m2/g. Meanwhile, applications of biochar to mitigate greenhouse gas emissions, such as reducing N2O from the soil, should use biochar with a low N content and a C/N ratio of more than 30 [78]. In this sense, DBC-450 and DBC-500 are appropriate for soil amendment and can lead to climate change mitigation from the agricultural sector.

As a material for soil amendment, the overall properties of all DBC biochar indicated that DBC biochar obtained from different pyrolysis temperatures could be used as a soil amendment. Data from a few works in the literature showing the application of biochar as a soil amendment in various conditions is presented in Table 4.

Table 4.

Applying biochar as a soil amendment.

Biochar interacts with the physical, physicochemical, and biological properties of soil. Reviews and meta-analyses by Joshep et al. [9] indicated that the mechanism of biochar in the soil occurs from the short term (within three weeks) to the long run (more than six months). Many previous studies have reported that biochar could adjust soil pH, which controls nutrient availability for root uptake, and the liable rate of organic C releases to be utilized by plant and soil microbes [11,26,46,68]. Huang et al. [36], Liang et al. [46], and Chandra and Bhattacharya [68] reported that biochar enhances germination and seedling growth range. The pH in the soil solution affects the elaboration of the nutrient release rate from biochar; therefore, seed germination rates vary in soils with different pH [68]. In sum, selecting biochar with suitable pH for soil conditions is important to the fundamental mechanism in the soil that supports the growth of plants.

Most biochar has been reported as alkaline and is used for acid soils [8,11,34]. However, all DBC biochar was acidic with a pH of 4.50–5.02, which is appropriate for improving alkaline soil. Cruz-Méndez et al. [34] reported that by applying bamboo biochar (pH 8.2) at a rate of 20% and 50% to cultivate tomatillos in soil with low buffer capacity (pH 7.6), the soil pH was 7 and 7.7, respectively, after harvest. However, it is also necessary to study the behavior of biochar to adjust the pH of soil due to the buffering capacity of the soil [68]. The mechanism of CEC is related to pH-dependent, variable charge properties, as well as the presence of soluble salt. Therefore, increasing CEC in the soil from amended biochar takes time because additional functional groups form on the biochar surface, increasing its ability to absorb and retain cations and anions [20,23,37,41]. The CEC is an important property that affects the better retention of nutrients in the soil and reduced fertilizer leaching [17,42].

Soil density influences the water retention of the soil and is an obstacle to the growth of plants. Biochar is a porous material with a low bulk density in relation to the soil [9,20,37]; therefore, adding biochar to the soil can improve water retention and water holding capacity of different soil types [36,69]. Given the porosity and large surface area of all DBC biochar, it has a positive effect on soil aeration and water retention in the soil. Biochar with micropores types and a large pore volume presents better water retention and water holding capacity [9,20,50,69]. Accordingly, DBC-500, with the highest porosity, is likely to increase soil aeration more than DBC-400 and DBC-450. However, the crucial fundamental properties are the capacity of biochar to adsorb cation nutrients in the soil with pH and CEC [9,16,17,68] and the nutrient of biochar. Therefore, DBC-450 seems to be the best biochar choice for soil supplementation. The previous literature indicates that the efficiency of biochar application as a soil amendment depends on the selection of appropriate biochar given the soil conditions, the particle size of biochar, and the rate of biochar applied [11,36,42,46,58]. Nonetheless, previous research has suggested that selection of biochar for agronomical purposes must be made case-by-case based on the biochar’s characteristics, the soil’s properties, and the goal function [27].

This research has pointed out that DBC waste could be repurposed for biochar, which is beneficial for agricultural applications and leads to sustainable consumption. Furthermore, the appropriate temperature for the production of biochar for soil amendment was chosen to develop a practical biochar furnace for wide use at the community and local levels.

4. Conclusions

The study indicated that DBCs are urban wastes that have the potential to be used as feedstock to produce biochar. The DBC feedstocks were produced at different pyrolysis temperatures, specifically, 400 °C, 450 °C, and 500 °C, with the same holding time of 60 min. The morphology and physicochemical properties of DBC biochar changed with the pyrolysis temperature. The influence of variable pyrolysis temperature (400 °C, 450 °C, 500 °C) was found in the physicochemical properties of the biochar, which could be summarized as a decrease in volatile materials, H, O, and nutrient contents and an increase in ash content, pH and C contents as affected by the pyrolysis temperature.

The DBC biochar obtained from different pyrolysis temperatures provides appropriate properties, including morphology and physicochemical properties, for agriculture. The DBC biochar was acidic, had high stability, and could remain in the soil for a long time. The study concluded that DBC biochar produced at 450 °C is the most suitable to apply as a soil amendment substance based on CEC, SSA, APD, and nutrient content.

Funding

This research was funded by the Thailand Science Research and Innovation Fund (fundamental fund), a basic research plan to drive the BCG economy under the project Urban Organic Waste Upcycling for Agricultural and Environmental, Chulalongkorn University (CUFRB65_BCG (36) 214_54_01).

Data Availability Statement

Not applicable.

Conflicts of Interest

The author declares no conflict of interest.

References

- Ferronato, N.; Torretta, V. Waste Mismanagement in Developing Countries: A Review of Global Issues. Int. J. Environ. Res. Public Health 2019, 16, 1060. [Google Scholar] [CrossRef] [PubMed]

- Srivastava, V.; Ismail, S.A.; Singh, P.; Singh, R.P. Urban solid waste management in the developing world with emphasis on India: Challenges and opportunities. Rev. Environ. Sci. Biotechnol. 2015, 14, 317–337. [Google Scholar] [CrossRef]

- Kaza, S.; Yao, L.C.; Bhada-Tata, P.; Van Woerden, F. What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050; World Bank Publications: Washington, DC, USA, 2018; Available online: https://openknowledge.worldbank.org/handle/10986/303172018 (accessed on 29 September 2022).

- Guerrero, L.A.; Maas, G.; Hogland, W. Solid waste management challenges for cities in developing countries. Waste Manag. 2013, 3, 220–232. [Google Scholar] [CrossRef] [PubMed]

- Luo, C. China’s 80 Billion Disposable Chopsticks a Burden on Forests. Available online: https://www.scmp.com/news/china/article/1188299/chinas-80-billion-disposable-chopsticks-burden-forests (accessed on 1 October 2022).

- Chen, Y.-H.; Chang, C.-C.; Chang, C.-Y.; Yuan, M.-H.; Ji, D.-R.; Shie, J.-L.; Lee, C.-H.; Chen, Y.-H.; Chang, W.-R.; Yang, T.-Y.; et al. Production of a solid bio-fuel from waste bamboo chopsticks by torrefaction for cofiring with coal. J. Anal. Appl. Pyrolysis 2017, 126, 315–322. [Google Scholar] [CrossRef]

- Jiang, J.; Zhu, J.; Ai, W.; Fan, Z.; Shen, X.; Zou, C.; Liu, J.; Zhang, H.; Yu, T. Evolution of disposable bamboo chopsticks into uniform carbon fibers: A smart strategy to fabricate sustainable anodes for Li-ion batteries. Energy Environ. Sci. 2014, 7, 2670–2679. [Google Scholar] [CrossRef]

- Ghodake, G.S.; Shinde, S.K.; Kadam, A.S.; Saratale, R.G.; Saratale, G.D.; Kumar, M.; Palem, R.R.; AL-Shwaiman, H.A.; Elgorban, A.M.; Syed, A.; et al. Review on biomass feedstocks, pyrolysis mechanism and physicochemical properties of biochar: State-of the-art framework to speed up vision of circular bioeconomy. J. Clean. Prod. 2021, 297, 126645. [Google Scholar] [CrossRef]

- Joseph, S.; Cowie, A.L.; Van Zwieten, L.; Bolan, N.; Budai, A.; Buss, W.; Cayuela, M.L.; Graber, E.R.; Ippolito, J.A.; Kuzyakov, Y.; et al. How biochar works, and when it doesn’t: A review of mechanisms controlling soil and plant responses to biochar. GCB Bioenergy 2021, 13, 1731–1764. [Google Scholar] [CrossRef]

- Yaashikaa, P.R.; Kumar, P.S.; Varjani, S.; Saravanan, A. A critical review on the biochar production techniques, characterization, stability and applications for circular bioeconomy. Biotechnol. Rep. 2020, 28, e00570. [Google Scholar] [CrossRef]

- Suthar, R.G.; Wang, C.; Nunes, M.C.N.; Chen, J.; Sargent, S.A.; Buckiln, R.A.; Gao, B. Bamboo biochar pyrolyzed at low temperature improves tomato plant growth and fruit quality. Agriculture 2018, 8, 153. [Google Scholar] [CrossRef]

- Huang, H.; Yao, W.; Li, R.; Ali, A.; Du, J.; Guo, D.; Xiao, R.; Guo, Z.; Zhang, Z.; Awasthi, M.K. Effect of pyrolysis temperature on chemical form, behavior and environmental risk of Zn, Pb and Cd in biochar produced from phytoremediation residue. Bioresour. Technol. 2018, 249, 487–493. [Google Scholar] [CrossRef]

- Zhu, L.; Lei, H.; Zhang, Y.; Zhang, X.; Bu, Q.; Wei, Y. A Review of Biochar Derived from Pyrolysis and Its Application in Biofuel Production. SF J. Mater. Chem. Eng. 2018, 1, 1007. [Google Scholar]

- Li, G.; Hu, R.; Wang, N.; Yang, T.; Xu, F.; Jiahui, W.; Huang, Z.; Pan, M.; Lyu, T. Cultivation of microalgae in adjusted wastewater to enhance biofuel production and reduce environmental impact: Pyrolysis performances and life cycle assessment. J. Clean. Prod. 2022, 355, 131768. [Google Scholar] [CrossRef]

- Huang, Z.; Zhang, J.; Pan, M.; Hao, Y.; Hu, R.; Xiao, W.; Li, G.; Lyu, T. Valorisation of microalgae residues after lipid extraction: Pyrolysis characteristics for biofuel production. Biochem. Eng. J. 2022, 179, 108330. [Google Scholar] [CrossRef]

- Tag, A.T.; Duman, G.; Ucar, S.; Yanik, J. Effects of feedstock type and pyrolysis temperature on potential applications of biochar. J. Anal. Appl. Pyrolysis 2016, 120, 200–206. [Google Scholar] [CrossRef]

- Domingues, R.R.; Trugilho, P.F.; Silva, C.A.; Melo, I.C.; Melo, L.C.A.; Magriotis, Z.M.; Sanchez-Monedero, M.A. Properties of biochar derived from wood and high-nutrient biomasses with the aim of agronomic and environmental benefits. PLoS ONE 2017, 12, e0176884. [Google Scholar] [CrossRef]

- Ronsse, F.; Hecke, S.V.; Dickinson, D.; Prins, W. Production and characterization of slow pyrolysis biochar: Influence of feedstock type and pyrolysis conditions. Glob. Chang. Biol. Bioenergy 2013, 5, 104–115. [Google Scholar] [CrossRef]

- Wijitkosum, S. Biochar derived from agricultural wastes and wood residues for sustainable agricultural and environmental applications. Int. Soil Water Conserv. Res. 2022, 10, 335–341. [Google Scholar] [CrossRef]

- Ippolito, J.A.; Cui, L.; Kammann, C.; Wrage-Mönnig, N.; Estavillo, J.M.; Fuertes-Mendizabal, T.; Cayuela, M.L.; Sigua, G.; Novak, J.; Spokas, K.; et al. Feedstock choice, pyrolysis temperature and type influence biochar characteristics: A comprehensive meta-data analysis review. Biochar 2020, 2, 421–438. [Google Scholar] [CrossRef]

- Bonelli, P.R.; Buonomo, E.L.; Cukierman, A.L. Pyrolysis of sugarcane bagasse and co-pyrolysis with an Argentinean subbituminous coal. Energy Sour. Part A 2007, 29, 731–740. [Google Scholar] [CrossRef]

- Chen, S.; Rotaru, A.E.; Shrestha, P.M.; Malvankar, N.S.; Liu, F.; Fan, W.; Nevin, K.P.; Lovley, D.R. Promoting Interspecies Electron Transfer with Biochar. Sci. Rep. 2014, 4, 5019. [Google Scholar] [CrossRef]

- Cheng, N.; Wang, B.; Wu, P.; Lee, X.; Xing, Y.; Chen, M.; Gao, B. Adsorption of emerging contaminants from water and wastewater by modified biochar: A review. Environ. Pollut. 2021, 273, 116448. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, S.D.; Junges, J.; Bassanesi, G.R.; Lazzarotto, I.P.; Osorio, E.; Godinho, M. Investigation of the structure of the biochar obtained by slow pyrolysis of elephant grass during its steam gasification. Chem. Eng. Technol. 2019, 42, 2546–2555. [Google Scholar] [CrossRef]

- Li, M.; Liu, Q.; Guo, L.J.; Zhang, Y.P.; Lou, Z.J.; Wang, Y.; Qian, G.R. Cu (II) removal from aqueous solution by Spartina alterniflora derived biochar. Bioresour. Technol. 2013, 141, 83–88. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Jing, Y.; Xiang, Y.; Zhang, R.; Lu, H. Responses of soil microbial community structure changes and activities to biochar addition: A meta-analysis. Sci. Total Environ. 2018, 643, 926–935. [Google Scholar] [CrossRef] [PubMed]

- Uchimiya, M.; Wartelle, L.H.; Klasson, K.T.; Fortier, C.A.; Lima, I.M. Influence of pyrolysis temperature on biochar property and function as a heavy metal sorbent in soil. J. Agric. Food Chem. 2011, 59, 2501–2510. [Google Scholar] [CrossRef]

- Chen, C.; Yan, X.; Xu, Y.; Yoza, B.A.; Wang, X.; Kou, Y.; Ye, H.; Wang, Q.; Li, Q.X. Activated Petroleum Waste Sludge Biochar for Efficient Catalytic Ozonation of Refinery Wastewater. Sci. Total Environ. 2019, 651, 2631–2640. [Google Scholar] [CrossRef]

- Fawzy, S.; Osman, A.I.; Yang, H.; Doran, J.; Rooney, D.W. Industrial biochar systems for atmospheric carbon removal: A review. Environ. Chem. Lett. 2021, 19, 3023–3055. [Google Scholar] [CrossRef]

- Wu, K.; Ali, I.; Xie, H.; Ullah, S.; Iqbal, A.; Wei, S.; He, L.; Huang, Q.; Wu, X.; Cheng, F.; et al. Impact of fertilization with reducing in nitrogen and phosphorous application on growth, yield and biomass accumulation of rice (Oryza sativa L.) under a dual cropping system. PeerJ 2021, 9, e11668. [Google Scholar] [CrossRef]

- Mia, S.; Dijkstra, F.A.; Singh, B. Long-term ageing of biochar: A molecular understanding with agricultural and environmental implications. Adv. Agron. 2017, 141, 1–51. [Google Scholar] [CrossRef]

- Qian, K.; Kumar, A.; Zhang, H.; Bellmer, D.; Huhnke, R. Recent advances in utilization of biochar. Renew. Sustain. Energy Rev. 2015, 42, 1055–1064. [Google Scholar] [CrossRef]

- Ferlito, F.; Torrisi, B.; Allegra, M.; Stagno, F.; Caruso, P.; Fascella, G. Evaluation of conifer wood biochar as growing media component for citrus nursery. Appl. Sci. 2020, 10, 1618. [Google Scholar] [CrossRef]

- Cruz-Méndez, A.S.; Ortega-Ramírez, E.; LuchoConstantino, C.A.; Arce-Cervantes, O.; Vázquez-Rodríguez, G.A.; Coronel-Olivares, C.; BeltránHernández, R.I. Bamboo Biochar and a Nopal-Based Biofertilizer as Improvers of Alkaline Soils with Low Buffer Capacity. Appl. Sci. 2021, 11, 6502. [Google Scholar] [CrossRef]

- Hernández-Mena, L.; Pecora, A.; Beraldo, A. Slow pyrolysis of bamboo biomass: Analysis of biochar properties. Chem. Eng. Trans. 2014, 37, 115–120. [Google Scholar] [CrossRef]

- Huang, H.; Reddy, N.G.; Huang, X.; Chen, P.; Wang, P.; Zhang, Y.; Huang, Y.; Lin, P.; Garg, A. Effects of pyrolysis temperature, feedstock type and compaction on water retention of biochar amended soil. Sci. Rep. 2021, 11, 7419. [Google Scholar] [CrossRef]

- Shaaban, M.; Van Zwieten, L.; Bashir, S.; Younas, A.; Núñez-Delgado, A.; Chhajro, M.A.; Kubar, K.A.; Ali, U.; Rana, M.S.; Mehmood, M.A.; et al. Concise review of biochar application to agricultural soils to improve soil conditions and fight pollution. J. Environ. Manag. 2018, 228, 429–440. [Google Scholar] [CrossRef]

- Das, S.K.; Ghosh, G.K.; Avasthe, R.K.; Sinha, K. Compositional heterogeneity of different biochar: Effect of pyrolysis temperature and feedstocks. J. Environ. Manag. 2021, 278, 111501. [Google Scholar] [CrossRef]

- Daful, A.G.; Chandraratne, M. Production from Biomass Waste-Derived Material. In Encyclopedia of Renewable and Sustainable Materials Biochar, 1st ed.; Choudhury, I., Hashmi, S., Eds.; Elsevier Science Publishing Co. Inc.: New York, NY, USA, 2018; pp. 1–9. [Google Scholar]

- Mohanty, S.K.; Valenca, R.; Berger, A.W.; Iris, K.; Xiong, X.; Saunders, T.M.; Tsang, D.C. Plenty of room for carbon on the ground: Potential applications of biochar for stormwater treatment. Sci. Total Environ. 2018, 625, 1644–1658. [Google Scholar] [CrossRef]

- Ahmad, M.; Rajapaksha, A.U.; Lim, J.E.; Zhang, M.; Bolan, N.; Mohan, D.; Vithanage, M.; Lee, S.S.; Yong, S. Biochar as a sorbent for contaminant management in soil and water: A review. Chemosphere 2014, 99, 19–33. [Google Scholar] [CrossRef]

- Yao, Y.; Gao, B.; Zhang, M.; Inyang, M.; Zimmerman, A.R. Effect of biochar amendment on sorption and leaching of nitrate, ammonium, and phosphate in a sandy soil. Chemosphere 2012, 89, 1467–1471. [Google Scholar] [CrossRef]

- Banik, C.; Lawrinenko, M.; Bakshi, S.; Laird, D.A. Impact of pyrolysis temperature and feedstock on surface charge and functional group chemistry of biochars. J. Environ. Qual. 2018, 47, 452–461. [Google Scholar] [CrossRef]

- Weber, K.; Quicker, P. Properties of biochar. Fuel 2018, 217, 240–261. [Google Scholar] [CrossRef]

- Sun, Y.; Gao, B.; Yao, Y.; Fang, J.; Zhang, M.; Zhou, Y.; Chen, H.; Yang, L. Effects of feedstock type, production method, and pyrolysis temperature on biochar and hydrochar properties. Chem. Eng. J. 2014, 240, 574–578. [Google Scholar] [CrossRef]

- Liang, C.; Gascó, G.; Fu, S.; Méndez, A.; Paz-Ferreiro, J. Biochar from pruning residues as a soil amendment: Effects of pyrolysis temperature and particle size. Soil Tillage Res. 2016, 164, 3–10. [Google Scholar] [CrossRef]

- Suliman, W.; Harsh, J.B.; Abu-Lail, N.I.; Fortuna, A.; Dallmeyer, I.; Garcia-perez, M. Modification of biochar surface by air oxidation: Role of pyrolysis temperature. Biomass Bioenergy 2016, 85, 1–11. [Google Scholar] [CrossRef]

- Adekunle, J.O.; Ibrahim, J.S.; Kucha, E.I. Proximate and ultimate analyses of biocoal briquettes of Nigerian’s Ogboyaga and Okaba sub-bituminous coal. Curr. Appl. Sci. Technol. 2015, 7, 114–123. [Google Scholar] [CrossRef]

- Li, S.; Harris, S.; Anandhi, A.; Chen, G. Predicting biochar properties and functions based on feedstock and pyrolysis temperature: A review and data syntheses. J. Clean. Prod. 2019, 215, 890–902. [Google Scholar] [CrossRef]

- Trigo, C.; Cox, L.; Spokas, K. Influence of pyrolysis temperature and hardwood species on resulting biochar properties and their effect on azimsulfuron sorption as compared to other sorbents. Sci. Total Environ. 2016, 566, 1454–1464. [Google Scholar] [CrossRef]

- Keiluweit, M.; Nico, P.S.; Johnson, M.G.; Kleber, M. Dynamic molecular structure of plant-derived black carbon (biochar). Environ. Sci. Technol. 2010, 44, 1247–1253. [Google Scholar] [CrossRef]

- Layek, J.; Narzari, R.; Hazarika, S.; Das, A.; Rangappa, K.; Devi, S.; Balusamy, A.; Saha, S.; Mandal, S.; Idapuganti, R.G.; et al. Prospects of Biochar for Sustainable Agriculture and Carbon Sequestration: An Overview for Eastern Himalayas. Sustainability 2022, 14, 6684. [Google Scholar] [CrossRef]

- Papageorgiou, A.; Azzi, E.S.; Enell, A.; Sundberg, C. Biochar produced from wood waste for soil remediation in Sweden: Carbon sequestration and other environmental impacts. Sci. Total Environ. 2021, 776, 145953. [Google Scholar] [CrossRef]

- Zhang, P.; Li, Y.; Cao, Y.; Han, L. Characteristics of tetracycline adsorption by cow manure biochar prepared at different pyrolysis temperatures. Bioresour. Technol. 2019, 285, 121348. [Google Scholar] [CrossRef]

- Schimmelpfennig, S.; Glaser, B. One step forward toward characterization: Some important material properties to distinguish biochars. J. Environ. Qual. 2012, 41, 1001–1013. [Google Scholar] [CrossRef]

- Rangabhashiyam, S.; Balasubramanian, P. The potential of lignocellulosic biomass precursors for biochar production: Performance, mechanism and wastewater application-A review. Ind. Crops Prod. 2019, 128, 405–423. [Google Scholar]

- AOAC International. Appendix F: Guidelines for Standard Method Performance Requirements. In AOAC Official Methods of Analysis, 2016. Available online: https://www.eoma.aoac.org/app_f.pdf (accessed on 25 August 2022).

- Association of Officiating Analytical Chemists (AOAC). Official Method of Analysis, 18th ed.; Association of Officiating Analytical Chemists: Washington, DC, USA, 2005. [Google Scholar]

- ASTM E2456-06; Standard Terminology Relating to Nanotechnology. ASTM International: West Conshohocken, PA, USA, 2012. [CrossRef]

- European Biochar Foundation (EBC). European Biochar Certificate—Guidelines for a Sustainable Production of Biochar; European Biochar Foundation (EBC): Arbaz, Switzerland, 2012; Available online: https://european-biochar.org (accessed on 25 August 2022).

- Soil Survey Division Staff. Soil Survey Manual (United States Department of Agriculture Handbook No. 18); Ditzler, C., Scheffe, K., Monger, H.C., Eds.; Government Printing Office: Washington, DC, USA, 2017. [Google Scholar]

- Song, W.; Guo, M. Quality variations of poultry litter biochar generated at different pyrolysis temperatures. J. Anal. Appl. Pyrolysis 2012, 94, 138–145. [Google Scholar] [CrossRef]

- Association of Officiating Analytical Chemists (AOAC). Official Methods of Analysis, 17th ed.; The Association of Official Analytical Chemists: Gaithersburg, MD, USA, 2000. [Google Scholar]

- Tomczyk, A.; Sokołowska, Z.; Boguta, P. Biochar physicochemical properties: Pyrolysis temperature and feedstock kind effects. Rev. Environ. Sci. Bio. 2020, 19, 191–215. [Google Scholar] [CrossRef]

- Jindo, K.; Mizumoto, H.; Sawada, Y.; Sanchez-Monedero, M.A.; Sonoki, T. Physical and chemical characterization of biochars derived from different agricultural residues. Biogeosciences 2014, 11, 6613–6621. [Google Scholar] [CrossRef]

- Dhyani, V.; Bhaskar, T. A comprehensive review on the pyrolysis of lignocellulosic biomass. Renew. Energy 2018, 129, 695–716. [Google Scholar] [CrossRef]

- Zhao, S.X.; Ta, N.; Wang, X.D. Effect of temperature on the structural and physicochemical properties of biochar with apple tree branches as feedstock material. Energies 2017, 10, 1293. [Google Scholar] [CrossRef]

- Chandra, S.; Bhattacharya, J. Influence of temperature and duration of pyrolysis on the property heterogeneity of rice straw biochar and optimization of pyrolysis conditions for its application in soils. J. Clean. Prod. 2019, 215, 1123–1139. [Google Scholar] [CrossRef]

- Sohi, S.P.; Krull, E.; Lopez-Capel, E.; Bol, R. A review of biochar and its use and function in soil. Adv. Agron. 2010, 105, 47–82. [Google Scholar] [CrossRef]

- International Biochar Initiative (IBI). Standardized Product Definition and Product Testing Guidelines for Biochar That Is Used in Soil; International Biochar Initiative: Washington, DC, USA, 2015. Available online: https://www.biochar-international.org/wp-content/uploads/2018/04/IBI_Biochar_Standards_V1.1.pdf (accessed on 25 August 2022).

- Parthasarathy, P.; Al-Ansari, T.; Mackey, H.R.; McKay, G. Effect of heating rate on the pyrolysis of camel manure. Biomass Convers. Biorefinery 2021, 9, 139. [Google Scholar] [CrossRef]

- ASTM D3175-20; Standard Test Method for Volatile Matter in the Analysis Sample of Coal and Coke. ASTM International: West Conshohocken, PA, USA, 2017. [CrossRef]

- ASTM D3174-11; Standard Test Method for Ash in the Analysis Sample of Coal and Coke from Coal. ASTM International: West Conshohocken, PA, USA, 2011.

- ASTM D3172-07a; Standard Practice for Proximate Analysis of Coal and Coke. ASTM International: West Conshohocken, PA, USA, 2013.

- Hassan, M.; Liu, Y.; Naidu, R.; Parikh, S.J.; Du, J.; Qi, F.; Willett, I.R. Influences of feedstock sources and pyrolysis temperature on the properties of biochar and functionality as adsorbents: A meta-analysis. Sci. Total Environ. 2020, 744, 140714. [Google Scholar] [CrossRef] [PubMed]

- Spokas, K.A. Review of the stability of biochar in soils: Predictability of O: C molar ratios. Carbon Manag. 2010, 1, 289. [Google Scholar] [CrossRef]

- Phillips, C.L.; Meyer, K.M.; Garcia-Jaramillo, M.; Weidman, C.S.; Stewart, C.E.; Wanzek, T.; Grusak, M.A.; Watts, D.W.; Novak, J.; Trippe, K.M. Towards predicting biochar impacts on plant-available soil nitrogen content. Biochar 2022, 4, 9. [Google Scholar] [CrossRef]

- Brassard, P.; Godbout, S.; Raghavan, V. Soil biochar amendment as a climate change mitigation tool: Key parameters and mechanisms involved. J. Environ. Manag. 2016, 1, 484–497. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).