1. Introduction

In the 21st century, resource scarcity and environmental pollution have become prominent problems restricting human development [

1]. Consequently, countries around the world have gradually attached importance to the development of renewable energy. The future of energy consumption is increasingly associated with the development of the so-called green energy [

2]. Lithium-ion batteries have been widely used and developed because of their excellent performance. Lithium-ion batteries are widely used in mobile electronics, electric vehicles, and spacecrafts [

3,

4,

5,

6]. Health assessments of batteries under normal operation have become a key issue in practical application processes [

7,

8]. The state prediction of a battery mainly includes the prediction of its state of charge (SOC) and state of health (SOH) [

9]. The indicators commonly used to measure battery aging are the remaining useful life (RUL) and SOH [

10]. These indicators are predicted by calculating the decay in battery capacity from experimental data on the current, voltage, and temperature of the battery, among others. According to the use of information, the prediction methods for the SOH for lithium-ion batteries can be divided into two categories: physical-model-based and data-based approaches [

11].

Physical-model-based approaches use a physical model that can describe battery degradation, then the physical model is combined with actual battery measurement data and usage conditions to identify the model parameters and predict the future degradation of the actual battery. Degradation mechanism models, equivalent circuit models, and empirical decay models are commonly used in physical-model-based approaches. In [

12], Ashwin et al. proposed a pseudo two-dimensional electrochemical lithium-ion battery model to study its capacity fading under cyclic charge–discharge conditions. A distributed thermal model coupled with internal chemical heating was used to accurately predict the temperature change inside the battery cell. The growth of solid electrolyte interphase (SEI) films, first discovered in 1979 by Peled [

13], was estimated based on different cut-off voltages and charging current rates. Rational use of this model can effectively improve the performance and service life of batteries under various operating conditions. However, the temperature, electrolyte, active materials, separator, electrode and crosstalk in actual lithium-ion batteries will affect the growth of the cathode electrolyte interphase (CEI) and SEI, thereby affecting the battery life and leading to prediction errors in the model [

14,

15,

16]. In [

17], a state–space model with non-integer derivatives was proposed, which is a combination of electrochemical impedance spectroscopy and an RC model. The authors adopted a particle swarm optimization algorithm and identified three model parameters using time domain test data. The experimental data showed that the proposed model had good accuracy and robustness and was suitable for the study of battery SOC, SOH estimation, and charge control. In the empirical decay model, some researchers have used the Bayesian Monte Carlo framework [

18] and relevance vector machine (RVM) algorithm [

19]. In addition, most had used a statistical random filter algorithm to track the decay information of the battery to obtain optimal parameters; therefore, it is also called the statistical filter model [

20,

21,

22,

23,

24].

Data-driven approaches use information from currently measured and historical data to identify the currently measured degradation states and predict future trends. The data-driven method does not require consideration of the physical and chemical changes inside the battery. It can directly analyze the implicit SOH information and its evolution law from the external characteristic parameters of the battery. Existing methods include time series analysis, neural network (NN), support vector machine (SVM), RVM, Gaussian process regression (GPR), and prediction methods of fusion models. The authors in [

25] used the AR model combined with the PF algorithm to predict the battery life. First, they analyzed the nonlinear degradation characteristics of the battery capacity and extracted the nonlinear accelerated degradation factor, which improved the prediction ability of the linear AR model. Finally, a regularized particle filter was used to design the RUL framework for lithium-ion battery fusion. The experiments showed that the prediction results of the model had good accuracy. The authors in [

26] proposed an online synthesis method based on the fusion of partial incremental capacity and artificial neural networks to estimate the SOH and RUL under constant current charging conditions. An advanced filtering method was used to smoothen the initial incremental capacity curve. Simultaneously, strongly correlated eigenvalues were extracted from the partial incremental curves using the correlation analysis method. A neural network model of the SOH and RUL was established to estimate the SOH and RUL simultaneously. Reference [

27] proposes a new method for the accurate estimation of battery SOH using the terminal voltage response characteristics of lithium-ion batteries under current pulse tests by SVM. Because the terminal voltage measured under the same conditions changes with the battery aging process, the feature was extracted from the voltage response under a specific current pulse test for SOH estimation. The authors in [

28] used wavelet denoising and a differential evolution algorithm to improve RVM, wherein the RUL of the battery was estimated from the denoised data. The experiments verified that the method can accurately predict the battery capacity and the battery capacity decline trend. The study focused on short-term battery SOH estimation and long-term RUL prediction. A hybrid method combining partial incremental capacity with Gaussian process regression was proposed in [

29], wherein a double GPR model was used to predict battery health. The authors in [

30] proposed that the battery equivalent model parameters be estimated based on the least-squares method to determine the internal resistance of the battery. They studied the effect of temperature on the decay rate of the battery life. This method can be used to predict the battery SOH under a normal operating state within a specific time interval and can correct the calculation results according to the temperature change.

With the rapid development of machine learning and artificial intelligence, data-driven methods have received increasing attention [

31,

32]. In recent years, the rapid development of computational capabilities has enabled the calculation using deep-learning algorithms to be faster. The emergence of an increasing number of deep learning algorithms has made the prediction of battery SOH very accurate [

33,

34,

35,

36]. However, for data-driven methods, many researchers still use various filters and GPR algorithms [

37,

38,

39], and only a few studies have used deep-learning algorithms [

40,

41]. During battery SOH prediction, the capacity of the battery and the calendar degradation data are used for prediction.

Considering the above research gaps, the main contributions of this work are as follows: (a) to deduce three groups of characteristic variables that have an obvious correlation with SOH through the battery charge–discharge data curve; (b) to verify the features determined in this study using the LSTM and TCN algorithms in deep learning and predict the battery SOH; (c) to build a battery accelerated aging experimental device for conducting battery aging charge and discharge experiments and to verify the three features proposed in this paper through experimental data; (d) to compare the performance of the deep learning algorithms LSTM and TCN through the NASA experimental data and data obtained from actual experiments.

The remainder of this paper is organized as follows.

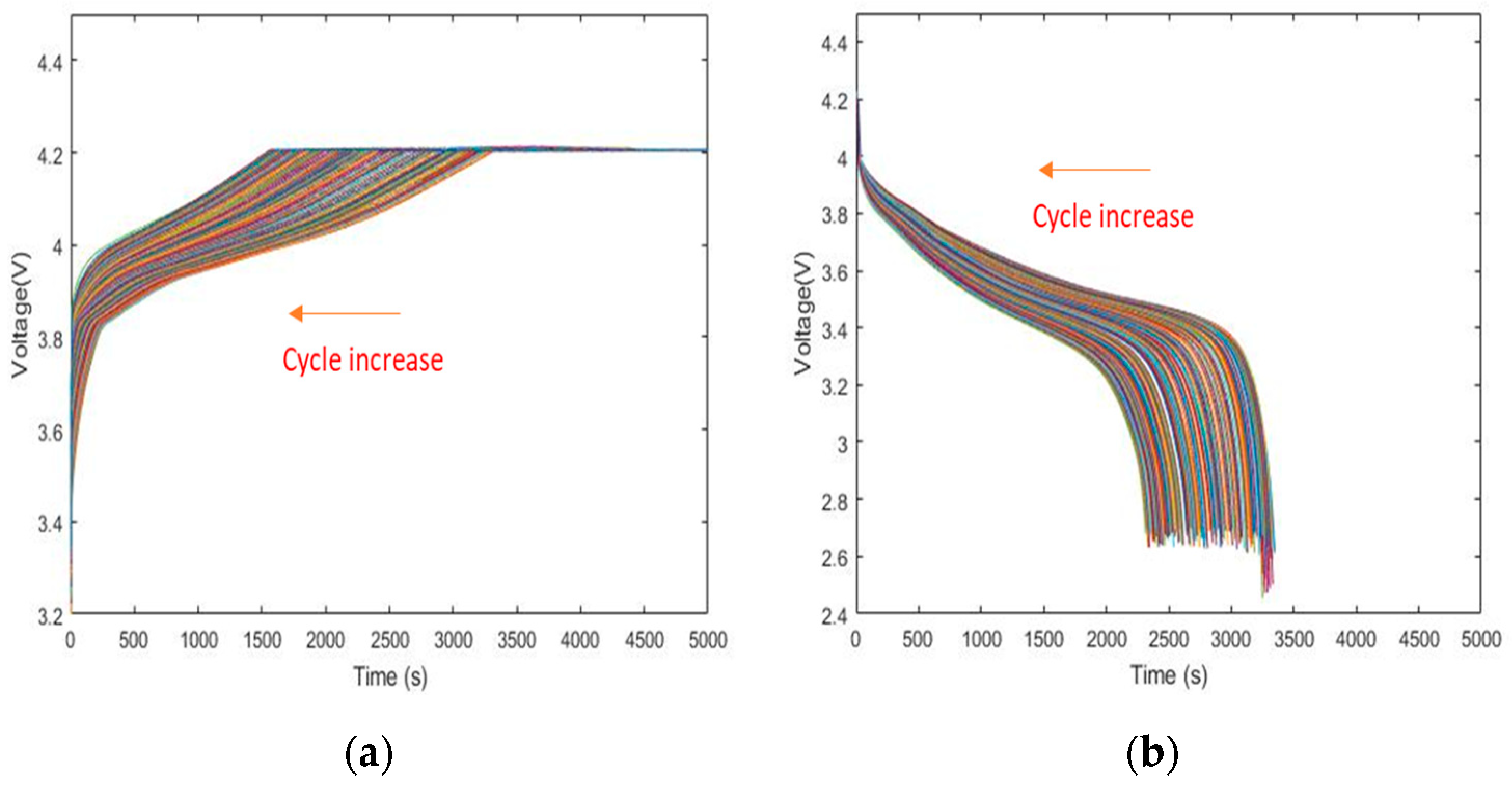

Section 2 discusses the trend of the lithium-ion battery SOH versus the charge–discharge time, wherein the charge–discharge voltage variation is presented in

Section 2.1 and the extraction of suitable feature variables that are significantly correlated with the SOH is presented in

Section 2.2.

Section 3 introduces the deep learning algorithms used in this study.

Section 4 demonstrates the use of the LSTM and TCN algorithms in deep learning to verify the three sets of features determined in this study that can predict the battery SOH.

Section 5 presents the battery aging charge and discharge experiment by building a battery-accelerated aging experimental device. Subsequently, the three features proposed in this study are verified via the deep learning algorithms using the data obtained from the experiment. Finally, the summary and conclusions of this study are presented in

Section 6.

3. Introduction to the Deep Learning Algorithms

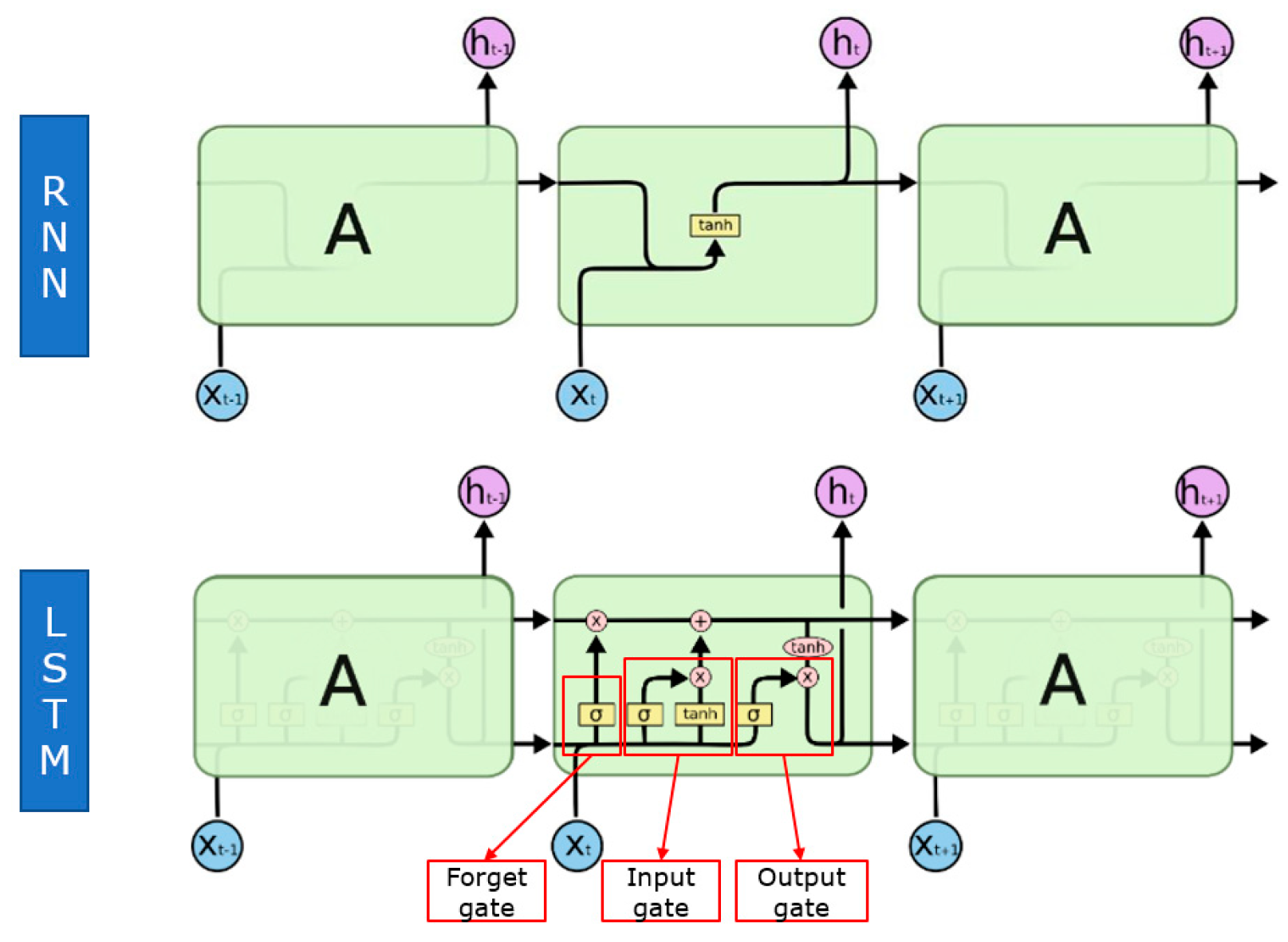

In this study, we compared two different architectures—one based on a recurrent neural network (RNN) and the other based on a convolutional neural network (CNN). For the RNN architecture, we used a long short-term memory (LSTM) algorithm and implemented a temporal convolution network (TCN) for the CNN architecture [

44]. This section introduces the two deep learning algorithms used in this study to predict the residual SOH values of lithium-ion batteries.

3.1. Long Short-Term Memory

LSTM is an improved RNN that overcomes a common problem of RNNs—they cannot handle long-distance dependencies. Compared with the basic RNN model, LSTM has two main improvements:

- (1)

The algorithm includes special variables, , to store the cell state information so that the network has long-term memory;

- (2)

The “gate operation” is introduced to change the multiplication of gradients into accumulation to solve the problem of gradient disappearance.

In the RNN model, the input is the hidden layer state at the previous moment, the input value is at the current moment, and the output is the hidden layer state at the current moment. The intermediate operation contains only one activation function.

In the LSTM model, the input is the hidden layer state

at the previous moment, the element state is

at the previous moment, the input value is

at the current moment, and the outputs are the hidden layer state

at the current moment and the element state

at the current moment. The calculation is more complicated than that inside the RNN. It is usually considered to be a three-gate operation: a forget gate, an input gate, and an output gate. The three gates are marked by red lines in

Figure 5.

3.2. Temporal Convolutional Network

The TCN model is based on the CNN model with the following improvements:

- (1)

Applicable sequence model: causal convolution;

- (2)

Memory history: dilated convolution, residual block.

Because the research object is the time series data, the designed TCN uses a 1-D convolutional network.

Figure 6 illustrates the causal and dilated convolutions in the TCN architecture. It can be observed that the value of each layer at moment t only depends on the value of the previous layer’s moment

,

, …, which reflects the characteristics of the causal convolution. The extraction of information from one layer to the previous layer is skipped, and the layer-by-layer dilated rate increases exponentially by a factor of two, reflecting the characteristics of dilated convolution. Owing to the use of dilated convolution, each layer must have padding (usually padded with 0); the size of the padding is

.

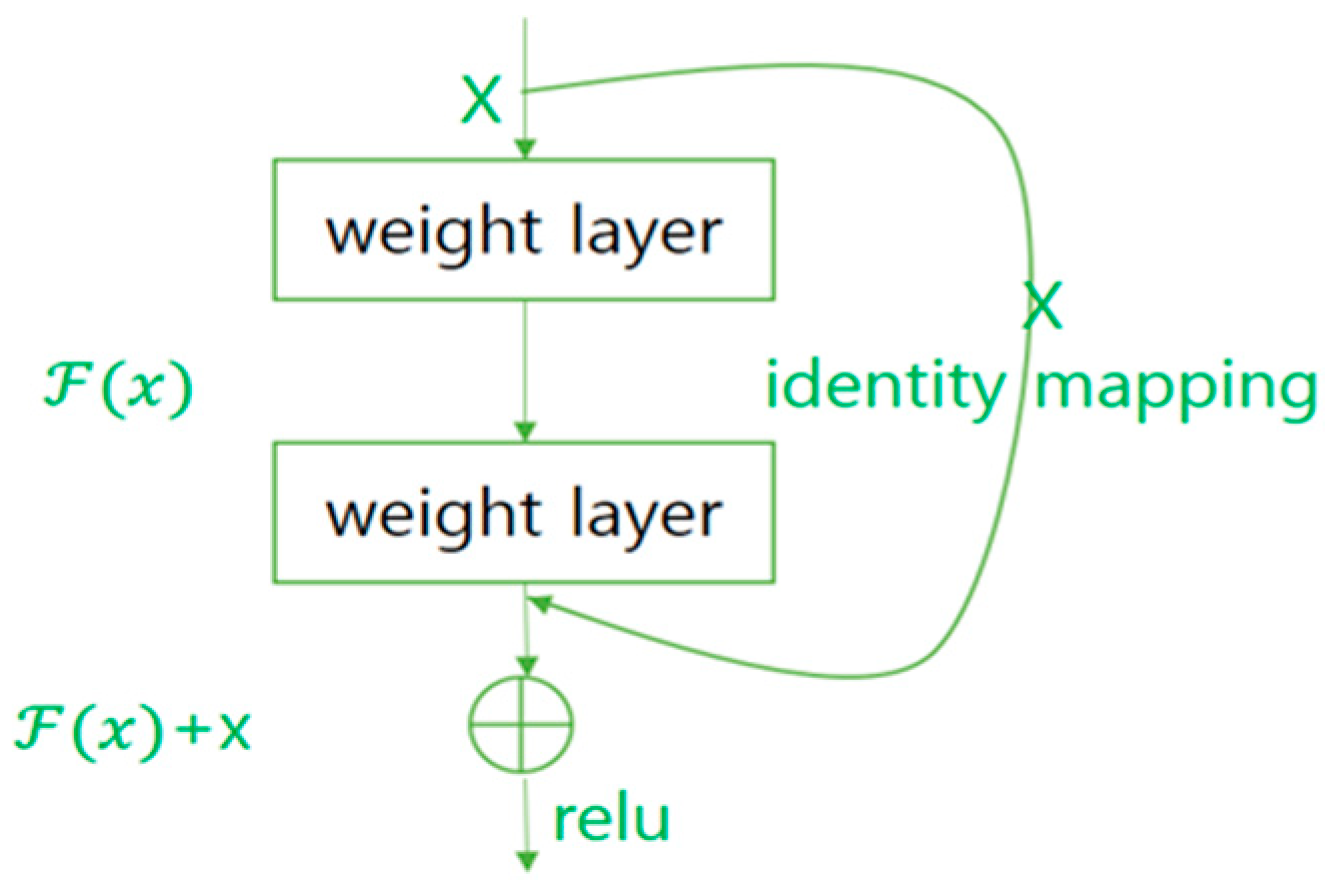

To solve the problem of network degradation, the redundant layer of a network produces an identity mapping function (where a deep network is equivalent to a shallow network). In general, it is difficult for a layer of the network to learn the identity mapping function , but if the network is designed as , the learning of the identity mapping function can be converted into the learning of the residual function . represents identity mapping and . When the parameters are initialized, the general weight parameters are relatively small, which is suitable for learning ; therefore, it is easier to fit the residuals, which is the basic idea behind a residual network.

Figure 7 shows the structure of the residual module. The module provides two choices: identity mapping (x, curved line on the right side, called the shortcut link) and residual mapping (

). If the network has already converged to an optimum, the algorithm continues to deepen the network and the residual mapping is pushed to 0; that is, only identity mapping proceeds. In theory, this means the network has reached an optimal condition. In addition, this means the network performance did not degrade with the increase in depth.

3.3. Training Model

Both algorithms must be slightly tuned to achieve good performance on the validation set. Here, each algorithm uses the first 20 datasets for the model training because the time series algorithms and the amount of data are small. Therefore, the training data are subjected to decreasing gradient data before training. For example, when the 1st–5th datasets are used as the training data, the 2nd–6th datasets are used as the validation data; when the 2nd–6th datasets are used as the training data, the 3rd–7th datasets are used as the validation data. This procedure is followed up to the 20th dataset. Subsequently, predictions are made for the datasets beyond the 20th dataset. These 20 datasets cover features 1, 2, and 3 of the first 20 SOH of each battery. When feature 1 is used to predict the SOH of battery B0005, the first 20 data points for feature 1 and the SOH need to be trained and then predicted. The inputs are the different features proposed in this paper, and the outputs are the SOH of the lithium-ion battery in LSTM and TCN algorithms. The plots of the predicted results are displayed in

Section 4.

4. SOH Prediction Based on Battery Charging and Discharging Time Feature

The algorithm uses time series data from NASA battery datasets that run until failure to train the model and for estimation of the SOH of a lithium-ion battery. In this study, we predicted the SOH of the battery by extracting the features from the battery charging and discharging properties. The SOH of the NASA lithium-ion is based on the available capacity data given in dataset, described by Equation (1):

where

is the current capacity of the battery and

is the rated capacity of the battery. As the battery ages, the SOH gradually decreases. According to IEEE standard 1188–1996, when the SOH of a lithium battery drops to 80%, the battery needs to be replaced. Therefore, the SOH threshold used in this paper is 80% of the rated capacity of the battery.

Figure 8 shows the predicted results for NASA 5, 6, 7, and 18 batteries using feature 1, which is the ratio of the constant-current charging time to the total charging time obtaining using the LSTM.

The battery SOH values were predicted well using feature 1. Extracted feature 2 is the ratio of the charge time to discharge time. The prediction results for batteries 5, 6, 7, and 18 obtained by the LSTM using feature 2 are shown in

Figure 9.

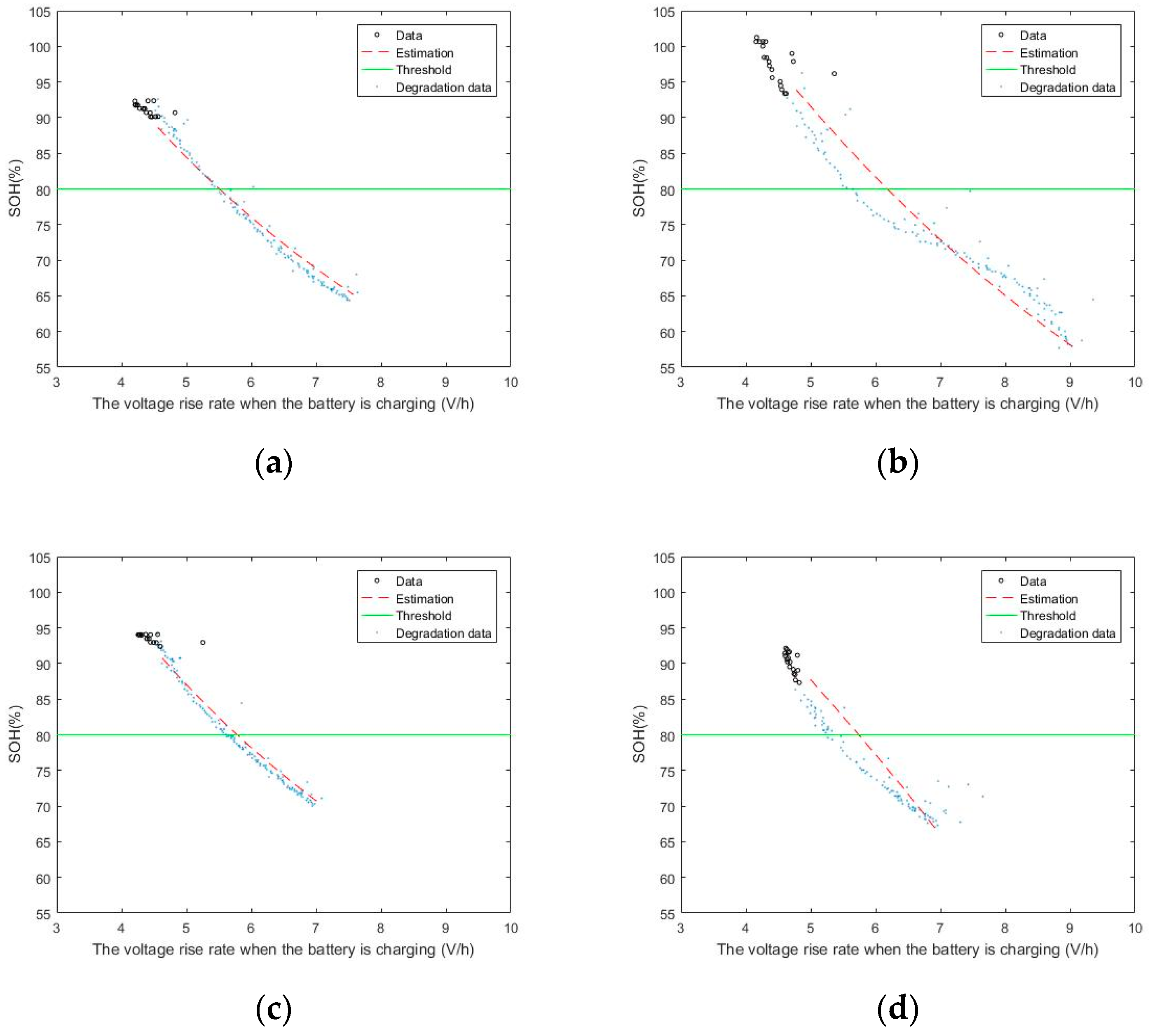

The prediction results for batteries 5, 6, 7, and 18 obtained by the LSTM using feature 3 are shown in

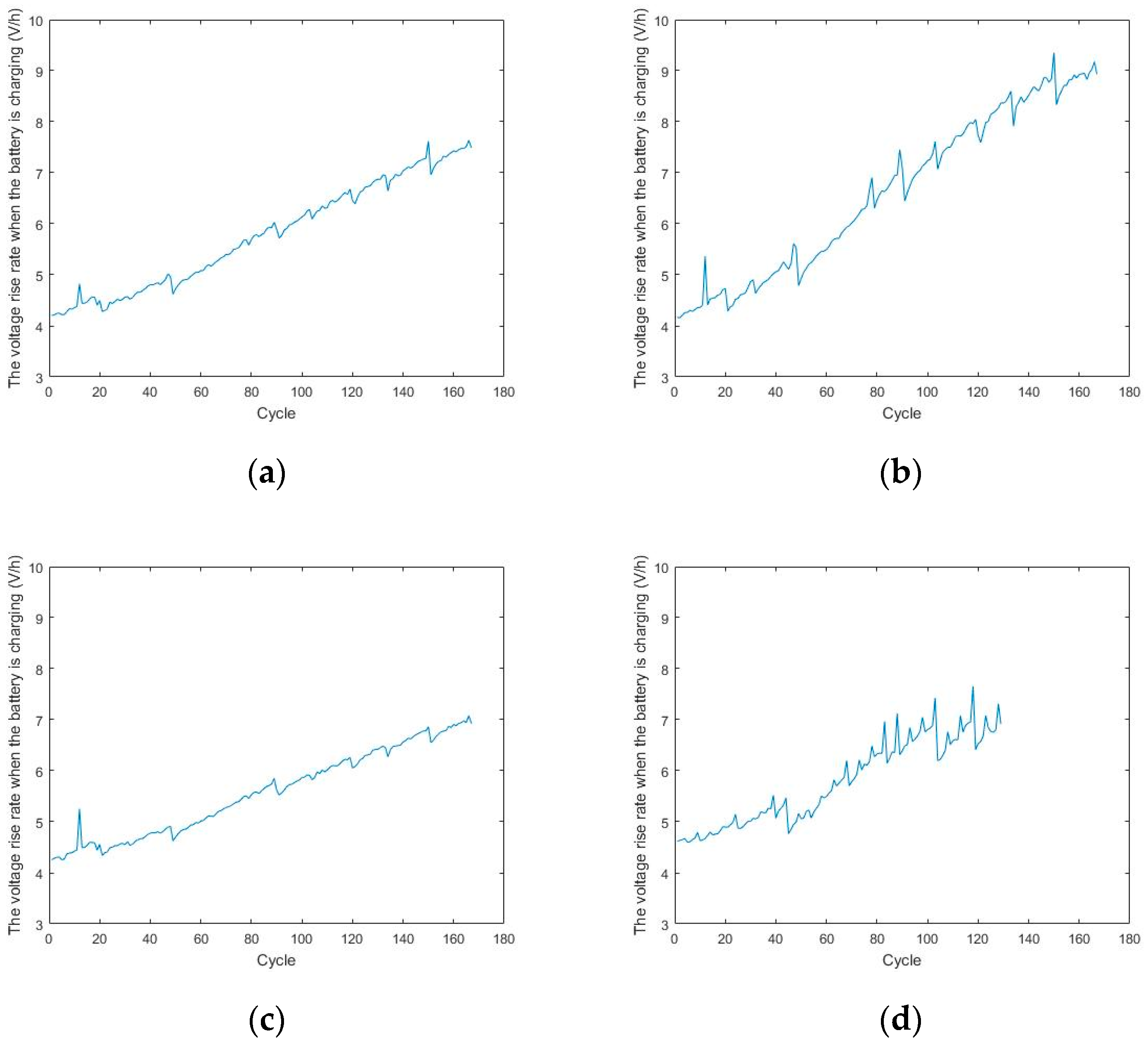

Figure 10. The extracted feature 3 is the voltage increase rate when the battery is charging.

The prediction results for batteries 5, 6, 7, and 18 obtained by the TCN using feature 1 are shown in

Figure 11.

Figure 12 shows the predicted results of TCN for NASA 5, 6, 7, and 18 batteries using Feature 2.

The prediction results for batteries 5, 6, 7, and 18 obtained by the TCN using feature 3 are shown in

Figure 13.

Table 2 lists the prediction results for different algorithms for each battery at 80% SOH using features 1, 2, and 3 by comparing LSTM, TCN, and real data to the threshold, respectively, to obtain the prediction performance. The closer the predicted result, the better the algorithm performance. It can be observed that the results predicted using the TCN algorithm are better than those using the LSTM algorithm.

To better demonstrate the accuracy of the prediction results, the relative error was used to calculate the SOH error values predicted by the LSTM and TCN with features 1, 2, and 3. The maximum relative errors of the features are shown in

Table 3.

The relative errors of the TCN are smaller than that of the LSTM when using features 1 and 3. When feature 2 is used to estimate the SOH of the battery, the relative error using TCN is larger than that using LSTM by approximately 1.29%. Overall, the TCN is more accurate than the LSTM in predicting the battery SOH based on charge–discharge characteristics.

5. Experiment Based Verification

To verify whether the conclusions drawn from NASA’s experimental data were correct, we established a battery-accelerated aging test system in the laboratory. In the developed test system, the voltage, current, temperature, and internal resistance of the battery cell during the charging and discharging processes are obtained by setting the parameters of the accelerated aging test. This section verifies the feasibility of estimating the battery SOH with charging and discharging characteristics using the experimentally obtained dataset.

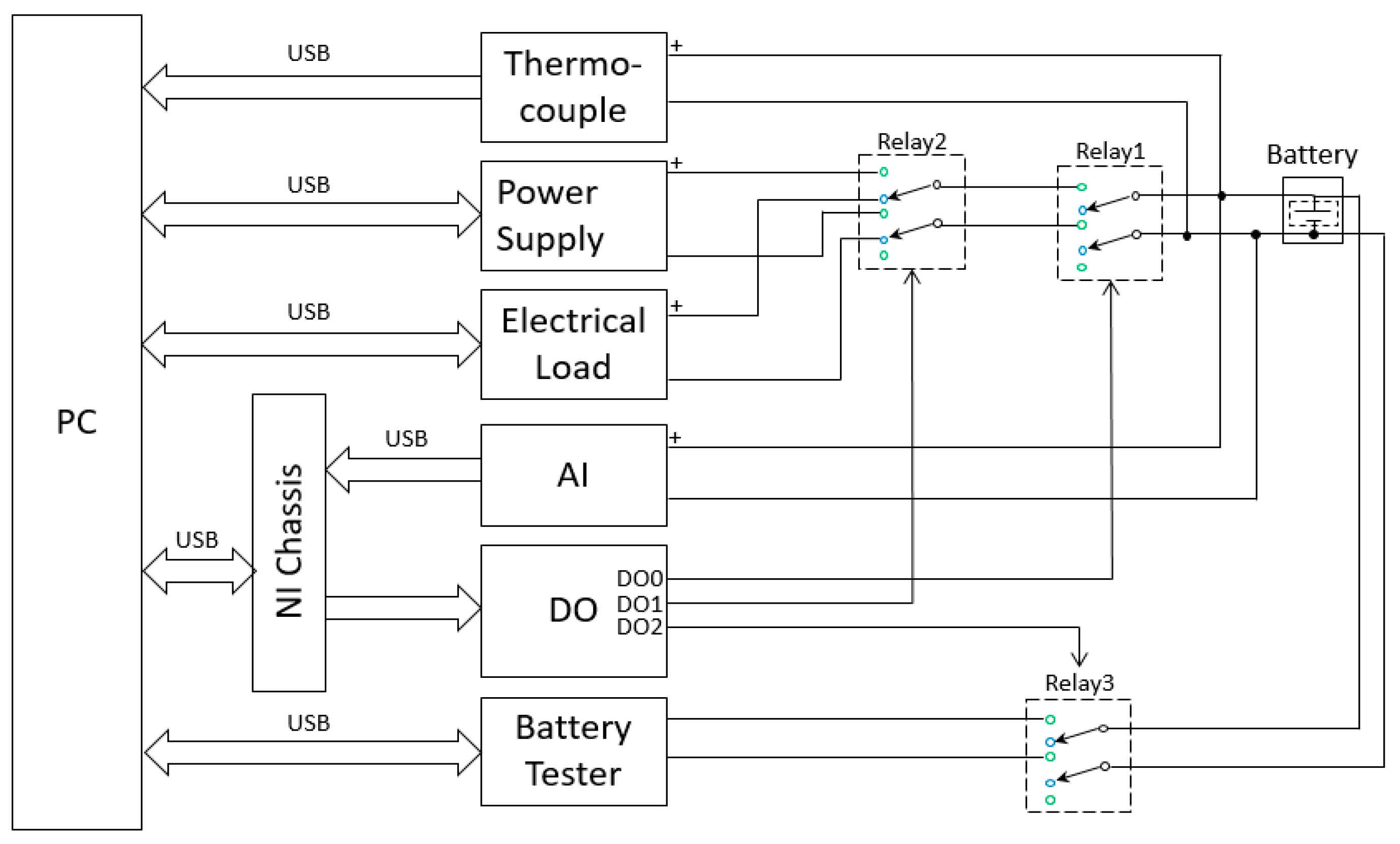

5.1. Experimental Design of the Structure and Control Logic

The experimental device use in the battery-accelerated aging test consists of a programmable DC power supply (PPS) that can charge the battery at constant current and voltage, a programmable electronic load (PEL) for constant current discharge, a battery tester (BT) that is used to measure the battery internal resistance, an NI chassis equipped with an analog input (AI) that measures the battery’s voltage and a digital output (DO) that can control the relay separately, a thermocouple that can measure the battery temperature, three relays, and a control PC [

45]. The battery-accelerated aging test system is shown in

Figure 14.

Table 4 lists the functions and typical specifications of this battery-accelerated aging test system.

The experimental procedure is explained as follows. At the beginning of the experiment, relays 1 and 2 are turned on simultaneously and the battery is connected to the power supply to start charging. In the charging state, constant-current charging is first used; when the charging voltage reaches the set constant-current charging cut-off voltage, the constant-current charging state is converted into the constant-voltage charging state. When the charging current decreases to the set constant-voltage charging cut-off current, relays 1 and 2 are turned off and the battery experiment enters the set rest state. This ensures that the battery temperature drops to 28 °C in the resting state. The functional schematic of the experiment is shown in

Figure 15.

After satisfying the conditions set by the rest state, only relay 1 is turned on and the state is transformed into the constant-current discharging state. The internal resistance of the battery is measured while discharging. In the discharging mode, when the voltage of the battery drops to the set discharging cut-off voltage, relay 1 is turned off again and the state is transformed to the rest state after discharge. The rest mode after discharging is the same as the rest mode after charging, which ensures that the temperature of the battery drops to 28 °C. Finally, after completing the set conditions for rest after the discharge, if the set number of cycles is not satisfied, the accelerated charge–discharge aging test of the battery is repeated. The flowchart of the experiment is shown in

Figure 16.

5.2. Experimental Data

The experiment used the same 18,650 battery as that used by NASA, but its capacity was 2.6 A. The experimental conditions for charging and discharging were similar to those used by NASA. The detailed charging conditions are listed in

Table 5. First, a constant current was used to charge the battery until the voltage reached 4.2 V. Subsequently, the charging mode was switched to constant voltage charging until the charging current decreased to 0.1 A. The discharging mode used a constant current to discharge the battery until the battery voltage dropped to 2.7 V.

A rest time was introduced after charging and discharging to ensure experimental safety. However, because the battery temperature was not high, there was no rest mode after charging. One of the loop cycles was selected and the collected dataset was plotted, as shown in

Figure 17.

As can be seen from these cycle data, the experimental battery took 7341 s to charge and 3229 s to discharge.

Figure 17a shows the voltage changes of the battery during constant-current charging, constant-voltage charging, and constant-current discharging. In

Figure 17b, the current is positive during charging and the discharging current is negative. During constant-current charging, the current is 1.95 A (0.75 C) and the battery temperature constant. In the current-voltage charging state, the battery temperature continues to decrease. However, it increases rapidly in the early stages of constant-current discharge. Toward the end of the discharge period, the temperature increases sharply again, then the battery voltage drops sharply when the voltage is below 3.2 V. It can be observed that the internal resistance increases with the increase in discharging depth.

5.3. Experiment-Based Verification Results

The lithium-ion battery was continuously charged and discharged through the built battery-accelerated aging experimental platform. The SOH predictions were performed for the experimental batteries based on the three charging features determined in this study regarding battery SOH. Although the input and output energies of the battery can be calculated by integrating the current against time using the ampere-hour integration method, the integration calculation and the degradation of the static flux caused by the degradation of the battery performance result in a large cumulative error and reduce the calculation accuracy [

46,

47,

48,

49]. Because it is difficult to directly measure the battery capacity, the internal resistance method was used to define the SOH of the battery in the experiment [

50,

51]. To distinguish it from the SOH based on the capacity of the NASA lithium-ion battery, the SOH defined based on the internal resistance is represented as shown in Equation (2) in the lowercase.

where

represents the internal resistance at the end of battery life,

is the current internal resistance of the battery, and

is the internal resistance of the new battery. The core idea of SOH prediction using this definition is to obtain the internal resistance value of the battery. In general engineering, the measurement value of the internal resistance of the battery is commonly used to measure the general health status of the current battery. In this paper, from the experimental data the current internal resistance of

is taken as the lithium-ion battery termination threshold.

For comparison with the SOH defined by the capacity as described in

Section 2,

Figure 18 shows the relationship between the SOH based on the capacity in the NASA 5 dataset and the SOH based on the internal resistance of the battery.

As observed from the figure, there are slight differences in the SOH depending on the definition. However, a decreasing trend is noted for the SOH as the number of cycles increase. Thus, it can be proven that the SOH defined by the internal resistance is correct.

As presented in

Table 6, the RMSE is used to compare two SOHs: the SOH calculated by the battery capacity measured using the ampere-hour integration method and that calculated by the internal resistance measured using the battery tester.

Notably, by comparing the experimental results of the two batteries, the RMSE values of the SOH calculated using the ampere-hour integration method and the internal resistance measured by the experiment were 0.0273 and 0.0547, respectively. The RMSE values were close to 0, indicating that the SOH values defined using the two methods were not very different. The internal resistance measured in the actual experiment can represent the SOH of the battery, similar to the battery capacity measured using the ampere-hour integration method.

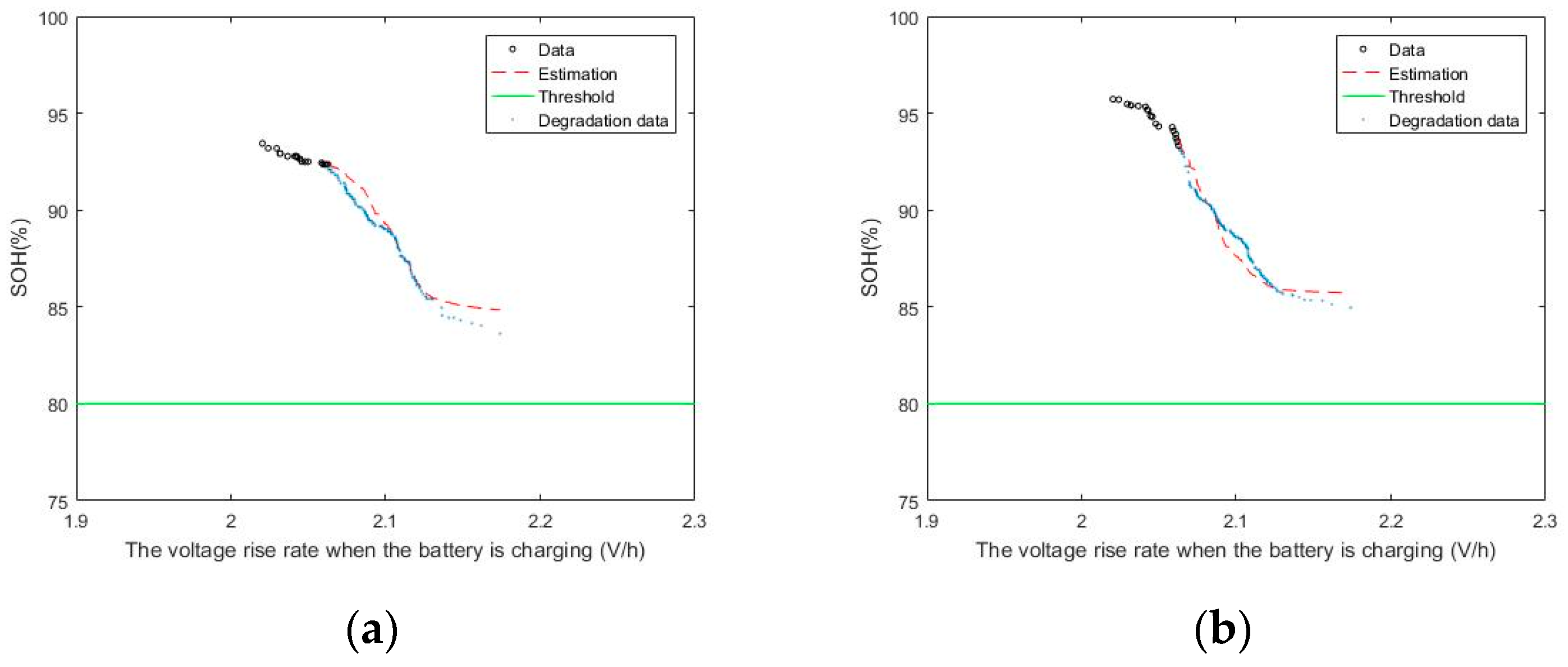

The prediction results for the SOH values obtained by the LSTM using features 1, 2, and 3 are shown in

Figure 19,

Figure 20 and

Figure 21, respectively.

The performance of lithium-ion batteries is better than that of ordinary batteries, and their service life is longer. Although the accelerated aging experiments for the lithium-ion batteries designed in this study did not significantly reduce the battery SOH below the threshold of 80%, the limited battery life degradation experiments proved the argument proposed in this study to predict the SOH of lithium batteries based on charging characteristics. To better compare the performance of the two deep learning algorithms, we chose the results predicted when the SOH was 86% for comparison.

Table 7 shows the predictions of the LSTM and TCN algorithms when the SOH was 86%.

Through the actual lithium-ion battery degradation experimental data, the LSTM and TCN algorithms can accurately predict the battery SOH according to the three charging characteristics proposed in this paper. For the same data, the prediction result for the TCN algorithm was more accurate than that of the LSTM.

6. Conclusions and Discussion

This study determined three characteristic relationships between battery charging and discharging using the battery experimental data published by NASA. These features include the ratio of the constant-current charging time to total charging time, the ratio of the charging time to discharging time, and the voltage increase rate when the battery is charging. We used two sequence prediction deep learning algorithms, LSTM and TCN, to verify the relationship between the three determined charging and discharging characteristics and to predict the SOH of the battery. The predicted results demonstrated that when the TCN algorithm is used with the three characteristic relationships of charging and discharging to predict the SOH of the battery, the predicted results are better than those of the LSTM algorithm. Furthermore, we also proved that the battery charging and discharging characteristics determined in this research can be used to predict battery SOH.

To verify the adaptability of the proposed method, one piece of equipment was prepared for the accelerated aging test of lithium-ion batteries. The test system was primarily composed of a programmable power supply, programmable electronic load, and battery internal resistance tester. The test system can perform charging and discharging degradation cycle tests and battery internal resistance measurements. Here, 200 cycles of charging and discharging data were obtained for a 2.6 Ah 18,650 battery, including current, voltage, internal resistance, and temperature data. The internal resistance was obtained using a battery internal resistance tester, and the SOH of the battery was calculated using the SOH calculation formula for the internal resistance. Owing to the individual differences in the batteries, the initial SOH was not the same. We demonstrated that the three charging characteristics proposed in this study can effectively predict the SOH of a battery. Two different deep learning algorithms were used to predict the battery life, and the prediction accuracy of the two algorithms was compared. From the perspective of predicting the SOH of the battery based on the three charging–discharging characteristics, the newly proposed TCN algorithm has advantages over LSTM.

The three features of the predicted battery SOH extracted in this paper are based on the data from full charge and discharge states as well as of continuous charge and discharge states under the same conditions. For charging and discharging data under random conditions of a battery in use, battery aging will be slower than under accelerated test conditions. With the aging of the battery in normal use, the battery capacity decreases and the charging and discharging times under the rated condition of the battery also shorten, increasing the feasibility of the SOH prediction of the battery under random conditions. Subsequent research could involve the design of random battery charging and discharging experiments to verify this method. In addition, this paper directly used the LSTM and TCN algorithms in deep learning through the proposed three charging features to predict the SOH of lithium-ion batteries, although we lacked a common benchmark work for comparison and the paper had certain limitations.