Multi-Degree-of-Freedom Load Reproduction by Electrohydraulic Digital-Servo Loading for Wind Turbine Drivetrain

Abstract

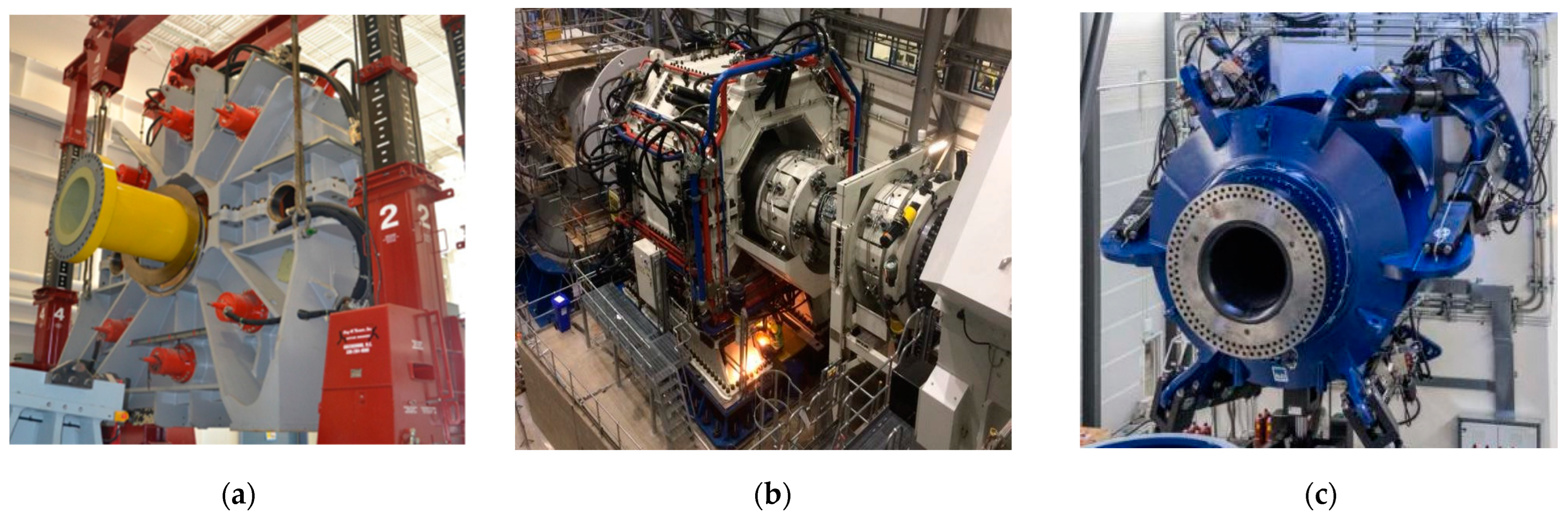

1. Introduction

2. Structural Schemes for NTL

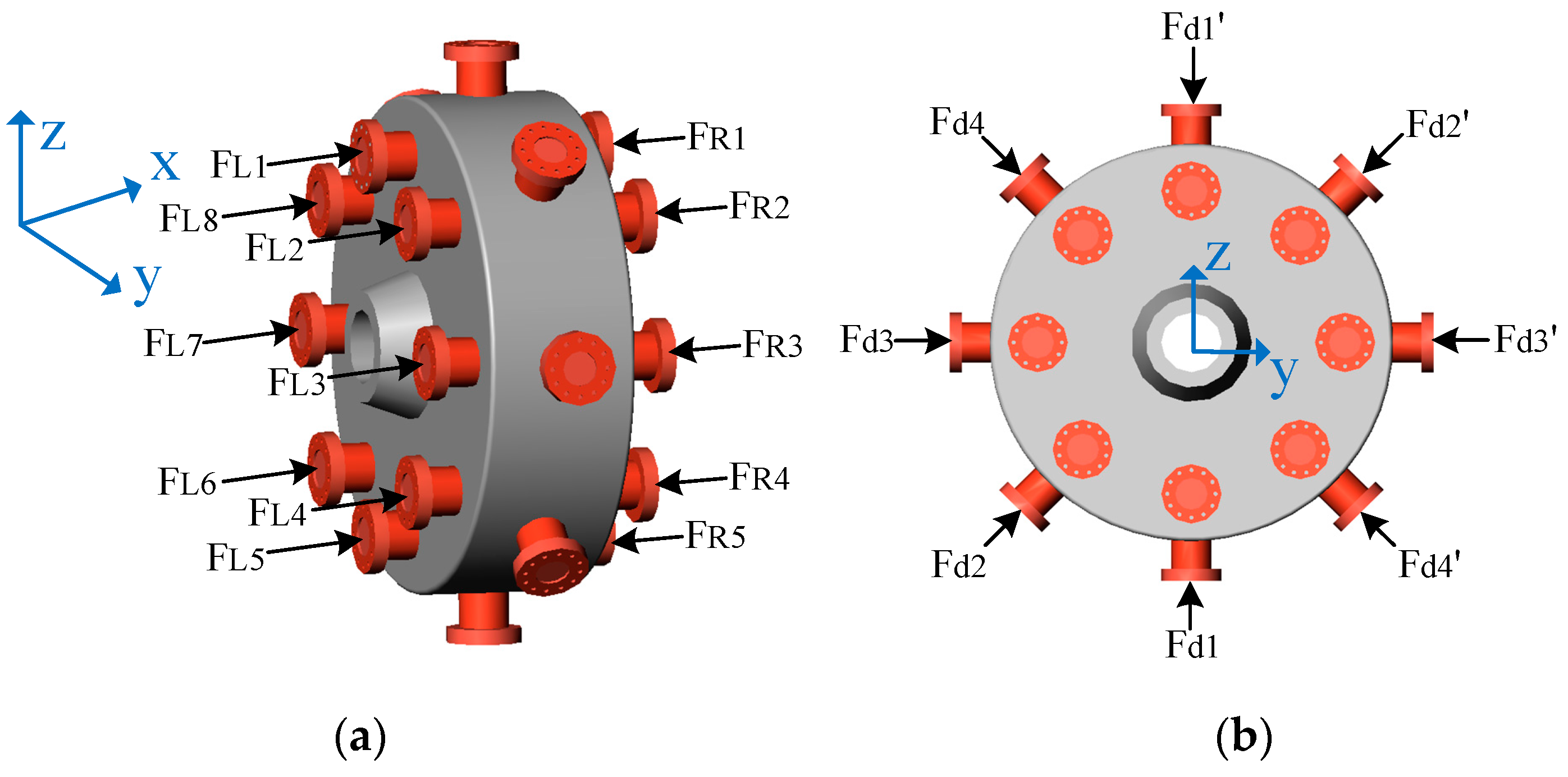

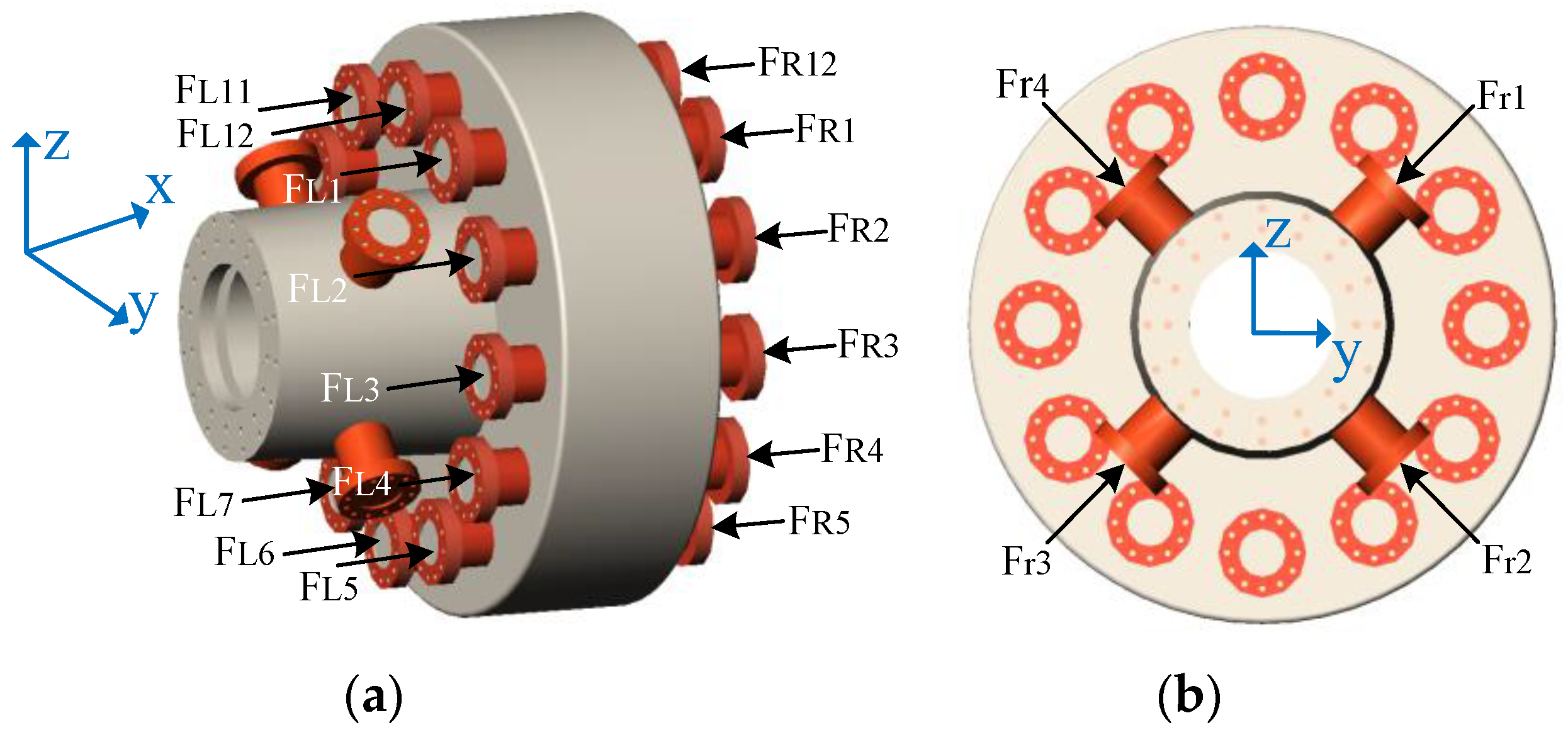

2.1. Symmetrical Loading Scheme

2.2. Radial Eccentric Loading Scheme

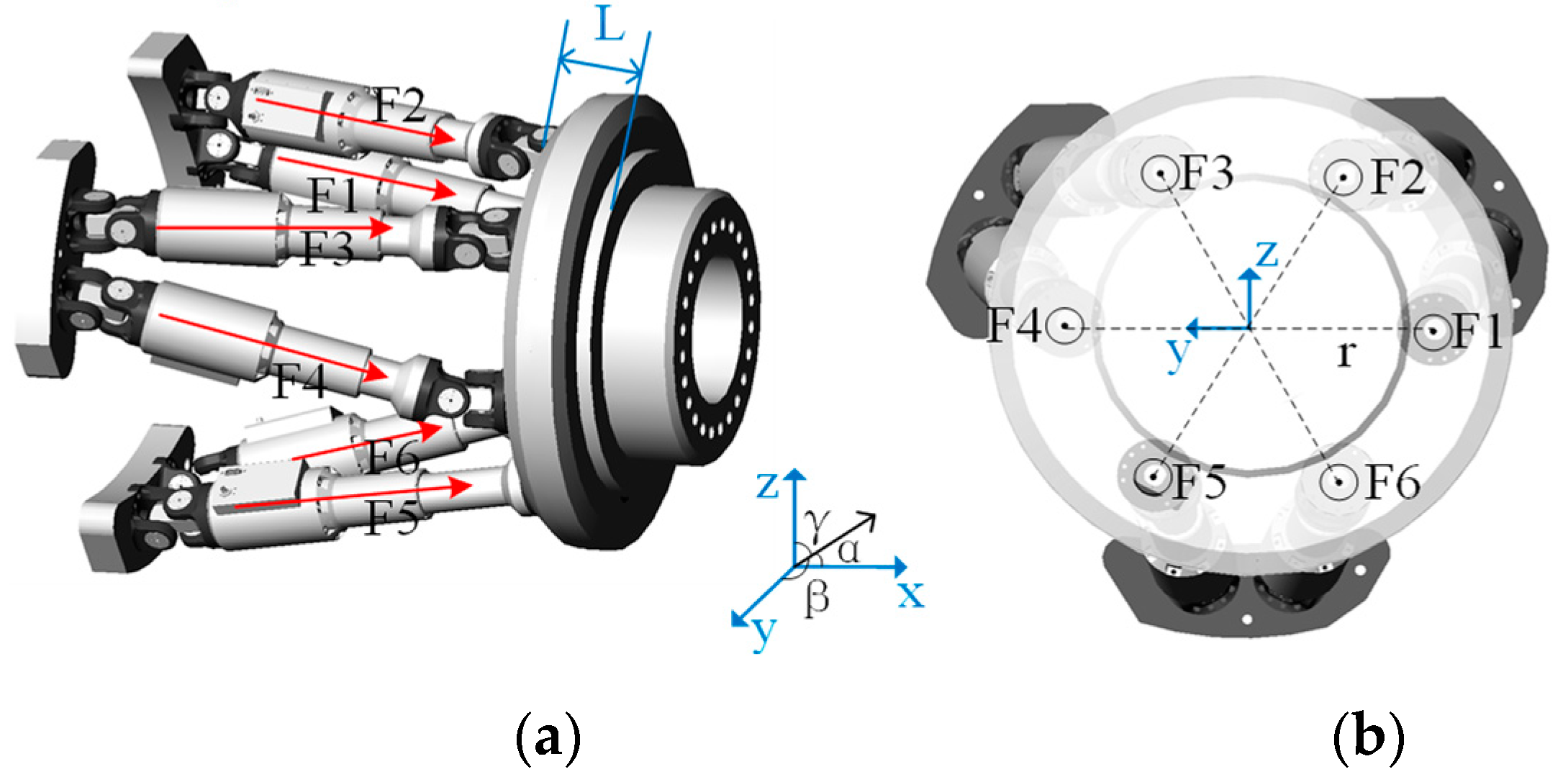

2.3. Parallel Six-Hydraulic-Cylinder Loading Scheme

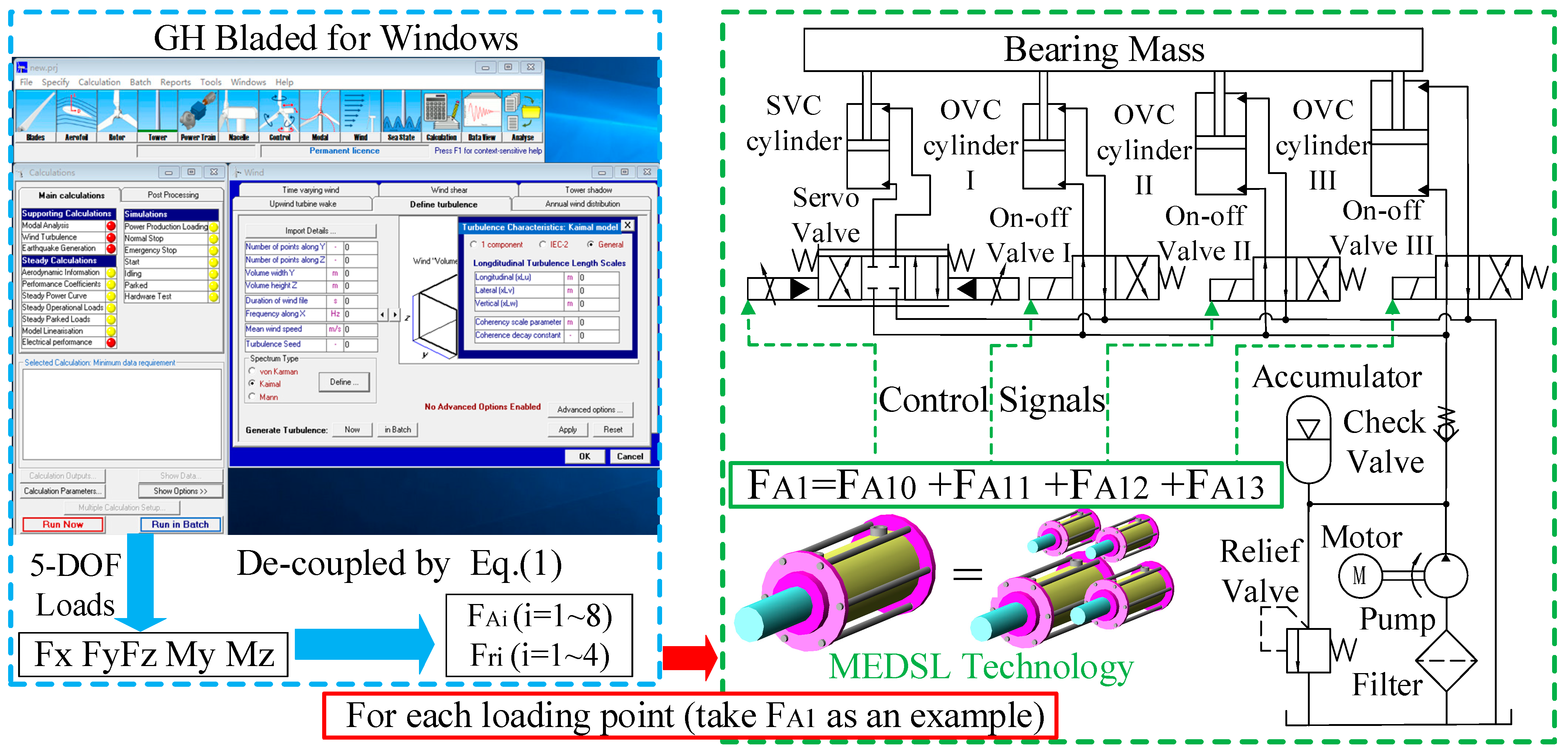

3. MEDSL Technology for Large-Scale Wind Turbine Test Bench

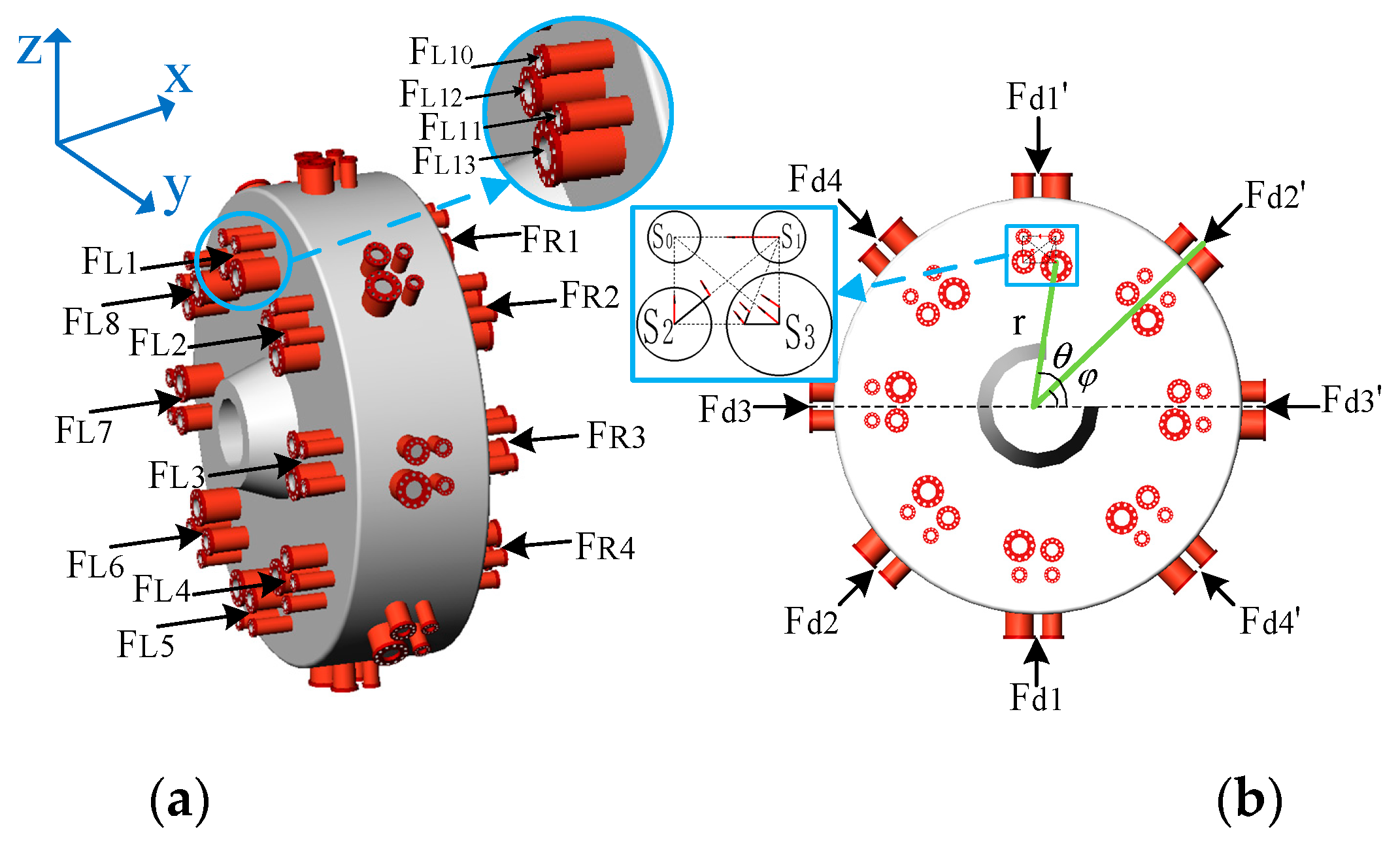

3.1. Structure

3.2. Loading Principle

4. Controller Development

4.1. Model of the SVC Cylinder Pressure System

4.2. SMC Design

4.3. Simulation Verification

5. Experimental Study and Discussion

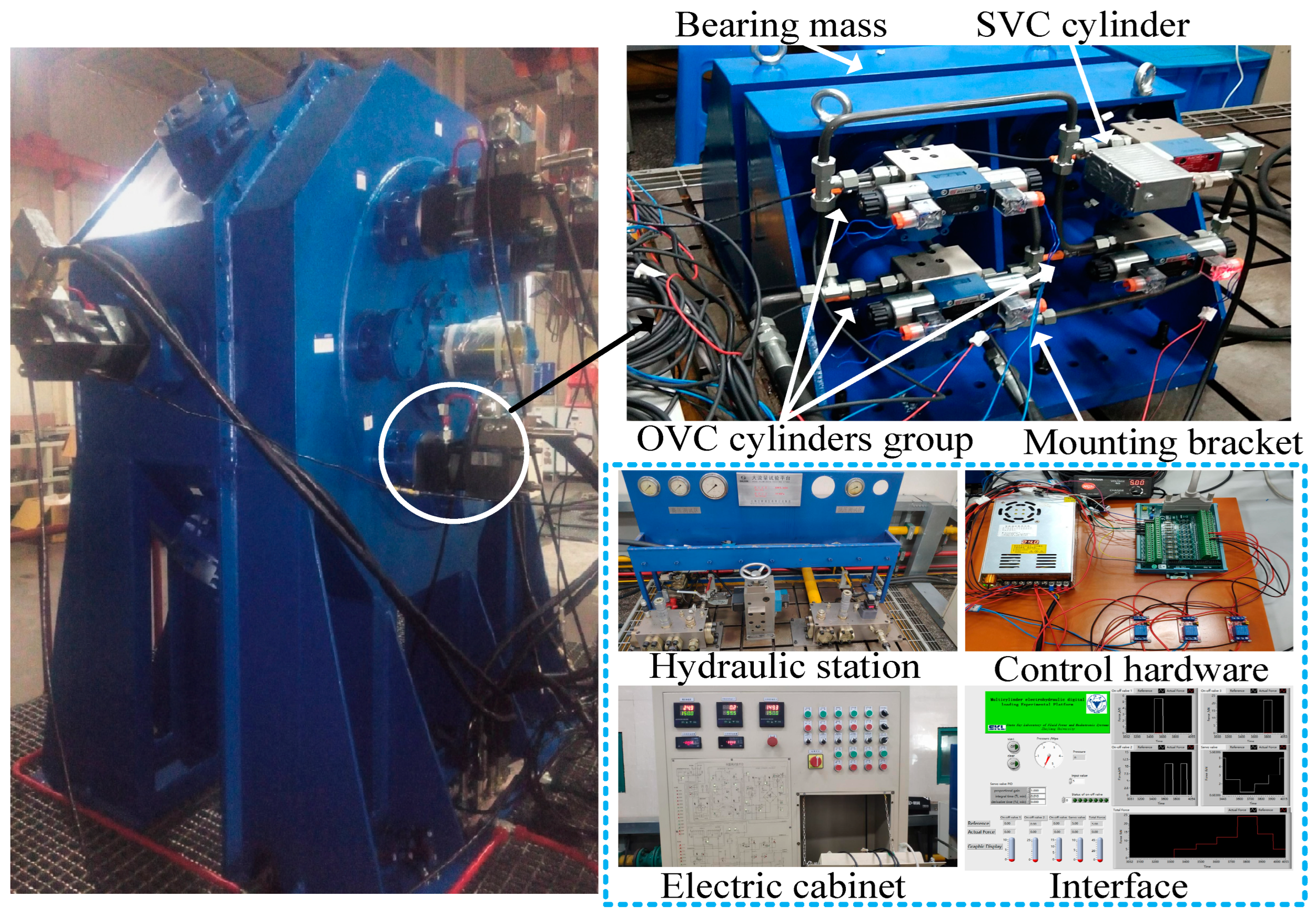

5.1. Experimental Setup

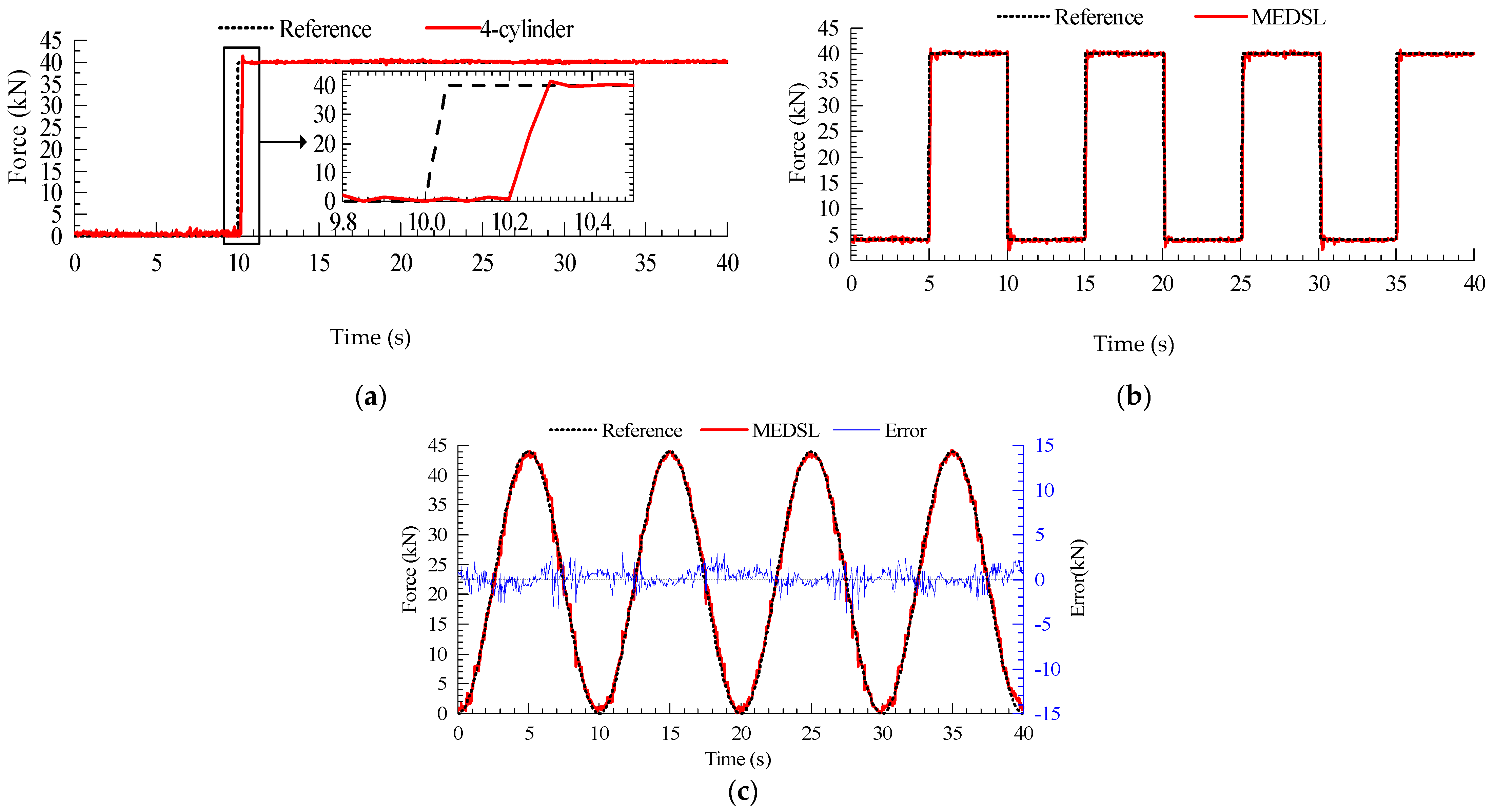

5.2. Experimental Results

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Global Wind Energy Council. Global Wind Report 2022. Available online: https://gwec.net/global-wind-report-2022/ (accessed on 4 April 2022).

- Hybrid Drives the World MySE 16.0-242 Offshore Wind Turbine. Available online: https://news.bjx.com.cn/html/20210820/1171553.shtml (accessed on 20 August 2021).

- The Target of Offshore Wind Turbine is 20MW. Available online: https://wind.in-en.com/html/wind-2405805.shtml (accessed on 16 August 2021).

- Zhang, D.H.; Wang, J.Q.; Lin, Y.G.; Si, Y.L.; Huang, C.; Yang, J.; Huang, B.; Li, W. Present situation and future prospect of renewable energy in China. Renew. Sustain. Energy Rev. 2017, 76, 865–871. [Google Scholar] [CrossRef]

- Pérez, J.M.P.; Márquez, F.P.G.; Tobias, A.; Papaelias, M. Wind turbine reliability analysis. Renew. Sustain. Energy Rev. 2013, 23, 463–472. [Google Scholar] [CrossRef]

- Oh, K.Y.; Lee, J.K.; Bang, H.J.; Park, J.Y.; Lee, J.S.; Epureanu, B.I. Development of a 20 kW wind turbine simulator with similarities to a 3 MW wind turbine. Renew. Energy 2014, 62, 379–387. [Google Scholar] [CrossRef]

- Pagitsch, M.; Jacobs, G.; Schelenz, R.; Bosse, D.; Liewen, C.; Reisch, S.; Deicke, M. Feasibility of large-scale calorimetric efficiency measurement for wind turbine generator drivetrains. J. Phys. Conf. Ser. 2016, 753, 072011. [Google Scholar] [CrossRef]

- Averous, N.R.; Stieneker, M.; Kock, S.; Andrei, C.; Helmedag, A.; De Doncker, R.W.; Hameyer, K.; Jacobs, G.; Monti, A. Development of a 4 MW full-Size wind-turbine test bench. IEEE J. Emerg. Sel. Top. Power Electron. 2017, 5, 600–609. [Google Scholar] [CrossRef]

- Jassmann, U.; Frehn, A.; Röttgers, H.; Santjer, F.; Mehler, C.; Beißel, T.; Kaven, L.; von den Hoff, D.; Frühmann, R.; Azarian, S.; et al. CertBench: Conclusions from the comparison of certification results derived on system test benches and in the field. Forsch. Ingenieurwes. 2021, 85, 353–371. [Google Scholar] [CrossRef]

- Fraunhofer Institute for Wind Energy Systems, Nacelle Testing and Examination of Electrical Characteristics [EB/OL]. Available online: https://www.iwes.fraunhofer.de/en/test-centers-and-measurements/nacelle-testing-and-certification-of-electrical-characteristics.html (accessed on 4 August 2018).

- McKinney, M.H.; Fox, J.C.; Collins, E.R.; Bulgakov, K.; Salem, T.E. Design, development, and commissioning of a multimegawatt test facility for renewable energy research. IEEE Trans. Ind. Appl. 2016, 52, 11–17. [Google Scholar] [CrossRef]

- Schkoda, R.F.; Fox, C. Integration of mechanical and electrical hardware for testing full scale wind turbine nacelles. In Proceedings of the 2014 Clemson University Power Systems Conference, Clemson, SC, USA, 11–14 March 2014; pp. 1–8. [Google Scholar]

- Schkoda, R.F. Sliding mode control of a hydraulically actuated load application unit with application to wind turbine drivetrain testing. IEEE Trans. Control Syst. Technol. 2015, 23, 2203–2215. [Google Scholar] [CrossRef]

- Bibo, A.; Panyam, M. Evaluation of dynamic testing of full-scale wind turbine drivetrains with hardware-in-the-loop. Wind Eng. 2022, 46, 1550–1569. [Google Scholar] [CrossRef]

- Giguère, P.; Wagner, J.R. Experimental verification of predicted capability of a wind turbine drivetrain test bench to replicate dynamic loads onto multi-megawatt nacelles. Wind Eng. 2022, 46, 1047–1064. [Google Scholar] [CrossRef]

- Giguère, P.; Wagner, J.R. Acceptance criteria for the tracking error of wind turbine drivetrain test bench when replicating dynamic loads. Wind Eng. 2021, 46, 160–176. [Google Scholar] [CrossRef]

- Schkoda, R.F. Static uncertainty analysis of a wind turbine test bench’s load. In Proceedings of the 2015 American Control Conference (ACC), Chicago, IL, USA, 1–3 July 2015; pp. 3150–3155. [Google Scholar]

- 5Wind Turbine Test Beds: 15 MW Test Rig, 7.5 MW Test Rig. Available online: http://clemsonenergy.com/wind-turbine-test-beds (accessed on 10 September 2017).

- Offshorre Renewable Energy, Powertrain Testing Services. Available online: https://ore.catapult.org.uk/what-we-do/testing-validation/powertrain-facilities/ (accessed on 14 January 2019).

- National Renewable Energy Cener, Powertrain Test Laboratories and Electrical Testing. Available online: http://www.cener.com/en/wind-turbine-test-laboratory-lea/powertrain-test-laboratories-and-electrical-testing/ (accessed on 24 January 2019).

- R&D Test Systems is Developing the World’s Largest Test Bench for LORC. Available online: https://www.rd-as.com/insights/worlds-largest-test-bench-lorc/ (accessed on 17 March 2020).

- ZF Wind Power and R&D Test Systems to Develop 30MW Test Bench. Available online: https://www.rd-as.com/insights/zf-wind-power-and-rd-test-systems-to-develop-30mw-test-bench/ (accessed on 7 September 2022).

- Jassmann, U.; Reiter, M.; Abel, D. Driving torque control for a nacelle test bench. J. Phys. Conf. Ser. 2014, 524, 012068–012079. [Google Scholar] [CrossRef]

- Yin, X.; Lin, Y.; Li, W.; Ye, H. Loading system and control strategy for simulating wind turbine loads. J. Vib. Control 2015, 23, 1739–1752. [Google Scholar] [CrossRef]

- Xu, X.; Han, X.; Liu, Y.; Liu, Y.; Liu, Y. Modeling and dynamic analysis on the direct operating solenoid valve for improving the performance of the shifting control system. Appl. Sci. 2017, 7, 1266. [Google Scholar] [CrossRef]

- Abedinifar, M.; Ertugrul, S.; Tayyar, G.T. Design optimization of a solenoid actuator using particle swarm optimization algorithm with multiple objectives. Adv. Mech. Eng. 2022, 14, 1–12. [Google Scholar] [CrossRef]

- Oh, U.; Nonaka, N.; Ishimoto, J. Valve Optimization with System-fluid-magnetic Co-simulation and Design of Experiments. Int. J. Automot. Technol. 2022, 23, 683–692. [Google Scholar] [CrossRef]

- Yin, X.; Lin, Y.; Li, W.; Ye, H.; Gu, Y.; Liu, H. Reproduction of five degree-of-freedom loads for wind turbine using equispaced electro-hydraulic actuators. Renew. Energy 2015, 83, 626–637. [Google Scholar] [CrossRef]

- Liu, H.; Li, Y.; Lin, Y.; Bao, J.; Li, W.; Wang, Y. The application of the digital controlled hydraulic cylinders group in pendulum wave energy. IEEE/ASME Trans. Mechatron. 2020, 25, 673–682. [Google Scholar] [CrossRef]

- Yao, J.; Jiao, Z.; Ma, D.; Yan, L. High-accuracy tracking control of hydraulic rotary actuators with modeling uncertainties. IEEE/ASME Trans. Mechatron. 2014, 19, 633–641. [Google Scholar] [CrossRef]

- Lin, Y.; Li, D.; Gu, Y.; Liu, H.; Feng, X.; Ding, J. Multi-cylinder electrohydraulic digital loading technology for reproduction of large load. Mechatronics 2021, 76, 102559. [Google Scholar] [CrossRef]

- Xiao, L.; Lu, B.; Yu, B.; Ye, Z. Cascaded sliding mode force control for a single-rod electrohydraulic actuator. Neurocomputing 2015, 156, 117–120. [Google Scholar] [CrossRef]

- Lyu, L.; Chen, Z.; Yao, B. Advanced valves and pump coordinated hydraulic control design to simultaneously achieve high accuracy and high efficiency. IEEE Trans. Control Syst. Technol. 2021, 29, 236–248. [Google Scholar] [CrossRef]

- Gu, Y.; Lin, Y.; Xu, Q.; Liu, H.; Li, W. Blade-pitch system for tidal current turbines with reduced variation pitch control strategy based on tidal current velocity preview. Renew. Energy 2018, 115, 149–158. [Google Scholar] [CrossRef]

- Deng, P.; Zeng, L.; Liu, Y. RBF neural network backstepping sliding mode adaptive control for dynamic pressure cylinder electrohydraulic servo pressure system. Complexity 2018, 2018, 4159639. [Google Scholar] [CrossRef]

- Cerman, O.; Hušek, P. Adaptive fuzzy sliding mode control for electro-hydraulic servo mechanism. Expert Syst. Appl. 2012, 39, 10269–10277. [Google Scholar] [CrossRef]

- Hau, E. Wind Turbines: Fundamentals, Technologies, Application, Economics; Springer: Berlin/Heidelberg, Germany, 2013; pp. 528–533. [Google Scholar]

| Loading Scheme | Loading Actuators | Loading Vectors | Advantage | Disadvantage |

|---|---|---|---|---|

| Symmetrical scheme | 24 | 12 | Simple solving procedure | Difficult hydrostatic support |

| Radial eccentric scheme | 28 | 16 | Can provide large bending moment | Complex calculation process |

| Parallel six-hydraulic-cylinder scheme | 6 | 6 | Few control vectors | Large displacement of the platform and complicated decoupling process |

| Component | Parameter | Value | Component | Parameter | Value |

|---|---|---|---|---|---|

| Hydraulic oil | Density/kg·m−3 | 850 | Hydraulic source | Pressure source/MPa | 5 |

| Bulk modulus/MPa | 800 | Pump displacement cc/rev | 100 | ||

| SVC cylinder | Piston diameter/mm | 50 | Typical speed of pump rev/min | 1500 | |

| Rod diameter/mm | 32 | ||||

| Cylinder stroke/mm | 50 | Load | Mass/kg | 20,000 | |

| a1 | 1646 | SMC | c1 | 50,000 | |

| a2 | 3.156 × 1014 | c2 | 10 | ||

| a3 | 363,100 | 10,000 | |||

| a4 | 11,460 | k | 20 | ||

| a5 | 147.4 | 0.001 |

| Type | Single SVC Cylinder | MEDSL | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Index | 5 kN steady-state load | Square load | Sinusoidal load | 40 kN steady-state load | Square load | Sinusoidal load | Random load | |||||

| PID | SMC | PID | SMC | PID | SMC | I | II | III | ||||

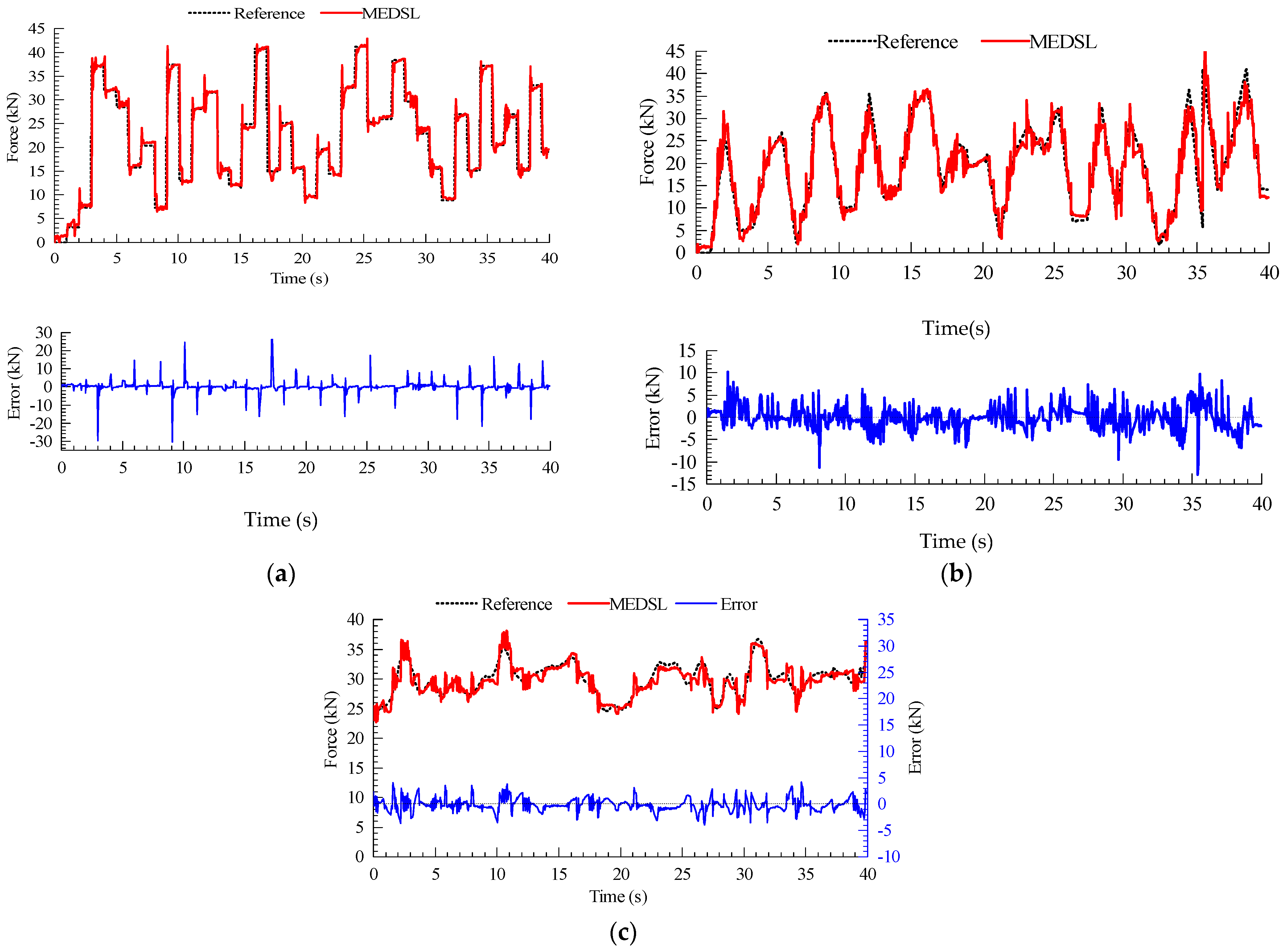

| Figure | Figure 11a | Figure 11b | Figure 11c | Figure 12a | Figure 12b | Figure 12c | Figure 13a | Figure 13b | Figure 13c | |||

| Response time (s) | 0.30 | 0.15 | 0.163 | 0.10 | 0.30 | 0.425 | ||||||

| Overshoot | 9.31% | 2.24% | 13.21% | 6.68% | 3.36% | 1.03% | ||||||

| Error range (kN) | 1.328 | 0.314 | 3.129 | 1.492 | 2.413 | 0.924 | 1.185 | 4.932 | 6.870 | 56.644 | 23.115 | 8.147 |

| Error average (kN) | 0.103 | 0.039 | 0.075 | 0.052 | 0.376 | 0.126 | 0.103 | 0.189 | 0.728 | 1.352 | 1.979 | 0.963 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, D.; Gu, Y.; Liu, H.; Lin, Y.; Song, J.; Shu, Y. Multi-Degree-of-Freedom Load Reproduction by Electrohydraulic Digital-Servo Loading for Wind Turbine Drivetrain. Energies 2023, 16, 4659. https://doi.org/10.3390/en16124659

Li D, Gu Y, Liu H, Lin Y, Song J, Shu Y. Multi-Degree-of-Freedom Load Reproduction by Electrohydraulic Digital-Servo Loading for Wind Turbine Drivetrain. Energies. 2023; 16(12):4659. https://doi.org/10.3390/en16124659

Chicago/Turabian StyleLi, Danyang, Yajing Gu, Hongwei Liu, Yonggang Lin, Jiajun Song, and Yongdong Shu. 2023. "Multi-Degree-of-Freedom Load Reproduction by Electrohydraulic Digital-Servo Loading for Wind Turbine Drivetrain" Energies 16, no. 12: 4659. https://doi.org/10.3390/en16124659

APA StyleLi, D., Gu, Y., Liu, H., Lin, Y., Song, J., & Shu, Y. (2023). Multi-Degree-of-Freedom Load Reproduction by Electrohydraulic Digital-Servo Loading for Wind Turbine Drivetrain. Energies, 16(12), 4659. https://doi.org/10.3390/en16124659