Evolutions in Gaseous and Liquid Fuel Cook-Stove Technologies

Abstract

1. Introduction

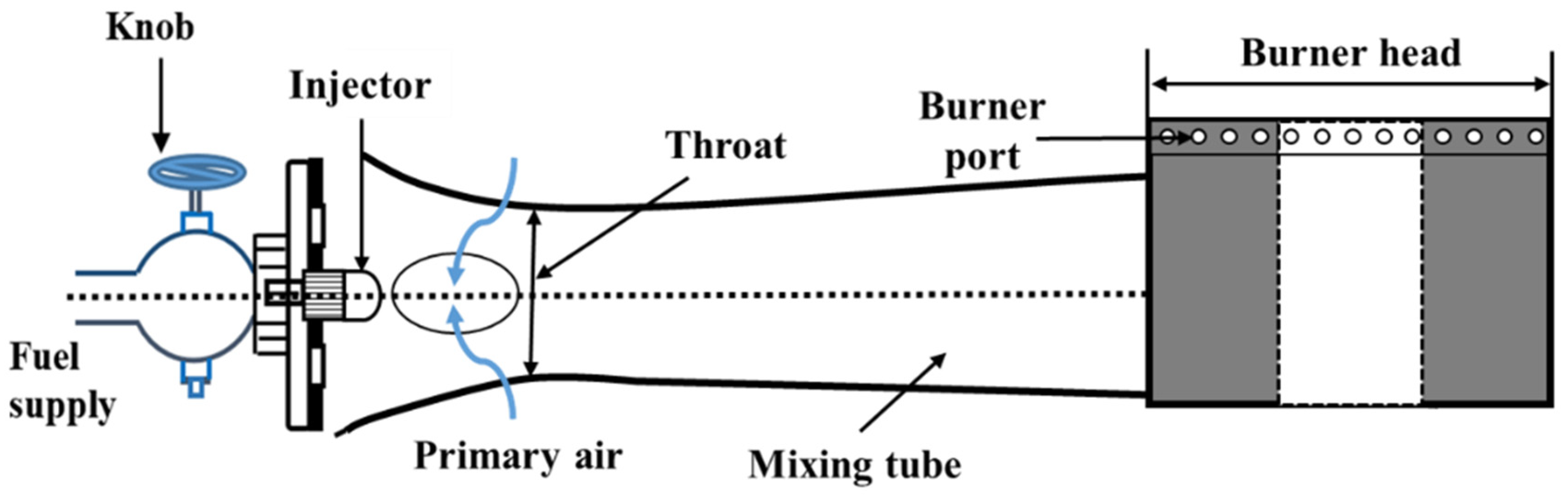

2. Operating Principles of Gaseous Fuel-Based Cook-Stoves

2.1. Cook-Stoves with Bunsen Burner Principle

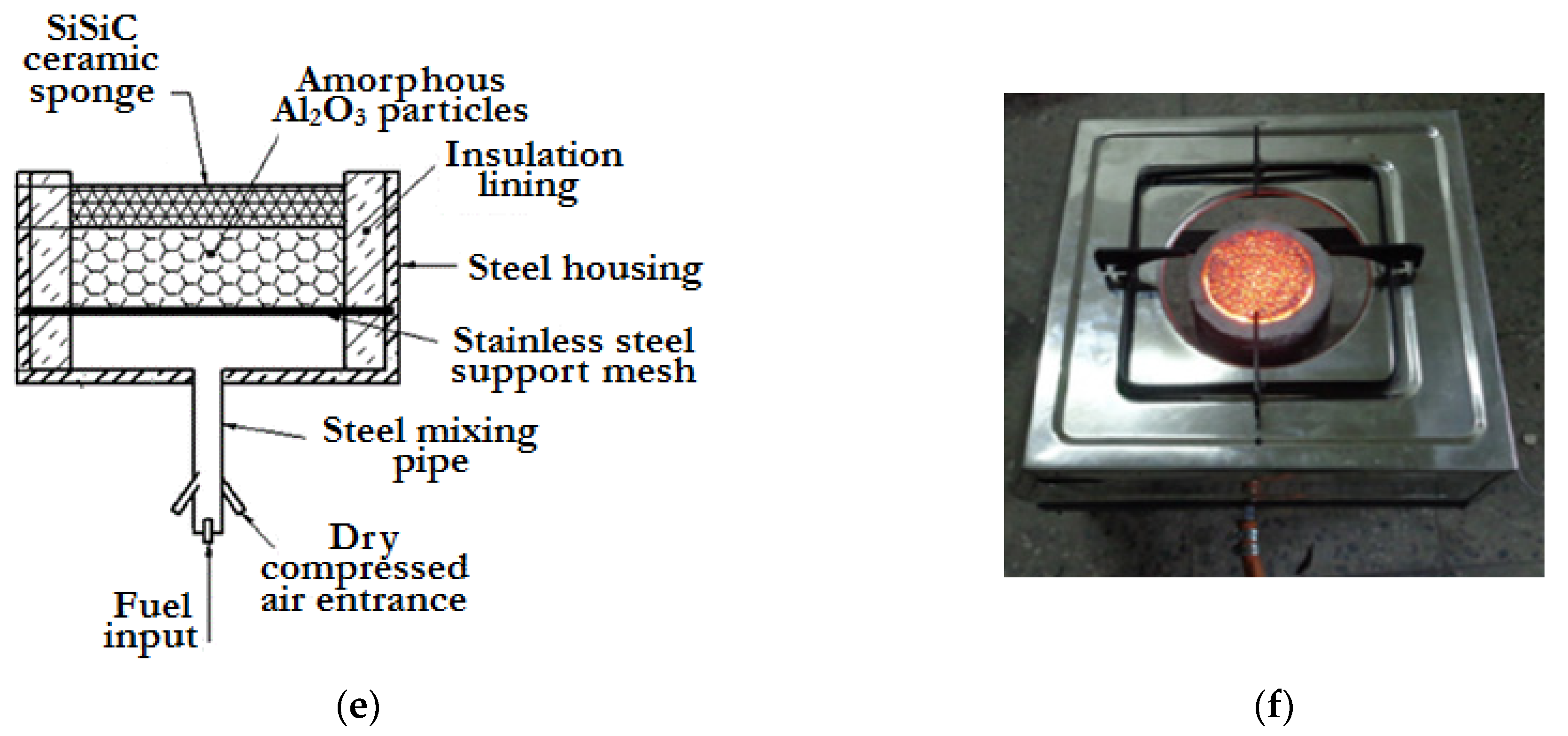

2.2. Cook-Stoves with Heat Recirculation Principle

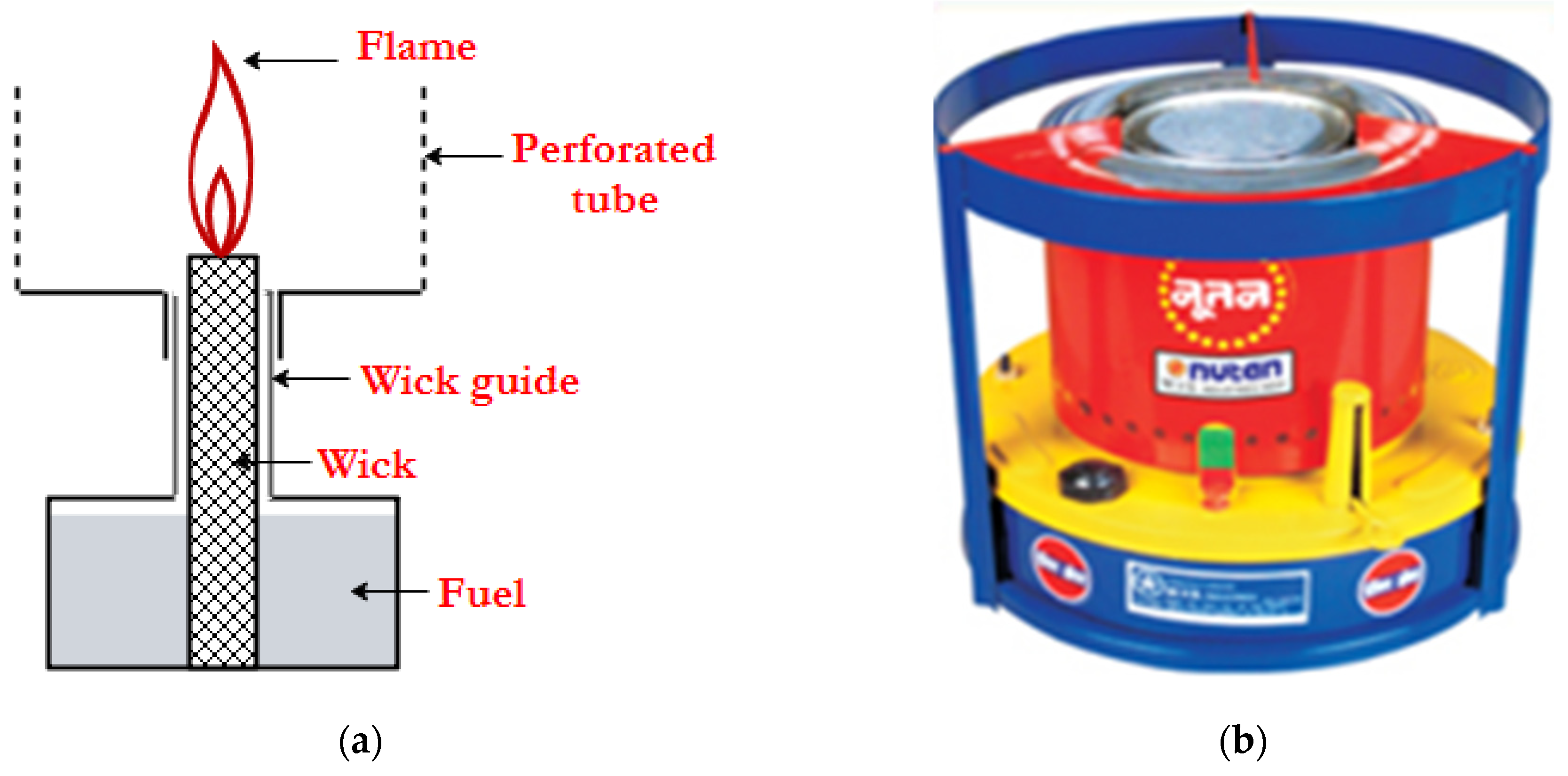

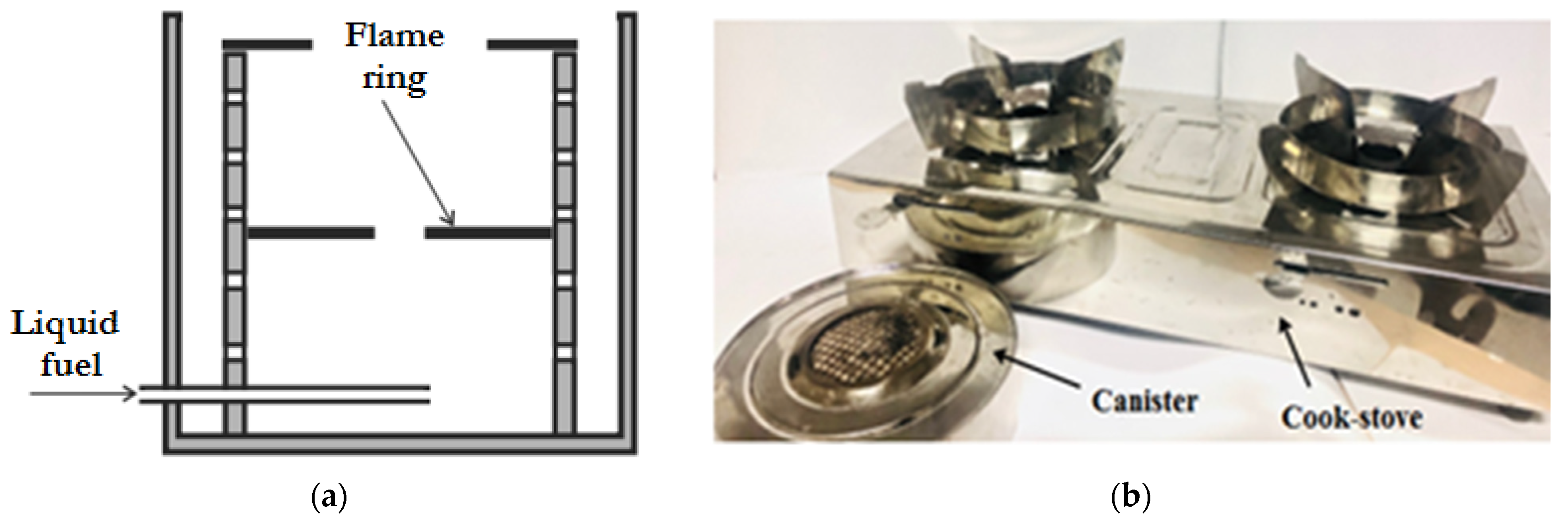

3. Liquid Fuel-Based Cook-Stoves Operating Principles

4. Cook-Stove Designs

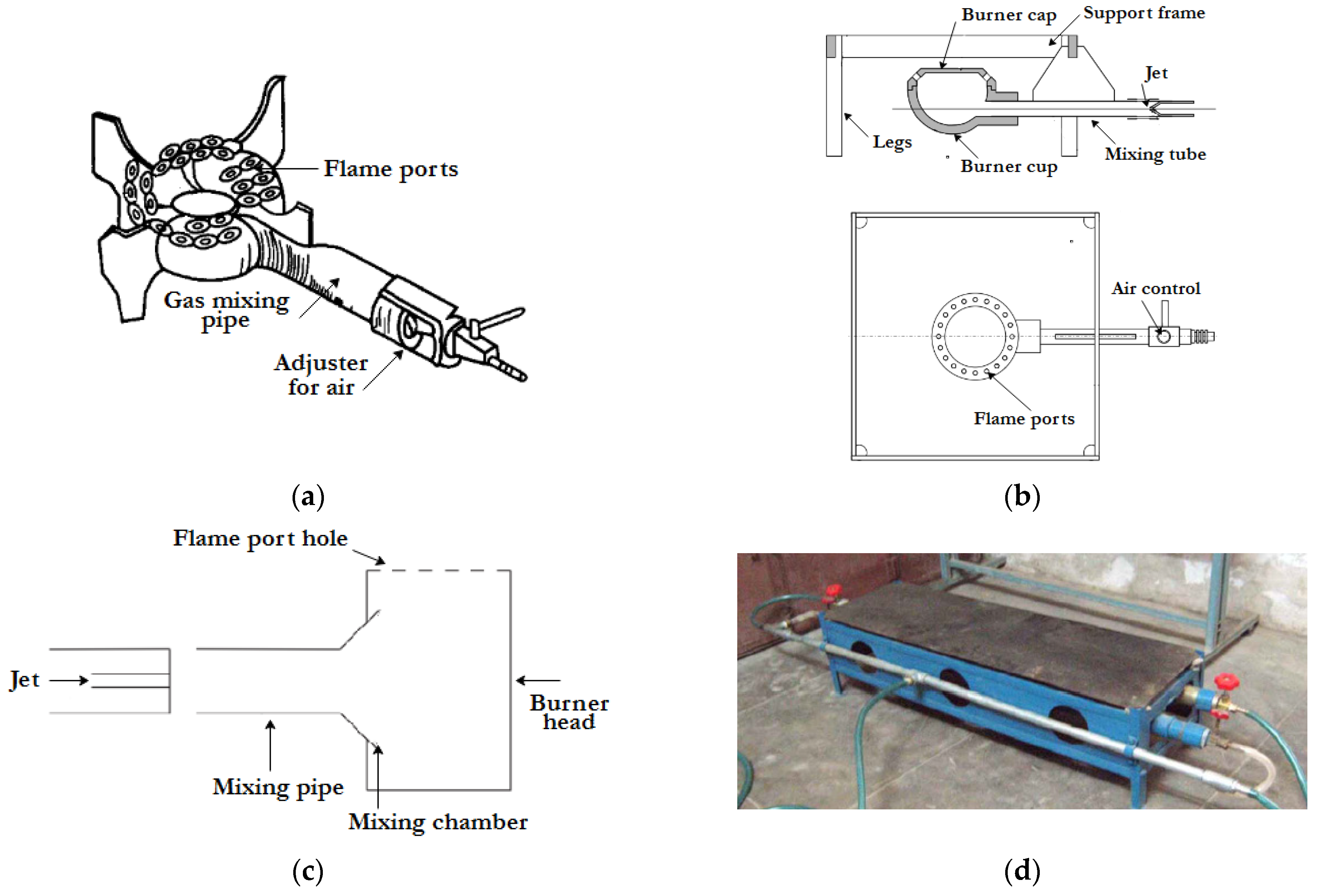

4.1. Gaseous Fuel Cook-Stove Designs

4.1.1. Liquefied Petroleum Gas (LPG)

| S. No. | Design Details | Fig. | Ref. |

|---|---|---|---|

| 1. | Swirl Burner I:

| Figure 8b | [36] |

| 2. |

| Figure 8c | [40] |

| 3. |

| Figure 8d | [41] |

| 4. |

| Figure 8e | [42] |

| 5. |

| Figure 8f | [43] |

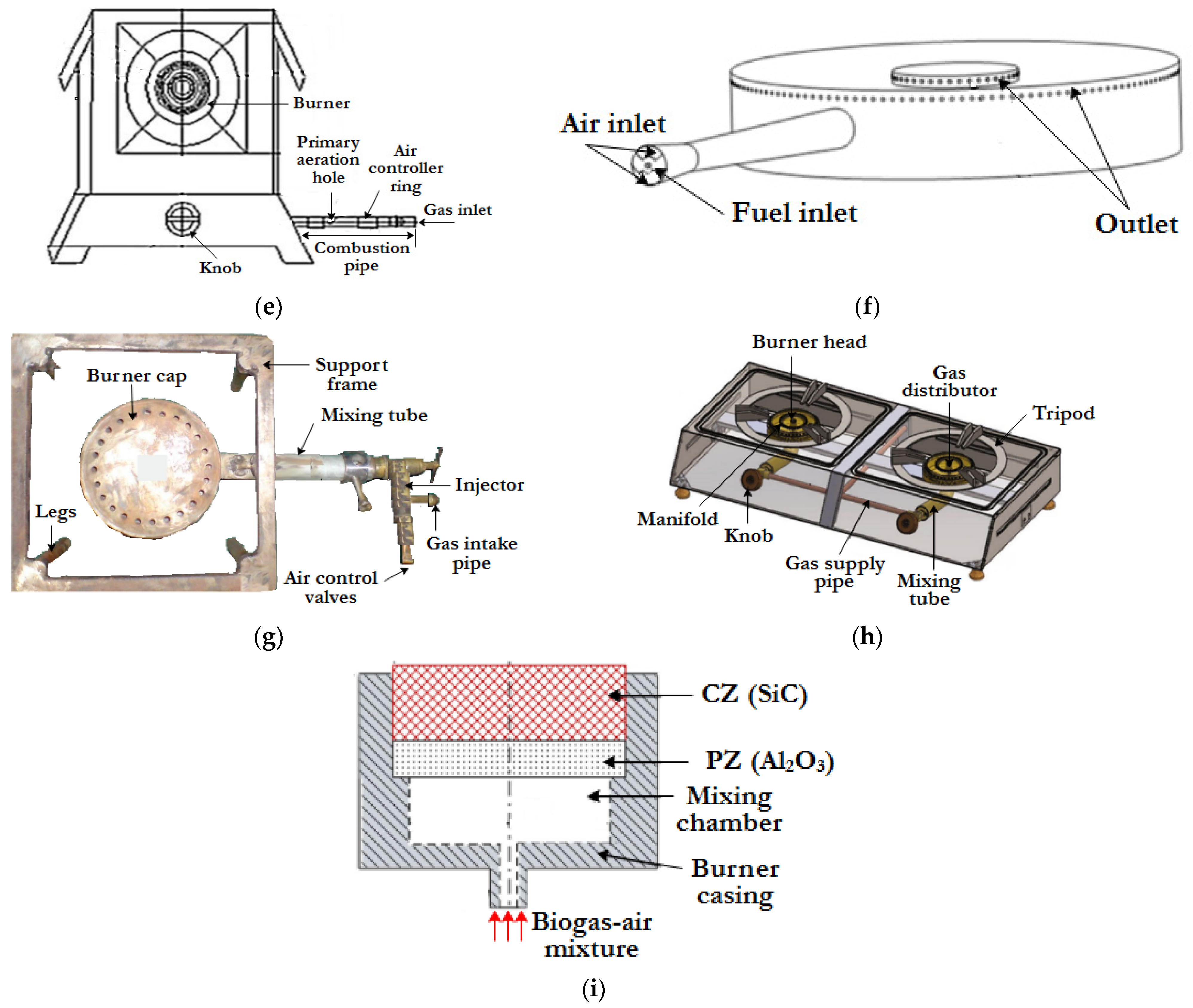

4.1.2. Biogas

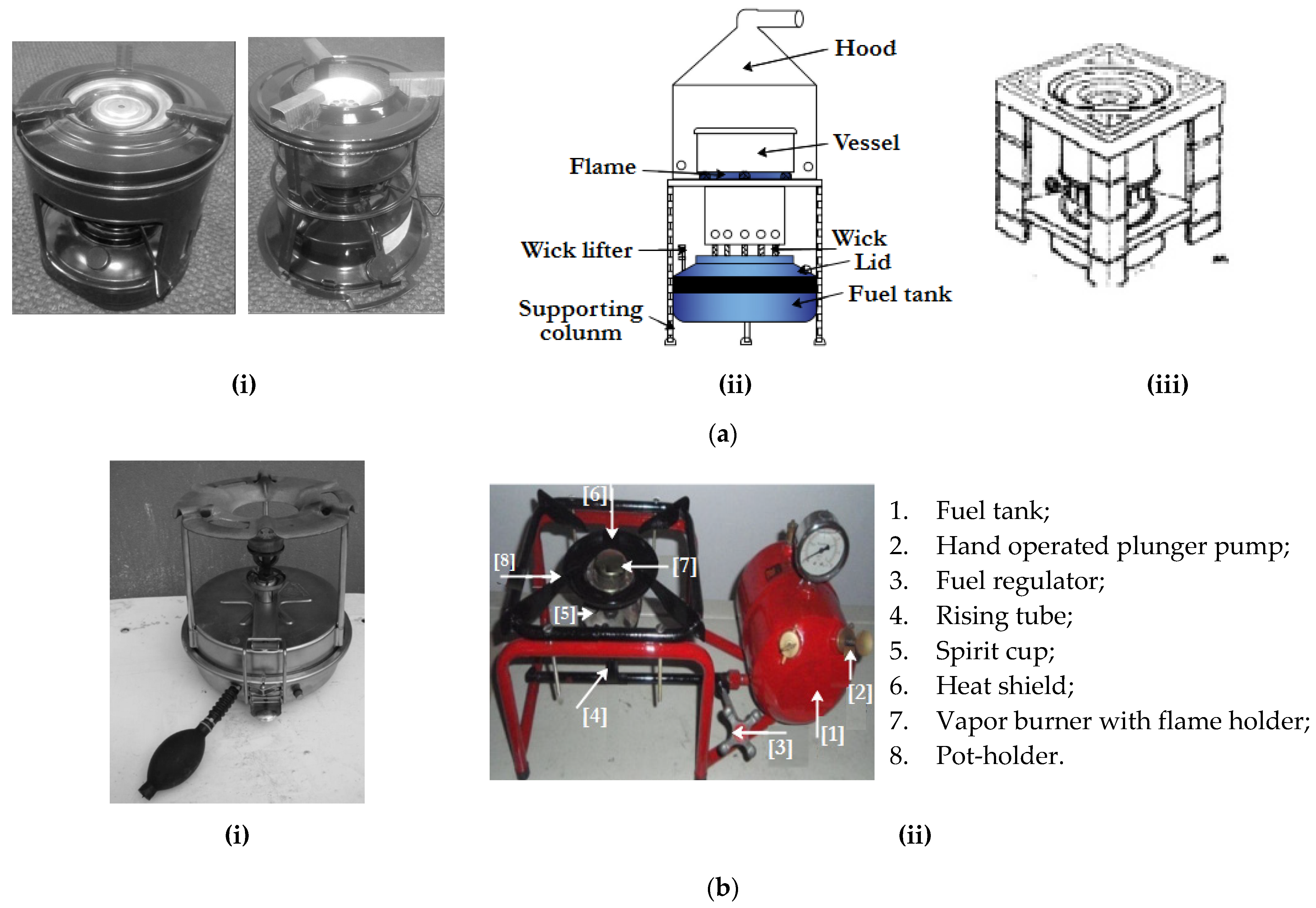

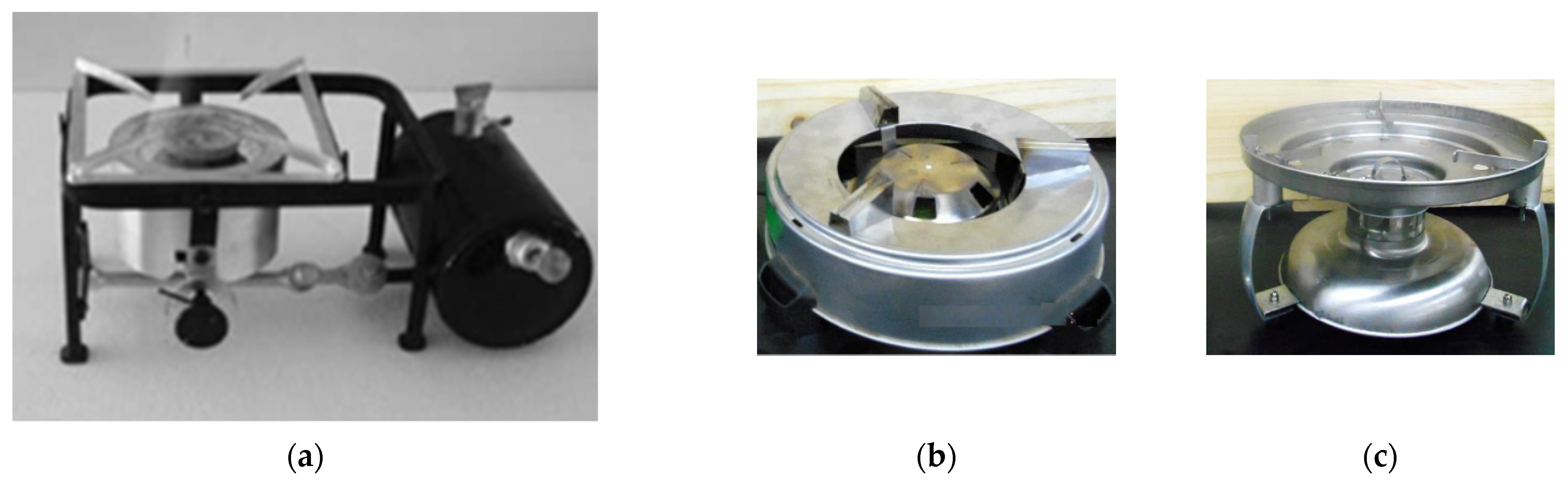

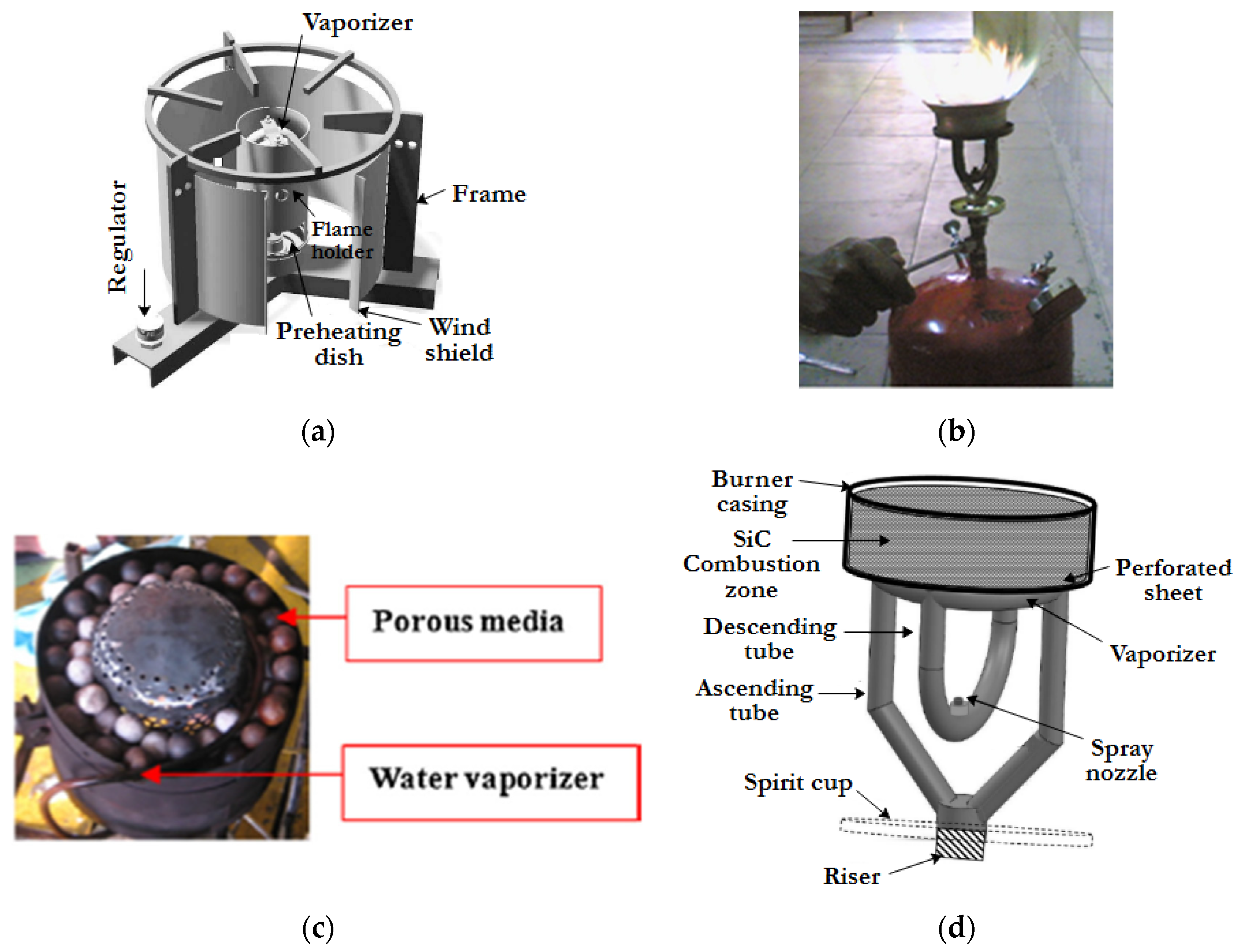

4.2. Liquid Fuel Cook-Stove Designs

4.2.1. Kerosene

4.2.2. Alcohol

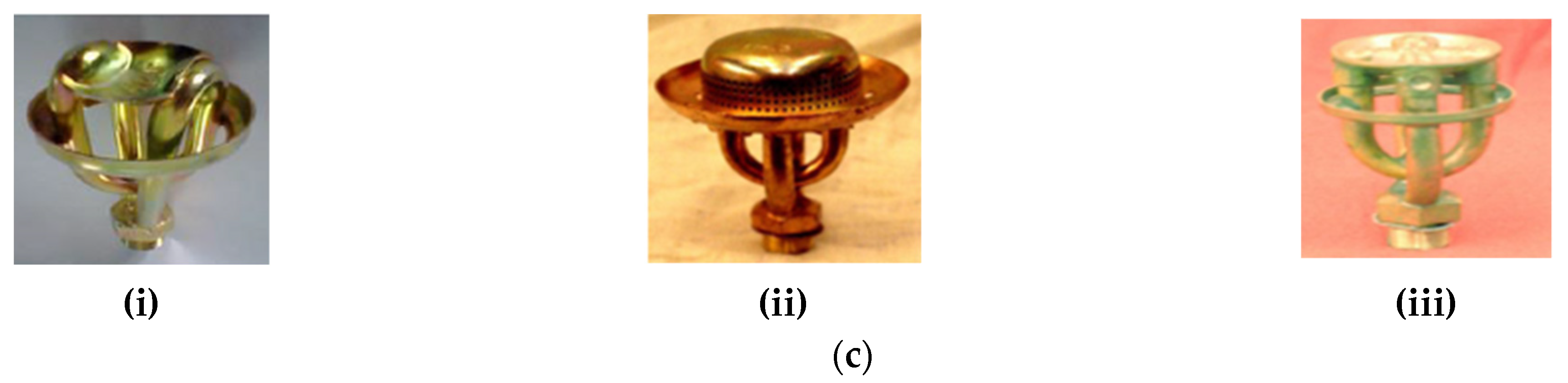

4.2.3. Plant Oils

5. Performances of Gaseous and Liquid Fuel Cook-Stoves

5.1. Performances of Gaseous and Liquid Fuel Cook-Stoves in Laboratory

5.1.1. Performances of Gaseous Fuel Cook-Stoves

LPG-Based Conventional Cook-Stoves

LPG-Based PRB Cook-Stoves

Biogas-Operated Cook-Stoves

5.1.2. Performances of Liquid Fuel Cook-Stoves

- Pressurized kerosene cook-stoves, either traditional or modified, show better performance than a wick stove when operated with either pure kerosene or its blends with plant oil;

- Proper combustion is challenging due to the high viscosity of plant oil;

- Only a few successful plant oil cook-stoves are available, but results related to their adoption and large-scale application are yet to be reported;

- PRB assisted cook-stoves for kerosene show improved performance compared with their conventional counterpart. Moreover, no attempt has been made to develop PRB assisted cook-stoves for alcohols;

- The potential risks associated with the flammability and toxicity of the alcohol fuel and low power rating of alcohol-based cook-stoves pose a major hindrance to accommodate various cooking practices in a household.

5.2. Performances of Gaseous and Liquid Fuel Cook-Stoves in Field

5.2.1. Performances of Gaseous Fuel Cook-Stove in Field

5.2.2. Performances of Liquid Fuel Cook-Stove in Field

5.3. Numerical Modelling of Gaseous Cook-Stoves

5.3.1. The Modeling Approach

5.3.2. Numerical Studies on Cook-Stoves

6. Health Issues Related to Use of Gaseous and Liquid Fuel Cook-Stoves

7. The Enablers and Barriers to the Adoption of Clean Cook-Stoves

- Socio-economic status of the user

- Education level of the user

- Selection of target group in government policies

- The convenience of cook-stove and/or fuel, including purchase/gathering, transporting, and storing

- Safety of stove and/or fuel

- Availability of fuel

- The economy of cook-stove and/or fuel

- Quality of stove/fuel performance.

8. Suggestions for Future Research

- Any modifications in cook-stove designs will have a large effect on the product’s performance and the user’s experience. However, to ensure commercial acceptability, new cook-stove designs must offer improved performance without compromising manufacturability, usability, strength, and durability. Factors such as the output power requirement for different cooking applications, affordability, fuel availability, and operational safety also need to be considered;

- Considering the proven record of improved performance, PRBs need extended field study to verify their durability, operational stability, and commercial viability, with different types of fuels;

- The reports on the performance of liquid fuels are limited. There is a need for a more thorough investigation on used cooking oil and other plant oils for rural reach as kerosene is being phased out of the market;

- Extensive field tests are needed to validate the performance of cook stoves with different types of fuels by following a standard protocol;

- Extended research is required on numerical modeling to ensure optimal burner design based on real operating parameters;

- The consumer must be given priority when making fuel/technology decisions. Understanding the tradeoffs between every technology or fuel, as well as the various manufacturing alternatives, could be made easier with the support of a consumer-centric approach. The market studies regarding consumer behavior and related studies would fetch a good framework for the policymaking related to future fuel/cooking technologies.

9. Concluding Remarks

- Cook-stoves are basically designed to achieve an optimized combustion and heat transfer performance, which ensures maximum heat transfer to the load with minimal pollutant emissions;

- The combustion and heat transfer performance could be enhanced with the careful design of burner geometry and external mixing chamber, and the judicious selection of the burner materials;

- The commercially available cook-stoves for gaseous and liquid fuels are designed on the free flame combustion principle. These cook-stoves offer higher thermal efficiency and reduced pollutant emissions compared with biomass-based cook-stoves. However, due to stricter norms and an increasing awareness about energy security and health concerns, the demand for better and advanced cook-stove technology has been growing;

- Pressurized cook-stoves show better performance compared with wick stoves when operated with either pure kerosene or its blends with plant oil;

- The porous media combustion technology is a viable manifestation of excess enthalpy/superadiabatic combustion by internal heat recuperation. It gives the time-tested combustion technique a fresh dimension with numerous benefits. Over the past few decades, Porous Radiant Burners (PRBs) have gained popularity for both residential and commercial cooking applications. The effectiveness of PRBs and their potential to replace CBs are being determined. However, long-term stability is still a concern and the report in this direction is limited;

- LPG has gained popularity among the many cooking fuels, whereas research on kerosene and natural gas is still lacking. Self-aspirated PRBs for biogas application are very limited. The recent development of self-aspirated PRBs for cook-stoves is promising as they can be a cleaner and energy-efficient alternative to CBs;

- In recent times, Methanol, ethanol, and their blends are emerging as alternatives to wood, charcoal, kerosene, etc., for cooking applications in underdeveloped nations. To some extent, they are also used in developing countries, which in turn reduces the import of crude oil;

- Reports show detrimental health issues such as respiratory diseases due to indoor air pollution by cook-stoves, and LPG and alcohol-based fuels are recommended to combat such problems;

- Household composition, education, socio-economic status, and ease of access to the fuel are significant factors affecting the choice of fuels for cooking. Furthermore, effective government policies enable a shift towards sustainable fuel transition.

Funding

Conflicts of Interest

References

- SDG7: Data and Projections (Access to Affordable, Reliable, Sustainable and Modern Energy for All). Available online: https://www.iea.org/reports/sdg7-data-and-projections/access-to-clean-cooking (accessed on 28 December 2022).

- IEA; International Renewable Energy Agency; United Nations Statistics Division; The World Bank; World Health Organization. Tracking SDG7: The Energy Progress Report 2020; Report; IEA: Paris, France, 2020. [Google Scholar]

- Clean Cooking Alliance: Delivering on the Sustainable Development Goals through Clean Cooking. Available online: https://www.cleancookingalliance.org/feature/delivering-on-the-sustainable-development-goals-through-clean-cooking.html (accessed on 28 December 2022).

- IEA; International Renewable Energy Agency; United Nations Statistics Division; The World Bank; World Health Organization. Tracking SDG 7: The Energy Progress Report 2019; Report; IEA: Paris, France, 2019. [Google Scholar]

- Turner, B. Energy Challenges for Clean Cooking in Asia, the Background, and Possible Policy Solutions; Working Paper 1007; Asian Development Bank Institute: Mandaluyong, Philippines, 2014. [Google Scholar]

- Quinn, A.K.; Bruce, N.; Puzzolo, E.; Dickinson, K.; Sturke, R.; Jack, D.W.; Mehta, S.; Shankar, A.; Sherr, K.; Rosenthal, J.P. An Analysis of Efforts to Scale up Clean Household Energy for Cooking around the World. Energy Sustain. Dev. 2018, 46, 1–10. [Google Scholar] [CrossRef]

- World Health Organization. Burning Opportunity: Clean Household Energy for Health, Sustainable Development, and Wellbeing of Women and Children; WHO: Geneva, Switzerland, 2016; ISBN 9789241565233. NLM Classification: WA 754.

- World Health Organization. Household Air Pollution and Health. Available online: https://www.who.int/news-room/fact-sheets/detail/household-air-pollution-and-health (accessed on 28 December 2022).

- Alem, Y.; Beyene, A.D.; Köhlin, G.; Mekonnen, A. Modeling Household Cooking Fuel Choice: A Panel Multinomial Logit Approach. Energy Econ. 2016, 59, 129–137. [Google Scholar] [CrossRef]

- Paudel, U.; Khatri, U.; Pant, K.P. Understanding the Determinants of Household Cooking Fuel Choice in Afghanistan: A Multinomial Logit Estimation. Energy 2018, 156, 55–62. [Google Scholar] [CrossRef]

- Rahut, D.B.; Ali, A.; Mottaleb, K.A.; Aryal, J.P. Wealth, Education and Cooking-Fuel Choices among Rural Households in Pakistan. Energy Strateg. Rev. 2019, 24, 236–243. [Google Scholar] [CrossRef]

- Liao, H.; Chen, T.; Tang, X.; Wu, J. Fuel Choices for Cooking in China: Analysis Based on Multinomial Logit Model. J. Clean. Prod. 2019, 225, 104–111. [Google Scholar] [CrossRef]

- Menghwani, V.; Zerriffi, H.; Dwivedi, P.; Marshall, J.D.; Grieshop, A.; Bailis, R. Determinants of Cookstoves and Fuel Choice among Rural Households in India. Ecohealth 2019, 16, 21–60. [Google Scholar] [CrossRef] [PubMed]

- Yasmin, N.; Grundmann, P. Home-Cooked Energy Transitions: Women Empowerment and Biogas-Based Cooking Technology in Pakistan. Energy Policy 2020, 137, 111074. [Google Scholar] [CrossRef]

- Anenberg, S.C.; Balakrishnan, K.; Jetter, J.; Masera, O.; Mehta, S.; Moss, J.; Ramanathan, V. Cleaner Cooking Solutions to Achieve Health, Climate, and Economic Cobenefits. Environ. Sci. Technol. 2013, 47, 3944–3952. [Google Scholar] [CrossRef]

- World Health Organization. Air Pollution, Technology and Design-Based Interventions. Available online: https://www.who.int/airpollution/household/interventions/technology/en/ (accessed on 28 December 2022).

- Malico, I.; Mujeebu, M.A. Potential of Porous Media Combustion Technology for Household Applications. Int. J. Adv. Thermofluid Res. 2015, 1, 50–69. [Google Scholar]

- Ismail, A.K.; Ibrahim, N.H.; Shamsuddin, K.A.; Abdullah, M.Z.; Zubair, M. A Practical Approach in Porous Medium Combustion for Domestic Application: A Review. IOP Conf. Ser. Mater. Sci. Eng. 2018, 370, 012004. [Google Scholar] [CrossRef]

- Khan, M.Y. Performance of LPG Cooking Stove: A Catch All Review. In Proceedings of the 5th International Multidisciplinary Research Conference (IMRC-2020), held virtually, 30–31 May 2020; pp. 70–74. [Google Scholar]

- Datta, A.; Das, M.; Ganguly, R. Design, Development, and Technological Advancements in Gas Burners for Domestic Cook Stoves: A Review. Trans. Indian Natl. Acad. Eng. 2021, 6, 569–593. [Google Scholar] [CrossRef]

- Jones, H.R.N. The Application of Combustion Principles to Domestic Gas Burner Design; Taylor & Francis: Milton Park, UK, 2005. [Google Scholar]

- Pantangi, V.K. Development and Performance Analysis of Porous Radiant Burners for Cooking Applications. Ph.D. Thesis, Indian Institute of Technology, Guwahati, India, 2010. [Google Scholar]

- Avdic, F. Application of the Porous Medium Gas Combustion Technique to Household Heating Systems with Additional Energy Sources. Doctoral Thesis, Universität Erlangen-Nürnberg, Erlangen, Germany, 2004. [Google Scholar]

- Mujeebu, M.A.; Abdullah, M.Z.; Mohamad, A.A.; Abu Bakar, M.Z. Trends in Modeling of Porous Media Combustion. Prog. Energy Combust. Sci. 2010, 36, 627–650. [Google Scholar] [CrossRef]

- Howell, J.R.; Hall, M.J.; Ellzey, J.L. Combustion of Hydrocarbon Fuels within Porous Inert Media. Prog. Energy Combust. Sci. 1996, 22, 121–145. [Google Scholar] [CrossRef]

- Wood, S.; Harris, A.T. Porous Burners for Lean-Burn Applications. Prog. Energy Combust. Sci. 2008, 34, 667–684. [Google Scholar] [CrossRef]

- Mujeebu, M.A.; Abdullah, M.Z.; Abu Bakar, M.Z.; Mohamad, A.A.; Abdullah, M.K. Applications of Porous Media Combustion Technology—A Review. Appl. Energy 2009, 86, 1365–1375. [Google Scholar] [CrossRef]

- Chen, C.-H.; Gowdagiri, S.; Kumar, S.; Ronney, P.D. Numerical and Experimental Study in Swiss Roll Heat-Recirculating Burner. In Proceedings of the 9th International Conference on Micro and Nanotechnology for Power Generation and Energy Conversion Applications, Washington, DC, USA, 1–4 December 2009; pp. 605–608. [Google Scholar]

- Jugjai, S.; Sanitjai, S. Parametric Studies of Thermal Efficiency in a Proposed Porous Radiant Recirculated Burner (PRRB): A Design Concept for the Future Burner. RERIC Int. Energy J. 1996, 18, 97–111. [Google Scholar]

- Vafai, K. Handbook of Porous Media, 2nd ed.; CRC Press; Taylor & Francis Group: Boca Raton, FL, USA, 2015. [Google Scholar]

- Mujeebu, M.A.; Abdullah, M.Z.; Abu Bakar, M.Z.; Mohamad, A.A.; Muhad, R.M.N.; Abdullah, M.K. Combustion in Porous Media and Its Applications—A Comprehensive Survey. J. Environ. Manag. 2009, 90, 2287–2312. [Google Scholar] [CrossRef]

- Khanna, V.; Goel, R.; Ellzey, J.L. Measurements of Emissions and Radiation for Methane Combustion within a Porous Medium Burner. Combust. Sci. Technol. 1994, 99, 133–142. [Google Scholar] [CrossRef]

- Sinha, G.S. Development and Performance Analysis of Self-Aspirated Porous Radiant Burners for Kerosene Pressure Stove. Ph.D. Thesis, Indian Institute of Technology, Guwahati, India, 2017. [Google Scholar]

- Berry, W.M.; Brumbaugh, I.V.; Moulton, G.F.; Shawn, G.B. Design of Atmospheric Gas Burners, No. 193; Technologic Papers of the Bureau of Standards; Washington Government Printing Office: Washington, DC, USA, 1921.

- Technology Refinement and Marketing Programme (TREMAP). An Indigennous Design of LPG Burner for Commmercial Cooking; TREMAP, Venture Center (Entrepreneurship Development Center): Pune, India, 2007. [Google Scholar]

- Zhen, H.S.; Leung, C.W.; Wong, T.T. Improvement of Domestic Cooking Flames by Utilizing Swirling Flows. Fuel 2014, 119, 153–156. [Google Scholar] [CrossRef]

- Das, M.; Ganguly, R.; Datta, A.; Verma, M.M.; Bera, A.K. Performance Improvement of a Domestic Liquefied Petroleum Gas Cook Stove Using an Extended Spill-Tray and an Annular Metal Insert. J. Therm. Sci. Eng. Appl. 2021, 13, 021016. [Google Scholar] [CrossRef]

- Jugjai, S.; Rungsimuntuchart, N. High Efficiency Heat-Recirculating Domestic Gas Burners. Exp. Therm. Fluid Sci. 2002, 26, 581–592. [Google Scholar] [CrossRef]

- Mujeebu, M.A.; Abdullah, M.Z.; Mohamad, A.A. Development of Energy Efficient Porous Medium Burners on Surface and Submerged Combustion Modes. Energy 2011, 36, 5132–5139. [Google Scholar] [CrossRef]

- Wu, C.Y.; Chen, K.H.; Yang, S.Y. Experimental Study of Porous Metal Burners for Domestic Stove Applications. Energy Convers. Manag. 2014, 77, 380–388. [Google Scholar] [CrossRef]

- Mishra, N.K. Development of Self-Aspirated Two-Layer Porous Radiant Burners for LPG Cooking Applications. Ph.D. Thesis, Indian Institute of Technology, Guwahati, India, 2015. [Google Scholar]

- Herrera, B.; Cacua, K.; Olmos-Villalba, L. Combustion Stability and Thermal Efficiency in a Porous Media Burner for LPG Cooking in the Food Industry Using Al2O3 Particles Coming from Grinding Wastes. Appl. Therm. Eng. 2015, 91, 1127–1133. [Google Scholar] [CrossRef]

- Mishra, N.K.; Muthukumar, P. Development and Testing of Energy Efficient and Environment Friendly Porous Radiant Burner Operating on Liquefied Petroleum Gas. Appl. Therm. Eng. 2018, 129, 482–489. [Google Scholar] [CrossRef]

- Ministry of New & Renewable Energy—Government of India. Available online: https://mnre.gov.in/ (accessed on 28 December 2022).

- Giwa, A.S.; Ali, N.; Ahmad, I.; Asif, M.; Guo, R.B.; Li, F.L.; Lu, M. Prospects of China’s Biogas: Fundamentals, Challenges and Considerations. Energy Rep. 2020, 6, 2973–2987. [Google Scholar] [CrossRef]

- Bangladesh National Biogas Program Monitoring Services. Available online: https://www.upm-cdm.eu/project/bangladesh-national-biogas-program-monitoring-services-12/ (accessed on 28 December 2022).

- Yasmin, N.; Grundmann, P. Adoption and Diffusion of Renewable Energy—The Case of Biogas as Alternative Fuel for Cooking in Pakistan. Renew. Sustain. Energy Rev. 2019, 101, 255–264. [Google Scholar] [CrossRef]

- Petro, L.M.; Machunda, R.; Tumbo, S.; Kivevele, T. Theoretical and Experimental Performance Analysis of a Novel Domestic Biogas Burner. J. Energy 2020, 2020, 8813254. [Google Scholar] [CrossRef]

- Kaushik, L.K.; Mahalingam, A.K.; Palanisamy, M. Performance Analysis of a Biogas Operated Porous Radiant Burner for Domestic Cooking Application. Environ. Sci. Pollut. Res. 2021, 28, 12168–12177. [Google Scholar] [CrossRef]

- Fulford, D. A Short Course on Biogas Stove Design; Kingdom Bioenergy, Ltd.: Wokingham, UK, 1996. [Google Scholar]

- Sasse, L.; Kellner, C.; Kimaro, A. Improved Biogas Unit for Developing Countries; Deutsche Gesellschaft für Technische Zusammenarbeit (GTZ) GmbH: Eschborn, Germany, 1991. [Google Scholar]

- Chandra, A.; Tiwari, G.N.; Yadav, Y.P. Hydrodynamical Modelling of a Biogas Burner. Energy Convers. Manag. 1991, 32, 395–401. [Google Scholar] [CrossRef]

- Kurchania, A.K.; Panwar, N.L.; Pagar, S.D. Design and Performance Evaluation of Biogas Stove for Community Cooking Application. Int. J. Sustain. Energy 2010, 29, 116–123. [Google Scholar] [CrossRef]

- Kurchania, A.K.; Panwar, N.L.; Pagar, S.D. Development of Domestic Biogas Stove. Biomass Convers. Biorefinery 2011, 1, 99–103. [Google Scholar] [CrossRef]

- Kandpal, J.B.; Maheshwari, R.C.; Kandpal, T.C. Indoor Air Pollution from Combustion of Wood and Dung Cake and Their Processed Fuels in Domestic Cookstoves. Energy Convers. Manag. 1995, 36, 1073–1079. [Google Scholar] [CrossRef]

- Itodo, I.N.; Agyo, G.E.; Yusuf, P. Performance Evaluation of a Biogas Stove for Cooking in Nigeria. J. Energy S. Afr. 2007, 18, 14–18. [Google Scholar] [CrossRef]

- Syamsuri, S.; Yustia, W.M. Performance Analysis of Biogas Stoves with Variations of Flame Burner for the Capacity of Biogas 1 M3/Day. ARPN J. Eng. Appl. Sci. 2015, 10, 10349–10353. [Google Scholar]

- Mulugeta, B.; Nega, D.T.; Demissie, S.W. Design, Optimization and CFD Simulation of Improved Biogas Burner for ‘Injera’ Baking in Ethiopia. Int. J. Eng. Res. Technol. 2017, 6, 58–63. [Google Scholar]

- Decker, T.; Baumgardner, M.; Prapas, J.; Bradley, T. A Mixed Computational and Experimental Approach to Improved Biogas Burner Flame Port Design. Energy Sustain. Dev. 2018, 44, 37–46. [Google Scholar] [CrossRef]

- Awulu, J.O.; Iyidiobu, B.N.; Ugbede, J. Cooking Performance of a Developed Biogas Burner (Stove). Int. J. Eng. Appl. Sci. Technol. 2020, 4, 11–16. [Google Scholar]

- Makonese, T.; Pemberton-Pigott, C.; Robinson, J.; Kimemia, D.; Annegarn, H. Performance Evaluation and Emission Characterisation of Three Kerosene Stoves Using a Heterogeneous Stove Testing Protocol (HTP). Energy Sustain. Dev. 2012, 16, 344–351. [Google Scholar] [CrossRef]

- Dinesha, P.; Kumar, S.; Rosen, M.A. Performance and Emission Analysis of a Domestic Wick Stove Using Biofuel Feedstock Derived from Waste Cooking Oil and Sesame Oil. Renew. Energy 2019, 136, 342–351. [Google Scholar] [CrossRef]

- MacCarty, N.; Still, D.; Ogle, D. Fuel Use and Emissions Performance of Fifty Cooking Stoves in the Laboratory and Related Benchmarks of Performance. Energy Sustain. Dev. 2010, 14, 161–171. [Google Scholar] [CrossRef]

- Mishra, S.C.; Muthukumar, P.; Sinha, G.S.; Sharma, M.; Mishra, N.K. Self Aspirated Pressurized Kerosene Cooking Stove with a Porous Radiant Burner. Application No: 201631037245, 31 October 2016. [Google Scholar]

- Rajvanshi, A.K.; Patil, S.M.; Mendonca, B. Low-Concentration Ethanol Stove for Rural Areas in India. Energy Sustain. Dev. 2007, 11, 94–99. [Google Scholar] [CrossRef]

- Masekameni, M.D.; Makonese, T.; Annegarn, H.J. A Comparison of Emissions and Thermal Efficiency of Three Improved Liquid Fuel Stoves. In Proceedings of the 2015 International Conference on the Domestic Use of Energy (DUE), Cape Town, South Africa, 31 March–1 April 2015; IEEE: New York, NY, USA, 2015; pp. 71–76. [Google Scholar]

- Jetter, J.; Ebersviller, S.; Williams, C.; Faircloth, J. Test Report-CleanCook Model A1 Stove with Alcohol Fuel-Air Pollutant Emissions and Fuel Efficiency; US Environmental Protection Agency: Cincinnati, OH, USA, 2015.

- Murren, J.; Debebe, M. Project Gaia’s Ethanol-Fueled CleanCook Stove Initiative and Its Impact on Traditional Cooking Fuels Used in Addis Ababa, Ethiopia; Shell Foundation Project Number: 21311; Addis Ababa Sub-cities Fuel Use Report; GAIA Association: Washington, DC, USA, 2006. [Google Scholar]

- Dometic ORIGO 3000 Double Burner—Non-Pressurized Alcohol Stove. Available online: https://www.marine.com/products/11-67992/dometic-origo-3000-single-burner-non-pressurized-alcohol-stove (accessed on 28 December 2022).

- Swanepoel, S.; Niekerk, V. Nova Report on Reseach into Domestic Stove Requirements and the Desirability of Methanol as Fuel on Behalf of Origo-Electrolux; Report. 2001. Available online: https://projectgaia.com/files/2001SouthAfricaORIGO3000.pdf (accessed on 28 December 2022).

- Hajamalala, A.M. Thermal Performance of a Low-Concentration Ethanol Stove without Pressure System. Curr. Sci. 2014, 107, 289–296. [Google Scholar]

- Stumpf, E.; Mühlbauer, W. Plant-Oil Cooking Stove for Developing Countries. Boil. Point 2002, 48, 37–38. [Google Scholar]

- Kratzeisen, M.; Müller, J. Effect of Fatty Acid Composition of Soybean Oil on Deposit and Performance of Plant Oil Pressure Stoves. Renew. Energy 2009, 34, 2461–2466. [Google Scholar] [CrossRef]

- Martin, K.; Stumpf, E.; Muller, J. Development of a Plant Oil Pressure Stove. In Proceedings of the Conference on International Agricultural Research for Development, Göttingen, Germany, 9–11 October 2007; pp. 1–4. [Google Scholar]

- Natarajan, R.; Karthikeyan, N.S.; Agarwaal, A.; Sathiyanarayanan, K. Use of Vegetable Oil as Fuel to Improve the Efficiency of Cooking Stove. Renew. Energy 2008, 33, 2423–2427. [Google Scholar] [CrossRef]

- Murthy, M.S.; Agiwal, S.A.; Bharambe, M.A.; Mishra, A.; Raina, A. Modified Kerosene Stove for Burning High Percentage Non Edible Straight Vegetable Oil Blends. In Proceedings of the 2011 IEEE 1st Conference on Clean Energy and Technology, CET 2011, Kuala Lumpur, Malaysia, 27–29 June 2011; pp. 145–150. [Google Scholar]

- Pande, M.Y.; Patil, S.; Desale, K.; Rajput, G.; Warke, K.; Patil, A. Experimental Investigation on Pressure Stove with Different Blends of Fuel. IOSR J. Mech. Civ. Eng. 2017, 14, 61–68. [Google Scholar] [CrossRef]

- Suhartono; Putri, T.A.; Fauziah, L. Performance Evaluation of a Pressurized Cooking Stove Using Vegetable Cooking Oils as Fuel. Int. J. Adv. Sci. Eng. Inf. Technol. 2017, 7, 1255–1261. [Google Scholar] [CrossRef]

- Suhartono; Suharto; Ahyati, A.E. The Properties of Vegetable Cooking Oil as a Fuel and Its Utilization in a Modified Pressurized Cooking Stove. IOP Conf. Ser. Earth Environ. Sci. 2017, 105, 012047. [Google Scholar] [CrossRef]

- Kakati, S.; Mahanta, P.; Kakoty, S.K. Performance Analysis of Pressurized Kerosene Stove with Porous Medium Inserts. J. Sci. Ind. Res. 2007, 66, 565–569. [Google Scholar]

- Lapirattanakun, A.; Charoensuk, J. Developement of Porous Media Burner Operating on Waste Vegetable Oil. Appl. Therm. Eng. 2017, 110, 190–201. [Google Scholar] [CrossRef]

- Kaushik, L.K.; Muthukumar, P. Thermal and Economic Performance Assessments of Waste Cooking Oil/Kerosene Blend Operated Pressure Cook-Stove with Porous Radiant Burner. Energy 2020, 206, 118102. [Google Scholar] [CrossRef]

- Kwok, L.C.; Leung, C.W.; Cheung, C.S. Heat Transfer Characteristics of an Array of Impinging Pre-Mixed Slot Flame Jets. Int. J. Heat Mass Transf. 2005, 48, 1727–1738. [Google Scholar] [CrossRef]

- Jugjai, S.; Tia, S.; Trewetasksorn, W. Thermal Efficiency Improvement of an LPG Gas Cooker by a Swirling Central Flame. Int. J. Energy Res. 2001, 25, 657–674. [Google Scholar] [CrossRef]

- Shrestha, J.N. A Study Report on Efficiency Measurement of Biogas, Kerosene and LPG Stoves; Center for Energy Studies Institute of Engineering, Tribhuvan University: Lalitpur, India, 2001. [Google Scholar]

- Li, H.B.; Wong, T.T.; Leung, C.W.; Probert, S.D. Thermal Performances and CO Emissions of Gas-Fired Cooker-Top Burners. Appl. Energy 2006, 83, 1326–1338. [Google Scholar] [CrossRef]

- Hou, S.S.; Lee, C.Y.; Lin, T.H. Efficiency and Emissions of a New Domestic Gas Burner with a Swirling Flame. Energy Convers. Manag. 2007, 48, 1401–1410. [Google Scholar] [CrossRef]

- Basu, D.; Saha, R.; Ganguly, R.; Datta, A. Performace Improvement of LPG Cook Stoves through Burner and Nozzle Modifications. J. Energy Inst. 2008, 81, 218–225. [Google Scholar] [CrossRef]

- Hou, S.S.; Chou, C.H. Parametric Study of High-Efficiency and Low-Emission Gas Burners. Adv. Mater. Sci. Eng. 2013, 2013, 154957. [Google Scholar] [CrossRef]

- Makmool, U.; Jugjai, S.; Tia, S. Structures and Performances of Laminar Impinging Multiple Premixed LPG-Air Flames. Fuel 2013, 112, 254–262. [Google Scholar] [CrossRef]

- Samantaray, B.B.; Pradhan, P.; Sahoo, D.K.; Mishra, P.C. Comparative Thermal Performance and Emission Analysis of Flat, Semi-Swirl and Full-Swirl Cooking Burners-Experimental Results. Procedia Eng. 2015, 127, 932–939. [Google Scholar] [CrossRef]

- Agarwal, P.; Anand, A.; Gupta, R. Performance Analysis of Conventional LPG Cooking Stove. Int. J. Appl. Bio-Eng. 2015, 9, 15–19. [Google Scholar] [CrossRef]

- Joon, V.; Kumari, H.; Chandra, A. Predicting Exposure Levels of Respirable Particulate Matter (PM2.5) and Carbon Monoxide for the Cook from Combustion of Cooking Fuels Predicting Exposure Levels of Respirable Particulate Matter (PM2.5) Fuels. In Proceedings of the 2011 International Conference on Chemistry and Chemical Process IPCBEE, Bangkok, Thailand, 7–9 May 2011; IACSIT Press: Singapore, 2011; Volume 10, pp. 229–232. [Google Scholar]

- Aroonjarattham, P. The Parametric Studied of High Pressure Gas Burner Affect Thermal Efficiency. Eng. J. 2016, 20, 33–48.94. [Google Scholar] [CrossRef]

- Shen, G.; Hays, M.D.; Smith, K.R.; Williams, C.; Faircloth, J.W.; Jetter, J.J. Evaluating the Performance of Household Liquefied Petroleum Gas Cookstoves. Environ. Sci. Technol. 2018, 52, 904–915.95. [Google Scholar] [CrossRef] [PubMed]

- Fakinle, B.S.; Oke, O.D.; Odunlami, O.A.; Sonibare, J.A.; Akeredolu, F.A.; Oni, O.S. Emission Characterization and Performance of Conventional Liquefied Petroleum Gas Cookstove Burners. Cogent Eng. 2019, 6, 1652228. [Google Scholar] [CrossRef]

- Saad, H.E.; Kamal, M.; Adel, A. Thermal and Combustion Characteristics of a Double Ring Burner with Different Swirling Flow Patterns. IOP Conf. Ser. Mater. Sci. Eng. 2019, 610, 012042. [Google Scholar] [CrossRef]

- Sutar, K.B.; Kumar, M.; Patel, M.K.; Kumar, A.; Mokashi, S.R. Experimental Investigation on Pot Design and Efficiency of LPG Utilization for Some Domestic Cooking Processes. Energy Sustain. Dev. 2020, 56, 67–72. [Google Scholar] [CrossRef]

- Lather, R. Performance Analysis of an LPG Cooking Stove for Improvements and Future Usability Perspective. In Proceedings of the National Conference on IC Engines and Combustion NfCICEC 2019: Advances in IC Engines and Combustion Technology, Kurukshetra, India, 1–4 November 2019; Lecture Notes in Mechanical Engineering. pp. 633–643. [Google Scholar]

- Pantangi, V.K.; Kumar, A.S.S.R.K.; Mishra, S.C.; Sahoo, N. Performance Analysis of Domestic LPG Cooking Stoves with Porous Media. Int. Energy J. 2007, 8, 139–144. [Google Scholar]

- Pantangi, V.K.; Mishra, S.C.; Muthukumar, P.; Reddy, R. Studies on Porous Radiant Burners for LPG (Liquefied Petroleum Gas) Cooking Applications. Energy 2011, 36, 6074–6080. [Google Scholar] [CrossRef]

- Muthukumar, P.; Shyamkumar, P.I. Development of Novel Porous Radiant Burners for LPG Cooking Applications. Fuel 2013, 112, 562–566. [Google Scholar] [CrossRef]

- Kaushik, L.K.; Deb, S.; Muthukumar, P. Energy Saving and Techno-Economic Assessment of Self Aspirated Domestic LPG Stove with Porous Radiant Burner. IOP Conf. Ser. Mater. Sci. Eng. 2018, 377, 012194. [Google Scholar] [CrossRef]

- Kaushik, L.K.; Muthukumar, P. Life Cycle Assessment (LCA) and Techno-Economic Assessment (TEA) of Medium Scale (5–10 KW) LPG Cooking Stove with Two-Layer Porous Radiant Burner. Appl. Therm. Eng. 2018, 133, 316–326. [Google Scholar] [CrossRef]

- Deb, S.; Muthukumar, P. Development and Performance Assessment of LPG Operated Cluster Porous Radiant Burner for Commercial Cooking and Industrial Applications. Energy 2021, 219, 119581. [Google Scholar] [CrossRef]

- Chandra, A.; Tiwari, G.N.; Srivastava, V.K.; Yadav, Y.P. Peformance Evaluation of Biogas Burners. Energy Convers. Mgmt 1991, 32, 353–358. [Google Scholar] [CrossRef]

- Smith, K.R.; Uma, R.; Kishore, V.V.N.; Lata, K.; Joshi, V.; Zhang, J.; Rasmussen, R.A.; Khalil, M.A.K. Greenhouse Gases from Small-Scale Combustion Devices in Developing Countries Phase IIA, Household Stoves in India; Environmental Protection Agency: Washington, DC, USA, 2000.

- Khandelwal, K.C.; Gupta, V.K. Popular Summary of the Test Reports on Biogas Stoves and Lamps Prepared by Testing Institutes in China, India and The Netherlands; SNV Netherlands Development Organization: Hague, The Netherlands, 2009. [Google Scholar]

- Kebede, D.; Kiflu, A. Design of Biogas Stove for Injera Baking Application. Int. J. Nov. Res. Eng. Sci. 2014, 1, 6–21. [Google Scholar]

- Obada, D.O.; Obi, A.I.; Dauda, M.; Anafi, F.O. Design and Construction of a Biogas Burner. Palest. Tech. Univ. Res. J. 2014, 2, 35–42. [Google Scholar] [CrossRef]

- Tumwesige, V.; Fulford, D.; Davidson, G.C. Biogas Appliances in Sub-Sahara Africa. Biomass Bioenergy 2014, 70, 40–50. [Google Scholar] [CrossRef]

- Zhang, J.; Smith, K.R.; Uma, R.; Ma, Y.; Kishore, V.V.N.; Lata, K.; Khalil, M.A.K.; Rasmussen, R.A.; Thorneloe, S.T. Carbon Monoxide from Cookstoves in Developing Countries: 1. Emission Factors. Chemosph. Glob. Chang. Sci. 1999, 1, 353–366. [Google Scholar] [CrossRef]

- Sharma, M.; Mishra, S.C.; Acharjee, P. Thermal Efficiency Study of Conventional Kerosene Pressure Stoves Equipped with Porous Radiant Inserts. Int. Energy J. 2009, 10, 247–254. [Google Scholar]

- Sharma, M.; Mishra, S.C.; Mahanta, P. An Experimental Investigation on Efficiency Improvement of a Conventional Kerosene Pressure Stove. Int. J. Energy Clean Environ. 2011, 12, 79–93. [Google Scholar] [CrossRef]

- Sharma, M.; Mahanta, P.; Mishra, S.C. Usability of Porous Burner in Kerosene Pressure Stove: An Experimental Investigation Aided by Energy and Exergy Analyses. Energy 2016, 103, 251–260. [Google Scholar] [CrossRef]

- Sharma, M.; Mishra, S.C.; Mahanta, P. Effect of Burner Configuration and Operating Parameters on the Performance of Kerosene Pressure Stove with Submerged Porous Medium Combustion. Appl. Therm. Eng. 2016, 107, 516–523. [Google Scholar] [CrossRef]

- Sinha, G.S.; Muthukumar, P. Study of Effects of Various Parameter on Thermal Efficiency of Porous Burner with Kerosene Pressure Stove. J. Phys. Conf. Ser. 2019, 1240, 012136. [Google Scholar] [CrossRef]

- Muthukumar, P.; Sinha, G.S.; Kaushik, L.K.; Sharma, M.; Priya, N.S.; Kanagaraj, S. Self-Aspirated Pressurized Kerosene Cooking Stove with a Porous Radiant Burner with Nanoparticles Blended. Application No: 201831003156 (TEMP/E-1/3419/2018-KOL), 27 January 2018. [Google Scholar]

- Kakati, S.; Mahanta, P. Experimental Evaluation of Performance of Pressure Stove by Using Plant Oil and Kerosene Blends. Int. J. Adv. Eng. Res. Sci. 2000, 6, 27–33. [Google Scholar]

- Jambhulkar, G.; Nitnaware, V.; Pal, M.; Fuke, N.; Khandelwal, P.; Sonule, P.; Narnawre, S.; Katekar, V.P. Performance Evaluation of Cooking Stove Working on Spent Cooking Oil. Int. J. Emerg. Sci. Eng. 2015, 3, 26–31. [Google Scholar]

- Wagutu, A.W.; Thoruwa, T.F.N.; Chhabra, S.C.; Lang’at-Thoruwa, C.C.; Mahunnah, R.L.A. Performance of a Domestic Cooking Wick Stove Using Fatty Acid Methyl Esters (FAME) from Oil Plants in Kenya. Biomass Bioenergy 2010, 34, 1250–1256. [Google Scholar] [CrossRef]

- Khan, M.Y.; Kumar, M.; Mittal, A. Performance of Wick Stove Fueled with Used Frying Oil-Kerosene Blends. In Proceedings of the International Conference on Advances in Mechanical Engineering 2010, Surat, India, 4–6 January 2010; pp. 1–6. [Google Scholar]

- Khan, M.Y.; Sharma, S.; Ahmed, S. Performance of Wick Stove Fueled with Karanja Oil-Kerosene Blends. In Proceedings of the National Conference on Recent Advances in Mechanical Engineering (RAME-11), Mathura, India, 1–2 April 2011; pp. 1–7. [Google Scholar]

- Nagaraju, Y.; Gopal, L. Development and Performance Assessment of a Pressurized Cook Stove Using a Blend of Pongamia Oil and Kerosene. Int. J. Sci. Res. 2013, 2, 99–100. [Google Scholar] [CrossRef]

- Shetty, D.; Sahu, D.; Kumar, R.; Bekal, S. Performance and Emission Characteristics of Pongamia Oil-Kerosene Blend Used in Commercial Kerosene Stove. Energy Power 2015, 5, 19–27. [Google Scholar]

- Saha, S.; Guha, A.; Roy, S. Experimental and Computational Investigation of Indoor Air Quality inside Several Community Kitchens in a Large Campus. Build. Environ. 2012, 52, 177–190. [Google Scholar] [CrossRef]

- Nandasena, S.; Wickremasinghe, R.; Kasturiratne, A.; Wimalasiri, U.; Tipre, M.; Larson, R.; Levitan, E.; Sathiakumar, N. Particulate Matter Fractions and Kitchen Characteristics in Sri Lankan Households Using Solid Fuel and LPG. bioRxiv 2018. [Google Scholar] [CrossRef]

- Giwa, S.O.; Nwaokocha, C.N.; Odufuwa, B.O. Air Pollutants Characterization of Kitchen Microenvironments in Southwest Nigeria. Build. Environ. 2019, 153, 138–147. [Google Scholar] [CrossRef]

- Rupakheti, D.; Oanh, N.T.K.; Rupakheti, M.; Sharma, R.K.; Panday, A.K.; Puppala, S.P.; Lawrence, M.G. Indoor Levels of Black Carbon and Particulate Matters in Relation to Cooking Activities Using Different Cook Stove-Fuels in Rural Nepal. Energy Sustain. Dev. 2019, 48, 25–33. [Google Scholar] [CrossRef]

- Johnson, M.A.; Garland, C.R.; Jagoe, K.; Edwards, R.; Ndemere, J.; Weyant, C.; Patel, A.; Kithinji, J.; Wasirwa, E.; Nguyen, T.; et al. In-Home Emissions Performance of Cookstoves in Asia and Africa. Atmosphere 2019, 10, 290. [Google Scholar] [CrossRef]

- Weyant, C.L.; Thompson, R.; Lam, N.L.; Upadhyay, B.; Shrestha, P.; Maharjan, S.; Rai, K.; Adhikari, C.; Fox, M.C.; Pokhrel, A.K. In-Field Emission Measurements from Biogas and Liquified Petroleum Gas (LPG) Stoves. Atmosphere 2019, 10, 729. [Google Scholar] [CrossRef]

- Simkovich, S.M.; Williams, K.N.; Pollard, S.; Dowdy, D.; Sinharoy, S.; Clasen, T.F.; Puzzolo, E.; Checkley, W. A Systematic Review to Evaluate the Association between Clean Cooking Technologies and Time Use in Low- and Middle-Income Countries. Int. J. Environ. Res. Public Health 2019, 16, 2277. [Google Scholar] [CrossRef] [PubMed]

- Ventrella, J.; Lefebvre, O.; MacCarty, N. Techno-Economic Comparison of the FUEL Sensor and Kitchen Performance Test to Quantify Household Fuel Consumption with Multiple Cookstoves and Fuels. Dev. Eng. 2020, 5, 100047. [Google Scholar] [CrossRef]

- Johnston, J.D.; Hawks, M.E.; Johnston, H.B.; Johnson, L.A.; Beard, J.D. Comparison of Liquefied Petroleum Gas Cookstoves and Wood Cooking Fires on PM2.5 Trends in Brick Workers’ Homes in Nepal. Int. J. Environ. Res. Public Health 2020, 17, 5681. [Google Scholar] [CrossRef]

- Sambandam, S.; Mukhopadhyay, K.; Sendhil, S.; Ye, W.; Pillarisetti, A.; Thangavel, G.; Natesan, D.; Ramasamy, R.; Natarajan, A.; Aravindalochanan, V.; et al. Exposure Contrasts Associated with a Liquefied Petroleum Gas (LPG) Intervention at Potential Field Sites for the Multi-Country Household Air Pollution Intervention Network (HAPIN) Trial in India: Results from Pilot Phase Activities in Rural Tamil Nadu. BMC Public Health 2020, 20, 1799. [Google Scholar] [CrossRef]

- Kephart, J.L.; Fandiño-Del-Rio, M.; Williams, K.N.; Malpartida, G.; Lee, A.; Steenland, K.; Naeher, L.P.; Gonzales, G.F.; Chiang, M.; Checkley, W.; et al. Nitrogen Dioxide Exposures from LPG Stoves in a Cleaner-Cooking Intervention Trial. Environ. Int. 2021, 146, 106196. [Google Scholar] [CrossRef]

- Islam, M.M.; Wathore, R.; Zerriffi, H.; Marshall, J.D.; Bailis, R.; Grieshop, A.P. In-Use Emissions from Biomass and LPG Stoves Measured during a Large, Multi-Year Cookstove Intervention Study in Rural India. Sci. Total Environ. 2021, 758, 143698. [Google Scholar] [CrossRef]

- Pandit, G.G.; Srivastava, P.K.; Mohan Rao, A.M. Monitoring of Indoor Volatile Organic Compounds and Polycyclic Aromatic Hydrocarbons Arising from Kerosene Cooking Fuel. Sci. Total Environ. 2001, 279, 159–165. [Google Scholar] [CrossRef]

- Andresen, P.R.; Ramachandran, G.; Pai, P.; Maynard, A. Women’s Personal and Indoor Exposures to PM2.5 in Mysore, India: Impact of Domestic Fuel Usage. Atmos. Environ. 2005, 39, 5500–5508. [Google Scholar] [CrossRef]

- Donoso-García, P.; Henríquez-Vargas, L. Numerical Study of Turbulent Porous Media Combustion Coupled with Thermoelectric Generation in a Recuperative Reactor. Energy 2015, 93, 1189–1198. [Google Scholar] [CrossRef]

- Boggavarapu, P.; Ray, B.; Ravikrishna, R.V. Thermal Efficiency of LPG and PNG-Fired Burners: Experimental and Numerical Studies. Fuel 2014, 116, 709–715. [Google Scholar] [CrossRef]

- Dwivedi, G.; Gohil, P.P.; Behura, A.K. Numerical Investigation of Thermodynamic Parameters for Performance Evaluation of Cooking Gas Stove Burner by Appending of Flame Shield. Mater. Today Proc. 2021, 46, 5696–5702. [Google Scholar] [CrossRef]

- Dey, S.; Das, M.; Ganguly, R.; Datta, A.; Verma, M.M.; Bera, A.K. Computational Fluid Dynamic Analyses of Flow and Combustion in a Domestic Liquified Petroleum Gas Cookstove Burner-Part I: Design Optimization of Mixing Tube-Burner Assembly. J. Therm. Sci. Eng. Appl. 2020, 12, 031010–031017. [Google Scholar] [CrossRef]

- Das, M.; Ganguly, R.; Datta, A.; Verma, M.M.; Bera, A.K. Computational Fluid Dynamic Analyses of Flow and Combustion in a Domestic Liquefied Petroleum Gas Cookstove Burner-Part II: Burning Characteristics and Overall Performance. J. Therm. Sci. Eng. Appl. 2020, 12, 031011–031018. [Google Scholar] [CrossRef]

- Deb, S.; Kaushik, L.K.; Kumar, M.A.; Satish, S.H.V.; Muthukumar, P. Clustered Porous Radiant Burner: A Cleaner Alternative for Cooking Systems in Small and Medium Scale Applications. J. Clean. Prod. 2021, 308, 127276. [Google Scholar] [CrossRef]

- World Health Organization. WHO Guidelines for Indoor Air Quality: Household Fuel Combustion; WHO: Geneva, Switzerland, 2014.

- Charron, D.; Lam, N.; Pennise, D.; Wofchuck, T. Ethanol as a Household Fuel in Madagascar: Health Benefits, Economic Assessment and Review of African Lessons for Scaling Up; World Bank: Washington, DC, USA, 2011. [Google Scholar]

- Pswarayi-Riddihough, I.; Martin, P.; Rajaonson, B.; Rajaobelison, R.; Miranda, R.; Dasgupta, S. Ethanol as a Household Fuel in Madagascar. Health Benefits, Economic Assessment, and Review of African Lessons for Scaling-up Volume I—Summary Report; Southern Africa 2011. Available online: https://documents1.worldbank.org/curated/en/564801468055752320/pdf/699820v10ESW0P0ry0Report0Eng0220911.pdf (accessed on 28 December 2022).

- Ohimain, E.I. The Benefits and Potential Impacts of Household Cooking Fuel Substitution with Bio-Ethanol Produced from Cassava Feedstock in Nigeria. Energy Sustain. Dev. 2012, 16, 352–362. [Google Scholar] [CrossRef]

- Adetona, O.; Li, Z.; Sjödin, A.; Romanoff, L.C.; Aguilar-villalobos, M.; Needham, L.L.; Hall, D.B.; Cassidy, B.E.; Naeher, L.P. Biomonitoring of Polycyclic Aromatic Hydrocarbon Exposure in Pregnant Women in Trujillo, Peru-Comparison of Different Fuel Types Used for Cooking. Environ. Int. 2013, 53, 1–8. [Google Scholar] [CrossRef]

- Epstein, M.B.; Bates, M.N.; Arora, N.K.; Balakrishnan, K.; Jack, D.W.; Smith, K.R. Household Fuels, Low Birth Weight, and Neonatal Death in India: The Separate Impacts of Biomass, Kerosene, and Coal. Int. J. Hyg. Environ. Health 2013, 216, 523–532. [Google Scholar] [CrossRef]

- Dutta, A.; Khramtsova, G.; Brito, K.; Alexander, D.; Mueller, A.; Chinthala, S.; Adu, D.; Ibigbami, T.; Olamijulo, J.; Odetunde, A.; et al. Household Air Pollution and Chronic Hypoxia in the Placenta of Pregnant Nigerian Women: A Randomized Controlled Ethanol Cookstove Intervention. Sci. Total Environ. 2018, 619–620, 212–220. [Google Scholar] [CrossRef]

- Alexander, D.A.; Northcross, A.; Karrison, T.; Morhasson-bello, O.; Wilson, N.; Atalabi, O.M.; Dutta, A.; Adu, D.; Ibigbami, T.; Olamijulo, J.; et al. Pregnancy Outcomes and Ethanol Cook Stove Intervention: A Randomized- Controlled Trial in Ibadan, Nigeria. Environ. Int. 2018, 111, 152–163. [Google Scholar] [CrossRef] [PubMed]

- Steenland, K.; Pillarisetti, A.; Kirby, M.; Peel, J.; Clark, M.; Checkley, W.; Chang, H.H.; Clasen, T. Modeling the Potential Health Benefits of Lower Household Air Pollution after a Hypothetical Liquified Petroleum Gas (LPG) Cookstove Intervention. Environ. Int. 2018, 111, 71–79. [Google Scholar] [CrossRef] [PubMed]

- Bates, M.N.; Pokhrel, A.K.; Chandyo, R.K.; Valentiner-Branth, P.; Mathisen, M.; Basnet, S.; Strand, T.A.; Burnett, R.T.; Smith, K.R. Kitchen PM2.5 Concentrations and Child Acute Lower Respiratory Infection in Bhaktapur, Nepal: The Importance of Fuel Type. Environ. Res. 2018, 161, 546–553. [Google Scholar] [CrossRef] [PubMed]

- Stapleton, E.M.; Kizhakke Puliyakote, A.; Metwali, N.; Jeronimo, M.; Thornell, I.M.; Manges, R.B.; Bilas, M.; Kamal Batcha, M.A.; Kumaravel, M.S.; Durairaj, K.; et al. Lung Function of Primary Cooks Using LPG or Biomass and the Effect of Particulate Matter on Airway Epithelial Barrier Integrity. Environ. Res. 2020, 189, 109888. [Google Scholar] [CrossRef] [PubMed]

- Imran, M.; Ozcatalbas, O. Determinants of Household Cooking Fuels and Their Impact on Women’s Health in Rural Pakistan. Environ. Sci. Pollut. Res. 2020, 27, 23849–23861. [Google Scholar] [CrossRef] [PubMed]

- Arku, R.E.; Brauer, M.; Duong, M.L.; Wei, L.; Hu, B.; Ah Tse, L.; Mony, P.K.; Lakshmi, P.V.M.; Pillai, R.K.; Mohan, V.; et al. Adverse Health Impacts of Cooking with Kerosene: A Multi-Country Analysis within the Prospective Urban and Rural Epidemiology Study. Environ. Res. 2020, 188, 109851. [Google Scholar] [CrossRef]

- Wang, Y.; Bailis, R. The Revolution from the Kitchen: Social Processes of the Removal of Traditional Cookstoves in Himachal Pradesh, India. Energy Sustain. Dev. 2015, 27, 127–136. [Google Scholar] [CrossRef]

- Kimemia, D.; Annegarn, H. Domestic LPG Interventions in South Africa: Challenges and Lessons. Energy Policy 2016, 93, 150–156. [Google Scholar] [CrossRef]

- Calzada, J.; Sanz, A. Universal Access to Clean Cookstoves: Evaluation of a Public Program in Peru. Energy Policy 2018, 118, 559–572. [Google Scholar] [CrossRef]

- Williams, K.N.; Kephart, J.L.; Fandiño-Del-Rio, M.; Condori, L.; Koehler, K.; Moulton, L.H.; Checkley, W.; Harvey, S.A. Beyond Cost: Exploring Fuel Choices and the Socio-Cultural Dynamics of Liquefied Petroleum Gas Stove Adoption in Peru. Energy Res. Soc. Sci. 2020, 66, 101591. [Google Scholar] [CrossRef]

- Olabisi, M.; Tschirley, D.L.; Nyange, D.; Awokuse, T. Energy Demand Substitution from Biomass to Imported Kerosene: Evidence from Tanzania. Energy Policy 2019, 130, 243–252. [Google Scholar] [CrossRef]

- Agbokey, F.; Dwommoh, R.; Tawiah, T.; Ae-Ngibise, K.A.; Mujtaba, M.N.; Carrion, D.; Abdulai, M.A.; Afari-Asiedu, S.; Owusu-Agyei, S.; Asante, K.P.; et al. Determining the Enablers and Barriers for the Adoption of Clean Cookstoves in the Middle Belt of Ghana-A Qualitative Study. Int. J. Environ. Res. Public Health 2019, 16, 1207. [Google Scholar] [CrossRef] [PubMed]

- Troncoso, K.; Segurado, P.; Aguilar, M.; Soares da Silva, A. Adoption of LPG for Cooking in Two Rural Communities of Chiapas, Mexico. Energy Policy 2019, 133, 110925. [Google Scholar] [CrossRef]

- Ochieng, C.A.; Murray, U.; Owuor, J.; Spillane, C. The Forgotten Half: Men’s Influence over Cookstove Adoption Decisions in Northern Kenya. Energy Res. Soc. Sci. 2021, 74, 101913. [Google Scholar] [CrossRef]

- Khanwilkar, S.; Gould, C.F.; DeFries, R.; Habib, B.; Urpelainen, J. Firewood, Forests, and Fringe Populations: Exploring the Inequitable Socioeconomic Dimensions of Liquified Petroleum Gas (LPG) Adoption in India. Energy Res. Soc. Sci. 2021, 75, 102012. [Google Scholar] [CrossRef] [PubMed]

| S. No. | Design Details | Fig. | Ref. |

|---|---|---|---|

| 1. |

| Figure 9a | [55] |

| 2. |

| Figure 9b | [50] |

| 3. |

| Figure 9c | [56] |

| 4. |

| Figure 9d | [53] |

| 5. |

| Figure 9e | [54] |

| 6. |

| Figure 9f | [58] |

| 7. |

| Figure 9g | [60] |

| 8. |

| Figure 9h | [48] |

| 9. |

| Figure 9i | [49] |

| S. No. | Design Details | Fig. | Ref. |

|---|---|---|---|

| 1. |

| Figure 10a | [65] |

| 2. | Fuel: Ethanol gel | Figure 10b | [66] |

| 3. | Fuel: Methanol | Figure 10c | [66] |

| S. No. | Design Details | Fig. | Ref. |

|---|---|---|---|

| 1. |

| Figure 12a | [73] |

| 2. |

| Figure 12b | [75] |

| 3. |

| Figure 12c | [81] |

| 4. |

| Figure 12d | [82] |

| S. No. | Thermal and Emission Performances | Ref. | ||||

|---|---|---|---|---|---|---|

| 1. | Thermal efficiency: 55% | [51] | ||||

| 2. | Thermal efficiency: 32 to 49% (unsteady state), 37 to 54% (steady state) | [106] | ||||

| 3. | Thermal efficiency: 67% (Biogas consumption rate: 8.18 g/min) | [48] | ||||

| 4. | Activities performed | Efficiency (%) | Biogas Consumption rate (m3/min) | [56] | ||

| Boiling water (1 L) | 20% | 0.69 | ||||

| Cooking rice (146.6 g) | 56% | 4.87 | ||||

| Cooking beans (123.3 g) | 53% | 4.87 | ||||

| 5. | Country | Gas consumption (L/h), Thermal efficiency (%) and CO emission (ppm) | CEEIC | DRES | GASTEC | [108] |

| Bangladesh | L/h | 474.5 | 211 | 500 | ||

| % | 57 | 64.5 | 52.1 | |||

| Ppm | >1180 | 5300 | 2800 | |||

| Cambodia | L/h | 762 | 489 | 808 | ||

| % | 55 | 48.1 | 45.6 | |||

| Ppm | >1180 | 2200 | 1700 | |||

| Ethiopia | L/h | 252.5 | 537 | 633 | ||

| % | 53 | 40.5 | 41.2 | |||

| Ppm | >1180 | 4350 | 4463 | |||

| India | L/h | 597 | 400 | 261 | ||

| % | 57 | 54.5 | 89.9 | |||

| Ppm | >1180 | 2840 | 85 | |||

| Lesotho | L/h | 270.5 | 217 | 354 | ||

| % | 41 | 45.1 | 45 | |||

| Ppm | 28 | 4350 | 8 | |||

| Nepal | L/h | 565.5 | 453 | 536 | ||

| % | 55 | 42.1 | 42.2 | |||

| Ppm | >1180 | 4350 | 2140 | |||

| Rwanda | L/h | 340 | 285 | 336 | ||

| % | 60 | 53.8 | 54.6 | |||

| Ppm | >1180 | 2250 | 2200 | |||

| Vietnam | L/h | 758 | 620 | 1039 | ||

| % | 39 | 21.2 | 31.5 | |||

| Ppm | >1180 | 4350 | 1100 | |||

| 6. | Cooking efficiency: 43.96% (Biogas consumption rate: 1 m3/h) | [53] | ||||

| 7. | Thermal efficiency: ~60% (Biogas consumption rate: 375 L/h) Emissions: CO—~150–180 ppm | [54] | ||||

| 8. | Thermal efficiency: 56.8% Emissions: CO—1.103 g/MJ Total HC—0.071 g | [59] | ||||

| 9. | Thermal efficiency: 51–62% (Biogas flow rate: 177–530 L/h) Emissions: CO—29–80 ppm NOx—<4 ppm | [49] | ||||

| Pollutants | Mean Concentration over Averaging Time | Comments | ||||

|---|---|---|---|---|---|---|

| 15 min | 1 h | 8 h | 24 h | 1 year | ||

| CO (mg/m3) | 100 | 35 | 10 | 7 | - | - |

| NO2 (μg/m3) | - | 200 | - | 40 | - | |

| PM2.5 | - | 25 | 10 | 24-h guideline max 3 days/year | ||

| PM10 | - | 50 | 20 | |||

| S. No. | Sample Size | Transition | Sample Location | Ref. | |

|---|---|---|---|---|---|

| To | From | ||||

| 1. | 43 household | Traditional chulha cook-stove | LPG and improved biomass stoves | 11 villages in Lag and Gadsa Valley, Himachal Pradesh, India | [159] |

| 2. | 200 households that had benefited from receipt of a free LPG kit project during the prior LPG promotion campaign | Electricity | LPG | Atteridgeville Township, South Africa | [160] |

| 3. | 458 households | Biofuels | LPG stove | Peru | [161] |

| 4. | 22 participants | Biomass stove | LPG stove | Peru | [162] |

| 5. | 10,168 households | Charcoal and firewood | Kerosene | Tanzania | [163] |

| 6. | 113 women | Biomass | BioLite and LPG | Ghana | [164] |

| 7. | 72 households | Firewood | LPG | Chiapas, Mexico | [165] |

| 8. | 23 married couples | Traditional cook-stove | Cleaner cook-stoves | West Pokot County in Northern Kenya | [166] |

| 9. | 4994 households | Traditional biomass | LPG | India | [167] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Palanisamy, M.; Kaushik, L.K.; Mahalingam, A.K.; Deb, S.; Maurya, P.; Shaik, S.R.; Mujeebu, M.A. Evolutions in Gaseous and Liquid Fuel Cook-Stove Technologies. Energies 2023, 16, 763. https://doi.org/10.3390/en16020763

Palanisamy M, Kaushik LK, Mahalingam AK, Deb S, Maurya P, Shaik SR, Mujeebu MA. Evolutions in Gaseous and Liquid Fuel Cook-Stove Technologies. Energies. 2023; 16(2):763. https://doi.org/10.3390/en16020763

Chicago/Turabian StylePalanisamy, Muthukumar, Lav Kumar Kaushik, Arun Kumar Mahalingam, Sunita Deb, Pratibha Maurya, Sofia Rani Shaik, and Muhammad Abdul Mujeebu. 2023. "Evolutions in Gaseous and Liquid Fuel Cook-Stove Technologies" Energies 16, no. 2: 763. https://doi.org/10.3390/en16020763

APA StylePalanisamy, M., Kaushik, L. K., Mahalingam, A. K., Deb, S., Maurya, P., Shaik, S. R., & Mujeebu, M. A. (2023). Evolutions in Gaseous and Liquid Fuel Cook-Stove Technologies. Energies, 16(2), 763. https://doi.org/10.3390/en16020763