Increasing Recoverable Oil in Northern Afghanistan Kashkari Oil Field by Low-Salinity Water Flooding

Abstract

1. Introduction

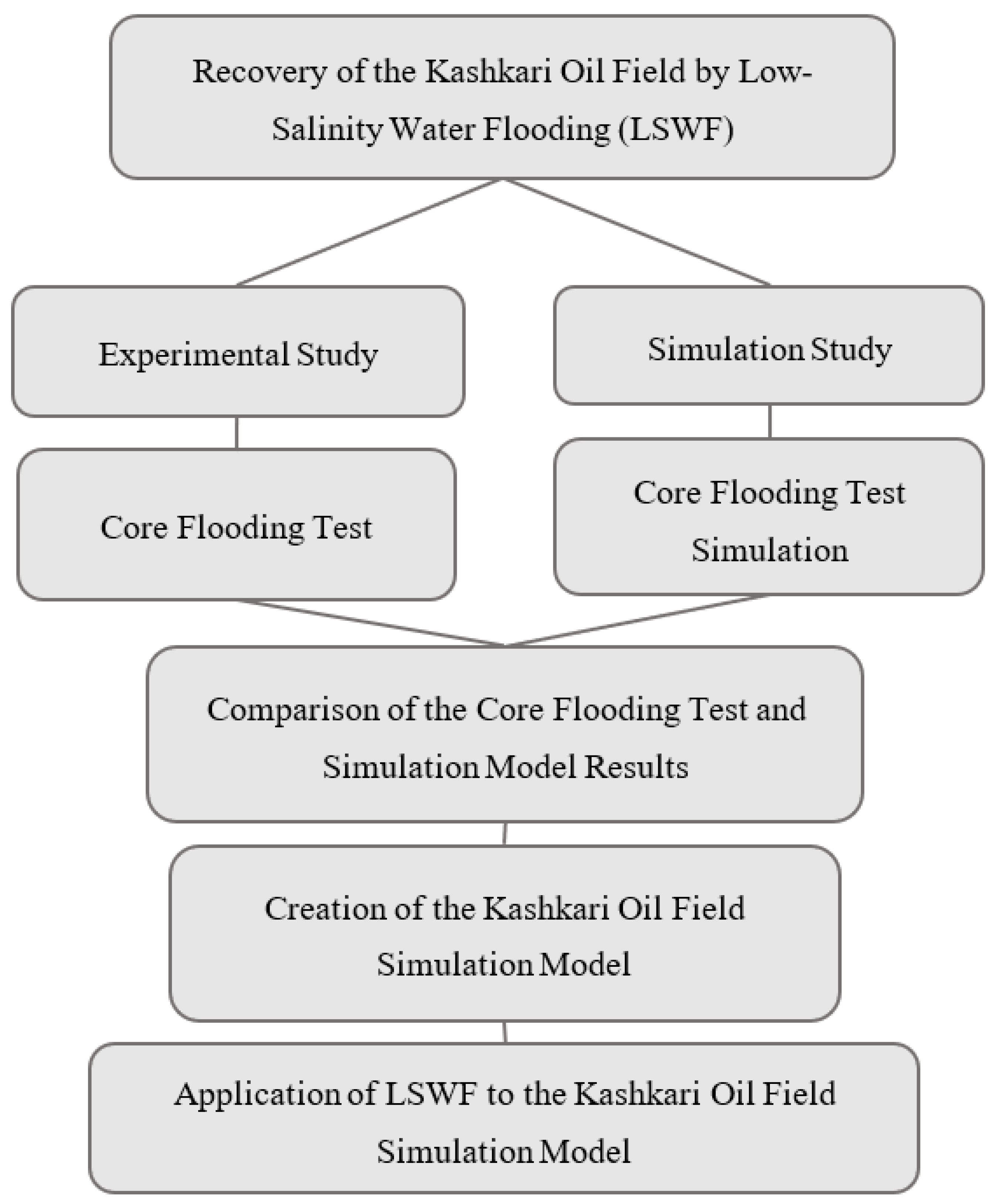

2. Materials and Methods

2.1. Experimental Studies

2.1.1. Kashkari Oil Field Information

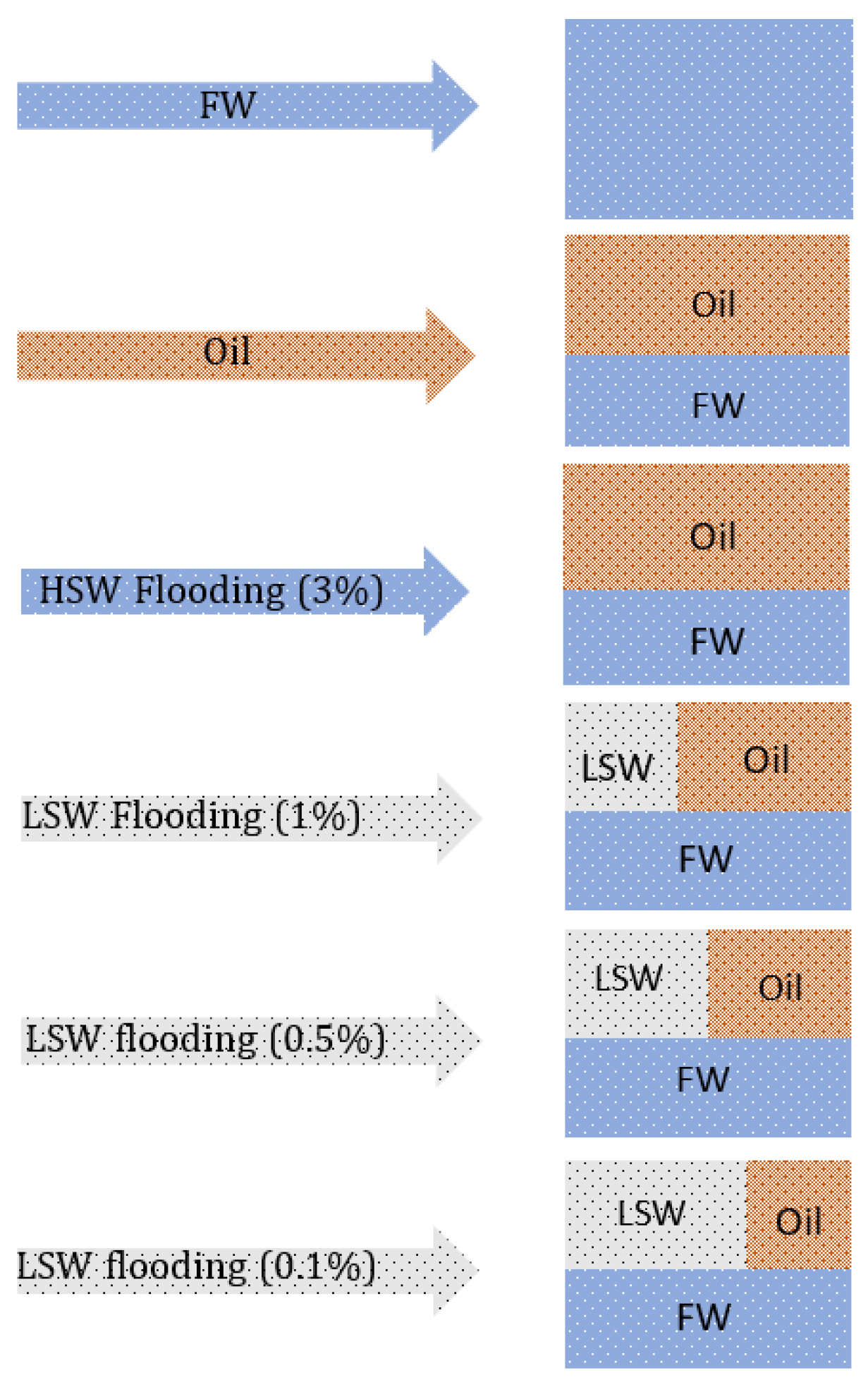

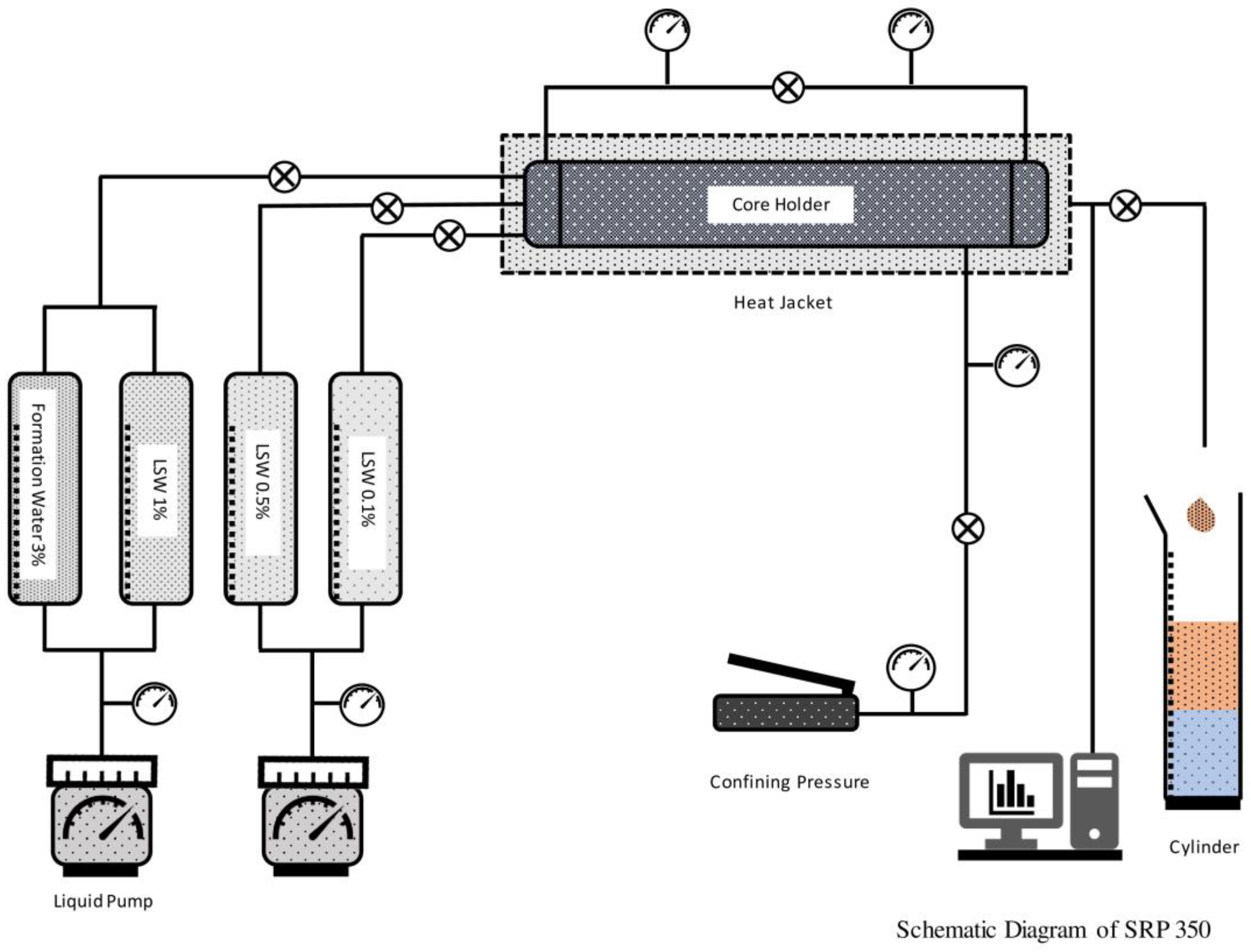

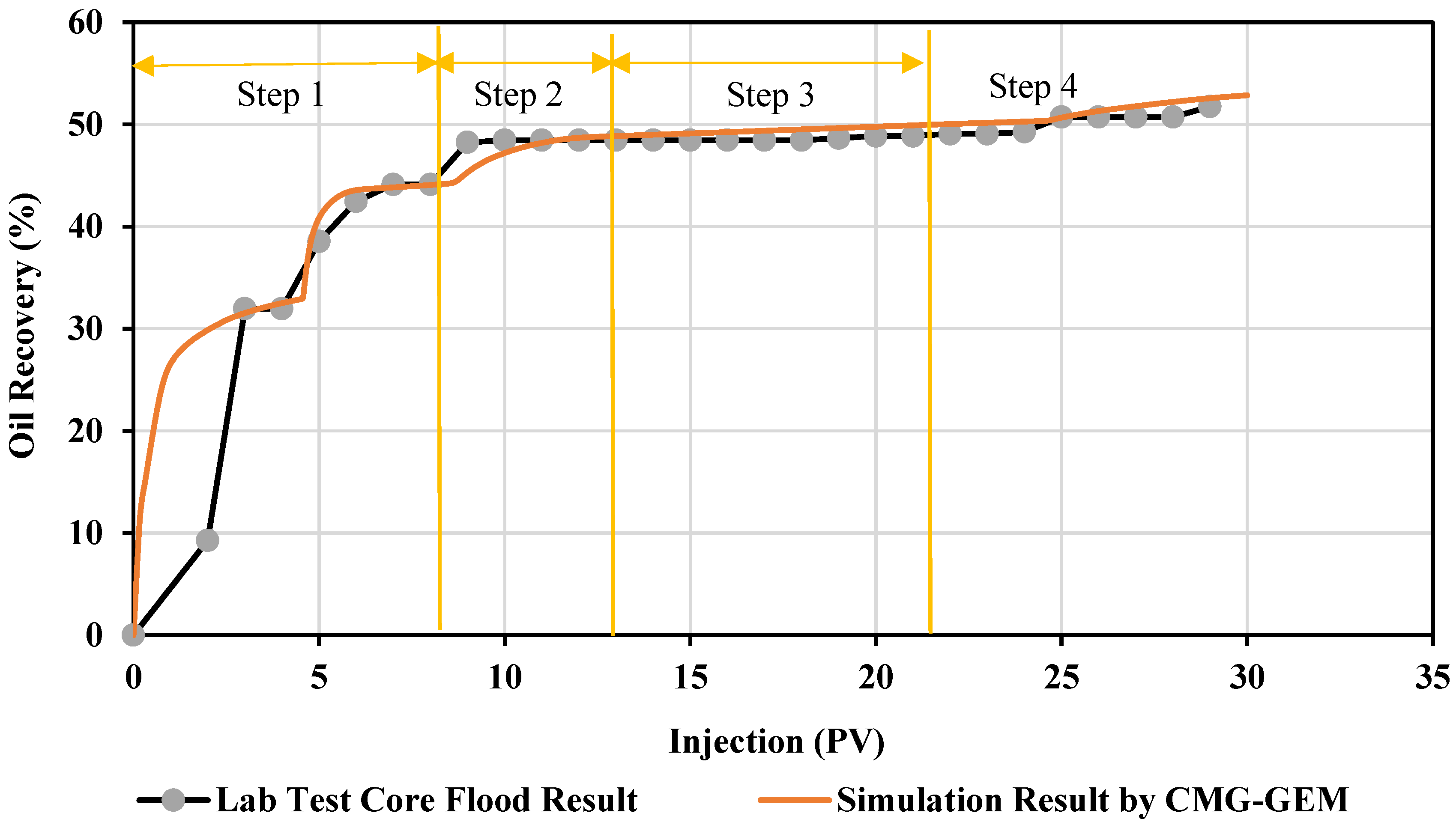

2.1.2. Core Flooding Laboratory Test

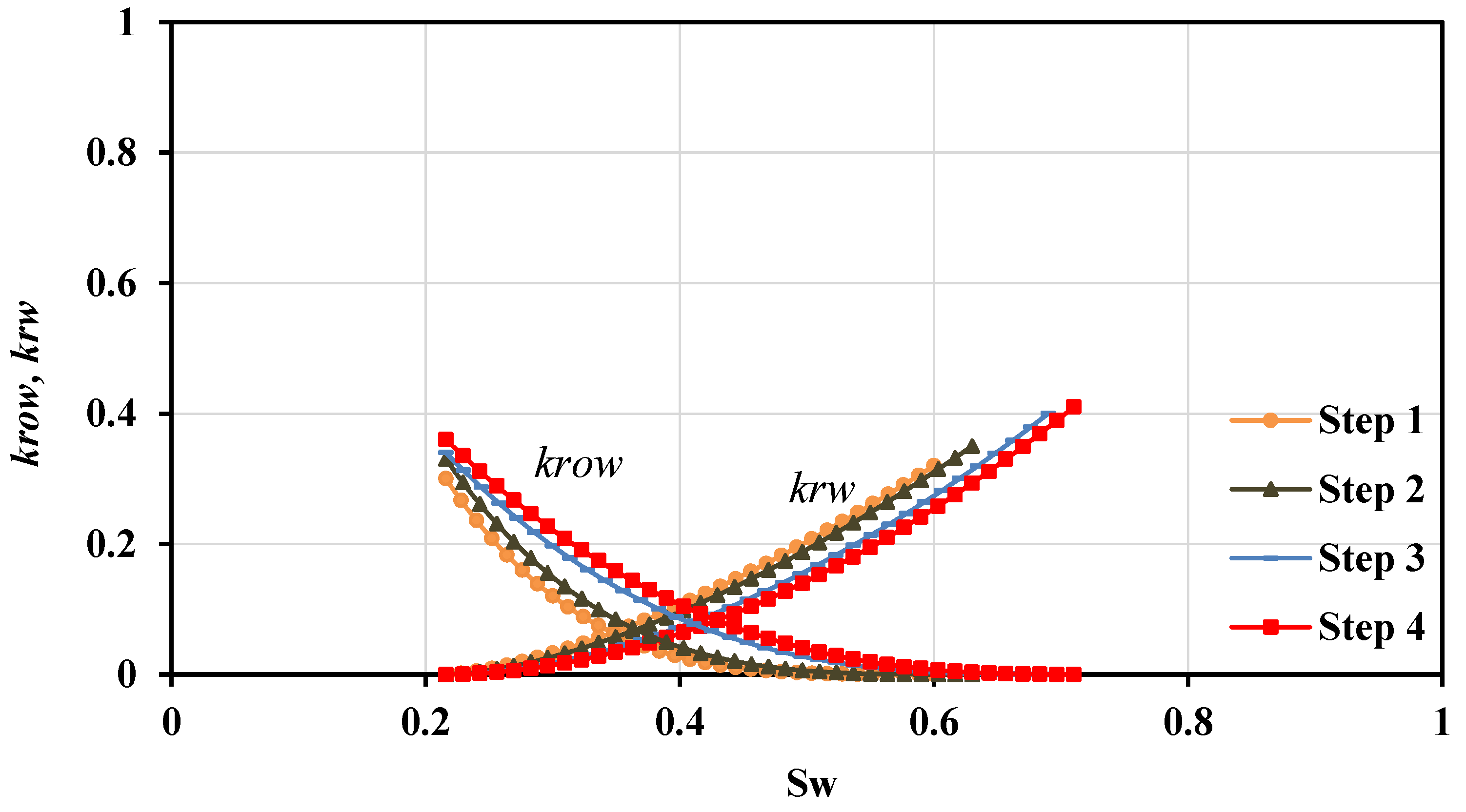

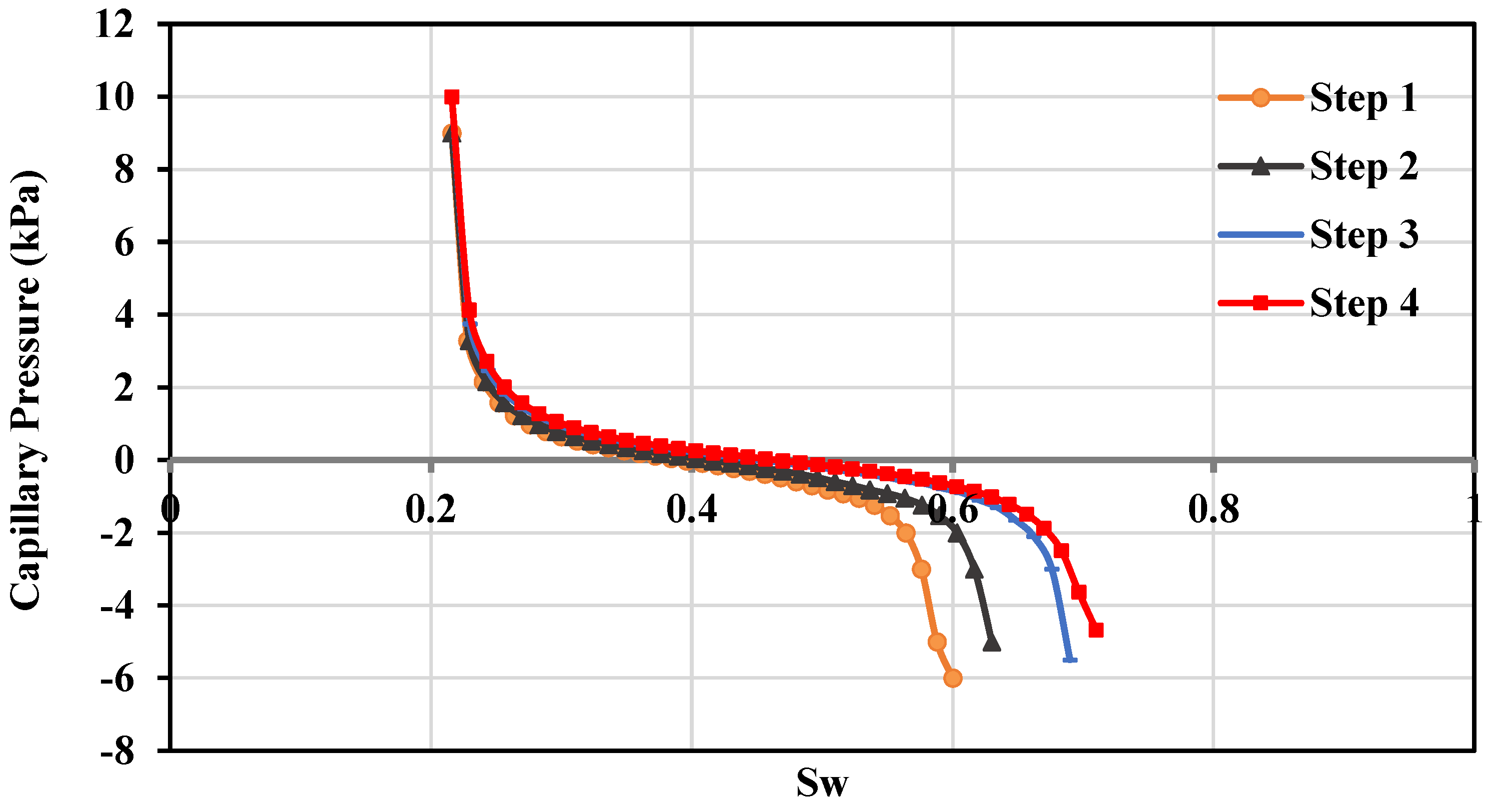

2.2. Numerical Modeling

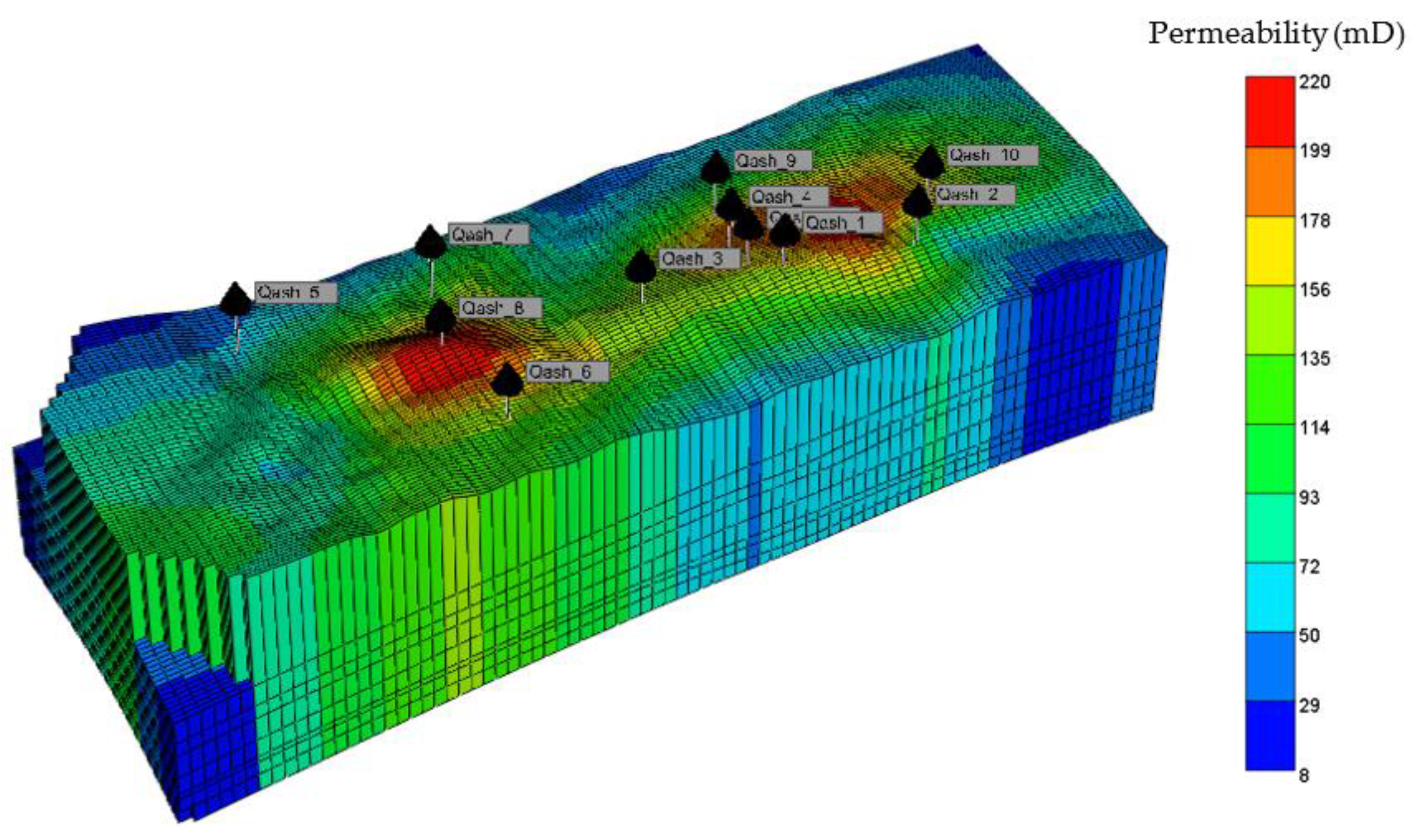

2.3. Kashkari Oil Field Simulation Model

2.4. Application of LSWF in the Kashkari Oil Field

3. Results and Discussion

3.1. Experiment and Simulation Results

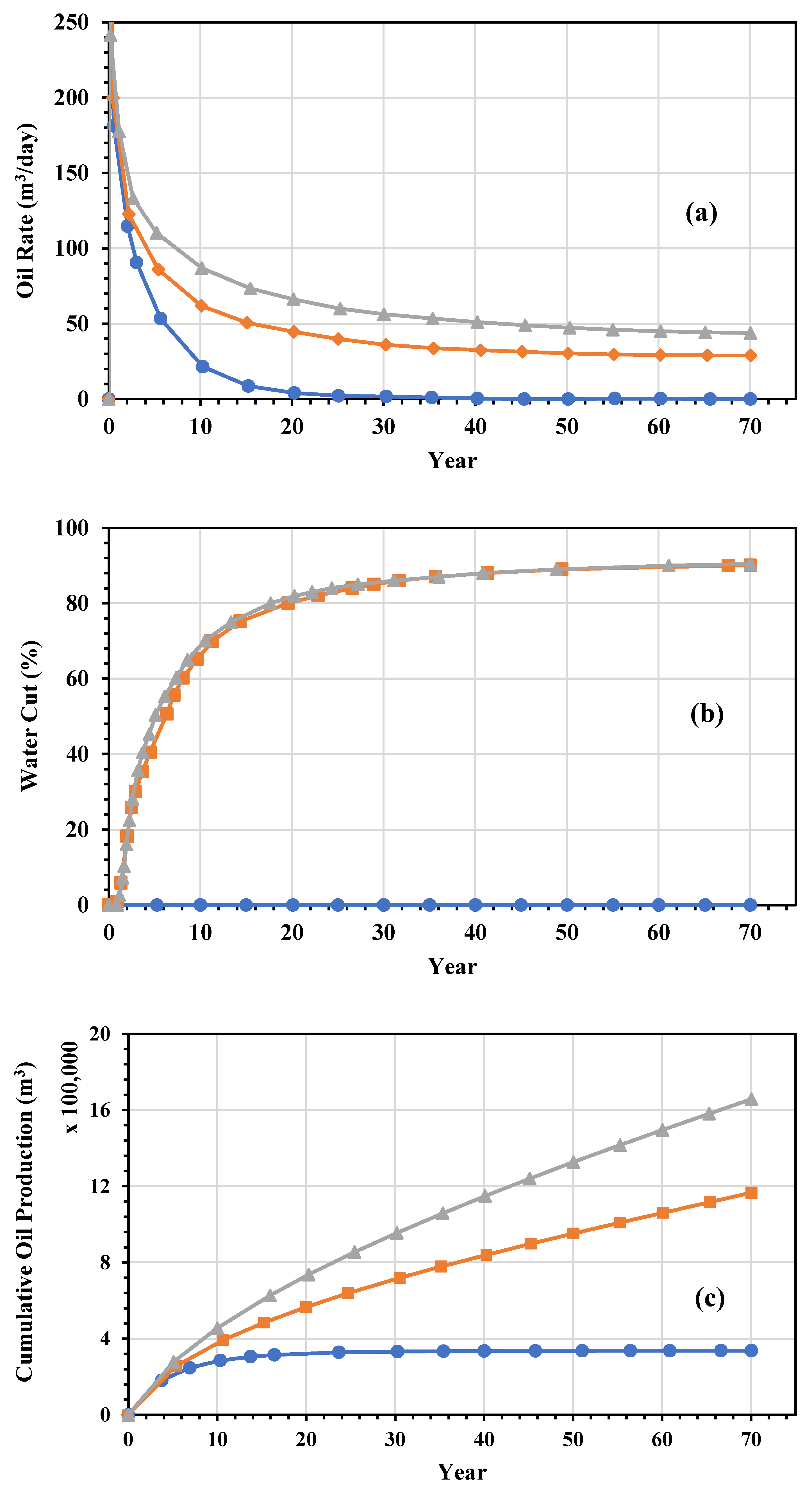

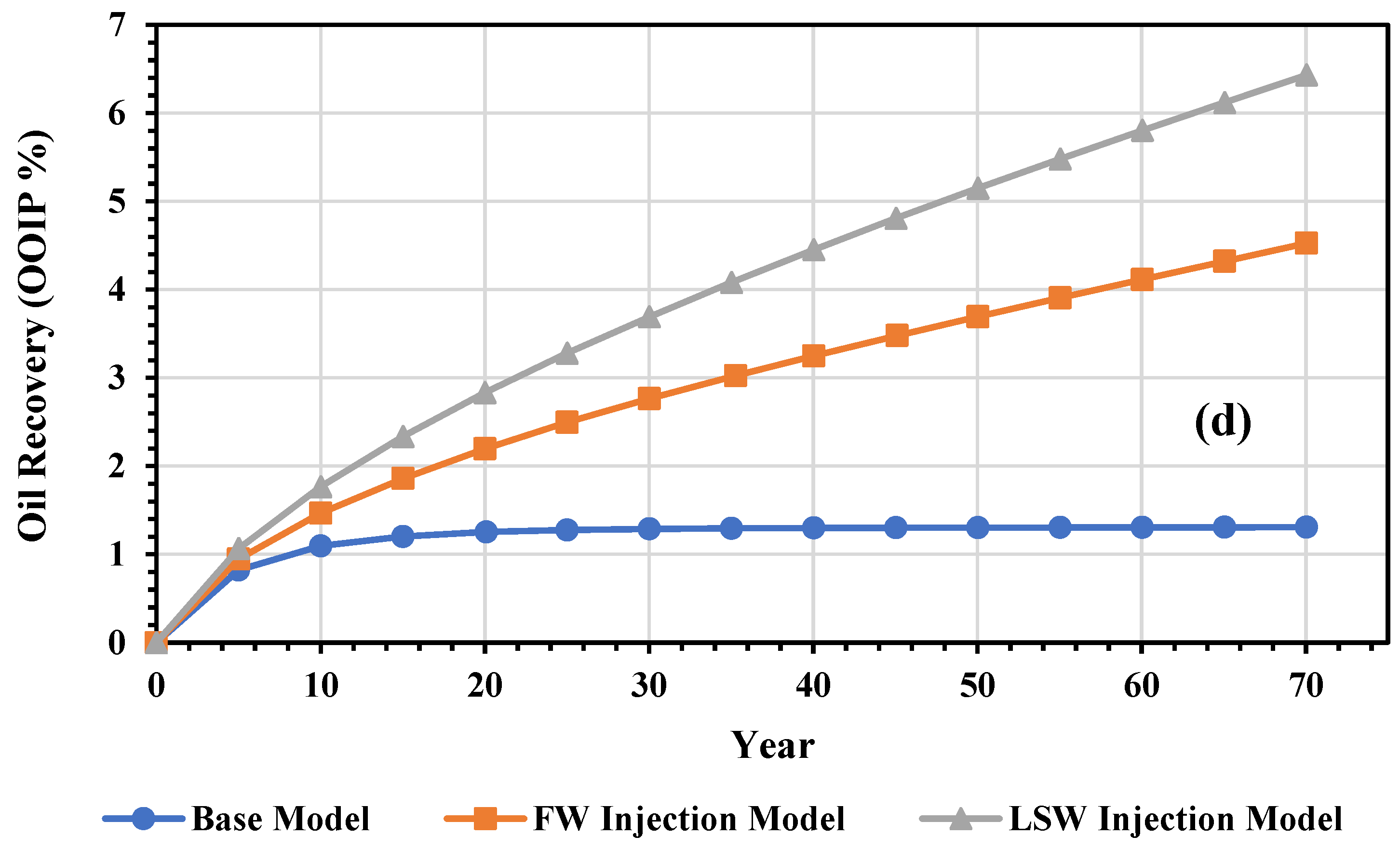

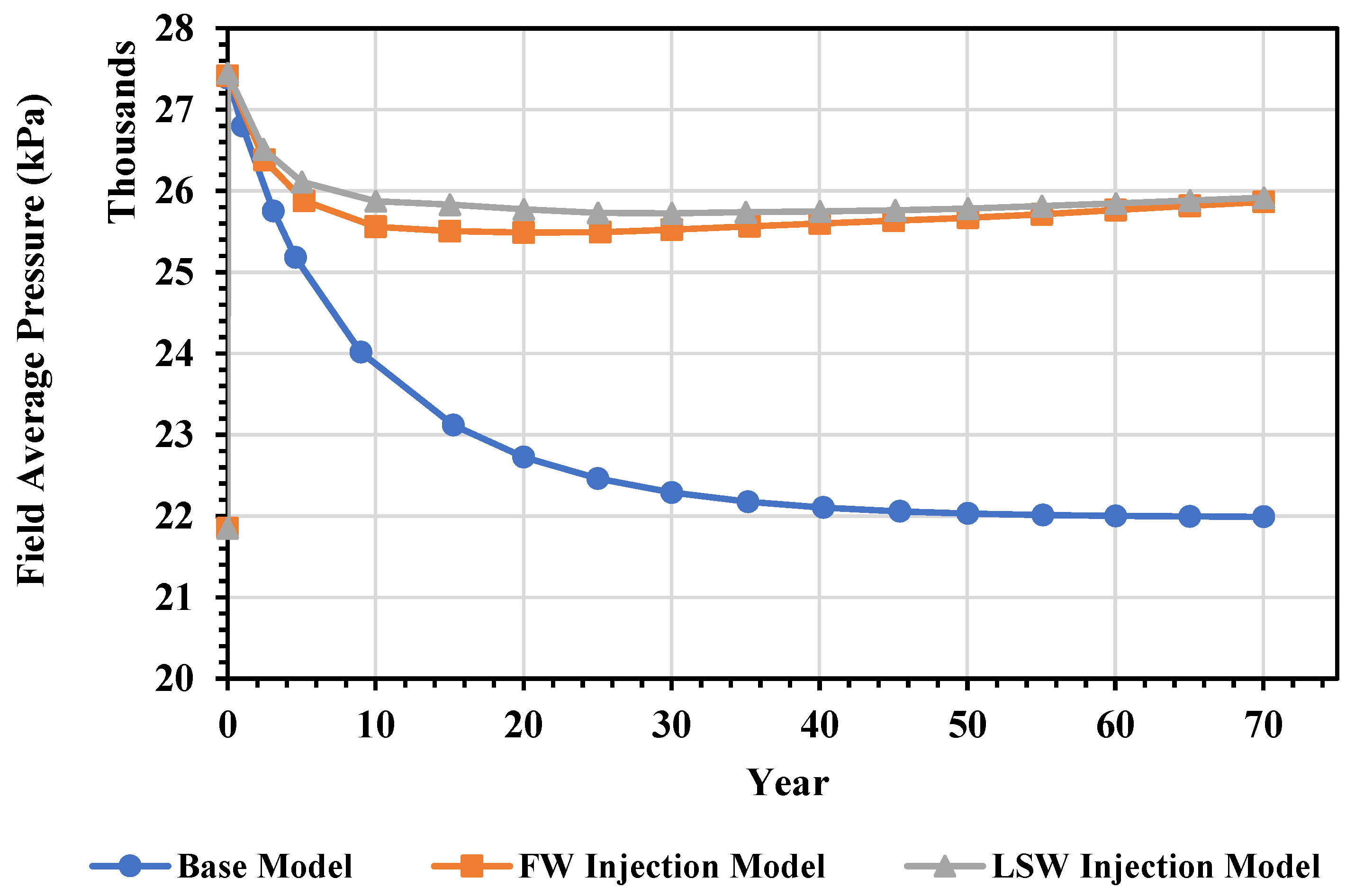

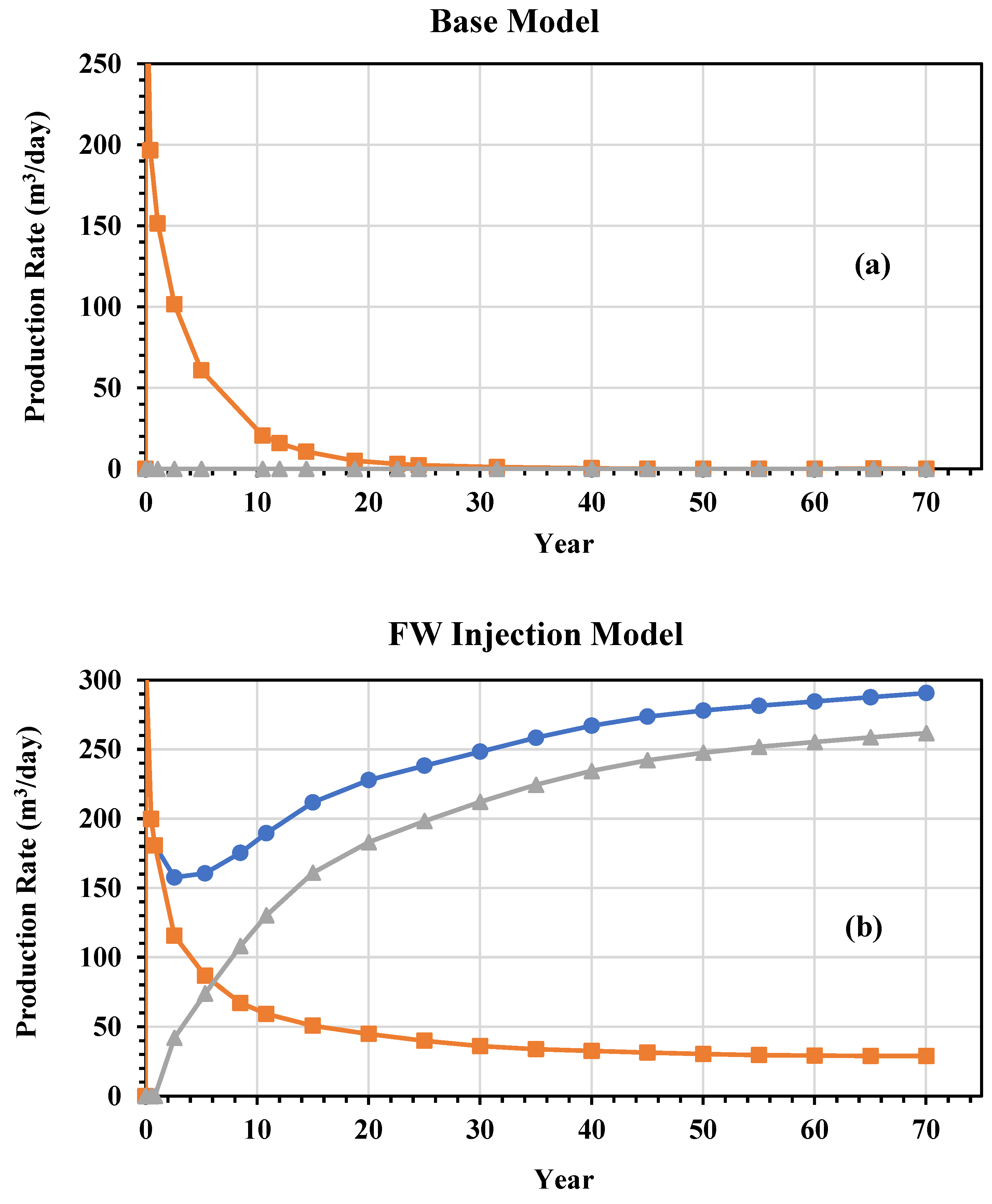

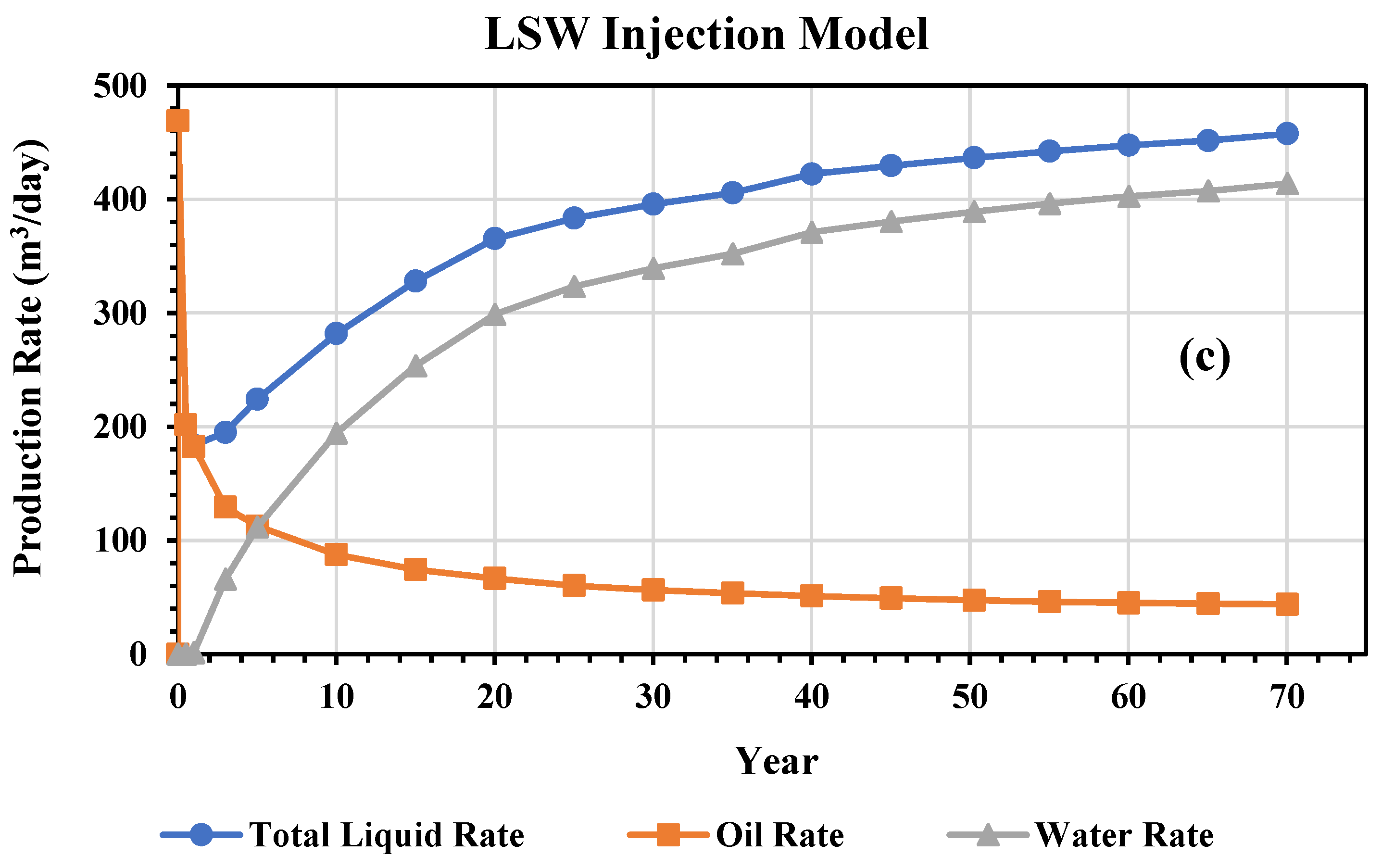

3.2. The Application of LSWF to the Kashkari Oil Field Result

4. Conclusions

- (1)

- The laboratory core flooding test showed that LSWF (with salinity 1%, 0.5% and 0.1%) can increase oil recovery up to a maximum of 8% after FW injection;

- (2)

- In CMG-GEM reservoir simulation software, it is possible to simulate intra-phase reactions, ion exchange, and dissolution/precipitation of minerals, and the behavior of ionic liquids can be observed;

- (3)

- The Kashkari oil field simulation model was established through CMG-GEM reservoir simulation software, and the LSWF (salinity 0.1%) oil recovery method was applied to it. The LSWF application showed a significant effect on the oil recovery of the model;

- (4)

- The LSW injection results showed a 5.1% increase in oil recovery compared with the base model, and a 1.9% increase compared with the FW injection model;

- (5)

- The result of LSWF (salinity 0.1%) on the Kashkari oil field shows that this technique can be an effective method for developing the Kashkari oil field.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| EoR | Enhanced oil recovery |

| MoMP | Ministry of Mines and Petroleum |

| CNPCI | China National Petroleum Corporation International |

| WOGL | Oil and Gas Group, Ltd. |

| CMG | Computer Modeling Group |

| LSW | Low-salinity water |

| LSWF | Low-salinity water flooding |

| PVI | Pore volume injection |

| PV | Pore volume |

| OFT | Oil finding technology |

| STARSTM | Thermal and Advanced Processes Simulator, software |

| GEMTM | Compositional and Unconventional Simulator, software |

| SGS | SGS Afghanistan Ltd. Oil and Gas Testing Laboratory in Hairatan, Afghanistan |

| SKUA-GOCADTM | Geomodelling software |

| EMERSONTM | American multinational corporation |

| GEOLOGTM | Geomodelling software |

| Rw | Water resistivity |

| Swi | Irreducible water saturation |

| Sorw | Residual oil saturation |

| kro max, krw max, krg max | Maximum relative permeability |

| Pc | Capillary pressure |

| PARADIGMTM | Reservoir model development software |

| Cf | Formation rock compressibility |

| San Saba | Core sample from San Saba, Texas |

| SRP-350 | Apparatus used for core flooding test |

| nh | Aqueous phase hydrocarbon components |

| na | Aqueous phase components |

| nm | Aqueous mineral components |

| FW | Formation water |

| mol/kg | Moles per kilogram |

| Temperature-dependent coefficients | |

| Ion size parameter | |

| zi | Valence number of species i |

| mi | Molality |

| rβ | Reaction rate |

| Reactive surface area for mineral β | |

| kβ, Keq,β and Qβ | Rate constant |

| Eaβ and k0β | Activation energy for reaction β (J/mol) |

| R | Universal gas constant (8.314 J/mol-K) |

| Ea | Activation energy |

| Reactive surface area | |

| New porosity | |

| Reference porosity with no mineral dissolution/precipitation | |

| Porosity with dissolution/precipitation | |

| ρβ | Mineral’s molar density |

| Rock compressibility | |

| p and p∗ | Current and reference pressures |

| Initial porosity | |

| k0 | Initial permeability |

| CEC | Cation exchanger capacity |

| BHP | Bottom hole pressure |

| FDP | Field development plan |

| PHREEQC | Mathematical software |

| MMbbl | One million barrels |

References

- Fink, J. Petroleum Engineer’s Guide to Oil Field Chemicals and Fluids; Gulf Professional Publishing: Houston, TX, USA, 2021. [Google Scholar]

- Bello, A.; Ozoani, J.; Kuriashov, D. Proppant transport in hydraulic fractures by creating a capillary suspension. J. Pet. Sci. Eng. 2022, 208, 109508. [Google Scholar] [CrossRef]

- Wu, Z.; Huiqing, L.; Wang, X.; Zhang, Z. Emulsification and improved oil recovery with viscosity reducer during steam injection process for heavy oil. J. Ind. Eng. Chem. 2018, 61, 348–355. [Google Scholar] [CrossRef]

- Eftekhari, A.A.; Krastev, R.; Farajzadeh, R. Foam stabilized by fly ash nanoparticles for enhancing oil recovery. Ind. Eng. Chem. Res. 2015, 54, 12482–12491. [Google Scholar] [CrossRef]

- Osei-Bonsu, K.; Shokri, N.; Grassia, P. Foam stability in the presence and absence of hydrocarbons: From bubble-to bulk-scale. Colloids Surf. A Physicochem. Eng. Asp. 2015, 481, 514–526. [Google Scholar] [CrossRef]

- Dang, C.; Nghiem, L.; Chen, Z.; Nguyen, Q. Modeling low salinity waterflooding: Ion exchange, geochemistry and wettability alteration. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 30 September–2 October 2013. [Google Scholar]

- Zeinijahromi, A.; Ahmetgareev, V.; Badalyan, A.; Khisamov, R.; Bedrikovetskya, P. Case study of low salinity water injection in Zichebashskoe field. J. Pet. Sci. Res. 2015, 4, 16–31. [Google Scholar] [CrossRef]

- Reiter, P.K. A Water-Sensitive Sandstone Flood Using Low Salinity Water; University of Oklahoma: Norman, OK, USA, 1961. [Google Scholar]

- Bernard, G.G. Effect of floodwater salinity on recovery of oil from cores containing clays. In Proceedings of the SPE California Regional Meeting, Los Angeles, CA, USA, 26–27 October 1967. [Google Scholar]

- Tang, G.; Morrow, N.R. Salinity, temperature, oil composition, and oil recovery by waterflooding. SPE Reserv. Eng. 1997, 12, 269–276. [Google Scholar] [CrossRef]

- Purswani, P.; Tawfik, M.S.; Karpyn, Z.T. Factors and mechanisms governing wettability alteration by chemically tuned waterflooding: A review. Energy Fuels 2017, 31, 7734–7745. [Google Scholar] [CrossRef]

- Jadhunandan, P.; Morrow, N.R. Effect of wettability on waterflood recovery for crude-oil/brine/rock systems. SPE Reserv. Eng. 1995, 10, 40–46. [Google Scholar] [CrossRef]

- Yildiz, H.O.; Morrow, N.R. Effect of brine composition on recovery of Moutray crude oil by waterflooding. J. Pet. Sci. Eng. 1996, 14, 159–168. [Google Scholar] [CrossRef]

- Austad, T.; Strand, S.; Madland, M.V.; Puntervold, T.; Korsnes, R.I. Seawater in chalk: An EOR and compaction fluid. SPE Reserv. Eval. Eng. 2008, 11, 648–654. [Google Scholar] [CrossRef]

- Austad, T.; Shariatpanahi, S.; Strand, S.; Black, C.; Webb, K. Conditions for a low-salinity enhanced oil recovery (EOR) effect in carbonate oil reservoirs. Energy Fuels 2012, 26, 569–575. [Google Scholar] [CrossRef]

- Fathi, S.J.; Austad, T.; Strand, S. “Smart water” as a wettability modifier in chalk: The effect of salinity and ionic composition. Energy Fuels 2010, 24, 2514–2519. [Google Scholar] [CrossRef]

- Zhang, P.; Tweheyo, M.T.; Austad, T. Wettability alteration and improved oil recovery in chalk: The effect of calcium in the presence of sulfate. Energy Fuels 2006, 20, 2056–2062. [Google Scholar] [CrossRef]

- Qiao, C.; Li, L.; Johns, R.T.; Xu, J. A mechanistic model for wettability alteration by chemically tuned waterflooding in carbonate reservoirs. SPE J. 2015, 20, 767–783. [Google Scholar] [CrossRef]

- Qiao, C.; Johns, R.; Li, L. Modeling low-salinity waterflooding in chalk and limestone reservoirs. Energy Fuels 2016, 30, 884–895. [Google Scholar] [CrossRef]

- Bader, M. Seawater versus produced water in oil-fields water injection operations. Desalination 2007, 208, 159–168. [Google Scholar] [CrossRef]

- Puntervold, T.; Strand, S.; Austad, T. New method to prepare outcrop chalk cores for wettability and oil recovery studies at low initial water saturation. Energy Fuels 2007, 21, 3425–3430. [Google Scholar] [CrossRef]

- Shariatpanahi, S.F.; Strand, S.; Austad, T. Evaluation of water-based enhanced oil recovery (EOR) by wettability alteration in a low-permeable fractured limestone oil reservoir. Energy Fuels 2010, 24, 5997–6008. [Google Scholar] [CrossRef]

- Strand, S.; Austad, T.; Puntervold, T.; Høgnesen, E.J.; Olsen, M.; Barstad, S.M.F. “Smart water” for oil recovery from fractured limestone: A preliminary study. Energy Fuels 2008, 22, 3126–3133. [Google Scholar] [CrossRef]

- Zhang, Y.; Xie, X.; Morrow, N.R. Waterflood performance by injection of brine with different salinity for reservoir cores. In Proceedings of the SPE Annual Technical Conference and Exhibition, Anaheim, CA, USA, 11–14 November 2007. [Google Scholar]

- Jerauld, G.R.; Lin, C.; Webb, K.J.; Seccombe, J.C. Modeling low-salinity waterflooding. SPE Reserv. Eval. Eng. 2008, 11, 1000–1012. [Google Scholar] [CrossRef]

- Zhang, P.; Tweheyo, M.T.; Austad, T. Wettability alteration and improved oil recovery by spontaneous imbibition of seawater into chalk: Impact of the potential determining ions Ca2+, Mg2+, and SO42−. Colloids Surf. A Physicochem. Eng. Asp. 2007, 301, 199–208. [Google Scholar] [CrossRef]

- Webb, K.; Black, C.; Edmonds, I. Low salinity oil recovery–The role of reservoir condition corefloods. In Proceedings of the IOR 2005-13th European Symposium on Improved Oil Recovery, Budapest, Hungary, 25–27 April 2005; p. cp-12-00045. [Google Scholar]

- Morrow, N.R.; Tang, G.-q.; Valat, M.; Xie, X. Prospects of improved oil recovery related to wettability and brine composition. J. Pet. Sci. Eng. 1998, 20, 267–276. [Google Scholar] [CrossRef]

- Webb, K.; Black, C.a.; Al-Ajeel, H. Low salinity oil recovery-log-inject-log. In Proceedings of the SPE/DOE Symposium on Improved Oil Recovery, Tulsa, OK, USA, 17–21 April 2004. [Google Scholar]

- McGuire, P.; Chatham, J.; Paskvan, F.; Sommer, D.; Carini, F. Low salinity oil recovery: An exciting new EOR opportunity for Alaska’s North Slope. In Proceedings of the SPE Western Regional Meeting, Irvine, CA, USA, 30 March–1 April 2005. [Google Scholar]

- Lager, A.; Webb, K.J.; Collins, I.R.; Richmond, D.M. LoSal enhanced oil recovery: Evidence of enhanced oil recovery at the reservoir scale. In Proceedings of the SPE Symposium on Improved Oil Recovery, Tulsa, OK, USA, 20–23 April 2008. [Google Scholar]

- Skrettingland, K.; Holt, T.; Tweheyo, M.T.; Skjevrak, I. Snorre low-salinity-water injection—Coreflooding experiments and single-well field pilot. SPE Reserv. Eval. Eng. 2011, 14, 182–192. [Google Scholar] [CrossRef]

- Austad, T.; Strand, S.; Høgnesen, E.; Zhang, P. Seawater as IOR fluid in fractured chalk. In Proceedings of the SPE International Symposium on Oilfield Chemistry, The Woodlands, TX, USA, 2–4 February 2005. [Google Scholar]

- Hognesen, E.J.; Strand, S.; Austad, T. Waterflooding of preferential oil-wet carbonates: Oil recovery related to reservoir temperature and brine composition. In Proceedings of the SPE Europec/EAGE Annual Conference, Madrid, Spain, 13–16 June 2005. [Google Scholar]

- Dang, C.; Nghiem, L.; Nguyen, N.; Chen, Z.; Nguyen, Q. Mechanistic modeling of low salinity water flooding. J. Pet. Sci. Eng. 2016, 146, 191–209. [Google Scholar] [CrossRef]

- Mehrad, A.T.; Zvolinski, V.; Kapralova, D.; Niazmand, M.A. Assessment of oil and gas resources of northern Afghanistan and their impact on energy security in the country. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Moscow, Russia, 16–17 April 2020; p. 012038. [Google Scholar]

- Watan Oil and Gas Group. Formation Evaluation & Geomodeling—Study, Kashkari Field, Afghanistan; Watan Oil and Gas Group: Dubai, United Arab Emirates, 2017; p. 91. [Google Scholar]

- Kashkari Oilfield Development Plan (1st Phase); Kabul, Afghanistan, 2013; p. 140.

- Sabawon, A.; Kurihara, M.; Waseda, A.; Nishita, H.; Okumura, F.; Nakashima, H. Estimation of petroleum source rocks based on the crude oil geochemistr y in Amu Darya Basin, northern Afghanistan. J. Jpn. Assoc. Pet. Technol. 2016, 81, 230–242. [Google Scholar] [CrossRef]

- Gas, W.G.O. Kashkari Field, Afghanistan 2017 Field Development Plan; Sarotaga Technology: Dubai, United Arab Emirates, 2017; p. 183. [Google Scholar]

- Geophysical, P. Formation Evaluation & Geomodeling—Study, Kashkari Field, Afghanistan.; Emerson, Paradigm Geophysical: Dubai, United Arab Emirates, 2017; p. 91. [Google Scholar]

- Promotion of Oil and Gas Producing Areas to the Private Sector, Executive Summery; Gustavson Associates: Boulder, CO, USA, 2005; p. 221.

- Kashkari Oilfield. Well No.: Kash-1, Geological Design for Workover; CNPCI Watan Oil and Gas Afghanistan Ltd.: Beijing, China, 2012; p. 29. [Google Scholar]

- Kashkari Oilfield. Well No.: Kash-3, Geological Design for Workover; CNPCI WATAN Oil and Gas Afghanistan Ltd.: Beijing, China, 2012; p. 30. [Google Scholar]

- Kashkari Oilfield. Well No.: Kash-4, Geological Design for Workover; CNPCI WATAN Oil and Gas Afghanistan Ltd.: Beijing, China, 2012; p. 31. [Google Scholar]

- Kashkari Oilfield. Well No.: Kash-9, Geological Design for Workover; CNPCI WATAN Oil and Gas Afghanistan Ltd.: Beijing, China, 2012; p. 29. [Google Scholar]

- Kashkari Oilfield. Well No.: Kash-10, Geological Design for Workover; CNPCI WATAN Oil and Gas Afghanistan Ltd.: Beijing, China, 2012; p. 28. [Google Scholar]

- Kashkari Oilfield. Well No.: Kash-21, Geological Design for Workover; CNPCI WATAN Oil and Gas Afghanistan Ltd.: Beijing, China, 2012; p. 7. [Google Scholar]

- Russian Production Report; State Institute on Design and Research in Oil Industry: USSR Ministry of Oil Industry: Moscow, Russia, 1980.

- Derkani, M.H.; Fletcher, A.J.; Abdallah, W.; Sauerer, B.; Anderson, J.; Zhang, Z.J. Low salinity waterflooding in carbonate reservoirs: Review of interfacial mechanisms. Colloids Interfaces 2018, 2, 20. [Google Scholar] [CrossRef]

- Al-Shalabi, E.W.; Sepehrnoori, K.; Delshad, M. Does the double layer expansion mechanism contribute to the LSWI effect on hydrocarbon recovery from carbonate rocks? In Proceedings of the SPE Reservoir Characterization and Simulation Conference and Exhibition, Abu Dhabi, United Arab Emirates, 16–18 September 2013. [Google Scholar]

- Dang, C.; Nghiem, L.; Nguyen, N.; Chen, Z.; Nguyen, Q. Modeling and optimization of low salinity waterflood. In Proceedings of the SPE Reservoir Simulation Symposium, Houston, TX, USA, 23–25 February 2015. [Google Scholar]

- Awolayo, A.N.; Sarma, H.K.; Nghiem, L.X. A comprehensive geochemical-based approach at modeling and interpreting brine dilution in carbonate reservoirs. In Proceedings of the SPE Reservoir Simulation Conference, Montgomery, TX, USA, 20–22 February 2017. [Google Scholar]

- Tunnish, A.; Shirif, E.; Henni, A. History matching of experimental and CMG-STARS results. J. Pet. Explor. Prod. Technol. 2019, 9, 341–351. [Google Scholar] [CrossRef]

- Computer Modelling Group Ltd. CMG—GEM Technical Manual; T2L 2M1; Computer Modelling Group Ltd.: Calgary, Canada, 2021. [Google Scholar]

| Salinity | |||||

|---|---|---|---|---|---|

| Type | (g/L) | ||||

| Na2SO4 | 33–39 | ||||

| Na2SO4 | 26–35 | ||||

| NaHCO3 | 11–16 | ||||

| Ion Contents (mg/L) | |||||

| Cl− | SO42− | HCO3− | Ca2+ | Mg2+ | K + and Na+ |

| 12,456.3 | 4172.8 | 2091.6 | 402.5 | 75.5 | 10,321.3 |

| Zone | Pressure (kPa) | Viscosity (cp) |

|---|---|---|

| XIa | 6398.0 | 2.1 |

| XIIa | 4212.9 | 2.19 |

| XIIb | 4398.0 | 3.4 |

| XIV | 2978.1 | 7.6 |

| Core ID | Sandstone |

|---|---|

| Core type | San Saba sandstone |

| Core diameter (mm) | 25.14 |

| Core length (mm) | 50.63 |

| Core weight (g) | 52.13 |

| Gas permeability (mD) | 63.68 |

| Pore volume (cc) | 5.44 |

| Bulk volume (cc) | 25.13 |

| Porosity (%) | 21.6 |

| Water permeability (mD) | 25 |

| Ion Contents (PPM) | Cl− | SO42− | HCO3− | Ca2+ | Mg2+ | Na+ | Total |

|---|---|---|---|---|---|---|---|

| FW (3%) | 12,488 | 4172 | 2091 | 402 | 75 | 10,278 | 29,506 |

| LSW (1%) | 4162 | 1390 | 697 | 134 | 25 | 3426 | 9834 |

| LSW (0.5%) | 2081 | 695 | 348 | 67 | 12 | 1713 | 4916 |

| LSW (0.1%) | 416 | 139 | 69 | 13 | 2 | 343 | 982 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mahdi, Z.; Abe, K.; Seddiqi, K.N.; Chiyonobu, S.; Fujii, H. Increasing Recoverable Oil in Northern Afghanistan Kashkari Oil Field by Low-Salinity Water Flooding. Energies 2023, 16, 534. https://doi.org/10.3390/en16010534

Mahdi Z, Abe K, Seddiqi KN, Chiyonobu S, Fujii H. Increasing Recoverable Oil in Northern Afghanistan Kashkari Oil Field by Low-Salinity Water Flooding. Energies. 2023; 16(1):534. https://doi.org/10.3390/en16010534

Chicago/Turabian StyleMahdi, Zabihullah, Kazunori Abe, Khwaja Naweed Seddiqi, Syun Chiyonobu, and Hikari Fujii. 2023. "Increasing Recoverable Oil in Northern Afghanistan Kashkari Oil Field by Low-Salinity Water Flooding" Energies 16, no. 1: 534. https://doi.org/10.3390/en16010534

APA StyleMahdi, Z., Abe, K., Seddiqi, K. N., Chiyonobu, S., & Fujii, H. (2023). Increasing Recoverable Oil in Northern Afghanistan Kashkari Oil Field by Low-Salinity Water Flooding. Energies, 16(1), 534. https://doi.org/10.3390/en16010534