Emission and Performance Evaluation of a Diesel Engine Using Addition of Ethanol to Diesel/Biodiesel Fuel Blend

Abstract

:1. Introduction

2. Materials and Methods

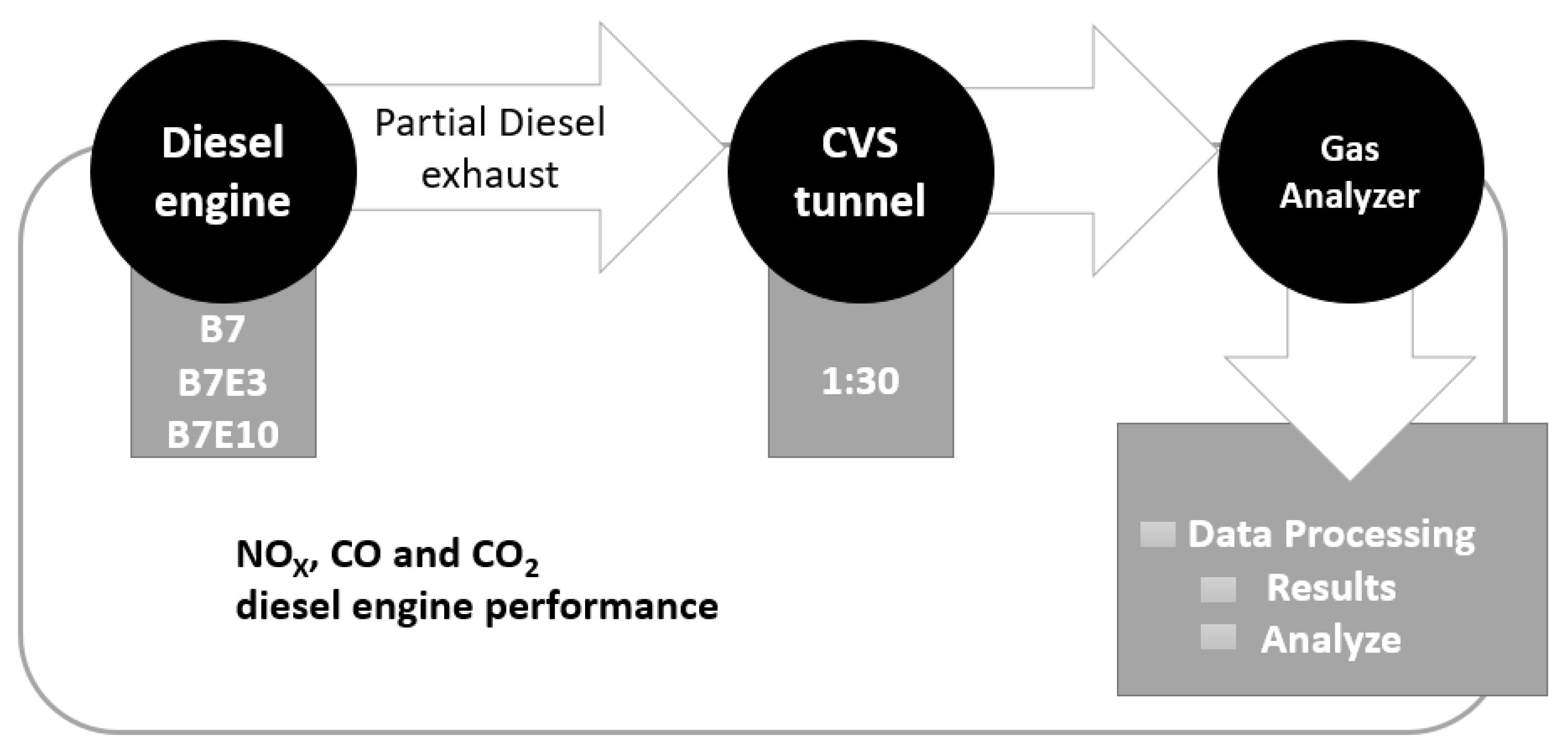

2.1. Experimental Setup

2.2. Experimental Procedure

3. Results

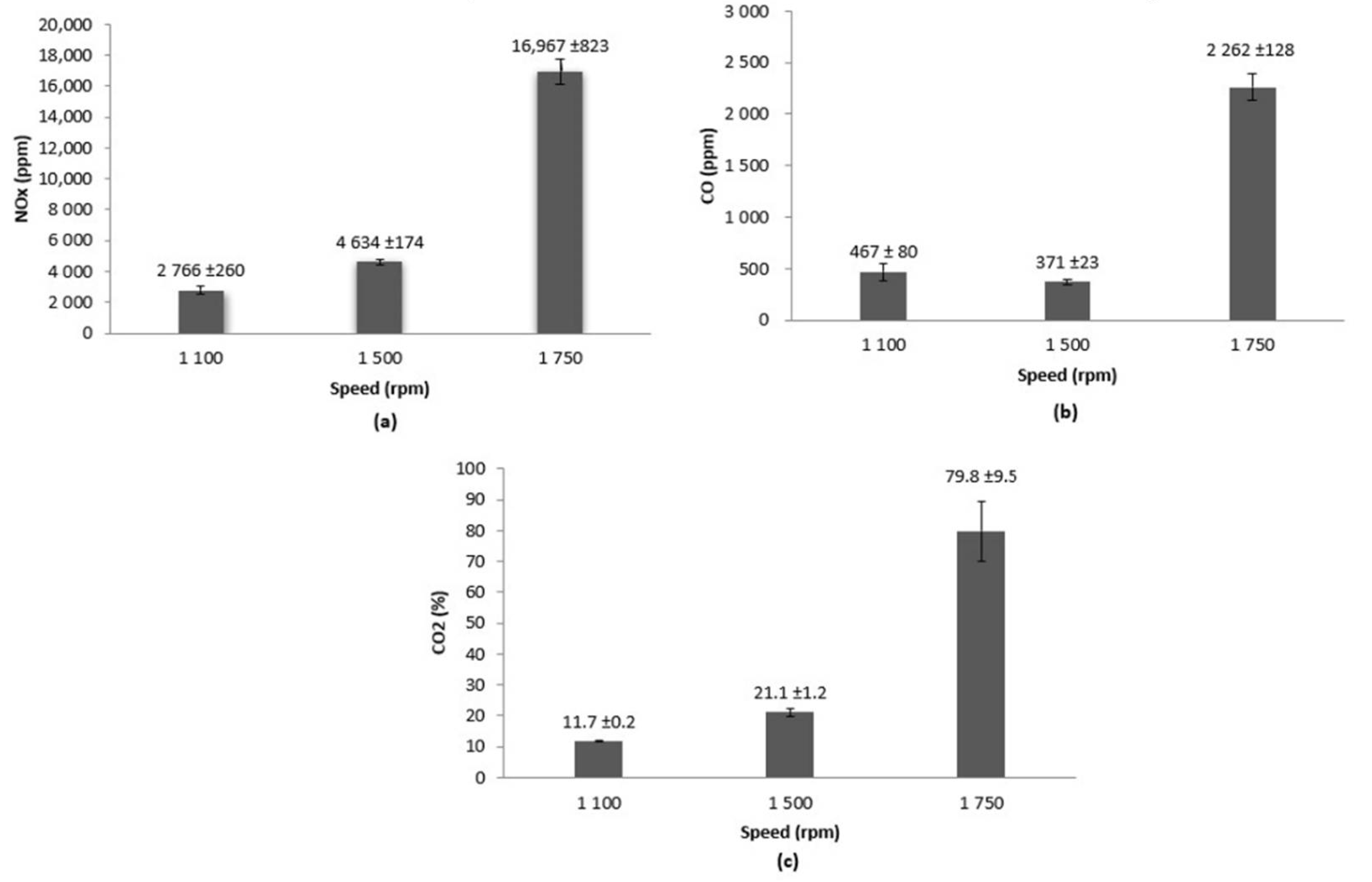

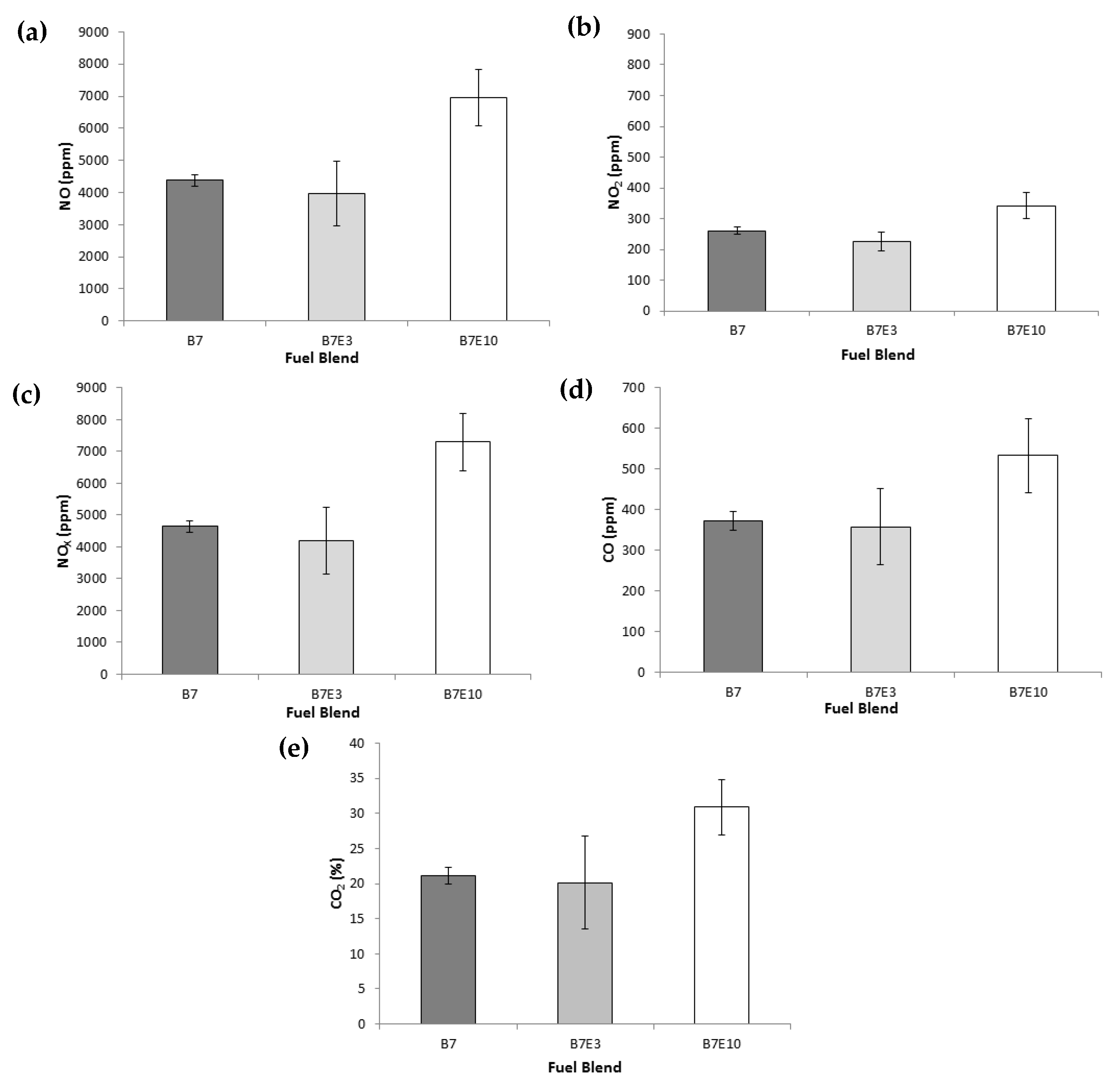

3.1. Evaluation of NOX, CO and CO2

3.2. Evaluation of Diesel Engine Performance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Uyumaz, A.; Aydoğan, B.; Yılmaz, E.; Solmaz, H.; Aksoy, F.; Mutlu, I.; Ipci, D.; Calam, A. Experimental investigation on the combustion, performance and exhaust emission characteristics of poppy oil biodiesel-diesel dual fuel combustion in a CI engine. Fuel 2020, 280, 118588. [Google Scholar] [CrossRef]

- Guarieiro, L.L.N.; Pereira, P.A.D.P.; Torres, E.A.; da Rocha, G.O.; de Andrade, J.B. Carbonyl compounds emitted by a diesel engine fuelled with diesel and biodiesel–diesel blends: Sampling optimization and emissions profile. Atmos. Environ. 2008, 42, 8211–8218. [Google Scholar] [CrossRef] [Green Version]

- Rezende, M.; de Lima, A.L.; Silva, B.; Mota, C.; Torres, E.; da Rocha, G.; Cardozo, I.; Costa, K.; Guarieiro, L.; Pereira, P.; et al. Biodiesel: An Overview II. J. Braz. Chem. Soc. 2021, 32, 1301–1344. [Google Scholar] [CrossRef]

- Pinto, A.C.; Guarieiro, L.L.N.; Rezende, M.J.C.; Ribeiro, N.M.; Torres, E.A.; Lopes, W.A.; Pereira, P.A.D.P.; De Andrade, J.B. Biodiesel: An overview. J. Braz. Chem. Soc. 2005, 16, 1313–1330. [Google Scholar] [CrossRef] [Green Version]

- Samuel, O.D.; Kaveh, M.; Oyejide, O.J.; Elumalai, P.; Verma, T.N.; Nisar, K.S.; Saleel, C.A.; Afzal, A.; Fayomi, O.; Owamah, H.; et al. Performance comparison of empirical model and Particle Swarm Optimization & its boiling point prediction models for waste sunflower oil biodiesel. Case Stud. Therm. Eng. 2022, 33, 101947. [Google Scholar] [CrossRef]

- Mohebbi, M.; Reyhanian, M.; Hosseini, V.; Said, M.F.M.; Aziz, A.A. The effect of diethyl ether addition on performance and emission of a reactivity controlled compression ignition engine fueled with ethanol and diesel. Energy Convers. Manag. 2018, 174, 779–792. [Google Scholar] [CrossRef]

- Ardebili, S.M.S.; Calam, A.; Yılmaz, E.; Solmaz, H. A comparative analysis of the engine performance and exhaust emissions characteristics of a diesel engine fueled with Mono ethylene glycol supported emulsion. Fuel 2020, 288, 119723. [Google Scholar] [CrossRef]

- Solmaz, H.; Ardebili, S.M.S.; Calam, A.; Yılmaz, E.; Ipci, D. Prediction of performance and exhaust emissions of a CI engine fueled with multi-wall carbon nanotube doped biodiesel-diesel blends using response surface method. Energy 2021, 227, 120518. [Google Scholar] [CrossRef]

- Çakmak, A.; Özcan, H. Analysis of combustion and emissions characteristics of a DI diesel engine fuelled with diesel/biodiesel/glycerol tert-butyl ethers mixture by altering compression ratio and injection timing. Fuel 2022, 315, 123200. [Google Scholar] [CrossRef]

- Oprescu, E.-E.; Dragomir, R.E.; Radu, E.; Radu, A.; Velea, S.; Bolocan, I.; Stepan, E.; Rosca, P. Performance and emission characteristics of diesel engine powered with diesel–glycerol derivatives blends. Fuel Process. Technol. 2014, 126, 460–468. [Google Scholar] [CrossRef]

- Guarieiro, L.L.N.; de Almeida Guerreiro, E.T.; dos Santos Amparo, K.K.; Manera, V.B.; Regis, A.C.D.; Santos, A.G.; Ferreira, V.P.; Leão, D.J.; Torres, E.A.; de Andrade, J.B. Assessment of the use of oxygenated fuels on emissions and performance of a diesel engine. Microchem. J. 2014, 117, 94–99. [Google Scholar] [CrossRef]

- Guarieiro, L.L.N.; de Souza, A.F.; Torres, E.A.; de Andrade, J.B. Emission profile of 18 carbonyl compounds, CO, CO2, and NOx emitted by a diesel engine fuelled with diesel and ternary blends containing diesel, ethanol and biodiesel or vegetable oils. Atmos. Environ. 2009, 43, 2754–2761. [Google Scholar] [CrossRef]

- Tutak, W.; Jamrozik, A.; Pyrc, M.; Sobiepański, M. A comparative study of co-combustion process of diesel-ethanol and biodiesel-ethanol blends in the direct injection diesel engine. Appl. Therm. Eng. 2017, 117, 155–163. [Google Scholar] [CrossRef]

- Shirneshan, A.; Bagherzadeh, S.A.; Najafi, G.; Mamat, R.; Mazlan, M. Optimization and investigation the effects of using biodiesel-ethanol blends on the performance and emission characteristics of a diesel engine by genetic algorithm. Fuel 2021, 289, 119753. [Google Scholar] [CrossRef]

- Liang, J.; Zhang, Q.; Chen, Z.; Zheng, Z.; Yang, C.; Ma, Q. The combustion and emission characteristics of diesel-ethanol blends with THF as cosolvents in a diesel engine operating with EGR. Fuel 2021, 298, 120843. [Google Scholar] [CrossRef]

- Kumar, K.S.; Raj, R.T.K. Effect of Di-Tertiary Butyl Peroxide on the performance, combustion and emission characteristics of ethanol blended cotton seed methyl ester fuelled automotive diesel engine. Energy Convers. Manag. 2016, 127, 1–10. [Google Scholar] [CrossRef]

- Mofijur, M.; Rasul, M.G.; Hyde, J.; Azad, A.K.; Mamat, R.; Bhuiya, M.M.K. Role of biofuel and their binary (diesel–biodiesel) and ternary (ethanol–biodiesel–diesel) blends on internal combustion engines emission reduction. Renew. Sustain. Energy Rev. 2016, 53, 265–278. [Google Scholar] [CrossRef] [Green Version]

- Aydın, F.; Öğüt, H. Effects of using ethanol-biodiesel-diesel fuel in single cylinder diesel engine to engine performance and emissions. Renew. Energy 2017, 103, 688–694. [Google Scholar] [CrossRef]

- De Oliveira, A.; de Morais, A.M.; Valente, O.S.; Sodre, J.R. Combustion characteristics, performance and emissions from a diesel power generator fuelled by B7-ethanol blends. Fuel Process. Technol. 2015, 139, 67–72. [Google Scholar] [CrossRef]

- Tse, H.; Leung, C.W.; Cheung, C.S. Investigation on the combustion characteristics and particulate emissions from a diesel engine fueled with diesel-biodiesel-ethanol blends. Energy 2015, 83, 343–350. [Google Scholar] [CrossRef]

- Sittichompoo, S.; Theinnoi, K.; Sawatmongkhon, B.; Wongchang, T.; Iamcheerangkoon, T.; Phugot, S. Promotion effect of hydrogen addition in selective catalytic reduction of nitrogen oxide emissions from diesel engines fuelled with diesel-biodiesel-ethanol blends. Alex. Eng. J. 2021, 61, 5383–5395. [Google Scholar] [CrossRef]

- Venu, H.; Raju, V.D.; Lingesan, S.; Soudagar, M.E.M. Influence of Al2O3nano additives in ternary fuel (diesel-biodiesel-ethanol) blends operated in a single cylinder diesel engine: Performance, combustion and emission characteristics. Energy 2021, 215, 119091. [Google Scholar] [CrossRef]

- Labeckas, G.; Slavinskas, S.; Mažeika, M. The effect of ethanol–diesel–biodiesel blends on combustion, performance and emissions of a direct injection diesel engine. Energy Convers. Manag. 2014, 79, 698–720. [Google Scholar] [CrossRef]

- Samuel, O.D.; Okwu, M.; Oyejide, O.J.; Taghinezhad, E.; Afzal, A.; Kaveh, M. Optimizing biodiesel production from abundant waste oils through empirical method and grey wolf optimizer. Fuel 2020, 281, 118701. [Google Scholar] [CrossRef]

- Samuel, O.D.; Waheed, M.A.; Taheri-Garavand, A.; Verma, T.N.; Dairo, O.U.; Bolaji, B.O.; Afzal, A. Prandtl number of optimum biodiesel from food industrial waste oil and diesel fuel blend for diesel engine. Fuel 2021, 285, 119049. [Google Scholar] [CrossRef]

- ANP. Preços de Produtores e Importadores de Derivados de Petróleo e Biodiesel. 2022. Available online: https://www.gov.br/anp/pt-br/assuntos/precos-e-defesa-da-concorrencia/precos/precos-de-produtores-e-importadores-de-derivados-de-petroleo (accessed on 4 April 2022).

- Figueiredo, B.B.; César, F.I.G. Comparative study of the efficiency in the production of second generation alcohol. Revista Científica Acertte. 2021, 1, 1–18. Available online: https://acertte.org/index.php/acertte/article/view/43/32 (accessed on 21 March 2022). [CrossRef]

- Man, X.; Cheung, C.; Ning, Z.; Wei, L.; Huang, Z. Influence of engine load and speed on regulated and unregulated emissions of a diesel engine fueled with diesel fuel blended with waste cooking oil biodiesel. Fuel 2016, 180, 41–49. [Google Scholar] [CrossRef]

- Datta, A.; Mandal, B. Impact of alcohol addition to diesel on the performance combustion and emissions of a compression ignition engine. Appl. Therm. Eng. 2016, 98, 670–682. [Google Scholar] [CrossRef]

- Lapuerta, M.; Armas, O.; Herreros, J. Emissions from a diesel–bioethanol blend in an automotive diesel engine. Fuel 2008, 87, 25–31. [Google Scholar] [CrossRef]

- Buyukkaya, E. Effects of biodiesel on a DI diesel engine performance, emission and combustion characteristics. Fuel 2010, 89, 3099–3105. [Google Scholar] [CrossRef]

- Mofijur, M.; Rasul, M.; Hyde, J. Recent Developments on Internal Combustion Engine Performance and Emissions Fuelled With Biodiesel-Diesel-Ethanol Blends. Procedia Eng. 2015, 105, 658–664. [Google Scholar] [CrossRef] [Green Version]

- Shaafi, T.; Velraj, R. Influence of alumina nanoparticles, ethanol and isopropanol blend as additive with diesel–soybean biodiesel blend fuel: Combustion, engine performance and emissions. Renew. Energy 2015, 80, 655–663. [Google Scholar] [CrossRef]

- Shi, X.; Yu, Y.; He, H.; Shuai, S.; Wang, J.; Li, R. Emission characteristics using methyl soyate–ethanol–diesel fuel blends on a diesel engine. Fuel 2005, 84, 1543–1549. [Google Scholar] [CrossRef]

- Agarwal, A.K. Biofuels (alcohols and biodiesel) applications as fuels for internal combustion engines. Prog. Energy Combust. Sci. 2007, 33, 233–271. [Google Scholar] [CrossRef]

- Bhale, P.V.; Deshpande, N.; Thombre, S.B. Improving the low temperature properties of biodiesel fuel. Renew. Energy 2009, 34, 794–800. [Google Scholar] [CrossRef]

- Ansari, N.A.; Sharma, A.; Singh, Y. Performance and emission analysis of a diesel engine implementing polanga biodiesel and optimization using Taguchi method. Process Saf. Environ. Prot. 2018, 120, 146–154. [Google Scholar] [CrossRef]

- Xing-Cai, L.; Jian-Guang, Y.; Wu-Gao, Z.; Zhen, H. Effect of cetane number improver on heat release rate and emissions of high speed diesel engine fueled with ethanol–diesel blend fuel. Fuel 2004, 83, 2013–2020. [Google Scholar] [CrossRef]

- Barabás, I.; Todoruţ, A.; Băldean, D. Performance and emission characteristics of an CI engine fueled with diesel–biodiesel–bioethanol blends. Fuel 2010, 89, 3827–3832. [Google Scholar] [CrossRef]

- Kowalewicz, A. Eco-diesel engine fuelled with rapeseed oil methyl ester and ethanol. Part 1: Efficiency and emission. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2005, 219, 715–723. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, J.; Tian, J.; Dong, R.; Zou, Z.; Gao, S.; Tan, D. Performance, combustion and emission characteristics investigations on a diesel engine fueled with diesel/ethanol/n-butanol blends. Energy 2022, 249, 123733. [Google Scholar] [CrossRef]

- Priyadharsini, P.; Dawn, S.; Arun, J. Four stroke diesel engine performance and emission studies of ethanol recovered from Kappaphycus alvarezii reject-solid food waste mixed substrates and its blends. Chemosphere 2021, 291, 132689. [Google Scholar] [CrossRef] [PubMed]

- Putrasari, Y.; Nur, A.; Muharam, A. Performance and Emission Characteristic on a Two Cylinder DI Diesel Engine Fuelled with Ethanol-Diesel Blends. Energy Procedia 2013, 32, 21–30. [Google Scholar] [CrossRef] [Green Version]

- Hulwan, D.B.; Joshi, S.V. Performance, emission and combustion characteristic of a multicylinder DI diesel engine running on diesel–ethanol–biodiesel blends of high ethanol content. Appl. Energy 2011, 88, 5042–5055. [Google Scholar] [CrossRef]

- Redel-Macías, M.; Leiva-Candia, D.; Soriano, J.; Herreros, J.; Cubero-Atienza, A.; Pinzi, S. Influence of Short Carbon-Chain Alcohol (Ethanol and 1-Propanol)/Diesel Fuel Blends over Diesel Engine Emissions. Energies 2021, 14, 1309. [Google Scholar] [CrossRef]

- Al-Esawi, N.; Al Qubeissi, M.; Kolodnytska, R. The Impact of Biodiesel Fuel on Ethanol/Diesel Blends. Energies 2019, 12, 1804. [Google Scholar] [CrossRef] [Green Version]

| Characteristics | B7 a | B7E3 | B7E10 | Standard |

|---|---|---|---|---|

| Density (20 °C kg/m3) | 836.7 | 835.7 | 830.9 | 815.0 to 850.0 * |

| Viscosity (40 °C mm2/s) | 2.70 | 2.47 | 2.30 | 2.0 to 4.5 ** |

| Cetane number [11] | ~48 | ~41 | - | 45 a |

| Latent heat of vaporization (kJ·kg−1) [11] | ~270 | ~350 | - | 250 a |

| Lower calorific value (kJ·kg−1) [11] | ~42.82 | ~41.73 | - | 43 a |

| Renewable fuel content (%) | 7 | 10 | 17 | - |

| Features | Engine |

|---|---|

| Power (Stand-by—1500 rpm—cv/kW/kVA) | 80/60/66 |

| Total displacement (L) | 3.87 |

| Number of cylinders | four, in line |

| Combustion system | four-strokes, direct-injection |

| Induction system | Turbocharged |

| Compression ratio | 15:1 |

| Engine cooling | Liquid |

| Operation temperature (°C) | 77/95 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Freitas, E.S.d.C.; Guarieiro, L.L.N.; da Silva, M.V.I.; Amparo, K.K.d.S.; Machado, B.A.S.; Guerreiro, E.T.d.A.; de Jesus, J.F.C.; Torres, E.A. Emission and Performance Evaluation of a Diesel Engine Using Addition of Ethanol to Diesel/Biodiesel Fuel Blend. Energies 2022, 15, 2988. https://doi.org/10.3390/en15092988

Freitas ESdC, Guarieiro LLN, da Silva MVI, Amparo KKdS, Machado BAS, Guerreiro ETdA, de Jesus JFC, Torres EA. Emission and Performance Evaluation of a Diesel Engine Using Addition of Ethanol to Diesel/Biodiesel Fuel Blend. Energies. 2022; 15(9):2988. https://doi.org/10.3390/en15092988

Chicago/Turabian StyleFreitas, Emmanuelle Soares de Carvalho, Lílian Lefol Nani Guarieiro, Marcus Vinícius Ivo da Silva, Keize Katiane dos Santos Amparo, Bruna Aparecida Souza Machado, Egidio Teixeira de Almeida Guerreiro, José Fernando Carneiro de Jesus, and Ednildo Andrade Torres. 2022. "Emission and Performance Evaluation of a Diesel Engine Using Addition of Ethanol to Diesel/Biodiesel Fuel Blend" Energies 15, no. 9: 2988. https://doi.org/10.3390/en15092988

APA StyleFreitas, E. S. d. C., Guarieiro, L. L. N., da Silva, M. V. I., Amparo, K. K. d. S., Machado, B. A. S., Guerreiro, E. T. d. A., de Jesus, J. F. C., & Torres, E. A. (2022). Emission and Performance Evaluation of a Diesel Engine Using Addition of Ethanol to Diesel/Biodiesel Fuel Blend. Energies, 15(9), 2988. https://doi.org/10.3390/en15092988