Simulations to Eliminate Backflow Power in an Isolated Three-Port Bidirectional DC–DC Converter

Abstract

1. Introduction

2. Method

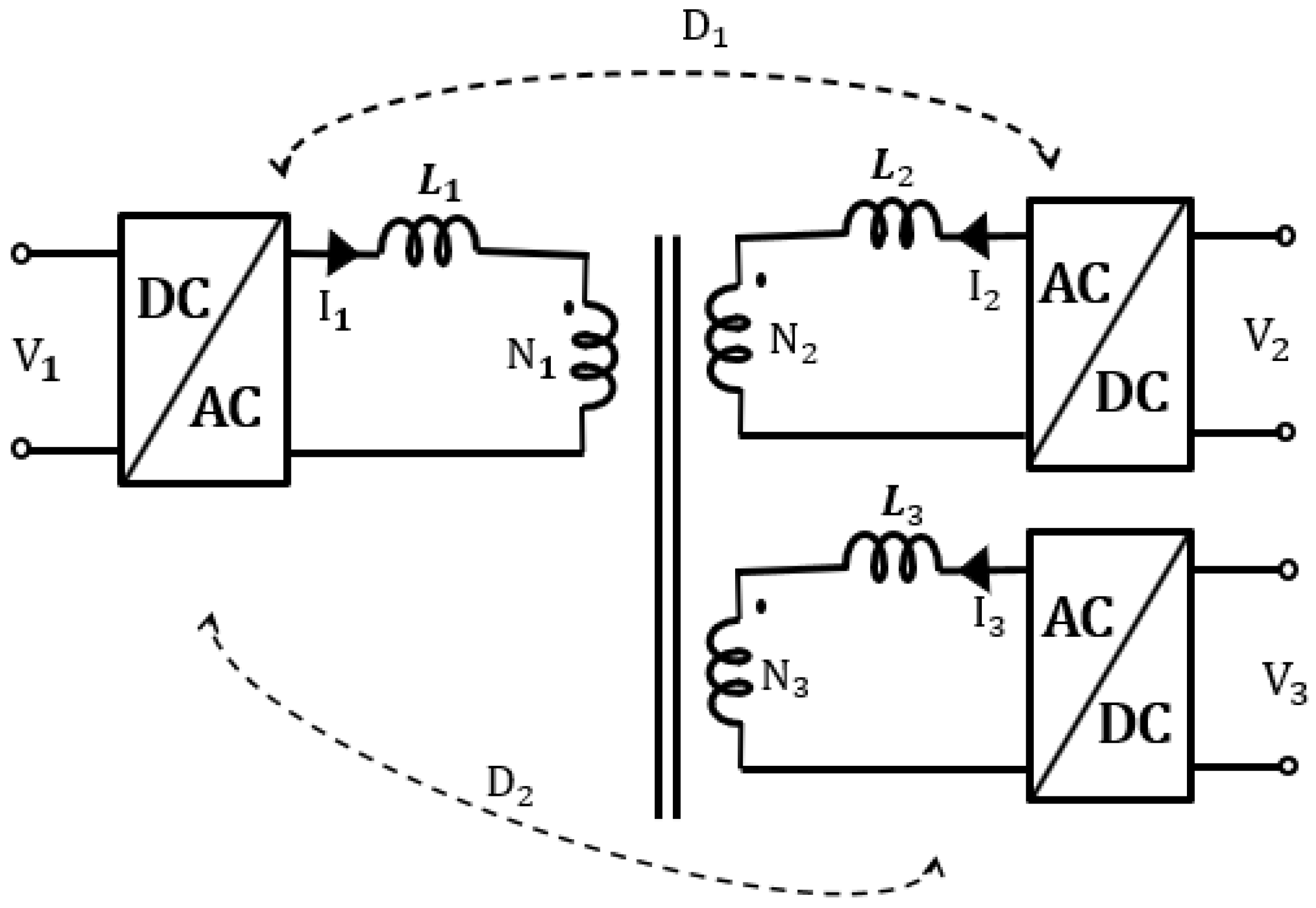

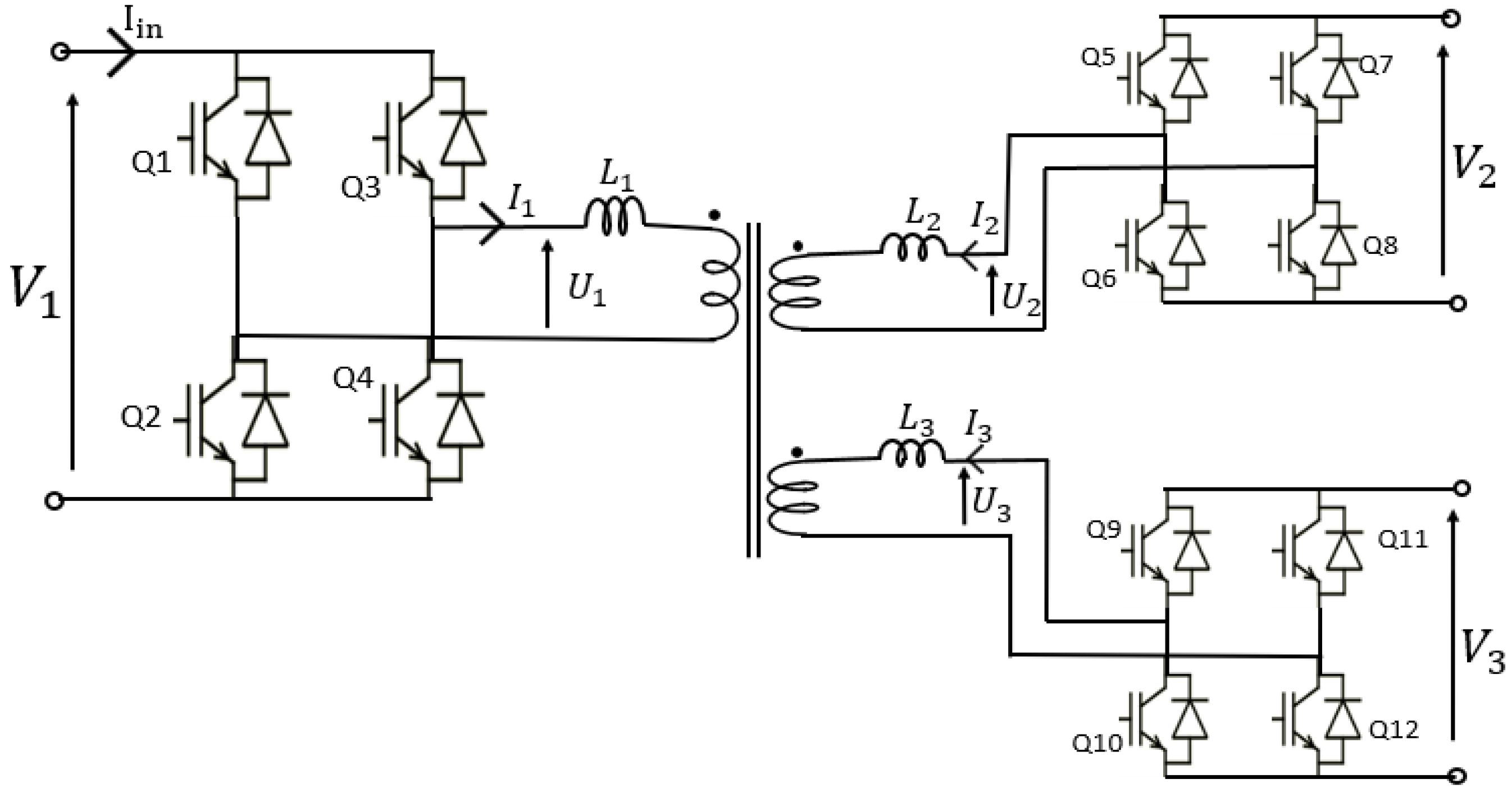

2.1. Circuit Description

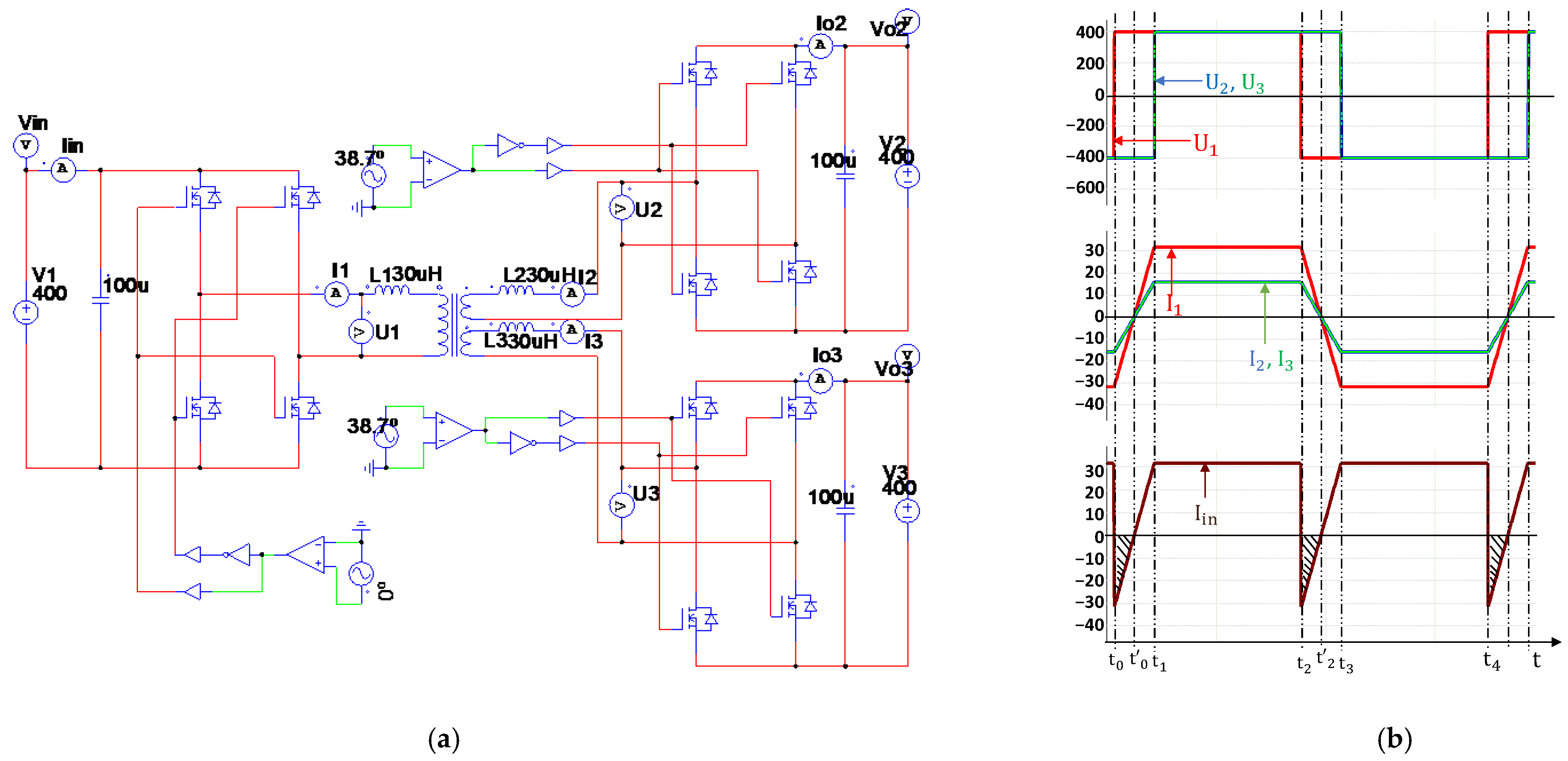

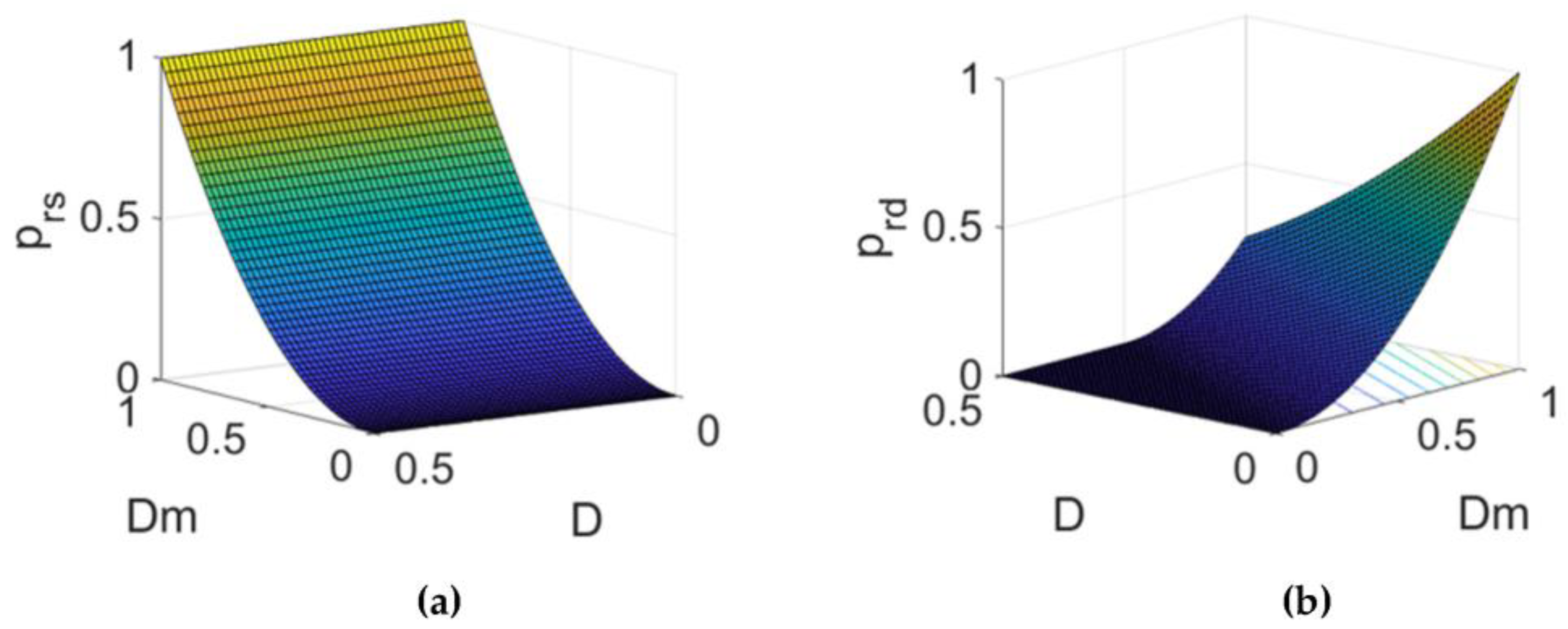

2.2. Backflow Power in SPS Operation

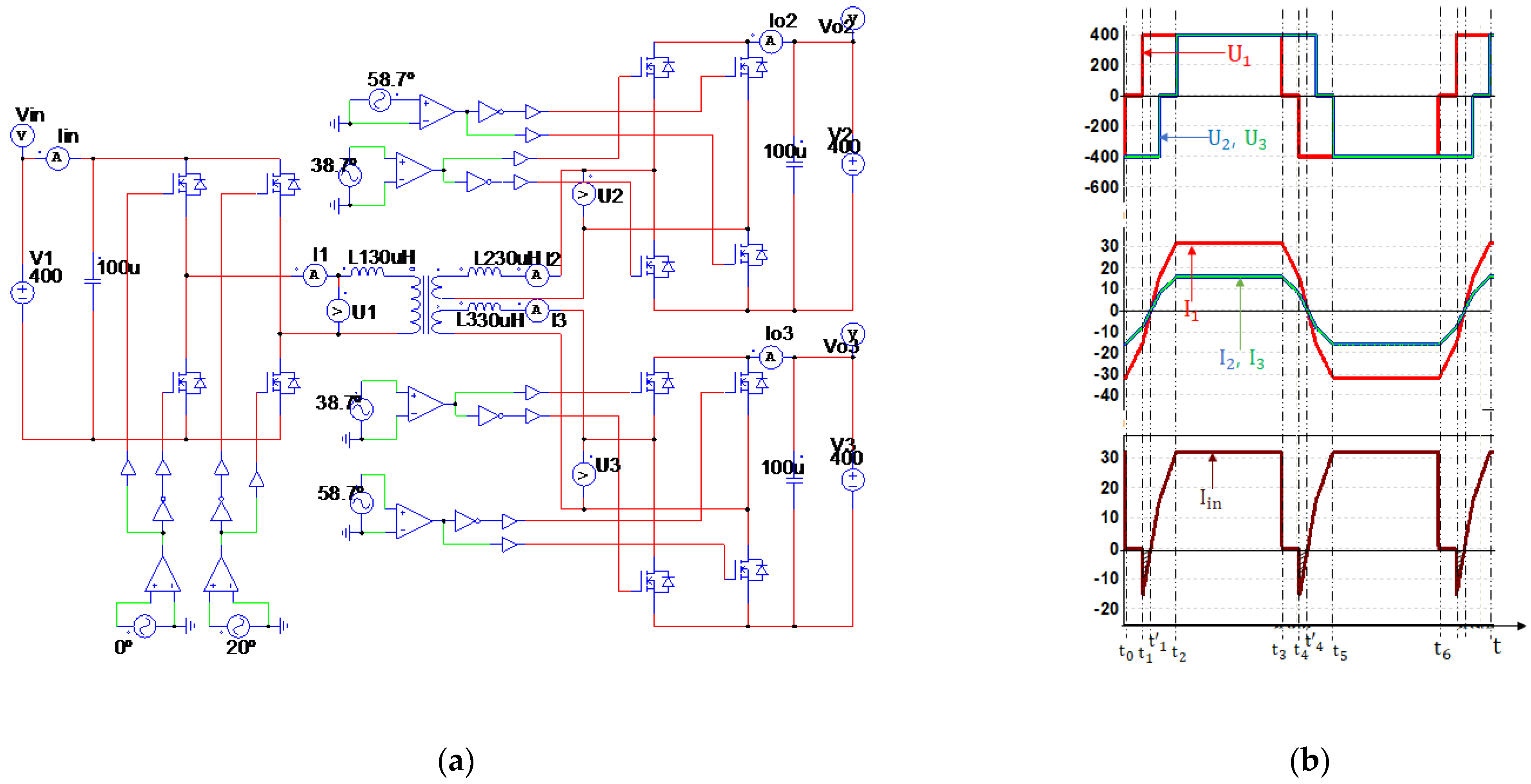

2.3. Backflow Power in DPS Operation

3. Results and Discursion

3.1. Backflow Power Eliminated with DPS

3.2. Characteristics of the Backflow Power and the Power Processed by the Converter

3.2.1. Characterization of the Backflow Power

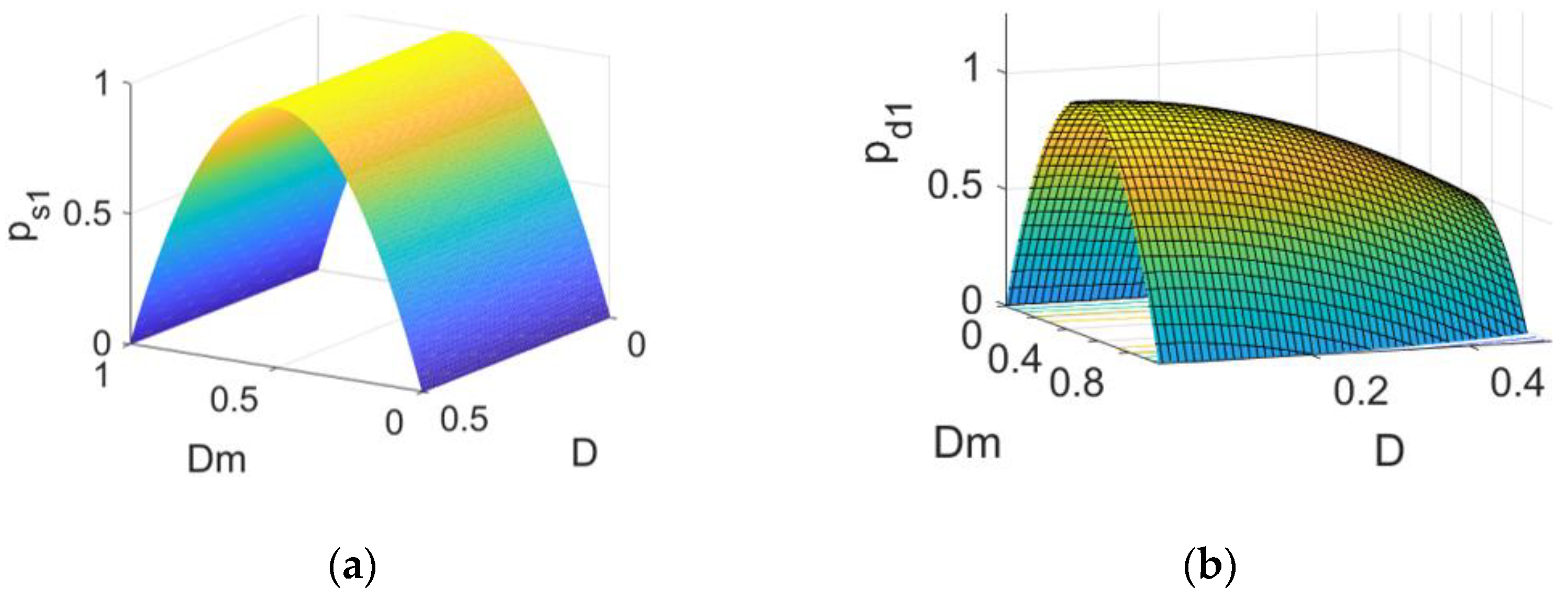

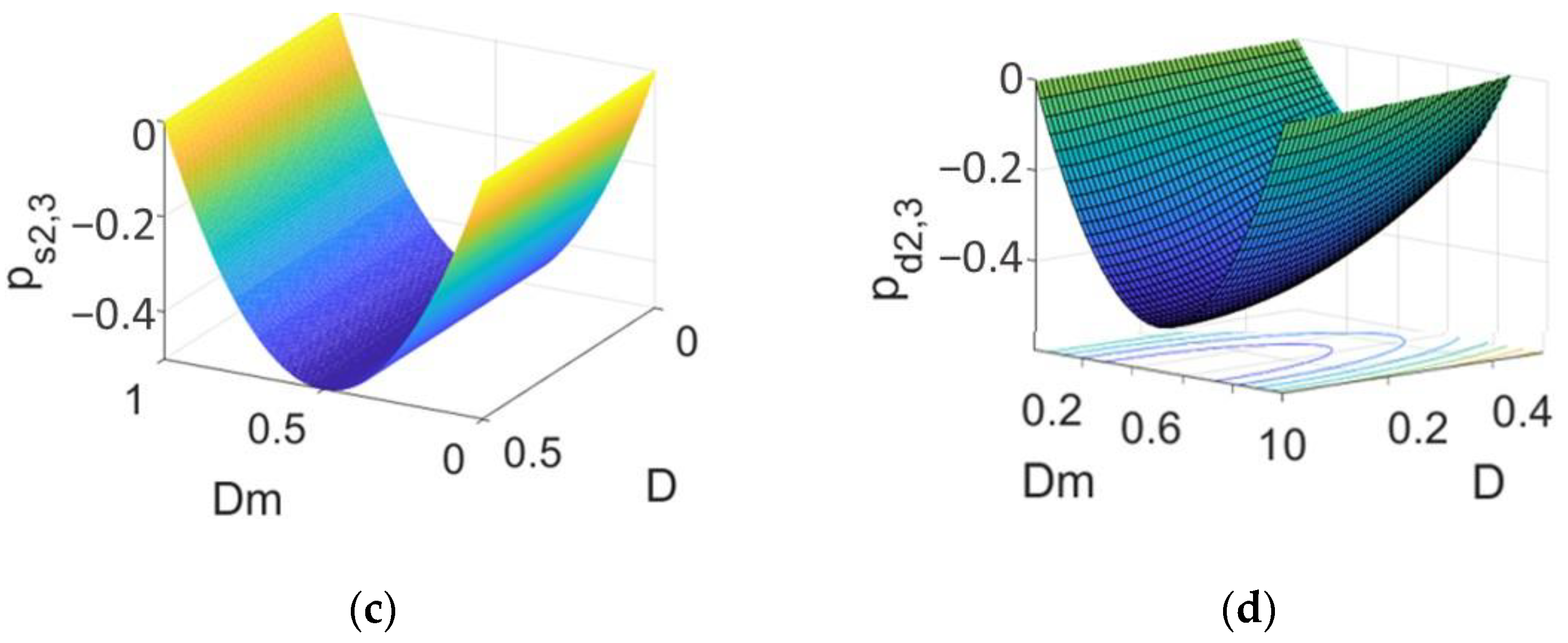

3.2.2. Characterization of the Processed Power at the Various Ports

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| DPS | Dual phase shift |

| SPS | Single phase shift |

| PSIM | Power SIM |

| TAB | Triple active bridge |

| RMS | Root mean square |

| DAB | Dual active bridge |

| SST | Solid state transformer |

| Symbols | |

| Internal phase-shift ratio | |

| Phase-shift ratio between ports 1 and 2 | |

| Phase-shift ratio between ports 1 and 3 | |

| Internal phase-shift angle | |

| Phase-shift angle between ports 1 and 2 | |

| Phase-shift angle between ports 1 and 3 | |

| DC-linked voltages at the different ports | |

| Voltages at the transformer terminals | |

| Number of turns of the different windings | |

| Transformer currents | |

| Leakage inductance of the windings | |

| Converter’s input current | |

| Voltage conversion ratios | |

| Backflow power with SPS control | |

| Backflow power with DPS control | |

| A | Area of the backflow region |

| T | Switching period |

| Average current | |

| Backflow power between ports 1 and 2 | |

| Backflow power between ports 1 and 3 | |

| Power processed at the ports with SPS | |

| Power processed at the ports with DPS | |

| Maximum possible power | |

| Ratio of backflow power with SPS on | |

| Ratio of backflow power with DPS on | |

| Ratio of power at the ports with SPS on | |

| Ratio of power at the ports with DPS on |

References

- Kim, J.-C.; Huh, J.-H.; Ko, J.-S. Optimization Design and Test Bed of Fuzzy Control Rule Base for PV System MPPT in Micro Grid. Sustainability 2020, 12, 3763. [Google Scholar] [CrossRef]

- Jung, S.; Yoon, Y.T.; Huh, J.-H. An Efficient Micro Grid Optimization Theory. Mathematics 2020, 8, 560. [Google Scholar] [CrossRef]

- Kim, J.-C.; Huh, J.-H.; Ko, J.-S. Improvement of MPPT Control Performance Using Fuzzy Control and VGPI in the PV System for Micro Grid. Sustainability 2019, 11, 5891. [Google Scholar] [CrossRef]

- Harrye, Y.A.; Ahmed, K.H.; Aboushady, A.A. Reactive power minimization of dual active bridge DC/DC converter with triple phase shift control using neural network. In Proceedings of the 2014 International Conference on Renewable Energy Research and Application (ICRERA), Milwaukee, WI, USA, 19–22 October 2014; pp. 566–571. [Google Scholar] [CrossRef]

- Zhao, B.; Yu, Q.; Sun, W. Extended-Phase-Shift Control of Isolated Bidirectional DC–DC Converter for Power Distribution in Microgrid. IEEE Trans. Power Electron. 2012, 27, 4667–4680. [Google Scholar] [CrossRef]

- Pereira, T.; Hoffmann, F.; Liserre, M. Potentials and Challenges of Multiwinding Transformer-Based DC-DC Converters for Solid-State Transformer. In Proceedings of the IECON 2021—47th Annual Conference of the IEEE Industrial Electronics Society, Toronto, ON, Canada, 13–16 October 2021; pp. 1–6. [Google Scholar] [CrossRef]

- Koneh, N.N.; Ko, J.-S.; Kim, D.-K. Characteristics of an AC/DC Hybrid Converter According to Load Fluctuation. Int. J. Eng. Trends Technol. 2021, 69, 205–210. [Google Scholar] [CrossRef]

- Ibrahim, A.A.; Caldognetto, T.; Mattavelli, P. Conduction Loss Reduction of Isolated Bidirectional DC-DC Triple Active Bridge. In Proceedings of the 2021 IEEE Fourth International Conference on DC Microgrids (ICDCM), Arlington, VA, USA, 18–21 July 2021; pp. 1–8. [Google Scholar] [CrossRef]

- Bai, H.; Mi, C. Eliminate Reactive Power and Increase System Efficiency of Isolated Bidirectional Dual-Active-Bridge DC–DC Converters Using Novel Dual-Phase-Shift Control. IEEE Trans. Power Electron. 2008, 23, 2905–2914. [Google Scholar] [CrossRef]

- Rahman, M.I.; Jovcic, D.; Ahmed, K.H. Reactive current optimization for high power dual active bridge DC/DC converter. In Proceedings of the 2013 IEEE Grenoble Conference, Grenoble, France, 16–20 June 2013; pp. 1–6. [Google Scholar] [CrossRef]

- Jain, A.K.; Ayyanar, R. Pwm control of dual active bridge: Comprehensive analysis and experimental verification. IEEE Trans. Power Electron. 2011, 26, 1215–1227. [Google Scholar] [CrossRef]

- Katagiri, K.; Nakagawa, S.; Kurosawa, K.; Arai, J.; Kado, Y.; Wada, K. Power flow control of triple active bridge converter equipped with AC/DC converter for constructing autonomous hybrid AC/DC microgrid systems. In Proceedings of the IECON 2017—43rd Annual Conference of the IEEE Industrial Electronics Society, Beijing, China, 29 October–1 November 2017; pp. 1441–1446. [Google Scholar] [CrossRef]

- Malan, W.L.; Vilathgamuwa, D.M.; Walker, G.R.; Hiller, M. A three port resonant solid-state transformer with minimized circulating reactive currents in the high frequency link. In Proceedings of the 2016 IEEE 2nd Annual Southern Power Electronics Conference (SPEC), Auckland, New Zealand, 5–8 December 2016; pp. 1–6. [Google Scholar] [CrossRef]

- Yapa, R.; Forsyth, A. Extended soft switching operation of the triple active bridge converter. In Proceedings of the 6th IET International Conference on Power Electronics, Machines and Drives (PEMD 2012), Bristol, UK, 27–29 March 2012; pp. 1–6. [Google Scholar] [CrossRef]

- Koneh, N.N.; Ko, J.-S.; Kim, D.-K. Simulations of the Comparative Study of the Single-Phase Shift and the Dual-Phase Shift-Controlled Triple Active Bridge Converter. Electronics 2022, 11, 3274. [Google Scholar] [CrossRef]

| Specification | Symbol | Value |

|---|---|---|

| DC linked voltages (v) | ||

| Switching frequency (kHz) | ||

| Turn ratio | ||

| Leakage inductance (µH) | ||

| Power (kw) | 10 | |

| Phase shift ratio | 0.215 | |

| Phase shift angle | 38.7° | |

| Internal phase shift angle | 20° |

| Time | Value |

|---|---|

| 0 | |

| T/2 | |

| T[1 + ]/2 | |

| T |

| Time | Value |

|---|---|

| 0 | |

| T/2 | |

| /2 | |

| T |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Koneh, N.N.; Ko, J.-S.; Kim, D.-K. Simulations to Eliminate Backflow Power in an Isolated Three-Port Bidirectional DC–DC Converter. Energies 2023, 16, 450. https://doi.org/10.3390/en16010450

Koneh NN, Ko J-S, Kim D-K. Simulations to Eliminate Backflow Power in an Isolated Three-Port Bidirectional DC–DC Converter. Energies. 2023; 16(1):450. https://doi.org/10.3390/en16010450

Chicago/Turabian StyleKoneh, Norbert Njuanyi, Jae-Sub Ko, and Dae-Kyong Kim. 2023. "Simulations to Eliminate Backflow Power in an Isolated Three-Port Bidirectional DC–DC Converter" Energies 16, no. 1: 450. https://doi.org/10.3390/en16010450

APA StyleKoneh, N. N., Ko, J.-S., & Kim, D.-K. (2023). Simulations to Eliminate Backflow Power in an Isolated Three-Port Bidirectional DC–DC Converter. Energies, 16(1), 450. https://doi.org/10.3390/en16010450