Abstract

The reduction of emissions in hard-to-abate industries is described in several proposals on the European and National levels. In order to meet the defined goals, the utilization of sustainable, non-fossil fuels for process heat generation in industrial furnaces needs to be intensified. The focus mainly lies on hydrogen () and its derivates. Furthermore, biofuels, e.g., dimethyl ether (DME), are considered. Besides possible changes in the process itself when substituting natural gas (NG) with alternative fuels, the emission of nitrogen oxides () is a major topic of interest. In current European standards and regulations, the emissions are specified in mg per m3 of dry off-gas and refer to a reference oxygen concentration. Within this study, this limit specification is investigated for its suitability for the use of various fuel-oxidizer combinations in industrial combustion applications. Natural gas is used as a reference, while hydrogen and DME are considered sustainable alternatives. Air and pure oxygen () are considered oxidizers. It is shown that the current specification, which is built on the use of fossil fuels, leads to non-comparable values for alternative fuels. Therefore, alternative limit definitions are discussed in detail. The most suitable alternative was found to be mg per kWh. This limit specification is finally being investigated for its compliance with current regulations on various aspects of Continuous Emission Monitoring Systems.

1. Introduction

With the European Green Deal [1], the European Commission adopted a set of proposals to reduce the specific emissions of Europe in the near future, thus aligning itself with the Paris Agreement [2]. Based on the level in 1990, net greenhouse gas emissions must be reduced by 50% by 2030 and to zero by 2050. To achieve these goals, the development, production, and utilization of decarbonized gaseous fuels need to be intensified. In particular, hydrogen () and other alternative fuels such as ammonia () and biofuels (e.g., dimethyl ether—DME ()) are described as “climate and resource front-runners” [1] and should therefore be prioritized. The European Hydrogen Strategy [3], based on the Green Deal, describes a roadmap for the implementation of hydrogen and its derivatives as a solution to achieve the emission reduction targets set by the European Commission.

As part of the European Union’s Green Deal initiative, the “Fit for 55” [4] and “REPowerEU” [5] packages define even more ambitious short-term goals. By 2030, the net emission reduction should be at least 55%, and a 45% share of renewable energy should be achieved.

In industrial furnaces, where process temperatures often exceed 1200 °C, direct electrification may not always be possible or at a low Technology Readiness Level (TRL) [6,7,8,9,10]. The application of hydrogen, the most prominent non-fossil fuel, is a topic of many studies, especially for sectors with high-temperature processes, e.g., steel [11,12,13], non-ferrous [14,15], cement [16,17], ceramics [18,19], and glass [20]. In parts of the processes, hydrogen is used as a feedstock or reductant, but it is also thoroughly discussed as a fuel to produce high-temperature heat. Burners used for high-temperature processes operate in non-premixed configurations in most cases, so potential limitations for the use of hydrogen due to flashbacks [21] are not relevant in this case.

Different non-fossil fuels are under investigation for a wide range of applications, showing the significant efforts on the decarbonization of industrial combustion: theoretical studies [22,23], application-oriented demonstration projects [24,25,26,27,28,29], investigation of the use of /natural gas (NG) blends in industrial furnaces [30,31,32,33], and first full-scale furnace conversions [34]. As an alternative fuel, pure ammonia and blends are investigated in demonstration projects [35] and at lab scale [36,37,38,39]. Furthermore, DME [40] and several other alternative fuels [41] are also under investigation and discussion.

As the energy transition moves towards more sustainable and decentralized electricity generation, which may include on-site hydrogen production, the availability of non-fossil fuels is not expected to be constant. This may also be the case for hydrogen supply via pipeline [3,42]. Therefore, switching to more flexible heating technologies, such as multi-fuel burners, is essential to be prepared for the future energy supply landscape. For on-site production, the oxygen () produced during electrolysis can also be used as an oxidizer, resulting in a reasonably lower primary energy demand for high-temperature processes [22,43]. This results in several different fuel-oxidizer configurations compared with today’s constant operating levels in technical combustion processes.

Nitrogen oxides () are one of the major pollutants in industrial combustion processes. These compounds are formed during combustion, and their emission limits are defined by legislation.

Within this study, current emission limits are investigated for their suitability for the use of various fuels and fuel-oxidizer combinations in industrial combustion applications. Natural gas is used as a reference, while hydrogen and DME represent hydrogen-based fuels and biofuels. For the oxidizers, air and pure oxygen are considered the main applications. To give a brief overview of industrial combustion, Section 2 presents the fundamental equations for this study and the current European standards and regulations for industrial emissions. Section 3 gives an example of the current limitations of the existing limit definitions, while in Section 4, alternative definitions are investigated to demonstrate their viability. The most suitable option is then discussed in Section 5. An example of the application of an alternative limit definition is given in Section 6. Finally, this study is summarized and gives a short outlook.

The scope of this work is specifically limited to industrial process heating applications. Electricity generation and boiler applications are not part of the investigations discussed in this study.

2. Fundamentals and Current Standards

2.1. Basic Equations of Combustion

The general oxidation of a species, , in a combustion process is described in Equation (1). Furthermore, the combustion of methane, , is given in Equation (2) as an example [44].

In the following calculations, all gases are considered ideal. Since all species have the same molar volume at standard conditions, the molar concentration of a species in a gaseous fuel mixture equals its volumetric concentration.

For the stoichiometric combustion of methane, two moles of are required per mole of . The required oxygen supply for the complete combustion process is expressed by the stoichiometric oxygen volume . For a fuel mixture as listed in Table 1, is obtained from Equation (3), where defines the concentration and the stoichiometric oxygen ratio of each species within the fuel mixture. It should be noted that the amount of oxygen in the fuel has to be subtracted.

Table 1.

Simplified composition of natural gas H (North Sea) [33].

The required oxygen is supplied by an oxidizer, which may be air, oxygen-enriched air, or, in some cases, pure oxygen. The minimum amount of oxidizer required for complete combustion is therefore obtained from Equation (4), where is the oxygen concentration in the oxidizer. For simplicity, it is often assumed that air has an oxygen concentration of = 0.21 (or 21 vol%) and a nitrogen concentration of = 0.79 (or 79 vol%). To ensure complete combustion of the fuel and avoid incomplete oxidation resulting in carbon monoxide () emissions when using carbon-containing fuels, most combustion processes require an excess of oxygen. The air ratio describes the ratio of the supplied amount of oxidizer to the minimum amount of oxidizer (Equation (5)) [44]. In theoretical combustion literature, the air ratio is often expressed as the fuel-air equivalence ratio .

In the case of combustion with excess oxygen (, the specific amounts of the off-gas species carbon dioxide (), water vapor (), oxygen (), and nitrogen () are given by Equations (6)–(9). The specific amounts of and , referred to as and , are formed according to the fuel species’ chemical reactions with oxygen. The specific amounts of moist and dry off-gas are given by Equations (10) and (11), respectively [44].

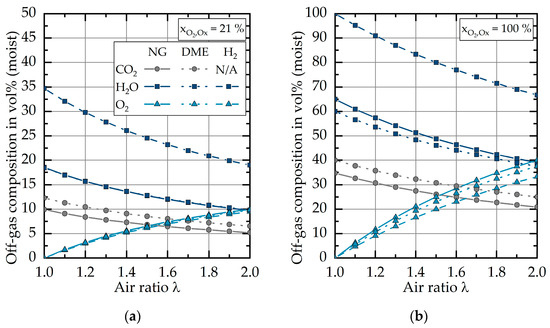

Figure 1 gives an overview of the theoretically calculated off-gas composition for the combustion of natural gas H as specified in Table 1, hydrogen, and DME for ≥ 1. The calculations have been performed for both air (a) and pure oxygen (b) as the oxidizer.

Figure 1.

Calculated moist off-gas composition for the combustion of natural gas H, hydrogen, and DME with air (a) and oxygen (b) for different air ratios (bal. N2).

In addition, the air ratio is calculated by using the measured oxygen concentration in the dry off-gas (Equation (13)) [44]. This equation is derived from the oxygen balance in Equation (12).

with

- Spec. volume of dry off-gas for .

Finally, the volume flow of dry and moist off-gas and are obtained by applying Equations (14) and (15) [44].

Here, the volume flow of the fuel is calculated using Equation (16) [45,46].

with

- Net calorific value;

- Thermal power of the combustion system;

The calculation of the net calorific value of a fuel mixture is given in Equation (17) [47].

with

- Net calorific value for species j in the fuel mixture.

To illustrate the equations described above, the differences in the physical properties and combustion characteristics of natural gas, hydrogen, and DME are shown in Table 2.

Table 2.

Comparison of physical properties and combustion characteristics of natural gas H (North Sea), hydrogen, and DME with air; calculations in accordance with [44,47,48].

2.2. Fundamentals and Legislation of Industrial NOx Emissions

On a European level, the Industrial Emissions Directive (IED) 2010/75/EU [49] establishes the framework within which industrial production plants in the EU must operate. Thus, the EU member states are committed to reducing their air pollution emissions. Namely, the National Emission Reduction Commitments Directive (NEC) EU 2016/2284 [50] defines five major air pollutants:

- Nitrogen oxides ();

- Non-methane volatile organic compounds ();

- Ammonia ();

- Sulfur dioxide ();

- Fine particulate matter ().

Permits for industrial installations are issued in accordance with the principles of the IED [49], which require the use of the Best Available Techniques (BAT) as a reference, including emission limit values. The conclusions of the BAT are set out in reference documents for specific industrial sectors (BREF: best available techniques reference document). The IED is further transposed into the national legislation of each EU member state. In Germany, for example, the implementation has been amended in the BImSchG [51]. The specific emission limit values are further defined in TA Luft [52], which is an administrative regulation of the BImSchG [51]. The scope of this work is limited to as the most relevant air pollutant for the investigated fuels [48,53].

The term nitrogen oxides mainly includes the species nitric oxide () and nitrogen dioxide (). In most technical combustion processes, NO is emitted and then further oxidized to at lower temperatures in the atmosphere. The definition of as an air pollutant is based on the toxic properties of and its derivatives [54].

NO formation through different pathways has been researched for many years and has been recently described and summarized by Glarborg et al. [55]:

- Thermal NO (Zeldovich-NO);

- Prompt NO (Fenimore-NO);

- Fuel NO;

- NO formation from reactions of -radicals;

- NO formation from reactions of .

Within the process heating industry, thermal NO [56] and prompt NO [57] are of main interest for conventional combustion regimes and gaseous fossil fuels [44]. The formation of NO for these mechanisms depends on the molecular in the oxidizer and in the fuel. The thermal pathway and in the fuel are of significant importance for the combustion of natural gas with pure oxygen due to the high combustion temperatures [58]. However, prompt NO is not relevant for hydrogen as fuel because of the absence of -radicals in the flame front [55]. Fuel NO is not to be considered since conventional gaseous fuels, nowadays used within the industry, have negligible amounts of fuel-bound nitrogen. This might change in the future when ammonia is utilized as fuel [59,60]. The latter two mechanisms via (first proposed by Bozelli and Dean [61] and investigated by several authors [62,63,64,65]) and (proposed by Malte and Pratt [66]) may not play a major role in natural gas firing. However, their contribution may be considered for hydrogen, ammonia, and other alternative fuels [67].

Several measures to reduce NO formation are already known and in use. Most of them aim to reduce the maximum temperature within the reactive zone and therefore reduce NO formation via the thermal pathway. The most prominent recent developments are MILD combustion [68] or flameless oxidation [69]. End-of-pipe solutions like selective catalytic reduction (SCR) are used to reduce to and before emitting them through the stack [70].

For downstream steel processing (hot rolling, cold rolling, wire drawing, and hot dip galvanizing), the BREF for the Ferrous Metals Processing Industry (FMP) [71] specifies the emission limits for different high-temperature processes. As an example, the document indicates emissions of 80 to 200 mg/m3 (new plants) and 100 to 350 mg/m3 (existing plants) for reheating installations for hot rolling. The indicated values refer to an excess oxygen concentration in the dry off-gas of 3.0 vol%. It is important to note that emission limits in the BREF FMP [71] have been defined mainly for natural gas-fired plants. Additional emission limits are defined for so-called “other fuels”, but hydrogen and other alternative fuels are not mentioned.

There are several techniques to measure NO concentrations in off-gas, but chemiluminescence is the most commonly used standard method acc. to EN 14792 [72]. The measuring principle relies on the reaction of NO molecules with ozone to form in an excited state. From its excited state, falls back to its ground state of and emits radiation. The radiation, measured by a detector, is directly proportional to the NO concentration. To measure concentrations, must first be catalytically reduced to NO in a separate converter.

The standard series EN 15267-1 to -4 [73,74,75,76] and EN 14181 [77] describe principles for the application of Continuous Emission Monitoring Systems (CEMS). Here, general methods are defined as well as certification, calibration, testing, and quality assurance procedures. The “requirements for measurement sections and sites and for the measurement objective, plan and report” are given in EN 15259 [78].

In conventional off-gas analyzer systems, the moist off-gas is extracted, dried, and filtered. The concentration is measured in in the dry off-gas. Equation (18) is used to convert the measured concentration in at an concentration of , to the calculated value in in the dry off-gas at a defined reference -concentration . The calculation of emissions refers to the density = 2.056 kg/m3 of . Usual values for the reference -concentration are 3.0 vol% or 5.0 vol%, depending on the application [52,71]. In most references, the equation is given for air combustion, i.e., = 0.21.

However, these calculations are only applicable for combustion processes with air as the oxidizer. Therefore, alternative approaches have been developed to be able to compare emissions from air combustion with those from oxygen-enriched or pure oxygen combustion. For the latter, the constant relation between the number of NO molecules and the number of molecules is considered in an approach formulated in the BREF FMP [71]. The recalculated emissions in are based on a reference concentration compared with the measured concentration in the dry off-gas (Equation (19)). A value of = 10.0 vol% is given in [71] as an example.

There are only brief discussions in the literature addressing some of the issues that arise when emissions for different fuels are compared [79,80,81,82]. In theoretical investigations of lab-scale applications, different emission definitions are found [58,83,84,85,86,87]. In these cases, all input parameters are well defined and known, simplifying the conversion of emissions to other limit definitions. Furthermore, these applications are not bound to industrial standards and regulations or underlie any quality control.

Accordingly, a holistic approach to this issue has not yet been taken. This study investigates several alternatives for the definition of limits, especially concerning comparability for different fuels and oxidizers, the quantities to be measured and calculated, and compliance with existing standards. The calculations are performed for three different fuels: Natural gas H (North Sea), hydrogen , and dimethyl ether (DME). Ammonia, which is also often discussed as an alternative fuel for future applications, is explicitly excluded from these considerations as it represents a special case of hydrogen combustion.

3. Problem Statement

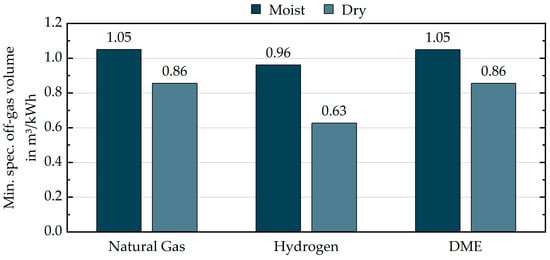

As introduced in Section 2.2, current limit specifications in existing standards are defined in of dry off-gas at a specific reference oxygen concentration. Therefore, the emissions are based on the amount of dry off-gas. However, Figure 1 and Table 2 illustrate the differences in the specific volume of moist off-gas and its composition, especially the water vapor concentration, for different fuels. Figure 2 shows these differences in more detail for a constant air ratio of = 1 for the combustion with air.

Figure 2.

Theoretical minimum amount of moist and dry off-gas ( = 1) for the combustion of natural gas H, hydrogen and DME with air.

A comparison of the combustion of natural gas, DME, and hydrogen with air shows that there are differences in the minimum specific volumes of moist and dry off-gas. DME and natural gas behave similarly, so only the difference between natural gas and hydrogen is discussed, which is 26.7% for dry and 8.5% for moist off-gas. Furthermore, the water vapor concentration of the off-gas is also different for the two fuels. For hydrogen, water vapor accounts for almost 35 vol% of the off-gas volume, while for natural gas it only accounts for 18.5 vol%. Consequently, the difference between dry and moist off-gas is higher for hydrogen combustion than for natural gas combustion.

These differences make it difficult to compare emissions between different fuels using the existing standards and regulations, i.e., on a dry off-gas basis.

To better understand the challenge, a comparison is performed between the measured emission in in dry off-gas and the corresponding mass flow in mg/h for different fuels with both air and oxygen as oxidizers. For the comparison, a measured value of 180 is used as the starting point for further calculations. The value is measured in the dry off-gas for a corresponding measured oxygen concentration of = 2.0 vol%.

3.1. Combustion with Air

First, the calculations are carried out with air as oxidizer. Considering the density of and Equation (20), the measured value of 180 is recalculated to 370.08 for all three fuels.

As mentioned above, the relevant standards and regulations require the consideration of a specific reference oxygen concentration in the dry off-gas. For many applications, a reference oxygen concentration of = 3.0 vol% is defined. The application of Equation (21) therefore gives a referenced value of 350.6 (3.0 vol% ). This value corresponds approximately to the current limit mentioned in [71].

To this point, the calculations above comply with the current standards and regulations. Since the off-gas volume differs for natural gas, hydrogen, and DME, the emission values are converted into a mass flow to ensure a consistent, unaltered comparison between the three fuels.

In order to obtain the mass flow from the industrial furnace, the air ratio corresponding to the referenced oxygen concentration in the off-gas must first be calculated for the different fuels by applying Equation (13). This results in air ratios of 1.09, 1.08, and 1.10 for natural gas, hydrogen, and DME, respectively. The specific volumes and volume flows of the dry off-gas are calculated using the basic combustion equations in Section 2.1. The total mass flow is then given by Equation (22) for dry off-gas. Alternatively, the mass flows can also be calculated using the corresponding values of the moist off-gas.

The measured concentration of 180 based on a thermal power input of 1 kW results in the following mass flows for the combustion of the three different fuels with air as an oxidizer:

- Natural gas: 350.14 mg/h

- Hydrogen: 256.74 mg/h

- DME: 350.21 mg/h

These calculations show that the same measured concentration in from the combustion of three different fuels with air gives the same emission values in according to the discussed standards and regulations. However, these values do not consider the different combustion characteristics of the fuels. In reality, the total mass flows are different. In this example, the mass flow for hydrogen combustion is approximately 27% lower compared with natural gas.

Therefore, the current limit specifications from existing standards and regulations result in “unfair” comparisons between different fuels and lead to the necessity of defining different limits depending on the fuel. Aiming at possible fuel-flexible operation of plants in the future, this is even more critical since the limit depends on the fuel composition.

3.2. Combustion with Oxygen

For combustion with pure oxygen as the oxidizer, it is in principle possible to specify the limit specification with reference to the dry off-gas for most fuels. However, this definition is not suitable for pure hydrogen combustion. If the calculations in Section 2.1 are carried out with an air ratio of = 1, i.e., no excess oxygen, the off-gas contains only , and therefore no dry off-gas will be measured. For an air ratio of > 1, oxygen is the only species other than air pollutants present in the dry off-gas and will therefore always approach values close to 100 vol%. Measuring the oxygen concentration in the dry off-gas is therefore not practical and will lead to significant uncertainties. Additionally, the consideration of measured and reference concentrations as mentioned above in Equation (19) is also not possible due to the lack of in the off-gas for pure hydrogen combustion.

4. Alternative Approaches for the Specification of NOx Limits

The calculations presented above show that it is not possible to compare the three different fuels using current standards and regulations. Indeed, although the same concentrations are measured in the off-gas, the total mass flows differ significantly. Consequently, consideration of the moist off-gas appears to be inevitable in order to achieve a universal limit specification. Therefore, this section describes alternative limit specifications, considering the varying off-gas compositions and combustion characteristics of different fuels.

A first approach is to conduct the calculations as presented in Section 3 for dry off-gas with moist off-gas. In this case, the different water vapor concentrations in the off-gasses of the fuels are considered.

The moist emissions can be either measured directly in the moist off-gas or calculated from the measured dry value in Equation (23) considering the measured water vapor concentration in the off-gas .

Analogously to Equation (20), multiplication with the density of gives the emissions in in Equation (24).

Again, the resulting value can be referenced to a specific oxygen concentration in the moist off-gas in Equation (25), where defines the measured (or calculated analogously to Equation (23)) oxygen concentration in the moist off-gas. As stated above, a reference oxygen concentration of = 3.0 vol% is often given. The theoretical combustion calculation of natural gas shows that an oxygen concentration of 3.0 vol% in the dry off-gas corresponds to an oxygen concentration of approx. 2.5 vol% in the moist off-gas. Therefore, this value is used as the moist reference oxygen concentration from here on.

However, this approach does not consider the differences in the specific volumes of moist off-gas for different fuels.

Therefore, as a second approach, the emissions are related to the net calorific value of the corresponding fuel in Equation (26). It has to be noted that this equation is defined in EN 267 [45] and EN 676 [45,46] for = 0.21 (air as oxidizer) and dry off-gas as basis. These standards refer to forced-draught burners for non-industrial applications. Alternatively, the calculation can be conducted with moist off-gas (Equation (27)).

with

- Spec. volume of moist off-gas for = 1.

An overview of the calculated values for different emission limit specifications for combustion with air is given in Table 3. The values refer to an oxygen concentration of 3.0 vol% in the dry off-gas and 2.5 vol% in the moist off-gas.

Table 3.

Different limit specifications for the combustion of NG, , and DME with air, based on a measured concentration of 180 ; reference concentrations in the off-gas: 3.0 vol% (dry) and 2.5 vol% (moist).

The same calculations are carried out for the combustion of pure oxygen as an oxidizer. As already stated in Section 3, universal calculations of limit specifications for the combustion of hydrogen with pure oxygen are only possible considering the moist off-gas. Therefore, a fixed measured emission of 180 is defined as the basis for further calculations with oxygen as an oxidizer. The measured oxygen concentration was set to 2.5 vol% (moist). The results are given in Table 4. It becomes clear that, similar to air combustion, the same measured concentration in results in different total mass flows for different fuels.

Table 4.

Different limit specifications for the combustion of NG, , and DME with pure oxygen, based on a measured concentration of 180 ; reference concentration in the off-gas: 2.5 vol% (moist).

5. Discussion

The presented alternative approaches in Section 4 show that the current limit specification in in existing standards and regulations for industrial applications may not be the best solution for comparing emissions of different fuel-oxidizer combinations. This is due to the differences in their physical properties and combustion characteristics, i.e., different specific volumes of off-gas, different water vapor concentrations in the off-gas, or different net calorific values.

Section 4 describes the comparison of emissions in by considering the moist instead of the dry off-gas as a first alternative approach. As of today, measurement techniques for moist off-gas with a high water vapor concentration (>40 vol%) are not yet commercially available [88] but are under development [24]. However, this approach still does not consider the different specific volumes of off-gas for the combustion of different fuels.

Considering the total mass flow in mg/h, a comparison between different fuel-oxidizer combinations would be possible independently of combustion characteristics. However, the mass flow depends on the actual heating power of the plant. Therefore, considering the mass flow, it would not be fair to compare applications with different power inputs.

In conclusion, the limit specification based on the net calorific value in mg/kWh seems to be the most appropriate alternative to consider either different combustion characteristics of the fuels or the non-constant (real) operation of the plants.

To evaluate the most appropriate limit specification in mg/kWh, different research questions to determine whether it is a suitable alternative for a universal future limit definition are discussed in the following.

Research Question 1. Is the limit definition comparable for flexible fuel/oxidizer systems?

As stated above, the limit specification in mg/kWh accounts for all the differences in physical properties and combustion characteristics of different fuels and oxidizers. To demonstrate the suitable correlation between the total mass flow and the limit specification of mg/kWh, the calculations from Section 4 are carried out in reverse with a fixed mass flow of = 300 mg/h and a thermal power input of = 1 kW for all fuels. To simplify the calculation, an excess oxygen concentration of 2.5 vol% in the moist off-gas is chosen, i.e., the reference oxygen concentration.

The combination of Equation (22), applied for moist off-gas, and Equation (25), gives emissions of 251.54 (natural gas), 274.90 (hydrogen), and 251.82 (DME) for combustion with air. These values are already referenced due to the fixed excess oxygen concentration of 2.5 vol% in the moist off-gas. The application of Equation (27) leads to a constant and fuel-independent value of 300 mg/kWh.

For pure oxygen combustion, emissions of 976.26 (natural gas), 876.52 (hydrogen), and 907.77 (DME) result from the application of Equation (22), again for moist off-gas, and Equation (25). Analogously to the case of air combustion, Equation (27) leads to a constant value of 300 mg/kWh.

The fact that this limit definition is comparable for all the investigated fuel-oxidizer combinations is confirmed by the reversed calculations, based on a fixed total mass flow, showing the same result for all three fuels. As the definition is comparable for different fuels and fuel blends, fuel-flexible operations are also covered by this approach.

Research Question 2. Which parameters have to be measured?

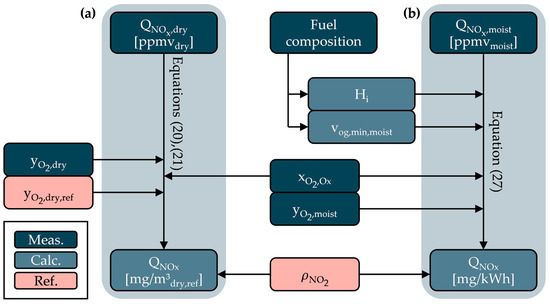

Figure 3 compares the calculation procedures for emissions based on current standards (a) and the proposed universal limit definition (b). It has to be noted that, as per current regulations, e.g., [52], the calculation of standardized emissions in reference to a specific amount of oxygen (dry off-gas) requires the measurement of the oxygen concentration in the dry off-gas.

Figure 3.

Schematic for emission calculation; current standards and regulations (a) and proposed universal limit definition (b).

For the universal limit definition, it is necessary to measure the following parameters:

- concentration: The measurement of the concentration has to be carried out in moist off-gas. In theory, and as shown in Section 4, the moist concentration could be calculated from the dry measurement. However, as indicated above, the measurement in dry off-gas is not possible for the special case of - combustion. Therefore, the general formulation of a universal emission limit requires measurement in moist off-gas. Another option would be to measure the concentration in the dry off-gas in combination with a quantitative analysis of the nitrate in the condensate. But this would pose additional challenges as it would require measurement of the condensate mass flow and additional chemical analytics on nitrate concentration.

- concentration: The oxygen concentration has to be measured in the moist off-gas. There are several issues to consider: On the one hand, the air ratio cannot be determined by measuring dry off-gas for the special case of - combustion, which will lead to significant uncertainties. On the other hand, the use of calculated concentrations is not applicable in reality because leaking air may influence NO formation and subsequently the resulting emissions. Therefore, the theoretical calculation underlies uncertainties that cannot be quantified.

- Fuel mixture composition: In order to calculate the relevant theoretical specific minimum volume of off-gas and the net calorific value for further conversion of the measured concentration, the measurement of the fuel mixture composition is necessary. Here, gas chromatography is the most common measurement technology in the field. Due to the significant cost of operating these devices, other measurement techniques may be considered in the future. As an alternative to an exact measurement, approximated values for and may be standardized for common fuels, e.g., in EN 676 [46]. The latter results in shortcomings concerning the fuel-flexible operation of a plant.

Research Question 3. Which values have to be calculated?

To quantify the emissions based on the specified limit definition in mg/kWh, it is required to calculate values based on the aforementioned measured parameters:

- Net calorific value: The calculation of the net calorific value of a gaseous fuel is standardized in EN ISO 6796 [47]. The corresponding calculation is described in Equation (17).

- Minimum specific volume of moist off-gas: To calculate from Equation (10), other basic combustion characteristics have to be calculated from the measured fuel composition. Therefore, Equations (3)–(10) are considered. They describe the calculation of the minimum amount of oxygen , the minimum amount of oxidizer and the specific amounts of , , and within the off-gas. It has to be noted that the calculation of basic combustion characteristics is not defined in any current standard.

Once the composition of the fuel mixture is known, the calculations are relatively easy to implement into a certified Continuous Emission Monitoring System (CEMS).

Research Question 4. Is the limit definition in compliance with existing standards?

Current guidelines for the measurement of stationary source emissions, emission measurement techniques, and the certification and quality assurance of automated measuring systems for emission monitoring are manifested in a series of standards. The content of relevant standards was carefully reviewed to answer this research question.

EN 14792 [72] describes the standard reference method of chemiluminescence for the determination of the mass concentration of nitrogen oxides. It is a classical extractive measurement technique, usually carried out on a dry basis. For this purpose, the off-gas sample is cooled down and the water is condensed out in a controlled manner to prevent the dissolution of exhaust gas species such as . However, the general description of the measurement equipment includes a possible arrangement for wet extractive measurement with a heated sample probe, a heated sample line, and a heated analyzer system. It is stated that all parts of the sampling device located upstream of the analyzer shall be composed of materials that neither react nor absorb . The temperature of the whole system must be sufficiently high to avoid any condensation of the off-gas sample. If this arrangement is used, the water vapor concentration of the off-gas must be measured as a reference value to be able to calculate the emissions on a moist basis. However, this setup was not part of the validation procedure carried out in the field to set up the standard. Therefore, measurement uncertainties are not conclusively tested, and specific challenges for this arrangement are not described. The calculation procedures in EN 14792 [72] exclusively refer to dry off-gas as a reference, in accordance with current EU directives [49]. This means that a revision of this standard will be necessary if measurement techniques and emission limits on a humid basis become more established. Otherwise, this standard will no longer be considered state-of-the-art.

The requirements for the measurement section and sites for measuring stationary source emissions are described in EN 15259 [78]. The calculation basis is similar to EN 14792 [72] and may need to be revised in the future. Nevertheless, the measurement of the water vapor concentration to determine the density of the off-gas is mentioned in the standard to allow a high-quality volume flow measurement. EN 14790 [89] is described as the standard for the measurement of water vapor concentration in off-gas.

The EN 15267 series of standards [73,74,75,76] describes the certification of automated measuring systems for continuous or periodic emission monitoring systems. EN 15267-1 [73] and -2 [74] outline the general principles, the initial assessment of the manufacturer’s quality management system, and post-certification surveillance for the manufacturing process. They do not address any specific issues relevant to this study.

EN 15267-3 [75] describes performance criteria and test procedures for automated measuring systems for the continuous monitoring of emissions from stationary sources. It states that measuring systems must include effective control of off-gas condensation, which implies that condensation should be prevented for measurement on a moist basis. If species are measured on a moist basis, measurement of the water vapor concentration in the off-gas is mandatory. This measurement must then also comply with the minimum requirements formulated in the standard. The whole standard is not limited to dry measurement, as not only dry but also moist calibration gases are mentioned for the calibration procedures.

Coming to EN 15267-4 [76], which describes the performance criteria and test procedures for automated measuring systems for periodic measurement, the formulation is consistent with EN 15267-3 [75] in most passages. Nevertheless, additional remarks are made when water vapor is present in concentrations high enough to cause cross-sensitivity in the measurement of other species. The water vapor concentration must then be measured for active compensation. Up to this point, no reason has been found to revise this standard. However, for portable automated measuring systems operating in hot and moist off-gas, the water vapor cross-sensitivity tests shall be performed at water vapor concentrations of 20 vol% and 30 vol%. Aiming at combustion, especially with as an oxidizer in the future, the water vapor concentration will be much higher with approx. 32 vol% for air combustion ( = 1.10) and up to 98 vol% for combustion ( = 1.04). Here, EN 15267-4 will have to be revised to match future measurement conditions. This could also lead to further development work, as water vapor in high concentrations often leads to cross-sensitivities because of its wide absorption spectrum compared with other gases [90].

EN 14181 [77] covers the quality assurance of automated measuring systems. In principle, the influence of water vapor is included. If a calibrated automated measuring device includes the measurement of water vapor concentration, the value can be used to convert concentrations measured on a moist basis to dry conditions. However, again, the calculations carried out refer to dry off-gas. As for the other standards describing the calculation of emission values, revision is mandatory if the definition for emission limits changes to comply with the future state-of-the-art.

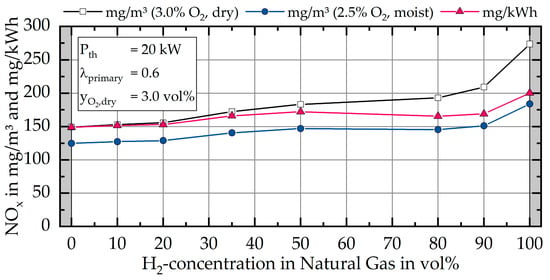

6. Example for the Application of the Proposed NOx Limit Definition

In an ongoing research project [91], experimental investigations have been conducted with a high-velocity cold air burner. The burner was designed based on a commercial self-recuperative burner gas block and operated inside a lab-scale furnace with a thermal power of 20 kW. In a parameter study, the effects of different parameters (air-fuel ratio, furnace temperature, air staging) on emissions were investigated.

As an example of the influence of different limit definitions in a real application, Figure 4 shows the emissions for different hydrogen concentrations blended into natural gas. It becomes clear that the conventional method of referring to the dry off-gas gives a significant leap from 90 to 100 vol% -admixture. This leap is reduced for alternative limit definitions.

Figure 4.

Comparison between different limit definitions for the combustion of -enriched natural gas, based on measurements from Sankowski et al. [91].

7. Summary and Outlook

The present study includes an introduction with basic equations of combustion and existing standards and regulations for industrial emissions. The detailed problem description provides the fundamental shortcomings of the current specification of limits, especially for alternative fuels such as hydrogen. An in-depth analysis of alternative approaches and a critical examination of the identified specification round off the investigations of this study.

Finally, the formulation based on the net calorific value of the fuel in mg/kWh proves to be the most suitable alternative to the existing limit definition. It is applicable to any combination of fuel(s) and oxidizer(s) and also covers fuel-flexible plant operation, as the specific properties of the fuel and the off-gas are considered at all times. Nevertheless, this presents a number of challenges, as today’s typical measurement techniques are mostly based on determining species concentrations in the dry off-gas. As with the current limit definition, the and concentrations of the off-gas must be measured, but in the moist off-gas. Compared with the existing limit definition, the composition of the fuel mixture must be known to calculate the required parameters. These are the lower calorific value, calculated acc. to EN ISO 6796, and the minimum specific amount of moist off-gas (for = 1). For the latter, there is currently no standardized calculation scheme. Minor adjustments will be needed to the standards for emissions measurement for stationary emissions. More urgently, however, is the need for suitable measuring devices to be available on the market to allow comprehensive testing and adequate quality control before a widespread rollout. Otherwise, extensive utilization of sustainable fuels such as hydrogen will be hardly possible because emissions cannot be measured and reported with appropriate quality.

Within this study, emissions originating from non-combustion sources, e.g., from the product inside a furnace, are not discussed. This topic is particularly important for processes in the glass, cement, and mineral industries. Nevertheless, emissions are defined for specific processes in today’s BAT documents, so this could be tackled by applying the same procedure in the future.

Other possible limit definitions that might have significant potential were also not part of this study. On the one hand, a limit definition based on the mass flow in relation to the productivity of the plant defined by seems to be an appropriate option. On the other hand, definitions building on the NOx mass flow in relation to the energy output, defined by , are discussed more and more in the electricity generation sector. Nevertheless, for industrial furnace processes, this will lead to exhausting discussions about how productivity is measured (input/output) and reported and how downtime periods are treated when there is no productivity but the furnace is still in operation and emitting . The latter is not applicable to material production processes, as the output of the process is the treated or produced material itself and not energy.

In summary, this study provides a new limit definition applicable to future fuel and oxidizer scenarios in high-temperature industrial processes, including fuel-flexible operations. It needs to be further studied and proven suitable under real-world process conditions before it can be implemented in legislation. In addition, suitable measurement equipment must be available to enable practical investigations to be carried out.

Author Contributions

Conceptualization, N.S. and T.E.; methodology, N.S., L.S. and E.B.; investigation, L.S., E.B. and N.S.; writing—original draft preparation, L.S., E.B. and N.S.; writing—review and editing, N.S., L.S., E.B., T.E. and H.P.; visualization, E.B., L.S. and N.S.; supervision, H.P., T.E. and N.S.; project administration, T.E. and N.S.; funding acquisition, T.E. and N.S. All authors have read and agreed to the published version of the manuscript.

Funding

This study was carried out as part of the HYINHEAT project. HYINHEAT is co-funded by the European Union under Grant Agreement No. 101091456. The views and opinions expressed are, however, those of the authors only and do not necessarily reflect those of the European Union, European Health, or the Digital Executive Agency (HaDEA). Neither the European Union nor the granting authority can be held responsible for them. The presented experimental data were generated during trials within the TTgoesH2 IGF-project (IGF-No. 31 LBG) funded by the Federal Ministry for Economic Affairs and Climate Action based on a resolution of the German Bundestag.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Acknowledgments

The authors would like to thank Moritz Siegfried and his colleagues from SICK AG for the valuable discussions during the preparation of this manuscript.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

Nomenclature

| Variable | Unit | Description |

| Net calorific value for species in the fuel mixture | ||

| Net calorific value (volumetric) | ||

| air ratio | ||

| specific oxidizer volume | ||

| minimum specific oxidizer volume for = 1 | ||

| mass flow | ||

| vol. concentration of oxygen in the fuel mixture (assumption in this paper: all gases behave ideally.) | ||

| specific oxygen volume for species j in the fuel mixture for = 1 | ||

| specific oxygen volume of the fuel mixture for = 1 | ||

| Thermal power of the combustion system | ||

| mass concentration of in the dry off-gas at reference -concentration | ||

| mass concentration of in the dry off-gas | ||

| mass concentration of in the moist off-gas at reference -concentration | ||

| mass concentration of in the moist off-gas | ||

| density of nitrogen dioxide () | ||

| specific volume of in the off-gas of species j | ||

| specific volume of in the off-gas of the fuel mixture | ||

| specific volume of in the off-gas of species j | ||

| specific volume of in the off-gas of the fuel mixture | ||

| specific volume of in the off-gas of the fuel mixture | ||

| specific volume of in the off-gas of the fuel mixture | ||

| specific volume of dry off-gas | ||

| specific volume of dry off-gas for = 1 | ||

| specific volume of moist off-gas | ||

| specific volume of moist off-gas for = 1 | ||

| volume flow of the fuel mixture | ||

| volume flow of dry off-gas | ||

| volume flow of moist off-gas | ||

| vol. concentration of species within the fuel mixture | ||

| vol. concentration of in the combustion air | ||

| vol. concentration of in the oxidizer | ||

| vol. concentration of in the combustion air | ||

| measured vol. concentration of in the dry off-gas | ||

| reference vol. concentration of in the dry off-gas | ||

| vol. concentration of in the moist off-gas | ||

| vol. concentration of in the dry off-gas | ||

| measured vol. concentration of in the dry off-gas | ||

| reference vol. concentration of in the dry off-gas | ||

| measured vol. concentration of in the moist off-gas | ||

| measured vol. concentration of in the moist off-gas | ||

| equivalence ratio |

References

- European Commission. The European Green Deal: COM(2019) 640 Final; European Commission: Brussels, Belgium, 2019. [Google Scholar]

- United Nations. Framework Convention on Climate Change. The Paris Agreement; United Nations: New York, NY, USA, 2015. [Google Scholar]

- European Commission. A Hydrogen Strategy for A Climate-Neutral Europe: COM(2020) 301 Final; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- European Commission. ‘Fit for 55′: Delivering the EU’s 2030 Climate Target on the Way to Climate Neutrality: COM(2021) 550 Final; European Commission: Brussels, Belgium, 2021. [Google Scholar]

- European Commission. REPowerEU Plan: COM(2022) 230 Final; European Commission: Brussels, Belgium, 2022. [Google Scholar]

- Pfeifer, H. Industrial Furnaces—Status and Research Challenges. Energy Procedia 2017, 120, 28–40. [Google Scholar] [CrossRef]

- Zaini, I.N.; Svanberg, R.; Sundberg, D.; Bölke, K.; Granqvist, J.; Lille, C.; Tarantino, N.; Yang, W. A pilot-scale test of plasma torch application for decarbonising the steel reheating furnaces. Therm. Sci. Eng. Prog. 2023, 40, 101766. [Google Scholar] [CrossRef]

- Zaini, I.N.; Svanberg, R.; Yang, W. Bilaga 3: Applications of thermal plasma torches for industrial furnaces: A review. In PLATIS—Plasma Technology in Steel Industry Furnaces; Tarantino, N., Malmqvist, H., Eds.; PLATIS: Stockholm, Sweden, 2021. [Google Scholar]

- Zaini, I.N.; Svanberg, R.; Yang, W. Bilaga 5: Applications of thermal plasma torch for steel heat-treatment furnaces: Results from the pilot-scale test. In PLATIS—Plasma Technology in Steel Industry Furnaces; Tarantino, N., Malmqvist, H., Eds.; PLATIS: Stockholm, Sweden, 2021. [Google Scholar]

- Zaini, I.N.; Svanberg, R.; Yang, W. Bilaga 8: Techno-economic analysis of thermal plasma torch application for heating furnaces. In PLATIS—Plasma Technology in Steel Industry Furnaces; Tarantino, N., Malmqvist, H., Eds.; PLATIS: Stockholm, Sweden, 2021. [Google Scholar]

- Shahabuddin, M.; Brooks, G.; Rhamdhani, M.A. Decarbonisation and hydrogen integration of steel industries: Recent development, challenges and technoeconomic analysis. J. Clean. Prod. 2023, 395, 136391. [Google Scholar] [CrossRef]

- Marocco, P.; Gandiglio, M.; Audisio, D.; Santarelli, M. Assessment of the role of hydrogen to produce high-temperature heat in the steel industry. J. Clean. Prod. 2023, 388, 135969. [Google Scholar] [CrossRef]

- Liu, W.; Zuo, H.; Wang, J.; Xue, Q.; Ren, B.; Yang, F. The production and application of hydrogen in steel industry. Int. J. Hydrogen Energy 2021, 46, 10548–10569. [Google Scholar] [CrossRef]

- Röben, F.T.; Schöne, N.; Bau, U.; Reuter, M.A.; Dahmen, M.; Bardow, A. Decarbonizing copper production by power-to-hydrogen: A techno-economic analysis. J. Clean. Prod. 2021, 306, 127191. [Google Scholar] [CrossRef]

- Peppas, A.; Politi, C.; Kottaridis, S.; Taxiarchou, M. LCA Analysis Decarbonisation Potential of Aluminium Primary Production by Applying Hydrogen and CCUS Technologies. Hydrogen 2023, 4, 338–356. [Google Scholar] [CrossRef]

- Habert, G.; Miller, S.A.; John, V.M.; Provis, J.L.; Favier, A.; Horvath, A.; Scrivener, K.L. Environmental impacts and decarbonization strategies in the cement and concrete industries. Nat. Rev. Earth Env. 2020, 1, 559–573. [Google Scholar] [CrossRef]

- Griffiths, S.; Sovacool, B.K.; Del Furszyfer Rio, D.D.; Foley, A.M.; Bazilian, M.D.; Kim, J.; Uratani, J.M. Decarbonizing the cement and concrete industry: A systematic review of socio-technical systems, technological innovations, and policy options. Renew. Sustain. Energy Rev. 2023, 180, 113291. [Google Scholar] [CrossRef]

- Lansdorf, T. Hydrogen—A Game Changer for the Ceramic Industry. Interceram. Int. Ceram. Rev. 2022, 71, 48–54. [Google Scholar] [CrossRef]

- Del Furszyfer Rio, D.D.; Sovacool, B.K.; Foley, A.M.; Griffiths, S.; Bazilian, M.; Kim, J.; Rooney, D. Decarbonizing the ceramics industry: A systematic and critical review of policy options, developments and sociotechnical systems. Renew. Sustain. Energy Rev. 2022, 157, 112081. [Google Scholar] [CrossRef]

- Zier, M.; Stenzel, P.; Kotzur, L.; Stolten, D. A review of decarbonization options for the glass industry. Energy Convers. Manag. X 2021, 10, 100083. [Google Scholar] [CrossRef]

- Fruzza, F.; Lamioni, R.; Tognotti, L.; Galletti, C. Flashback of H2-enriched premixed flames in perforated burners: Numerical prediction of critical velocity. Int. J. Hydrogen Energy 2023. [Google Scholar] [CrossRef]

- Schmitz, N.; Sankowski, L.; Kaiser, F.; Schwotzer, C.; Echterhof, T.; Pfeifer, H. Towards CO2-neutral process heat generation for continuous reheating furnaces in steel hot rolling mills—A case study. Energy 2021, 224, 120155. [Google Scholar] [CrossRef]

- Sankowski, L.; Kaiser, F.; Schmitz, N.; Schwotzer, C.; Pfeifer, H. CO2-neutral Process Heating for Carburizing Furnaces—An Ecological Analysis. HTM J. Heat Treat. Mater. 2023, 78, 3–16. [Google Scholar] [CrossRef]

- Community Research and Development Information Service. Hydrogen Technologies for Decarbonization of Industrial Heating Processes (HyInHeat)—Fact Sheet; Publications Office of the European Union: Brussels, Belgium, 2023. [Google Scholar]

- Community Research and Development Information Service. Advancing Hydrogen (H2) Technologies and Smart Production Systems to Decarbonise the Glass and Aluminium Sectors (H2Glass)—Fact Sheet; Publications Office of the European Union: Brussels, Belgium, 2023. [Google Scholar]

- Community Research and Development Information Service. HYbrid Technologies for Sustainable Steel reHEATing (HyTecHeat)—Fact Sheet; Publications Office of the European Union: Brussels, Belgium, 2022. [Google Scholar]

- Community Research and Development Information Service. Gradual Integration of REnewable Non-Fossil ENergy Sources and Modular HEATing Technologies in EAF for Progressive CO2 Decrease (GreenHeatEAF)—Fact Sheet; Publications Office of the European Union: Brussels, Belgium, 2023. [Google Scholar]

- European Steel Technology Platform. FullH2Reheat. Available online: https://www.estep.eu/clean-steel-partnership/list-of-csp-projects/fullh2reheat/ (accessed on 20 July 2023).

- RINA Consulting. DevH2forEAF. Available online: https://www.devh2eaf.eu (accessed on 20 July 2023).

- Kandilli, C.; Ayna, O.M.; Sahin, M. Evaluation of the performance of a hydrogen enriched combustion system for ceramic sector. Int. J. Hydrogen Energy 2015, 40, 11195–11206. [Google Scholar] [CrossRef]

- Busson, E.; Mühlbach, M.; Schmitz, N.; Wünning, J.G.; Pfeifer, H. An experimental study on the flexible use of hydrogen as fuel in radiant tubes for steel annealing lines. In Proceedings of the European Combustion Meeting 2023 11th European Combustion Meeting, Rouen, France, 26–28 April 2023. [Google Scholar]

- Philipp, M.; Schmitz, N.; Pfeifer, H.; Kowert, A. Development of a Low-Emission Combustion Concept for Hydrogen in Multi-Fuel-Burners. In Proceedings of the European Combustion Meeting 2023 11th European Combustion Meeting, Rouen, France, 26–28 April 2023. [Google Scholar]

- Cirrilli, F.; Luzzo, I.; Bendotti, M.; Venturi, A. Characterization of side burners of reheating furnace. In Proceedings of the H2 for Green Steel. Hydrogen Route for a Green Steelmaking Process and Applications, Paris, France, 30 November–1 December 2022. [Google Scholar]

- Bissoli, E.; Malfa, E.; Astesiano, D.; Della Rocca, A.; Wuppermann, C. Flexible hydrogen heating technologies with low environmental impact. In Proceedings of the H2 for Green Steel. Hydrogen Route for a Green Steelmaking Process and Applications, Paris, France, 30 November–1 December 2022. [Google Scholar]

- AGC Inc. Ammonia Combustion Technology Development Project including AGC Selected as NEDO-Commissioned Project: Aiming to Achieve Net Zero Carbon by 2050 with Innovative Glass Melting Technology. Available online: https://www.agc.com/en/news/detail/1202704_2814.html (accessed on 20 July 2023).

- Kikuchi, K.; Murai, R.; Hori, T.; Akamatsu, F. Fundamental Study on Ammonia Low-NOx Combustion Using Two-Stage Combustion by Parallel Air Jets. Processes 2022, 10, 23. [Google Scholar] [CrossRef]

- Murai, R.; Nakatsuka, N.; Higashino, H.; Akamatsu, F. Review of Fundamental Study on Ammonia Direct Combustion in Industrial Furnaces. In CO2 Free Ammonia as an Energy Carrier; Aika, K., Kobayashi, H., Eds.; Springer Nature Singapore: Singapore, 2023; pp. 627–640. ISBN 978-981-19-4766-7. [Google Scholar]

- Ariemma, G.B.; Sorrentino, G.; Sabia, P.; Joannon, M.D.; Ragucci, R. Ammonia/Hydrogen blends MILD Combustion. In Proceedings of the European Combustion Meeting 2023 11th European Combustion Meeting, Rouen, France, 26–28 April 2023. [Google Scholar]

- Biebl, M.; Leicher, J.; Giese, A.; Görner, K. Experimental and simulation investigations of the combustion of blends of ammonia with hydrogen and natural gas in industrial non-premixed burners. In Proceedings of the European Combustion Meeting 2023 11th European Combustion Meeting, Rouen, France, 26–28 April 2023. [Google Scholar]

- Sharma, S.; Savarese, M.; Coussement, A.; Parente, A. Decarbonisation potential of dimethyl ether/hydrogen mixtures in a flameless furnace: Reactive structures and pollutant emissions. Int. J. Hydrogen Energy 2023, 48, 2401–2427. [Google Scholar] [CrossRef]

- Kohse-Höinghaus, K. Combustion in the future: The importance of chemistry. Proc. Combust. Inst. 2020, 38, 1–56. [Google Scholar] [CrossRef]

- International Energy Agency. The Future of Hydrogen: Seizing Today’s Opportunities; International Energy Agency: Paris, France, 2019. [Google Scholar]

- Baukal, C.E. Oxygen-Enhanced Combustion, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2013; ISBN 9781439862285. [Google Scholar]

- Pfeifer, H. Fuels and Combustion. In Handbook of Thermoprocessing Technologies, 2nd ed.; Beneke, F., Nacke, B., Pfeifer, H., Eds.; Vulkan-Verlag: Essen, Germany, 2015; pp. 204–242. ISBN 9783802724749. [Google Scholar]

- DIN EN 267:2021-09; Forced Draught Burners for Liquid Fuels. Beuth Verlag: Berlin, Germany, 2021.

- DIN EN 676:2023-03; Forced Draught Burners for Gaseous Fuels. Beuth Verlag: Berlin, Germany, 2023.

- DIN EN ISO 6976:2016-12; Natural Gas—Calculation of Calorific Values, Density, Relative Density and Wobbe Indices from Composition. Beuth Verlag: Berlin, Germany, 2016.

- Technical Rule DVGW G 260 (A)—Gas Quality; DVGW e. V.: Bonn, Germany, 2021.

- Directive 2010/75/EU on Industrial Emissions (Integrated Pollution Prevention and Control); European Parliament and the Council: Strasbourg, France, 2010.

- Directive (EU) 2016/2284 on the Reduction of National Emissions of Certain Atmospheric Pollutants; European Parliament and the Council: Strasbourg, France, 2016.

- Gesetz zum Schutz vor Schädlichen Umwelteinwirkungen Durch Luftverunreinigungen, Geräusche, Erschütterungen und Ähnliche Vorgänge: Bundes-Immissionsschutzgesetz—BImSchG; Federal Government of Germany: Berlin, Germany, 2013.

- Federal Ministry for Environment, Nature Conservation, Nuclear Safety and Consumer Protection. Neufassung der Ersten Allgemeinen Verwaltungsvorschrift zum Bundes-Immissionsschutzgesetz (Technische Anleitung zur Reinhaltung der Luft—TA Luft). Gemeinsames Minist. 2021, 72, 1050–1191. [Google Scholar]

- Joos, F. Technische Verbrennung: Verbrennungstechnik, Verbrennungsmodellierung, Emissionen; mit 65 Tabellen; Springer: Berlin/Heidelberg, Germany, 2006; ISBN 978-3-540-34334-9. [Google Scholar]

- WHO. Air Quality Guidelines: Particulate Matter, Ozone, Nitrogen Dioxide and Sulfur Dioxide; World Health Organization: Geneva, Switzerland, 2006; ISBN 9289021926. [Google Scholar]

- Glarborg, P.; Miller, J.A.; Ruscic, B.; Klippenstein, S.J. Modeling nitrogen chemistry in combustion. Prog. Energy Combust. Sci. 2018, 67, 31–68. [Google Scholar] [CrossRef]

- Zeldovich, J. The Oxidation of Nitrogen in Combustion and Explosions. Acta Physicochim. U.R.S.S 1946, XXI, 577–628. [Google Scholar]

- Fenimore, C.P. Formation of nitric oxide in premixed hydrocarbon flames. Symp. Int. Combust. 1971, 13, 373–380. [Google Scholar] [CrossRef]

- Gaber, C.; Schluckner, C.; Wachter, P.; Demuth, M.; Hochenauer, C. Experimental study on the influence of the nitrogen concentration in the oxidizer on NOx and CO emissions during the oxy-fuel combustion of natural gas. Energy 2021, 214, 118905. [Google Scholar] [CrossRef]

- Lyon, R.K. The NH3-NO-O2 reaction. Int. J. Chem. Kinet. 1976, 8, 315–318. [Google Scholar] [CrossRef]

- Kobayashi, H.; Hayakawa, A.; Somarathne, K.K.A.; Okafor, E.C. Science and technology of ammonia combustion. Proc. Combust. Inst. 2019, 37, 109–133. [Google Scholar] [CrossRef]

- Bozzelli, J.W.; Dean, A.M. O + NNH: A possible new route for NOX formation in flames. Int. J. Chem. Kinet. 1995, 27, 1097–1109. [Google Scholar] [CrossRef]

- Konnov, A.A.; Colson, G.; Ruyck, J.d. The new route forming NO via NNH. Combust. Flame 2000, 121, 548–550. [Google Scholar] [CrossRef]

- Klippenstein, S.J.; Harding, L.B.; Glarborg, P.; Miller, J.A. The role of NNH in NO formation and control. Combust. Flame 2011, 158, 774–789. [Google Scholar] [CrossRef]

- Hayhurst, A.N.; Hutchinson, E.M. Evidence for a New Way of Producing NO via NNH in Fuel-Rich Flames at Atmospheric Pressure. Combust. Flame 1998, 114, 274–279. [Google Scholar] [CrossRef]

- Haworth, N.L.; Mackie, J.C.; Bacskay, G.B. An Ab Initio Quantum Chemical and Kinetic Study of the NNH + O Reaction Potential Energy Surface: How Important Is This Route to NO in Combustion? J. Phys. Chem. A 2003, 107, 6792–6803. [Google Scholar] [CrossRef]

- Malte, P.C.; Pratt, D.T. Measurement of atomic oxygen and nitrogen oxides in jet-stirred combustion. Symp. Int. Combust. 1975, 15, 1061–1070. [Google Scholar] [CrossRef]

- Durocher, A.; Meulemans, M.; Versailles, P.; Bourque, G.; Bergthorson, J.M. Back to basics—NO concentration measurements in atmospheric lean-to-rich, low-temperature, premixed hydrogen–air flames diluted with argon. Proc. Combust. Inst. 2021, 38, 2093–2100. [Google Scholar] [CrossRef]

- Cavaliere, A.; Joannon, M.d. Mild Combustion. Prog. Energy Combust. Sci. 2004, 30, 329–366. [Google Scholar] [CrossRef]

- Wünning, J. Flameless oxidation to reduce thermal no-formation. Prog. Energy Combust. Sci. 1997, 23, 81–94. [Google Scholar] [CrossRef]

- Li, J.; Chang, H.; Ma, L.; Hao, J.; Yang, R.T. Low-temperature selective catalytic reduction of NOx with NH3 over metal oxide and zeolite catalysts—A review. Catal. Today 2011, 175, 147–156. [Google Scholar] [CrossRef]

- Aries, E.; Gómez Benavides, J.; Mavromatis, S.; Klein, G.; Chronopoulos, G.; Roudier, S. Best Available Techniques (BAT) Reference Document for the Ferrous Metals Processing Industry: Industrial Emissions Directive 2010/75/EU (Integrated Pollution Prevention and Control); Publications Office of the European Union: Luxembourg, 2022. [Google Scholar]

- DIN EN 14792:2017-05; Stationary Source Emissions—Determination of Mass Concentration of Nitrogen Oxides—Standard Reference Method: Chemiluminescence. Beuth Verlag: Berlin, Germany, 2017.

- DIN EN 15267-1:2009-07; Air Quality—Certification of Automated Measuring Systems—Part 1: General Principles. Beuth Verlag: Berlin, Germany, 2009.

- DIN EN 15267-2:2009-07; Air Quality—Certification of Automated Measuring Systems—Part 2: Initial Assessment of the AMS Manufacturer’s Quality Management System and Post Certification Surveillance for the Manufacturing Process. Beuth Verlag: Berlin, Germany, 2009.

- DIN EN 15267-3:2008-03; Air Quality—Certification of Automated Measuring Systems—Part 3: Performance Criteria and Test Procedures for Automated Measuring Systems for Monitoring Emissions from Stationary Sources. Beuth Verlag: Berlin, Germany, 2008.

- DIN EN 15267-4:2017-05; Air Quality—Certification of Automated Measuring Systems—Part 4: Performance Criteria and Test Procedures for Automated Measuring Systems for Periodic Measurements of Emissions from Stationary Sources. Beuth Verlag: Berlin, Germany, 2017.

- DIN EN 14181:2015-02; Stationary Source Emissions—Quality Assurance of Automated Measuring Systems. Beuth Verlag: Berlin, Germany, 2015.

- DIN EN 15259:2008-01; Air Quality—Measurement of Stationary Source Emissions—Requirements for Measurement Sections and Sites and for The measurement Objective, Plan and Report. Beuth Verlag: Berlin, Germany, 2008.

- Leicher, J. Hydrogen for industrial process heating: Challenges and opportunities. In Proceedings of the ToTEM—Topic Oriented Technical Meeting H2 Hydrogen for Industrial Decarbonization, Paris, France, 13 October 2022. [Google Scholar]

- Leicher, J.; Giese, A.; Görner, K. Vergleichbarkeit von Stickoxid-Emissionen bei wasserstoffreichen Brenngasen. Prozesswärme 2023, 52–56. [Google Scholar]

- Baukal, C.E.; Eleazer, P.B. Quantifying NOx for industrial combustion processes. J. Air Waste Manag. Assoc. 1998, 48, 52–58. [Google Scholar] [CrossRef]

- Douglas, C.M.; Shaw, S.L.; Martz, T.D.; Steele, R.C.; Noble, D.R.; Emerson, B.L.; Lieuwen, T.C. Pollutant Emissions Reporting and Performance Considerations for Hydrogen–Hydrocarbon Fuels in Gas Turbines. J. Eng. Gas Turbines Power 2022, 144, 91003. [Google Scholar] [CrossRef]

- Dutka, M.; Ditaranto, M.; Løvås, T. NOx emissions and turbulent flow field in a partially premixed bluff body burner with CH4 and H2 fuels. Int. J. Hydrogen Energy 2016, 41, 12397–12410. [Google Scholar] [CrossRef]

- Mariani, A.; Unich, A.; Minale, M. Methane/hydrogen Blends in Controlled Auto Ignition Engines with Egr: Evaluation of NOx Emissions. Chem. Eng. Trans. 2019, 74, 301–306. [Google Scholar]

- Glanville, P.; Fridlyand, A.; Sutherland, B.; Liszka, M.; Zhao, Y.; Bingham, L.; Jorgensen, K. Impact of Hydrogen/Natural Gas Blends on Partially Premixed Combustion Equipment: NOx Emission and Operational Performance. Energies 2022, 15, 1706. [Google Scholar] [CrossRef]

- Gersen, S.; van der Stel, J.; Bsibsi, M. Hydrogen as a fuel for the metal industry. In Proceedings of the H2 for Green Steel. Hydrogen Route for a Green Steelmaking Process and Applications, Paris, France, 30 November–1 December 2022. [Google Scholar]

- Schluckner, C.; Gaber, C.; Demuth, M.; Hochenauer, C. Scrutiny of residual nitrogen content and different nozzle designs on NOx formation during oxy-fuel combustion of natural gas. Fuel 2020, 277, 118065. [Google Scholar] [CrossRef]

- German Environment Agency. Reinhaltung der Luft/Luftüberwachung in Deutschland—Messeinrichtungen: Eignungsgeprüfte Kontinuierlich Arbeitende Emissionsmesseinrichtungen—Messobjekt: Feuchte; German Environment Agency: Dessau-Rosslau, Germany, 2021.

- DIN EN 14790:2017-05; Stationary Source Emissions—Determination of the Water Vapour in Ducts—Standard Reference Method. Beuth Verlag: Berlin, Germany, 2017.

- Wiegleb, G. Gas Measurement Technology in Theory and Practice; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2023; ISBN 978-3-658-37231-6. [Google Scholar]

- Sankowski, L. Influence of H2 and H2-blends on NOx-emissions of a cold air high velocity burner in flame and flameless operation. In Proceedings of the ToTEM—Topic Oriented Technical Meeting H2 Hydrogen for industrial decarbonization, Paris, France, 13 October 2022. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).