Abstract

European manufacturing companies are currently in a very difficult situation. On the one hand, they have to strive for sustainable development. On the other hand, they have to face problems related to the geopolitical situation and the pursuit of cleaner production (including restrictive regulations on emissions). A significant increase in electricity prices means that companies have to take steps to use electricity rationally without reducing the level of production or incurring other additional costs. In this study, attention was paid to the influence of quality tools (QTs) in production process (PP) management on increasing energy efficiency (EE). Based on the literature review, it was found that the most frequently described QTs, i.e., SMED, TPM, Six Sigma, SPC, FMEA, 5S, or Poka-Yoke, used to improve PP did not take into account their impact on the EE of the enterprises. Therefore, the main purpose of this study was to examine this correlation and show that QTs can be helpful in shaping the energy management system (EMS). Achieving the research goal was possible thanks to surveys carried out among manufacturing companies. Using statistical tests, the existence of a statistically significant correlation was proved between QTs and EMS elements.

1. Introduction

The topic of effective energy use, especially by industrial enterprises, is still current, especially in the present situation faced by energy markets around the world. For units other than households, starting from 2018, there was an increase in electricity prices that spread across the entire European energy market [1]. In the European Union (EU) countries, the level of wholesale energy prices, the price as which sellers buy it, remains under pressure from the high gas and coal prices and the costs of purchasing CO2 emissions. For example, in Poland, as much as 59% of the average energy price is due to the prices of CO2 emission allowances resulting from the EU climate policy [2]. Despite this, according to the International Energy Agency (IEA) in 2021, a significant increase was observed in the consumption of such non-renewable raw materials as coal and oil, which resulted in the second highest annual increase in CO2 emissions in history (2 billion tons in absolute value) [3]. The reason for this is seen in the increase in gas prices, which led to greater demand for coal, despite the fact that the production of electricity from renewable sources also recorded the largest growth in history, and its share in electricity production in 2020 in the EU exceeded 22% [1,4].

Therefore, European enterprises are facing a challenge related to a significant increase in electricity prices and must take steps regarding its rational use without the need to reduce drastically the level of production or incur other additional costs. These types of activities fall within the scope of the energy management system. As noted by numerous authors, the broadly understood modern industrial production also covering logistics and environmental issues cannot exist without an energy management system (EMS) [5,6,7,8]. Already in the 1990s, it was noted that many investments in the energy efficiency (EE) of enterprises were not implemented despite their apparent profitability, whereas their causes could be seen in limited rationality, problems of the principal–agent, and ethics [9]. This is also confirmed by the latest publications in this field, in which the authors assessed EE and identified the occurring barriers [10,11].

The problem is that many enterprises, especially small- and medium-sized ones, do not have an appointed EMS. However, they take many actions and use such methods in the management of production processes (PPs) that can be included in it. Nevertheless, in the scientific literature, there is a clear research gap in the analysis of the use of quality tools to reduce energy consumption in production processes. Existing studies tend to focus more on production optimization. Our research provides evidence that the implementation of selected quality tools can be beneficial not only in terms of improving production processes but also in reducing energy consumption. Therefore, the main goal of this study was to examine the correlation between the use of selected quality methods and tools in PP and EE and to show that these methods can be helpful in shaping EMS.

Achieving the research purpose required both qualitative and quantitative research. Qualitative research is one that provides insight and understanding of a problem. It is usually an unstructured, exploratory research method that investigates highly complex phenomena that cannot be explained by quantitative research. This can be the basis for generating ideas or hypotheses for subsequent quantitative research. Quantitative research, on the other hand, is a form of research based on the methods of the natural sciences that produces figures and hard facts. They aim to establish a cause-and-effect relationship between two variables using mathematical, computational, and statistical methods. For the purposes of this research, a qualitative research plan was developed, the main tool of which was a questionnaire addressed to manufacturing companies. Ultimately, 111 enterprises located in Poland participated in the study, of which the largest percentage (43%) were large enterprises, while the remaining groups of enterprises (medium, small, and micro) recorded an almost identical share in the study, amounting to approx. 20%. In the next step, quantitative research related to the analysis of the collected data and the use of statistical methods that allow the testing of qualitative features was used. For this purpose, non-parametric (chi-square) tests were utilized, as they are carried out without relying on population distribution or population parameters [12]. These methods are described in Section 3.

In this work, the definition of energy efficiency was used, defined as an indicator, which was the ratio of the results, services, goods, or energy obtained to the energy input [9]. Therefore, the reduction of energy consumption, by assumption, would cause an increase in this indicator, assuming that the level of production (results) was maintained at the same level. In this paper, terms such as “actions raising the EE” or “actions related to EE” are used, which is synonymous with improving the use of energy in production processes.

Additional research objectives were also adopted to investigate the following:

- O1. The reasons for implementing actions raising the EE are correlated with the method/quality tools used in the improvement of PP.

- O2. The areas of implementing actions raising EE are correlated with the method/quality tools used in the improvement of PP.

- O3. The method/quality tools used in the improvement of PP have an impact on the actions related to EE.

The conducted research is the basis for drawing wider conclusions, and based on them, it can be acknowledged that quality methods in production management can be considered as the missing EMS element.

2. Quality Management Methods in Production and Energy Efficiency—A Literature Review

2.1. Energy Efficiency in Research—A General Outlook

Starting from 1995, 74,407 (as at 27 October 2022) articles containing PP and EE in the title, the summary, or specified by the authors’ keywords were recorded in the ScienceDirect database. Most of these, more than 85%, were research articles (63,699), while the second largest group (5521) were reviewing articles constituting approximately 7% of all works in this field. However, when we correlated the terms Management Method and EE in this search engine, our results were reduced to just more than half (35,927—as of 22 November 2022) in the form of studies issued since 1995. Here, also, a similar tendency to the distribution of individual types of publications was noted. The participation of research articles was in the range of 84–89%, while the share of reviews was between 7 and 10%. The table below (Table 1) contains data on these publications obtained by narrowing the range of dates to the period 2010–2022.

Table 1.

List of the number of publications in the period 2010–2022 of selected areas.

The quantities presented in Table 1 are significant and require the experience and valuable time of a literature researcher for their review. Nevertheless, just over 5500 of these works were published in the form of open access and open archive, and we focused on these works.

2.2. Energy Efficiency in Production Processes—A Review of Research Studies

Among the numerous publications (more than 3.5 million in ScienceDirect) in the field of PP, those that prevail present new solutions, production methods, and improvements affecting productivity or speed or a reduction in costs and necessary material and intangible resources. It is noted, in fact, that a small percentage of these publications (approx. 2%) examined issues related to the effectiveness of energy use in production companies. This issue can be presented in various ways, which is also reflected in the literature. The basic trends appear, namely technical and economic.

The technical aspect includes the analysis of a specific process and testing the effectiveness of energy use by introducing improvements in the process, such as the field of lean, new production methods and the use of other resources or modern solutions in the field of intelligent industry. The works with a technical aspect also include those in which the research was based on measuring the parameters of the machines, devices, or entire systems/processes and those used in quantitative research.

On the other hand, the economic aspect concerns the energy efficiency research for entire production companies or for the processes implemented in them. This aspect takes into account the key performance indicators (KPI), occurring barriers, and energy efficiency indicators implemented mainly due to surveys or case studies and uses methods in the field of science method management and quality (primarily statistical, quantitative, and qualitative methods). At the same time, it is noted that some of the works covered both technical and economic aspects [13]. Examples of publications presenting these issues are included in Table 2.

Table 2.

EE and PP terms in publications—examples.

This study omitted articles in which EE companies were discussed in the context of obtaining energy due to ecological sources. We focused on those in which specific PPs and their impact on EE or those in which qualitative methods affecting production activities in the context of EE were presented.

2.3. Energy Efficiency Tools and Methods

Due to the fact that the number of industrial enterprises is still growing, there is a need to reduce the energy consumption of their production and the corresponding greenhouse gas emissions. In this context, EE has become a key factor of sustainable production success, and the methods of achieving it represent an elementary point on the way to obtaining it. At the same time, energy management, and especially its effectiveness, requires a thorough assessment of the entire production process through a multi-disciplinary approach covering several departments, such as management, quality, IT, production, and technical office [42]. Therefore, methods and tools aimed at supporting energy assessment and cooperation of stakeholders and in improving EE in the manufacturing processes are important current research areas [39,43]. Although the implementation of EE is increasingly applied and recognized by decision-makers around the world as one of the most effective ways of alleviating rising energy prices, counteracting potential environmental threats, and increasing energy security, it is the choice of which tools will be used to obtain it that is the challenge [44]. Assessment methods and tools are necessary in activities related to energy management because they allow decision-makers to identify the possibility of improving and tracking the impact of their decisions on energy consumption [45]. These tools can help industrial companies in addressing both the knowledge and the organizational barriers related to the implementation of energy consumption reduction means [46]. They allow the monitoring and analysis of energy consumption in the enterprise and its production processes, and they are the first step towards increasing EE [39]. Several studies emphasized that the implementation of these methods and tools turned out to be profitable, and high indicators of implementation in the field of improving EE were recorded [41,47,48]. In addition, energy assessment tools and methods increase the transparency of energy consumption in real time and improve energy awareness. They allow one to analyze various aspects of production (technologies, raw materials, time, etc.) and to assess their impact on EE [49]. In addition, assessment methods and tools provide production companies with a complete, pragmatic method of measuring, controlling, and improving EE in production systems [39]. Experience has shown that an important problem when choosing the right tools aimed at improving efficiency is the diagnosis of the energy consumption itself [50]. The authors of another work also agreed with this opinion, proposing a critical analysis of the existing energy management system (EMS) using energy audits and the implementation of technological and economic enforcement studies which served as the basis for the design, implementation, and valuation of various energy sources (steam, hot water, compressed air, electricity, and water) [40,51]. Identifying places and effective reduction of energy and emission consumption requires a systematic approach. For this purpose, an EMS helps effectively to reduce energy consumption and CO2 emissions. In another work, a structured EE system (Structse®) which allowed for the detailed measurement and tracking of energy efficiency, as opposed to measuring ordinary energy consumption, was introduced [52]. Structse® provides full transparency and the possibility of further improvement, up to the limits of the best available technology. The need to use funds and appropriate performance indicators to compare energy consumption profiles by machines and processes and to compare their EE with competition efficiency in the industrial environment were also noticed by other authors [53]. Focusing on this challenge, they proposed methods supporting production companies in the development of energy efficiency indicators. For this purpose, a seven-stage production development method was proposed, for which key performance indicators (E-KPI) were developed. These indicators allowed the interpretation of the cause-and-effect relationships and, thus, supported the companies in their operational decision-making processes. As a consequence, the proposed method supported the identification of weaknesses and areas of improvement in energy efficiency related to production management and operations. The use of system thinking may also be an important solution in improving energy efficiency. In this case, subsequent authors proposed a framework consisting of four stages—motivation, abilities, implementation, and results—as well as a feedback loop [54]. The implementation of four stages will lead to positive feedback for future EE implementation. The deliberate consideration of energy consumption and resources arouses increasingly more interest in production companies. However, especially in small- and medium-sized enterprises (SMEs) oriented to implement activities aimed at improving the efficiency of energy use, difficulties exist due to various obstacles, such as unattractive depreciation terms, inefficient data collection, lack of ways, lack of transparency, or large workload (staff/time) [55]. The transfer of attention from energy-saving technologies to the dissemination of energy management practices may increase the potential for improving energy efficiency in this case. As demonstrated in another work, the specific potential of electricity (the amount of MWh of energy saved for one energy efficiency) was higher in the case of behavioral activities than technological activities [56]. What is more, this study showed that EE related to behavioral changes had a shorter return time. This research is not intended to reject the current use of industrial EE achieved by distributing technology but rather to contribute to a better understanding of how the full potential of energy efficiency can be achieved by taking into account not only the relationships between human and machine and between human and human but also the process approach, including quality management, which is focused on continual improvement using knowledge.

After analyzing the rules, methods, and concepts of improvement of EE in PP, presented in the above studies, the question arose: Do production companies actually use the selected methods of EE improvement, and if so, in what areas and what reasons do they follow?

In recent years, many literature reviews have been carried out on topics related to energy management. At the same time, these studies focused mainly on modeling and analyzing the production systems, tools for calculating emissions, and sustainable development, as well as tools and techniques of comparative analysis [16,57,58,59,60,61,62,63,64]. However, we did not find studies that focused on determining whether and which quality management tools, alone or in combination, contribute to improving EE. In some research papers, this is only a side topic, or there is a mention of the lack of such research [65,66,67,68]. Therefore, we agree with the authors that there is a lack of comprehensive analysis of quality methods and tools to improve energy awareness and assess their impact on EE [49,65,69]. Quality methods, such as SMED, TPM, Six Sigma, SPC, FMEA, 5S, and Poka-Yoke, which are used to improve the PPs do not take into account their impact on the EE of companies [4,5,6,38,68,70,71,72,73,74,75,76,77,78,79]. This study takes into account this aspect. In view of the above, the purpose of the presented research is to verify the correlation between the use of selected quality tools and methods in the PP and EE of enterprises and to show that these methods can be helpful in shaping an EMS.

3. Materials and Methods

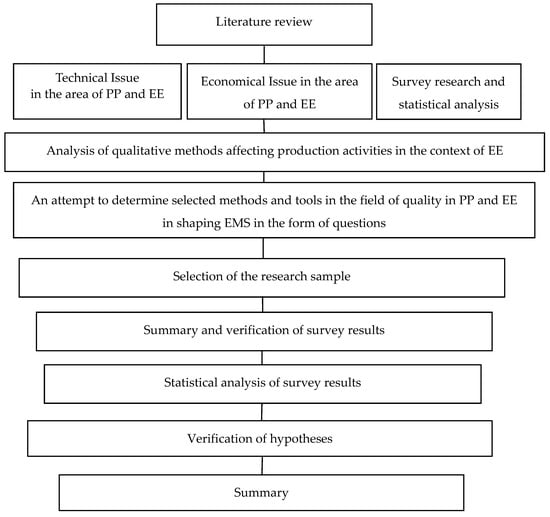

The presented research is the result of analysis of the scientific literature and identification of the cognitive gap in the area in question. This gap results from the approach taken by researchers of this issue that is slightly different to that presented in this study. Available publications contain the characteristics of barriers, indicators, and methods used as EMSs, but they do not examine the impact of their broad use in enterprises, the improvement methods in the field of quality management on EE, or the EMSs, if defined. Figure 1 presents the procedure used in this research.

Figure 1.

The procedure of this research.

The stages of the study included the following:

- Analysis of scientific literature, which aimed to obtain the most concise summary of information from the largest possible number of available literature sources using the systematic literature review method [80] and to identify the research gap.

- Preparation of a research tool in the form of a questionnaire, containing a total of 13 basic questions and a record. Depending on the thematic answers chosen by the respondents, there were 3 transition paths through closed and semi-open questions (the principle of redirection to the appropriate question number after a specific answer). The research entities were manufacturing companies based in Poland; therefore, the questionnaire was prepared in Polish.

- Implementation of surveys. This stage was relatively long (from March to August, 2021) despite the fact that the computer-assisted web interview survey method is very helpful in this type of research [81]. The questionnaires were filled in directly by the respondents or by the interviewer based on the answers of the study participants (data were not collected independently from available online literature sources). The data collection stage was key, and its extension was determined by the need to obtain a minimum of 100 good quality surveys (i.e., containing full data) for data analysis. The questionnaire provided full anonymity of respondents, which included those responsible for production, quality, or EMS/EE. No sensitive data were collected. The link to the examination was made publicly available using social media and email contacts and was often preceded by a telephone conversation. As a result, 111 correctly completed surveys were collected.

- Data analysis using available and properly selected statistical methods, which took into account the so-called cleaning data collected in the previous stage. It consisted of format, completeness, reasonableness, and limit checks and allowed subsequent correcting or eliminating of suspect records [82,83]. Several activities were carried out on the material prepared in this way, including:

- development of response statistics, including a breakdown of the percentage of individual responses and the percentage of all responses;

- examination of the frequency of multiple-choice questions;

- creation of cross tables presenting the distribution of attendance and the percentage shares of individual categories;

- extraction of aggregated variables;

- demonstration of the lack or existence of a relationship between variables using the chi-square test of independence.

The chi-square test of independence was used in the study, which is most often used in qualitative research based on a nominal scale [84]. The procedure for the chi-square independence test is as follows:

- The null hypothesis is accepted (H0—the variables X and Y are independent):H0: P(X = xi, Y = yj) = P(X = xi, ◦) P(◦, Y = yj)

- versus the alternative hypothesis (H1: X and Y variables are not independent):where the values of the examined features X and Y are xi and yj, respectively, and the symbol ◦ means that the variable from this item is not taken into account in the current distribution.H1: P(X = xi, Y = yj) ≠ P(X = xi, ◦) P(◦, Y = yj)

- The null hypothesis is verified. The null hypothesis is verified first by creating an independence table, called the contingency table, with the number of rows r and the number of columns s. Then, the table is filled with empirical numbers nij (i = 1, 2, …, r, j = 1, 2, …, s), which denote how many elements in the sample had the values of features xi and yj. Then, the boundary numbers ni. and n.j are determined. Based on these numbers, theoretical numbers are calculated for each combination (i, j) of features X and Y using the formula:

The test of the χ2 statistic is calculated according to the formula:

However, if the null hypothesis is true, then this statistic has a chi-square distribution with the number of degrees of freedom equal to (r − 1)(s − 1). Then, using the inequality χ2 ≥ χ2α,(r−1)(s−1), the right-hand critical area is determined. The critical value χ2α,(r−1)(s−1) is read from the chi-square distribution table for k = (r − 1)(s − 1) degrees of freedom and for a predetermined level of significance α, maintaining the relation P(χ2 ≥ χ2α,(r−1)(s−1))= α. If the value of χ2 meets the condition χ2 ≥ χ2α,(r−1)(s−1), the null hypothesis H0 is rejected, while if the value χ2 meets the condition χ2 < χ2α,(r−1)(s−1), there are no grounds to reject the hypothesis of non-independence of the examined variables. This stage was carried out in free RSTUDIO 2022.07.2 build 576 based on R.

- 5.

- Interpretation of the results of the study and the development of final conclusions referring to existing scientific research.

The attempt to fill the research gap required answers to specific research questions:

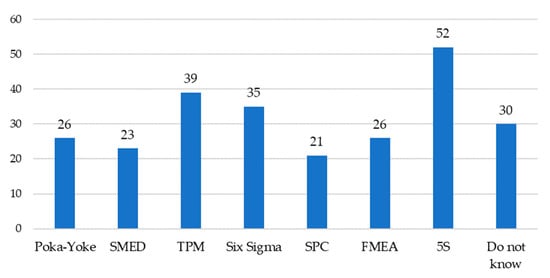

Question 1. What are the methods and quality tools most commonly used in enterprises in the field of PP management? This question is related to the specific objectives O1, O2, and O3. In order to answer the above question, basic tools and quality methods, i.e., Poka-Yoke, SMED, TPM, Six Sigma, SPC, FMEA, and 5S, were distinguished in Question 11 of the survey as well as accommodating the possibility of respondents adding their own answers. The concepts listed in the survey’s question were briefly described to minimize the risk of rejecting a given answer due to the lack of knowledge of the nomenclature. Of course, respondents in this case had the ability to mark more than 1 answer.

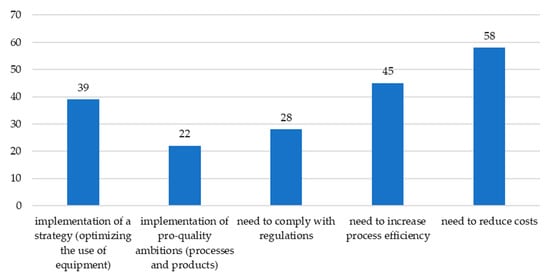

Question 2. What are the reasons for implementing EE? This is related to the specific objective O1. On the basis of a literature review, several groups were distinguished here: the implementation of a strategy focused on optimizing the use of machines and equipment, the implementation of the pro-quality ambitions of the company in the field of processes and products, the need to adapt to the regulations, the need to increase process efficiency, and the need to reduce costs. In the survey structure, it was Question 7 in which more than 1 answer could be marked.

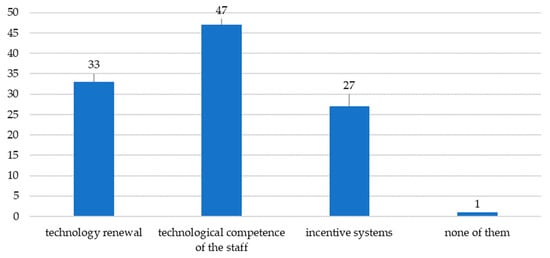

Question 3. What are the areas of implementing EEs in the studied enterprises? This is related to the specific objective O2, and the following areas were distinguished here (Question 8): technology renewal, raising the technological competence of the staff, creating incentive systems that encourage creative problem solving, and implementation of improvement ideas. Here, also, a place was provided for respondents to enter an additional answer. Only 1 of the respondents used the last option but did not identify the area, adding only “in none of the above areas”. For this question, respondents could also mark more than 1 answer.

Question 4. Do enterprises take actions related to increasing EE? This question is related to the specific objective O3, and it was included in the questionnaire under number 5. This was presented as a typical binary variable, so respondents had to choose one of two options (yes or no).

These questions became the basis for putting forth the following hypotheses of this work:

Hypothesis 1:

Tools and methods of quality management in PP affect EMS elements used in enterprises.

Hypothesis 2:

The reasons for implementing EEs are correlated with the methods and quality tools used by enterprises in the field of PP management.

Hypothesis 3:

The areas of the implementation of EE increases are correlated with the methods and quality tools in the field of PP management.

Hypothesis 4:

The quality management tools and methods used in PP are correlated with the actions related to EE.

4. Results

4.1. Quality Methods and Tools in Production Companies

The first research question was posed: What are the methods and quality tools most commonly used in enterprises in the field of PP management? The results are presented in Figure 2.

Figure 2.

Quality tools/methods used in enterprises—density.

After analyzing the results, it can be stated that 27% of respondents of the examined enterprises did not know whether they use the mentioned methods. However, 47% replied in the affirmative that the 5S method was used, and 35% recorded the use of TPM.

The first research hypothesis, which is “Tools and methods of quality management in PP affect EMS elements used in enterprises”, was examined in the next step.

At the same time, based on the literature, elements such as persons/teams responsible for energy management, monitoring the costs of energy consumption, conducting periodic analyses and reports on energy consumption, developing energy-saving recommendations, developing EE programs, and providing records of EE activities were distinguished. Respondents were asked about which EMS elements occur in the examined enterprises in the 13th survey question (the results are presented in Table 3).

Table 3.

Matrix: quality tools/methods and EMS elements.

In order to verify the H1 research hypothesis, a zero hypothesis was proposed:

H0—there is a statistically significant relationship between the quality methods used in enterprises in PP management and the occurrence of EMS elements.

In relation to the alternative hypothesis:

H1—there is no statistically significant relationship between the quality methods used in enterprises in PP management and the presence of EMS elements.

The data were tested with a chi-square test, and the results are presented in Table 4.

Table 4.

Chi-square test results for relation: quality tools/methods and EMS elements.

Several important conclusions were drawn. First, the people/teams responsible for energy management were influenced by the SMED concept (p = 0.011). This conclusion is actually not surprising. The SMED methodology is a set of techniques and tools that enable shortening of the changeover times of machines, devices, and production processes. SMED results in a very large shortening and simplification of the changeover process, which is also associated with improved EE. Managers’ view on the use of the SMED method from the point of view of improving efficiency may become the first element contributing to its improvement (as seen by the results of reducing energy consumption in the visualization tables, this can significantly affect the motivation for further improvement). In this case, it can also affect the monitoring of energy consumption costs. In this area, according to the respondents, no management concept had a significant impact. On the other hand, with regard to monitoring the costs of energy consumption, no management concept had a significant statistical impact. However, it was shown that the SMED concept (p = 0.000) and the 5S concept (p = 0.033) had an impact on conducting periodic analyses and providing reports on energy consumption. The 5S concept in the surveyed enterprises was indicated as the basis for identifying places where its use should be improved. The introduction of transparency and order in the workplace will make it possible to carry out inspections and draw appropriate conclusions regarding the state of energy use. Another conclusion was the statistically documented impact of the TPM concept (p = 0.000) and the Six Sigma concept (p = 0.012) on the development of recommendations for energy-saving operation and the impact of the TPM concept (p = 0.005) and SPC (p = 0.039) on the development of an energy efficiency implementation program. Application of these concepts led to an increase in the efficiency of the machine park with the precise configuration of the machines and devices to the needs and specificity of the company’s production processes. This allowed for the elimination of energy waste and losses, increased the life of the machine park, reduced overproduction, and ensured greater PP stability. In contrast, the record of energy efficiency projects was not significantly affected by any management concept.

4.2. Reasons for Implementing EE Activities in Enterprises

Another research question posed in this work was related to the reasons that the companies are guided by implementing the EEs. The analysis of the responses for this variable is shown in Figure 3.

Figure 3.

Reasons for EE actions—density.

A density analysis of the responses given to this question allowed us to conclude that the most common reasons for the implementation of EE activities were the need to reduce costs (52%) and the need to increase process efficiency (41%). The results in relation to the quality and tools used by enterprises in the field of production process management are presented in Table 5.

Table 5.

Matrix: quality tools/methods and reasons for EE actions.

Next, the second hypothesis (The reasons for implementing EEs are correlated with the methods and quality tools used by enterprises in the field of PP management) was verified.

In order to verify the second research hypothesis, a statistical zero hypothesis was adopted:

H0—there is a statistically significant relationship between the reasons for implementing EE and the methods and quality tools used by enterprises in the field of production process management.

An alternative hypothesis was also proposed:

H1—there is no statistically significant relationship between the reasons for implementing EE and the methods and tools used by enterprises in the field of production process management.

In order to verify the hypothesis, the chi-square test was again used. The results of the analysis are presented in Table 6.

Table 6.

Chi-square test results for relation: quality tools/methods and reasons for EE actions.

Based on the results, the following conclusions can be drawn:

- The concepts of Poka-Yoke (p = 0.000), SMED (p = 0.000), TPM (p = 0.000), Six Sigma (p = 0.004), SPC (p = 0.001), and FMEA (p = 0.022) affected the implementation of the strategy focused on optimizing the use of machines and devices.

- No concept had an impact on the implementation of its own pro-quality ambitions in the field of processes and products.

- Six Sigma (p = 0.006), SPC (p = 0.039), and FMEA (p = 0.019) affected the need to adapt to the regulations.

- TPM (p = 0.000) and SPC (p = 0.000) affected the need to increase process efficiency; TPM (p = 0.001) and SPC (p = 0.003) affected the need to reduce costs.

The strategy can be defined as a long-term plan, containing the main goals and tasks of the organization, the directions of action, and the allocation of funds necessary to achieve the defined goals. The unique configuration of resources in the company affects the implementation of the adopted goals. In the surveyed enterprises, the strategy focusing on optimizing the use of machinery and equipment had a fundamental impact on shaping the competitive advantage in the market. In this case, the application of concepts such as Poka-Yoke (p = 0.000), SMED (p = 0.000), TPM (p = 0.000), Six Sigma (p = 0.004), SPC (p = 0.001), and FMEA (p = 0.022) could significantly affect not only the product itself but also the financial condition of the company. For enterprises, the search for the most effective use of energy may now become the key to the survival and development of the company on the market. The FMEA method was also noteworthy. Respondents indicated that it enabled them to adapt to market requirements. This method provided great opportunities to identify potential sources of waste, including the waste of energy use.

4.3. Analysis of the EE Areas

The answer to the question “What are the areas of implementing EEs in the studied enterprises?” was another step in this research work. The results are shown in Figure 4.

Figure 4.

EE activity areas—density.

In this case, raising the technological competence of the staff in increasing EE area had the largest (42%) significance for the respondents, while in the scope of motivational systems, the smallest percentage of indications (24%) was obtained.

In order to examine the third research hypothesis, a matrix was prepared containing the correlated respondents’ answers, as seen in Table 7.

Table 7.

Matrix: quality tools/methods and EE activities areas.

In the light of Hypothesis 3 (The areas of implementing EEs are correlated with the methods and quality tools used by enterprises in the field of PP management), a statistical zero hypothesis was constructed:

H0—there is a statistically significant relationship between areas of implementing EE and the methods and quality tools used by enterprises in the field of production process management.

In relation to the alternative hypothesis:

H1—there is no statistically significant relationship between the areas of the implementation of EEs and the methods used by enterprise methods and quality tools in the field of production process management.

H0 was examined by available statistical methods (i.e., performing chi-square tests), and the results are presented in Table 8.

Table 8.

Chi-square test results for relation: quality tools/methods and EE activities areas.

The analysis of the results we received led to the following conclusions. The TPM concept (p = 0.001) significantly affected the area of technology renewal policy. The competitiveness of enterprises in the modern economy was strongly conditioned by innovation, that is, by the ability to develop and implement new technological and organizational solutions and new products. Most enterprises in Poland are practically unable to introduce innovative solutions. This is mainly due to the high costs of developing and implementing innovations. However, new technologies are a necessity for competitive global economies. In this area, it is important to notice the need to change or modernize manufacturing processes. In the examined cases, the TPM concept had a significant impact on the development of the technology renewal policy (p = 0.001). Thanks to its use, companies could see the losses generated by the resources involved in a given process. In this case, the use of energy should become a basic element to which managers will pay attention.

On the other hand, in the area of improving the technological competence of personnel, the SMED (p = 0.043), TPM (p = 0.027), and SPC (p = 0.012) concepts had a significant impact. The application of these concepts was based not only on training operators so that they are able to handle minor repairs on their own but also on providing them with the tools needed to do so. The maintenance of movement learns to change its operation from reactive to preventive and then to predictive. Managers, on the other hand, learn about changes in the improvement strategy or energy use standards. The staffing is based on continual cooperation between production and maintenance. The goal is to eliminate waste in the production process, improve everyday work, or find root causes of failures that generate energy costs.

In the area of creating motivational systems encouraging the solution of problems in creative ways and implementing improving ideas, the FMEA concept (p = 0.015) had a significant impact. Increasingly, human resources was recognized as an important and unique—because it is difficult to copy—asset and a factor responsible for the efficient use of energy. Without properly selected, well-educated and continually learning, effectively motivated, and properly rewarded employees, a modern organization is not able to meet the challenges of the globalization era. The modified FMEA method seems to be a good solution for quickly diagnosing potential threats and using them to create incentive systems that encourage creative problem-solving and the implementation of ideas that improve the use of energy. It is also a good way to record information about potential threats, monitor them, and record actions taken to minimize their potential negative effects.

4.4. Analysis of the Correlation of EE and Tools/Quality Methods

The last of the research hypotheses examined the following: “The quality management tools and methods used in PP are correlated with undertaken activities related to EE”.

In order to compare the structure (percentage) indicators, the Z-test was used in this case. The results of the answer distribution, taking into account this correlation, are provided in Table 9.

Table 9.

Matrix: quality tools/methods and EE activities.

An analysis of the results allowed us to state that in any case when applying any concept, the company was significantly more likely to take action related to EE improvement. Therefore, generally speaking, companies that used selected quality management methods were also focused on increasing energy efficiency and taking action in this area.

5. Discussion and Conclusions

Industrial production is considered one of the largest sectors in terms of energy demand, which significantly contributes to global greenhouse gas emissions. The latest report of the UN intergovernmental climate change team (IPCC) emphasized that the increase in greenhouse gas emissions in the world causes rapid climate change. Already in 2030, the average temperature in the world will reach a decisive 1.5 °C threshold above the level before the industrial era, which will not only reduce food production and increase the sea level but also lead to extreme climate phenomena (IPCC, 2018). Thus, EE in industry has become an important target for industrial enterprises. There is and there will continue to be a need for a systematic approach to reducing energy consumption in enterprises. The existing methods presented in various works focus on optimizing specific technological processes and do not include the entire production system [13,24,38,79,80]. In addition, they are based on a detailed quantitative analysis of processes, which requires a much work in the data acquisition phase. These processes are most often capital-intensive and burdened with a high risk in the return of invested capital. Experience shows that the transformation of the profitable potential of energy savings, in particular the possibility of improving the use of energy in all sectors, in investments encounters many barriers and unforeseen transaction costs [9,11,29]. Hence, there is great resistance to changes within decision-makers themselves. Enterprises do not always produce large amounts of products. There is an erroneous conclusion that in the production system any of the EE improvement elements can be used in this case. This way of thinking is confirmation that the heart of the case has been omitted and is incomprehensible. The concept of improving EE is not only about imitating the right tools and methods in a specific production system [10,23,33]. It boils down to developing rules appropriate for a given enterprise and compulsory compliance with them in order to achieve high EE in the production processes that permanently increases value for clients and society. This, of course, means increasing competitiveness and profitability. Therefore, the research presented in this work, which takes into account the EE context in relation to the methods and quality tools used in PPs, shed new light on this issue. In the literature, there are numerous representative examples of energy-saving methods [85,86,87,88]. However, the presented study provides specific guidelines to businesses on how to reduce the energy intensity of production processes by implementing selected quality tools. The strategy of using quality management methods is presented as an alternative to expensive and complicated EE apprenticeships from the technology side. Theoretical considerations, followed by empirical research and analyses of the results obtained, allowed the formulation of the following statements and contributions: there are significant differences in the assessment most commonly used in methods and quality tools in the field of PP management. After analyzing the results, it can be stated that 27% of respondents of the surveyed enterprises did not know whether their methods are used. However, 47% answered in the affirmative that a 5S method was used, and 35% recorded the use of TPM. From the point of view of the surveyed companies, the reasons for implementing EE activities are the need to reduce costs (52%) and the need to increase process efficiency (41%). This indicates the existence of a higher awareness of the importance of costs and activities undertaken by enterprises in the area of energy use. The need to reduce costs is influenced by the TPM (p = 0.001) and SPC (p = 0.003) concepts. As part of the modification/implementation of the activities that improve the efficiency of energy use in this case, the area of raising the technological competence of the staff in order to increase EE had the largest (42%) importance for respondents, while in the field of motion systems, the smallest percent of indications were obtained (24%). In the area of raising technological competences of the staff, TPM (p = 0.027), SPC (p = 0.012), and SMED (p = 0.043) had the most significant impact. Enterprises that indicated the motivational system as an element of increasing the efficiency of energy use emphasized the significant concept of FMEA (p = 0.015), encouraging creative problem-solving and implementing ideas in improving the studied area. Regarding the correlation of the tools and methods of quality management in the production processes with the undertaken actions related to raising EE, the analysis of the results allowed us to state that, in each case, when using any concept (Poka-Yoke, SMED, TPM, SIX SIGMA, SPC, FMEA, 5S), the company was more commonly following operations related to EE. At the same time, it was found that the TPM concept was the most often presented method when making decisions regarding the effectiveness of energy use. This was justified based on the activities of the elimination of interference during the operation of individual machines, devices, or other equipment components that had an impact on the effectiveness of a given production area. It was a valuable source of information that, properly used, became the basis of the activities optimizing the energy use in production processes.

Therefore, in the context of the purpose of this work, which was verification of the correlation between the use of selected quality tools and methods in the PP and EE of enterprises and showing that these methods can be helpful in shaping EMS, it was achieved. It has been confirmed that the use of selected methods/quality tools in the PP may affect certain EMS areas, and their relationship with EE activities is noticed.

The conclusions drawn from the research have significant international relevance, as they contribute to the understanding of the relationship between the use of quality tools and methods in production processes (PP) and energy efficiency (EE) in enterprises. The study highlights the novel approach taken in exploring these tools and their impact on shaping an energy management system (EMS).

The research findings provided valuable insights into the effectiveness of selected quality tools, such as 5S, TPM, and SPC, in improving production processes and reducing energy consumption. The study demonstrated that these tools can be viable alternatives to costly and complex energy efficiency apprenticeships from a technological perspective.

Moreover, the research highlighted the importance of raising technological competencies and implementing motivational systems in enhancing energy efficiency practices. The findings emphasized the significant role of concepts such as FMEA and creative problem-solving in driving improvements in the studied area.

The analysis revealed a positive correlation between the adoption of quality management methods and tools in production processes and the implementation of energy efficiency measures. Regardless of the specific concept used, companies are more likely to undertake operations related to energy efficiency when utilizing these tools. The TPM concept, in particular, emerged as a prominent method for optimizing energy use by addressing interference and enhancing effectiveness in production areas.

Therefore, the research’s key messages lie in the exploration of how selected quality tools and methods can contribute to shaping an energy management system and improving energy efficiency practices within the enterprises. These findings have global implications for organizations seeking innovative approaches to energy management and production optimization.

Author Contributions

Conceptualization, M.G. and M.D.; methodology, M.G. and M.D.; software, M.D.; validation, M.D.; formal analysis, M.G. and M.D.; investigation, M.D.; resources, M.G.; writing—original draft preparation. M.G and M.D.; writing - review and editing, M.G and M.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The collected data are available on request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Electricity Prices for Non-Household Consumers. Available online: https://ec.europa.eu/eurostat/web/main/data/database (accessed on 7 November 2022).

- Energy Regulatory Office. Electric Energy Market. Available online: https://www.ure.gov.pl (accessed on 2 November 2022).

- Executive Summary. World Energy Outlook 2021. Available online: www.iea.org (accessed on 16 November 2022).

- Share of Energy from Renewable Sources. Available online: https://appsso.eurostat.ec.europa.eu (accessed on 7 November 2022).

- Abbas, S.Z.; Kousar, A.; Razzaq, S.; Saeed, A.; Alam, M.; Mahmood, A. Energy management in South Asia. Energy Strategy Rev. 2018, 21, 25–34. [Google Scholar] [CrossRef]

- Daroń, M.; Górska, M. Importance of Machine Modernization in Energy Efficiency Management of Manufacturing Companies. Energies 2021, 14, 8383. [Google Scholar]

- Franz, E.; Erler, F.; Langer, T.; Schlegel, A.; Stoldt, J.; Richter, M.; Putz, M. Requirements and Tasks for Active Energy Management Systems in Automotive Industry. Procedia Manuf. 2017, 8, 175–182. [Google Scholar] [CrossRef]

- Javied, T.; Huprich, S.; Franke, J. Cloud based Energy Management System Compatible with the Industry 4.0 Requirements. IFAC-Pap. 2019, 52, 171–175. [Google Scholar] [CrossRef]

- DeCanio, S.J. Barriers within firms to energy-efficient investments. Energy Policy 1993, 21, 906–914. [Google Scholar] [CrossRef]

- Cagno, E.; Accordini, D.; Trianni, A.; Katic, M.; Ferrari, N.; Gambaro, F. Understanding the impacts of energy efficiency measures on a Company’s operational performance: A new framework. Appl. Energy 2022, 328, 120118. [Google Scholar] [CrossRef]

- Jalo, N.; Johansson, I.; Kanchiralla, F.M.; Thollander, P. Do energy efficiency networks help reduce barriers to energy efficiency?—A case study of a regional Swedish policy program for industrial SMEs. Renew. Sustain. Energy Rev. 2021, 151, 111579. [Google Scholar] [CrossRef]

- Turhan, N.S. Karl Pearson’s chi-square tests. Educ. Res. Rev. 2020, 15, 575–580. [Google Scholar]

- Hadi, M.A.; Brillinger, M.; Wuwer, M.; Schmid, J.; Trabesinger, S.; Jäger, M.; Haas, F. Sustainable peak power smoothing and energy-efficient machining process thorough analysis of high-frequency data. J. Clean. Prod. 2021, 318, 128548. [Google Scholar] [CrossRef]

- Chojnacka, K.; Mikula, K.; Izydorczyk, G.; Skrzypczak, D.; Witek-Krowiak, A.; Moustakas, K.; Ludwig, W.; Kułażyński, M. Improvements in drying technologies—Efficient solutions for cleaner production with higher energy efficiency and reduced emission. J. Clean. Prod. 2021, 320, 128706. [Google Scholar] [CrossRef]

- Bhadbhade, N.; Patel, M.K. Analysis of energy efficiency improvement and carbon dioxide abatement potentials for Swiss Food and Beverage sector. Resour. Conserv. Recycl. 2020, 161, 104967. [Google Scholar] [CrossRef]

- Li, K.; Gao, Y.; Zhang, S.; Liu, G. Study on the energy efficiency of bioethanol-based liquid hydrogen production process. Energy 2022, 238, 122032. [Google Scholar] [CrossRef]

- Ngo, H.T.; Kaci, A.; Kadri, E.H.; Ngo, T.T.; Trudel, A.; Lecrux, S. Energy consumption reduction in concrete mixing process by optimizing mixing time. Energy Procedia 2017, 139, 810–816. [Google Scholar] [CrossRef]

- Bruni, G.; Rizzello, C.; Santucci, A.; Alique, D.; Incelli, M.; Tosti, S. On the energy efficiency of hydrogen production processes via steam reforming using membrane reactors. Int. J. Hydrogen Energy 2019, 44, 988–999. [Google Scholar] [CrossRef]

- Belaissaoui, B.; Le Moullec, Y.; Hagi, H.; Favre, E. Energy Efficiency of Oxygen Enriched Air Production Technologies: Cryogeny vs Membranes. Energy Procedia 2014, 63, 497–503. [Google Scholar] [CrossRef]

- Kellens, K.; Rodrigues, G.C.; Dewulf, W.; Duflou, J.R. Energy and Resource Efficiency of Laser Cutting Processes. Phys. Procedia 2014, 56, 854–864. [Google Scholar] [CrossRef]

- Moejes, S.N.; Visser, Q.; Bitter, J.H. van Boxtel, A.J.B. Closed-loop spray drying solutions for energy efficient powder production. Innov. Food Sci. Emerg. Technol. 2018, 47, 24–37. [Google Scholar] [CrossRef]

- Thiede, S.; Turetskyy, A.; Loellhoeffel, T.; Kwade, A.; Kara, S.; Herrmann, C. Machine learning approach for systematic analysis of energy efficiency potentials in manufacturing processes: A case of battery production. CIRP Ann. 2020, 69, 21–24. [Google Scholar] [CrossRef]

- Zhang, H.; Li, L.; Li, L.; Cai, W.; Liu, J.; Sutherland, J.W. An integrated energy efficiency evaluation method for forging workshop based on IoT and data-driven. J. Manuf. Syst. 2022, 65, 510–527. [Google Scholar] [CrossRef]

- Shihata, L.A.; Ghaly, A.A.; Kiefer, J. Potentials of Energy Efficiency Improvement in Manufacturing Plants. Procedia CIRP 2022, 107, 729–733. [Google Scholar] [CrossRef]

- De Medeiros, E.M.; Noorman, H.; Filho, R.M.; Posada, J.A. Production of ethanol fuel via syngas fermentation: Optimization of economic performance and energy efficiency. Chem. Eng. Sci. X 2020, 5, 100056. [Google Scholar] [CrossRef]

- Leiden, A.; Herrmann, C.; Thiede, S. Cyber-physical production system approach for energy and resource efficient planning and operation of plating process chains. J. Clean. Prod. 2021, 280, 125160. [Google Scholar] [CrossRef]

- Bauerdick, C.J.H.; Helfert, M.; Menz, B.; Abele, E. A Common Software Framework for Energy Data Based Monitoring and Controlling for Machine Power Peak Reduction and Workpiece Quality Improvements. Procedia CIRP 2017, 61, 359–364. [Google Scholar] [CrossRef]

- Damrath, F.; Strahilov, A.; Bär, T.; Vielhaber, M. Establishing Energy Efficiency as Criterion for Virtual Commissioning of Automated Assembly Systems. Procedia CIRP 2014, 23, 137–142. [Google Scholar] [CrossRef]

- Ekwaro-Osire, H.; Bode, D.; Thoben, K.-D.; Ohlendorf, J.-H. Identification of Machine Learning Relevant Energy and Resource Manufacturing Efficiency Levers. Sustainability 2022, 14, 15618. [Google Scholar] [CrossRef]

- Rohdin, P.; Thollander, P. Barriers to and driving forces for energy efficiency in the non-energy intensive manufacturing industry in Sweden. Energy 2006, 31, 1836–1844. [Google Scholar] [CrossRef]

- Snow, S.; Clerc, C.; Horrocks, N. Energy audits and eco-feedback: Exploring the barriers and facilitators of agricultural energy efficiency improvements on Australian farms. Energy Res. Soc. Sci. 2021, 80, 102225. [Google Scholar] [CrossRef]

- Niza, I.L.; Luz, I.M.d.; Bueno, A.M.; Broday, E.E. Thermal Comfort and Energy Efficiency: Challenges, Barriers, and Step towards Sustainability. Smart Cities 2022, 5, 1721–1741. [Google Scholar] [CrossRef]

- Bernat, T.; Flaszewska, S.; Lisowski, B.; Lisowska, R.; Szymańska, K. Facing Environmental Goals for Energy-Efficiency Improvements in Micro and Small Enterprises Operating in the Age of Industry 4.0. Energies 2022, 15, 6577. [Google Scholar] [CrossRef]

- Dörr, M.; Wahren, S.; Bauernhansl, T. Methodology for Energy Efficiency on Process Level. Procedia CIRP 2013, 7, 652–657. [Google Scholar] [CrossRef]

- Beisheim, B.; Rahimi-Adli, K.; Krämer, S.; Engell, S. Energy performance analysis of continuous processes using surrogate models. Energy 2019, 183, 776–787. [Google Scholar] [CrossRef]

- Andersson, E.; Dernegård, H.; Wallén, M.; Thollander, P. Decarbonization of industry: Implementation of energy performance indicators for successful energy management practices in kraft pulp mills. Energy Rep. 2021, 7, 1808–1817. [Google Scholar] [CrossRef]

- Perone, C.; Romaniello, R.; Leone, A.; Berardi, A.; Tamborrino, A. Towards energy efficient scheduling in the olive oil extraction industry: Comparative assessment of energy consumption in two management models. Energy Convers. Manag. X 2022, 16, 100287. [Google Scholar] [CrossRef]

- Ribeiro, I.M.; Godina, R.; Pimentel, C.; Silva, F.J.G.; Matias, J.C.O. Implementing TPM supported by 5S to improve the availability of an automotive production line. Procedia Manuf. 2019, 38, 1574–1581. [Google Scholar] [CrossRef]

- Bunse, K.; Vodicka, M.; Schönsleben, P.; Brülhart, M.; Ernst, F.O. Integrating energy efficiency performance in production management—Gap analysis between industrial needs and scientific literature. J. Clean. Prod. 2011, 19, 667–679. [Google Scholar] [CrossRef]

- Gordić, D.; Babić, M.; Jovičić, N.; Šušteršič, V.; Končalović, D.; Jelić, D. Development of energy management system—Case study of Serbian car manufacturer. Energy Convers. Manag. 2010, 51, 2783–2790. [Google Scholar] [CrossRef]

- Kannan, R.; Boie, W. Energy management practices in SME––Case study of a bakery in Germany. Energy Convers. Manag. 2003, 44, 945–959. [Google Scholar] [CrossRef]

- Johansson, M.T.; Thollander, P. A review of barriers to and driving forces for improved energy efficiency in Swedish industry—Recommendations for successful in-house energy management. Renew. Sustain. Energy Rev. 2018, 82 Pt 1, 618–628. [Google Scholar] [CrossRef]

- Svensson, A.; Paramonova, S. An analytical model for identifying and addressing energy efficiency improvement opportunities in industrial production systems—Model development and testing experiences from Sweden. J. Clean. Prod. 2017, 142, 2407–2422. [Google Scholar] [CrossRef]

- Sarkar, A.; Singh, J. Financing energy efficiency in developing countries—Lessons learned and remaining challenges. Energy Policy 2010, 38, 5560–5571. [Google Scholar] [CrossRef]

- May, G.; Kiritsis, D. Business Model for Energy Efficiency in Manufacturing. Procedia CIRP 2017, 61, 410–415. [Google Scholar] [CrossRef]

- Meyers, S.; Schmitt, B. Chester-Jones, M.; Sturm, B. Energy efficiency, carbon emissions, and measures towards their improvement in the food and beverage sector for six European countries. Energy 2016, 104, 266–283. [Google Scholar] [CrossRef]

- Kluczek, A.; Olszewski, P. Energy audits in industrial processes. J. Clean. Prod. 2017, 142, 3437–3453. [Google Scholar] [CrossRef]

- Papetti, A.; Menghi, R.; Domizio, G.; Di Germani, M.; Marconi, M. Resources value mapping: A method to assess the resource efficiency of manufacturing systems. Appl. Energy 2019, 249, 326–342. [Google Scholar] [CrossRef]

- Schulze, M.; Nehler, H.; Ottosson, M.; Thollander, P. Energy management in industry—A systematic review of previous findings and an integrative conceptual framework. J. Clean. Prod. 2016, 112, 3692–3708. [Google Scholar] [CrossRef]

- Domínguez, M.; Fuertes, J.J.; Díaz, I.; Cuadrado, A.A.; Alonso, S.; Morán, A. Analysis of electric power consumption using Self-Organizing Maps. IFAC Proc. 2011, 44, 12213–12218. [Google Scholar] [CrossRef]

- Kubule, A.; Ločmelis, K.; Blumberga, D. Analysis of the results of national energy audit program in Latvia. Energy 2020, 202, 117679. [Google Scholar] [CrossRef]

- Drumm, C.; Busch, J.; Dietrich, W.; Eickmans, J.; Jupke, A. STRUCTese®—Energy efficiency management for the process industry. Chem. Eng. Process. Process Intensif. 2013, 67, 99–110. [Google Scholar] [CrossRef]

- May, G.; Barletta, I.; Stahl, B.; Taisch, M. Energy management in production: A novel method to develop key performance indicators for improving energy efficiency. Appl. Energy 2015, 149, 46–61. [Google Scholar] [CrossRef]

- Chai, K.-H.; Yeo, C. Overcoming energy efficiency barriers through systems approach—A conceptual framework. Energy Policy 2012, 46, 460–472. [Google Scholar] [CrossRef]

- Fawcett, T.; Hampton, S. Why & how energy efficiency policy should address SMEs. Energy Policy 2020, 140, 111337. [Google Scholar] [CrossRef]

- Paramonova, S.; Thollander, P.; Ottosson, M. Quantifying the extended energy efficiency gap-evidence from Swedish electricity-intensive industries. Renew. Sustain. Energy Rev. 2015, 51, 472–483. [Google Scholar] [CrossRef]

- Debnath, K.B.; Mourshed, M. Challenges and gaps for energy planning models in the developing-world context. Nat. Energy 2018, 3, 172–184. [Google Scholar] [CrossRef]

- Li, X. Research on optimization of setup time for product in the multi-product production system. Microprocess. Microsyst. 2021, 80, 103618. [Google Scholar] [CrossRef]

- Garwood, T.L.; Hughes, B.R.; Oates, M.R.; O’Connor, D.; Hughes, R. A review of energy simulation tools for the manufacturing sector. Renew. Sustain. Energy Rev. 2018, 81, 895–911. [Google Scholar] [CrossRef]

- Thiede, S.; Posselt, G.; Herrmann, C. SME appropriate concept for continuously improving the energy and resource efficiency in manufacturing companies. CIRP J. Manuf. Sci. Technol. 2013, 6, 204–211. [Google Scholar] [CrossRef]

- Pohl, J.; Hilty, L.M.; Finkbeiner, M. How LCA contributes to the environmental assessment of higher order effects of ICT application: A review of different approaches. J. Clean. Prod. 2019, 219, 698–712. [Google Scholar] [CrossRef]

- Saad, W.; Bennis, M.; Chen, M. A Vision of 6G Wireless Systems: Applications, Trends, Technologies, and Open Research Problems. IEEE Netw. 2020, 34, 134–142. [Google Scholar] [CrossRef]

- Rogers, J.G.; Cooper, S.J.; Norman, J.B. Uses of industrial energy benchmarking with reference to the pulp and paper industries. Renew. Sustain. Energy Rev. 2018, 95, 23–37. [Google Scholar] [CrossRef]

- Boyd, G.; Dutrow, E.; Tunnessen, W. The evolution of the ENERGY STAR® energy performance indicator for benchmarking industrial plant manufacturing energy use. J. Clean. Prod. 2008, 16, 709–715. [Google Scholar] [CrossRef]

- Teixeira, P.; Sá, J.C.; Silva, F.J.G.; Ferreira, L.P.; Santos, G.; Fontoura, P. Connecting lean and green with sustainability towards a conceptual model. J. Clean. Prod. 2021, 322, 129047. [Google Scholar] [CrossRef]

- Bhamu, J.; Sangwan, S.K. Reduction of Post-kiln Rejections for Improving Sustainability in Ceramic Industry: A Case Study. Procedia CIRP 2015, 26, 618–623. [Google Scholar] [CrossRef]

- Sundararajan, N.; Terkar, R. Improving productivity in fastener manufacturing through the application of Lean-Kaizen principles. Mater. Today Proc. 2022, 62, 1169–1178. [Google Scholar] [CrossRef]

- Chena, S.; Fan, S.; Xionga, J.; Zhanga, W. The Design of JMP/SAP Based Six Sigma Management System and its Application in SMED. Procedia Eng. 2017, 174, 416–424. [Google Scholar] [CrossRef]

- Menghi, R.; Papetti, A.; Germani, M.; Marconi, M. Energy efficiency of manufacturing systems: A review of energy assessment methods and tools. J. Clean. Prod. 2019, 240, 118276. [Google Scholar] [CrossRef]

- Toki, G.F.I.; Ahmed, T.; Hossain, M.E.; Alave, R.K.K.; Faruk, M.O.; Mia, R.; Islam, S.R. Single Minute Exchange Die (SMED): A sustainable and well-timed approach for Bangladeshi garments industry. Clean. Eng. Technol. 2022, 12, 100592. [Google Scholar] [CrossRef]

- Vieira, T.; Sá, J.C.; Lopes, M.P.; Santos, G.; Félix, M.J.; Ferreira, L.P.; Silva, F.J.G.; Pereira, M.T. Optimization of the cold profiling process through SMED. Procedia Manuf. 2019, 38, 892–899. [Google Scholar] [CrossRef]

- Silva, A.; Sá, J.C.; Santos, G.; Silva, F.J.G.; Ferreira, L.P.; Pereira, M.T. Implementation of SMED in a cutting line. Procedia Manuf. 2020, 51, 1355–1362. [Google Scholar] [CrossRef]

- Dos Reis, M.D.O.; Godina, R.; Pimentel, C.; Silva, F.J.G.; Matias, J.C.O. A TPM strategy implementation in an automotive production line through loss reduction. Procedia Manuf. 2019, 38, 908–915. [Google Scholar] [CrossRef]

- Ahmad, M.F.; Zakuan, N.; Jusoh, A.; Takala, J. Relationship of TQM and Business Performance with Mediators of SPC, Lean Production and TPM. Procedia-Soc. Behav. Sci. 2012, 65, 186–191. [Google Scholar] [CrossRef]

- Falcón, R.G.; Alonso, D.V.; Fernández, L.M.G.; Pérez-Lombard, L. Improving energy efficiency in a naphtha reforming plant using Six Sigma methodology. Fuel Process. Technol. 2012, 103, 110–116. [Google Scholar] [CrossRef]

- Antosz, K.; Jasiulewicz-Kaczmarek, M.; Waszkowski, R.; Machado, J. Application of Lean Six Sigma for sustainable maintenance: Case study. IFAC-Pap. 2022, 55, 181–186. [Google Scholar] [CrossRef]

- Rasay, H.; Taghipour, S.; Sharifi, M. An integrated Maintenance and Statistical Process Control Model for a Deteriorating Production Process. Reliab. Eng. Syst. Saf. 2022, 228, 108774. [Google Scholar] [CrossRef]

- Faghih-Roohi, A.; Akcay, A.; Zhang, Y.; Shekarian, E.; de Jong, E. A group risk assessment approach for the selection of pharmaceutical product shipping lanes. Int. J. Prod. Econ. 2020, 229, 107774. [Google Scholar] [CrossRef]

- Barbosa Santos, R.; de Oliveira, U.R.; Rocha, H.M. Failure mapping for occupational safety management in the film and television industry. Int. J. Prod. Econ. 2018, 203, 1–12. [Google Scholar] [CrossRef]

- Parris, D.L.; Peachey, J.W. A Systematic Literature Review of Servant Leadership Theory in Organizational Contexts. J. Bus. Ethics 2013, 113, 377–393. [Google Scholar] [CrossRef]

- Macer, T.; Wilson, S. FocusVision 2015 Annual Technology Report, Full Report; Meaning Ltd.: London, UK, 2016. [Google Scholar]

- Mathew, C.; Güntsch, A.; Obst, M.; Vicario, S.; Haines, R.; Williams, A.R.; de Jong, Y.; Goble, C. A semi-automated workflow for biodiversity data retrieval, cleaning, and quality control. Biodiv. Data J. 2014, 11, 4221. [Google Scholar]

- Gueta, T.; Carmel, Y. Quantifying the value of user-level data cleaning for big data: A case study using mammal distribution models. Ecol. Inform. 2016, 34, 139–145. [Google Scholar] [CrossRef]

- Białek, J.; Depta, A. Statystyka Dla Studentów z Programem STAT_STUD 1.0; Wyd. C. H. Beck: Warszawa, Poland, 2010. [Google Scholar]

- He, Y.; Wu, P.; Li, Y.; Wang, Y.; Tao, F.; Wang, Y. A generic energy prediction model of machine tools using deep learning algorithms. Appl. Energy 2020, 275, 115402. [Google Scholar] [CrossRef]

- Li, X.; Lan, Y.; Jiang, P.; Cao, H.; Zhou, J. An efficient computation for energy optimization of robot trajectory. IEEE Trans. Ind. Electron. 2021, 69, 11436–11446. [Google Scholar] [CrossRef]

- Fiori, C.; Kyoungho, A.; Rakha, H.A. Power-based electric vehicle energy consumption model: Model development and validation. Appl. Energy 2016, 168, 257–268. [Google Scholar] [CrossRef]

- Zhang, J., II; Campbell, J.F.; Sweeney, D.C.; Hupman, A.C. Energy consumption models for delivery drones: A comparison and assessment. Transp. Res. Part D Transp. Environ. 2021, 90, 102668. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).