Genetically Optimized Extended Kalman Filter for State of Health Estimation Based on Li-Ion Batteries Parameters

Abstract

:1. Introduction

2. Reference Model

2.1. Model Description

2.2. Model Tuning and Validation

2.2.1. Tuning of Model Parameters

2.2.2. Model Validation

3. KF and EKF for Cell Parameter Identification

3.1. Kalman Filter

| Algorithm 1: Summary of non-linear extended Kalman filter equation. |

Non-linear state-space model Definitions 1. Initialization For , set , 2. Computation For k = 1, 2, …, compute 2.1 Time Update State Estimate: Error covariance: 2.2 Measurement update Kalman gain: Output evaluation: State estimation: Error covariance: and are independent, zero-mean Gaussian noise process of covariance matrices and , respectively [21]. . . |

3.2. Extended Kalman Filter Applied to the Cell Parameters Estimations

3.3. Genetic Algorithm for EKF Covariance Matrices

- (1)

- InitializationIn the initial function, the number m of individuals of the population to observe is defined. At the initial step, the set of genes for the m individuals are arbitrarily chosen, within very wide predefined domains. The initial generation is defined as:

- (2)

- FitnessFor each individual , the corresponding set of genes, indicated in the rows of (11), are used as coefficients of the covariance matrices of the EKF presented in Section 3.2. For each set of genes, during the evolution of the corresponding EKF algorithm, the fitness function (12) for is continuously updated. This function is the root mean square error between the actual voltage and the estimated output voltage of the EKF at each computation step k.This choice of the fitness function (12) is crucial for obtaining the correct results of the optimization process. After applying the EKF to the available measured data, by using the m sets of genes as covariance coefficients, an initial vector containing the results of the fitness function is obtained.

- (3)

- SelectionWith the selection function, the process enters in an iterative cycle, where each i cycle represents a new generation of individuals. In this function, the two individuals having the lowest fitness value are selected from the current population and defined as “parents”. To avoid the premature problem, two parents with the same genes cannot be chosen. In this case, the following individual is taken.

- (4)

- CrossoverThe crossover function generates l “children” individuals using a linear combination of the two previously selected parents. The Crossover Function matrix and the generated l children are defined as:Among the several known crossover functions [39], two have been chosen: the one-point crossover and the standard crossover. Therefore, by applying these two crossover functions to the two selected parents, four children are generated .

- (5)

- MutationIn the evolutionary process, some random mutations appear between two generations. Gene mutation of the children occurs with a predefined probability p, and in case of mutation, the new value is randomly chosen inside a predefined domain. The domain is in discrete form and is represented by , where the s ranges from to 4 and the step , so the whole domain is . The domain is defined so that all “’reasonable” points are inside. In this way, there are no points fixed by the choice of the domain itself. This function is called: Mutation Function .Once the new vector of children individuals (with ) is obtained, a sequence of l EKF elaborations is performed. Each EKF elaboration uses the new covariance coefficients given by the children’s genes and by using the same reference measured cell quantities. During the evolution of each EKF, the new fitness values for the children are calculated by using the same fitness function introduced in (12).

- (6)

- PopulationUpdate The next generation of the population is composed by a combination of parents and children, where the l worse parents are substituted by the children. In this way, the maximum amount of elements is always m. In this case, the number of parents m are 20, as the number of children l are 4 and the retained parents are 16.The resulting fitness functions of the new population are simply obtained by merging the corresponding fitness functions of selected parents and children.The fitness vector is used at the next iteration for the selection step, which selects the two parents of the new generation. It is worth noting that, with this genetic algorithm, at each new generation, the EKF elaboration is limited to the new l individuals (children only) of the population. The genetic algorithm continues to evolve, generation after generation, until a satisfactory result is achieved. This is represented by a target for the fitness value.

4. Experimental Tests

4.1. Execution of the Optimization Procedure

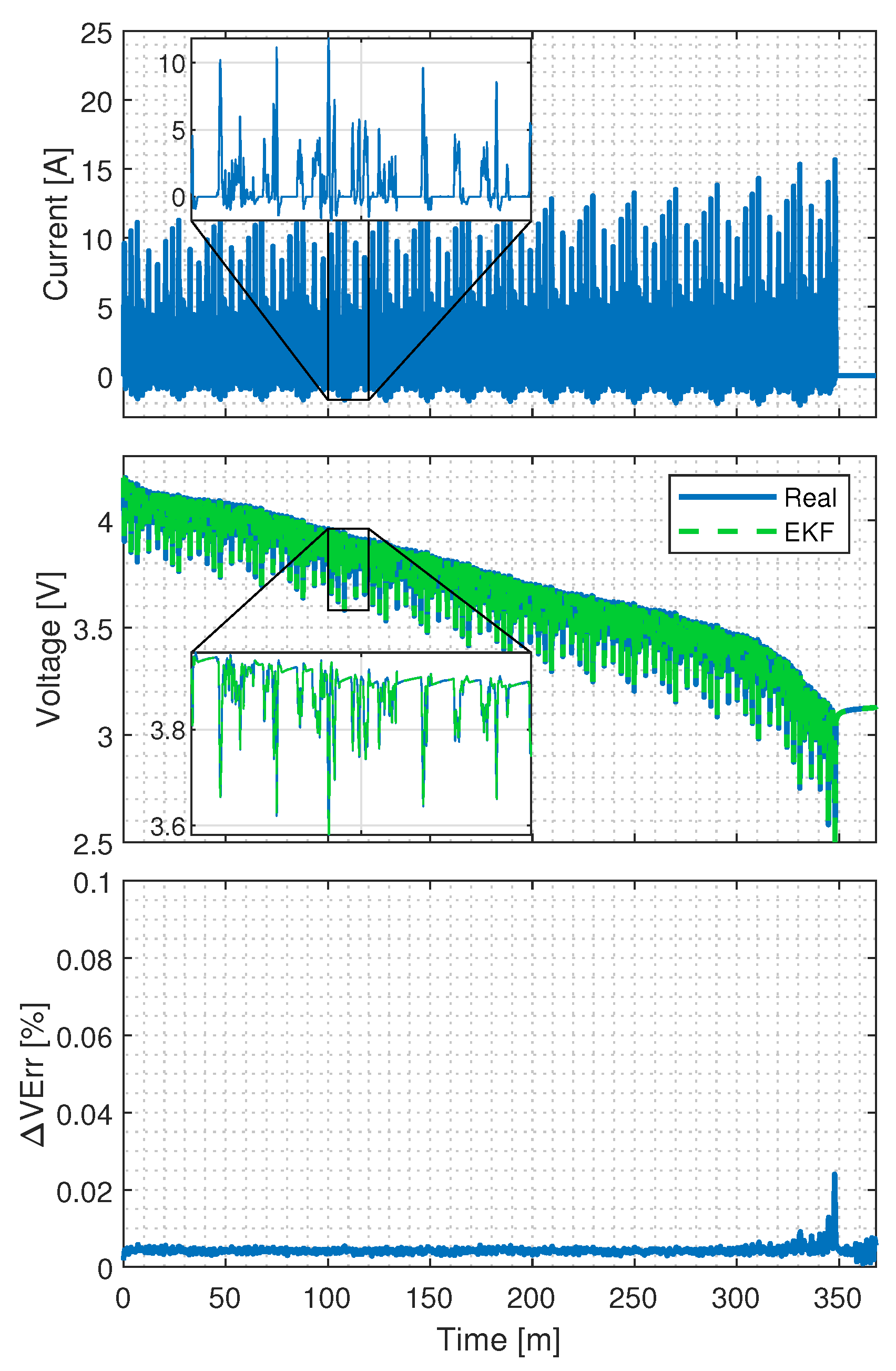

4.2. EKF Testing

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Plett, G.L. Battery Management Systems, Volume II: Equivalent-Circuit Methods; Artech House: Norwood, MA, USA, 2016. [Google Scholar]

- Smith, K.; Shi, Y.; Santhanagopalan, S. Degradation mechanisms and lifetime prediction for lithium-ion batteries—A control perspective. In Proceedings of the 2015 American Control Conference (ACC), Chicago, IL, USA, 1–3 July 2005; pp. 728–730. [Google Scholar] [CrossRef]

- Plett, G.L. Battery Management Systems, Volume I: Battery Modeling; Artech House: Norwood, MA, USA, 2015. [Google Scholar]

- Campestrini, C.; Heil, T.; Kosch, S.; Jossen, A. A comparative study and review of different Kalman filters by applying an enhanced validation method. J. Energy Storage 2016, 8, 142–159. [Google Scholar] [CrossRef]

- Dong, H.; Jin, X.; Lou, Y.; Wang, C. Lithium-ion battery state of health monitoring and remaining useful life prediction based on support vector regression-particle filter. J. Power Sources 2014, 271, 114–123. [Google Scholar] [CrossRef]

- Li, W.; Liang, L.; Liu, W.; Wu, X. State of Charge Estimation of Lithium-Ion Batteries Using a Discrete-Time Nonlinear Observer. IEEE Trans. Ind. Electron. 2017, 64, 8557–8565. [Google Scholar] [CrossRef]

- Jokić, I.; Zečević, Z.; Krstajić, B. State-of-charge estimation of lithium-ion batteries using extended Kalman filter and unscented Kalman filter. In Proceedings of the 2018 23rd International Scientific-Professional Conference on Information Technology (IT), Zabljak, Montenegro, 19–24 February 2018; pp. 1–4. [Google Scholar] [CrossRef]

- Cong, J.; Wang, S.; Wu, B.; Fernandez, C.; Xiong, X.; Coffie-Ken, J. A state-of-charge estimation method of the power lithium-ion battery in complex conditions based on adaptive square root extended Kalman filter. Energy 2021, 219, 119603. [Google Scholar] [CrossRef]

- Andrea, D. Battery Management Systems for Large Lithium-Ion Battery Packs; Artech House: Boston, MA, USA, 2010. [Google Scholar]

- Yu, Q.; Xiong, R.; Lin, C.; Shen, W.; Deng, J. Lithium-Ion Battery Parameters and State-of-Charge Joint Estimation Based on H-Infinity and Unscented Kalman Filters. IEEE Trans. Veh. Technol. 2017, 66, 8693–8701. [Google Scholar] [CrossRef]

- Guha, A.; Patra, A. State of Health Estimation of Lithium-Ion Batteries Using Capacity Fade and Internal Resistance Growth Models. IEEE Trans. Transp. Electrif. 2018, 4, 135–146. [Google Scholar] [CrossRef]

- Ramachandran, R.; Ganeshaperumal, D.; Subathra, B. Parameter Estimation of Battery Pack in EV using Extended Kalman Filters. In Proceedings of the 2019 IEEE International Conference on Clean Energy and Energy Efficient Electronics Circuit for Sustainable Development (INCCES), Krishnankoil, India, 18–20 December 2019; pp. 1–5. [Google Scholar] [CrossRef]

- Liuyi, L.; Wei, Y. State-of-Charge and State-of-Health Estimation for Lithium-Ion Batteries Based on Dual Fractional-Order Extended Kalman Filter and Online Parameter Identification. IEEE Access 2021, 9, 47588–47602. [Google Scholar] [CrossRef]

- Gholizadeh, M.; Salmasi, F.R. Estimation of State of Charge, Unknown Nonlinearities, and State of Health of a Lithium-Ion Battery Based on a Comprehensive Unobservable Model. IEEE Trans. Ind. Electron. 2014, 61, 1335–1344. [Google Scholar] [CrossRef]

- Remmlinger, J.; Buchholz, M.; Meiler, M.; Bernreuter, P.; Dietmayer, K. State-of-health monitoring of lithium-ion batteries in electric vehicles by on-board internal resistance estimation. J. Power Sources 2011, 196, 5357–5363. [Google Scholar] [CrossRef]

- Rossi, C.; Pontara, D.; Falcomer, C.; Bertoldi, M. Simplified Parameters Estimation forthe Dual Polarization Model of Lithium-Ion Cell. In Proceedings of the ELECTRIMACS 2019, Salerno, Italy, 21–23 May 2019; Zamboni, W., Petrone, G., Eds.; Lecture Notes in Electrical Engineering. Springer: Cham, Switzerland, 2020; Volume 697, pp. 129–144. [Google Scholar] [CrossRef]

- Gao, L.; Liu, S.; Dougal, R.A. Dynamic lithium-ion battery model for system simulation. IEEE Trans. Components Packag. Technol. 2002, 25, 495–505. [Google Scholar] [CrossRef] [Green Version]

- Gao, Z.; Chin, C.S.; Woo, W.L.; Jia, J.; Toh, W.D. Lithium-ion battery modeling and validation for smart power system. In Proceedings of the 2015 International Conference on Computer, Communications, and Control Technology (I4CT), Kuching, Malaysia, 21–23 April 2015; pp. 269–274. [Google Scholar] [CrossRef]

- Ahmed, R.; Gazzarri, J.; Onori, S.; Habibi, S.; Jackey, R.; Rzemien, K.; Tjong, J.; LeSage, J. Model-Based Parameter Identification of Healthy and Aged Li-ion Batteries for Electric Vehicle Applications. SAE Int. J. Altern. Powertrains 2015, 4, 233–247. [Google Scholar] [CrossRef] [Green Version]

- Damiano, A.; Musio, C.; Marongiu, I. Experimental validation of a dynamic energy model of a battery electric vehicle. In Proceedings of the 2015 International Conference on Renewable Energy Research and Applications (ICRERA), Palermo, Italy, 22–25 November 2015; pp. 803–808. [Google Scholar] [CrossRef]

- Haykin, S. Kalman Filtering and Neural Networks; John Wiley & Sons: New York, NY, USA, 2001. [Google Scholar]

- Plett, G.L. Extended Kalman filtering for battery management systems of LiPB-based HEV battery packs Part 1. Background. J. Power Sources 2004, 134, 252–261. [Google Scholar] [CrossRef]

- Plett, G.L. Extended Kalman filtering for battery management systems of LiPB-based HEV battery packs: Part 2. Modeling and identification. J. Power Sources 2004, 134, 262–276. [Google Scholar] [CrossRef]

- Han, J.; Kim, D.; Sunwoo, M. State-of-charge estimation of lead-acid batteries using an adaptive extended Kalman filter. J. Power Sources 2009, 188, 606–612. [Google Scholar] [CrossRef]

- Vasebi, A.; Partovibakhsh, M.; Bathaee, S.M.T. A novel combined battery model for state-of-charge estimation in lead-acid batteries based on extended Kalman filter for hybrid electric vehicle applications. J. Power Sources 2007, 174, 30–40. [Google Scholar] [CrossRef]

- Vasebi, A.; Bathaee, S.; Partovibakhsh, M. Predicting state of charge of lead-acid batteries for hybrid electric vehicles by extended Kalman filter. Energy Convers. Manag. 2008, 49, 75–82. [Google Scholar] [CrossRef]

- Liu, Z.; Li, Z.; Zhang, J.; Su, L.; Ge, H. Accurate and Efficient Estimation of Lithium-Ion Battery State of Charge with Alternate Adaptive Extended Kalman Filter and Ampere-Hour Counting Methods. Energies 2019, 12, 757. [Google Scholar] [CrossRef] [Green Version]

- Bhangu, B.S.; Bentley, P.; Stone, D.A.; Bingham, C.M. Observer techniques for estimating the state-of-charge and state-of-health of VRLABs for hybrid electric vehicles. In Proceedings of the 2005 IEEE Vehicle Power and Propulsion Conference, Chicago, IL, USA, 7–9 September 2005; 10p. [Google Scholar] [CrossRef] [Green Version]

- Zhang, F.; Liu, G.; Fang, L. A battery State of Charge estimation method with extended Kalman filter. In Proceedings of the 2008 IEEE/ASME International Conference on Advanced Intelligent Mechatronics, Xi’an, China, 2–5 July 2008; pp. 1008–1013. [Google Scholar] [CrossRef]

- He, H.; Qin, H.; Sun, X.; Shui, Y. Comparison Study on the Battery SoC Estimation with EKF and UKF Algorithms. Energies 2013, 6, 5088–5100. [Google Scholar] [CrossRef]

- Zarchan, P.; Musoff, H. Fundamentals of Kalman Filtering: A Practical Approach, 3rd ed.; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2009. [Google Scholar]

- Biswas, A.; Gu, R.; Kollmeyer, P.; Ahmed, R.; Emadi, A. Simultaneous State and Parameter Estimation of Li-Ion Battery with One State Hysteresis Model Using Augmented Unscented Kalman Filter. In Proceedings of the 2018 IEEE Transportation Electrification Conference and Expo (ITEC), Long Beach, CA, USA, 13–15 June 2018; pp. 1065–1070. [Google Scholar] [CrossRef]

- Yang, S.; Zhou, S.; Hua, Y.; Zhou, X.; Liu, X.; Pan, Y.; Ling, H.; Wu, B. A parameter adaptive method for state of charge estimation of lithium-ion batteries with an improved extended Kalman filter. Sci. Rep. 2021, 11, 2045–2322. [Google Scholar] [CrossRef]

- He, H.; Xiong, R.; Zhang, X.; Sun, F.; Fan, J. State-of-Charge Estimation of the Lithium-Ion Battery Using an Adaptive Extended Kalman Filter Based on an Improved Thevenin Model. IEEE Trans. Veh. Technol. 2011, 60, 1461–1469. [Google Scholar] [CrossRef]

- Xia, B.; Wang, H.; Tian, Y.; Wang, M.; Sun, W.; Xu, Z. State of Charge Estimation of Lithium-Ion Batteries Using an Adaptive Cubature Kalman Filter. Energies 2015, 8, 5916–5936. [Google Scholar] [CrossRef] [Green Version]

- Ayzah, A.N.; Joelianto, E.; Widyotriatmo, A. State of Charge (SoC) and State of Health (SoH) Estimation of Lithium-Ion Battery Using Dual Extended Kalman Filter Based on Polynomial Battery Model. In Proceedings of the 2019 6th International Conference on Instrumentation, Control, and Automation (ICA), Bandung, Indonesia, 31 July–2 August 2019; pp. 88–93. [Google Scholar] [CrossRef]

- Nikolaos, W.; Adermann, J.; Frericks, A.; Pak, M.; Reiter, C.; Lohmann, B.; Lienkamp, M. Revisiting the dual extended Kalman filter for battery state-of-charge and state-of-health estimation: A use-case life cycle analysis. J. Energy Storage 2018, 19, 73–87. [Google Scholar] [CrossRef]

- Goldberg, D.E. Genetic Algorithms in Search, Optimization and Machine Learning; Addison-Wesley: Boston, MA, USA, 1989. [Google Scholar]

- Sivanandam, S.N.; Deepa, S.N. Introduction to Genetic Algorithms; Springer: Berlin/Heidelberg, Germany; New York, NY, USA, 2007. [Google Scholar]

- Ahmad, F.; Isa, N.A.M.; Osman, M.K.; Hussain, Z. Performance comparison of gradient descent and Genetic Algorithm based Artificial Neural Networks training. In Proceedings of the 2010 10th International Conference on Intelligent Systems Design and Applications, Cairo, Egypt, 29 November–1 December 2010; pp. 604–609. [Google Scholar] [CrossRef]

- Hu, X.; Feng, F.; Liu, K.; Zhang, L.; Xie, J.; Liu, B. State estimation for advanced battery management: Key challenges and future trends. Renew. Sustain. Energy Rev. 2019, 114, 109334. [Google Scholar] [CrossRef]

| Power Supply | TDK-Lambda GEN60-40 |

| Electronic Load | BK Precision 8514 |

| Wattmeter | Yokogawa WT310EH |

| Cryostat | Jeio Tech RW3-0525P |

| Controller | NI cRIO-9066 |

| Test | Cell Name | Cycle Number | Avg Verr [%] |

|---|---|---|---|

| 1“Cycle A” | LG“INR2170050T” | 1 | 0.94 |

| 2“Cycle A” | LG“INR2170050T” | 100 | 0.59 |

| 3“Cycle A” | LG“INR2170050T” | 200 | 0.40 |

| 4“Cycle A” | SAMSUNG“INR2170050E” | 1 | 0.76 |

| 5“Cycle A” | SAMSUNG“INR2170050E” | 100 | 0.97 |

| 5“Cycle A” | SAMSUNG“INR2170050E” | 300 | 0.84 |

| 6“Cycle A” | SAMSUNG“INR2170050E” | 500 | 1.04 |

| 7“Cycle A” | MOLICEL“INR21700P42A” | 1 | 0.83 |

| Filter Type | Model Type | State Variables | Covariances , | Methodology | Voltage Error | Reference |

|---|---|---|---|---|---|---|

| AKF | Thevenin | [1] [1] | adaptive estimation | Max < 20% Avg N/A | [24] | |

| EKF | RC model | [, , Vb, ] | N/A | Max < 5% Avg N/A | [25] | |

| EKF | RC model | [, , Vb, ] | 10−4][10] | N/A | Max < 4% Avg N/A | [26] |

| EKF | SP model | [SOC, ] | N/A | computed each iteration | Max < 5% Avg < 2% | [27] |

| EKF | SP model | [SOC, ] | N/A | Max < 10% Avg < 5% | [12] | |

| EKF | SP model | [, ] | [28] | Max < 2% Avg N/A | [29] | |

| EKF | SP model | [, ] | N/A | N/A | Max < 10% Avg 0.17% | [30] |

| DEKF | SP model | [, ] [, C, , ] | [31] | Max < 2% Avg N/A% | [4] | |

| I EKF | SP model | N/A | improve method [32] | Max < 1.4% Avg N/A% | [33] | |

| EKF | DP model | N/A | N/A | Max < 4.8% Avg 0.06% | [34] | |

| ACKF | DP model | [, , ] | N/A | adaptive estimation | Max < 2.2% Avg N/A% | [35] |

| AEKF | DP model | [, , ] | adaptive estimation | Max < 2.2% Avg N/A% | [34] | |

| DEKF | DP model | R2, C2] | 10−9, 10−3] [5 × 10−7][0.0013] | [31] | Max < 2% Avg N/A% | [4] |

| DEKF | DP model | N/A | N/A | Max < 1% Avg N/A% | [36] | |

| DEKF | DP model | numerical optimization | Max < 1% Avg N/A% | [37] |

| Population m | 20 |

| Children l | 4 |

| Mutation Probability p | |

| Mutation Range | |

| Fitness Target | |

| Last Generation | 1000 |

| Cell | Cycles | |||||

|---|---|---|---|---|---|---|

| LG | 1-A | |||||

| SAMSUNG | 1-A | |||||

| MOLICEL | 1-A |

| Manufacturer | Cycles Number | RMSE (19) (ppm) | ME (21) (ppm) | MAE (23) (%) |

|---|---|---|---|---|

| LG | 1-A | 80.41 | 3.52 | 0.19 |

| LG | 1-B | 65.17 | 1.94 | 0.07 |

| LG | 1-C | 78.53 | 0.77 | 0.09 |

| Molicell | 1-A | 58.18 | −1.73 | 0.29 |

| Molicell | 1-B | 61.12 | −2.39 | 0.06 |

| Molicell | 1-C | 54.69 | −0.25 | 0.05 |

| Samsung | 1-A | 57.72 | −3.30 | 0.17 |

| Manufacturer | Cycles Number | RMSE (19) (ppm) | ME (21) (ppm) | MAE (23) (%) |

|---|---|---|---|---|

| LG | 1-A | 4.80 | 1.80 | 41.11 |

| LG | 1-B | 5.61 | 1.84 | 41.70 |

| LG | 1-C | 21.28 | −3.17 | 82.50 |

| Molicell | 1-A | 12.80 | −1.17 | 58.38 |

| Molicell | 1-B | 8.02 | −1.34 | 89.50 |

| Molicell | 1-C | 19.13 | −10.55 | 61.74 |

| Samsung | 1-A | 4.14 | 2.18 | 51.35 |

| Manufacturer | Cycles Number | RMSE (19) (ppm) | ME (21) (ppm) | MAE (23) (%) |

|---|---|---|---|---|

| LG | 100-B | 65.15 | −3.86 | 0.23 |

| LG | 200-B | 61.49 | −4.33 | 0.09 |

| Samsung | 100-A | 66.69 | −4.86 | 0.21 |

| Samsung | 300-A | 69.68 | −5.43 | 0.24 |

| Samsung | 500-A | 60.29 | −2.61 | 0.16 |

| Samsung | 500-B | 58.83 | −1.79 | 0.10 |

| Samsung | 500-C | 56.94 | −2.84 | 0.09 |

| Manufacturer | Cycles Number | RMSE (19) (ppm) | ME (21) (ppm) | MAE (23) (%) |

|---|---|---|---|---|

| LG | 100-B | 2.83 | −1.62 | 56.51 |

| LG | 200-B | 3.60 | −0.91 | 60.78 |

| Samsung | 100-A | 3.00 | 0.53 | 46.85 |

| Samsung | 300-A | 3.19 | 1.68 | 53.27 |

| Samsung | 500-A | 5.40 | 1.95 | 57.08 |

| Samsung | 500-B | 5.32 | 4.20 | 57.08 |

| Samsung | 500-C | 3.50 | 2.63 | 57.08 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rossi, C.; Falcomer, C.; Biondani, L.; Pontara, D. Genetically Optimized Extended Kalman Filter for State of Health Estimation Based on Li-Ion Batteries Parameters. Energies 2022, 15, 3404. https://doi.org/10.3390/en15093404

Rossi C, Falcomer C, Biondani L, Pontara D. Genetically Optimized Extended Kalman Filter for State of Health Estimation Based on Li-Ion Batteries Parameters. Energies. 2022; 15(9):3404. https://doi.org/10.3390/en15093404

Chicago/Turabian StyleRossi, Claudio, Carlo Falcomer, Luca Biondani, and Davide Pontara. 2022. "Genetically Optimized Extended Kalman Filter for State of Health Estimation Based on Li-Ion Batteries Parameters" Energies 15, no. 9: 3404. https://doi.org/10.3390/en15093404

APA StyleRossi, C., Falcomer, C., Biondani, L., & Pontara, D. (2022). Genetically Optimized Extended Kalman Filter for State of Health Estimation Based on Li-Ion Batteries Parameters. Energies, 15(9), 3404. https://doi.org/10.3390/en15093404