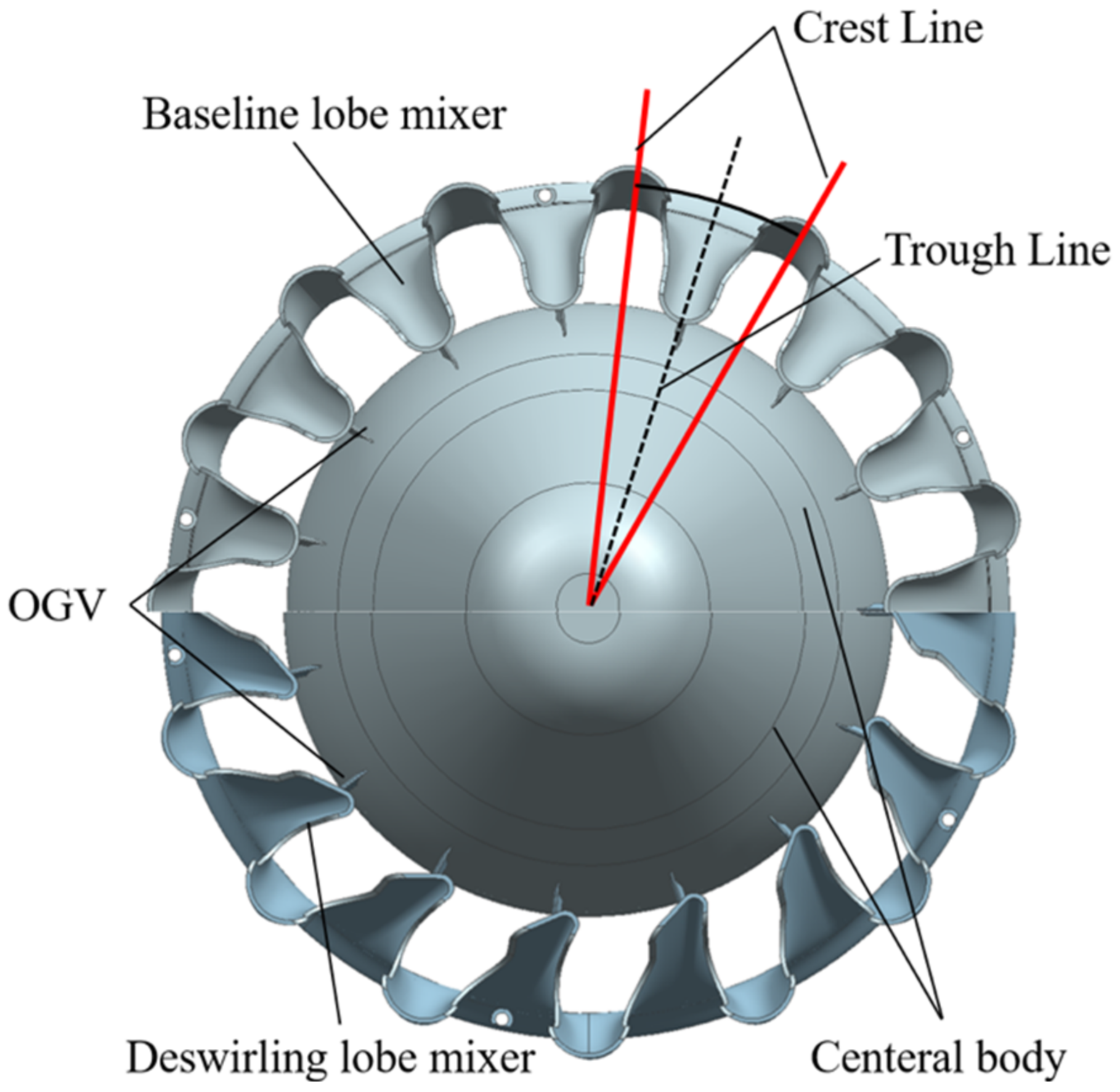

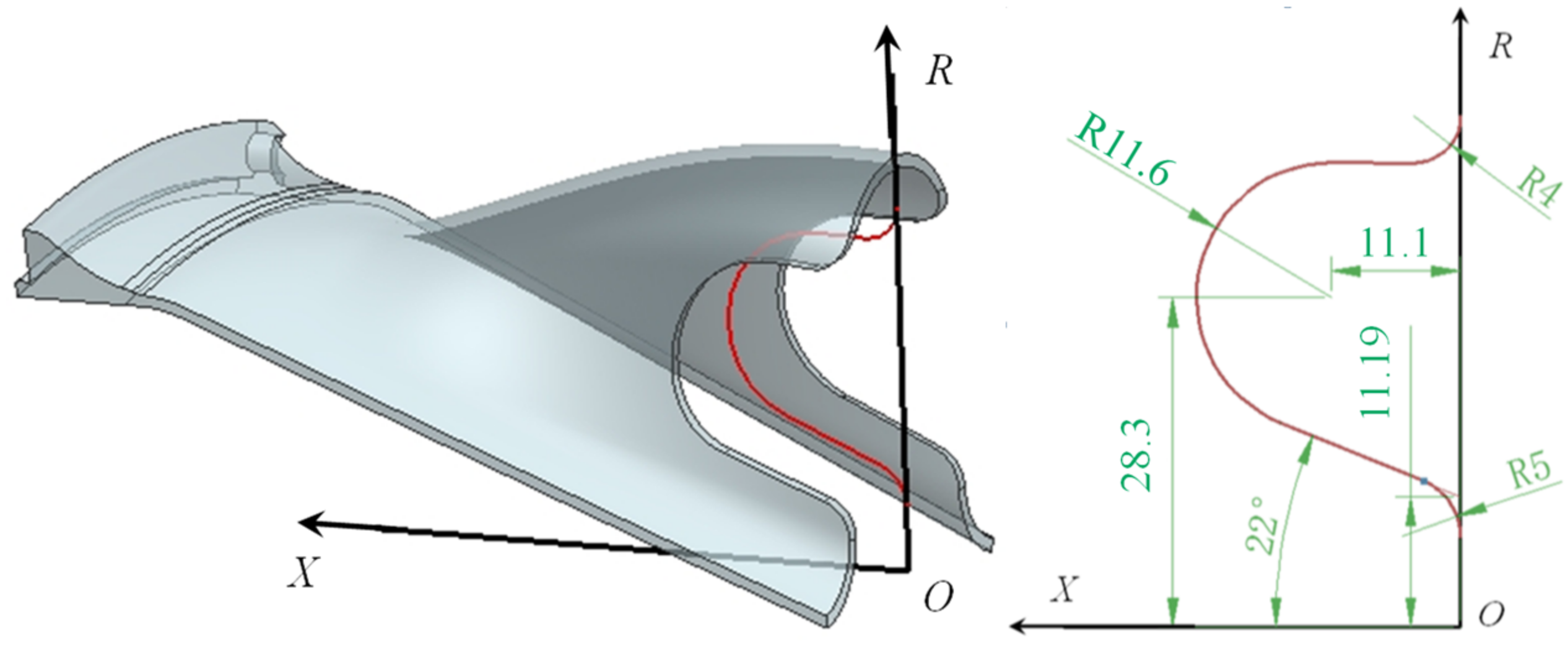

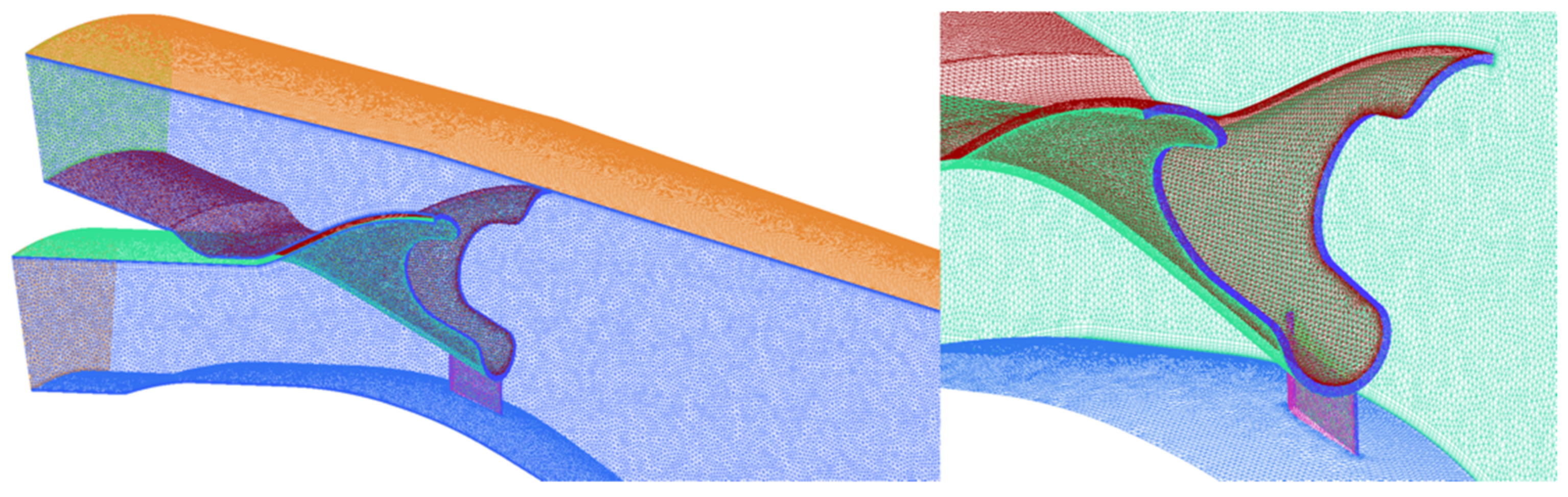

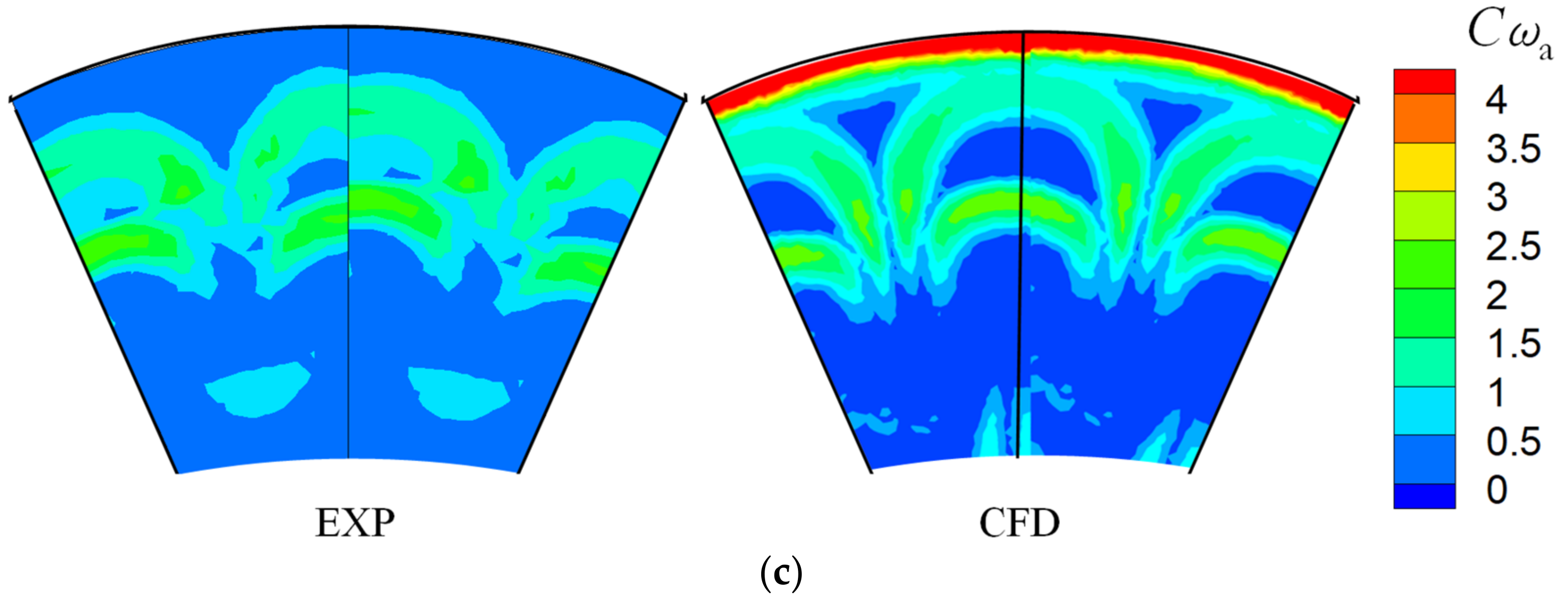

This paper studies four different geometric models of the lobed mixer, including two types of lobed mixers and an integrated OGV. The de-swirling mechanism of the integrated OGVs is first examined under design conditions. Then, the off-design cases with inlet swirls ranging from 0° to 35° are analyzed to estimate the influence of the integrated OGVs on the aerodynamic performance of the lobed mixer.

3.1. Mixing Mechanism of IDLM on Design Condition

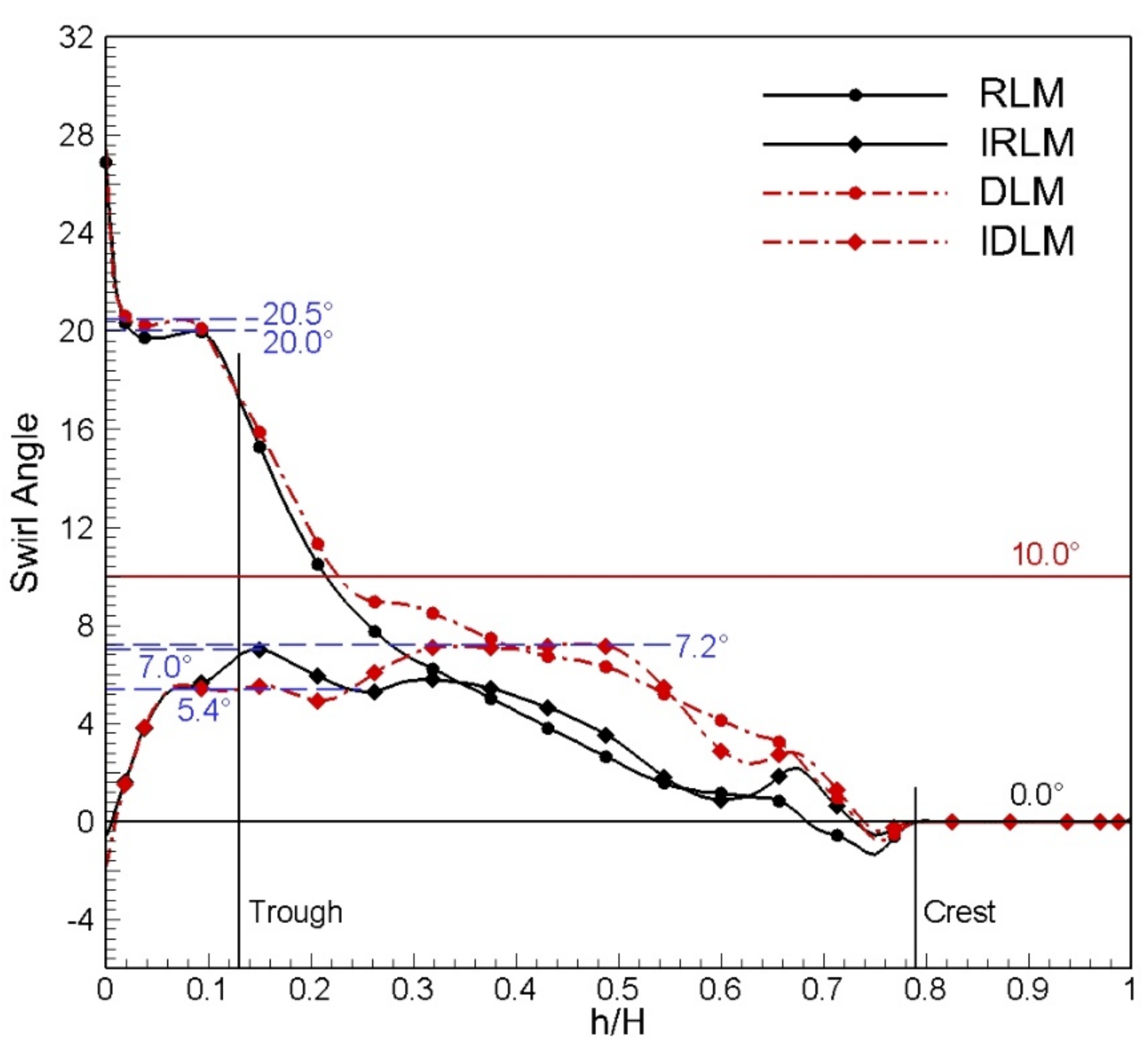

Figure 9 shows the radial distribution of the pitch-wise mass-averaged flow angle at the outlet of the lobed mixer (x = 0.4 Ln) for cases with a core inlet swirl of 20°. The positions corresponding to the trough and crest of the lobed mixer are marked. The abscissa represents the dimensionless height, and H is the channel height of this section. Between the trough and the central body (0 < h/H < 0.13), there is a strong leakage swirling flow for both the scalloped reference lobed mixer (RLM) and the scalloped de-swirling lobed mixer (DLM). Their flow angles are 20° and 20.5°, respectively, roughly equivalent to the core inlet flow angle. The leakage swirling flow of DLM is slightly higher than that of RLM, which may be due to the enhancement of leakage swirling flow caused by the raised ridge line of the DLM trough. Under the acceleration effect of the tapered central body, this strong leakage swirling flow can reach a flow angle of more than 50° when it reaches the exhaust system outlet section, causing a backflow in the center of the jet and increasing total pressure loss and thrust loss of the exhaust system. After integrating with the low-pressure turbine outlet guide vane, this part of the leakage swirling flow is well suppressed: the flow angle in this region downstream of IRLM is less than 7° and remains at around 5.4° for IDLM. Even under the acceleration effect of the tapered central body, the tangential flow angle at the outlet is still less than 20°, effectively suppressing backflow in the center of jet flow and reducing thrust loss and total pressure loss of the exhaust system. As only a small part of the lobed mixer around the trough de-swirls core inlet swirl, there is a high residual swirling flow in region 0.13 < h/H < 0.24 downstream of RLM and DLM, with its flow angle decreasing sharply as h increases. This high residual swirling flow can cause flow separation around the lobe’s trough, resulting in increased thrust and total pressure loss [

21,

23]. After integrating with OGV, the residual tangential flow angle in the corresponding region downstream of IRLM is less than 7° and is further reduced to about 5.4° for IDLM. This shows that integrating OGV significantly improves the de-swirl ability in this region and that IDLM has a better de-swirl effect than IRLM. In the region of 0.24 < h/H < 0.79, as the inner swirling flow goes deeper into the lobed mixer, the de-swirl ability of the lobed mixer increases with h, causing the residual swirl angle in this area downstream of the lobed mixer to continue decreasing as h increases. This residual swirl angle at the same height position downstream of DLM is greater than that of RLM. The average residual swirl angle of DLM is 6.5°, and RLM’s is 3.8°. A higher swirl angle is maintained downstream of DLM to enhance streamwise vortices and accelerate jet mixing in this area. After integrating with the low-pressure turbine outlet guide vane, although the residual swirl angle downstream of IRLM at the same height position has slightly increased, its distribution trend is roughly consistent with that of RLM. The distribution trend of the residual swirl angle downstream of IDLM is also approximately the same as that of DLM: it first remains at around 7.2° and then quickly drops to 0°. It can be seen that the residual swirl angle downstream of DLM and IDLM is greater than that of RLM and IRLM but not greater than 10°. According to the authors’ early research conclusions, when there is a weak swirling flow (<10°) remaining downstream of the lobed mixer, it not only does not increase thrust loss but also helps to enhance streamwise vortices and accelerate jet mixing. In other words, compared with RLM, DLM has better mixing performance, especially IDLM, which will be discussed in detail below.

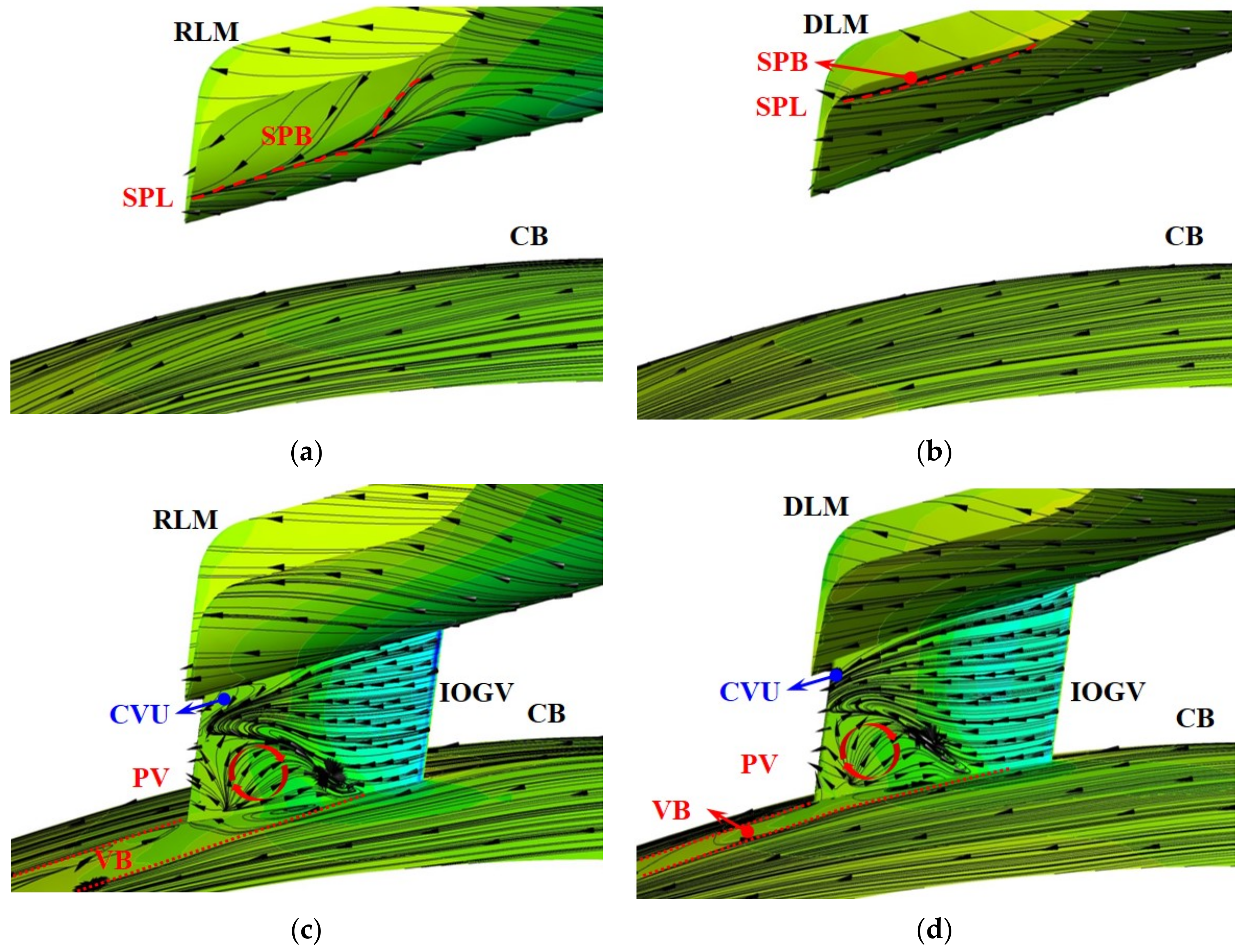

Figure 10 shows the limiting streamlines on the IOGV, central body, and inner surface of different lobed mixers for cases with an inlet swirl of 20°. Before integrating OGV, there are separation bubbles (marked as SPB in the figure) on the inner surface near the trough of RLM and DLM. Compared to the separation line (marked by the red dashed line ‘SPL’ in

Figure 10) on RLM, the separation position on DLM is more delayed, and its separation bubble is much smaller than that on RLM, which will be beneficial in reducing separation loss. In the radial interval corresponding to the separation bubble, the mass-averaged inlet swirl angle upstream of RLM and DLM is 15.8° and 16.7°, respectively. This means that DLM can significantly suppress flow separation on the inner surface of the lobed mixer even with a larger inlet swirl angle, showing that the de-swirling lobe design concept greatly enhances the tolerance of the lobed mixer to inlet swirl. After integrating with OGV, there is no flow separation on IRLM and IDLM, indicating that IOGV is beneficial in enhancing de-swirl ability around the lobe’s trough.

On the other hand, although no flow separation is seen on the suction surface of IOGV in IRLM and IDLM cases, an apparent passage vortex (marked as PV in

Figure 10) and corner vortex (marked as CVU in

Figure 10) appear respectively in the root region and tip area near the trailing edge of OGV. In comparison to the DLM case, the PV in the IRLM case appears at a more upstream position and has a larger radial height when it reaches the trailing edge of IOGV. When the PV detaches from the trailing edge of IOGV, it forms a wider vortex band on the central body, as shown by the VB bounded with the red dotted line in

Figure 10. This indicates that the PV on IOGV in the IRLM case has a larger circumferential scale than that in the IDLM case. The passage vortex is mainly influenced by the loading and radial secondary flow of the airfoil. Under conditions with the same loading of IOGV, the PV in the IRLM case is greater than that in the IDLM case, indicating that IRLM has a stronger radial secondary flow. Although a stronger PV will increase loss, it can also enhance streamwise vortices and accelerate jet mixing to a certain extent. The development trend of CVU at the tip region of IOGV is almost identical for both the IRLM and IDLM cases.

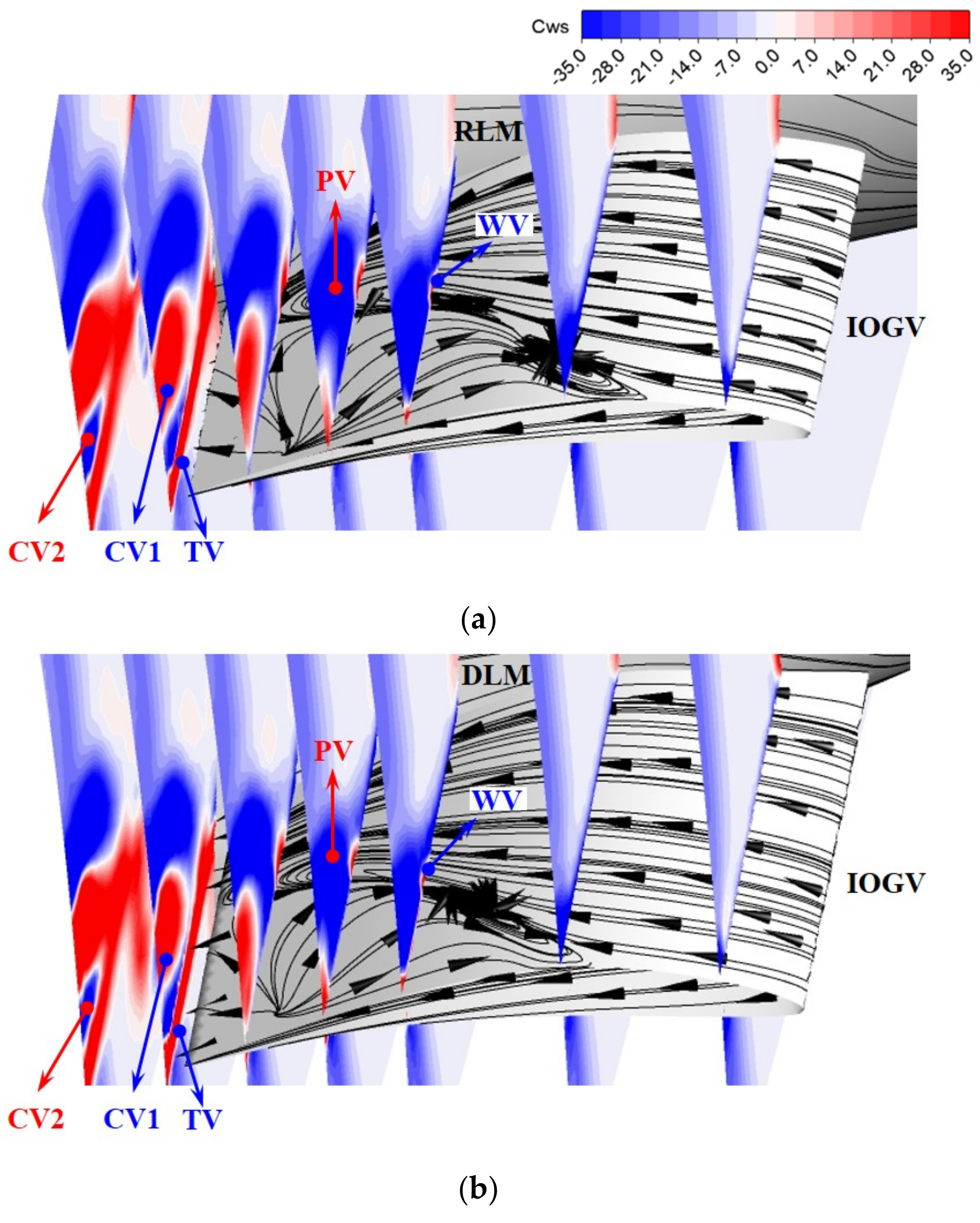

To further compare the vortex structure at the root of IOGV for different integrated lobed mixers,

Figure 11 displays the streamwise vorticity contour at various axial sections in the IOGV channel. In both conditions, there is a passage vortex (PV), wall vortex (WV), corner vortex (CV1 and CV2), and trailing edge shedding vortex (TV) in the IOGV passage. PV has the largest scale and strength, followed by CV1 and TV. At the same axial section, the scale and strength of PV and CV1 in the IRLM case are greater than those in the IDLM case, which is consistent with the previous conclusion on PV in

Figure 10. The scale and strength of TV on the same section in both cases are roughly equivalent, primarily because TV is mainly affected by the radius of the IOGV trailing edge. Compared to the RLM and DLM conditions, the strong vortex structure appearing at the root of IOGV will significantly enhance jet mixing between the central body and lobe trough. The IRLM case has the strongest vortex structure at the root of IOGV among the four cases, with a core inlet swirl of 20°, indicating that its jet mixing in this area is most intense.

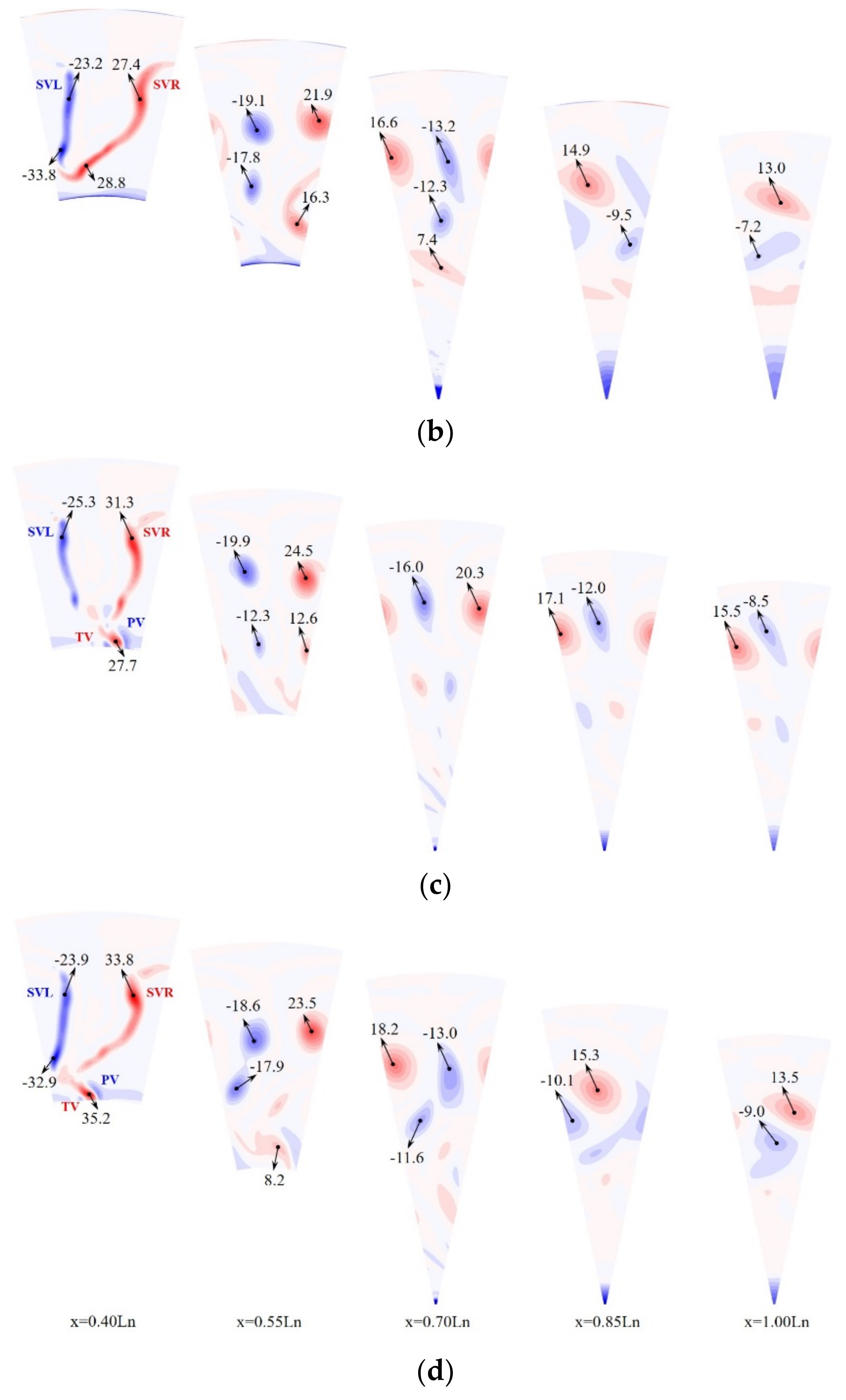

Figure 12 displays the streamwise vorticity contour downstream of the lobed mixers under different conditions with a core inlet swirl 20°. Also, it marks the maximum vorticity values of each vortex core. As the x = 0.4 Ln section is located 5 mm downstream of the lobed mixers, jet mixing between bypass flow and core flow has just started, and streamwise vorticity has not yet dissipated on this section. Therefore, it can approximately characterize the total strength of streamwise vortices under this condition. In this section, the maximum vorticity values of the left streamwise vortex (SVL) and right streamwise vortex (SVR) downstream of DLM are −33.8 and 27.4, respectively, greater than those in the RLM case. It indicates that the streamwise vortices downstream of DLM are stronger than those in the RLM case. This is because (1) when designing DLM, the authors intentionally designed an outlet metal angle to retain a certain residual swirl downstream of the lobed mixer, which is beneficial for enhancing streamwise vortices; (2) as shown in

Figure 9, the residual swirl downstream of DLM is stronger than that in the RLM case, further enhancing streamwise vortices in this case. Additionally, due to the geometric bending of DLM, its SVR range is larger than that in the RLM case. All these factors show that the scale and strength of streamwise vortices are greater than those in the RLM case, inevitably enhancing jet mixing efficiency in this case. With interaction between streamwise vortices, maximum vorticity in RLM and DLM cases first decays sharply to x = 0.7 Ln section and then their decay rates slow down, indicating that dissipation of streamwise vortex mainly occurs upstream of x = 0.7 Ln section. The decay rate of maximum streamwise vorticity downstream of DLM is greater than that in the RLM case. Finally, the maximum vorticity values at the x = 0.85 Ln and 1.00 Ln sections downstream of RLM and DLM are roughly equivalent. The increase in the decay rate of streamwise vorticity is related to their greater initial strength and stronger residual swirl downstream of DLM. Under the influence of a strong residual swirl, a streamwise vortex is entrained and moved to the right side. On the x = 0.7 Ln section, it can be seen that SVR downstream of DLM almost entirely moves out from the right side, while SVR downstream of RLM just crosses the right boundary. This entrainment process will further enhance interaction between streamwise vortices and azimuthal vortices, thus accelerating the decay rate of streamwise vortices downstream of DLM to a certain extent. On sections downstream of the central body (X > 0.7 Ln), there are strong vorticity regions at the center of this section in both RLM and DLM cases, as shown by the blue vortex band at the sector center on the x = 0.7 Ln–1.00 Ln section. This is because strong residual swirls remain between the lobe trough and central body in both RLM and DLM cases, which are further accelerated by the central body and finally induce a backflow downstream of the central body. This backflow corresponds to the high vorticity region at the sector center.

After integrating OGV, the maximum values of total streamwise vorticity in the two integrated lobed mixers have increased significantly: compared to RLM and DLM cases, maximum streamwise vorticity has increased by 9.3 and 6.4 in IRLM and IDLM cases, respectively. This is because the core flow between the lobe crest and the central body is involved in radial secondary flow inside the lobed mixer after integrating OGV. In other words, the lower boundary of streamwise circulation integral downstream of the lobed mixer is expanded from the lobe trough to the central body, greatly enhancing streamwise vortices downstream of the integrated lobed mixer. Upstream of x = 0.7 Ln section, the decay rate of maximum streamwise vorticity of SVL and SVR in IRLM and IDLM cases is greater than those in RLM and DLM cases. While maximum vorticity decay rates in all four cases are roughly equivalent downstream of x = 0.7 Ln section, after integrating OGV, strong trailing edge shedding vortices and passage vortices downstream of IOGV interact with streamwise vortices, accelerating dissipation of streamwise vortices in the corresponding area: (1) as shown on x = 0.55 Ln section in

Figure 12c,d, maximum vorticity in this area is 12.6 and 8.2 in IRLM and IDLM cases respectively, while they are 13.5 and 17.8 in RLM and DLM cases; (2) on x = 0.7 Ln section, streamwise vortices in this area have dissipated completely in IRLM and IDLM cases, while there are still clear vortex cores in RLM and DLM cases. Downstream of the central body, the range and maximum vorticity value of the high vortex band at the sector center for IRLM and IDLM cases are significantly reduced compared to those in RLM and DLM cases. This is because integrated lobed mixers effectively suppress leakage swirling flow between the lobe trough and the central body, reducing its flow angle from 20° to below 7° (

Figure 9). Even if this weak leakage swirling flow is accelerated by a central body, it cannot induce backflow downstream of the central body, which will be beneficial for reducing total pressure loss and thrust loss of the exhaust system.

Compared to maximum vorticity (Cws, max = 31.3) in the IRLM case, maximum streamwise vorticity in the IDLM case increases by 8% on x = 0.4 Ln section, and then the decay rate of maximum vorticity shown on downstream sections is also greater than that in IRLM case. As analyzed above, this is mainly due to the design concept of DLM, which reserves a certain strength of residual swirling flow. In addition, the strength of the trailing edge shedding vortex downstream of IOGV in the IDLM case is also greater than that in the IRLM case, with their maximum values on x = 0.4 Ln section being 35.5 and 27.7, respectively. Therefore, compared to the IRLM case, stronger streamwise vortices interact with stronger trailing edge shedding vortex in the IDLM case, inevitably accelerating the dissipation of streamwise vortices in this area: streamwise vortices in the IDLM case have almost dissipated on x = 0.55 Ln section, while there are still two clear vortex cores on this section in IRLM case until x = 0.7 Ln section.

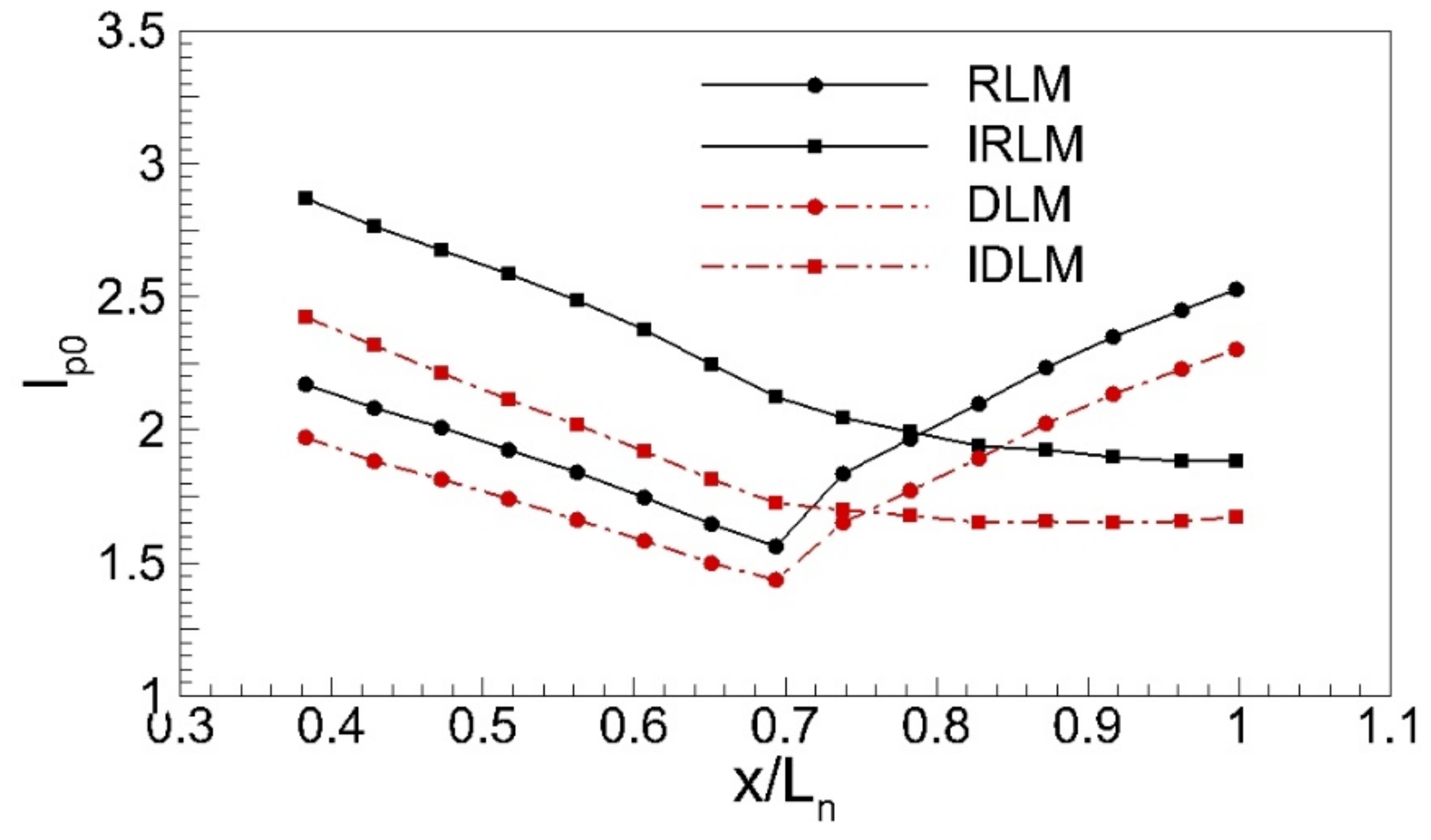

Figure 13 shows the total pressure mixing index distribution in four cases with a core inlet swirl 20°. Mixing indexes of two non-integrated lobed mixers show a trend of first linear decrease and then linear increase: (1) in the region from the trailing edge of the lobed mixer to the tail edge of the central body (0.38 < x/Ln < 0.7), jet mixing is mainly dominated by streamwise vortices and mixing index continues to decrease with vortices interaction, indicating that jet uniformity has been continuously improved; (2) while downstream of the central body (x/Ln > 0.7), mixing index increases continuously, indicating that jet uniformity is deteriorated due to backflow induced by leakage swirling flow between lobe trough and the central body. On each section, the mixing index in the DLM case is smaller than that in the RLM case, indicating that jet downstream DLM has better uniformity. After integrating with OGV, due to the influence of passage vortex and trailing edge shedding vortex, initial mixing indexes are larger than those downstream of non-integrated lobed mixers. As shown in x = 0.4 Ln section in

Figure 13, the mixing indexes of IRLM and IDLM are 2.87 and 2.42, respectively, while RLM and DLM are 2.17 and 1.97, respectively. In the region of x < 0.7 Ln, mixing indexes of integrated lobed mixers also show a linear decrease trend. Their decay rates are greater than those of non-integrated lobed mixers, indicating that jet mixing downstream of integrated lobed mixer is more intense than those downstream of non-integrated lobed mixer, consistent with the previous conclusion that integrated lobed mixers are beneficial for accelerating jet mixing by enhancing streamwise vortices. Since integrated lobed mixer suppresses backflow downstream of the central body, mixing indexes downstream of x = 0.7 Ln section in integrated lobed mixers gradually decrease and tend to stable values. Compared to the IRLM case, a smaller initial mixing index on x = 0.4 Ln section in the IDLM case indicates better initial jet uniformity. On x = 0.7 Ln section, the decay rate of the mixing index in the IDLM case slows down significantly. It tends to be stable downstream of x = 0.83 Ln section, while the mixing index still maintains a large decay rate in the region of 0.7 Ln < x < 0.83 Ln for IDLM case, then slows down slightly, and finally tends to stable value on x = 0.96 Ln section. This indicates that most jet mixing has been almost completed upstream of x = 0.7 Ln section in IDLM cases, while jet mixing continues until x = 0.83 Ln section in IRLM case. That is to say, jet mixing in the IDLM case is faster than in the IRLM case. On the nozzle outlet (x = 1.0 Ln), the mixing index (Ip0 = 1.67) in the IDLM case is smaller than that (Ip0 = 1.88) in the IRLM case, indicating that the jet flow of the IDLM case is more uniform at the outlet.

Table 2 shows the total pressure loss and Relative Thrust (

Tre) on the nozzle outlet for the four cases with core inlet swirl of 20°, and also gives their gain (Δ

Y and Δ

Tre) relative to those of the RLM case. The total pressure loss in the DLM case has increased by 7.78% compared with that of the RLM case, which may be related to the enhanced jet mixing and the stronger leakage swirl between the lobe trough and central body in the DLM case. Similarly, it can also see that the total pressure loss in the IDLM case is greater than that of the IRLM case. However, the total pressure losses of the two integrated lobed mixers are significantly lower than those of the non-integrated lobed mixers due to the effective suppression of leakage swirling flow.

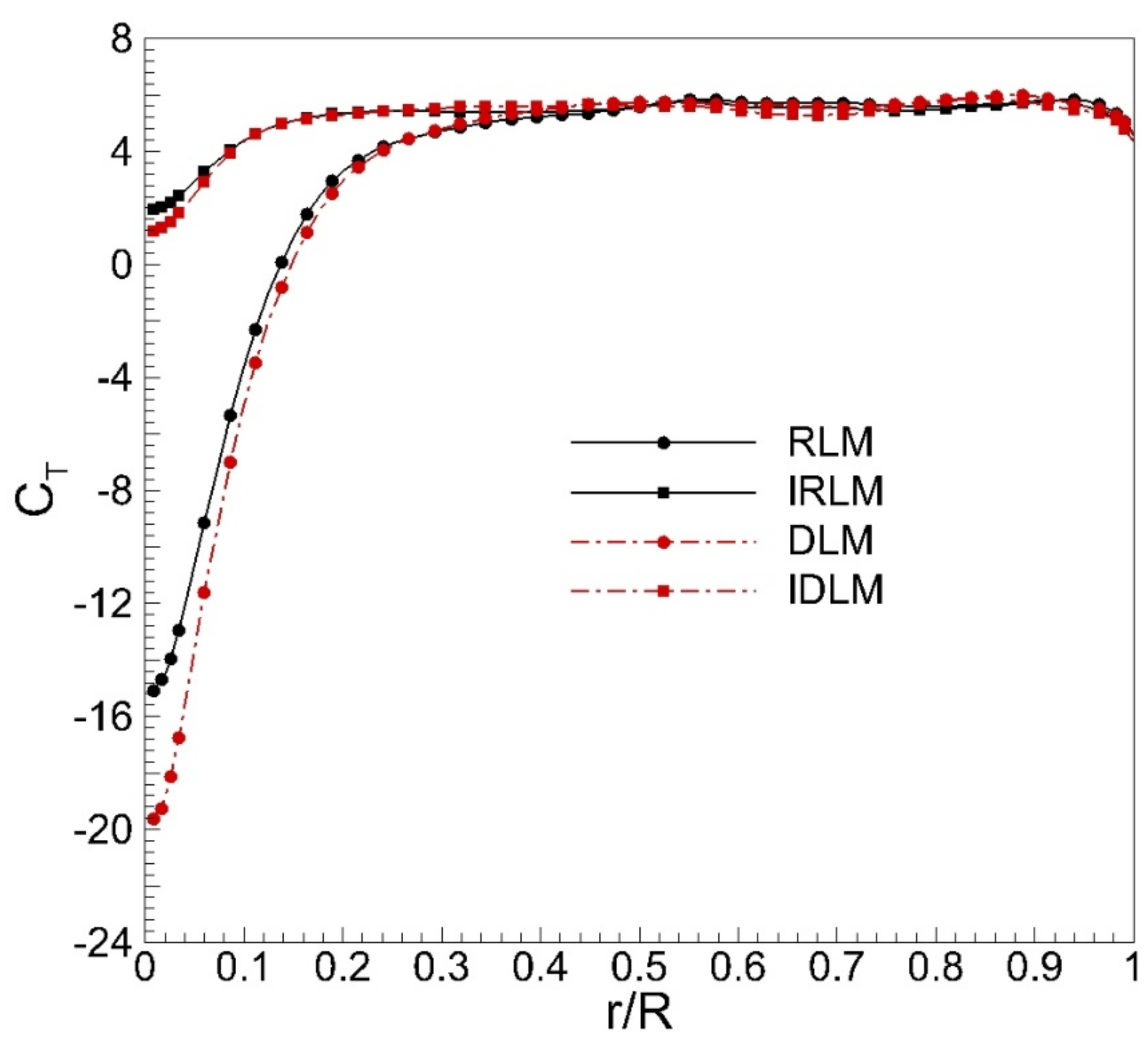

Figure 14 shows the radial distribution of pitch-wise mass-averaged thrust coefficient on the nozzle outlet for the four cases with a core inlet swirl of 20°. Due to the strong swirling flow and the wake of the central body, there are thrust deficit regions at the jet center for all cases, while the thrust coefficients are roughly equivalent in the outer ring (r > 0.4R). Compared with the RLM case, the depth and width of the thrust deficit region in the DLM case are greater due to the more leakage swirling flow between the central body and the raised tough ridge line of DLM. Although the thrust loss in the center area is greater in the DLM case, its overall thrust coefficient has increased by 1.32% (

Table 2) compared with the RLM case, indicating that the enhanced suppression effect on the inlet swirl of the outer-ring is also beneficial to improve the thrust in the DLM case. After integrating with OGV, due to the suppression effect of IOGV on the leakage swirling flow between the lobe trough and central body, the depth and width of the thrust deficit area in the jet center have been significantly reduced compared with the non-integrated lobed mixers. Compared with IRLM, although the thrust loss in the jet center is greater in the IDLM case (similar to the DLM case), its total thrust gain relative to the RLM case is 3.18% (

Table 2) and is still greater than that (Δ

Tre = 3.01% in

Table 1) of the IRLM case, indicating that IDLM has the best comprehensive effect of improving the output thrust of the exhaust system.

3.2. Performance of IDLM on off-Design Condition

Figure 15 presents the radial distribution of the tangential flow angle on the x = 0.4 Ln section downstream of the two integrated lobed mixers for different inlet swirl cases. When the inlet swirl is less than 20°, that is, under conditions of positive attack angle, flow angles in the area (0 < r/H < 0.2) corresponding to the Integrated Outlet Guide Vane (IOGV) in Integrated Radial Lobed Mixer (IRLM) cases increase radially, but their maximum values remain between 0° and 5°, which is insufficient to induce backflow downstream of the central body. For the region corresponding to the lobed mixer: (1) when 0.2 < r/H < 0.4, the flow angle remains relatively stable at certain values within the range of 0–5°, and these stable values increase with increasing inlet swirl; (2) when 0.4 < r/H < 0.79, flow angle decreases continuously and approaches 0°. This indicates that the IRLM retains a good ability to organize inlet swirl under positive attack angle conditions. Compared to IRLM cases, the flow angle in the region 0 < r/H < 0.2 for Integrated Diagonal Lobed Mixer (IDLM) cases is lower, indicating that the IDLM has superior de-swirl ability compared to the IRLM. In the region 0.26 < r/H < 0.55, flow angles for both mixers are relatively stable at fixed values, and these fixed values increase with increasing inlet swirl. In this region, fixed flow angles downstream of the IDLM are greater than those downstream of the IRLM for cases with core inlet swirl < 20°. The increase in these residual flow angles enhances streamwise vortices, suggesting that the IDLM can effectively utilize inlet swirl to accelerate jet mixing under positive attack angle conditions. Under conditions of negative attack angle (inlet swirl > 20°), flow angle distributions downstream of the two integrated lobed mixers exhibit double-hump shapes, with the Integrated Outlet Guide Vane (IOGV) corresponding to the first hump region and the lobed mixer corresponding to the second. The flow angle in the first hump region is greater than that in the second, indicating that the de-swirl ability of the IOGV is weaker than that of the lobed mixer under negative attack angle conditions. Flow angles in both hump regions for the Integrated Diagonal Lobed Mixer (IDLM) are greater than those for the Integrated Radial Lobed Mixer (IRLM). The difference between them increases with increasing inlet swirl: (1) an increase in flow angle in the first hump region for the IDLM indicates that raising the trough ridge line further increases IOGV loading and its deviation angle, reducing its de-swirl ability. In particular, in the case with a core inlet swirl of 35°, the peak value for its outlet flow angle reaches 17.4°, which may induce backflow and increase thrust loss and total pressure loss; (2) an increase in peak flow angle in the second hump region may be related to outlet metal angle reserved by the IDLM, which will enhance streamwise vortices and accelerate jet mixing but may also increase mixing loss.

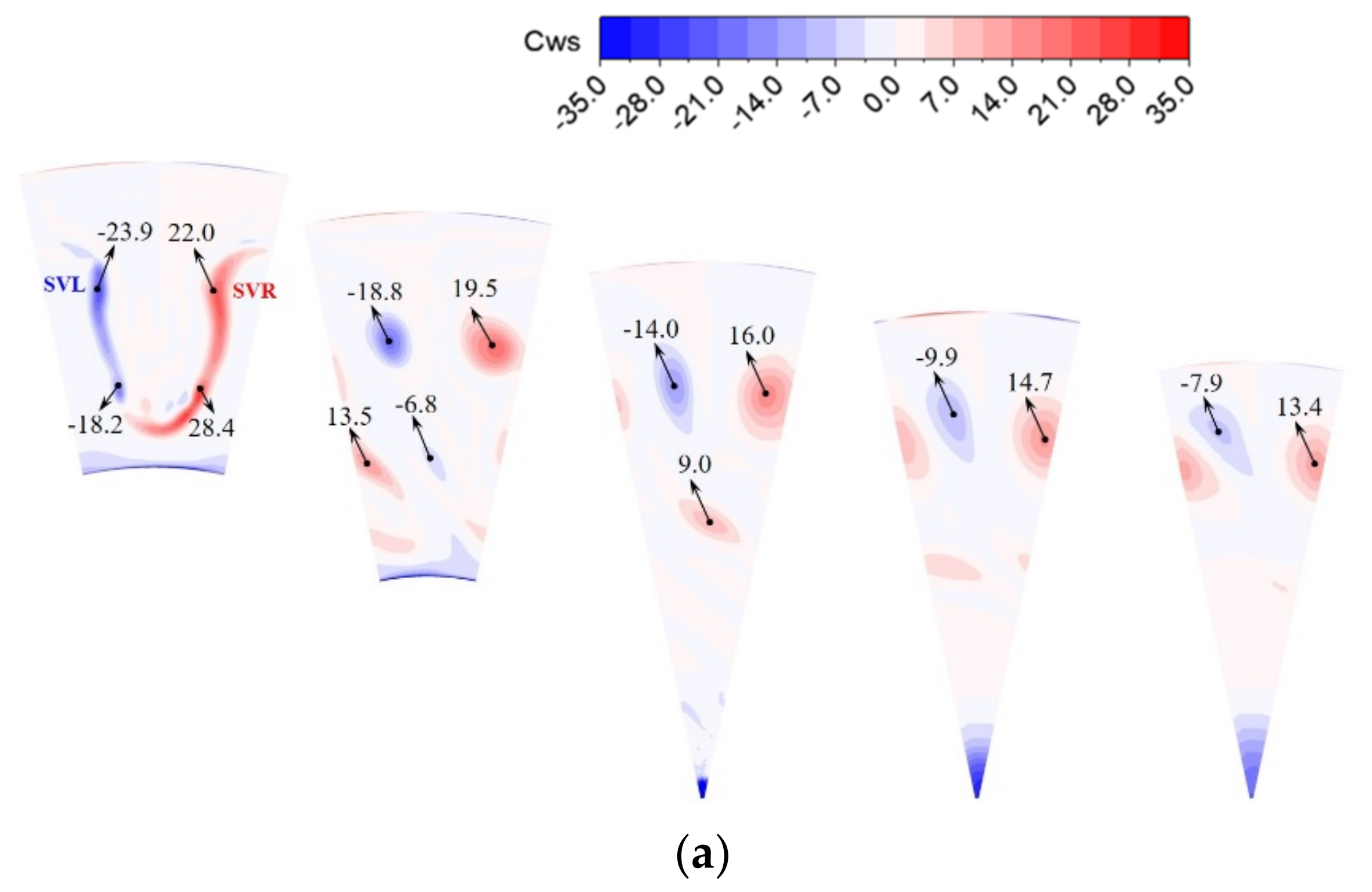

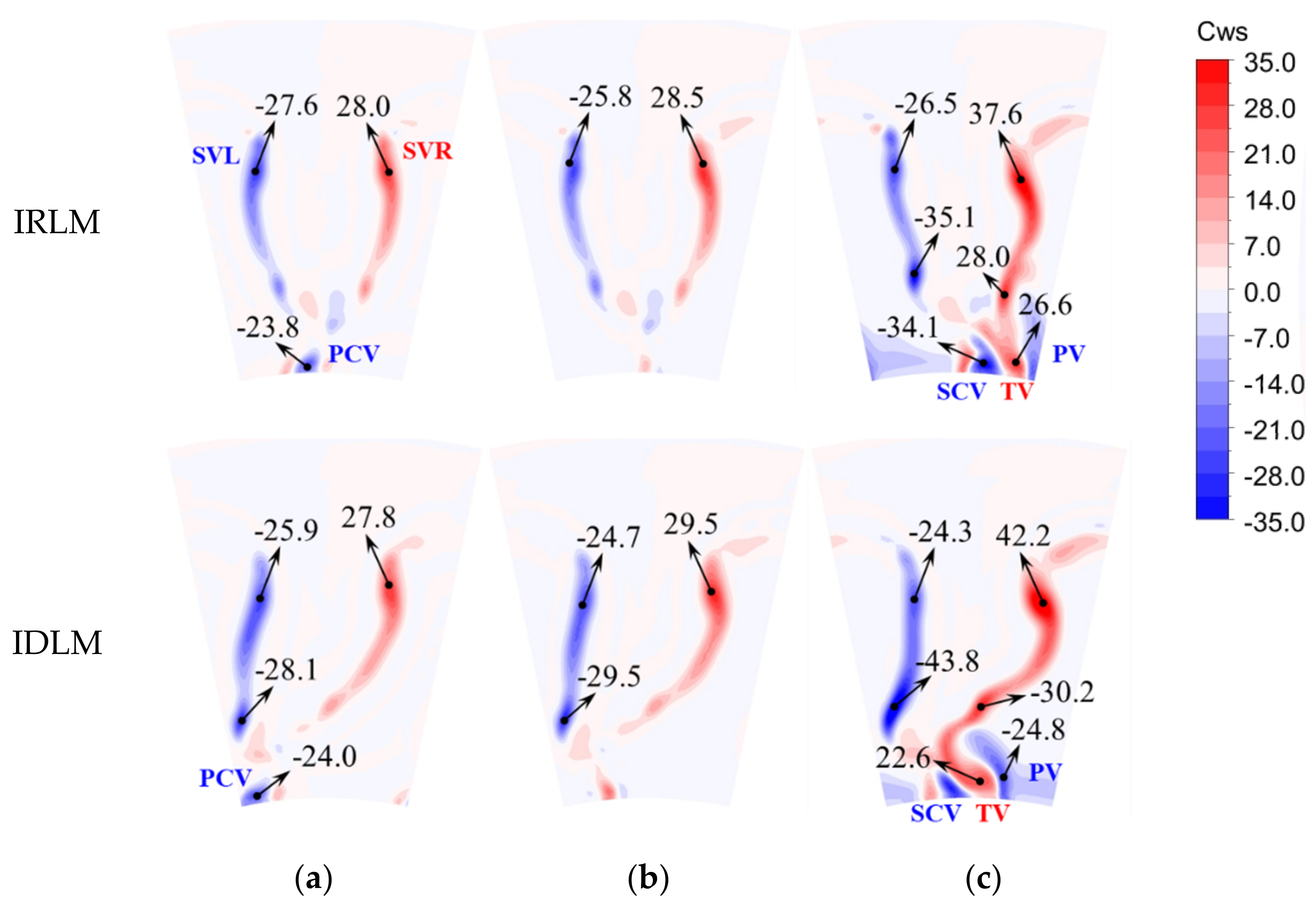

To compare the influence of inlet swirl on vortex structure downstream of the lobe mixer under non-design conditions,

Figure 16 presents streamwise vorticity contours on the x = 0.4 Ln section downstream of the Integrated Radial Lobed Mixer (IRLM) and Integrated Diagonal Lobed Mixer (IDLM) in cases with core inlet swirls of 0°, 10° and 30°. For both lobed mixers, peak vorticity and the range of Streamwise Vortex Left (SVL) and Streamwise Vortex Right (SVR) increase with increasing inlet swirl, indicating that an increase in inlet swirl is beneficial for enhancing streamwise vortex downstream of the lobed mixers. Under identical conditions, peak streamwise vorticity for the IDLM is greater than that for the IRLM. For example, in the case with a core inlet swirl of 30°, the maximum streamwise vorticities for the IRLM and IDLM are 37.6 and 42.2, respectively. This suggests that even under non-design conditions, the de-swirling lobed mixer can effectively utilize inlet swirl to enhance streamwise vortices further and accelerate jet mixing. In the region downstream of the Integrated Outlet Guide Vane (IOGV), flow separation and corner vortex on the pressure surface of the IOGV (as indicated by PCV in the case with a core inlet of 0°) become dominant factors in jet mixing with increasing positive attack angle. Comparing cases with different lobed mixers, peak values and ranges for this corner vortex are approximately equivalent, indicating that it is largely unaffected by the type of lobed mixer. With increasing negative attack angle, ranges for Passage Vortex (PV) and Trailing Edge Shedding Vortex (TV) downstream of IOGV are significantly larger than those downstream of corresponding lobed mixers in cases with a core inlet swirl of 20°. This indicates that increasing the negative attack angle can enhance PV and TV to some extent. In this section, peak vorticity values for both lobed mixers in cases with negative attack angles are lower than those with a core inlet swirl of 20°. This may be due to accelerated vortex dissipation in these cases. Compared to Integrated Radial Lobed Mixer (IRLM) cases, the range of Passage Vortex (PV) and Trailing Edge Shedding Vortex (TV) in Integrated Diagonal Lobed Mixer (IDLM) cases under a negative attack angle is significantly larger. This is related to the degraded de-swirl ability of the Integrated Outlet Guide Vane (IOGV) in IDLM cases with a negative attack angle.

To comprehensively evaluate the influence of the inlet swirl on the mixing efficiency of the two integrated lobe mixers,

Figure 17 presents the distributions of the total pressure mixing index for various cases. Under conditions of positive attack angle, the Ip0 trends for both lobed mixers are generally consistent: (1) they decrease linearly until the x = 0.828 Ln section; (2) downstream of this section, their decay rates slow down due to the influence of the central body’s wake, but they still maintain a linear downward trend. In ascending order of Ip0 on each section under positive attack angle conditions, the order of cases for the Integrated Radial Lobed Mixer (IRLM) is 5°, 10°, 0° and 15°. This indicates that jet uniformity downstream of the IRLM in the 5° case is optimal among all cases with a positive attack angle. The Ip0 trend for each positive attack angle condition is consistent with the IRLM: jet uniformity in the 5° case is optimal among all Integrated Diagonal Lobed Mixer (IDLM) cases with positive attack angles. The Ip0 for the IDLM under its worst positive attack angle condition (α = 15°) is still lower than that of the best IRLM case (α = 5°). This suggests that overall jet uniformity downstream of the IDLM is superior to that downstream of the IRLM. In cases with a negative attack angle (α > 20°), the Ip0 on the x = 0.4 Ln section downstream of both lobed mixers is lower than that in cases with positive attack angle, and Ip0 on the same section decreases with increasing inlet swirl for different lobed mixers. This may be due to the enhancement of pre-mixing downstream of the scalloped notch by inlet swirl. Under conditions of negative attack angle, the Ip0 for the Integrated Radial Lobed Mixer (IRLM) decreases linearly until the x = 0.7 Ln section. Then it increases linearly downstream of this section due to backflow and wakes downstream of the central body. As a result, the Ip0 at the nozzle outlet in cases with a negative attack angle is greater than that of the IRLM case with a core inlet swirl of 5°. This suggests that under negative attack angle conditions, the increase in jet uniformity resulting from enhanced mixing in IRLM cases with negative attack angles cannot offset the rise in jet non-uniformity caused by backflow and wake downstream of the central body. On the x = 0.4 Ln section, the Ip0 for the Integrated Diagonal Lobed Mixer (IDLM) is lower than the IRLM under identical negative attack angle conditions. This indicates that the enhancement effect of the inlet swirl on pre-mixing of the scalloped notch in IDLM cases with a negative attack angle is superior to that in IRLM cases. Similarly, in the region 0.4 Ln < x < 0.7 Ln, both Ip0 and its decay rate for the IDLM are lower than those for the corresponding IRLM case. In the region 0.7 Ln < x < 1.0 Ln, increases in Ip0 for IDLM cases is significantly less than for IRLM cases. This suggests that even though higher residual swirl around the central body in IDLM cases with negative attack angle (as shown in

Figure 15) induces larger backflow downstream of the central body compared to corresponding IRLM cases, overall jet uniformity for the IDLM remains superior to that for the IRLM.

Figure 18 illustrates the thrust coefficient and total pressure loss for the two-lobed mixers at the outlet under varying inlet swirl conditions. The thrust coefficient is calculated as the thrust gain relative to the thrust of the Radial Lobed Mixer (RLM) case with a core inlet swirl of 20°. The maximum thrust gain for both lobed mixers occurs when the core inlet swirl equals 0°. As the core inlet swirl increases, the thrust gain decreases and even becomes negative when the inlet swirl exceeds 25°. Under conditions of positive attack angle, the thrust gain for the Integrated Diagonal Lobed Mixer (IDLM) is approximately equivalent to that of the Integrated Radial Lobed Mixer (IRLM). However, under conditions of negative attack angle, the thrust coefficient for the IDLM is significantly greater than that of the IRLM, with a maximum difference of 2.15% occurring in the case with a core inlet of 35°. This indicates that the enhanced de-swirl ability of the IDLM is beneficial for increasing its thrust under non-design conditions, particularly under negative attack angle conditions.

Under conditions of positive attack angle, the total pressure loss for both lobed mixers remains relatively constant and is approximately lower than that observed in the inlet swirl 20° case. However, as the negative attack angle increases, there is a sharp increase in the total pressure loss for both lobed mixers. This may be attributed to the growth of separation bubbles on the suction surface of the Integrated Outlet Guide Vane (IOGV) and enhanced backflow downstream of the central body. Compared to the Integrated Radial Lobed Mixer (IRLM) cases, there is a slight increase in total pressure loss for the Integrated Diagonal Lobed Mixer (IDLM) under various conditions. This may be due to more intense mixing downstream of the IDLM under each condition.