1. Introduction

Nowadays, the world problem of environmental pollution and energy shortage has aroused the great attention of human society [

1]. With the increasing familiarity with renewable energy, human beings have begun to utilize renewable energy such as wind, solar, biomass, tidal, hydropower, geothermal, and other renewable energy for power generation; renewable energy has dramatically alleviated the rapid shortage of conventional energy [

2]. The earth is rich in wind energy, which has a high utilization value in renewable energy; therefore, wind energy development has attracted much attention [

3]. Wind power is applied to generate electricity, attracting more and more scholars and researchers. With the application of aerodynamics, aerospace technology, and high-power electronic technology in new wind turbines, wind power technology has made rapid progress in the past decade [

4]. In addition, with the strengthening awareness of environmental protection and the energy crisis, to promote the continuous extensionally utilization of renewable energy, countries have issued plans, which have made the enlargement momentum of the wind power industry more intense [

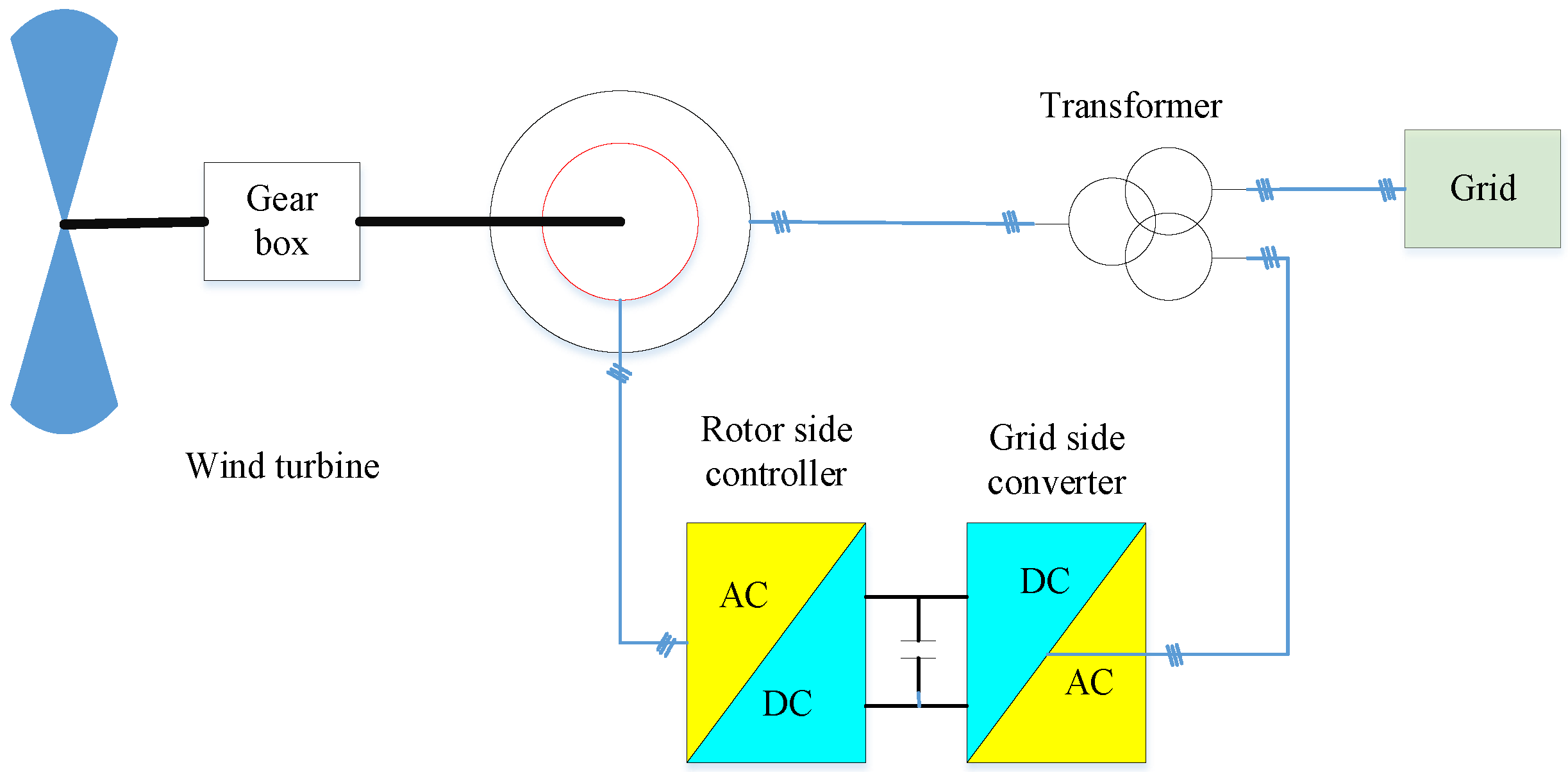

5]. In recent years, the appearance of doubly fed induction generators (DFIGs) offering the rated capacity of wind turbines gradually increased [

6]. The DFIGs can flexibly adjust the active and reactive power, operate with variable speed, track the maximum wind energy, and reduce the mechanical stress. Furthermore, the converter of the DFIGs only needs to transmit 25–30% slip power of the rated power. Therefore, the converter of the DFIGs has the characteristics of small capacity and low cost [

7]. Thus, the DFIGs have been widely applied in high-power wind power generation [

8]. The particle swarm optimization (PSO) algorithm-based optimized controller improves the dynamic performance of DFIG-based wind power systems [

9]. The proportional–integral (PI) parameters of the converter in the grid-connected DFIG are optimized via a genetic algorithm (GA). The optimized converter can improve the working reliability of the unit, prolong the use time of the unit, and expand the stable operation area of the wind farm [

10]. A chemical reaction optimization algorithm is used to tune the optimal PI parameters, which then ensures optimal power point tracking of the DFIG-based wind power system [

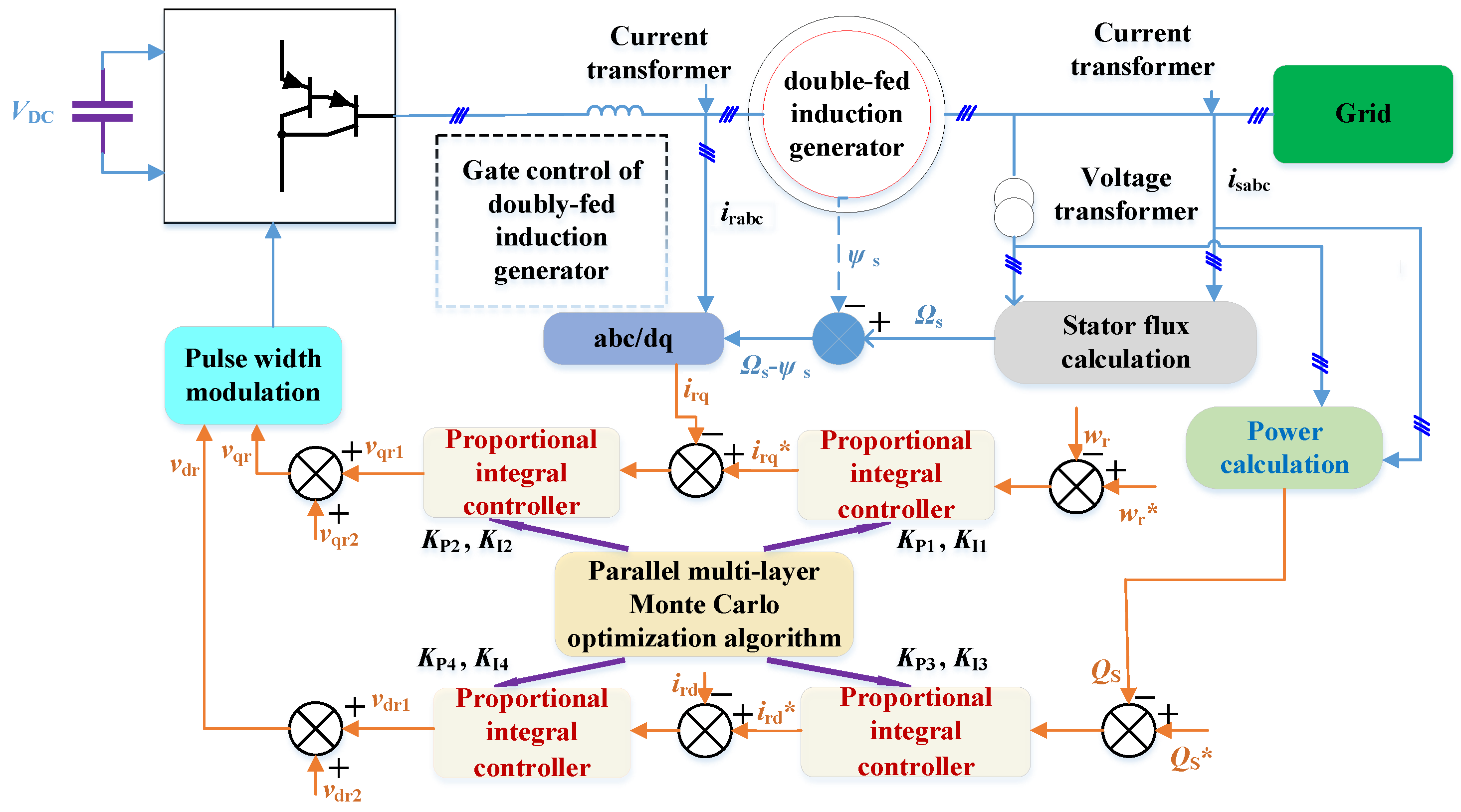

11]. In the DFIGs-based wind power system, the PI parameters of the rotor-side controller (RSC) can be optimized to make the rotor angular velocity track the optimal rotational speed at the wind speed as much as possible according to the random mutation of the wind speed, which can help to increase the wind power conversion rate of the system, and at the same time, improve the control performance of the RSC as much as possible. Generally, the control parameters of the DFIGs can be manually adjusted based on the linearized model of the original DFIGs for a particular operating condition; however, the control performance may be significantly degraded with the continuous change in the operating conditions. Therefore, to adapt to the different operating conditions, it is indispensable to find a reliable and effective method to adjust the optimal PI control parameters based on various operating conditions.

Wind turbines are generally related to the actual wind conditions and require maximum wind energy utilization [

12]. Therefore, the study on letting the wind turbines output the maximum power under different wind speeds is of practical significance and economic benefit. Maximum power point tracking (MPPT) has been one of the major control targets for picking up the maximum power of wind turbines to the greatest extent [

13]. Numerous studies have focused on realizing the MPPT for the DFIGs and proposed some implementation methods [

14]. The real-time MPPT algorithm has the advantage that maximum power tracking can be achieved by adjusting the reference power curve when the system parameters change slightly [

15]. Tip-speed ratio control maintenance at the optimal point has been applied in the MPPT of a DFIG [

16]. R. Garduno and M. Borunda et al. proposed a fuzzy controller to extract wind power [

17]. K. Tahir and C. Belfedal et al. adjusted and dominated the torque of the wind turbine from the perspective of torque control to achieve the MPPT [

18]. The hill-climbing searching algorithm can adjust the rotor velocity of the DFIG under different operating conditions and enhance the energy conversion efficiency [

19,

20]. The improved variable step hill-climbing searching algorithm has been proposed to implement MPPT for wind turbines [

21].

In the methods mentioned above, the optimal control signal can be calculated using the estimated wind speeds. Nevertheless, the control strategies of these methods are comparatively complex. The vector combined with the PI control with a simple structure has been applied for reactive and active power decoupling control [

22]. The PI controller is characterized by its reliable operation and simple structure. Furthermore, the PI control systems can be easily realized with general electronic circuits and motor equipment. Thus, the PI control occupies many industrial production control processes and is the primary control method in engineering practice [

23]. Conventional optimization methods based on the gradient may not obtain the optimal parameters with the accuracy and precision of system models [

24]. Numerous metaheuristic optimization algorithms have become increasingly prevalent to obtain optimal control parameters over the past two decades [

25]. The metaheuristic algorithms are simple. The error index of indirect power control shows that the PI parameters tuned via the PSO algorithm are more satisfied than those manually adjusted [

26]. In Ref. [

27], an active power optimization dispatching strategy based on a genetic algorithm GA has been proposed in a DFIG-based wind farm. The moth flame optimization (MFO) algorithm [

28] has been utilized for acquiring satisfactory parameters in the robust correlative control system in a DFIG-based wind turbine [

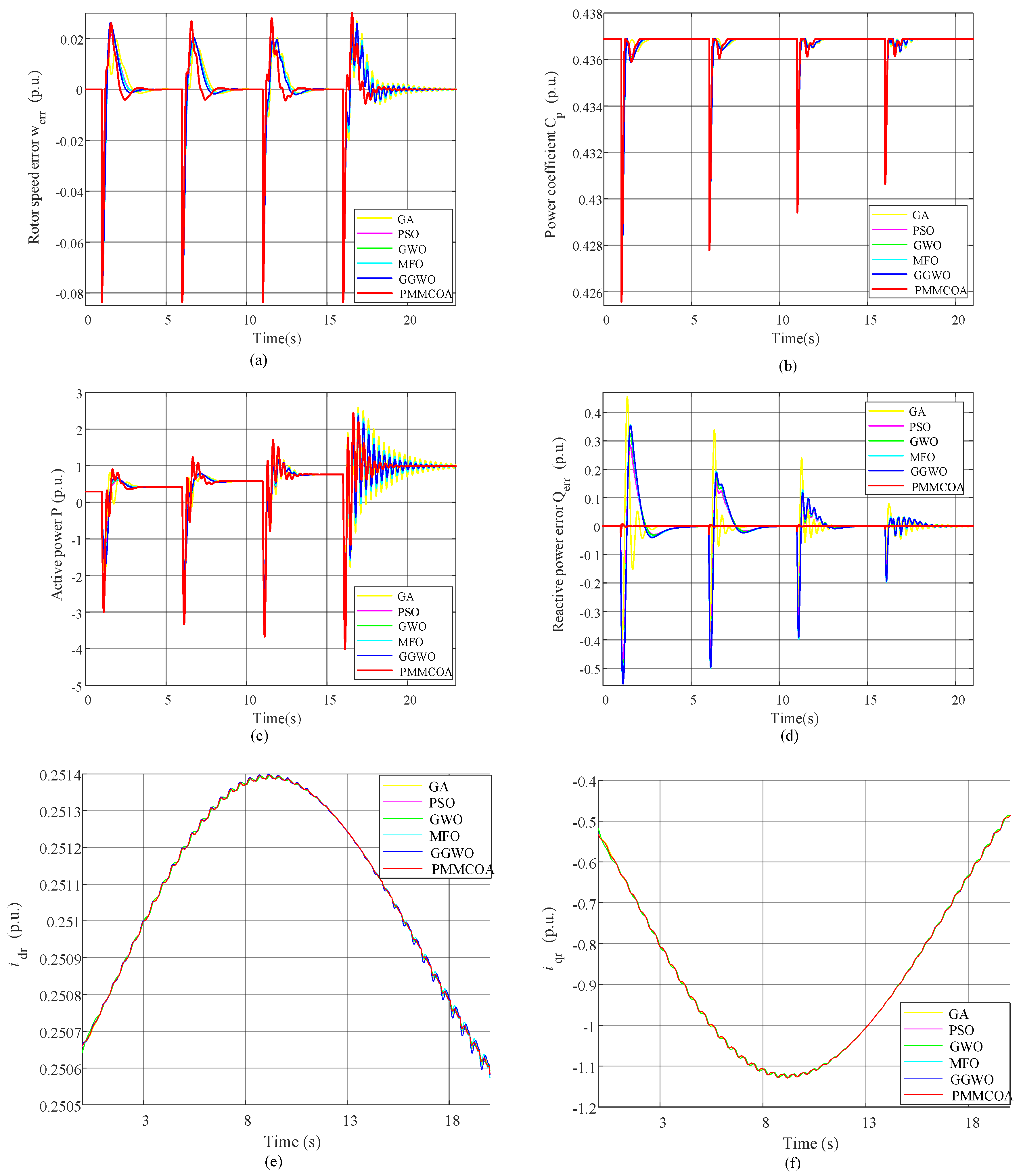

29]. Grey wolf optimization (GWO) was proposed for optimization by Mirjalili of Griffith University in Australia in 2014. A grouped grey wolf optimizer (GGWO) has been developed to achieve maximum power extraction. A method for tuning the PI parameters has not considered the change in the control response caused by a sudden change in grid voltage [

30].

The Monte Carlo method plays a vital role in numerical calculations guided by the probability and statistics theory, which can achieve approximate solutions using many random experiments, can solve definite mathematical and stochastic problems, is a powerful tool for systems analysis and design, and has been widely applied in natural science, engineering technology, and the national economy [

31]. Shi et al. proposed a nested partition optimization method with global search, local search, easy implementation, parallelism, and globality [

32]. In Ref. [

33], a pure adaptive Monte Carlo optimization with the improvement of pure random search algorithms has been proposed. The pure adaptive search has certain flaws because an effective method that can generate a uniform distribution of random numbers within a common convex domain has not yet been found. The no-free lunch theorem [

34] logically proves that a specific metaheuristic algorithm may find effective and reliable results on some specific issues; however, when the same algorithm is applied to other problems, bad and unrealistic results may occur [

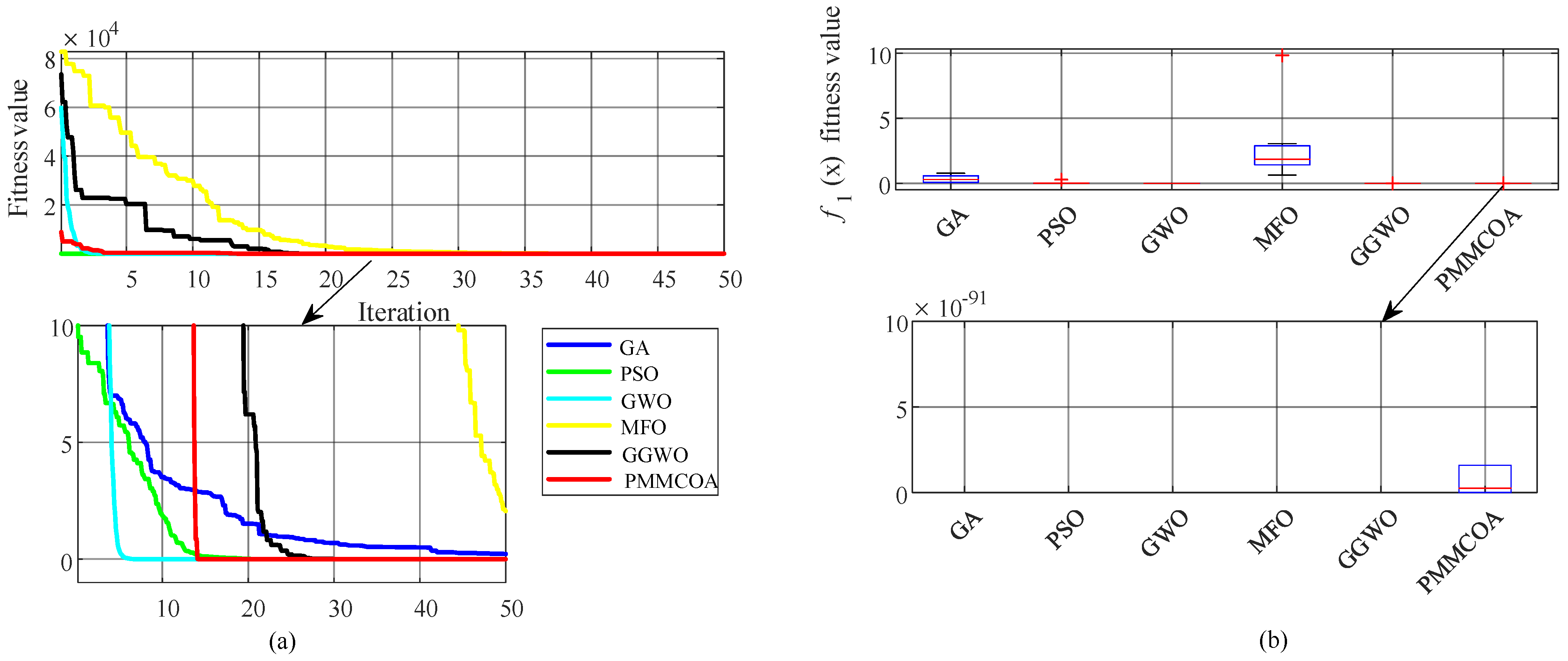

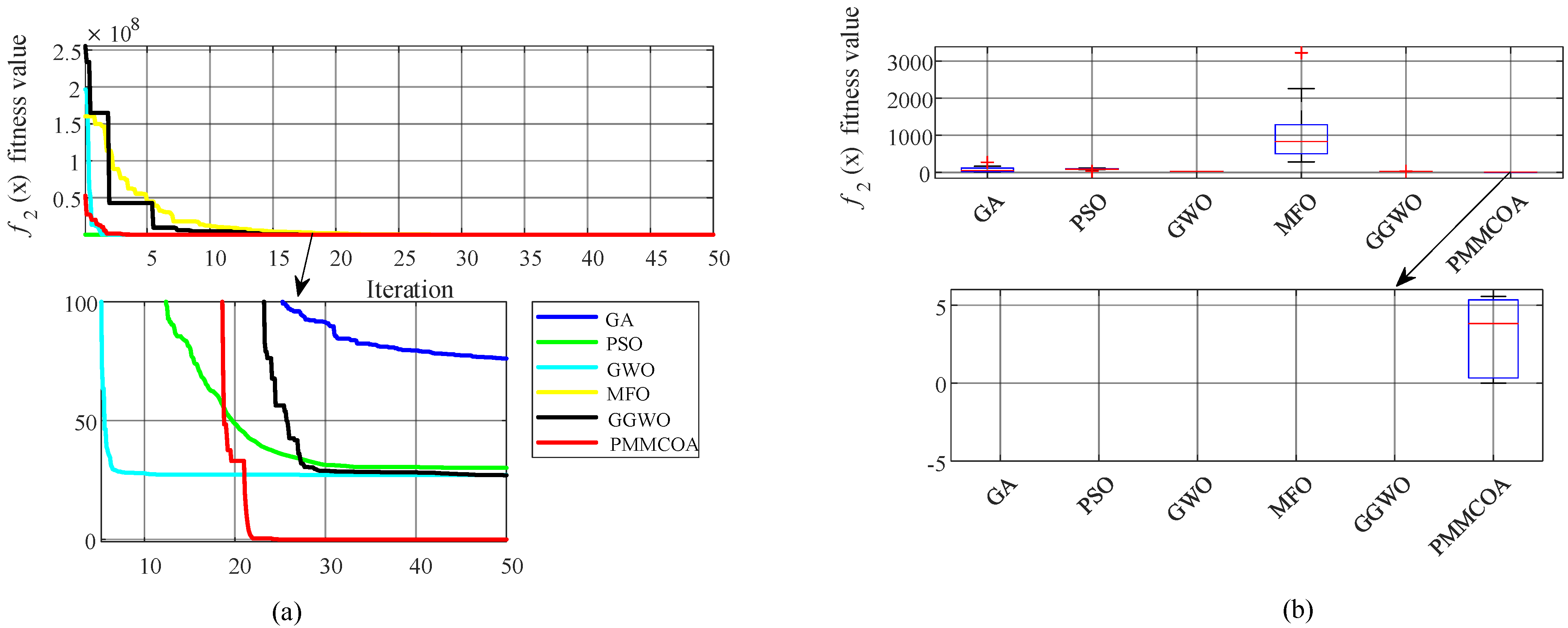

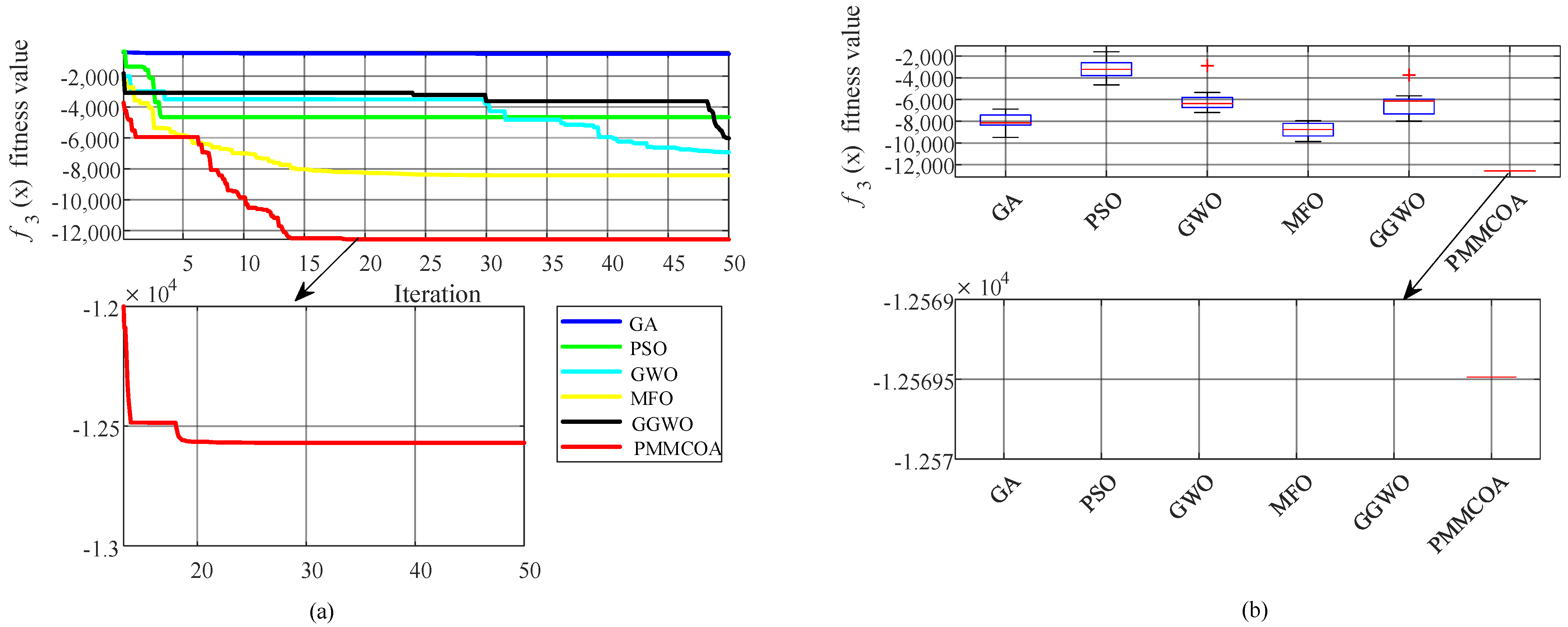

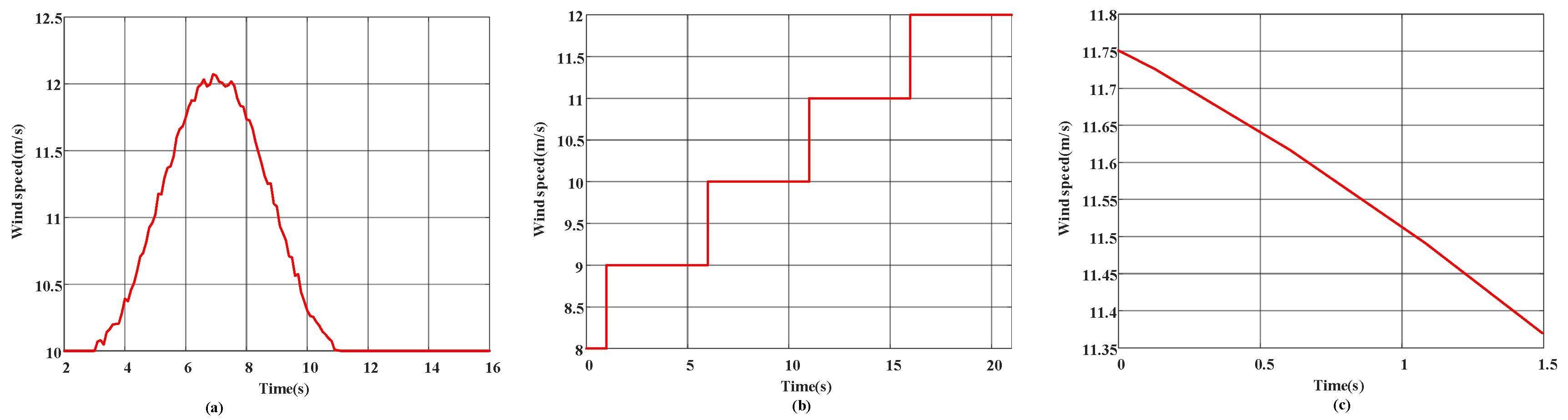

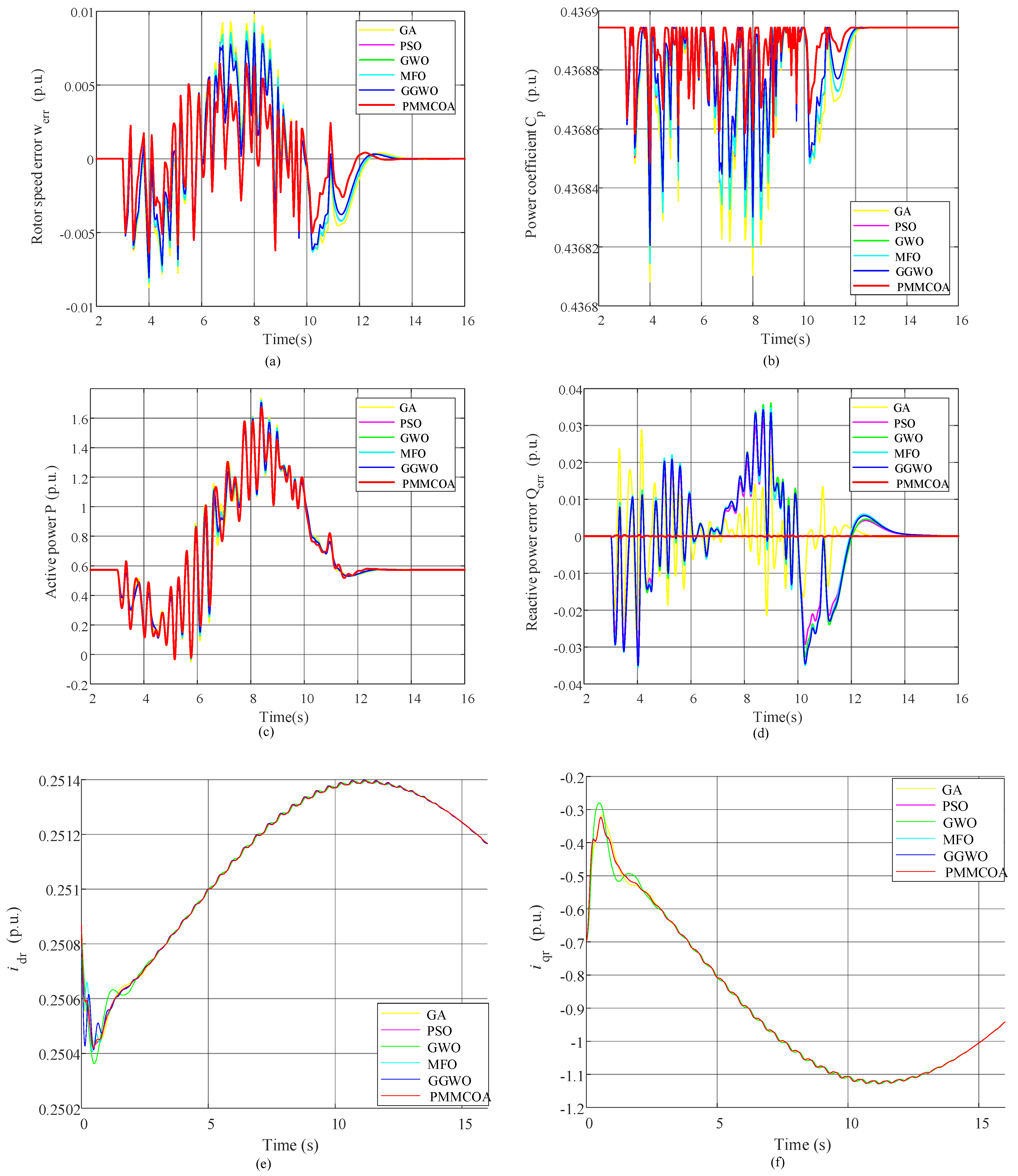

35]. The GA, the PSO, the MFO, the GWO, and the GGWO have all been employed for the parameters optimization of the DFIG-based wind turbines; however, these algorithms are underdeveloped and under-explored, which may lead to premature convergence and may not readily lead to the globally optimal parameters for DFIG-based wind turbines. The conventional Monte Carlo algorithm can theoretically obtain the global optimal PI parameters via countless experiments; however, abundant experiment time is required; consequently, the Monte Carlo method can be improved to obtain satisfactory PI parameters. To optimize the PI parameters of the rotor RSC of a DFIG-based wind power generation system, a parallel multi-layer Monte Carlo optimization algorithm (PMMCOA) is proposed for obtaining satisfactory PI parameters within DFIG-based wind turbines in this work. Two examples are tested; one applies three typical benchmark functions for proving the feasibility of the PMMCOA, and the other employs the PMMCOA to minimize the controller fitness value of a DFIG. The optimization results of the PMMCOA are compared with five representative metaheuristic algorithms. Two examples demonstrate the effectiveness and feasibility of PMMCOA in optimizing the DFIG controller parameters; meanwhile, the second example verifies that the optimized controller parameters can enable a DFIG-based wind turbine to achieve the MPPT.

This work includes the following contributions.

- (1)

In this work, a new algorithm called PMMCOA is proposed. The proposed PMMCOA mainly realizes the optimization process via multiple layers, multiple regions, and multiple granularities. Compared to multiple heuristics, the PMMCOA directly employs a multi-layer randomized search, which is simple to implement and avoids lengthy parameter adjustments. The major feature of the PMMCOA is that the global search performance is strong, and the local development capability is satisfactory. Three benchmark functions verify the effectiveness and feasibility of the PMMCOA.

- (2)

The PMMCOA is applied to find the parameters of the optimal PI controller.

- (3)

The PMMCOA-optimized controllers offer less overslip, lower volatility, and desirable efficiency for wind energy conversion. The PMMCOA grants the wind power system based on the optimized controller, which has high operating stability.

- (4)

The PMMCOA-optimized controller enables the DFIG-based wind power system to implement MPPT with some ability to alleviate unexpected grid voltage variations.

- (5)

Compared to other iterative processes that require references to animal behavior or brainstorming to generate optimization, the Monte Carlo stochastic approach proposed in this work is simpler and requires no optimization of many parameters.

- (6)

Compared to the original heuristic algorithm that only searches at a large global scale, the layer-by-layer, spatially contracted Monte Carlo approach proposed in this work can quickly contract the feasible domains to be searched and can quickly locate the space of optimal solutions.

The remaining work is divided into four contents. The roots and procedures for implementing PMMCOA are described in

Section 2. The optimal structure of the controller system based on PMMCOA for DFIG is given in

Section 3.

Section 4 verifies the superiority of the PMMCOA for optimizing the controller parameters.

Section 5 briefly concludes this work.

2. Proposed Parallel Optimization

To achieve MPPT, a PMMCOA is proposed for acquiring satisfactory PI parameters of the RSC of DFIG-based wind turbines. Then, the PMMCOA is introduced in detail.

The Monte Carlo method can be regarded as a numerical calculation way based on “random numbers”. The vital idea of the Monte Carlo is an infinite number of sample points in the definition domain. However, the Monte Carlo calculation needs enough calculation time, and the capacity of the computer is limited. Thus, the Monte Carlo method may not be practical.

Inspired by the Monte Carlo method, this work presents a PMMCOA, which can greatly reduce the calculation time of the Monte Carlo method and obtain the minimum numerical solution approximately.

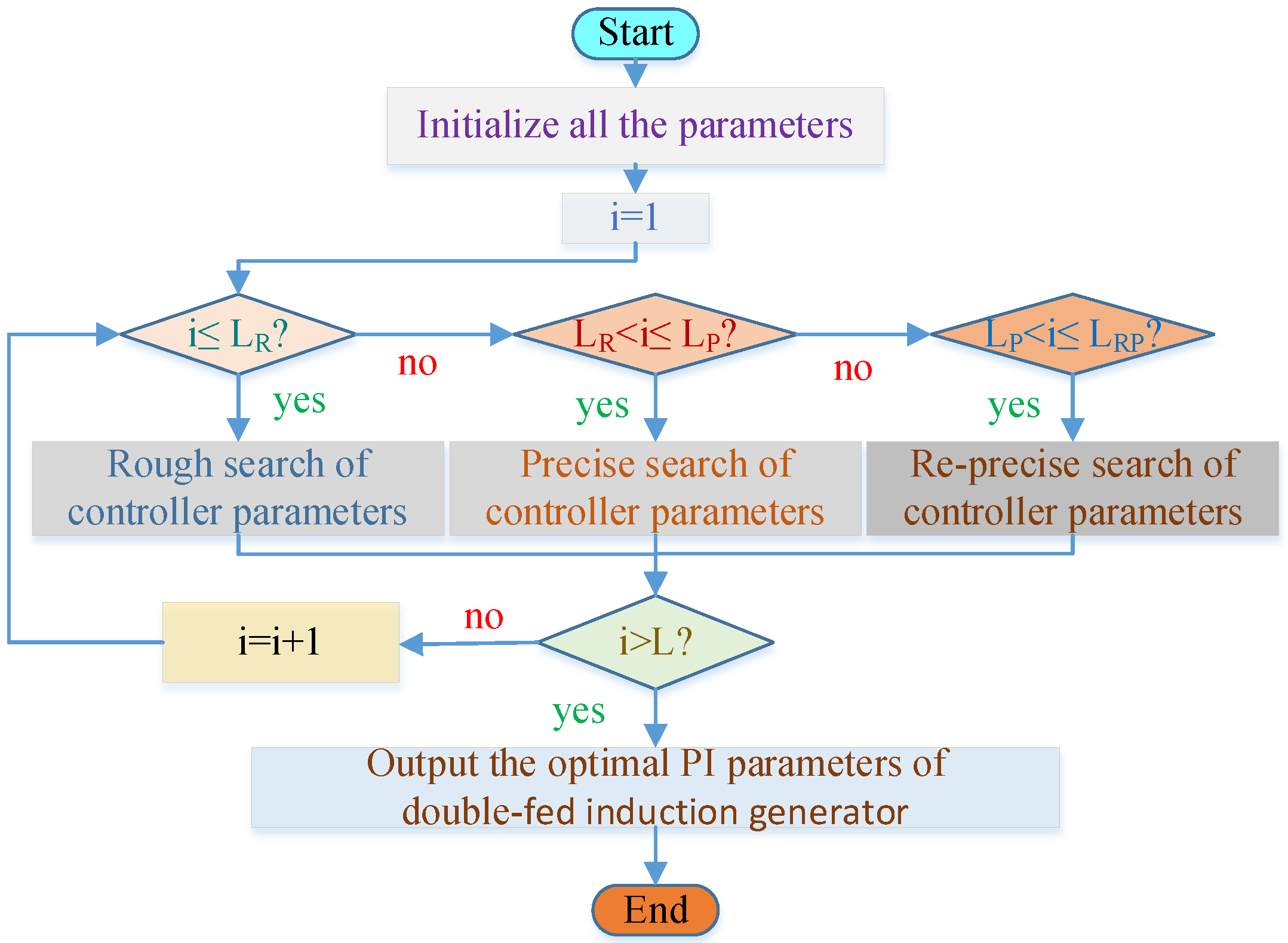

The rough, precise, and re-precise search of PMMCOA is shown in

Figure 1. To facilitate the explanation, a continuous optimization problem is considered. The objective function value

is calculated as

where

is the domain of the variable

, and

represents the spatial dimension.

2.1. Rough Search

The rough search is explained in detail. In

Figure 1, the “area A” indicates the possible areas which are defined by the limit

as

,

.

Step 1: select Monte Carlo random points at random in “area A”. (); where denotes the current layer of the proposed algorithm, ).

Step 2: the adaptation value of

is obtained by combining

and

in

Figure 1.

Step 3: different plausible domains are gained (

by redefining the top and bottom borders around

, where the

is shown in Equation (2);

;

), as shown in “areas B, C, and D”.

Step 4: select Monte Carlo random points at random in “area C” (). The adaptation value of is obtained by combining and .

Step 5: (, where the is shown in Equation (2); ; ).

Step 6: select Monte Carlo random points at random in “area D” ().

Step 7: “area G” is obtained ( by defining the top and bottom bounds around , where the is shown in Equation (2); ; ).

Step 8: select Monte Carlo random points at random.

Step 9: the point which serves as the optimal result of layer ().

Step 10: if , set “region B” in step 3 to equal “region A”.

2.2. Precise Search

Most steps of a precise search are the same as that of a rough search. The precise search has a new definition of the

, as follows.

Most steps of a precise search are the same as that of a rough search. The different steps of the precise search are listed as follows.

Step 1: .

Step 3: Equation (2) transforms into Equation (3); .

Step 5: Equation (2) is converted into Equation (3); .

Step 7: Equation (2) turns into Equation (3); .

Step 10: if , allow “area B” in step 3 to equal “area A”; then, start a new cycle (, where the is shown in (3); ; ). Otherwise, the precise search ends.

2.3. Re-Precise Search

To achieve a more accurate search, two piecewise functions are defined, as shown in

Table 1. The new definitions of the

in the re-precise search are

The parallelism of the PMMCOA can be accomplished by distributing numerous core processing units to the servers. Multiple computers connected in a local area network can realize the PMMCOA parallelism.