Compositional Analysis of Biodiesel Particulate Matter (BPM) from a Non-Road Diesel Generator

Abstract

1. Introduction

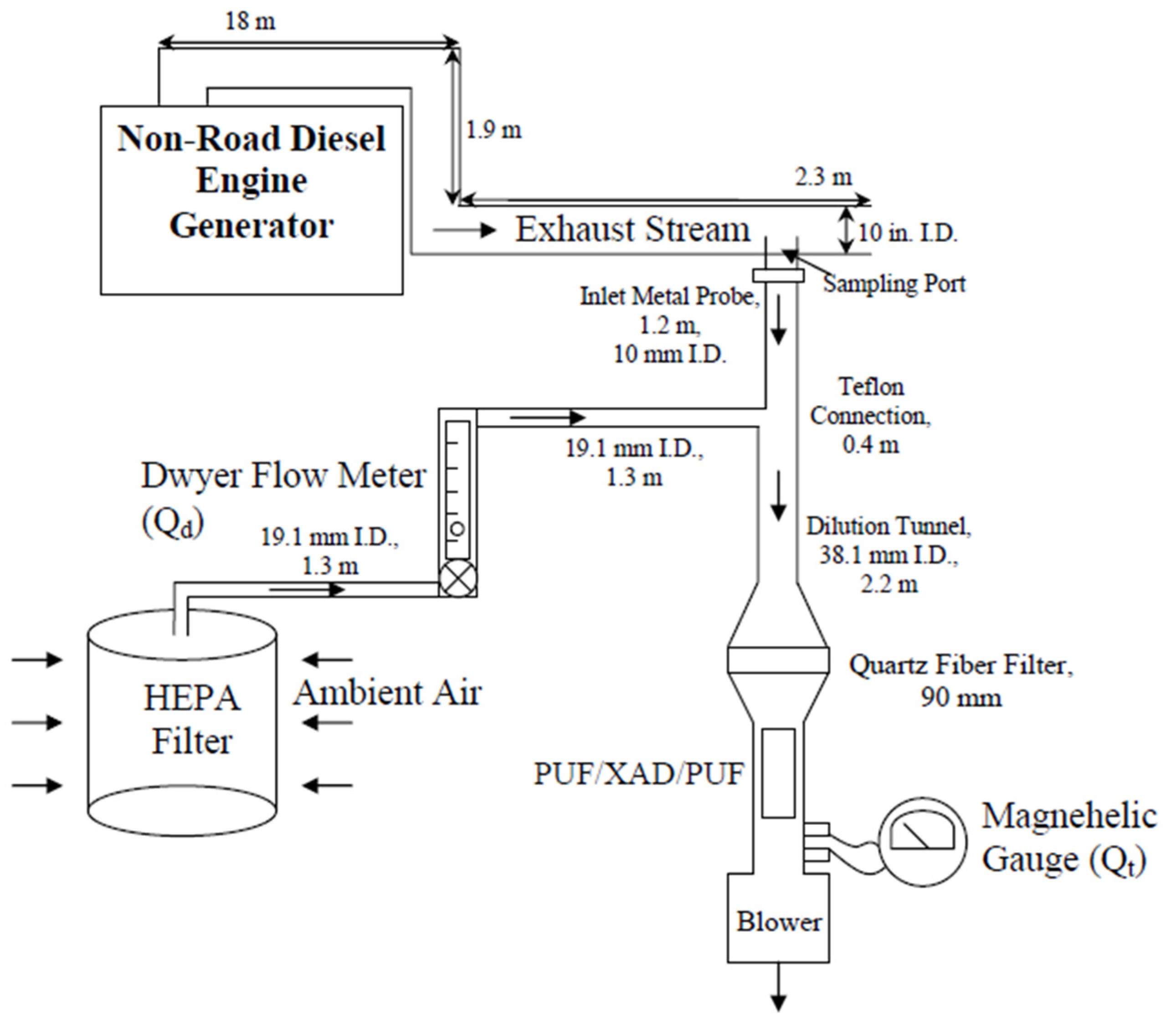

2. Materials and Methods

3. Results and Discussion

3.1. Gaseous Emissions from B0, B50 and B100

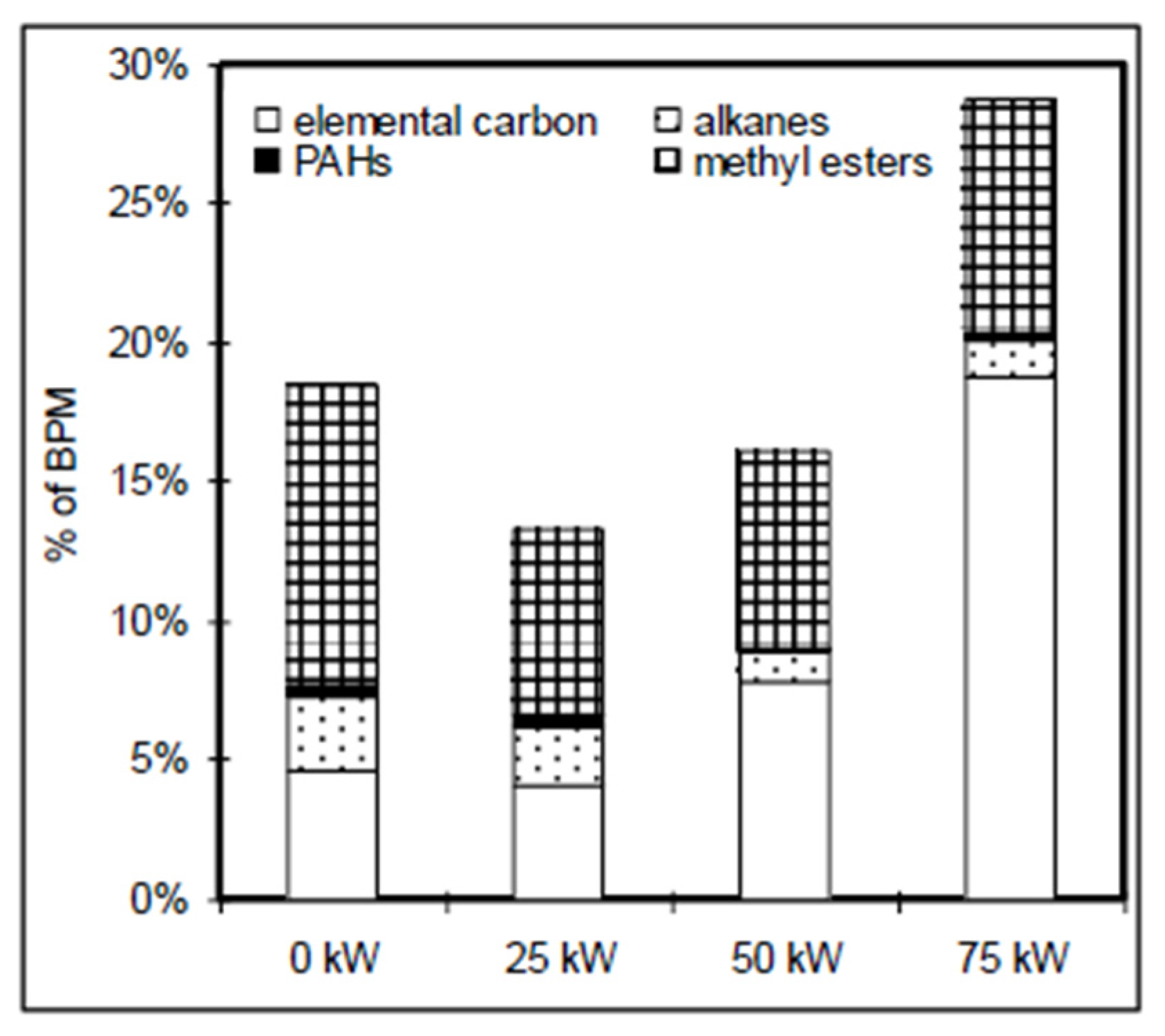

3.2. Organic Composition of BPM

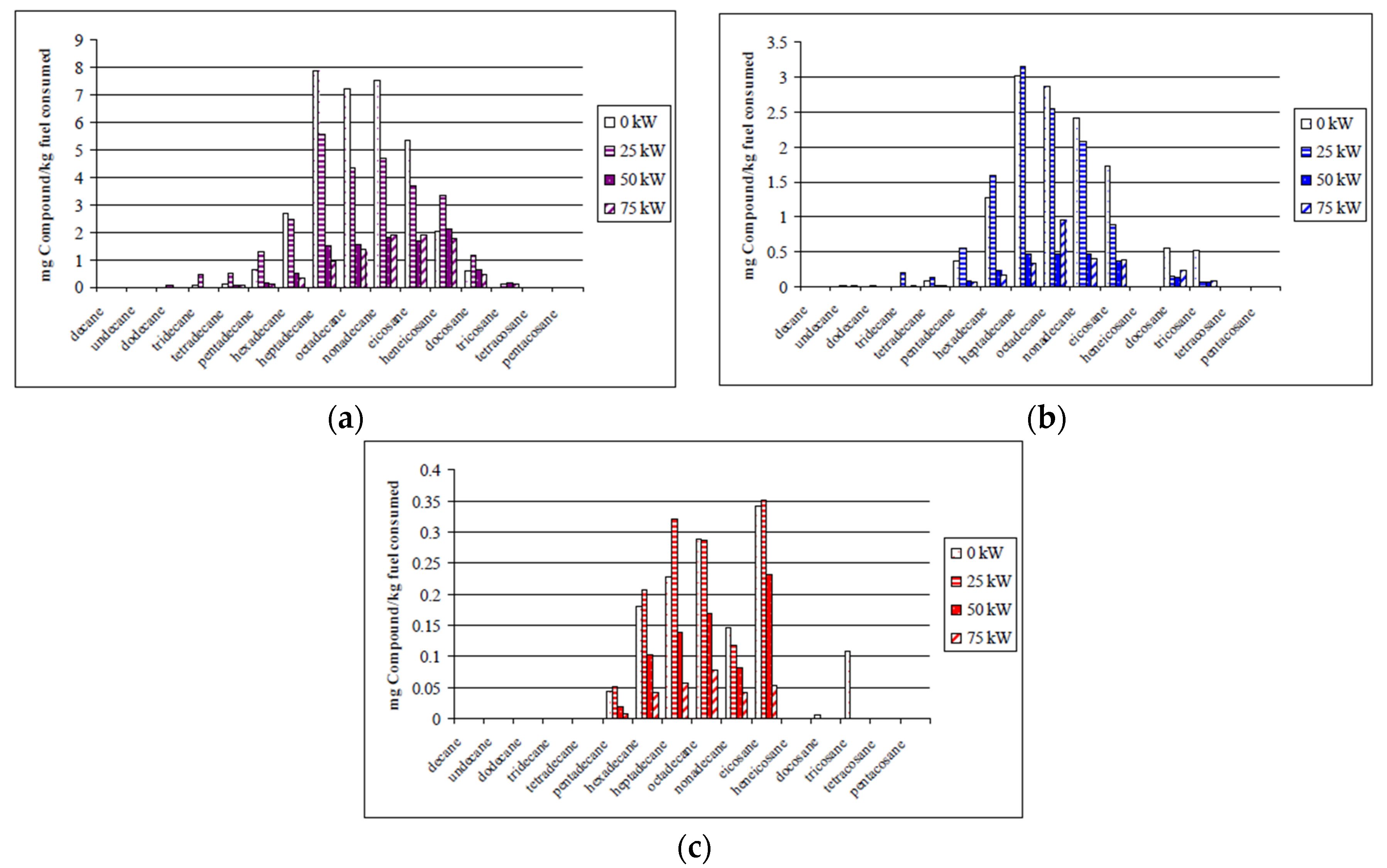

3.2.1. n-Alkanes

3.2.2. PAHs

3.2.3. FAMEs

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- EIA. Available online: https://www.eia.gov/totalenergy/data/monthly/#renewable (accessed on 4 March 2023).

- Biodiesel Blends. Alternative Fuels Data Center: Biodiesel Blends. n.d. Available online: https://afdc.energy.gov/fuels/biodiesel_blends.html (accessed on 28 March 2023).

- Rodrigues, A.C.C. Policy, regulation, development and future of biodiesel industry in Brazil. Clean. Eng. Technol. 2021, 4, 100197. [Google Scholar] [CrossRef]

- Brazil Sets 10% Biodiesel Blending Mandate for 2022. Enerdata. 21 December 2021. Available online: https://www.enerdata.net/publications/daily-energy-news/brazil-sets-10-biodiesel-blending-mandate2022.html#:~:text=The%20Brazilian%20President%20has%20approved%20a%20resolution%20by,make%20biodiesel%20much%20more%20expensive%20than%20fossil%20diesel (accessed on 30 March 2023).

- Tenny, K.; Baldino, C. Potential Biofuel Production Pathways in Indonesia. ICCT BRIEFING. Available online: https://theicct.org/sites/default/files/publications/Potential-biofuel-pathways-indonesia-EN-apr2021.pdf (accessed on 1 March 2021).

- Zulqarnain; Yusoff, M.H.M.; Ayoub, M.; Jusoh, N.; Abdullah, A.Z. The Challenges of a Biodiesel Implementation Program in Malaysia. Processes 2020, 8, 1244. [Google Scholar] [CrossRef]

- About Biodiesel—European Biodiesel Board (EBB). European Biodiesel Board (EBB)—Promoting the Use of Biodiesel in the EU. (2023, February 27). Available online: https://ebb-eu.org/about-biodiesel-2/ (accessed on 28 March 2023).

- Shroeder, & Simet. (2022). On Track to Lower Emissions. BiodieselMagazine.com. Available online: https://biodieselmagazine.com/articles/2518147/on-track-to-lower-emissions (accessed on 11 April 2023).

- Maes, R.R.; Potters, G.; Fransen, E.; Calderay Cayetano, F.; Van Schaeren, R.; Lenaerts, S. Finding the Optimal Fatty Acid Composition for Biodiesel Improving the Emissions of a One-Cylinder Diesel Generator. Sustainability 2021, 13, 12089. [Google Scholar] [CrossRef]

- Zarrinkolah, M.T.; Hosseini, V. Detailed Analysis of the Effects of Biodiesel Fraction Increase on the Combustion Stability and Characteristics of a Reactivity-Controlled Compression Ignition Diesel-Biodiesel/Natural Gas Engine. Energies 2022, 15, 1094. [Google Scholar] [CrossRef]

- ANL/ESD/08-2; Life-Cycle Assessment of Energy and Greenhouse Gas Effects of Soybean-Derived Biodiesel and Renewable Fuels. Argonne National Laboratory: Cass Ave, IL, USA, 2008.

- EPA420-P-02-001; A Comprehensive Analysis of Biodiesel Impacts on Exhaust Emissions—Draft Technical Report. U.S. Environmental Protection Agency, Office of Transportation and Air Quality, Assessments and Standards Division: Washington, DC, USA, 2002.

- Tzillah, A. The Emissions of Criteria Air Pollutants from Biodiesel Fuel Usage. Master’s Thesis, University of Cincinnati, Cincinnati, OH, USA, 2009. [Google Scholar]

- Lapuerta, M.; Armas, O.; Rodriguez Fernandez, J. Effect of biodiesel fuels on diesel engine emissions. Prog. Energy Combust. Sci. 2008, 34, 198–223. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, H.; Lee, C.-F.F. Particulate matter emission characteristics of diesel engines with biodiesel or biodiesel blending: A Review. Renew. Sustain. Energy Rev. 2016, 64, 569–581. [Google Scholar] [CrossRef]

- Popovicheva, O.; Engling, G.; Lin, K.-T.; Persiantseva, N.; Timofeev, M.; Kireeva, E.; Völk, P.; Hubert, A.; Wachtmeister, G. Diesel/biofuel exhaust particles from modern internal combustion engines: Microstructure, composition, and Hygroscopicity. Fuel 2015, 157, 232–239. [Google Scholar] [CrossRef]

- Chien, Y.C.; Lu, M.; Chai, M.; Boerio, F.J. Characterization of Biodiesel and Biodiesel Particulate Matter by TG, TG-MS, and FTIR. Energy Fuels 2009, 23, 202–206. [Google Scholar] [CrossRef]

- Ulusoy, Y. Investigation of particulate matter by FTIR, TEM and elemental analyses in a diesel engine operating on diesel and waste cooking oil-biodiesel. Environ. Sci. Pollut. Res. 2019, 27, 500–509. [Google Scholar] [CrossRef]

- Liang, F.; Lu, M.; Keener, T.; Liu, Z.; Khang, S. The organic composition of diesel particulate matter, diesel fuel and engine oil of a non-road diesel generator. J. Environ. Monit. 2005, 7, 983–988. [Google Scholar] [CrossRef]

- Chai, M.; Lu, M.; Tzillah, A. The Compositional Analysis of Biodiesel Fuel and Biodiesel Particulate Matter. In Proceedings of the 102nd A&WMA Annual Conference and Exhibition, Detroit, MI, USA, 16–19 June 2009. [Google Scholar]

- Chai, M.; Lu, M. Experimental Investigation of the Oxidation of Methyl Oleate, One of the Major Biodiesel Fuel Components. In Synthetic Liquids Production and Refining; ACS Book Series; American Chemical Society: Washington, DC, USA, 2011; pp. 289–312. [Google Scholar]

- Usta, N.; Öztürk, E.; Can, Ö.; Conkur, E.; Nas, S.; Çon, A.; Can, A.; Topcu, M. Combustion of biodiesel fuel produced from hazelnut soap stock/waste sunflower oil mixture in a Diesel engine. Energy Convers. Manag. 2005, 46, 741–755. [Google Scholar] [CrossRef]

- Tsolakis, A. Effects on Particle Size Distribution from the Diesel Engine Operating on RME-Biodiesel with EGR. Energy Fuels 2006, 20, 1418–1424. [Google Scholar] [CrossRef]

- Liu, Z.; Lu, M.; Keener, T.; Birch, E.; Khang, S.; Liang, F. Variations of the particulate carbon distribution for a nonroad diesel generator. Environ. Sci. Technol. 2005, 39, 7840–7844. [Google Scholar] [CrossRef]

- Gomez, M.; Howard-Hildige, R.; Leahy, J.; O’Reilly, T.; Supple, B.; Malone, M. Emission and performance characteristics of a 2-Litre Toyota diesel van operating on esterified waste cooking oil and mineral diesel fuel. Environ. Monit. Assess. 2000, 65, 13–20. [Google Scholar] [CrossRef]

- Teoh, Y.H.; How, H.G.; Sher, F.; Le, T.D.; Nguyen, H.T.; Yaqoob, H. Fuel Injection Responses and Particulate Emissions of a CRDI Engine Fueled with Cocos nucifera Biodiesel. Sustainability 2021, 13, 4930. [Google Scholar] [CrossRef]

- Pietikäinen, M.; Väliheikki, A.; Oravisjärvi, K.; Kolli, T.; Huuhtanen, M.; Niemi, S.; Virtanen, S.; Karhu, T.; Keiski, R.L. Particle and Nox emissions of a non-road diesel engine with an SCR unit: The Effect of Fuel. Renew. Energy 2015, 77, 377–385. [Google Scholar] [CrossRef]

- Mehregan, M.; Moghiman, M. Effects of nano-additives on pollutants emission and engine performance in a urea-SCR equipped diesel engine fueled with blended-biodiesel. Fuel 2018, 222, 402–406. [Google Scholar] [CrossRef]

- Guarieiro, A.L.; Santos, J.V.D.S.; Eiguren-Fernandez, A.; Torres, E.A.; da Rocha, G.O.; de Andrade, J.B. Redox activity and PAH content in size-classified nanoparticles emitted by a diesel engine fuelled with biodiesel and diesel blends. Fuel 2014, 116, 490–497. [Google Scholar] [CrossRef]

- Durbin, T.; Collins, J.; Norbeck, J.; Smith, M. Effects of Biodiesel, Biodiesel Blends, and a Synthetic Diesel on Emissions from Light Heavy-Duty Diesel Vehicles. Environ. Sci. Technol. 2000, 34, 349–355. [Google Scholar] [CrossRef]

- Lin, Y.-F.; Wu, Y.-G.; Chang, C.-T. Combustion characteristics of waste-oil produced biodiesel/diesel fuel blends. Fuel 2007, 86, 1772–1780. [Google Scholar] [CrossRef]

- Turrio-Baldassarri, L.; Battistelli, C.L.; Conti, L.; Crebelli, R.; De Berardis, B.; Iamiceli, A.L.; Gambino, M. Emission comparison of urban bus engine fueled with diesel oil and biodiesel blend. Sci. Total Environ. 2004, 327, 147–162. [Google Scholar] [CrossRef] [PubMed]

- Borillo, G.C.; Tadano, Y.S.; Godoi, A.F.; Pauliquevis, T.; Sarmiento, H.; Rempel, D.; Yamamoto, C.I.; Marchi MR, R.; Potgieter-Vermaak, S.; Godoi, R.H.M. Polycyclic aromatic hydrocarbons (pahs) and nitrated analogs associated to particulate matter emission from a euro V-SCR engine fuelled with Diesel/biodiesel blends. Sci. Total Environ. 2018, 644, 675–682. [Google Scholar] [CrossRef] [PubMed]

- Karavalakis, G.; Fontaras, G.; Ampatzoglou, D.; Kousoulidou, M.; Stournas, S.; Samaras, Z.; Bakeas, E. Effects of low concentration biodiesel blends application on modern passenger cars. part 3: Impact on PAH, Nitro-Pah, and oxy-pah emissions. Environ. Pollut. 2010, 158, 1584–1594. [Google Scholar] [CrossRef] [PubMed]

| B0 | B50 | |||||

|---|---|---|---|---|---|---|

| Load (kW) | EC | OC | OC/EC Ratio | EC | OC | OC/EC Ratio |

| 0 | 0.25 | 0.66 | 2.68 | 0.18 | 0.69 | 3.74 |

| 25 | 0.31 | 0.59 | 1.93 | 0.09 | 0.65 | 7.09 |

| 50 | 0.35 | 0.42 | 1.19 | 0.25 | 0.62 | 2.48 |

| 75 | 0.53 | 0.31 | 0.58 | 0.37 | 0.46 | 1.23 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, M.; Tzillah, A.; Chai, M.; Aloraimi, O. Compositional Analysis of Biodiesel Particulate Matter (BPM) from a Non-Road Diesel Generator. Energies 2023, 16, 5010. https://doi.org/10.3390/en16135010

Lu M, Tzillah A, Chai M, Aloraimi O. Compositional Analysis of Biodiesel Particulate Matter (BPM) from a Non-Road Diesel Generator. Energies. 2023; 16(13):5010. https://doi.org/10.3390/en16135010

Chicago/Turabian StyleLu, Mingming, Aisha Tzillah, Ming Chai, and Omer Aloraimi. 2023. "Compositional Analysis of Biodiesel Particulate Matter (BPM) from a Non-Road Diesel Generator" Energies 16, no. 13: 5010. https://doi.org/10.3390/en16135010

APA StyleLu, M., Tzillah, A., Chai, M., & Aloraimi, O. (2023). Compositional Analysis of Biodiesel Particulate Matter (BPM) from a Non-Road Diesel Generator. Energies, 16(13), 5010. https://doi.org/10.3390/en16135010