Abstract

The use of photovoltaics (PVs) and/or photo-thermal (PTs) as primary solar-energy solutions is limited by the low solar conversion of PVs due to the spectral mismatch between the incident radiation and/or the PV material. The PTs are curtailed by the limited absorbance and the low thermal conductivity of the working fluid. A possible solution is the use of luminophores able to perform luminescent down-shifting (LDS) conversion and to incorporate them in liquid or solid layers, which act as spectral beam splitters (SBSs). Dispersed in solid polymer layers, luminophores lead to luminescent solar concentrators (LSC). When dispersed in liquid and placed in front of PVs, luminophores act as working fluids and as SBS, leading to hybrid photovoltaic–photo-thermal (PVT) systems. Here, the SBS filters for PV and PVT systems are reviewed. The contribution of luminophores to electrical and thermal energy production is discussed from theoretical, experimental, and economical perspectives. Recent SBS architectural concepts which combine different optical elements are also considered. These architectures can harness the advantageous properties of LSCs, spectral modulators, and hybridisation in a single structure. By combining these different light-management strategies inside of a single structure, an improvement in the electrical and/or thermal energy production can be achieved.

1. Introduction

In recent decades, the global energy demand has continuously increased. Unfortunately, this increase was supported mainly by an increased reliance on traditional fossil-fuel-based energy generation, although support for implementing green-energy solutions started to become popular [1,2]. Between 1990 and 2020, the energy consumption increased from 800 to 14,300 millions of tonnes-of-oil equivalent (Mtoe) [3]. Projections indicate that by 2050, the energy demand will increase by two orders of magnitude and, hence, there is a need to develop energy-security measures with minimum damages to the environment [4,5,6]. A study involving 36 nations has shown that there is a strong correlation between a nation’s gross domestic product (GDP) and its energy demands, which are also driven by the pursuit of higher standards of living [7]. Fossil fuels, such as gas and oil, play a significant role in meeting this growing energy demand, primarily due to their extensive international market and well-established infrastructure [8]. The widespread use of cost-effective fossil fuels has also resulted in substantial emissions of carbon dioxide (CO2) into the Earth’s atmosphere, with the rise in fossil-fuel dependency being directly correlated with the rise of CO2 levels in the atmosphere [9]. Numerous studies have established a clear link between carbon emissions, improved quality of life, and economic growth, revealing bidirectional causality between these factors [10,11,12]. Consequently, the unrestricted use of fossil fuels is one of the most pressing concerns that humanity currently faces, with drastic health and environmental effects [13,14,15].

Allowing the general public an economic incentive to use renewable technologies has shown promising results in nations geographically located at higher latitudes where, normally, individuals may be discouraged from implementing solar technologies due to poor irradiance when compared to equatorial nations [16]. The lack of provision of cost-effective means of delivering renewable energy, while also delivering cost-effective deployment strategies to a national grid system, is a tremendous barrier, which hinders the wide adoption of these devices [16,17,18,19].

A popular method for generating renewable energy, which has been widely used and discussed, is the implementation of PV energy systems. Such PV systems are capable of converting sunlight into usable energy though passive conversion methods [20]. These cells are composed of semiconductor materials, with silicon the most commonly used due to its abundance and favourable electrical properties [21].

The use of PV panels is now considered a viable and well-established method of implementing renewable-energy-generation systems within power-generating infrastructures [18,22], but these only recently started to be considered as possible viable alternatives to the fossil-fuel-based energy sources, i.e., to be considered as primary energy sources. This is due to the fact that there are limitations which, ultimately, hinder the wider uptake of these devices. Two severe limitations that influence PV development are related to the spectral management of the incident light and the thermal management of the PV under ambient conditions.

Environmental temperatures can directly influence the efficiencies of solar cells, with studies highlighting that a temperature increase of 1 °C results in efficiency reductions of up to 0.50% [23,24,25,26,27]. In addition to the decrease observed in PV-cell efficiency, elevated device temperatures can give rise to an array of structural and physical flaws within the module [26,28,29,30]. These flaws encompass phenomena such as the discoloration or darkening of the silicon within cells, the delamination of packaging layers, and the formation of heat-induced “hot spots” on the material [28,29,30]. Consequently, addressing these challenges is imperative to prevent an escalation in PVs’ operational costs and to prevent the need for replacement modules. A secondary concern pertains to the subsequent management, specifically the end-of-life processing, of PV cells, resulting in a reduction in the sustainability of solar modules due to difficulties which arise from recycling these devices [31,32,33,34,35].

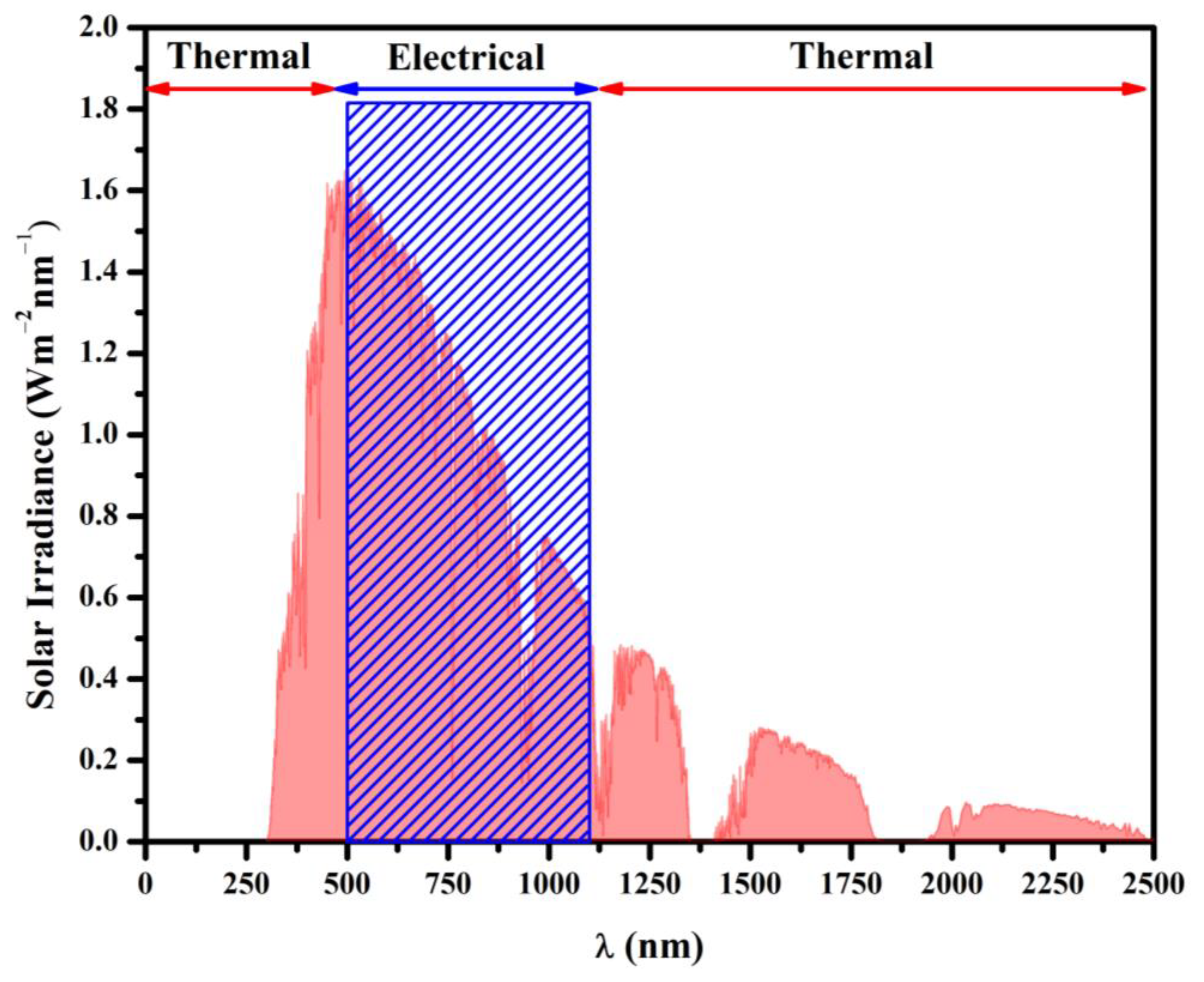

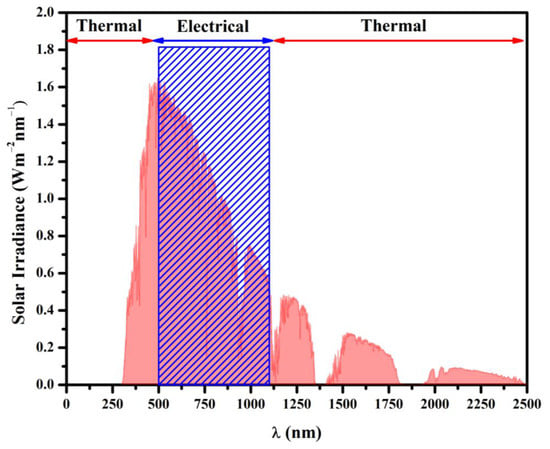

The poor spectral compatibility between a solar cell device and the incident solar spectrum is a limiting factor in electrical energy generation, leading to low specific power (W/kg). Thus, it is a noticeable challenge in the wider implementation of PV devices. A PV device is only capable of capturing energy from a limited segment of the solar spectrum, which it harvests to generate electrical power. This restricted spectral window is ~500 nm–1000 nm for standard monocrystalline silicon (m-Si) cell (Figure 1). This electrical operational window is based on the bandgap energy (Eg) of the PV material in question and, thus, it results in poor electrical conversion efficiencies of 10–25% [36].

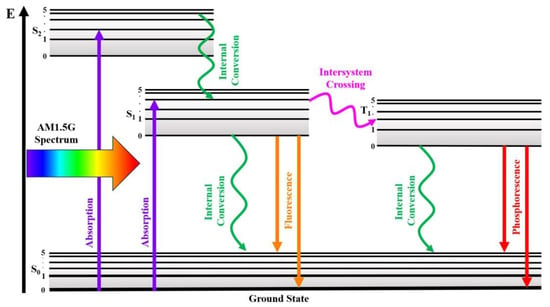

Figure 1.

Typical representation of the AM1.5G spectrum. The regions that contribute to thermal and electrical energy production are highlighted. Thus, traditional unmodulated solar cells are forced to produce energy within this small electrical region; the remaining thermal energy is lost through various mechanisms when a PV system is used.

Therefore, there is a demand to increase the amount of solar energy converted. For PV systems, this can be achieved either by increasing the photons collected in the electrical region or through the development of a hybrid energy system which is capable of harvesting both electrical and thermal energy. The electrical conversion efficiency of the cell can be improved through correct spectral modulation, allowing more useable photons to interact with the device. Thermal energy can be harvested for further downstream processes, but also to reduce the overall operational temperature of the solar cell, resulting in improved overall efficiencies. Finally, by implementing an economically beneficial retrofitting architecture, the sustainability of PV systems can be improved through longer usable operational timelines while being cost-effective.

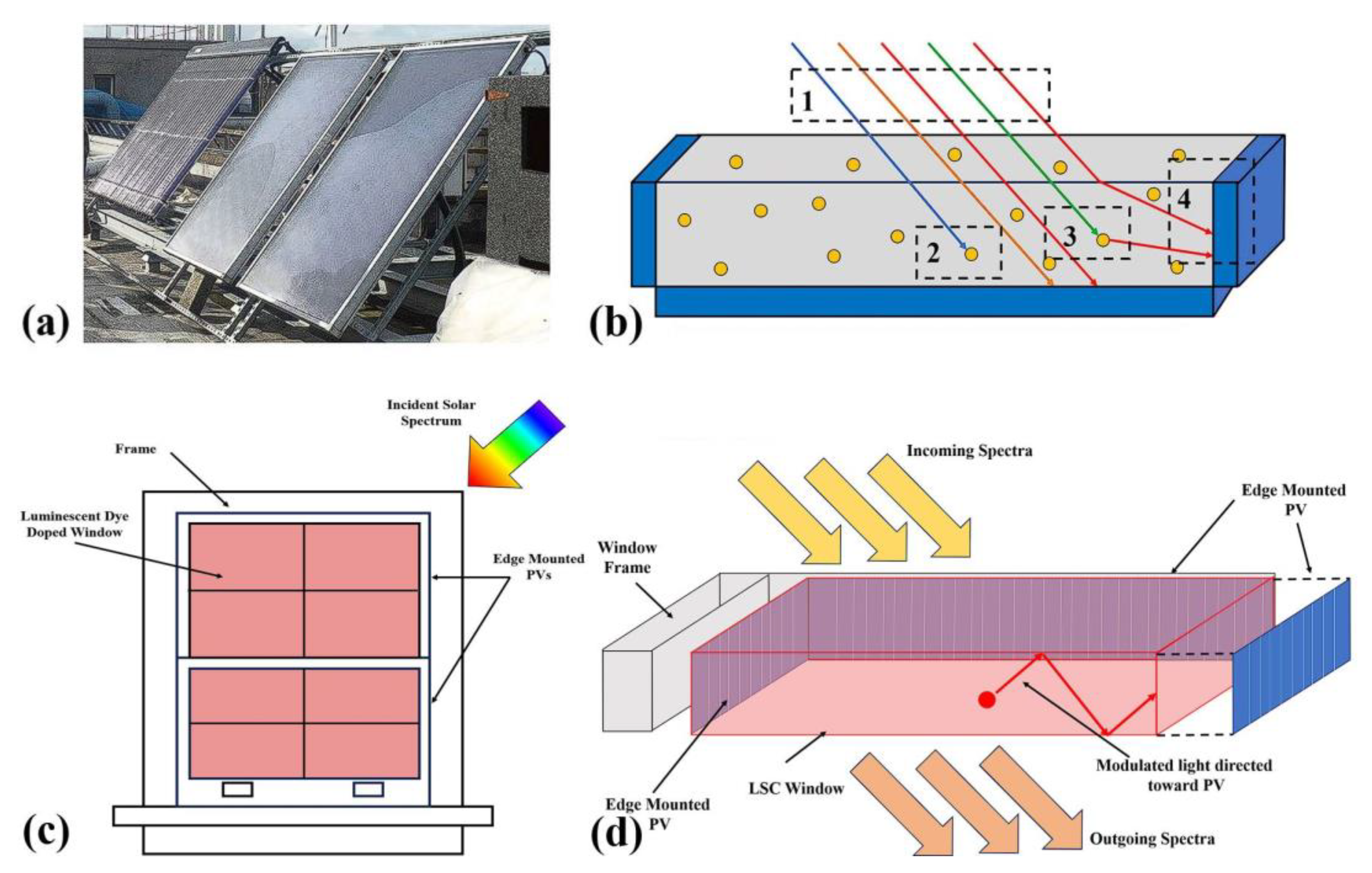

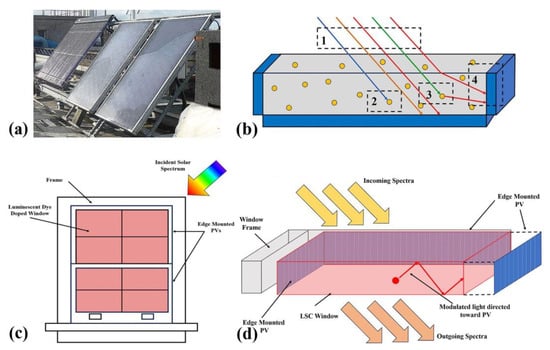

The implementation of a traditional PV-module system is subject to various constraints and limitations, such as the heavy weight (which reduces the specific power), the difficulty in building integration, and geometries [37]. The majority of current technologies use a standard planar-geometry silicon module (Figure 2a). Traditionally, silicon solar panels are fixed to roofs (Figure 2a) and placed in large arrays. This requires strict design limitations with fixed geometries, which can cause issues for designing aesthetically pleasing architectural structures [37,38]. Hence, the demand has arisen for a power-generation system which is capable of providing more control over the geometries and the subtle implementation of solar-energy technologies. The design of a PV system which can fit seamlessly into an aesthetically pleasing building or structure represents is of particular interest as an issue for engineers and architects to overcome [38], leading to the development of the luminescent solar concentrator (LSC).

Figure 2.

(a) Standard implementation of PVs upon the roof of a residential or commercial building. (b) Basic schematic of an LSC device. When the incident light (1) interacts with an LSC (which is traditionally a polymer-based material) various interactions take place. For the light with a wavelength which is within the absorption window of the luminescent species used, an absorption event (2) can take place. Luminescent events (3) can take place, emitting light with a wavelength suitable for conversion into electricity by the PV. (4) The primary benefit of the LSC device is that the edges of the device are composed of either PV cells or mirrors (blue) to increase the amount of captured light. These cells and/or mirrors are placed on the bottom and/or edges of the LSC device, as shown (c) A schematic of a “Smart Window” LSC configuration. In this configuration, a tinted window based on the luminophore species is used to modulate the incident light towards frame-mounted solar panels. (d) The locations of PVs within the frame and the directionality of the modulated light towards the PV are presented. The PVs, which are mounted on the edges of the window, encapsulated within the window frame, are also shown in their attachment points along the edges of the design.

2. Luminescent Solar Concentrators

The fundamental function of these LSC devices is to concentrate a large area of incident light and focus it onto a smaller PV area through passive means [39]. The employment of a passive method of concentrating light toward a PV in a light-trapping medium removes the need for techniques such as direct sun-tracking rotors or large dish-shaped concentrating mirrors, thus reducing the overall cost of the device in question [40,41]. Such designs allow multiple PVs to be situated on the edges of the medium to encourage more energy conversion from captured light (Figure 2b). These LSC devices can also operate in both diffuse and direct light; thus, they increase solar-energy collection and conversion [42,43]. The concept of developing a ‘light-trapping medium through which spectral conversion can take place via luminescence was first reported by Weber and Lambe in 1976 [44]. Their design considered a planar host material with dispersed luminescent species embedded, with a semiconductor photocell at one edge. Opposite the PV, a mirror surface was placed [44]. One year later Goetzberger and Greube undertook a study which explored this concept in more depth, highlighting the possibility of incorporating layers of transparent luminescent doped materials to produce higher efficiencies and more complex designs [45].

The basic design of an LSC (Figure 2b) allows sunlight to be incident upon the top surface of its (polymer or glass) host material’s waveguide. This light (usually of lower wavelengths then the spectral window in which the PV is most efficient) is absorbed by the luminescent materials which are embedded within the waveguide. This embedding can be undertaken in various ways, such that they can be applied in a surface layer, on a side of the waveguide, or contained within a liquid solution between two transparent layers. The absorbed light is then re-emitted at a longer wavelength in the spectral window of the PV, while a fraction of the re-emitted light is trapped in the waveguide by total internal reflection, becoming concentrated along the edges of the plate. Small PV cells can then be attached to the edges of the waveguide to harness this light and convert it to electricity (Figure 2b).

A full-scale development involving the use of LSC devices is the Smart Window (Figure 2c), which has the advantage of producing energy while being aesthetically tailored to the specifications or preferences of the designer for future incorporation into various architectural structures, as the PVs, which are located at the edges of the LSC, are encapsulated within the window frame (Figure 2d) [46]. The LSCs can be tinted a variety of colours through the use of fluorescent dyes, which can be dispersed within the encapsulation layer [47,48,49,50,51]. Encouraging aesthetic possibilities were produced by Aghaei et al., who produced 19 different mosaic configurations with a wide range of colours [51]. This process provides a few benefits, the first of which is the aesthetic feature of selecting a colour which can appeal to commercial markets [48,52,53]. The second benefit is the provision of a spectral-shift response to increase the wavelength range over which the solar cell can harvest photons [48,54]. Another major benefit of LSCs is the potential to provide a low levelised cost of energy (LCOE) due to the low costs which are associated with the fabrication of these devices. This is thoroughly outlined by Currie et al., with reports indicating an LCOE of approximately EUR 0.2–EUR 0.3/kWh [52,55,56]. An LSC device is not bounded to the fixed planar geometries of traditional designs, as novel geometries can be produced. This allows LSCs to be incorporated within a larger number of geographical areas, such as high-density urban ZNES, where large-scale PV arrays cannot be placed.

The fundamental operation of the LSC device is thoroughly evaluated through a series of parameters which relate to its geometric design, power output, and optical efficiencies. The first of these parameters is the “geometric gain” (Gg) of the device [57,58,59,60,61,62]. This gain is given as the ratio of the top surface-device area (Asurface) with respect to the area along the edges, as described by Equation (1);

Following the geometric gain of the device, it is important to understand the optical efficiency (OE), which represents the overall ratio of the output energy () to the power input into the system (), which represents the AM1.5G spectrum from any wavelength range from λmin to λmax [61]

The concentration of photons (Cp) within the system is, then, the product of the geometric gain (Equation (1)) and the optical efficiency (Equation (2)) [61]

and the total solar concentration ratio (C) is defined as [61]

where EQE(λ) is the external quantum efficiency of the PV solar cell in question. The total solar-concentration ratio is thus the measurement of an LSC device’s ability to concentrate photons towards the edges of the LSC through a spectrally modulating material over a specific wavelength region.

The electrical characteristics of the LSC device can be obtained via the device’s power-conversion efficiencies (PCEs) [61]

where the is the open-circuit voltage, is the short-circuit current density, is the fill factor, and is the total power density of the incident solar radiation [61,63].

Batchelder et al. conducted a thorough analysis of organic dyes within planar LSC devices fabricated with PMMA [64]. Their study provided a comprehensive outline of the operations of the planar LSC devices, and it highlighted the stability of the organic dye investigated, with the results showing that 50% degradation was found after 2400 h within the PMMA. Building upon these works, the successful fabrication and operation of a single-layer LSC device was first confirmed under experimental conditions by Heilder in 1981 [65]. While Heilder’s results highlight optical and electrical efficiencies of 75% and 9% respectively, they laid the important groundwork upon which future experiments would build. Realising the multilayer luminescent doped design of Goetzberger and Gruebe, Drake et al. were able to provide experimental data which confirmed its success in 1982 [66].

Current LSC research is focused on investigating pathways through which to integrate these devices into the construction industry to produce building-integrated LSCs [52,67,68]. The unique properties of LSC fabrication, which allow them to be tailored to specific colours, makes them very desirable for architects who are attempting to incorporate aesthetics and functionality into their designs. The so-called ‘Smart Window’ has been thoroughly investigated by Aste et al. [48,53,68]. These studies investigated the use of various organic dyes within a planar-slab LSC, which was surrounded on each edge by silicon solar cells (Figure 2d). The use of these organic dyes allowed the window to take on different colours as an added aesthetic benefit. These window designs were tested by Vossen et al. for use within an office space [69]. The report produced by Vossen et al. primarily targeted the appeal of these windows to the general public as an aesthetic choice rather than efficiency [69]. Recently, Makaraov et al. investigated reductions in loss mechanisms and practical factors for these LSC windows to encourage commercial uptake, with PCE values of 4.4%, based on National Renewable Energy Laboratory (NREL)-certified performances [46]. Aghaei et al. reported PCE values as high as 11.6% based on a Coumarin compound in a cubic configuration [51]. The experiments provided positive results for the wider adoption of these devices should they reach the market in a large volume.

3. Spectral Management of PV Systems

As mentioned above, the loss mechanisms relating to the spectral management of a PV system are related to the limited spectral response from the solar-cell material [36]. These losses occur, along with other issues, from two main sources: (a) sub-bandgap (Eg) photons (E < Eg), which are unable to be absorbed by the semiconductor material, and (b) the excess energy from high-energy photons (E > Eg), which are dissipated through the non-radiative relaxation of excited electrons to the conduction band. This results in the generation of heat. One method of managing the short wavelength is to engineer the electronic properties of a solar device [70,71,72]. The major drawback of these modulations is the extensive relative cost and expertise required to implement the changes [73,74].

Another option is to use luminescent species, which are known to absorb photons of particular wavelengths and emit them at longer wavelengths matching the bandgap energy of the solar-cell material, i.e., in the spectral region where the PV has its highest efficiency. This spectral shifting procedure [36,75,76,77,78] is known as luminescent downshifting (LDS). The research within the area of LDS is a growing field for PV applications [36,76,78,79,80,81], but upshifting (i.e., absorption at higher wavelengths and emission at lower wavelengths) is also possible [82,83].

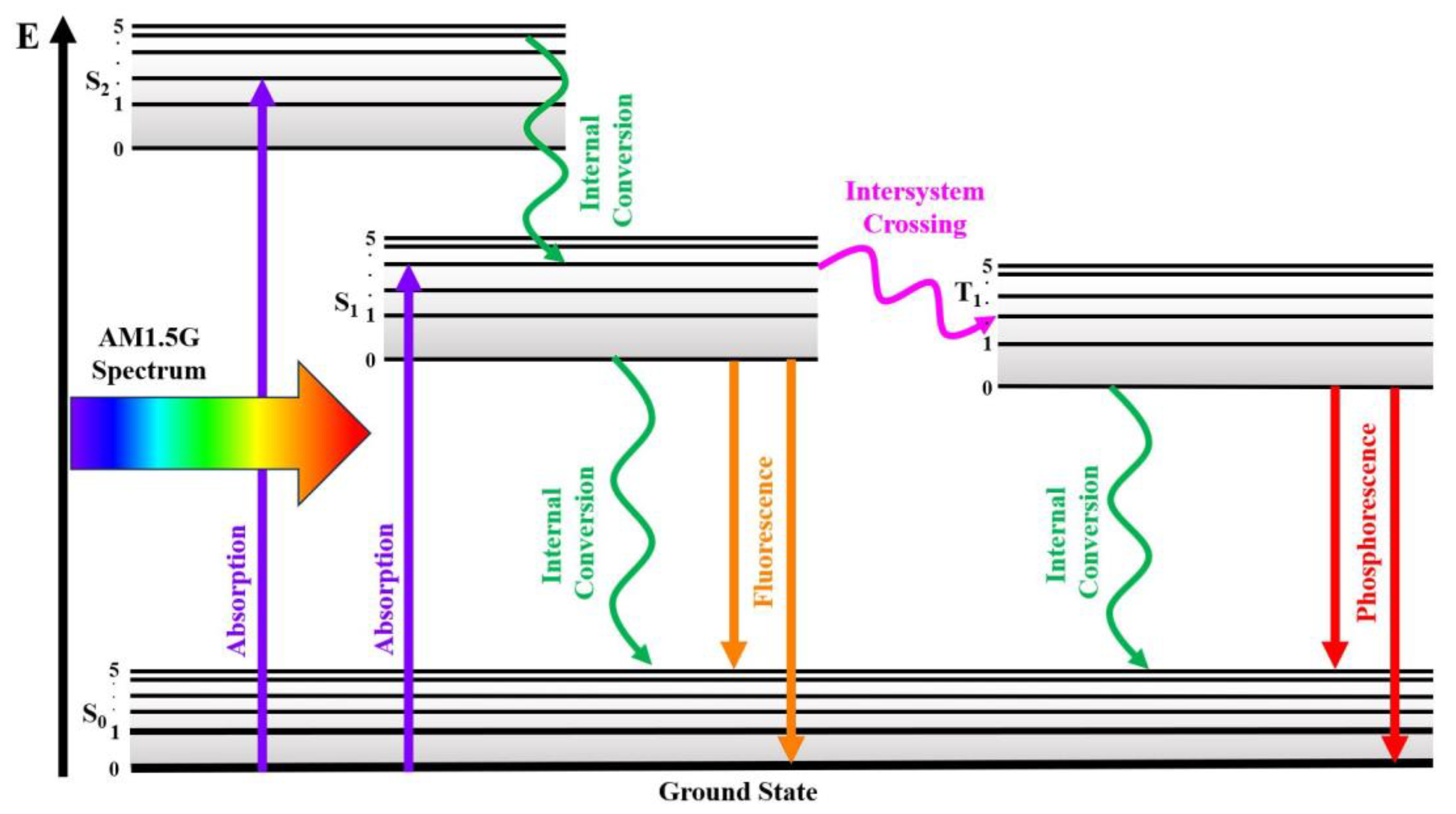

The luminescent species’ presence within PV devices is fundamental to LDS operation as they are responsible for the absorption and reemission of the photons. These species are placed in a host material, which can act as a waveguide [36]. The absorption of a photon with a suitable wavelength promotes a ground-state electron to one of the higher vibrational levels of the electronic state [84,85,86]. The relaxation of the process back to its ground state leads to the emission of photons with higher wavelengths, as outlined in the Jablonski diagram (Figure 3).

Figure 3.

Jablonski diagram, which shows the pathways for photon generation with higher wavelengths within a luminescent material [84,85,86].

To design an LDS layer, a comprehensive criterion was listed by Huang et al. [87]. Thus, careful consideration should be given to the solar-cell spectral window. A matching luminophore should have a wide absorption band within the region of the poor spectral response of the solar cell. The luminophore should also possess a high absorption coefficient, along with a high luminescent quantum efficiency [87]. Luminophores with this property ensure that all incident light undergoes emission events, enhancing the overall power-conversion efficiency. Once emission events have occurred, it should be ensured that the range of emission is as narrow as possible [88]. Re-emitted photons should have a narrowband emission peak within the region of high spectral response (also known as the spectral window) of the device. The luminophore should also possess a large Stokes shift (the difference in maxima between the absorption and emission bands of the luminophore). An inadequate Stokes shift can lead to the reabsorption of re-emitted photons, resulting in an overall efficiency loss within the device [87,88].

A popular method through which to attempt to create a spectrally shifting device involves the incorporation of either organic dyes or quantum dots (QDs) within the transparent polymer matrix that forms the structure of the LSC device [54,89,90,91,92]. Other alternative methods of introducing a form of spectral modulation can be achieved through rare-earth ions, as was well reviewed in [93,94]. The major benefits of introducing such materials are their good photostability, high absorption coefficient, and significant Stokes shift [95,96,97,98,99].

Organic dyes are popular luminescent species for use within LSC applications [76,77,100,101]. They offer a range of advantages over other species (e.g., quantum dots) due to their relatively high absorption coefficients and high luminescent quantum yields [79,102]. Aesthetically, the selection of an organic dye for such spectral modulation applications also provides users with a myriad of colours to develop their devices [47,103,104]. The shortcomings of organic dyes include their narrow absorption bands; hence, they require careful selection based on the other components used. These narrow absorption bands can result in these dyes possessing small Stokes shifts, which results in re-absorption losses, as the emissions and absorption bands overlap [88].

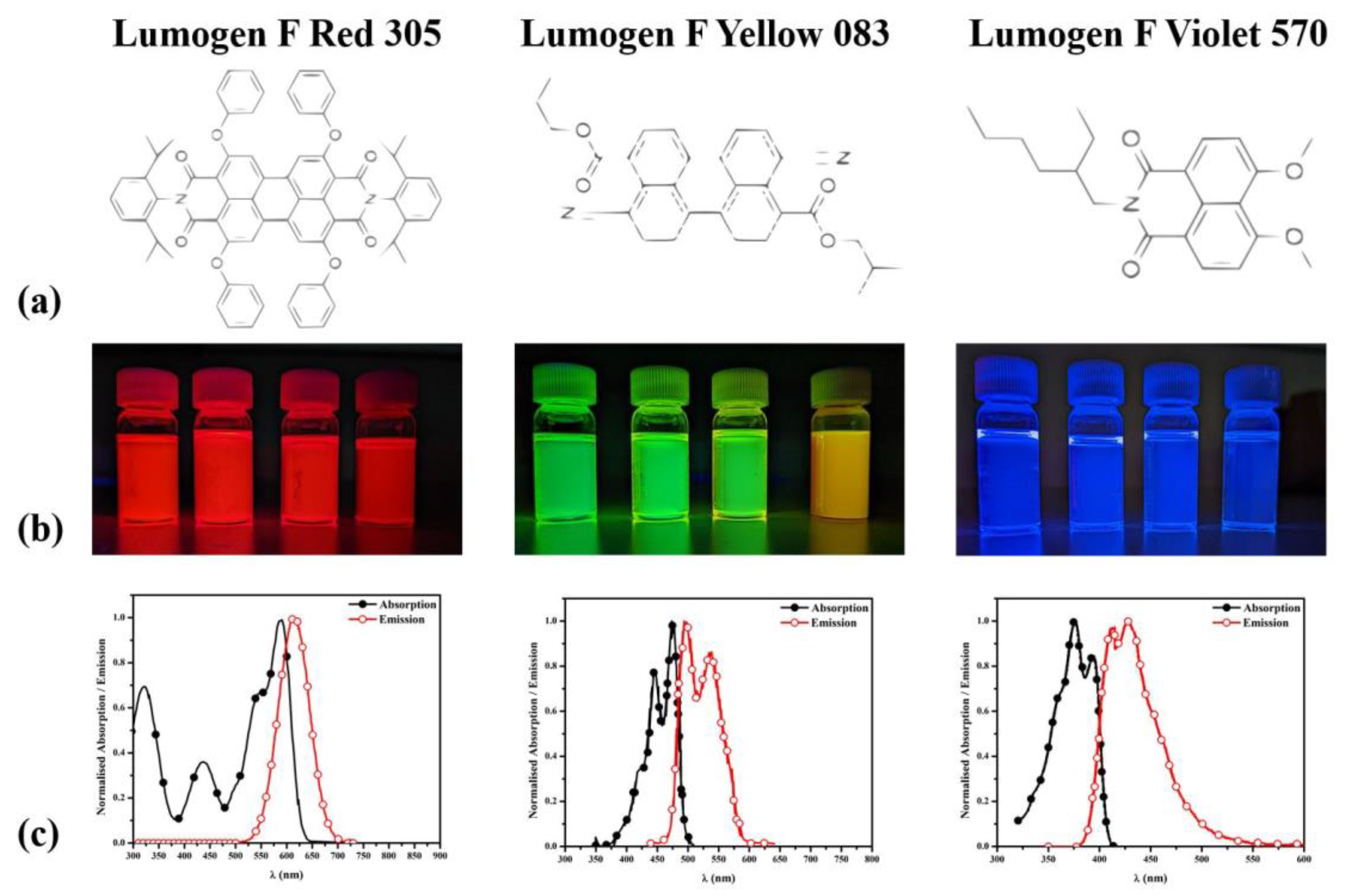

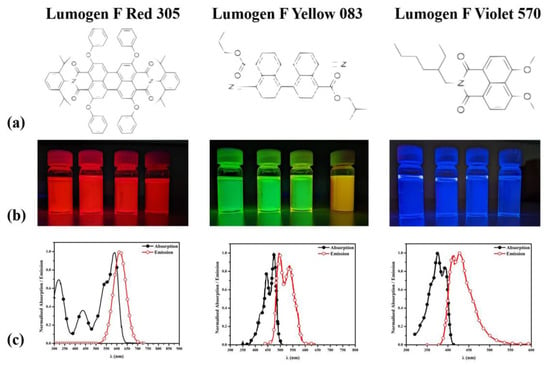

A popular dye family used within LSC devices is the perylene-based Lumogen Dye series (Figure 4). These dyes are based on naphtalimides, perylenes, and courmarin chemical architectures [51,105,106,107]. The absorption of these dyes ranges from 377 nm to 520 nm, with emissions from 411 nm to 61 3 nm, and with high quantum yields [39,93]. Hence, incorporating these dyes into LSC devices allows adequate spectral shifting. The production of organic dyes which have large Stokes shifts counters the narrow absorbance band of these dyes, with the aim of reducing losses through re-absorption. The major benefit of using organic dyes (either commercial or synthesised) is the ease with which they are incorporated within the host matrix of the LSC. A popular method for fabricating LSC devices is to disperse the organic dye throughout a polymer material, such as PMMA, EVA, or PDMS [51,68,107,108,109,110,111].

Figure 4.

(a) Molecular structure of three popular organic dye species, Lumogen F Red 305, Lumogen F Yellow 083, and Lumogen F Violet 570. (b) Photographs of these luminophore species dispersed in liquid samples at different concentrations and (c) normalised absorption and emission spectra of the three Lumogen dye species.

An important consideration when implementing organic dyes for LSC applications is related to their photostability. Griffini et al. tested the photodegradation of a perylene-based organic dye dispersed within a PMMA matrix [92]. Their studies revealed drastic reductions in the absorbance and fluorescence emissions of this dye over a 5-hour period, during which the device was subjected to UV radiation. The absorbance values in this experiment dropped by 70% over this 5-hour period, with the most intense fall seen after 1 h (i.e., a 30% reduction). However, while these results are drastic, the study attempted to model degradation pathways for these molecules and, hence, no encapsulation layer was used [92]. An analysis of the actual outdoor testing of LSC devices with organic dyes was conducted by Delgado-Sanchez [110], who monitored the long-term outdoor photodegradation of a PMMA planar waveguide, which was used alongside the Lumogen F Red 305 (LFR305) perylene dye. The fabrication of this LSC was undertaken by mimicking a ‘Smart Window’ and testing its viability for commercial purposes. The LSC device was left outdoors (in Seville, Spain) for a period of 4 months. In total, 40 samples were developed, with 10 samples recovered every month to monitor the degradation over time. These samples were compared to a control sample. Aesthetically, the devices showed signs of surface defects, such as the bubbling and shrinking of the luminescent coating. However, these defects were explained as inefficient procedures in the lamination and fabrication stages. No degradation was detected for the organic compounds used within these tests (i.e., no emission-peak shifting for the dye, and no secondary photoemission spectra) [110]. Hence, improvements in the fabrication processes used for these devices could allow them to be manufactured in a configuration that permits their integration within buildings and/or other architectural structures.

Despite the many advantageous optical characteristics exhibited by organic dyes when employed in simple LDS or LSC structures, the overall contribution of these structures to the energy-harvesting efficiency of the underlying PV has been marginal in most cases [112]. This is primarily due to the reduction in the light-trapping efficiency of the structure (LDS or LSC), which results from the combination of the omnidirectional nature of the emission process, surface-reflection losses, and re-absorption losses [112]. In an attempt to address and overcome these loss mechanisms, a number of different photon-management strategies have begun to be collectively implemented into the architectures of organic-dye-based LDS and LSC devices.

These strategies include the addition of antireflection coatings (ARC), which are designed to either reduce the reflection losses arising at the front surface of the device or act as band-stop filters, which enhance the control over the propagation of the luminescent photons inside the host matrix. For instance, Walshe et al. demonstrated that the integration of a single-layer ARC into a PMMA-based LDS-PV device can enhance its light-trapping efficiency by as much as 22.5% [113]. In a PMMA-based luminescent structure that possesses a refractive index of ~1.5, the omnidirectional nature of the emission process results in as much as 26% of the luminescent irradiance becoming lost to the surrounding environment in the form of what is known as “escape cone losses” [114]. However, through the utilisation of multilayered ARCs, known as distributed Bragg reflectors (DBRs), this loss pathway can be addressed due to DBRs simultaneously exhibiting high transmission for photons within the luminophore absorption band and high reflectivity for photons within the luminophore-emission band. For example, the work of Goldschmidt et al. demonstrated how the addition of a DBR consisting of alternating layers of SiO2 and SnO2 nanoparticles on top of an organic-dye-based LSC resulted in a device that produced 3.7 times more energy than a pristine standalone solar cell [115].

Another type of photon-management strategy that has shown promise in its ability to overcome the non-ideal optical properties of the luminescent materials available is plasmon-enhanced luminescence. In this strategy, metal nanoparticles of various shapes and sizes are dispersed into the host matrix of the luminescent structure to both modulate the interaction of the solar irradiance with the luminophore and/or modify the physical properties of the encapsulating layer which covers and protects the PV. For example, Sethi et al. demonstrated how the implementation of gold-core silver-shell nanoparticles into an LSC device that contained the luminophore LFR305 increased the power-conversion efficiency of the device by 20% compared to an LSC lacking these nanoparticles [116]. In addition to offering a method for enhancing the emission intensity of the selected luminophore, the inclusion of metal nanoparticles into the host material has demonstrated a plethora of complementary benefits for LDS and LSC applications. These include, among others, the prolongation of the photostability of the luminophore and control over the directionality of the downshifted irradiance [117,118].

An alternative to the use of dyes is the use of quantum dots (QD). The main advantage of using QDs for LSC applications over organic luminescent species is the wider absorption spectra of the QDs, which include parts of the UV region of the solar spectrum. This allows a larger quantity of photons to be absorbed and then re-emitted for energy conversion within the solar cell. The use of a commercial organic dye (e.g., the popular Lumogen F Red 305) results in a fixed absorption peak, under which the material absorbs the largest quantity of photons. The use of QDs subverts this limitation because they possess the ability to alter their absorption bands within certain limits by altering the size of the nanocrystal [119]. Whilst work has been undertaken to reduce the reabsorption losses (linked to the use of organic dyes through the extension of the Stokes shifts of these dyes), with QDs, this is not necessary, as QDs have much larger shifts compared to these dyes [120]. Li et al. conducted experiments with CuInS/ZnS QDs within a concentrating PMMA device using a commercial c-Si solar cell [120]. The control LSC device consisted of pure PMMA and the solar cell and power-conversion efficiencies of 2.73% were measured. However, by incorporating the QDs within the polymer matrix, the efficiency was raised to 8.71% [120]. Similar results were reported by Zhou et al., who developed high-efficiency LSCs using varying PbS/CdS-sized QDs and reported an efficiency of 6.1%, which demonstrates the benefit of high controllability through the use of QDs [119].

A widely explored QD for luminescent applications is lead sulphide (PbS) [121,122,123,124], which possesses a strong and wide absorption band extending to the infra-red region of the solar spectrum, along with a large Stokes shift of 122 nm [125]. The use of PbS as a viable QD within LSC devices was questioned by Scherbatyuk et al. [126]. This was due to the extinction coefficient of PbS being 2 × 104 L mol−1 cm−1, while the CdSe/ZnS is 3 × 105 L mol−1 cm−1. While the concentration required is higher, the wavelength spectral range over which PbS absorbs and emits is larger than that of CdSe/ZnS, and this results in higher efficiencies [126]. Recent studies have attempted to divert from the use of toxic heavy metals, such as Cd and Pb, in favour of more environmentally friendly materials. Environmentally friendly LSC designs which incorporate nontoxic materials, such as carbon, non-toxic metals, or silicon QDs, have been explored with encouraging results [127,128,129,130].

4. LSC Geometries

Traditional solar-energy-generating systems are composed upon a flat planar surface. This geometry can become a limiting factor when attempting to integrate these structures into existing buildings or locations. Whilst research into LSC ‘Smart Window’ devices poses new applications for passive-energy-generating systems with novel integration strategies, they still conform to this traditional (planar) geometry. Modern research within the space of LSCs is pushing the boundaries of the various geometries of devices that can be produced, such as a bio-inspired leaf design [131,132]. The leaf, designed by Huang et al. was designed to mimic a natural leaf and provide passive cooling through channels within the device. Encouraging reports indicate PCE of up to 15% [131]. McIntosh et al. first explored a theoretical comparison using ray-tracing models between the traditional planar geometry and cylindrically shaped LSC devices in 2007 [133]. Their analysis included a wide range of parameters across both geometries, such as external reflection, escape-cone losses, and host absorption and concentration. The results of their simulation study show that the cylindrically doped LSC waveguide was capable of providing an increase in power conversion that was ~1.2–1.5 times higher than with the undoped cylindrical LSC. The optical conversion results in the study agree with the theoretical values produced by McIntosh, with an increase in optical conversion that was 1.9 times greater than that with traditional planar geometries [133,134].

However, McIntosh et al. highlight that, within their model, cylindrical LSCs experience a higher absorption rate than traditional geometries (which can lead to a higher rate of losses from the device through re-absorption losses within the host material). The theoretical evaluations performed by McIntosh et al. were validated and optimised for real-world applications in the study performed by Wang et al. in 2010 [135]. In their study Wang et al. fabricated an optical fibre geometry, which was doped with organic dyes as a means of providing spectral shift and tinting to the fibre. These devices were tested under real-world conditions, as they were placed atop a building in Kuala Lumpur, yet no power-conversion efficiencies were reported. The fibres in this study were 2 mm in diameter. In their recommendations, the authors state that larger-diameter fibres (~10 mm) can result in optimal performances. Inman et al. [124] produced a cylindrical LSC design which was doped with QDs, as a means of investigating the proposed enhancements from curved surfaces proposed by McIntosh [133]. From this experiment, hollow and solid cylindrical LSCs were fabricated and tested for characteristics such as photostability and photocurrent yields in laboratory conditions. The results of this experiment revealed that the hollow cylindrical LSC had a higher absorption of incident photons, with lower reabsorption, when compared to the solid cylindrical and flat planar samples, with the hollow structure absorbing ~20–30% more. These results indicate that the cylindrical model could be more widely adopted, leading to the investigation of more novel structures investigated.

Banaei et al. evaluated more practical aspects of optical fibre waveguides, investigating the addition of external cladding [136]. Incident light would be concentrated by the external cladding and become trapped within the doped-optical-fibre LSC’s core which would guide the photons to a perpendicular PV cell, a deviation from Wang et al.’s study, which investigated a concentration on a plate. The cladding architectures within Banaei et al.’s study consisted of rectangular, cylindrical, and rectangular-with-cylindrical-lens caps, in a novel approach. The results of these simulations highlight that optical fibre geometry is superior to traditional planar geometries across all the tested variables [136]. The optical efficiency of these fibres was 2–5% larger than that of flat-plate LSCs, with the photon concentration increasing up to 33%. Mateen et al. provided improvements to an LSC device by incorporating cylindrical optical fibres beneath an LSC plate to aid in directing light to a PV cell [137]. Their results indicate that by including the optical fibres and a white scattering plate, an increase in PCE of ~65% compared with an LSC with a black absorbing layer was achieved [137]. Similarly, Jakubowski et al. investigated melt-spun polymers as a method of producing low-cost LSCs, highlighting the cost-effectiveness of the solution by enhancing the illumination-angle-dependence of solar cells [138]. Optimising this design would require improvements to the geometric gain of the LSC to fit a smaller form-factor solar cell, thus reducing the overall costs of fabrication.

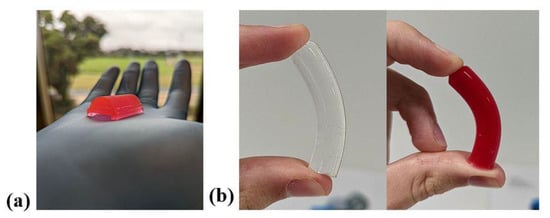

A Further investigation into the novel use of unique LSC geometries for commercial applications was conducted by Vishwanathan et al., who provided a comparison study between a square-planar-geometry LSC and a flexible curved LSC for streetlights [58]. The application of these LSCs would allow them to be mounted in a square planar design or wrapped around standard streetlights (flexible design) as a means of providing widespread passive energy generation for a region. The fabrication of these LSCs would imply the use of LFR305 as a luminophore dispersed within a PMMA matrix. To develop the ‘bent’ geometry, a polyethylene terephthalate (PET) backplate was bent with strips of the LSC PMMA waveguide attached [58]. This allowed a flexible structure that would not damage the PMMA by causing breaks or cracks. The results of this study show that the flexible LSC design was capable of achieving electrical conversion efficiencies of up to 3.4% compared to the 2.8% provided by the flat-plate structure. Vishwanathan et al. note that the flexible structure was not hindered by high angular-dependence sensitivity and, hence, that it would be capable of performing well on sunny and cloudy days. Therefore, such designs can be of interest for a large number of higher-latitude regions, such as the nations within the European Union, and benefit nations attempting to adhere to EU regulations regarding higher levels of renewable-energy generation. Advancements in comparative studies involving cylindrical optical fibres were conducted by Mateen et al. [137]. The developed LSC design had an LSC layer atop an array of cylindrical optical fibres and a white scattering layer. The design allowed incoming photons to pass through a luminophore-doped layer past an optical fibre and, finally, to interact with a reflective layer. Hence, the probability of photons’ re-absorption was minimised, as the photons were directed to the optical fibre after undergoing an emission event, and they were redirected to the solar cell at the edge of the LSC. This design provided some success with power-efficiency, ratings for this design reaching 0.91%. Within this study, the optical fibre was used as a method of transporting emitted photons to the edges of the waveguide. It was not used as a means of concentrating light onto the surface of the luminophore doped layer. A further novel architecture for LSC designs was explored by Gajic et al. who developed a circular-disk-shaped LSC [139] using a different polymer host, namely PDMS. The generation of a series of novel polymer-based luminescent doped structures which can be retrofitted atop an existing operational solar cell can produce a wide range of opportunities for further exploration. In particular, the use of PDMS allows the development of a method for fabricating a series of curved surfaces (Figure 5a) and flexible cylinders (Figure 5b), which can be implemented in a large array of architectures and designs for seamless integration with operational PVs. Such designs can be used as concentrators to direct incident light towards a PV cell for higher solar-conversion efficiencies and can even be used in combination with luminescent dyes for architectural design integration and aesthetics (Figure 5b) [49,52,67]. Carbone et al. assessed the viability of a flexible PDMS disk for use in LSC applications [107]. This work highlighted the bend-angle performance of such a device and characterised the PCE of the device over various bent configurations.

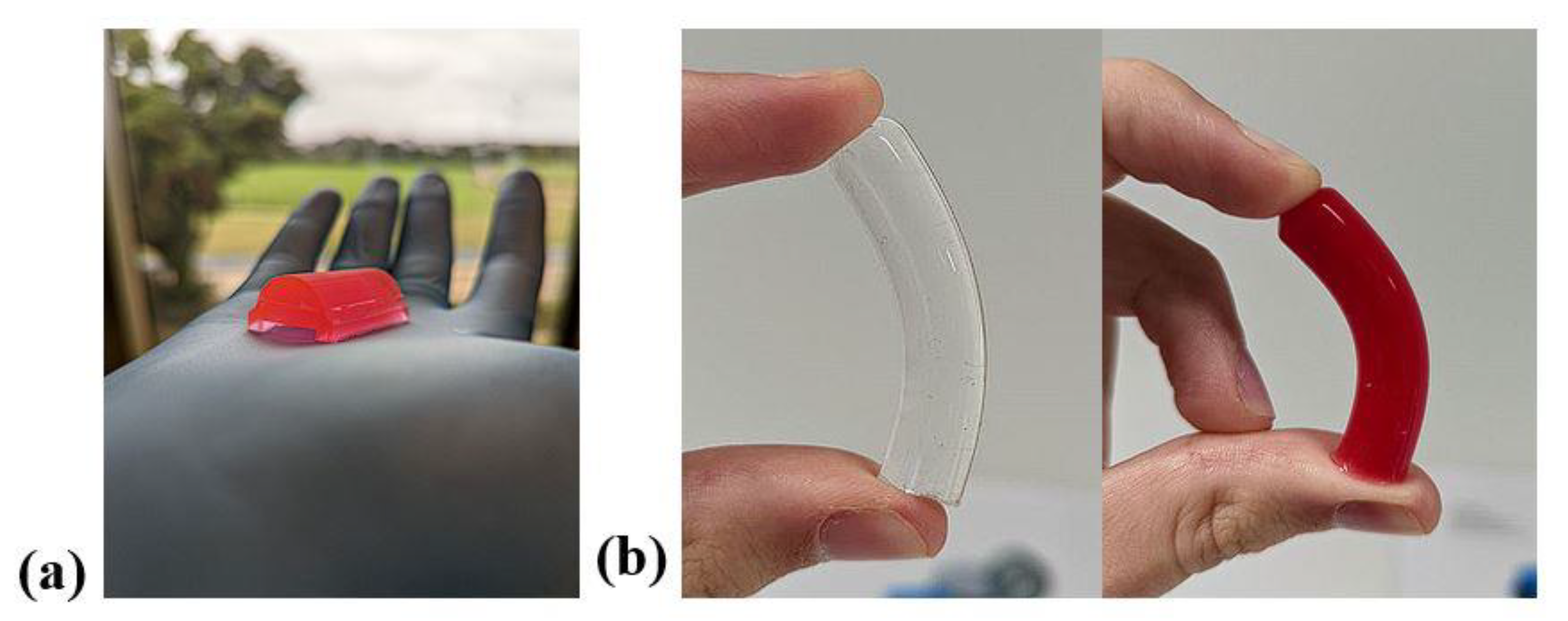

Figure 5.

Examples of a variety of novel and flexible LSC geometries, which can be fabricated using flexible polymers (in this case, PDMS). (a) A dome-shaped LSC PDMS design doped with LFR305 to sit atop a solar cell and (b) designs based on flexible cylindrical PDMS LSC, both undoped and doped, with LFR305 for light trapping.

5. Hybrid Photovoltaic–Thermal Devices

Solar-energy generation is a good method to offset the carbon emissions used to produce electrical energy. The LSC and LDS methods are techniques that make it possible to combat the spectral-mismatch losses which occur in solar devices to improve PCE. As mentioned earlier in this text, thermal losses are important limitations which also need to be addressed. Reductions in increases in operational temperatures can lead to better overall efficiencies in PV systems, as they can operate in optimal conditions. This leads to efficiencies closer to their designed values and longer lifetimes. Therefore, the ability to mitigate and control temperature rises is highly beneficial. One way to achieve this is to extract heat from the system and use it in heating applications (e.g., hot water for homes, green houses etc.) [140]. This is an important consideration, since the electric energy market does not encompass the entire energy demand. Coupled with the demand for electricity, there is also demand for heating systems, whose use could also allow the decarbonisation by limiting the use of the traditional methods based on fossil fuels [141,142,143,144,145]. The provision of heating and cooling to buildings and industrial sectors within Europe accounts for 47% of the total energy consumption [145]. This led the Renewable Energy Sources Directive (RED) to implement a target which aims to achieve renewable energy uptake of 32% within the EU, with 40% of this target devoted solely to the heating-and-cooling sector [146].

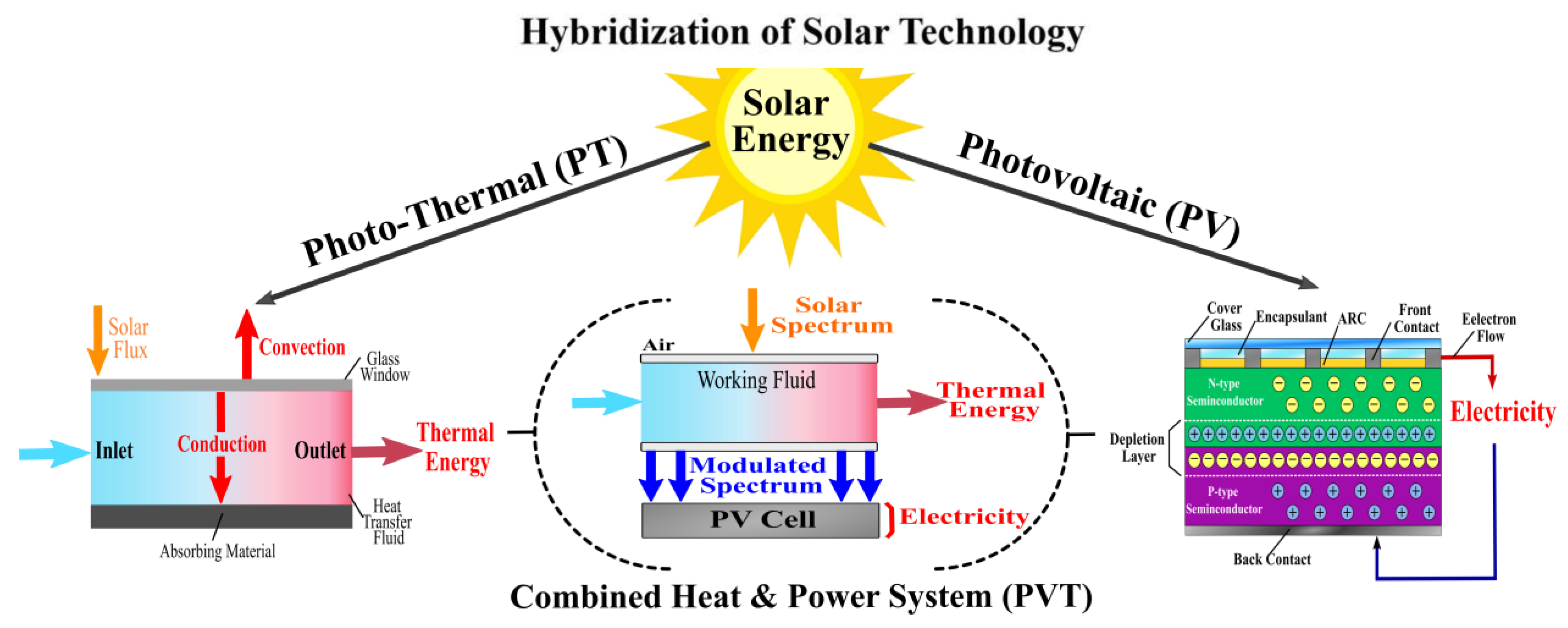

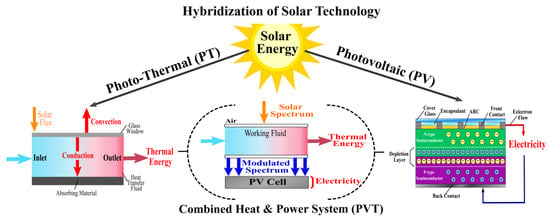

Whilst traditional solar energy is extracted as electrical output via PV cells (Figure 6 right), a photothermal device (Figure 6 left) is capable of converting incoming sunlight into usable heat energy. Photothermal (PT) systems are capable of harvesting thermal energy from incident solar radiation by directing the incident light onto a working fluid which flows through typically a piped channel. Standard configurations of these systems are flat-plate collectors [147,148,149], evacuated tube collectors [150,151,152], and even a parabolic dish-collector system [153,154]. Common working fluids which have been investigated for the purposes of PT systems include water, oils, glycols, and nanofluids [75,155,156,157,158,159,160,161,162,163,164,165].

Figure 6.

Fundamental working principle of a hybrid photovoltaic photothermal (PVT) coupled system. This can produce energy via electrical energy generation from the traditional PV system (right) and also allows the production of thermal energy from the PT (left) component through the use of a fluorescent working fluid. This working fluid has the operational role of reducing the overall temperature which is seen upon the PV, and it is capable of being doped with a luminescent species to provide spectral modulation through spectral matching to increase the efficiency of electrical generation.

An option with which to increase solar-energy conversion is to couple the traditional PV and PT systems into a hybrid system, the photovoltaic–photothermal system (PVT) (Figure 6, central). In a traditional configuration, a PVT system involves the use of a series of pipes under the PV, through which a cooling fluid flows. In this configuration, there is no interaction between the incoming solar radiation and the working fluid. A recent approach involves the placement of the working fluid in front of a solar cell, as with LSC/LDS layers. In this case, the entire structure can operate as a spectral beam splitter PVT (SBS-PVT) [75,160,166,167,168,169,170,171,172,173]. Coupling in this manner (Figure 6) allows the working liquid to act as a spectral modulator and a heat-transfer fluid. A potential attraction of this technology is the widely diverse geometry and systems to which it can conform [174].

These systems attempt to perform a level of spectral modulation on the incoming incident solar radiation to provide spectral matching for the spectral window of the PV cell by using the liquid as an LDS and as a working thermal fluid (i.e., for cell cooling and heat removal) to obtain enhanced efficiencies in solar-energy conversion [75,167]. In the SBS-PVT configuration, the presence of a luminescent or nano-doped fluid serves the dual role of acting as a spectral modulation medium for the PV system and as heat-transfer fluid for the PT component. As a result, the dynamic between the thermal power and the electrical power delivered by the PVT system can be controlled by adjusting the optical and thermal properties of the (liquid) optical filter. It has been shown that through the combination of a PT with a PV system in this hybrid configuration, the efficiency of the solar-energy conversion (i.e., electrical plus thermal) can reach 91% [175].

In such SBS-PVT/ systems, in which the working fluid is placed atop the PV cell, incident sunlight interacts with the luminophore material present within the working fluid before coming into contact with the PV [176,177]. Thus, the incoming radiation that reaches the PV is modulated to have a more ideal spectral profile, for i.e., to match, the bandgap of the solar material. The importance of a system such as this is the fact that this configuration lends itself to easy methods of retrofitting existing standalone PV devices. This retrofitting enables PVs to have longer lifespans through thermal management while also increasing the electrical output of the device via spectral modulation. In total, this form of retrofitting can increase the sustainability of such devices by extending their lifetime, mitigating the hazardous downstream end-of-life process [30,31].

Popular investigations into these systems are primarily focused on nanofluids, with silver nanoparticles introduced in the working fluid receiving more attention due to the plasmonic effects that such nanoparticles can introduce [157,160,166,178,179,180,181]. A noticeable omission from the literature relates to the use of low-cost commercial-grade luminophore materials in SBS-PVT systems. The inclusion of such materials would enable further optimisation of the geometries and designs due to the ease of implementation compared to the considerable costs related to the synthesis/production process of a nanofluid, as well as the time investment and the expertise required.

Another important consideration, proposed by Ju et al., when implementing an SBS-PVT working fluid in such a configuration is the inclusion of an air gap between the working fluid and the solar cell [182]. The inclusion of such a gap allows total thermal decoupling. As the thickness of the air gap increases, the heat transfer between the fluid and the PV decreases [182], opening a direction for further research into the determination of the optimal working distances for the thermal management of the system.

One of the most significant benefits of implementing an SBS-PVT system lies in its economic potential [167]. Han et al. were able to provide evidence that an Ag/CoSO4 nanofluid used as an SBS-PVT device yielded economic value that was 35.9% greater when compared to PV alone through investigations of the systems’ merit functions [160]. Analyses involving the merit function consider various factors that relate to the operational effectiveness of the SBS-PVT system [75,160,167,177]. To evaluate whether a working fluid can convert solar energy into electrical and thermal energy more efficiently within a PVT system, a merit function is implemented following equation 6 [75,160,166,167].

where and are the filtered and unfiltered electrical power output of the silicon cell, respectively, is the thermal power output of the PVT system when a working fluid is employed, and, is the factor of the worth of the electricity to the thermal energy [75,166,167]. Classically, heat-transfer fluids are evaluated using a 3:1 worth factor of electricity to thermal energy [157,157,160,161,178,180]. Hence, the inclusion of a merit function within a study such as this allows an economic analysis to be considered in a study, since the investigation will be able to relate to existing worth factors in particular regions [173]. Huang et al. were able to show an economic value enhancement of 67.8% over a standalone PV system with a total efficiency that was 63.3% higher for silver nanofluids [157]. A major benefit of these hybridisation results is the simplicity of retrofitting a PV cell to achieve them. Whilst previous studies incorporating PVT technology utilised large-scale parabolic collecting troughs, the results presented by Han et al. and Huang et al. demonstrate that simply by placing the working fluid in the path of the PV in question, enhancements can be achieved [157,160].

6. Conclusions

As renewable-energy demands have risen to combat the use of fossil fuels, solar energy has been shown to be a viable solution. However, the uptake of solar-energy technologies has been limited by a series of factors, like the spectral mismatch and the thermal management, as well as by factors related to building integration due to weights and geometries. Furthermore, solar-cell technologies have been shown to result in difficult and environmentally damaging end-of-life cycles and, hence, the requirement to enhance the operational lifetimes of PVs is necessary. This can be achieved through economically viable (retrofitting) methods.

Thus, LSC devices represent a solution with which to further encourage the uptake of solar-energy systems due to the tailoring of their direct application towards building integration, with a focus on consumer-end implementation from an aesthetic point of view. This is complemented by its ability to increase the quantity of light that falls upon solar cells to encourage higher electrical energy efficiencies. Designs of LSC devices have also been shown to offer a wide range of geometries, from flexible surfaces to cylindrical systems, with economic benefits found through the use of concentrating designs to improve solar-energy-conversion efficiency, as well as protective abilities that extend PV lifetimes.

The SBS-PVT systems offer the potential to further increase the energy-conversion efficiency of solar devices. Thus, SBS-PVT devices enable energy conversions to rise by close to 90%. The SBS-PVT systems provide higher energy-conversion efficiency, and their economic potential is established by the rise in their reported economic value [157,160]. The combination of an SBS-PVT system which incorporates the dynamic geometries offered by LSC or LDS structures is also a suitable arrangement.

The major benefit of the SBS-PVT system is the ability to remove excess heat from the working PV cell during operation and, thus, not only to increase the efficiency of the device through thermal management, but also to extend the PV lifetime [23,24,25,26,27]. End-of-life reports for PV modules have showcased the great difficulties which surround the management of PV waste. By 2050, it is expected that 76 million tonnes of waste will be produced from PV sources [183]. This waste is of great ecological importance due to its toxicity to the environment [31,32,33,34,35] Hence, it is vital for the future of PV systems to focus on the manufacturing of PVs using ecologically friendly materials and/or the waste reduction. The latter can be achieved by the extended lifetime offered through the thermal management of the system allowed by the hybridisation of PVT fluids [75,173,179,181].

The simplicity of retrofitting SBS-PVT devices to existing PV systems highlights the great potential for the integration of existing systems [173]. The coupling of the retrofitting of a PV device with the aesthetic direction of building integrated PV devices will provide the basis of support for localised energy generation within residential or commercial buildings [18,37,48,52,53,67,68,69]. The encouragement of these forms of energy-generation system increases the overall energy security of populations while also aiding in reducing energy costs for commercial and residential dwellings. This uptake would adhere to policy directives outlined by the EU and, thus, contribute to overall decarbonisation efforts [184,185,186].

The future of this technology is not limited to building integration, since potential has also been observed in the agriculture [93,187,188,189,190]. Spectral modulation has been identified as having favourable results for the growth of particular plants by blocking out specific wavelengths of lights which are harmful to crops [93]. Future studies should further explore this potential by incorporating the SBS-PVT design of a hybrid working fluid into the thermal management of greenhouse environments through reductions in heating and cooling costs, as 65–85% of the energy demand is attributed to these processes [191]. The majority of these energy demands are met through the use of fossil fuels and, thus, the further implementation of renewable energy systems such as these SBS-PVT technologies is paramount [192].

Previous studies extensively investigated the potential of SBS-PVT systems in planar systems using (silver- or other metal-based) nanofluids. However, future investigations should focus on implementing commercial-grade luminophore materials that are already available, as they show significant potential for LDSs within working fluids [173]. Additionally, by incorporating the SBS-PVT system with an LSC, a wide variety of geometries and designs can be investigated, as this can lead to further enhancements of solar-energy-conversion efficiency and further help in adopting solar energy as a viable option for decarbonizing energy production in both industrial and residential sectors.

Author Contributions

Conceptualisation, K.C., J.W. and G.A.; methodology, K.C., J.W. and G.A.; formal analysis, K.C., J.W. and G.A.; investigation, K.C., J.W. and G.A.; resources, J.D., S.J.M. and G.A.; writing—original draft preparation, K.C., J.W., J.D., S.J.M. and G.A.; writing—review and editing, K.C., J.W. and G.A.; visualisation, K.C. and J.W.; supervision, J.D., S.J.M. and G.A.; project administration, G.A.; funding acquisition, J.D. and G.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by European Space Agency, grant number 400013471 and by TU Dublin Scholarship programme.

Data Availability Statement

No new data were created or analyzed in this study.

Acknowledgments

The authors would like to acknowledge the funding bodies (European Space Agency and the TU Dublin Fellowship programme) for the financial support.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kılıç Depren, S.; Kartal, M.T.; Çoban Çelikdemir, N.; Depren, Ö. Energy Consumption and Environmental Degradation Nexus: A Systematic Review and Meta-Analysis of Fossil Fuel and Renewable Energy Consumption. Ecol. Inf. 2022, 70, 101747. [Google Scholar] [CrossRef]

- Mutezo, G.; Mulopo, J. A Review of Africa’s Transition from Fossil Fuels to Renewable Energy Using Circular Economy Principles. Renew. Sustain. Energy Rev. 2021, 137, 110609. [Google Scholar] [CrossRef]

- Gyamfi, B.A.; Kwakwa, P.A.; Adebayo, T.S. Energy Intensity among European Union Countries: The Role of Renewable Energy, Income and Trade. Int. J. Energy Sect. Manag. 2023, 17, 801–819. [Google Scholar] [CrossRef]

- Carfora, A.; Pansini, R.V.; Scandurra, G. Energy Dependence, Renewable Energy Generation and Import Demand: Are EU Countries Resilient? Renew. Energy 2022, 195, 1262–1274. [Google Scholar] [CrossRef]

- Rabbi, M.F.; Popp, J.; Máté, D.; Kovács, S. Energy Security and Energy Transition to Achieve Carbon Neutrality. Energies 2022, 15, 8126. [Google Scholar] [CrossRef]

- Li, X.; Lepour, D.; Heymann, F.; Maréchal, F. Electrification and Digitalization Effects on Sectoral Energy Demand and Consumption: A Prospective Study towards 2050. Energy 2023, 279, 127992. [Google Scholar] [CrossRef]

- Fotis, P.; Karkalakos, S.; Asteriou, D. The Relationship between Energy Demand and Real GDP Growth Rate: The Role of Price Asymmetries and Spatial Externalities within 34 Countries across the Globe. Energy Econ. 2017, 66, 69–84. [Google Scholar] [CrossRef]

- Yu, Z.; Lanre Ridwan, I.; ur Rehman Irshad, A.; Tanveer, M.; Khan, S.A.R. Investigating the Nexuses between Transportation Infrastructure, Renewable Energy Sources, and Economic Growth: Striving towards Sustainable Development. Ain Shams Eng. J. 2023, 14, 101843. [Google Scholar] [CrossRef]

- Rezaei Sadr, N.; Bahrdo, T.; Taghizadeh, R. Impacts of Paris Agreement, Fossil Fuel Consumption, and Net Energy Imports on CO2 Emissions: A Panel Data Approach for Three West European Countries. Clean Technol Env. Policy 2022, 24, 1521–1534. [Google Scholar] [CrossRef]

- Wimbadi, R.W.; Djalante, R. From Decarbonization to Low Carbon Development and Transition: A Systematic Literature Review of the Conceptualization of Moving toward Net-Zero Carbon Dioxide Emission (1995–2019). J. Clean Prod. 2020, 256, 120307. [Google Scholar] [CrossRef]

- Mardani, A.; Streimikiene, D.; Cavallaro, F.; Loganathan, N.; Khoshnoudi, M. Carbon Dioxide (CO2) Emissions and Economic Growth: A Systematic Review of Two Decades of Research from 1995 to 2017. Sci. Total Environ. 2019, 649, 31–49. [Google Scholar] [CrossRef] [PubMed]

- Cibulka, S.; Giljum, S. Towards a Comprehensive Framework of the Relationships between Resource Footprints, Quality of Life, and Economic Development. Sustainability 2020, 12, 4734. [Google Scholar] [CrossRef]

- Maciejczyk, P.; Chen, L.C.; Thurston, G. The Role of Fossil Fuel Combustion Metals in PM2.5 Air Pollution Health Associations. Atmosphere 2021, 12, 1086. [Google Scholar] [CrossRef]

- Romanello, M.; Di Napoli, C.; Drummond, P.; Green, C.; Kennard, H.; Lampard, P.; Scamman, D.; Arnell, N.; Ayeb-Karlsson, S.; Ford, L.B.; et al. The 2022 Report of the Lancet Countdown on Health and Climate Change: Health at the Mercy of Fossil Fuels. Lancet 2022, 400, 1619–1654. [Google Scholar] [CrossRef]

- Perera, F.; Nadeau, K. Climate Change, Fossil-Fuel Pollution, and Children’s Health. New Engl. J. Med. 2022, 386, 2303–2314. [Google Scholar] [CrossRef]

- Steffen, B. Estimating the Cost of Capital for Renewable Energy Projects. Energy Econ. 2020, 88, 104783. [Google Scholar] [CrossRef]

- Gervais, E.; Shammugam, S.; Friedrich, L.; Schlegl, T. Raw Material Needs for the Large-Scale Deployment of Photovoltaics–Effects of Innovation-Driven Roadmaps on Material Constraints until 2050. Renew. Sustain. Energy Rev. 2021, 137, 110589. [Google Scholar] [CrossRef]

- Ghaleb, B.; Asif, M. Assessment of Solar PV Potential in Commercial Buildings. Renew. Energy 2022, 187, 618–630. [Google Scholar] [CrossRef]

- Pablo-Romero, P.; Pozo-Barajas, R.; Sánchez, J.; García, R.; Holechek, J.L.; Geli, H.M.E.; Sawalhah, M.N.; Valdez, R. A Global Assessment: Can Renewable Energy Replace Fossil Fuels by 2050? Sustainability 2022, 14, 4792. [Google Scholar] [CrossRef]

- Bosio, A.; Pasini, S.; Romeo, N. The History of Photovoltaics with Emphasis on CdTe Solar Cells and Modules. Coatings 2020, 10, 344. [Google Scholar] [CrossRef]

- Siva Ramkumar, M.; Felshiya Rajakumari, R.; Kannan, N.; Premkumar, R.; Mohanasundaram, S.; Purushotham, S.; Ramya, D.; Rajan, K.; Jerold, S.; Chelladurai, S. Semiconductor Materials for Solar PV Technology and Challenges towards Electrical. Adv. Mater. Sci. Eng. 2022, 2022, 7272489. [Google Scholar] [CrossRef]

- Fazal, M.A.; Rubaiee, S. Progress of PV Cell Technology: Feasibility of Building Materials, Cost, Performance, and Stability. Sol. Energy 2023, 258, 203–219. [Google Scholar] [CrossRef]

- Divitini, G.; Cacovich, S.; Matteocci, F.; Cinà, L.; Di Carlo, A.; Ducati, C. In Situ Observation of Heat-Induced Degradation of Perovskite Solar Cells. Nature Energy 2016, 1, 15012. [Google Scholar] [CrossRef]

- Kherici, Z.; Kahoul, N.; Cheghib, H.; Younes, M.; Chekal Affari, B. Main Degradation Mechanisms of Silicon Solar Cells in Algerian Desert Climates. Sol. Energy 2021, 224, 279–284. [Google Scholar] [CrossRef]

- Sato, D.; Yamada, N. Review of Photovoltaic Module Cooling Methods and Performance Evaluation of the Radiative Cooling Method. Renew. Sustain. Energy Rev. 2019, 104, 151–166. [Google Scholar] [CrossRef]

- Kumar, K.; Sharma, S.D.; Jain, L.; Al Khaimah, R. Standalone Photovoltaic (PV) Module Outdoor Testing Facility for UAE Climate; CSEM-UAE Innovation Center LLC: Ras Al Khaimah, United Arab Emirates, 2007. [Google Scholar]

- Haidar, Z.A.; Orfi, J.; Kaneesamkandi, Z. Experimental Investigation of Evaporative Cooling for Enhancing Photovoltaic Panels Efficiency. Results Phys. 2018, 11, 690–697. [Google Scholar] [CrossRef]

- Park, N.C.; Oh, W.W.; Kim, D.H. Effect of Temperature and Humidity on the Degradation Rate of Multicrystalline Silicon Photovoltaic Module. Int. J. Photoenergy 2013, 2013, 925280. [Google Scholar] [CrossRef]

- Kaplani, E. Detection of Degradation Effects in Field-Aged c-Si Solar Cells through IR Thermography and Digital Image Processing. Int. J. Photoenergy 2012, 2012, 396792. [Google Scholar] [CrossRef]

- Kokul, S.R.; Bhowmik, S. Recycling of Crystalline Silicon Photovoltaic Solar Panel Waste to Modified Composite Products. Prog. Rubber Plast. Recycl. Technol. 2021, 37, 327–339. [Google Scholar] [CrossRef]

- Wang, X.; Tian, X.; Chen, X.; Ren, L.; Geng, C. A Review of End-of-Life Crystalline Silicon Solar Photovoltaic Panel Recycling Technology. Sol. Energy Mater. Sol. Cells 2022, 248, 111976. [Google Scholar] [CrossRef]

- Tao, M.; Fthenakis, V.; Ebin, B.; Steenari, B.M.; Butler, E.; Sinha, P.; Corkish, R.; Wambach, K.; Simon, E.S. Major Challenges and Opportunities in Silicon Solar Module Recycling. Prog. Photovolt. Res. Appl. 2020, 28, 1077–1088. [Google Scholar] [CrossRef]

- Guo, J.; Liu, X.; Yu, J.; Xu, C.; Wu, Y.; Pan, D.; Senthil, R.A. An Overview of the Comprehensive Utilization of Silicon-Based Solid Waste Related to PV Industry. Resour. Conserv. Recycl. 2021, 169, 105450. [Google Scholar] [CrossRef]

- Il Kwak, J.; Nam, S.H.; Kim, L.; An, Y.J. Potential Environmental Risk of Solar Cells: Current Knowledge and Future Challenges. J. Hazard Mater. 2020, 392, 122297. [Google Scholar] [CrossRef]

- Venkatachary, S.K.; Samikannu, R.; Murugesan, S.; Dasari, N.R.; Subramaniyam, R.U. Economics and Impact of Recycling Solar Waste Materials on the Environment and Health Care. Env. Technol. Innov. 2020, 20, 101130. [Google Scholar] [CrossRef]

- Klampaftis, E.; Ross, D.; McIntosh, K.R.; Richards, B.S. Enhancing the Performance of Solar Cells via Luminescent Down-Shifting of the Incident Spectrum: A Review. Sol. Energy Mater. Sol. Cells 2009, 93, 1182–1194. [Google Scholar] [CrossRef]

- Richards, B.S.; Howard, I.A. Luminescent Solar Concentrators for Building Integrated Photovoltaics: Opportunities and Challenges. Energy Env. Sci. 2023, 16, 3214–3239. [Google Scholar] [CrossRef]

- Kalluvettukuzhy, N.K.; Maciejczyk, M.R.; Underwood, I.; Robertson, N. Visually Attractive and Efficient Photovoltaics through Luminescent Downshifting. J. Mater. Chem. A Mater. 2023, 11, 13195–13200. [Google Scholar] [CrossRef]

- Debije, M.G.; Verbunt, P.P.C. Thirty Years of Luminescent Solar Concentrator Research: Solar Energy for the Built Environment. Adv. Energy Mater. 2012, 2, 12–35. [Google Scholar] [CrossRef]

- Skouri, S.; Ben Haj Ali, A.; Bouadila, S.; Ben Salah, M.; Ben Nasrallah, S. Design and Construction of Sun Tracking Systems for Solar Parabolic Concentrator Displacement. Renew. Sustain. Energy Rev. 2016, 60, 1419–1429. [Google Scholar] [CrossRef]

- Yan, J.; Liu, Y.X.; Peng, Y.D. Study on the Optical Performance of Novel Dish Solar Concentrator Formed by Rotating Array of Plane Mirrors with the Same Size. Renew. Energy 2022, 195, 416–430. [Google Scholar] [CrossRef]

- Li, Y.; Sun, Y.; Zhang, Y. Luminescent Solar Concentrators Performing under Different Light Conditions. Sol. Energy 2019, 188, 1248–1255. [Google Scholar] [CrossRef]

- Debije, M.G.; Rajkumar, V.A. Direct versus Indirect Illumination of a Prototype Luminescent Solar Concentrator. Sol. Energy 2015, 122, 334–340. [Google Scholar] [CrossRef]

- Weber, W.H.; Lambe, J. Luminescent Greenhouse Collector for Solar Radiation. Appl. Opt. 1976, 15, 2299–2300. [Google Scholar] [CrossRef] [PubMed]

- Goetzberger, A.; Greube, W. Solar Energy Conversion with Fluorescent Collectors. Appl. Phys. 1977, 14, 123–139. [Google Scholar] [CrossRef]

- Makarov, N.S.; Korus, D.; Freppon, D.; Ramasamy, K.; Houck, D.W.; Velarde, A.; Parameswar, A.; Bergren, M.R.; McDaniel, H. Minimizing Scaling Losses in High-Performance Quantum Dot Luminescent Solar Concentrators for Large-Area Solar Windows. ACS Appl. Mater. Interfaces 2022, 14, 29679–29689. [Google Scholar] [CrossRef] [PubMed]

- Klampaftis, E.; Ross, D.; Kocher-Oberlehner, G.; Richards, B.S. Integration of Color and Graphical Design for Photovoltaic Modules Using Luminescent Materials. IEEE J. Photovolt. 2015, 5, 584–590. [Google Scholar] [CrossRef]

- Aste, N.; Buzzetti, M.; Del Pero, C.; Fusco, R.; Testa, D.; Leonforte, F. Visual Performance of Yellow, Orange and Red LSCs Integrated in a Smart Window. Energy Procedia 2017, 105, 967–972. [Google Scholar] [CrossRef]

- Reinders, A.; Kishore, R.; Slooff, L.; Eggink, W. Luminescent Solar Concentrator Photovoltaic Designs. Jpn. J. Appl. Phys. 2018, 57, 08RD10. [Google Scholar] [CrossRef]

- Mateen, F.; Ahsan Saeed, M.; Won Shim, J.; Hong, S.K. Indoor/Outdoor Light-Harvesting by Coupling Low-Cost Organic Solar Cell with a Luminescent Solar Concentrator. Sol. Energy 2020, 207, 379–387. [Google Scholar] [CrossRef]

- Aghaei, M.; Pelosi, R.; Wong, W.W.H.; Schmidt, T.; Debije, M.G.; Reinders, A.H.M.E. Measured Power Conversion Efficiencies of Bifacial Luminescent Solar Concentrator Photovoltaic Devices of the Mosaic Series. Prog. Photovolt. Res. Appl. 2022, 30, 726–739. [Google Scholar] [CrossRef]

- Smith, D.E.; Hughes, M.D.; Borca-Tasciuc, D.A. Towards a Standard Approach for Annual Energy Production of Concentrator-Based Building-Integrated Photovoltaics. Renew. Energy 2022, 186, 469–485. [Google Scholar] [CrossRef]

- Aste, N.; Buzzetti, M.; Del Pero, C.; Fusco, R.; Leonforte, F.; Testa, D. Triggering a Large Scale Luminescent Solar Concentrators Market: The Smart Window Project. J. Clean. Prod. 2019, 219, 35–45. [Google Scholar] [CrossRef]

- Debije, M.G.; Verbunt, P.P.C.; Nadkarni, P.J.; Velate, S.; Bhaumik, K.; Nedumbamana, S.; Rowan, B.C.; Richards, B.S.; Hoeks, T.L. Promising Fluorescent Dye for Solar Energy Conversion Based on a Perylene Perinone. Appl. Opt. 2011, 50, 163–169. [Google Scholar] [CrossRef] [PubMed]

- Currie, M.J.; Mapel, J.K.; Heidel, T.D.; Goffri, S.; Baldo, M.A. High-Efficiency Organic Solar Concentrators for Photovoltaics. Science 2008, 321, 226–228. [Google Scholar] [CrossRef]

- van Sark, W.G.J.H.M. Luminescent Solar Concentrators—A Low Cost Photovoltaics Alternative. Renew. Energy 2013, 49, 207–210. [Google Scholar] [CrossRef]

- Griffini, G.; Levi, M.; Turri, S. Thin-Film Luminescent Solar Concentrators: A Device Study towards Rational Design. Renew. Energy 2015, 78, 288–294. [Google Scholar] [CrossRef]

- Vishwanathan, B.; Reinders, A.H.M.E.; de Boer, D.K.G.; Desmet, L.; Ras, A.J.M.; Zahn, F.H.; Debije, M.G. A Comparison of Performance of Flat and Bent Photovoltaic Luminescent Solar Concentrators. Sol. Energy 2015, 112, 120–127. [Google Scholar] [CrossRef]

- Van Der Burgt, J.S.; Needell, D.R.; Veeken, T.; Polman, A.; Garnett, E.C.; Atwater, H.A. Unlocking Higher Power Efficiencies in Luminescent Solar Concentrators through Anisotropic Luminophore Emission. ACS Appl. Mater. Interfaces 2021, 13, 40742–40753. [Google Scholar] [CrossRef]

- Warner, T.; Ghiggino, K.P.; Rosengarten, G. A Critical Analysis of Luminescent Solar Concentrator Terminology and Efficiency Results. Sol. Energy 2022, 246, 119–140. [Google Scholar] [CrossRef]

- Rafiee, M.; Chandra, S.; Ahmed, H.; McCormack, S.J. An Overview of Various Configurations of Luminescent Solar Concentrators for Photovoltaic Applications. Opt. Mater. 2019, 91, 212–227. [Google Scholar] [CrossRef]

- Barik, P.; Pradhan, M. Plasmonic Luminescent Solar Concentrator. Sol. Energy 2021, 216, 61–74. [Google Scholar] [CrossRef]

- Cojocaru, L.; Uchida, S.; Tamaki, K.; Jayaweera, P.V.V.; Kaneko, S.; Nakazaki, J.; Kubo, T.; Segawa, H. Determination of Unique Power Conversion Efficiency of Solar Cell Showing Hysteresis in the I-V Curve under Various Light Intensities. Sci. Rep. 2017, 7, 11790. [Google Scholar] [CrossRef] [PubMed]

- Batchelder, J.S.; Zewai, A.H.; Cole, T. Luminescent Solar Concentrators. 1: Theory of Operation and Techniques for Performance Evaluation. Appl. Opt. 1979, 18, 3090. [Google Scholar] [CrossRef] [PubMed]

- Heidler, K. Efficiency and Concentration Ratio Measurements of Fluorescent Solar Concentrators Using a Xenon Measurement System. Appl. Opt. 1981, 20, 773. [Google Scholar] [CrossRef] [PubMed]

- Thomas, W.R.L.; Drake, J.M.; Lesiecki, M.L.; Sansregret, J. Organic Dyes in PMMA in a Planar Luminescent Solar Collector: A Performance Evaluation. Appl. Opt. 1982, 21, 2945–2952. [Google Scholar] [CrossRef]

- Meinardi, F.; Bruni, F.; Brovelli, S. Luminescent Solar Concentrators for Building-Integrated Photovoltaics. Nat. Rev. Mater. 2017, 2, 17072. [Google Scholar] [CrossRef]

- Nie, Y.; He, W.; Liu, X.; Hu, Z.; Yu, H.; Liu, H. Smart Luminescent Solar Concentrator as a BICPV Window. Build Simul. 2022, 15, 1789–1798. [Google Scholar] [CrossRef]

- Vossen, F.M.; Aarts, M.P.J.; Debije, M.G. Visual Performance of Red Luminescent Solar Concentrating Windows in an Office Environment. Energy Build. 2016, 113, 123–132. [Google Scholar] [CrossRef]

- Lin, Y.; Firdaus, Y.; Insan Nugraha, M.; Liu, F.; Karuthedath, S.; Emwas, A.-H.; Zhang, W.; Seitkhan, A.; Neophytou, M.; Faber, H.; et al. 17.1% Efficient Single-Junction Organic Solar Cells Enabled by n-Type Doping of the Bulk-Heterojunction. Adv. Sci. 2020, 7, 1903419. [Google Scholar] [CrossRef]

- Nassiri Nazif, K.; Kumar, A.; Hong, J.; Lee, N.; Islam, R.; McClellan, C.J.; Karni, O.; Van De Groep, J.; Heinz, T.F.; Pop, E.; et al. High-Performance p-n Junction Transition Metal Dichalcogenide Photovoltaic Cells Enabled by MoOxDoping and Passivation. Nano Lett. 2021, 21, 3443–3450. [Google Scholar] [CrossRef]

- Wu, X.; Li, B.; Zhu, Z.; Chueh, C.C.; Jen, A.K.Y. Designs from Single Junctions, Heterojunctions to Multijunctions for High-Performance Perovskite Solar Cells. Chem. Soc. Rev. 2021, 50, 13090–13128. [Google Scholar] [CrossRef] [PubMed]

- Zhang, F.; Yang, X.; Wang, H.; Cheng, M.; Zhao, J.; Sun, L. Structure Engineering of Hole-Conductor Free Perovskite-Based Solar Cells with Low-Temperature-Processed Commercial Carbon Paste as Cathode. ACS Appl. Mater. Interfaces 2014, 6, 16140–16146. [Google Scholar] [CrossRef] [PubMed]

- Saleh, A.; Pellet, N.; Zakeeruddin, S.M.; Dar, M.I.; Grätzel, M. A Fully Printable Hole-Transporter-Free Semi-Transparent Perovskite Solar Cell. Eur. J. Inorg. Chem. 2021, 2021, 3752–3760. [Google Scholar] [CrossRef]

- Walshe, J.; Carron, P.M.; McCormack, S.; Doran, J.; Amarandei, G. Organic Luminescent Down-Shifting Liquid Beam Splitters for Hybrid Photovoltaic-Thermal (PVT) Applications. Sol. Energy Mater. Sol. Cells 2021, 219, 110818. [Google Scholar] [CrossRef]

- Alonso-Álvarez, D.; Ross, D.; Richards, B.S. Luminescent Down-Shifting for CdTe Solar Cells: A Review of Dyes and Simulation of Performance. In Proceedings of the 2012 38th IEEE Photovoltaic Specialists Conference, Austin, TX, USA, 3–8 June 2012; pp. 9–14. [Google Scholar] [CrossRef]

- Glenn, A.; McLoughlin, C.; Ahmed, H.; Akbari, H.; Chandra, S.; McCormack, S. The Viability of Organic Dyes in Luminescent Down-Shifting Layers for the Enhancement of Si Solar Cell Efficiency. Mater. Sci. Forum 2020, 995, 71–76. [Google Scholar] [CrossRef]

- Li, Y.; Lin, H.; Zeng, J.; Chen, J.; Chen, H. Enhance Short-Wavelength Response of CIGS Solar Cell by CdSe Quantum Disks as Luminescent down-Shifting Material. Sol. Energy 2019, 193, 303–308. [Google Scholar] [CrossRef]

- Ayala Barragan, M.F.; Chandra, S.; Cass, B.; McCormack, S.J. Defining Critical Parameters in a Luminescent Downshifting Layer for PV Enhancement. In Sustainable Energy Development and Innovation; Springer: Berlin/Heidelberg, Germany, 2022; pp. 865–870. [Google Scholar] [CrossRef]

- Sekar, S.; Venkataprasad Bhat, S. BCNO Silica Gel-Based Green Transparent and Efficient Luminescent Downshifting Layer for Si Solar Cells. Sustain. Energy Fuels 2021, 5, 2046–2054. [Google Scholar] [CrossRef]

- Alexandre, M.; Chapa, M.; Haque, S.; Mendes, M.J.; Águas, H.; Fortunato, E.; Martins, R. Optimum Luminescent Down-Shifting Properties for High Efficiency and Stable Perovskite Solar Cells. ACS Appl. Energy Mater. 2019, 2, 2930–2938. [Google Scholar] [CrossRef]

- Golesorkhi, B.; Nozary, H.; Fürstenberg, A.; Piguet, C. Erbium Complexes as Pioneers for Implementing Linear Light-Upconversion in Molecules. Mater. Horiz. 2020, 7, 1279–1296. [Google Scholar] [CrossRef]

- McKenna, B.; Evans, R.C. Towards Efficient Spectral Converters through Materials Design for Luminescent Solar Devices. Adv. Mater. 2017, 29, 1606491. [Google Scholar] [CrossRef]

- Ahmed, H.; Sethi, A.; Doran, J.; Mccormack, S.J. Plasmonic Interaction in Enhanced Luminescent Down-Shifting Layers for Photovoltaic Devices. In Plasmonics: Advances in Research and Applications; Nova Science Publishers: Hauppauge, NY, USA, 2017. [Google Scholar]

- Khan, F.; Kim, J.H. N-Functionalized Graphene Quantum Dots with Ultrahigh Quantum Yield and Large Stokes Shift: Efficient Downconverters for CIGS Solar Cells. ACS Photonics 2018, 5, 4637–4643. [Google Scholar] [CrossRef]

- Valeur, B.; Berberan-Santos, M.N. Molecular Fluorescence: Principles and Applications, 2nd ed.; Wiley: Hoboken, NJ, USA, 2012. [Google Scholar] [CrossRef]

- Huang, X.; Han, S.; Huang, W.; Liu, X. Enhancing Solar Cell Efficiency: The Search for Luminescent Materials as Spectral Converters. Chem. Soc. Rev. 2012, 42, 173–201. [Google Scholar] [CrossRef] [PubMed]

- Sanguineti, A.; Sassi, M.; Turrisi, R.; Ruffo, R.; Vaccaro, G.; Meinardi, F.; Beverina, L. High Stokes Shift Perylene Dyes for Luminescent Solar Concentrators. Chem. Commun. 2013, 49, 1618–1620. [Google Scholar] [CrossRef]

- Guesmi, H.; Aissat, A.; Safi, M.; Berbezier, I. Efficiency Improvement of GaAs Quantum Dot in GaAs1-XPx Matrix for Solar Cell Applications. Microelectron. J. 2020, 99, 104738. [Google Scholar] [CrossRef]

- Sadeghi, S.; Bahmani Jalali, H.; Srivastava, S.B.; Melikov, R.; Baylam, I.; Sennaroglu, A.; Nizamoglu, S. High-Performance, Large-Area, and Ecofriendly Luminescent Solar Concentrators Using Copper-Doped InP Quantum Dots. iScience 2020, 23, 101272. [Google Scholar] [CrossRef]

- Cappelluti, F.; Gioannini, M.; Khalili, A. Impact of Doping on InAs/GaAs Quantum-Dot Solar Cells: A Numerical Study on Photovoltaic and Photoluminescence Behavior. Sol. Energy Mater. Sol. Cells 2016, 157, 209–220. [Google Scholar] [CrossRef]

- Griffini, G.; Brambilla, L.; Levi, M.; Del Zoppo, M.; Turri, S. Photo-Degradation of a Perylene-Based Organic Luminescent Solar Concentrator: Molecular Aspects and Device Implications. Sol. Energy Mater. Sol. Cells 2013, 111, 41–48. [Google Scholar] [CrossRef]

- Essahili, O.; Ouafi, M.; Moudam, O. Recent Progress in Organic Luminescent Solar Concentrators for Agrivoltaics: Opportunities for Rare-Earth Complexes. Sol. Energy 2022, 245, 58–66. [Google Scholar] [CrossRef]

- Li, B.; Tian, F.; Cui, X.; Xiang, B.; Zhao, H.; Zhang, H.; Wang, D.; Li, J.; Wang, X.; Fang, X.; et al. Review for Rare-Earth-Modified Perovskite Materials and Optoelectronic Applications. Nanomaterials 2022, 12, 1773. [Google Scholar] [CrossRef]

- Kataria, V.; Mehta, D.S. Multispectral Harvesting Rare-Earth Oxysulphide Based Highly Efficient Transparent Luminescent Solar Concentrator. J. Rare Earths 2022, 40, 41–48. [Google Scholar] [CrossRef]

- Cardoso, M.A.; Correia, S.F.H.; Frias, A.R.; Gonçalves, H.M.R.; Pereira, R.F.P.; Nunes, S.C.; Armand, M.; André, P.S.; de Zea Bermudez, V.; Ferreira, R.A.S. Solar Spectral Conversion Based on Plastic Films of Lanthanide-Doped Ionosilicas for Photovoltaics: Down-Shifting Layers and Luminescent Solar Concentrators. J. Rare Earths 2020, 38, 531–538. [Google Scholar] [CrossRef]

- Cai, T.; Wang, J.; Li, W.; Hills-Kimball, K.; Yang, H.; Nagaoka, Y.; Yuan, Y.; Zia, R.; Chen, O.; Cai, T.; et al. Mn2+/Yb3+ Codoped CsPbCl3 Perovskite Nanocrystals with Triple-Wavelength Emission for Luminescent Solar Concentrators. Adv. Sci. 2020, 7, 2001317. [Google Scholar] [CrossRef]

- Darwish, A.M.; Sarkisov, S.S.; Patel, D.N.; Mele, P.; Latronico, G.; Wilson, S.; Cho, K.; Giri, A.; Koplitz, B.; Hui, D. Nanocolloid Simulators of Luminescent Solar Concentrator Photovoltaic Windows. Nanotechnol. Rev. 2022, 11, 1167–1180. [Google Scholar]

- Kataria, V.; Mehta, D.S. Shape Engineered Y2O3: Eu3+ Nanodots for Stokes Shifting High-Efficiency PMMA Based Transparent Luminescent Solar Concentrator. J. Lumin. 2022, 248, 118955. [Google Scholar] [CrossRef]

- Alonso-Álvarez, D.; Ross, D.; Klampaftis, E.; McIntosh, K.R.; Jia, S.; Storiz, P.; Stolz, T.; Richards, B.S. Luminescent Down-Shifting Experiment and Modelling with Multiple Photovoltaic Technologies. Prog. Photovolt. Res. Appl. 2015, 23, 479–497. [Google Scholar] [CrossRef]

- Rothemund, R. Optical Modelling of the External Quantum Efficiency of Solar Cells with Luminescent Down-Shifting Layers. Sol. Energy Mater. Sol. Cells 2014, 120, 616–621. [Google Scholar] [CrossRef]

- Volpi, G.; Galliano, S.; Buscaino, R.; Viscardi, G.; Barolo, C. Fluorescent Trifluoromethylated Imidazo[1,5-a]Pyridines and Their Application in Luminescent down-Shifting Conversion. J. Lumin. 2022, 242, 118529. [Google Scholar] [CrossRef]

- Lee, S.; Yoo, G.Y.; Kim, B.; Kim, M.K.; Kim, C.; Park, S.Y.; Yoon, H.C.; Kim, W.; Min, B.K.; Do, Y.R. RGB-Colored Cu(In,Ga)(S,Se) 2 Thin-Film Solar Cells with Minimal Efficiency Loss Using Narrow-Bandwidth Stopband Nano-Multilayered Filters. ACS Appl. Mater. Interfaces 2019, 11, 9994–10003. [Google Scholar] [CrossRef]

- Ji, C.; Zhang, Z.; Masuda, T.; Kudo, Y.; Guo, L.J. Vivid-Colored Silicon Solar Panels with High Efficiency and Non-Iridescent Appearance. Nanoscale Horiz. 2019, 4, 874–880. [Google Scholar] [CrossRef]

- Kinderman, R.; Slooff, L.H.; Burgers, A.R.; Bakker, N.J.; Büchtemann, A.; Danz, R.; Van Roosmalen, J.A.M. I-V Performance and Stability Study of Dyes for Luminescent Plate Concentrators. J. Sol. Energy Eng. 2007, 129, 277–282. [Google Scholar] [CrossRef]

- Menéndez-Velázquez, A.; Torres-García, S.; García-Delgado, A.B.; Morales, D.; Medina-Alayón, M.; Acosta-Mora, P.; del-Castillo, J.; Esparza, P.; Borges, M.E.; Yanes, A.C.; et al. Towards a Luminescent Solar Concentrator with Ultra-Broadband Absorption and Spectral Conversion for Optimizing Photovoltaic Solar Cell Response: “The Photonic Cannon Shot”. Opt. Mater. 2023, 142, 114005. [Google Scholar] [CrossRef]