Synergy between Photovoltaic Panels and Green Roofs

Abstract

1. Introduction

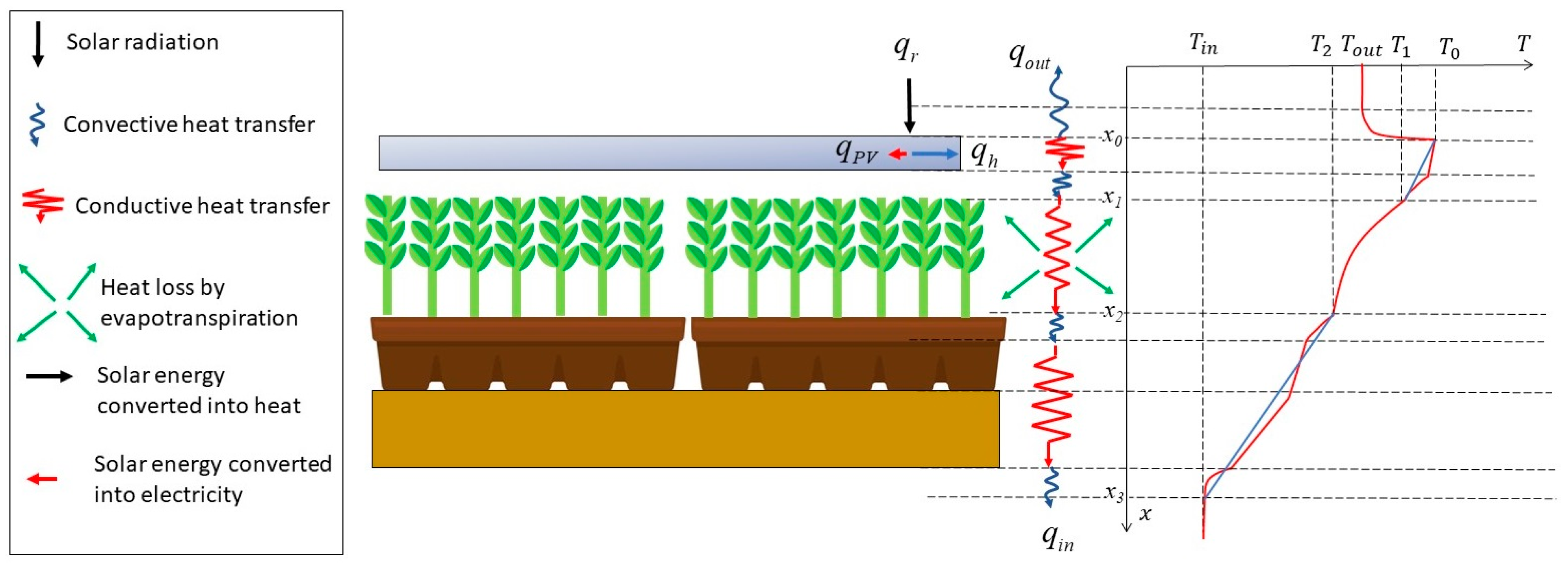

2. Synergy Analysis

- is the incident solar radiation (ISR) in the PV panels,

- is the fraction of the solar radiation converted into electricity,

- is the fraction of the solar radiation converted into heat,

- is the efficiency of the solar panels,

- is the temperature of the PV panel,

- is the outdoor air temperature,

- is the U-value due to the convection of the PV panels with the surrounding environment,

- is the U-value due to the conduction of the PV panels with its environment and supporting structure, and

- is the temperature of the boundary layer below the PV panels.

- is the incoming heat flow in the building,

- is the temperature in the GR measured above the boundary layer,

- is the indoor temperature, measured below the boundary layer,

- is the U-value of the roof, which is calculated in terms of the boundary layers, the thicknesses, and the materials of the various layers of the GR.

- are the outdoor and indoor temperatures,

- are the elements of the inverse of the U-matrix,

- is the heat produced in the PV panels (W/m2), and

- is the heat flow due to evapotranspiration (W/m2).

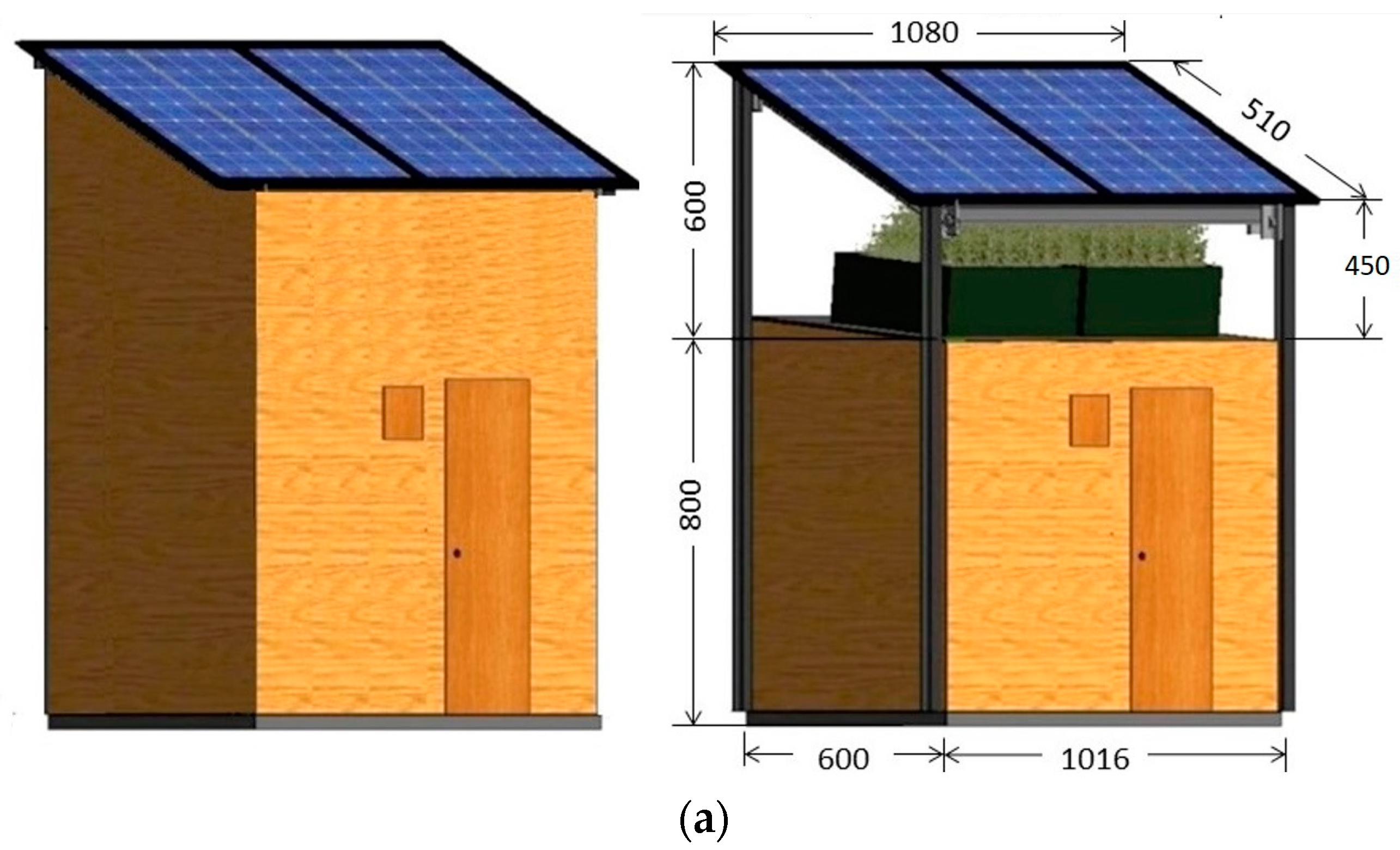

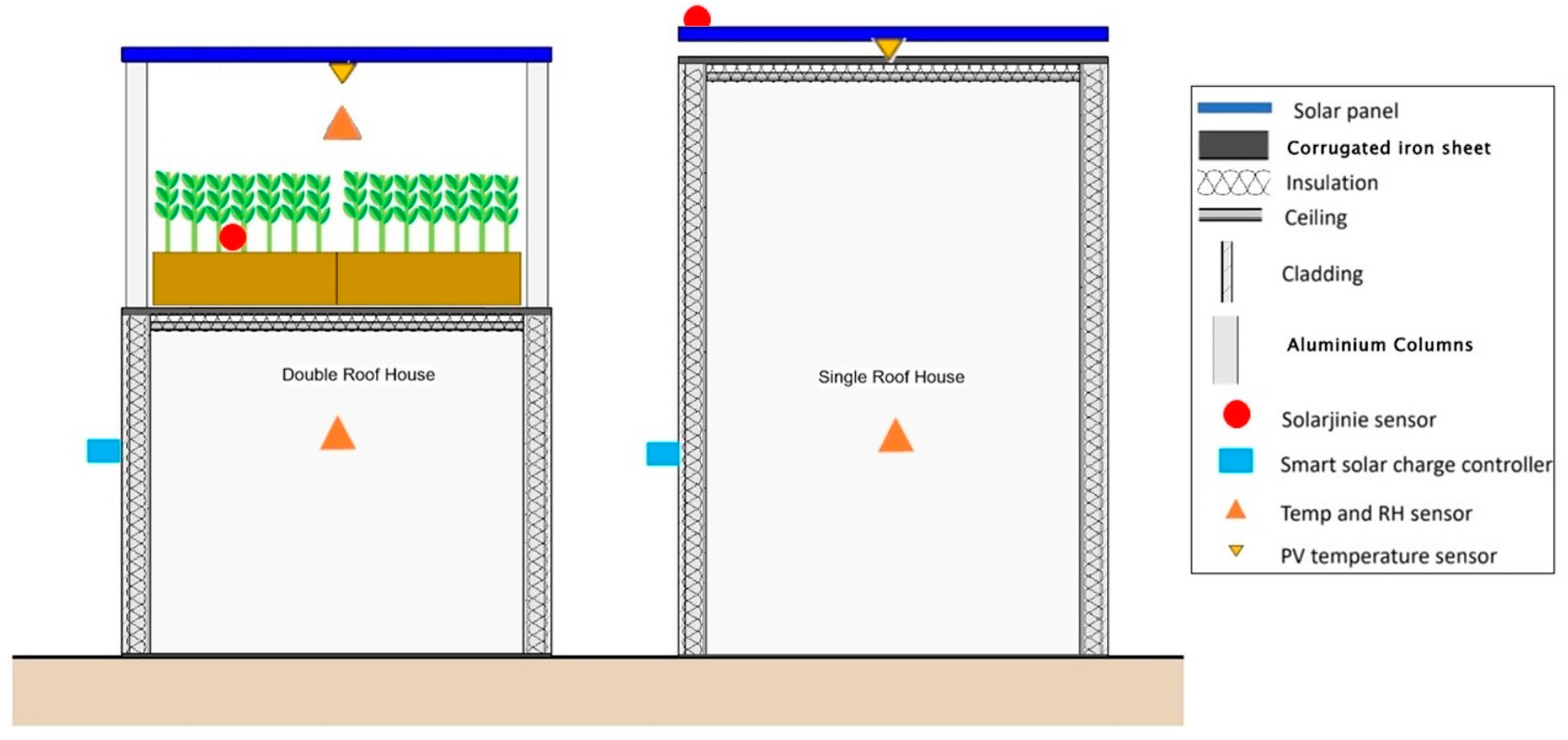

3. Physical Model for the Double Roof

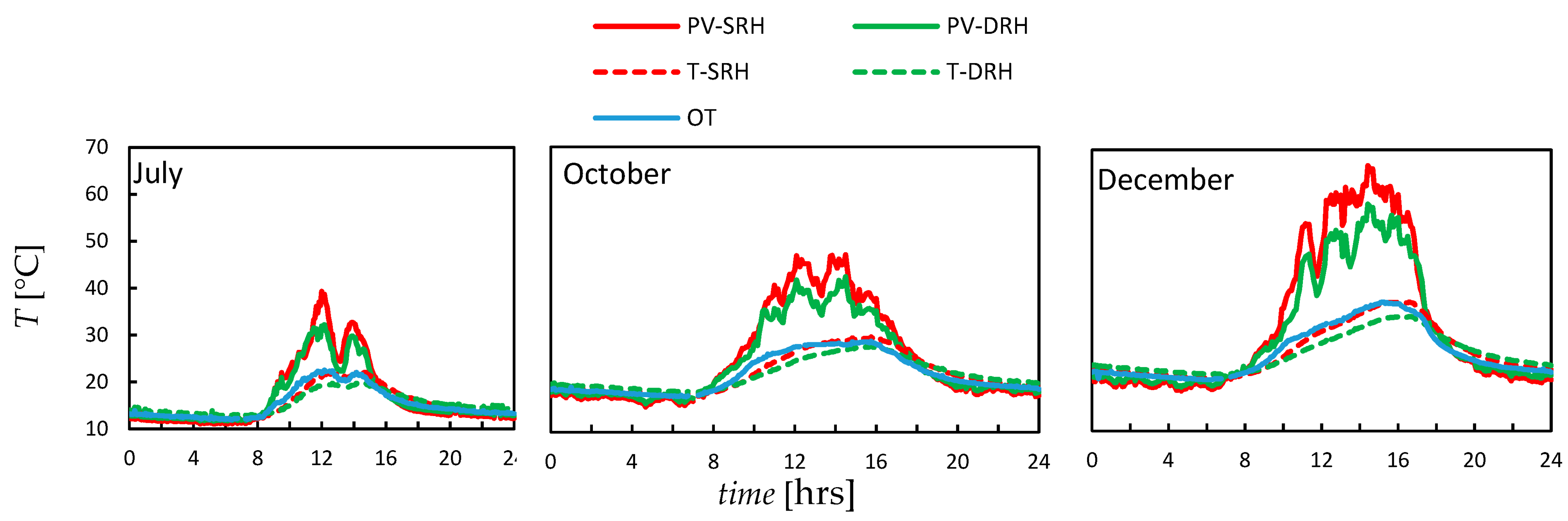

4. Result and Analysis

4.1. Thermal Comfort Parameters (Air Temperature)

- are the ambient (feels-like) temperature and the dry bulb temperature

- is the water vapor pressure, which is calculated in terms of the dry bulb temperature and the relative humidity by the equation [40]:

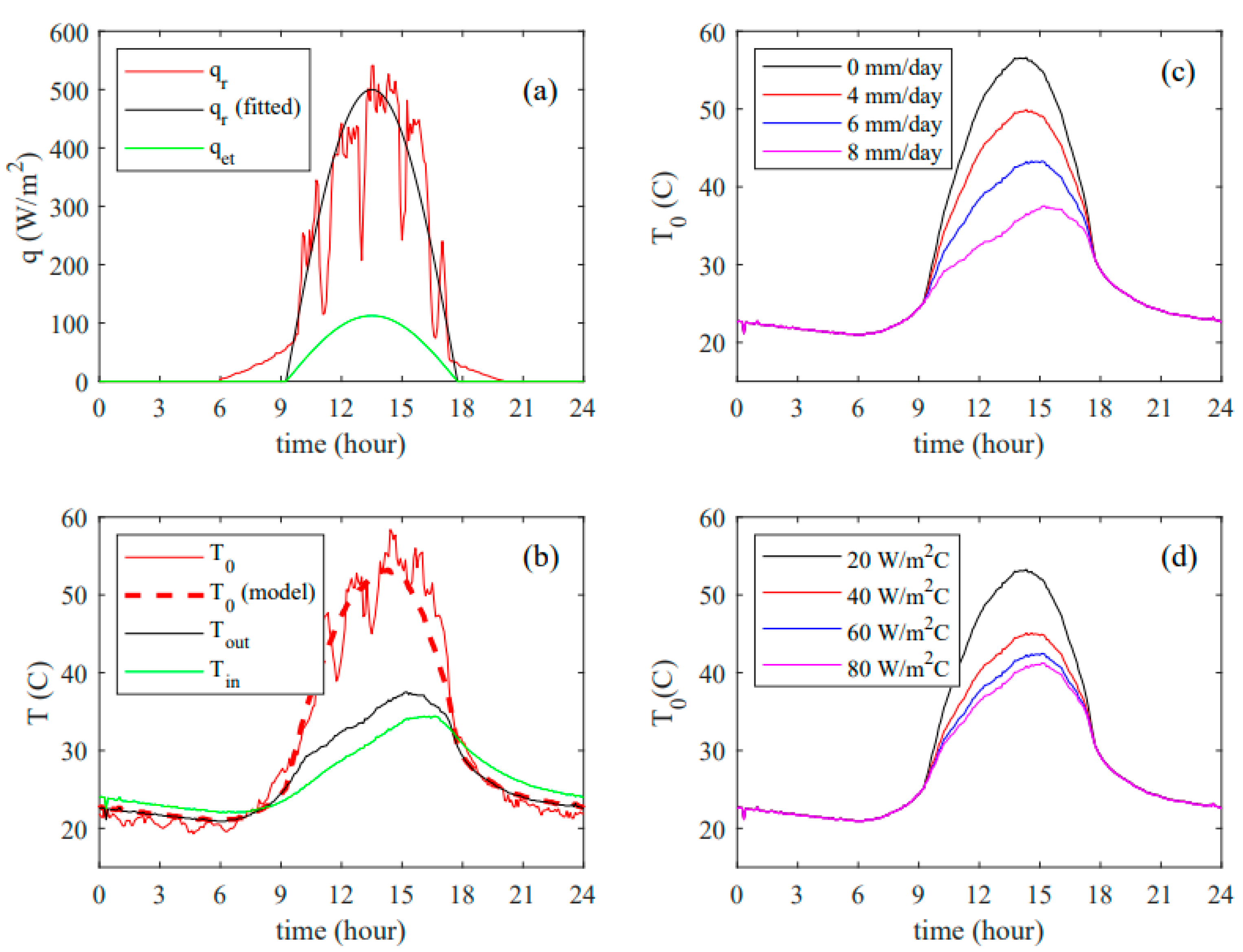

4.2. PV Rear Side Temperature

4.3. Energy Yield

4.4. Numerical Validation

5. Conclusions

6. Future Directions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ramírez-Márquez, C.; Martín, M. Chapter 10—Photovoltaic solar energy. In Sustainable Design for Renewable Processes; Martín, M., Ed.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 397–439. [Google Scholar] [CrossRef]

- Asdrubali, F.; Desideri, U. (Eds.) Chapter 7—High Efficiency Plants and Building Integrated Renewable Energy Systems. In Handbook of Energy Efficiency in Buildings; Butterworth-Heinemann: Oxford, UK, 2019; pp. 441–595. [Google Scholar] [CrossRef]

- Wajs, J.; Golabek, A.; Bochniak, R.; Mikielewicz, D. Air-cooled photovoltaic roof tile as an example of the BIPVT system—An experimental study on the energy and exergy performance. Energy 2020, 197, 117255. [Google Scholar] [CrossRef]

- Zhang, T.; Wang, M.; Yang, H. A Review of the Energy Performance and Life-Cycle Assessment of Building-Integrated Photovoltaic (BIPV) Systems. Energies 2018, 11, 3157. [Google Scholar] [CrossRef]

- Rahman, D.M.; Hasanuzzaman, M.; Abd Rahim, N. Effects of various parameters on PV-module power and efficiency. Energy Convers. Manag. 2015, 103, 348–358. [Google Scholar] [CrossRef]

- Krauter, S.; Araújo, R.G.; Schroer, S.; Hanitsch, R.; Salhi, M.J.; Triebel, C.; Lemoine, R. Combined photovoltaic and solar thermal systems for facade integration and building insulation. Sol. Energy 1999, 67, 239–248. [Google Scholar] [CrossRef]

- Hossain, M.F. Chapter Five—Infrastructure and Transportation. In Sustainable Design and Build; Hossain, M.F., Ed.; Butterworth-Heinemann: Oxford, UK, 2019; pp. 231–300. [Google Scholar] [CrossRef]

- Kristin, L.G.; Rowe, D.B. The Role of Extensive Green Roofs in Sustainable Development. HortScience 2006, 41, 1276–1285. [Google Scholar] [CrossRef]

- Ganguly, A.; Chowdhury, D.; Neogi, S. Performance of Building Roofs on Energy Efficiency—A Review. Energy Procedia 2016, 90, 200–208. [Google Scholar] [CrossRef]

- Lazzarin, R.M.; Castellotti, F.; Busato, F. Experimental measurements and numerical modelling of a green roof. Energy Build. 2005, 37, 1260–1267. [Google Scholar] [CrossRef]

- Ouldboukhitine, S.-E.; Belarbi, R.; Sailor, D.J. Experimental and numerical investigation of urban street canyons to evaluate the impact of green roof inside and outside buildings. Appl. Energy 2014, 114, 273–282. [Google Scholar] [CrossRef]

- Bowler, D.E.; Buyung-Ali, L.; Knight, T.M.; Pullin, A.S. Urban greening to cool towns and cities: A systematic review of the empirical evidence. Landsc. Urban Plan. 2010, 97, 147–155. [Google Scholar] [CrossRef]

- Wilkinson, S.; Feitosa, R.C. Retrofitting Housing with Lightweight Green Roof Technology in Sydney, Australia, and Rio de Janeiro, Brazil. Sustainability 2015, 7, 1081–1098. [Google Scholar] [CrossRef]

- Castiglia Feitosa, R.; Wilkinson, S. Modelling green roof stormwater response for different soil depths. Landsc. Urban Plan. 2016, 153, 170–179. [Google Scholar] [CrossRef]

- Dixon, T.; Wilkinson, S. Building Resilience in Urban Settlements Through Green Roof Retrofit. In Green Roof Retrofit; John Wiley & Sons: Hoboken, NJ, USA, 2016; pp. 1–13. [Google Scholar] [CrossRef]

- Wilkinson, S.J.; Reed, R. Green roof retrofit potential in the central business district. Prop. Manag. 2009, 27, 284–301. [Google Scholar] [CrossRef]

- Catalano, C.; Baumann, N. Biosolar Roofs: A Symbiosis between Biodiverse Green Roofs and Renewable Energy. CityGreen 2017, 2017, 42–49. [Google Scholar]

- Permpituck, S.; Namprakai, P. The energy consumption performance of roof lawn gardens in Thailand. Renew. Energy 2012, 40, 98–103. [Google Scholar] [CrossRef]

- Shafique, M.; Kim, R.; Rafiq, M. Green roof benefits, opportunities and challenges—A review. Renew. Sustain. Energy Rev. 2018, 90, 757–773. [Google Scholar] [CrossRef]

- Coma, J.; Pérez, G.; Solé, C.; Castell, A.; Cabeza, L.F. Thermal assessment of extensive green roofs as passive tool for energy savings in buildings. Renew. Energy 2016, 85, 1106–1115. [Google Scholar] [CrossRef]

- Imran, H.M.; Kala, J.; Ng, A.W.M.; Muthukumaran, S. Effectiveness of green and cool roofs in mitigating urban heat island effects during a heatwave event in the city of Melbourne in southeast Australia. J. Clean. Prod. 2018, 197, 393–405. [Google Scholar] [CrossRef]

- Spala, A.; Bagiorgas, H.S.; Assimakopoulos, M.N.; Kalavrouziotis, J.; Matthopoulos, D.; Mihalakakou, G. On the green roof system. Selection, state of the art and energy potential investigation of a system installed in an office building in Athens, Greece. Renew. Energy 2008, 33, 173–177. [Google Scholar] [CrossRef]

- Hoffmann, S.; Koehl, M. Effect of humidity and temperature on the potential-induced degradation. Prog. Photovolt. Res. Appl. 2014, 22, 173–179. [Google Scholar] [CrossRef]

- Singh, P.; Singh, S.N.; Lal, M.; Husain, M. Temperature dependence of I–V characteristics and performance parameters of silicon solar cell. Sol. Energy Mater. Sol. Cells 2008, 92, 1611–1616. [Google Scholar] [CrossRef]

- Shafique, M.; Luo, X.; Zuo, J. Photovoltaic-green roofs: A review of benefits, limitations, and trends. Sol. Energy 2020, 202, 485–497. [Google Scholar] [CrossRef]

- Vidyanandan, K.V. An Overview of Factors Affecting the Performance of Solar PV Systems. Energy Scan 2017, 27, 2–8. [Google Scholar]

- Willoughby, J. 30—Insulation. In Plant Engineer’s Reference Book, 2nd ed.; Snow, D.A., Ed.; Butterworth-Heinemann: Oxford, UK, 2002; pp. 30-18–30-31. [Google Scholar] [CrossRef]

- Narayanan, R.; Parthkumar, P.; Pippia, R. Solar energy utilisation in Australian homes: A case study. Case Stud. Therm. Eng. 2021, 28, 101603. [Google Scholar] [CrossRef]

- Oke, T.R. Boundary Layer Climates; Routledge: Oxford, UK, 2002. [Google Scholar]

- Arias Calluari, K.; Alonso-Marroquín, F. Structural Analysis of an Off-Grid Tiny House; AIP Publishing: Melville, NY, USA, 2017; Volume 1856, p. 020001. [Google Scholar]

- Kapsalis, V.C.; Vardoulakis, E.; Karamanis, D. Simulation of the cooling effect of the roof-added photovoltaic panels. Adv. Build. Energy Res. 2014, 8, 41–54. [Google Scholar] [CrossRef]

- Szeicz, G. Solar radiation for plant growth. J. Appl. Ecol. 1974, 11, 617–636. [Google Scholar] [CrossRef]

- Amthor, J.S. From sunlight to phytomass: On the potential efficiency of converting solar radiation to phyto-energy. New Phytol. 2010, 188, 939–959. [Google Scholar] [CrossRef] [PubMed]

- Kume, A. Importance of the green color, absorption gradient, and spectral absorption of chloroplasts for the radiative energy balance of leaves. J. Plant Res. 2017, 130, 501–514. [Google Scholar] [CrossRef]

- Gupta, S.; Anand, P.; Kakkar, S.; Sagar, P.; Dubey, A. Effect of evapotranspiration on performance improvement of photovoltaic-green roof integrated system. J. Renew. Energy Smart Grid Technol. 2017, 12, 63–76. [Google Scholar]

- Jahanfar, A.; Drake, J.; Sleep, B.; Margolis, L. Shading effects of photovolatic panels on the evapotranspiration process in extensive green roofs. In Proceedings of the Novatech 2016-9ème Conférence Internationale sur les Techniques et Stratégies Pour la Gestion Durable de Leau dans la Ville/9th International Conference on Planning and Technologies for Sustainable Management of Water in the City, GRAIE, Lyon, France, 28 June–3 July 2016. [Google Scholar]

- Besir, A.B.; Cuce, E. Green roofs and facades: A comprehensive review. Renew. Sustain. Energy Rev. 2018, 82, 915–939. [Google Scholar] [CrossRef]

- Younes, C.; Abishdid, C.; Bitsuamlak, G. Air infiltration through building envelopes: A review. J. Build. Phys. 2012, 35, 267–302. [Google Scholar] [CrossRef]

- Georgiou, G.; Eftekhari, M.; Lupton, T. Investigating the effect of tightening residential envelopes in the Mediterranean region. In Proceedings of the 14th International Conference on Sustainable Energy Technologies (SET 2015), Singapore, 25–27 August 2015. [Google Scholar]

- Qiu, R.; Li, L.; Kang, S.; Liu, C.; Wang, Z.; Cajucom, E.P.; Zhang, B.; Agathokleous, E. An improved method to estimate actual vapor pressure without relative humidity data. Agric. For. Meteorol. 2021, 298, 108306. [Google Scholar] [CrossRef]

- Chemisana, D.; Lamnatou, C. Photovoltaic-green roofs: An experimental evaluation of system performance. Appl. Energy 2014, 119, 246–256. [Google Scholar] [CrossRef]

- Hui, S.C.; Chan, S.-C. Integration of green roof and solar photovoltaic systems. In Proceedings of the Joint Symposium 2011: Integrated Building Design in the New Era of Sustainability, Hong Kong, China, 22 November 2022; pp. 1–12. [Google Scholar]

- Royo, P.; Ferreira, V.J.; López-Sabirón, A.M.; Ferreira, G. Hybrid diagnosis to characterise the energy and environmental enhancement of photovoltaic modules using smart materials. Energy 2016, 101, 174–189. [Google Scholar] [CrossRef]

- Schwingshackl, C.; Petitta, M.; Wagner, J.E.; Belluardo, G.; Moser, D.; Castelli, M.; Zebisch, M.; Tetzlaff, A. Wind effect on PV module temperature: Analysis of different techniques for an accurate estimation. Energy Procedia 2013, 40, 77–86. [Google Scholar] [CrossRef]

- Sudhakar, P.; Santosh, R.; Asthalakshmi, B.; Kumaresan, G.; Velraj, R. Performance augmentation of solar photovoltaic panel through PCM integrated natural water circulation cooling technique. Renew. Energy 2021, 172, 1433–1448. [Google Scholar] [CrossRef]

- Heck, K.; Coltman, E.; Schneider, J.; Helmig, R. Influence of Radiation on Evaporation Rates: A Numerical Analysis. Water Resour. Res. 2020, 56, e2020WR027332. [Google Scholar] [CrossRef]

- Al Samman, S.; Eftekhari, M.P.; Coakley, D.P.; Angelopoulos, C.P.; Dimitriou, V.P. Sensor Location Methodology for Improved IEQ Monitoring in Working Environments; American Society of Heating, Refrigeration and Air Conditioning Engineers, Inc.: Atlanta, GA, USA, 2022; pp. 1–8. [Google Scholar]

- Shen, C.; Lv, G.; Zheng, K.; Ruan, C.; Zhang, C.; Dong, Y. Modeling and investigating the detailed characteristics of solar lighting/heating system based on spectrum split of nanofluids. Energy Built Environ. 2020, 3, 30–39. [Google Scholar] [CrossRef]

- Stanley, C.; Mojiri, A.; Rosengarten, G. Spectral light management for solar energy conversion systems. Nanophotonics 2016, 5, 161–179. [Google Scholar] [CrossRef]

| Measuring Variable | Measuring Device | Measuring Range | Accuracy | Weblink |

|---|---|---|---|---|

| Air temperature | WS2000 | −10 °C to 60 °C | ±2 °C | https://ambientweather.com/ws-2000-smart-weather-station, accessed on 12 November 2021 |

| Relative humidity | 10 to 99% | ±5% | ||

| Solar radiation intensity | Solarjinie | 0–1200 W/m2 | ±20 W/m2 | https://www.enerjin.com, accessed on 5 December 2021 |

| PV rear-surface temperature | Solarjinie | −10 °C to 80 °C | ±2 °C | |

| Solar energy production | Victron MPPT 100/50, and Solar charge controller | −30 to 60 °C | ±10 Wh | https://www.victronenergy.com/solar-charge-controllers/smartsolar-100-30-100-50, accessed on 1 April 2022 |

| −35 to 60 °C | - | https://tinyurl.com/y54r3t95, accessed on 1 April 2022 |

| Component | Symbol | k (W/m C) | H (m) | U (W/m2 C) | R (m2 C/W) |

|---|---|---|---|---|---|

| Boundary layer | U0 | 20 | 0.05 | ||

| Solar panel | U1 | 0.5 | 0.005 | 100.0 | 0.01 |

| Foliage | U2 | 1 | 0.45 | 2.2 | 0.45 |

| Roof | U3 | 0.05 | 0.03 | 1.7 | 0.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alonso-Marroquin, F.; Qadir, G. Synergy between Photovoltaic Panels and Green Roofs. Energies 2023, 16, 5184. https://doi.org/10.3390/en16135184

Alonso-Marroquin F, Qadir G. Synergy between Photovoltaic Panels and Green Roofs. Energies. 2023; 16(13):5184. https://doi.org/10.3390/en16135184

Chicago/Turabian StyleAlonso-Marroquin, Fernando, and Ghulam Qadir. 2023. "Synergy between Photovoltaic Panels and Green Roofs" Energies 16, no. 13: 5184. https://doi.org/10.3390/en16135184

APA StyleAlonso-Marroquin, F., & Qadir, G. (2023). Synergy between Photovoltaic Panels and Green Roofs. Energies, 16(13), 5184. https://doi.org/10.3390/en16135184