Experimental and Numerical Analysis of Rotor–Rotor Interaction Characteristics inside a Multistage Transonic Axial Compressor

Abstract

:1. Introduction

2. The Scope of Paper

- (1)

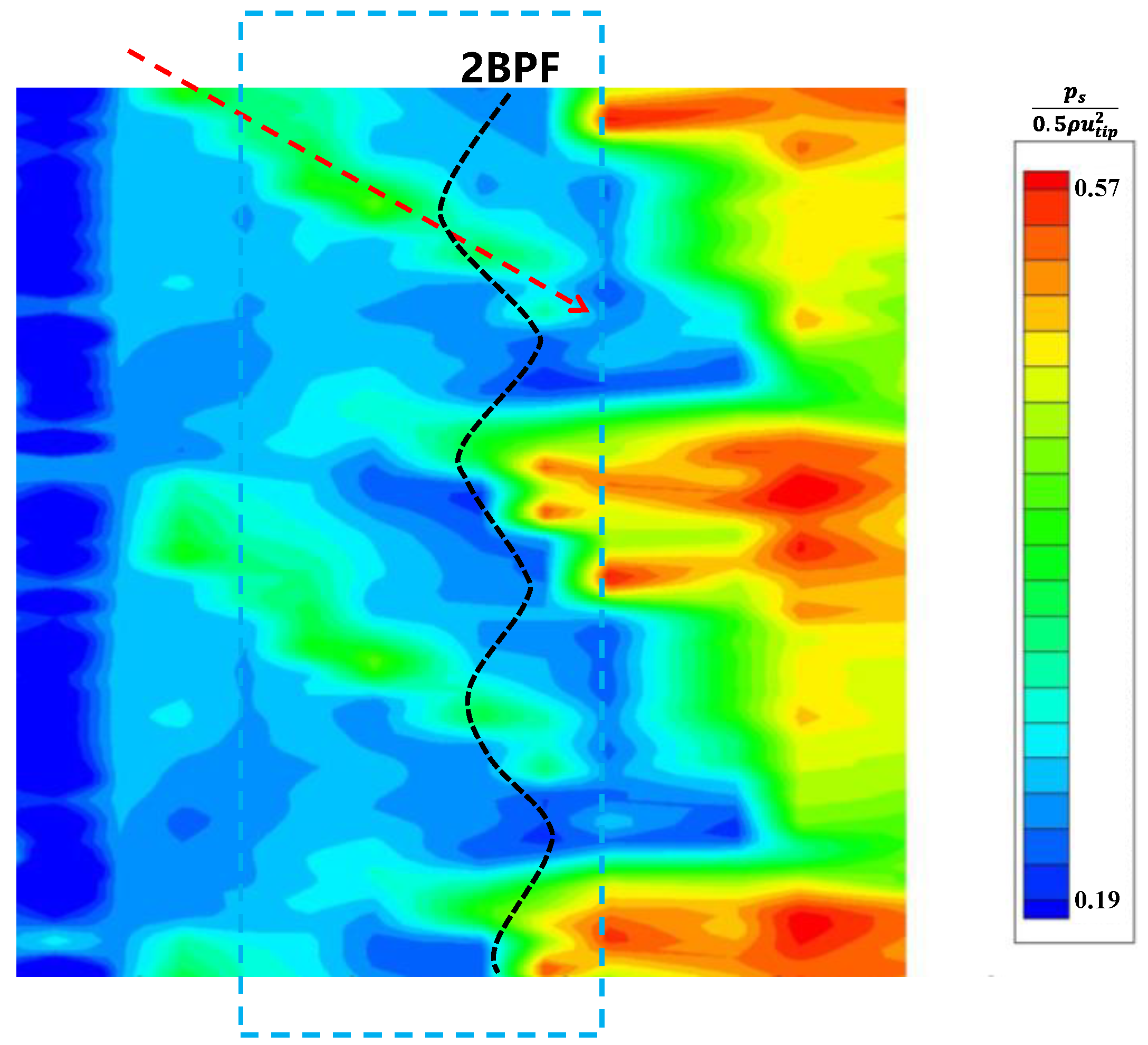

- The axial propagation characteristics of the R1 disturbances within the R2 passage, especially for a special shock wave-related R1-2BPF disturbance;

- (2)

- The circumferential propagation characteristics of the R1 disturbances within the R2 passage and its mechanisms;

- (3)

- The influence of the operation condition on the propagation of R1 disturbances within R2.

3. Experimental and Numerical Methods

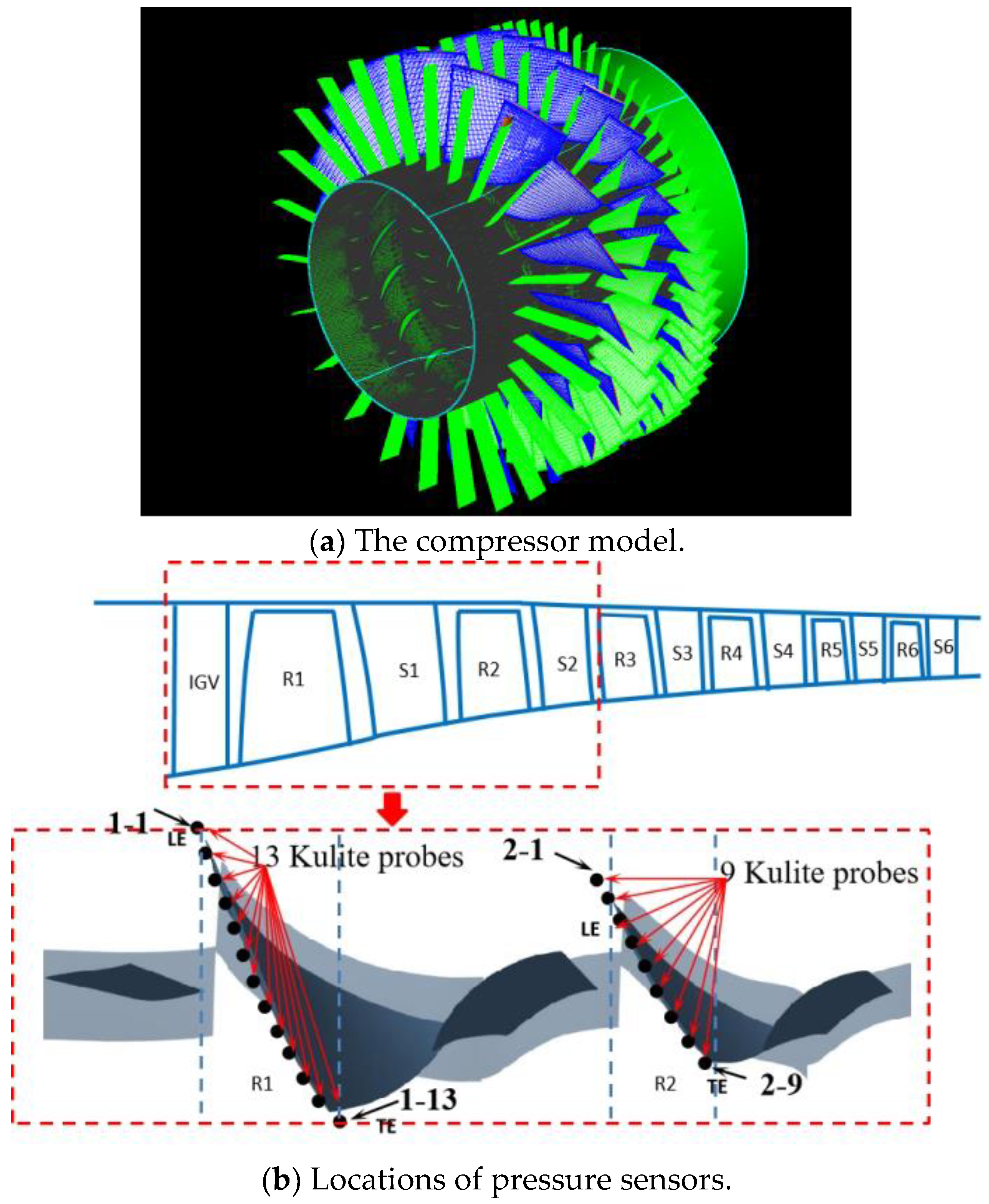

3.1. Experimental Approaches

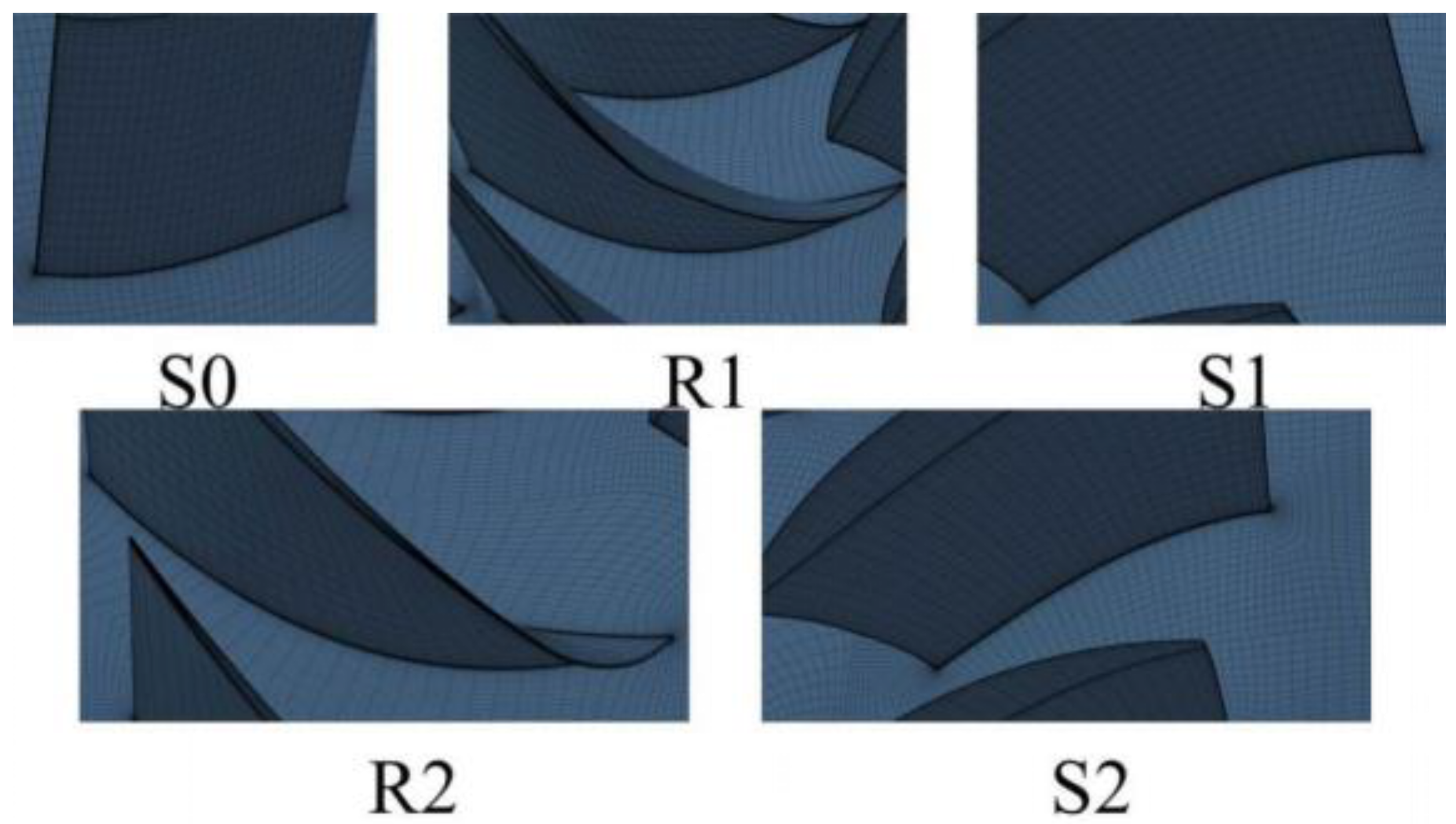

3.2. Numerical Methods

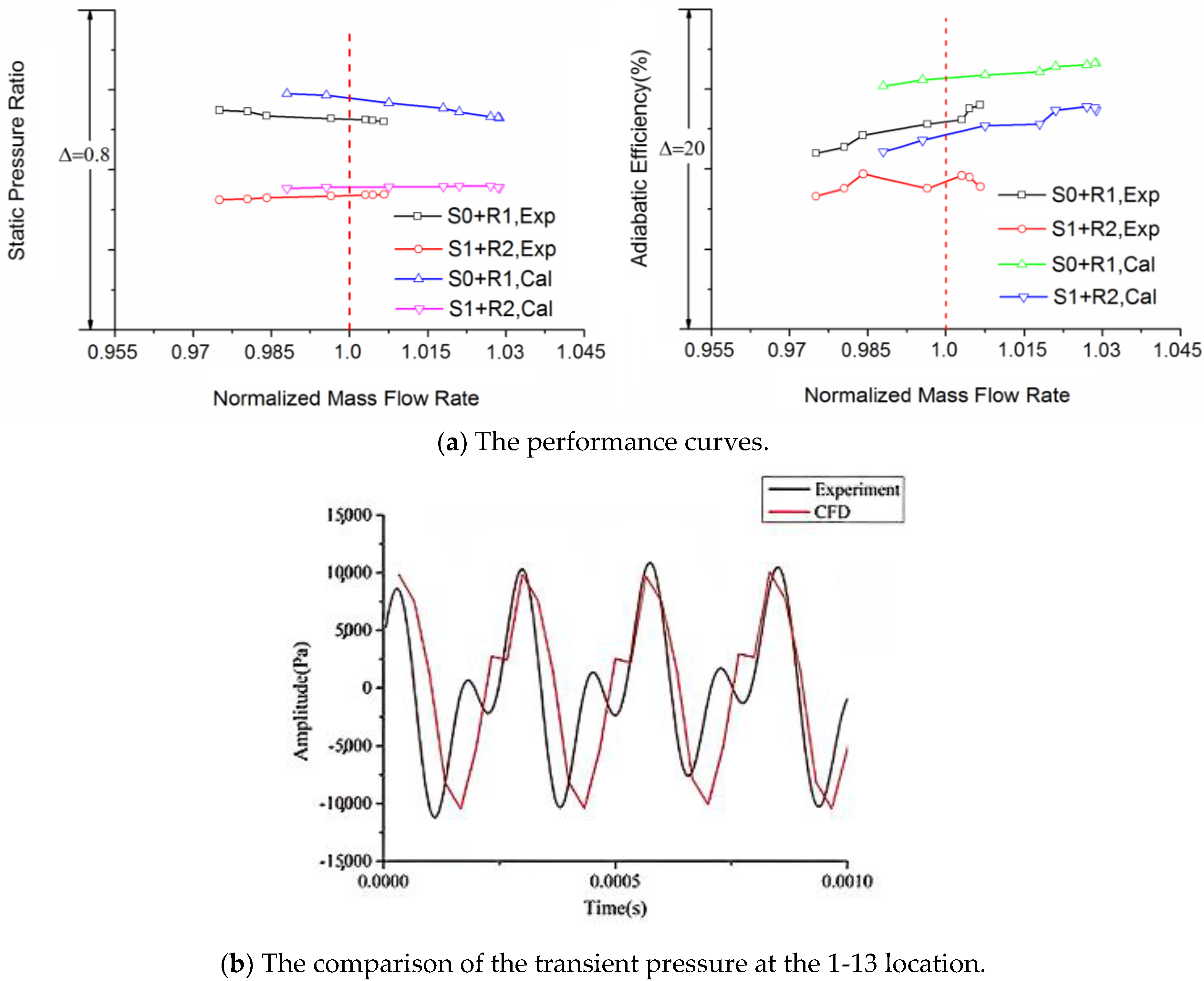

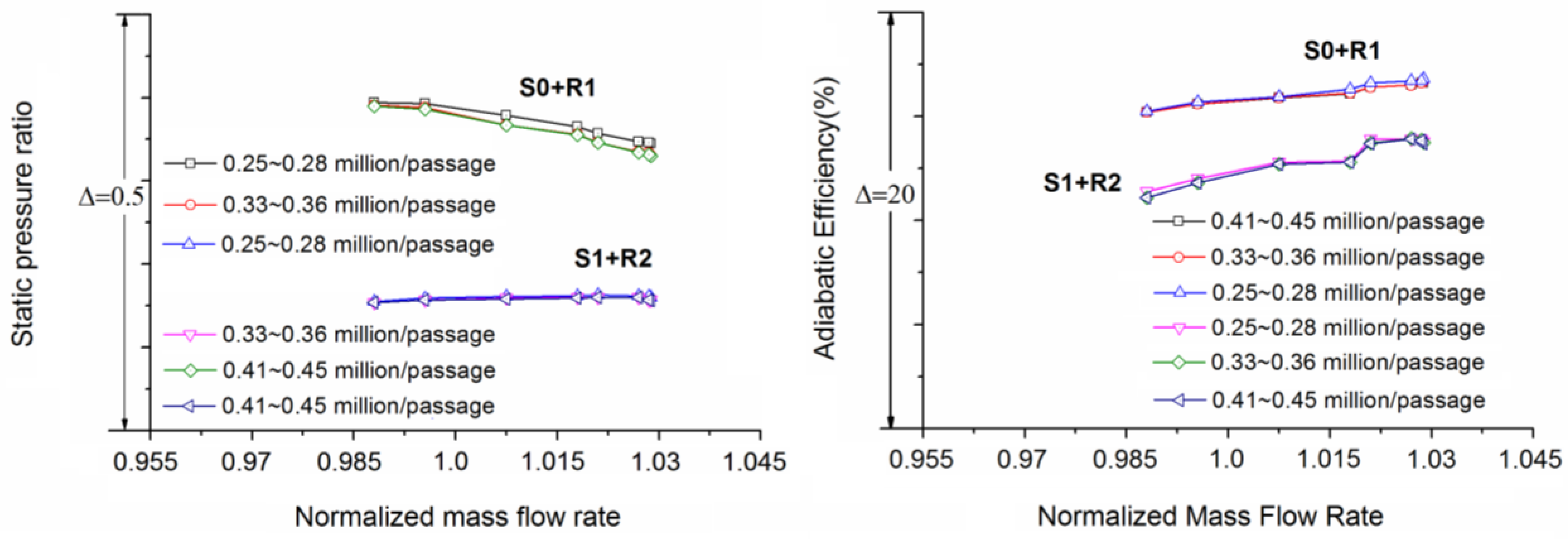

3.3. Validation of the Numerical Method

4. Results and Discussions

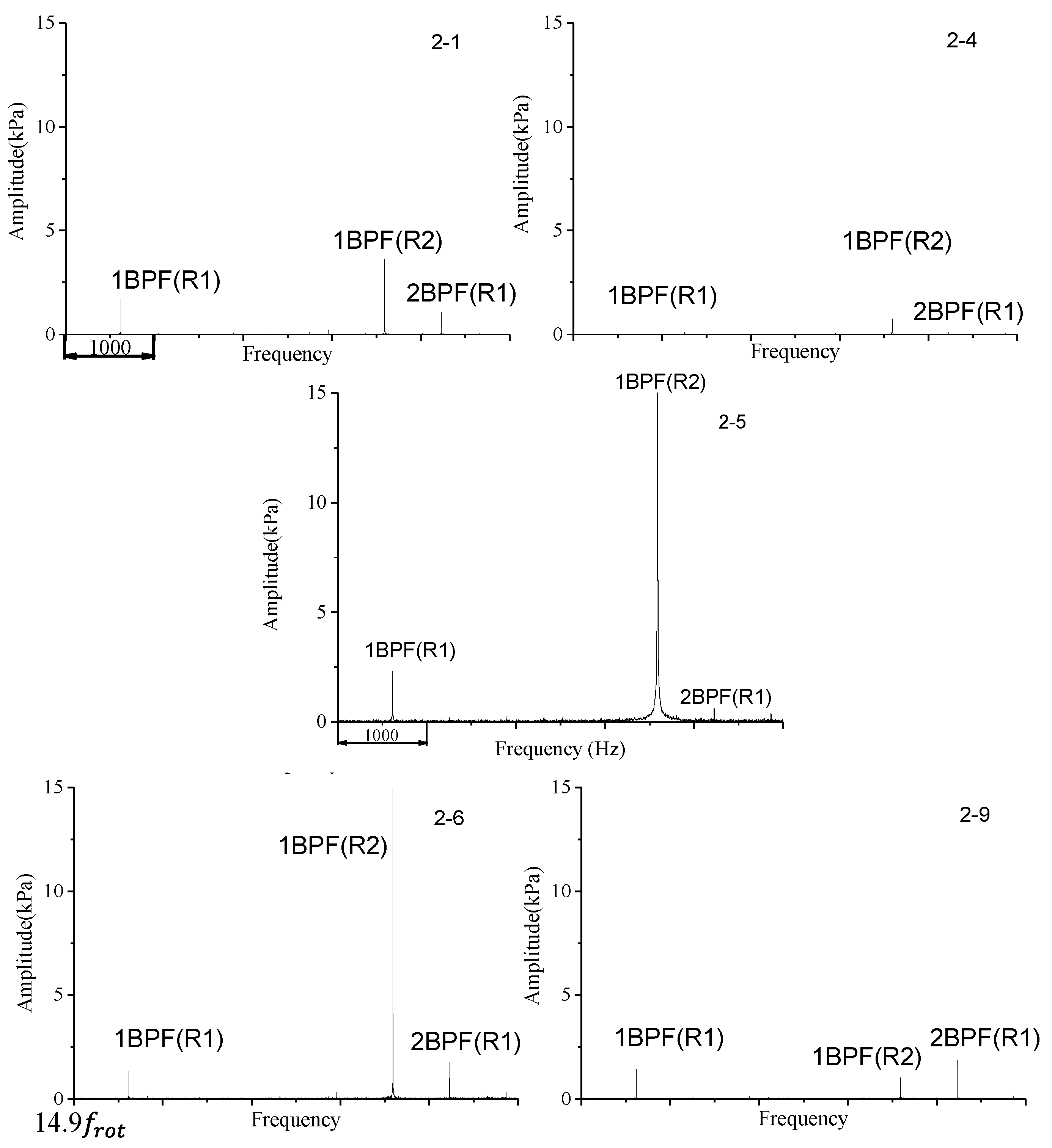

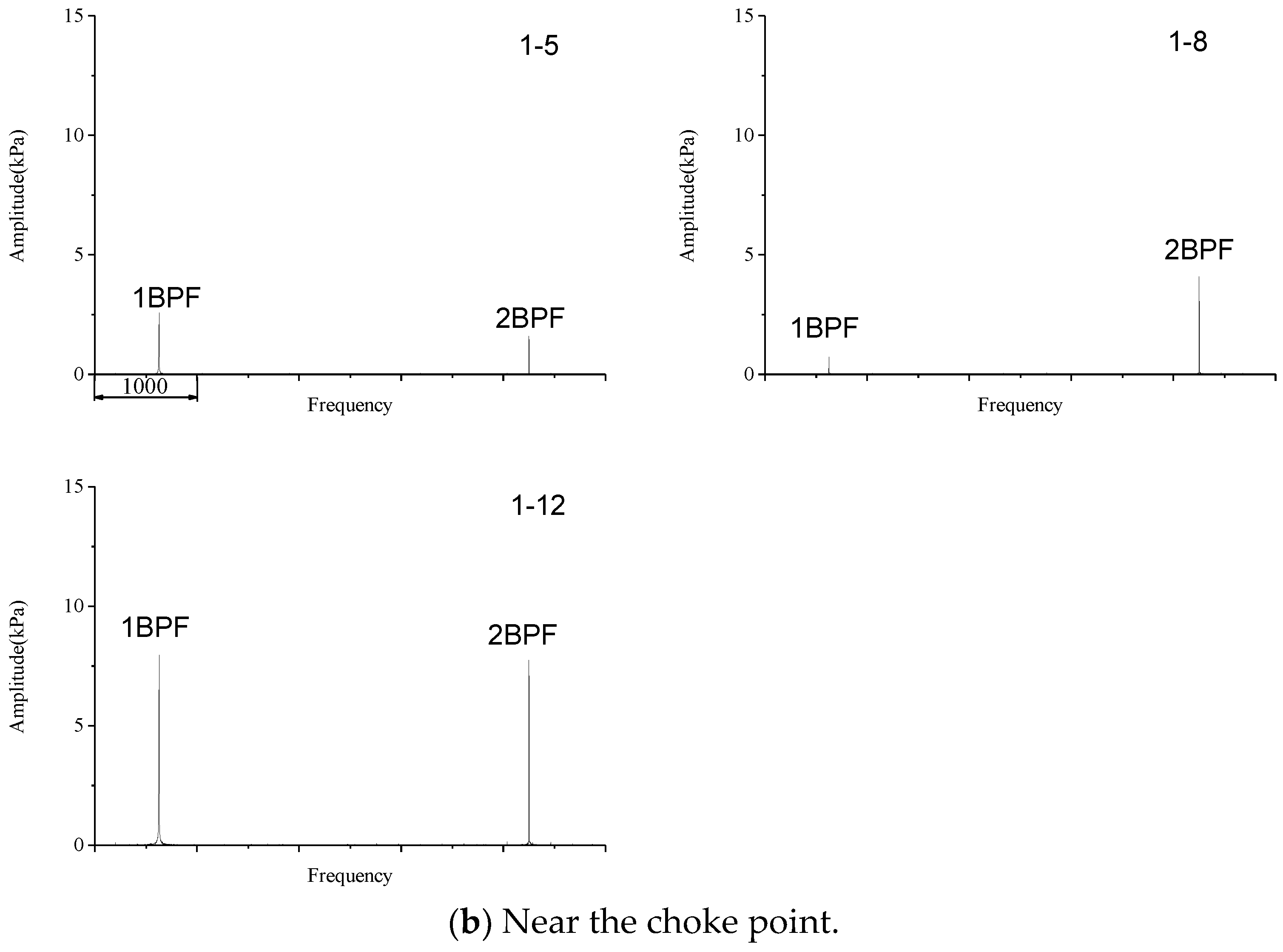

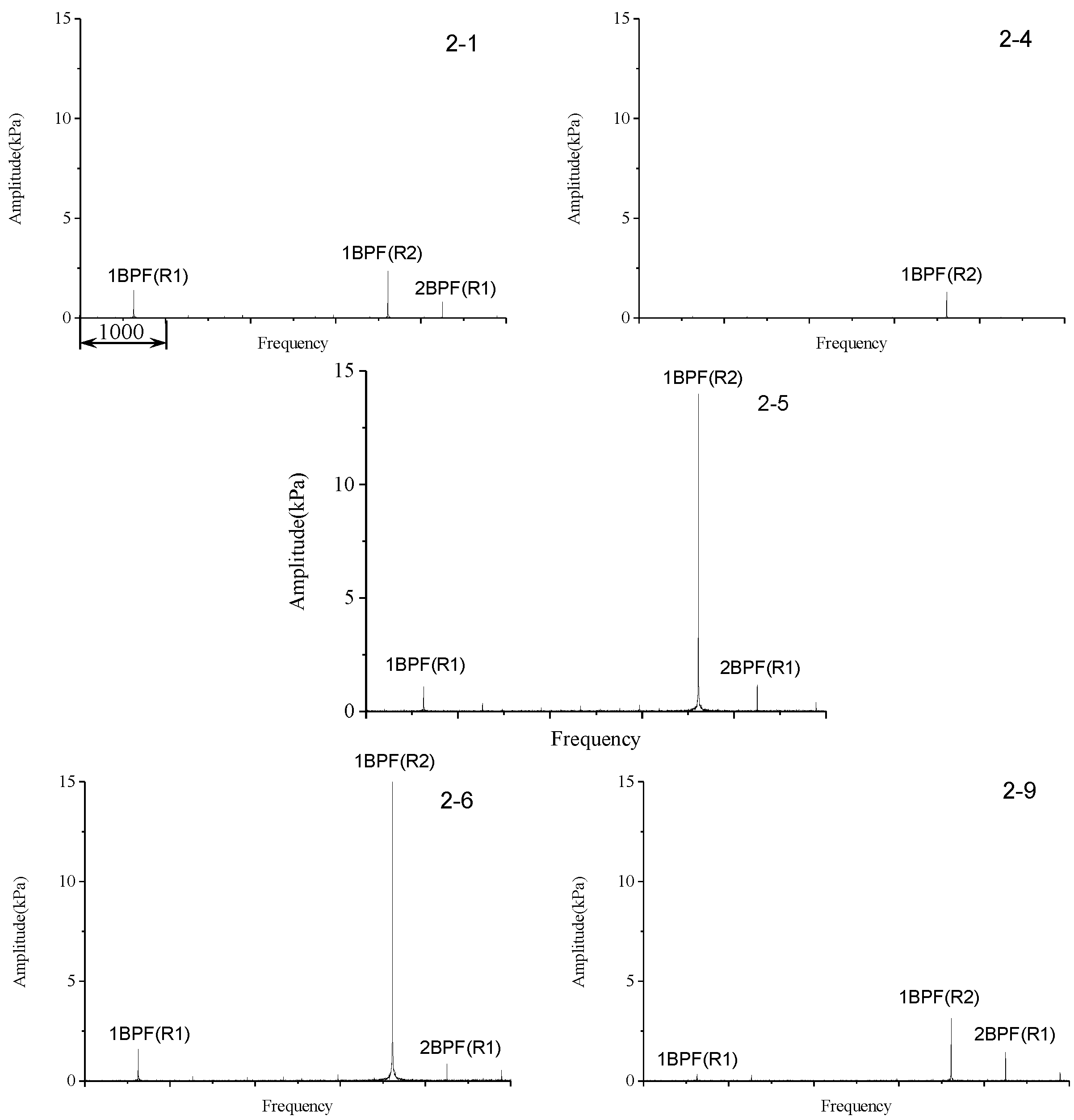

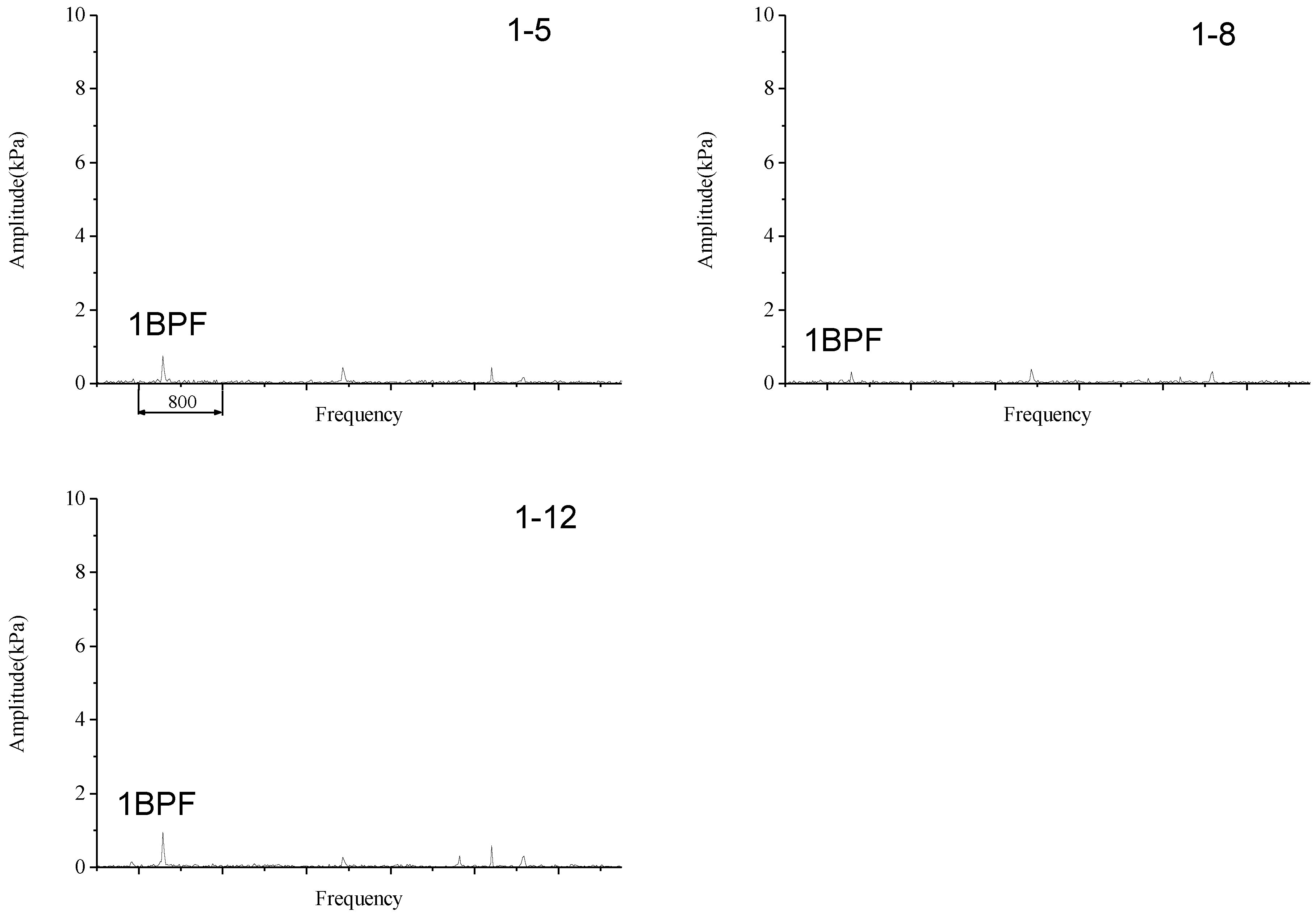

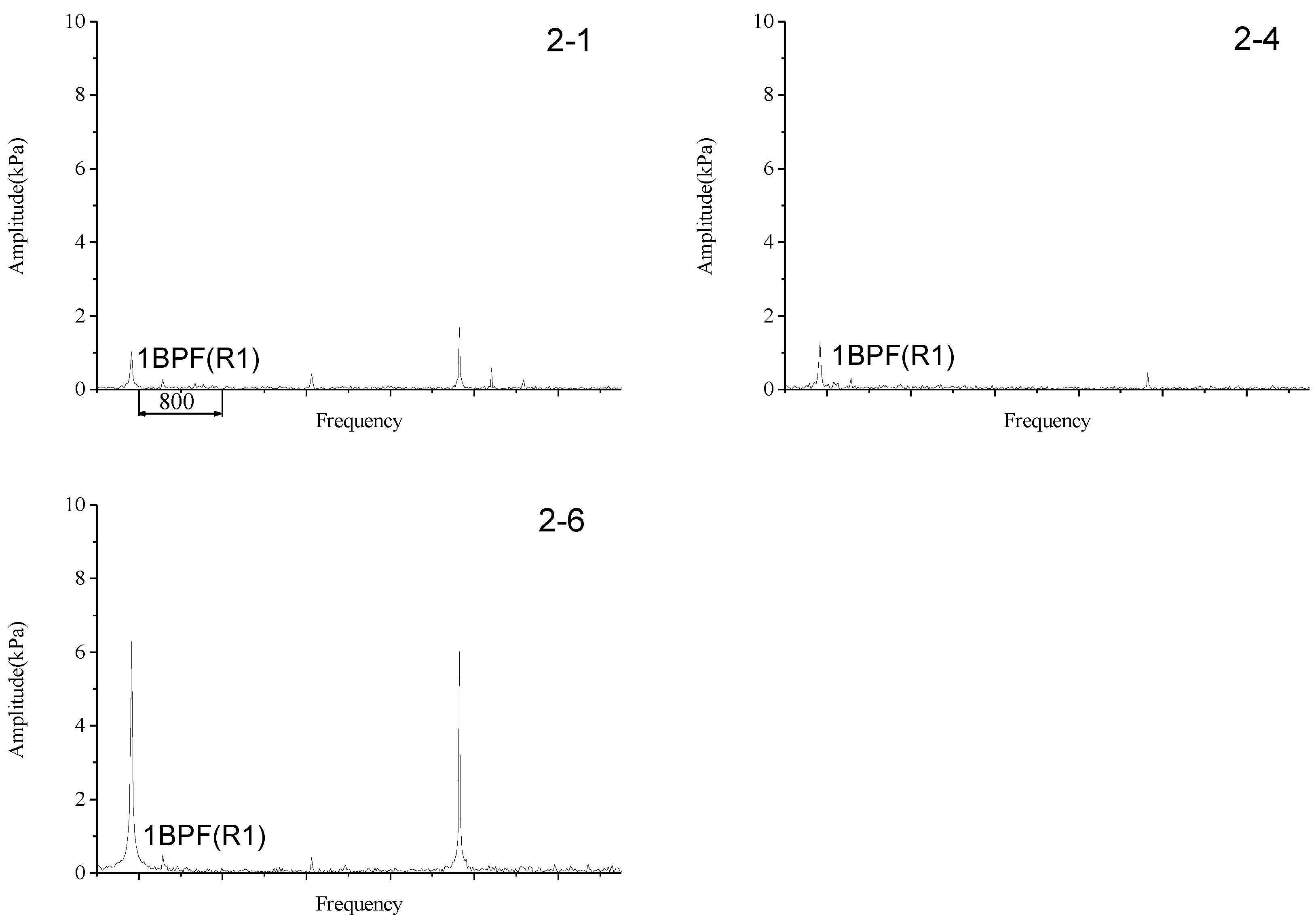

4.1. Frequency Spectrum inside R2

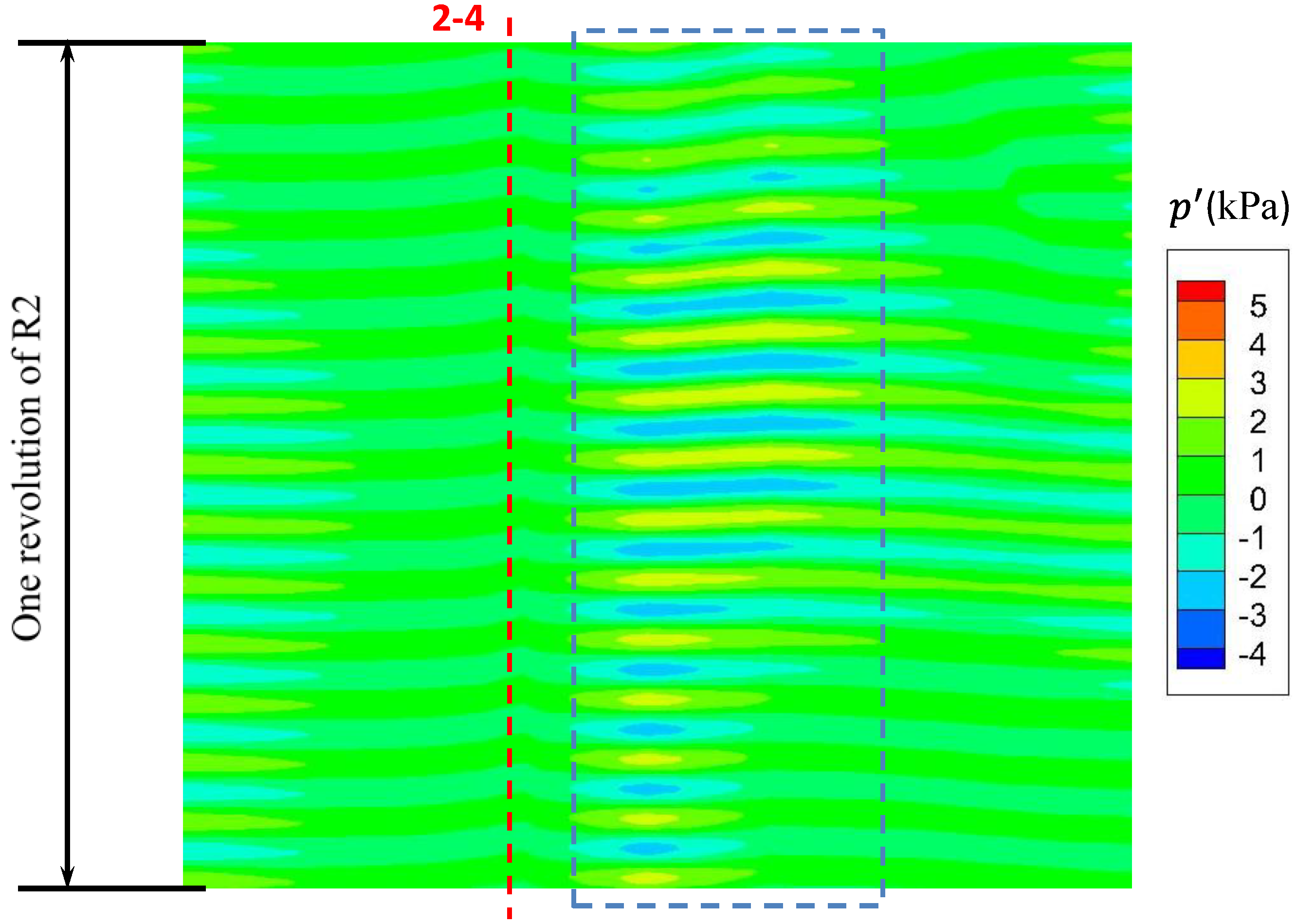

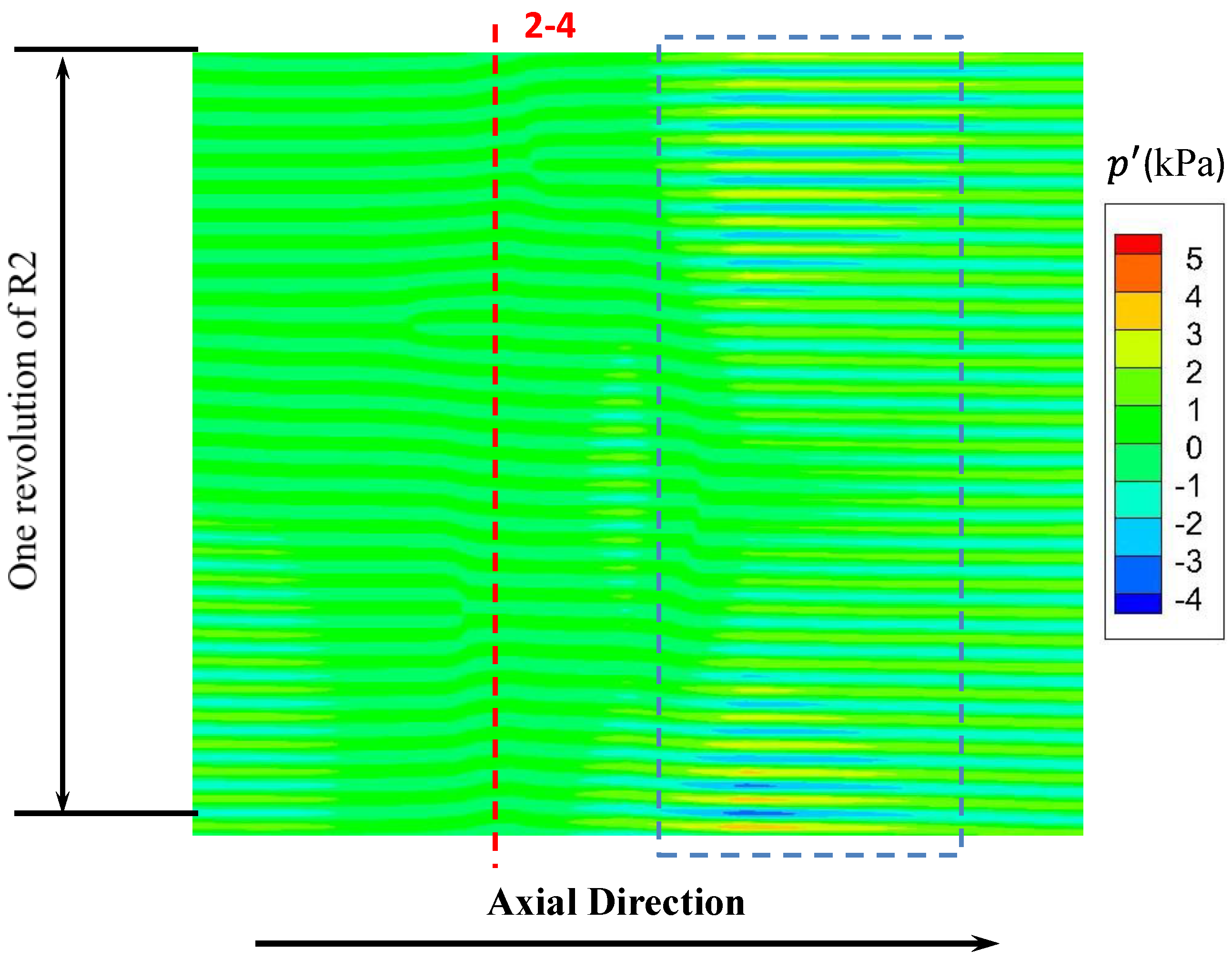

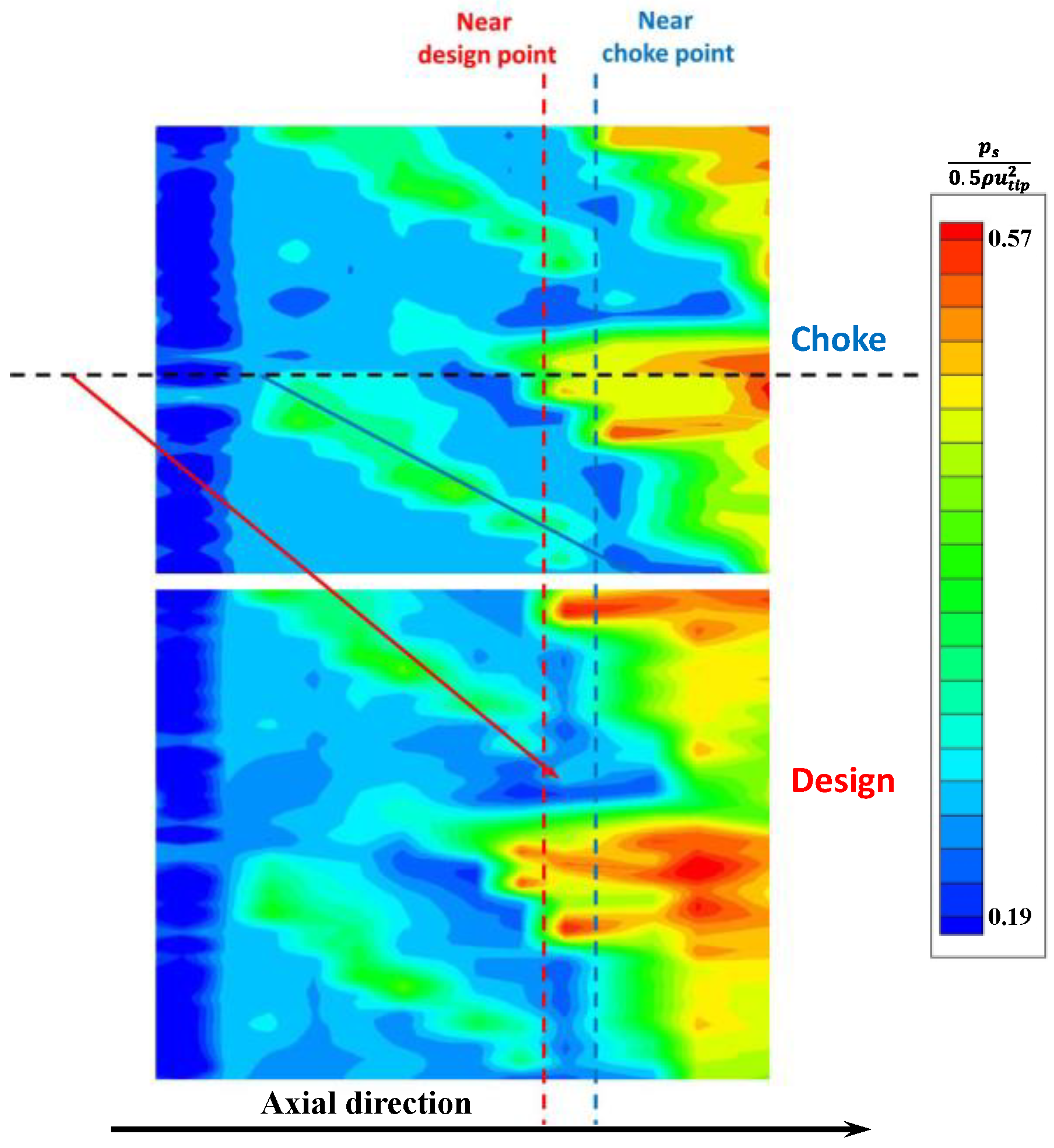

4.2. Flow Details inside R2

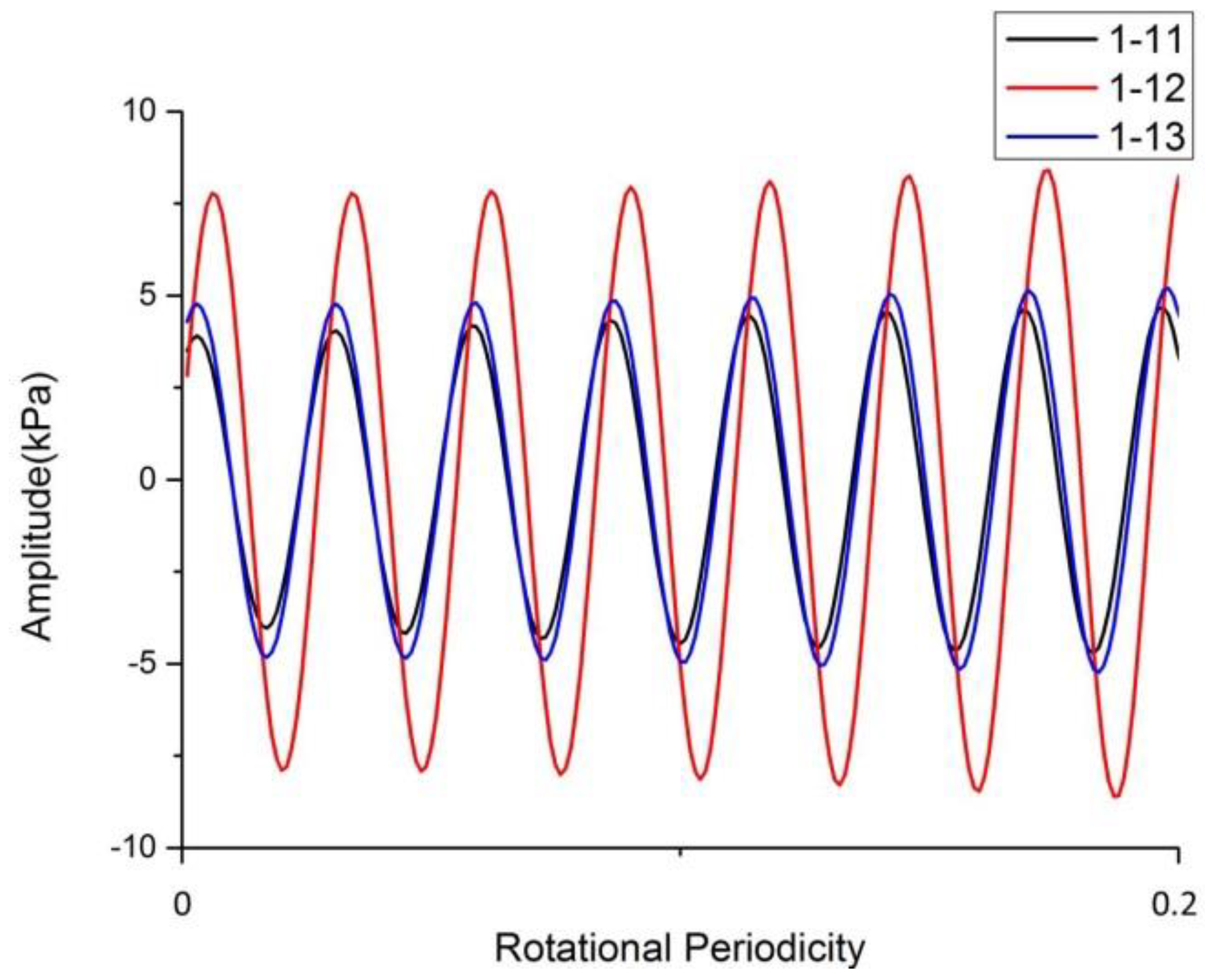

4.3. Influence of Operating Conditions

5. Conclusions

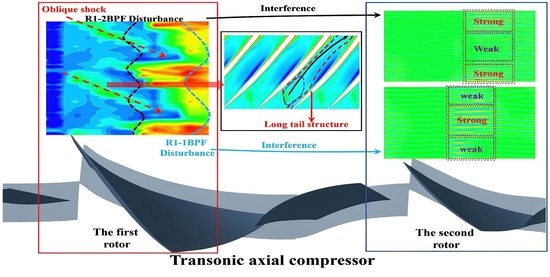

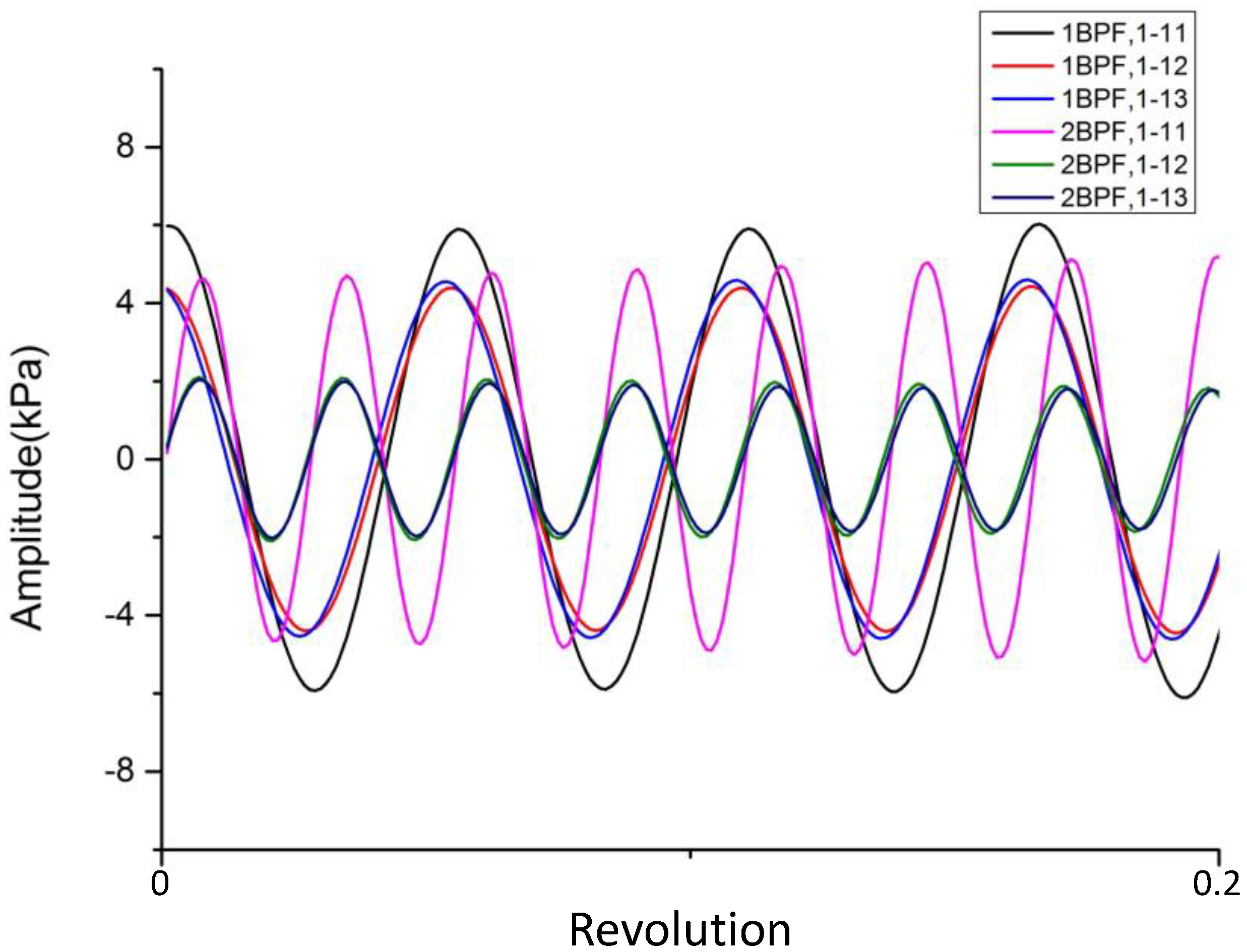

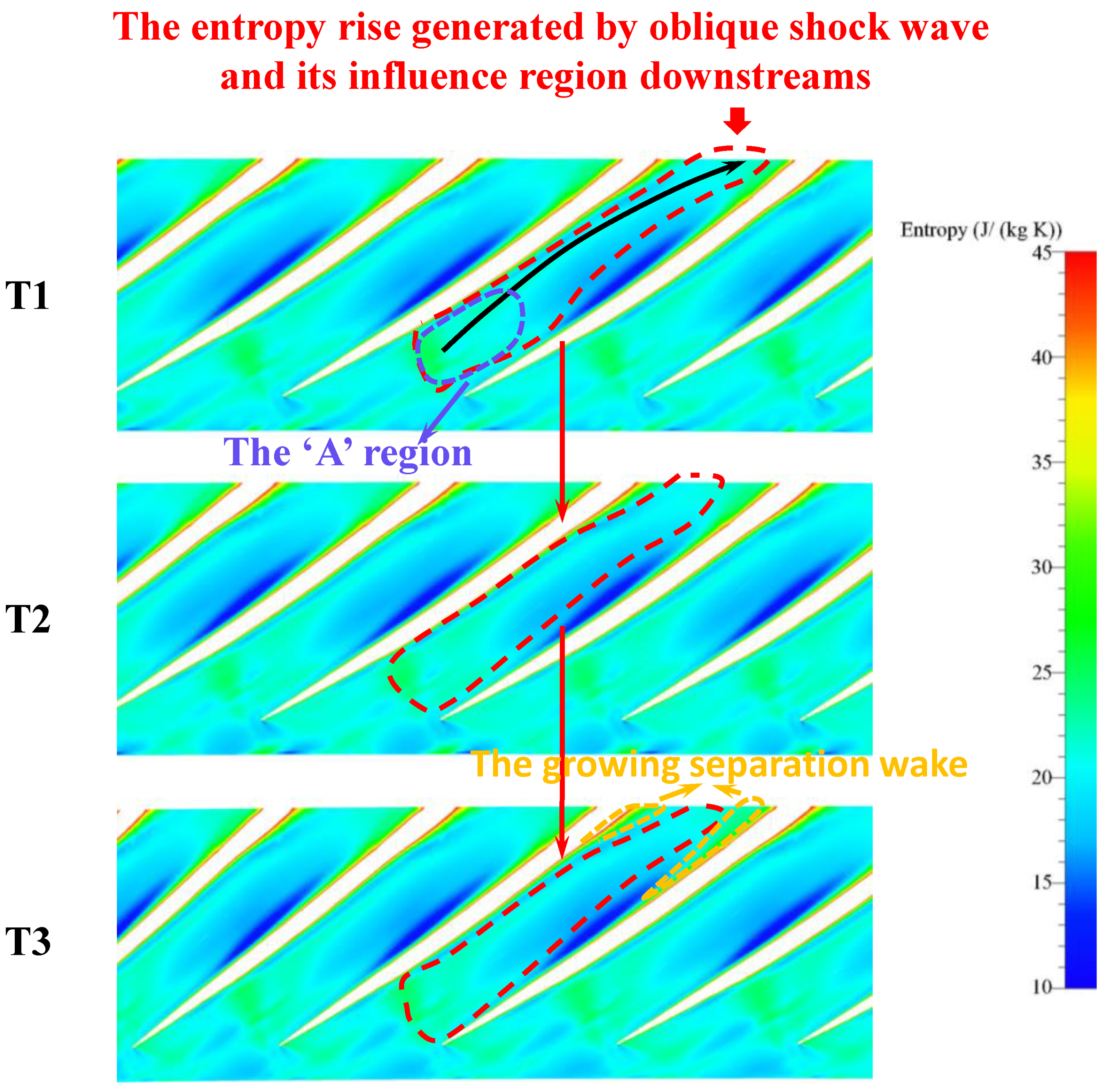

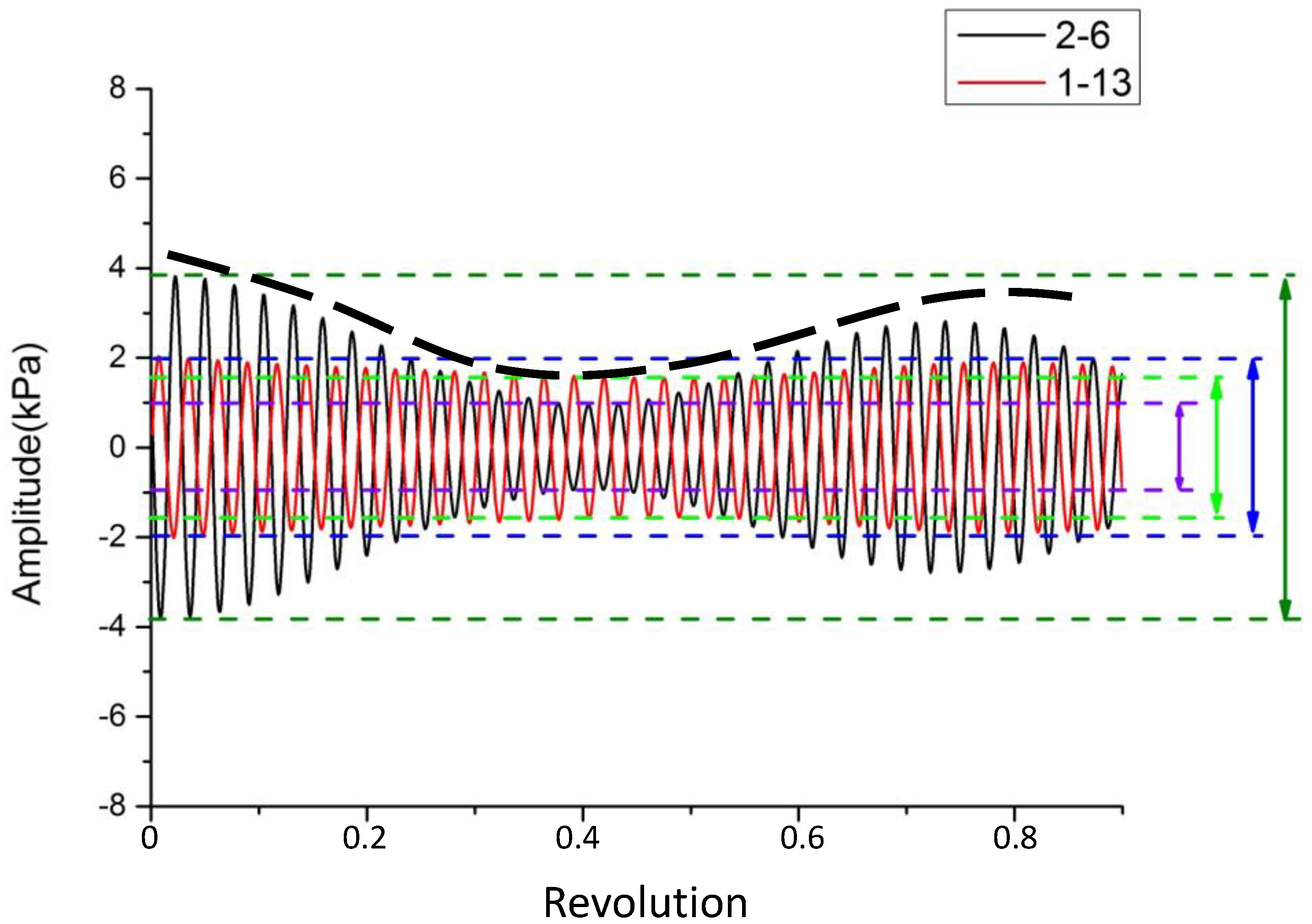

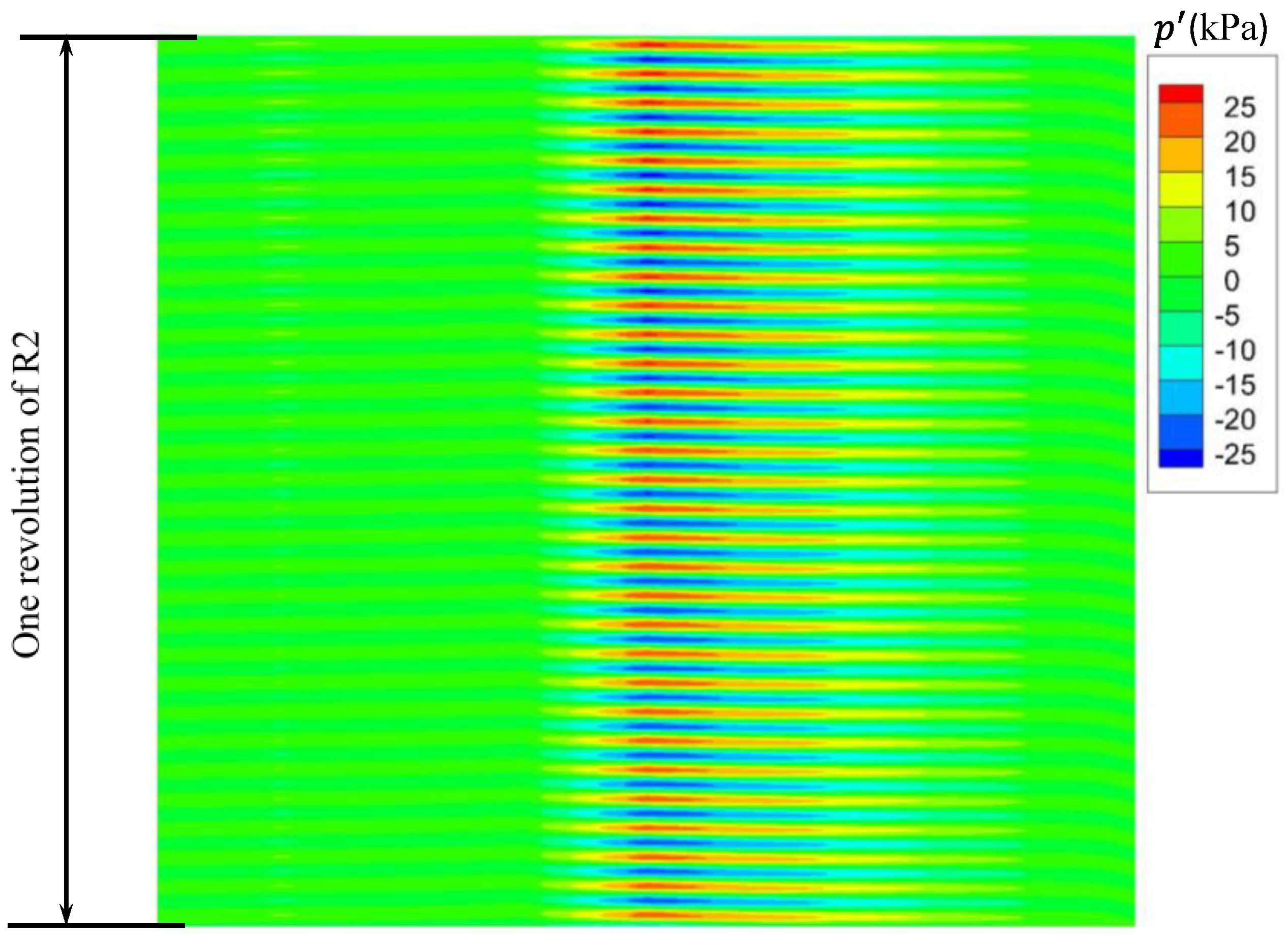

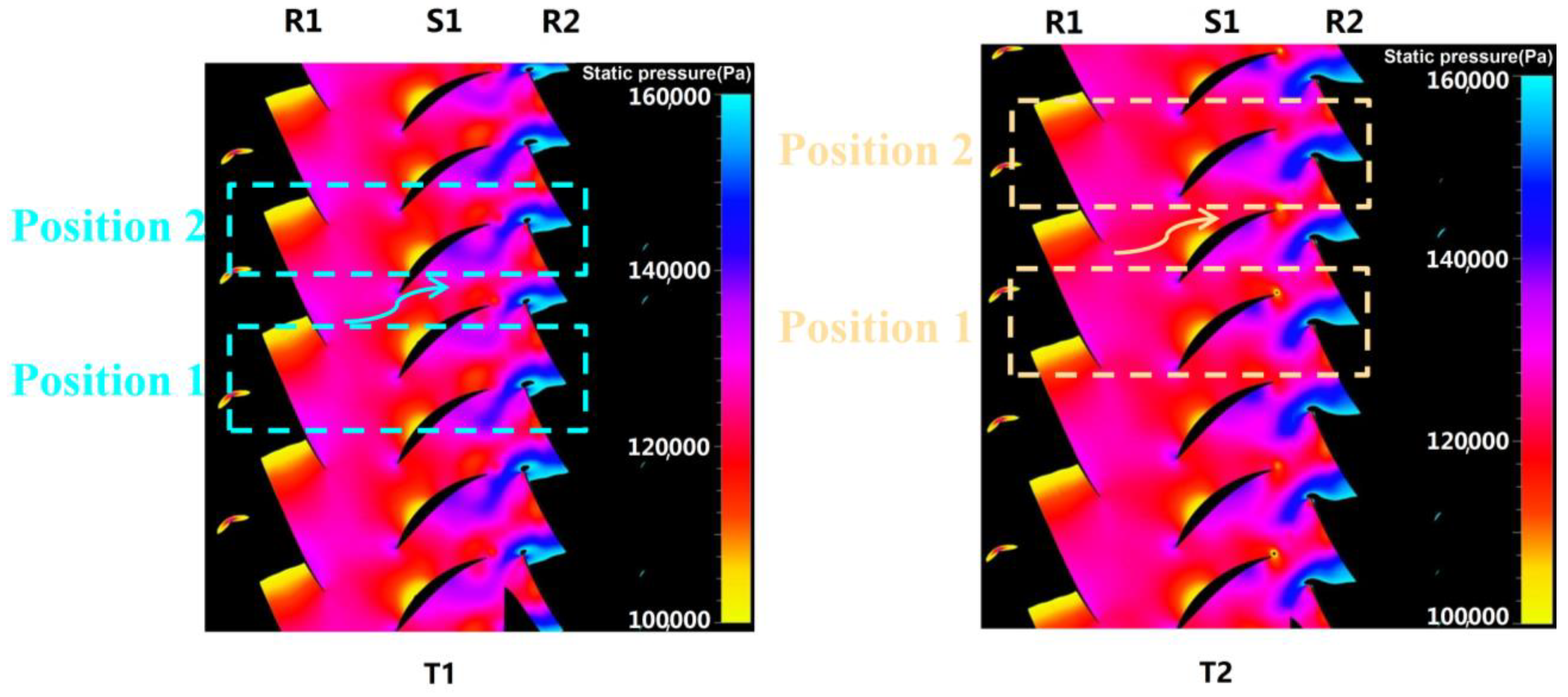

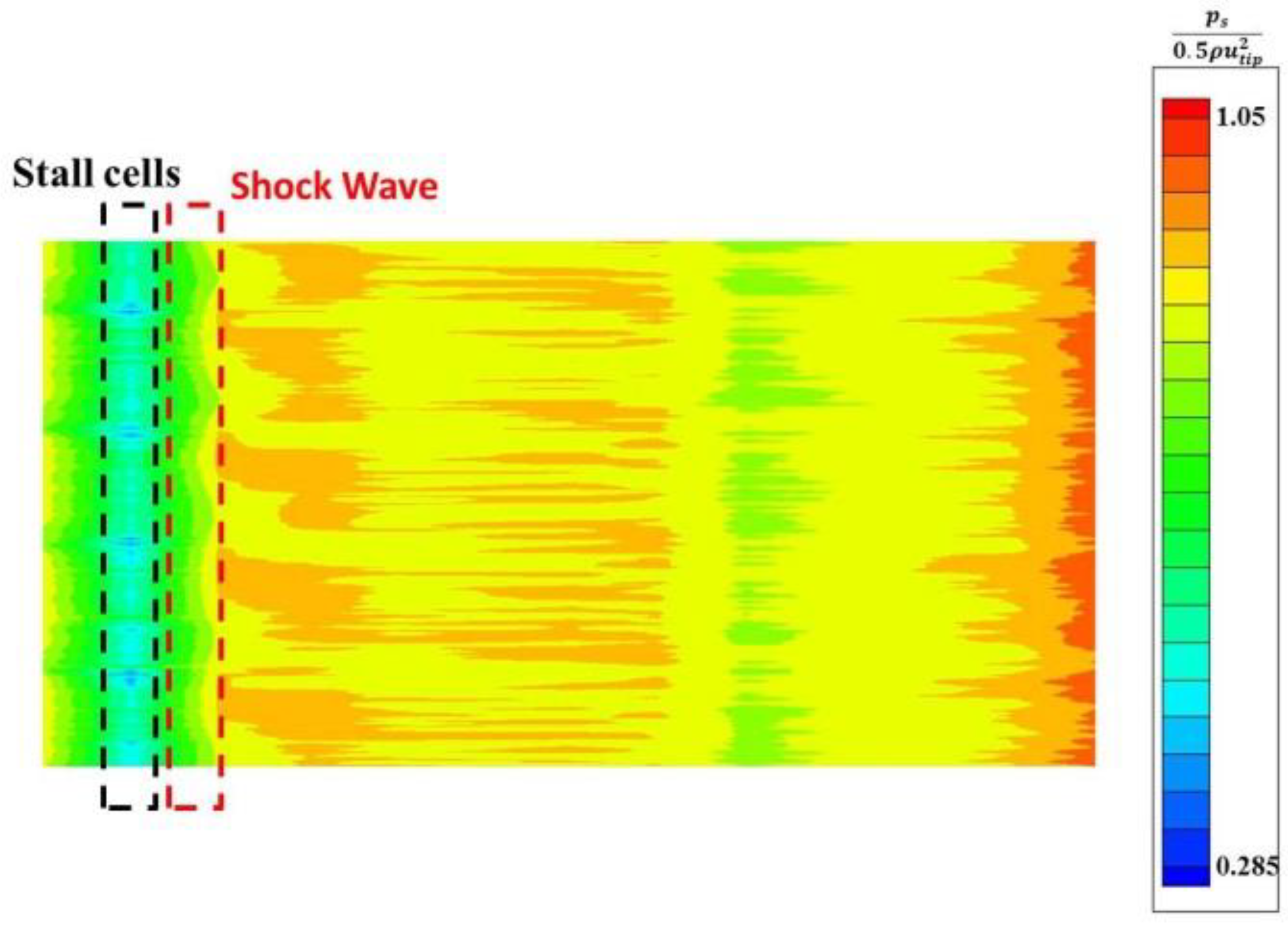

- When away from the surge limit, the R1-1BPF and R1-2BPF pressure disturbances from the R1 rotor, which averagely exceed 9% of the pressure rise of R2, are prominently found in the R2 passage. As usual, the R1-1BPF disturbance is mainly caused by the separation wake effect at the rear part of R1. However, the R1-2BPF disturbance here does not characterize the harmonic of the R1 wake disturbance, but the interaction between the oblique shock wave and the high-pressure region on the blade pressure surface. Both of the disturbances asynchronously propagate inside the R2 passage.

- The major influence of the R1 shock wave, which is in the form of a ‘long tail’ flow structure, obviously reaches the exit of R1 and has effects on the upper parts of S1 and R2.

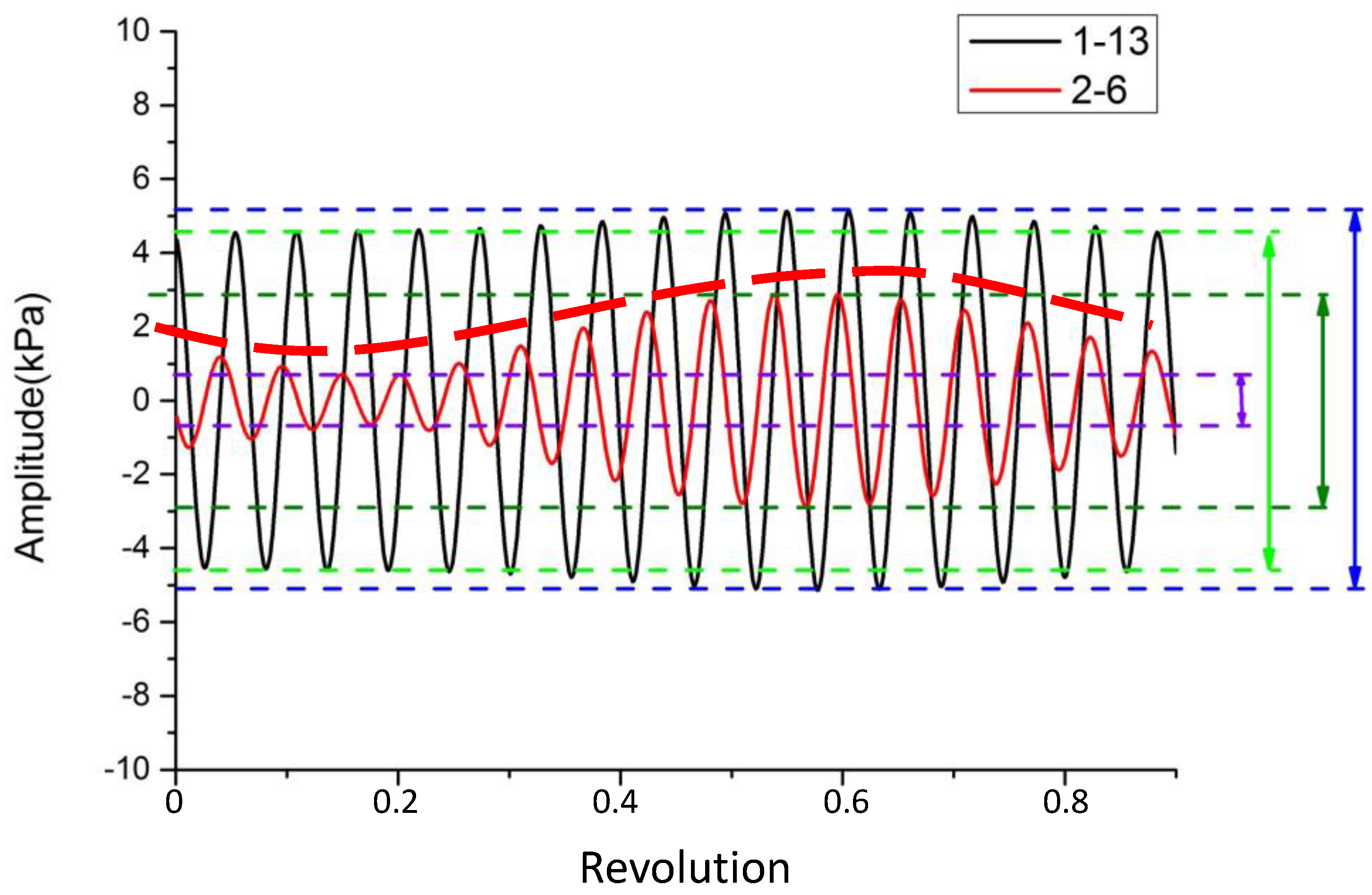

- The amplitudes of R1-1BPF and R1-2BPF do not keep declining along the R2 chord, while a sudden increase is found near the middle of the chord, which is related to the coupling effect of the flow separation at the leading edge and the interference flow structures from R1. For R2, the region most sensitive to the R1-1BPF and R1-2BPF effect is concentrated in the part from the middle to the rear of the passage.

- The characteristics of the interaction between R1and R2 near the design point are similar to those near the choke point, except for some quantitative differences. However, under the effects of the spilled shock wave and flow chaos inside R1, the R1-1BPF and R1-2BPF disturbances inside R2 almost vanish at the surge limit.

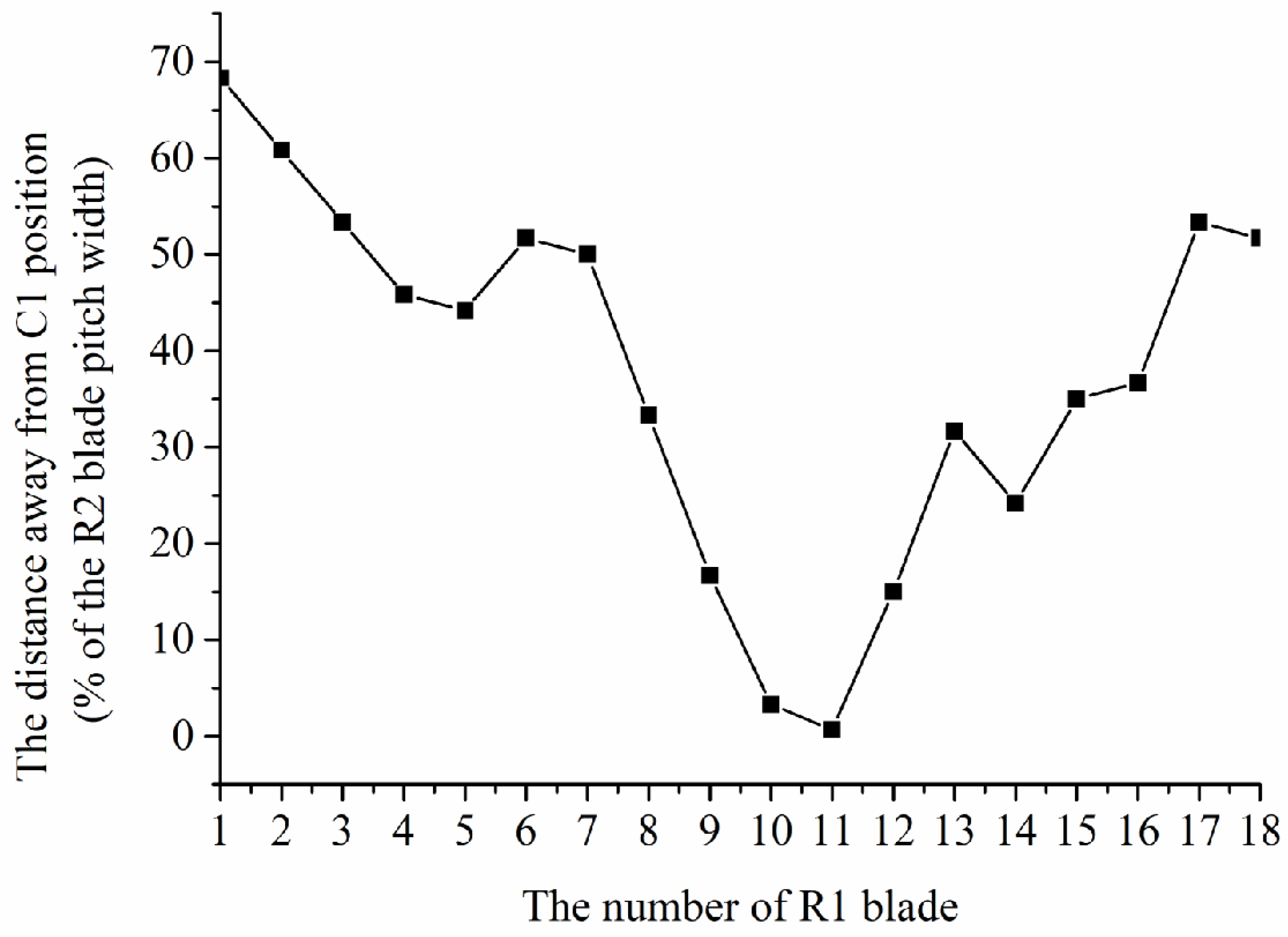

- The relative clocking position of the R1 and R2 blades significantly influences the circumferential propagations of R1-1BPF and R1-2BPF inside the R2 passage. It is simply the coupling effect of the separation wake at S1-TE and the invasion of the high-pressure region from R2-LE that controls the passing-through of the shock wave influence from R1. Under such an effect, the pressure circumferential non-uniformity grows evidently from the R1 exit to the middle of R2.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| BPF | blade-passing frequency |

| rotating frequency of the compressor shaft | |

| LE | leading edge |

| S1 | first stator |

| TE | trailing edge |

| pressure rise within R2 | |

| pressure rise | |

| the assemble average pressure disturbance at a specific phase | |

| pressure coefficient | |

| R1 | first rotor |

| R1-1BPF | disturbance of R1 at the blade-passing frequency |

| R1-2BPF | disturbance of R1 at the second harmonic of the blade-passing frequency |

| R2 | second rotor |

| tip tangential speed of R1 | |

| density of air |

References

- Ottavy, X.; Trebinjac, I.; Vouillarmet, A. Analysis of the interrow flow field within a transonic axial compressor: Part 1-Experimental investigation. ASME J. Turbomach. 2001, 123, 49–56. [Google Scholar] [CrossRef]

- Ottavy, X.; Trebinjac, I.; Vouillarmet, A. Analysis of the interrow flow field within a transonic axial compressor: Part 2-Unsteady flow analysis. ASME J. Turbomach. 2001, 123, 57–63. [Google Scholar] [CrossRef]

- Lecheler, S.; Schnell, R.; Stubert, B. Experimental and numerical investigation of the flow in a 5-stage transonic compressor rig. In Proceedings of the ASME Turbo Expo 2001: Power for Land, Sea, and Air, New Orleans, LA, USA, 4–7 June 2001. [Google Scholar]

- Gorrell, S.E.; Okiishi, T.H.; Copenhaver, W.W. Stator-Rotor interactions in a transonic compressor-Part 1: Effect of blade-row spacing on performance. ASME J. Turbomach. 2003, 125, 328–335. [Google Scholar] [CrossRef]

- Gorrell, S.E.; Okiishi, T.H.; Copenhaver, W.W. Stator-Rotor interactions in a transonic compressor-Part 2: Description of a loss-producing mechanism. ASME J. Turbomach. 2003, 125, 336–345. [Google Scholar] [CrossRef]

- Mailach, R.; Vogeler, K. Aerodynamic blade row interaction in an axial compressor-Part 1-Unsteady boundary layer development. ASME J. Turbomach. 2004, 126, 35–44. [Google Scholar] [CrossRef]

- Wheeler, A.P.S.; Miller, R.J. Compressor wake/leading-edge interactions at off-design incidences. In Proceedings of the ASME Turbo Expo 2008: Power for Land, Sea, and Air, Berlin, Germany, 9–13 June 2008. [Google Scholar]

- Wheeler, A.P.S.; Sofia, A.; Miller, R.J. The effect of leading-edge geometry on wake interactions in compressors. In Proceedings of the ASME Turbo Expo 2007: Power for Land, Sea, and Air, Montreal, QC, Canada, 14–17 May 2007. [Google Scholar]

- Yamagami, M.; Kodama, H.; Kato, D.; Tsuchiya, N.; Horiguchi, Y.; Kazawa, J. Unsteady flow effects in a high-speed multistage axial compressor. In Proceedings of the ASME Turbo Expo 2009: Power for Land, Sea, and Air, Orlando, FL, USA, 8–12 June 2009. [Google Scholar]

- Zhao, H.; Wang, Z.; Xi, G. Unsteady flow structures in the tip region for a centrifugal compressor impeller before the rotating stall. Sci. China Technol. Sci. 2017, 60, 924–934. [Google Scholar] [CrossRef]

- Stading, J.; Friedrichs, J.; Waitz, T.; Dobriloff, C.; Becker, B.; Gummer, V. The potential of rotor and stator clocking in a 2.5-stage low-speed axial compressor. In Proceedings of the ASME Turbo Expo 2012: Turbine Technical Conference and Exposition, Copenhagen, Denmark, 11–15 June 2012. [Google Scholar]

- Fruth, F.; Vogt, D.M.; Bladh, R.; Fransson, T.H. Unsteady forcing vs. efficiency-the effect of clocking on a transonic industrial compressor. In Proceedings of the ASME 2013 Fluids Engineering Division Summer Meeting, Incline Village, NV, USA, 7–11 July 2013. [Google Scholar]

- Milidonis, K.F.; Semlitsch, B.; Hynes, T. Effect of clocking on compressor noise generation. AIAA J. 2018, 56, 4225–4231. [Google Scholar] [CrossRef]

- Geng, S.J.; Chen, N.X.; Zhang, H.W.; Huang, W.G. An improvement on the efficiency of a single rotor transonic compressor by reducing the shock wave strength on the blade suction surfaces. J. Therm. Sci. 2012, 21, 127–135. [Google Scholar] [CrossRef]

- Hsu, S.T.; Wo, A.M. Reduction of unsteady blade loading by beneficial use of vertical and potential disturbances in an axial compressor with rotor clocking. ASME J. Turbomach. 1998, 120, 705–713. [Google Scholar] [CrossRef]

- He, L.; Chen, T.; Wells, R.G.; Li, Y.S.; Ning, W. Analysis of rotor-rotor and stator-stator interferences in multi-stage turbomachines. ASME J. Turbomach. 2002, 124, 564–571. [Google Scholar] [CrossRef]

- Mileshin, V.; Druzhinin, Y.; Stepanov, A. Numerical and experimental investigations of clocking effect in a two-stage compressor with . In Proceedings of the ASME Turbo Expo 2015: Turbine Technical Conference and Exposition, Montreal, QC, Canada, 15–19 June 2015. [Google Scholar]

- Miserda, R.F.B.; Reckziegel, F.S.; Balduino, L.F. Direct noise computation of the rotor-rotor interaction modes in counter-rotating cascades. In Proceedings of the 25th AIAA/CEAS Aeroacoustics Conference, Delft, The Netherlands, 20–24 May 2019. [Google Scholar]

- Huang, X.Q.; Wang, D.X. Time-space spectral method for rotor-rotor/stator-stator interactions. ASME J. Turbomach. 2019, 141, 111006. [Google Scholar] [CrossRef]

- Smith, N.R.; Key, N.L. Unsteady vane boundary layer response to rotor-rotor interactions in a multistage compressor. J. Propulus. Power 2014, 30, 416–425. [Google Scholar] [CrossRef]

- Ernst, M.; Michel, A.; Jeschke, P. Analysis of rotor-stator-interaction and blade-to-blade measurements in a two stage axial flow compressor. ASME J. Turbomach. 2011, 133, 011027. [Google Scholar] [CrossRef]

- Zhao, J.; Lu, Q.; Yang, D.; Xiang, H. The mechanism analysis of rotor/rotor interference phenomenon within the multistage transonic compressor. Exp. Tech. 2022. [Google Scholar] [CrossRef]

- Spalart, P.; Allmaras, S. A one-equation turbulence model for aerodynamic flows. In Proceedings of the 30th Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 6–9 January 1992. [Google Scholar]

- Celik, I.B.; Ghia, U.; Roache, P.J.; Freitas, C.J. Procedure of estimation and reporting of uncertainty due to discretization in CFD applications. ASME J. Fluid Eng. 2008, 130, 078001. [Google Scholar]

- Denton, J.D.; Xu, L. The effect of lean and sweep on transonic fan performance. In Proceedings of the ASME Turbo Expo 2002: Power for Land, Sea, and Air, Amsterdam, The Netherlands, 3–6 June 2002. [Google Scholar]

- Day, I.J. Stall, Surge, and 75 years of research. ASME J. Turbomach. 2016, 138, 011001. [Google Scholar] [CrossRef]

| Normalized Mass Flow Rate | Uncertainty of Efficiency (S0 + R1) | Uncertainty of Efficiency (S1 + R2) | Uncertainty of Pressure Ratio (S0 + R1) | Uncertainty of Pressure Ratio (S1 + R2) |

|---|---|---|---|---|

| 1.0292 | 0.00214 | 0.00657 | 0.000195 | 0.000849 |

| 1.0277 | 0.000278 | 0.000513 | 0.00045 | 0.004562 |

| 1.0215 | 0.000279 | 0.000287 | 0.000228 | 0.001374 |

| 1.0185 | 0.00028 | 0.000752 | 0.000268 | 0.004593 |

| 1.0077 | 0.00073 | 0.00029 | 0.000247 | 0.004625 |

| 0.9954 | 0.000282 | 0.00015 | 0.001869 | 0.000845 |

| 0.9877 | 0.00118 | 0.000065 | 0.001235 | 0.004625 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, J.; Lu, Q.; Yang, D. Experimental and Numerical Analysis of Rotor–Rotor Interaction Characteristics inside a Multistage Transonic Axial Compressor. Energies 2022, 15, 2627. https://doi.org/10.3390/en15072627

Zhao J, Lu Q, Yang D. Experimental and Numerical Analysis of Rotor–Rotor Interaction Characteristics inside a Multistage Transonic Axial Compressor. Energies. 2022; 15(7):2627. https://doi.org/10.3390/en15072627

Chicago/Turabian StyleZhao, Jiayi, Qingfei Lu, and Dangguo Yang. 2022. "Experimental and Numerical Analysis of Rotor–Rotor Interaction Characteristics inside a Multistage Transonic Axial Compressor" Energies 15, no. 7: 2627. https://doi.org/10.3390/en15072627

APA StyleZhao, J., Lu, Q., & Yang, D. (2022). Experimental and Numerical Analysis of Rotor–Rotor Interaction Characteristics inside a Multistage Transonic Axial Compressor. Energies, 15(7), 2627. https://doi.org/10.3390/en15072627