4.1. Analysis of Environmental Impacts

Table 8 shows the overall ecological impacts of the PV system, while

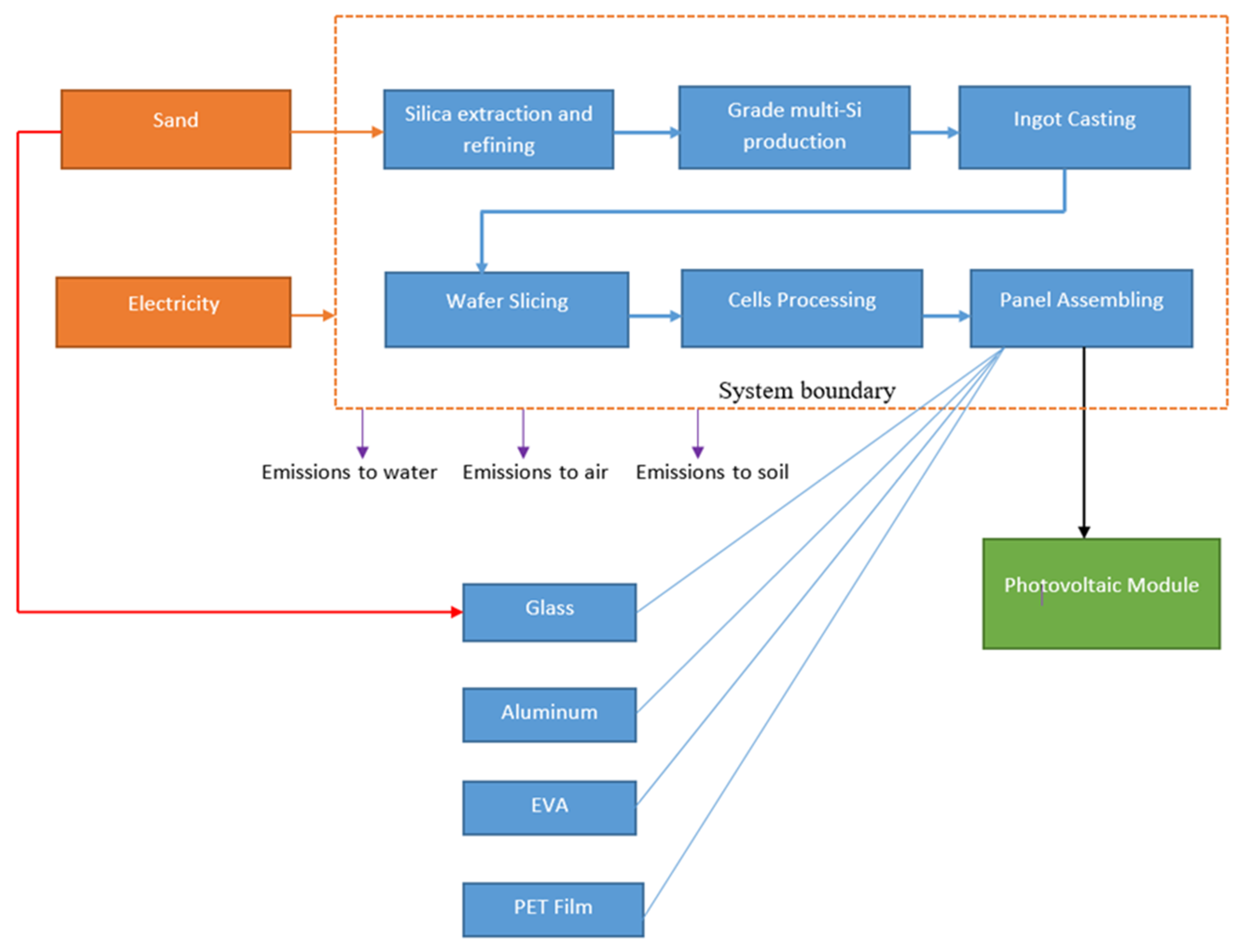

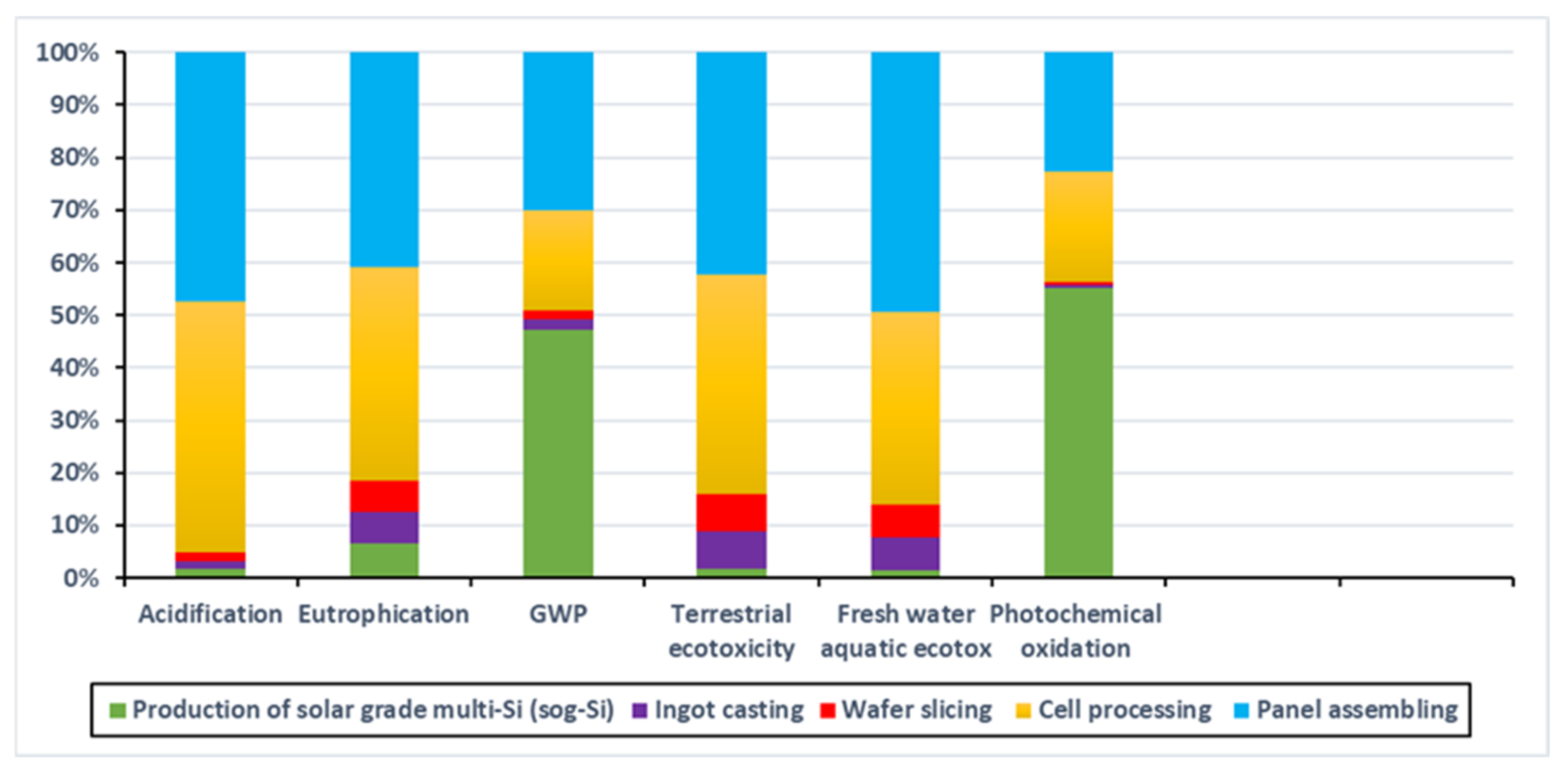

Figure 4 shows the percentage contribution of each environmental impact category in various stages of PV system production.

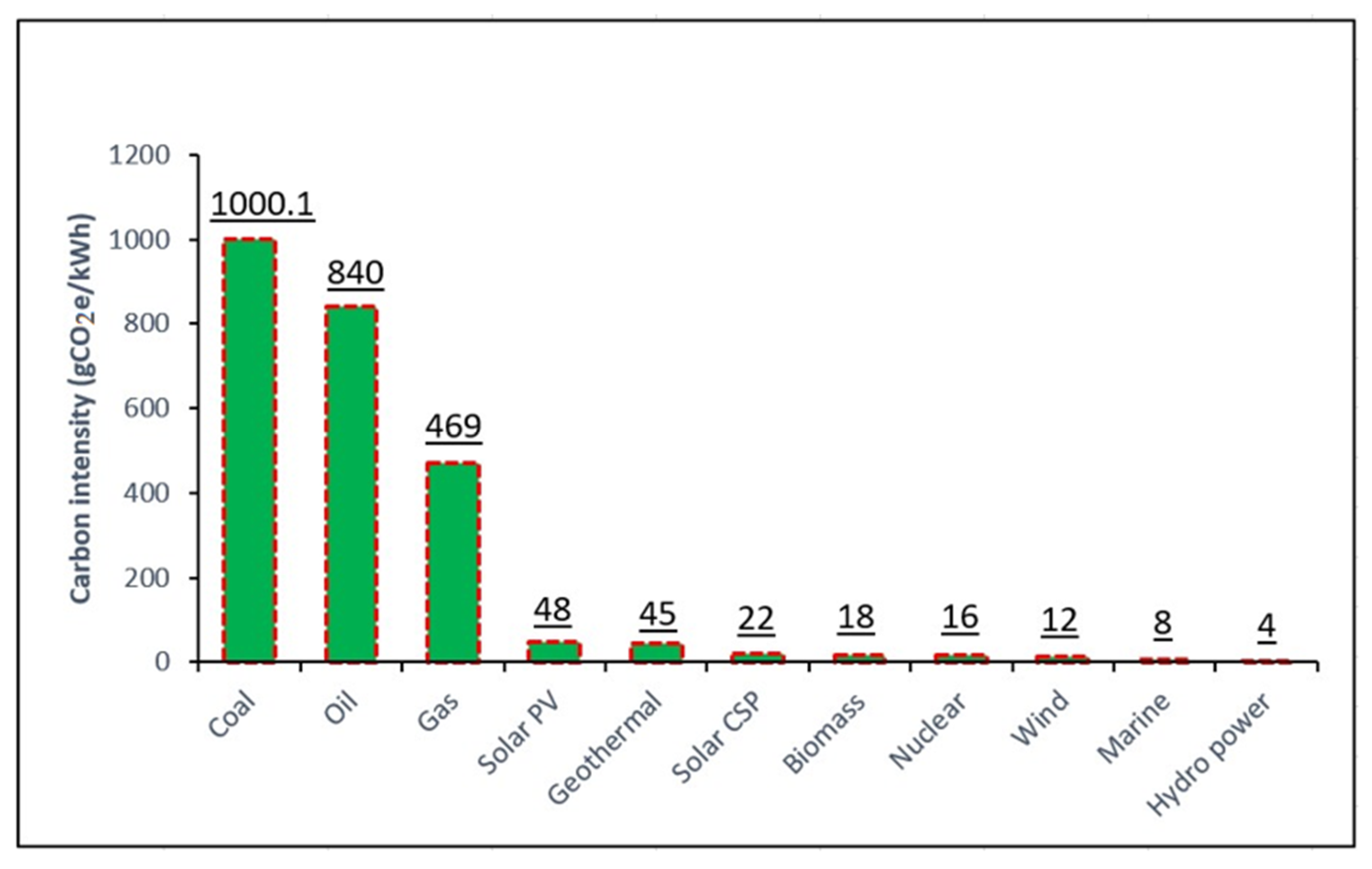

The life cycle assessment of the PV system indicated an AP value of 9.33 × 104 kg SO2 eq./kWh, predominantly originating from the release of emissions into the atmosphere. A significant fraction of this AP value (around 72.9%) was contributed by sulfur dioxide, which can be mainly attributed to the energy consumption during each stage of the PV system. It is noteworthy that Pakistan relies heavily on thermal processes, such as coal, natural gas, and oil, for generating electricity, which results in the emission of considerable amounts of nitrogen oxides and sulfur dioxide.

The PV system environmental impact was quantified by its EP of 3.15 × 10−2 kg PO43− eq./kWh, primarily driven by emissions to air and freshwater, which included phosphate, nitrogen oxides, and nitrate. Phosphate emissions to freshwater constituted 45.4% of the total EP, primarily due to the production of electricity in Pakistan, where thermal processes generate most of the electricity, leading to the release of phosphate into the water during coal mining and power generation. The emission of nitrogen oxides to air accounted for 44.6% of the total EP, primarily due to the steam and electricity utilization generated from fossil fuels in Pakistan, which emit significant nitrogen oxide amounts.

The GWP of a PV system was estimated to be 5.30 × 10

−2 kg CO

2 eq./kWh, with carbon dioxide and methane accounting for 83.3% and 11.7%, respectively. The most significant contributors were the solar-grade multi-Si (sog-Si) production stage, which accounted for nearly 50% of the GWP (

Figure 4), owing to high steam and electricity consumption. Cell production also had a considerable impact on GWP due to electricity usage. The underlying reason was the predominance of thermal processes in the generation of Pakistani electricity, which releases substantial amounts of greenhouse gases. Nevertheless, in module production, the consumption of material had a greater effect on GWP than electricity use. Specifically, aluminum framing and PVF film contributed 46.1% and 26.4%, respectively, while only 8.2% accounted for electricity use. This was because the production processes for PVF and aluminum emitted substantial CO

2 amounts.

The calculated value of TE of the PV system was 3.25 × 10−5 kg 1,4 DB eq./kWh, with the largest impact coming from emissions to air and fresh water. Emissions to air were responsible for 74.3% of the total TE value and consisted of heavy metals, organic and inorganic emissions. Heavy metals, such as selenium, chromium, arsenic, and nickel were mainly emitted during steam and electricity consumption, as well as in the material used during module production. These metals were present in the fossil fuels used to generate Pakistani electricity and steam. Organic and inorganic air emissions were primarily polychlorinated dibenzo-p-dioxins and hydrogen fluoride, which were produced during waste glass disposal in wafer production and the consumption of energy. Freshwater emissions contributed 25.7% to the TE value and consisted mainly of heavy metals, including vanadium (+III), selenium, and thallium, produced during electricity generation.

The life cycle assessment of the PV system resulted in an FWAE value of 5.96 × 10−2 kg 1,4 DB-eq./kWh. The analysis identified cell processing and panel assembling stages with the highest contribution to the ecotoxicity impact. Specifically, cell processing contributed 34.3% and panel assembling contributed 49.7% to the total impact. The elements that are contributing to freshwater aquatic ecotoxicity in the cell processing stage include chemicals such as HCl and nitric acid used for cleaning and etching of the silicon wafer. In addition, solvents such as n-methyl-2-pyrrolidone (NMP) and isopropanol used in the manufacturing of cells may also contribute to ecotoxicity. Similarly, in the panel assembling stage, the elements that contribute to FWAE include lead (Pb) and cadmium (Cd) from soldering and silver (Ag) from the front metallization process. The use of PVF as a backsheet material and the formation of NOx during the manufacturing process of the backsheet material also contributes to the ecotoxicity impact.

The evaluation of the PV module production’s potential environmental impact resulted in a PO value of 1.85 × 10−5 kg ethane eq./kWh. The impact was primarily driven by the emission of inorganic and organic compounds into the atmosphere. Sulfur dioxide was identified as the most significant contributor, accounting for 56.1% of the total impact. This was mainly attributed to the utilization of steam and electricity during the solar-grade multi-Si (sog-Si) production, wafers, cells, and ingots including the use of the PVF film and aluminum frame during module production. Nitrogen dioxide was also a significant contributor, accounting for 15% of the total impact, and had similar characteristics to sulfur dioxide. The second-largest contributor was non-methane volatile organic compounds (NMVOC), resulting from the consumption of the PVF, EVA, and aluminum frame during the production of the module, NMVOC air emissions during the production of the cell, and the steam and electricity utilization in every production stage.

These results underscore the necessity of considering the entire life cycle of PV modules to identify potential mitigation measures and minimize their environmental impact, from the raw material extraction and processing stages to the end-of-life disposal stage, to identify potential mitigation measures and minimize their environmental impact. By assessing the environmental impact of PV modules throughout their life cycle, it is possible to determine the stages with the highest contribution to the overall environmental impact. Such stages, known as “hotspots,” can then be targeted to minimize the modules’ impact on the environment.

4.3. EPBT and Primary Energy Demand

The EPBT has gained popularity as a commonly utilized parameter, owing to its easily interpretable input–output format. Its calculation method is simplified and can be expressed as follows:

where the energy invested in the PV module is equal to the total primary energy consumed during the production, transportation, installation, and end-of-life disposal of the PV module, and the annual energy production of the PV module is equal to the product of the PV module’s rated power and the average number of peak sunshine hours per day at the installation site.

It is important to note that the use of EPBT has been placed under scrutiny, and alternative indexes have been proposed, such as the GHG payback time, defined as the period during which the PV module must operate to offset the emissions embedded in its production [

32,

33]; however, in this paper the use of EPBT has been deemed to be more appropriate, mainly due to its wider use in the open literature, that allows easier evaluation of the obtained results.

By utilizing the data acquired and the OpenLCA® database, the cumulative primary energy demand (taking into account both renewable and non-renewable resources) of the PV system was assessed to be 0.519 MJ/kWh based on the net calorie value. Accordingly, for a 200 Wp multi-crystalline silicon PV system, the total primary energy demand was found to be 2530 MJ, with calculations eliminating all negligible flows comprising less than 0.1%.

Non-renewable resources such as natural gas, coal, and oil were the primary contributors to the primary energy demands of the PV system. This was primarily a result of the energy-intensive production phases required for the manufacture of solar-grade multi-Si and cells, which primarily utilized electricity generated from thermal processes. The module assembly stage, which involved the production of EVA copolymer, PVF film, and PET film, primarily contributed to the consumption of crude oil and natural gas. The primary energy demand is maximum for the production of solar-grade multi-Si stage (49%) followed by panel assembling (25%), production of cells (19%), and ingots (5%).

Based on the calculated primary energy demand and a rated power of 1 kW for the PV module, the energy invested in the PV module can be estimated as 20,240 MJ based on industry averages (as the average payback period of multi-Si PV is 8 years). Using this value and the annual average solar radiation and peak sunshine hours, the EPBT for different regions in Pakistan is shown in

Table 9.

According to the results, EPBT of multi-Si PV systems in Pakistan was found to be significantly lower than their lifespan, regardless of the region where they were installed. Optimal locations for installation were identified as Balochistan, Sindh, and Punjab, with an EPBT of approximately 2 to 3 years, indicating that the energy consumed during the system’s life cycle stages was recovered within this time frame. The EPBT in Gilgit-Baltistan and Azad Jammu and Kashmir regions was also reasonable, at between 3 to 3.5 years, suggesting that PV system development in Pakistan was a feasible option for energy purposes.

4.4. Sensitivity Analysis

A sensitivity analysis was performed to evaluate the effects on environmental impacts and primary energy demand. This analysis was conducted while keeping the processing technology constant. This study exclusively utilized the information provided in

Table 2, encompassing module characteristics and solar radiation details. The sensitivity analysis aimed to ascertain the impact of certain factors on environmental consequences and energy demand. These factors included the consumption of electricity and steam during the production of solar-grade multi-Si, the usage and disposal of glass during the wafer slicing process, the electricity consumption during cell processing, as well as the consumption of aluminum and glass during the assembly of modules.

A decrease of 10% in the utilization of electricity during the manufacturing process of solar-grade multi-Si would precipitate a 3.36% reduction in the primary energy demand (

Table 10). Conversely, an increase of 10% in electricity consumption would lead a corresponding increase of 3.36% in the primary energy demand. The dominant factor affecting primary energy demand, AP, and EP was the electricity consumption observed during the production of solar-grade multi-Si. Subsequently, the influence lessened in the order of electricity consumption during cell processing, steam consumption during solar-grade multi-Si production, and the consumption of aluminum and glass during the assembly of modules. Similarly, the primary influence on the GWP and PO originated from electricity consumption during the production of solar-grade multi-Si. Subsequently, the effects of electricity consumption during cell processing took place, trailed by aluminum consumption during module assembly, steam consumption during solar-grade multi-Si production, and finally, the utilization of glass during module assembly. In terms of TE, the paramount impact stemmed from electricity consumption during the production of solar-grade multi-Si, accounting for approximately 2.97% (

Table 10). This was trailed by the influence of glass consumption and disposal during wafer slicing, which amounted to 2.10%. On the FWAE, the most significant factor was aluminum consumption during module assembly. Notably, a reduction of 10% in aluminum consumption during module assembly would correspondingly result in a substantial 7.00% decrease in the FWAE.