Quest for the Co-Pyrolysis Behavior of Rice Husk and Cresol Distillation Residue: Interaction, Gas Evolution and Kinetics

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Methods

2.2.1. TG-MS

2.2.2. Kinetic Analysis

3. Results and Discussion

3.1. Thermogravimetric Analysis

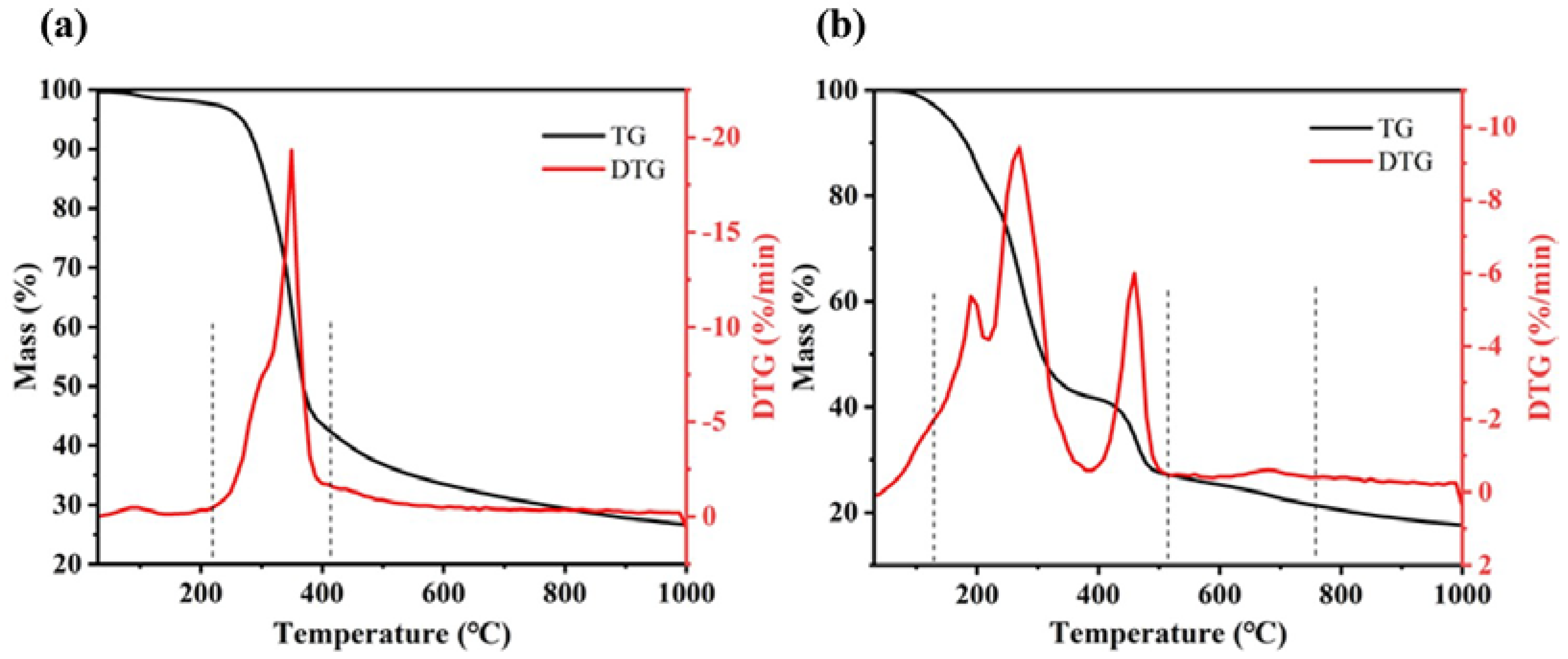

3.1.1. Individual Samples

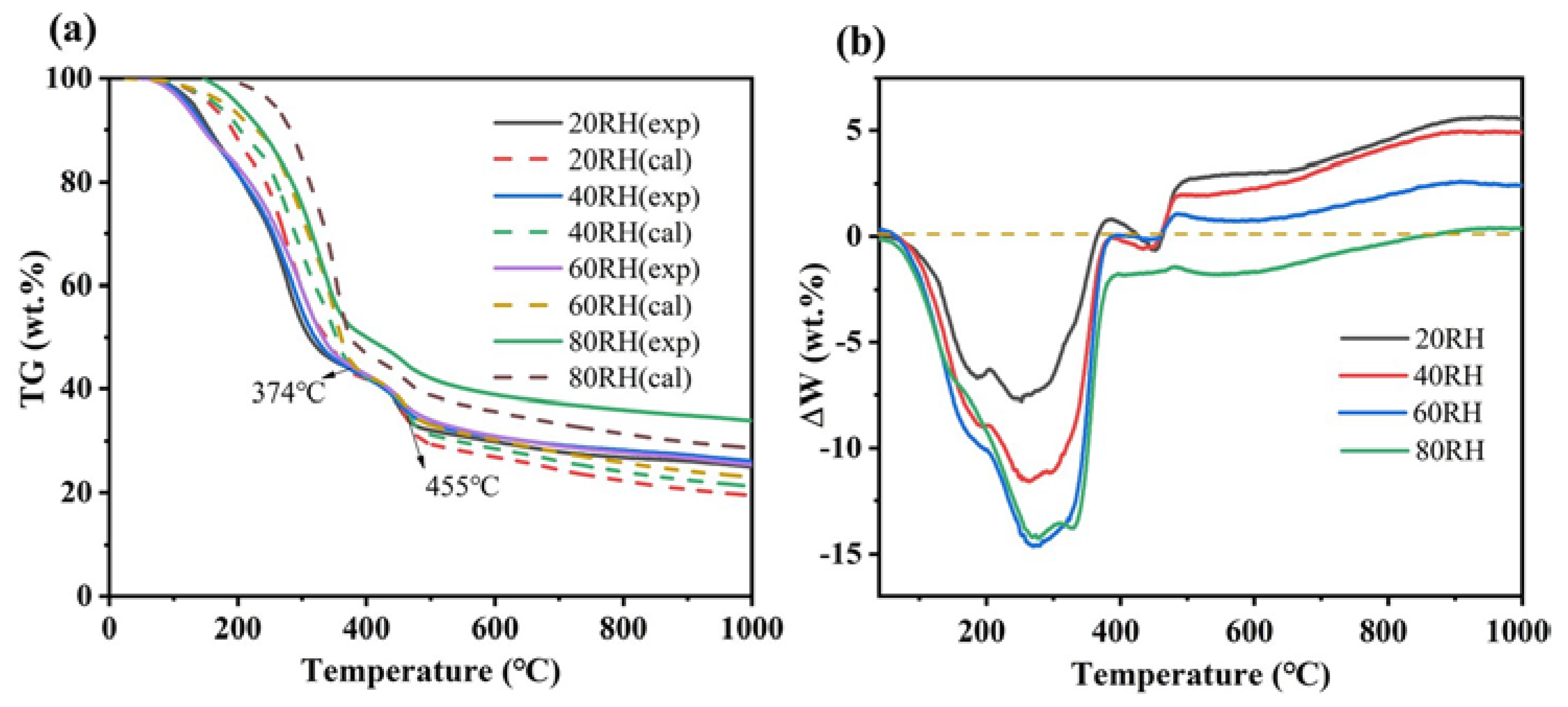

3.1.2. Blend Samples

3.2. Interactive Effects Analysis

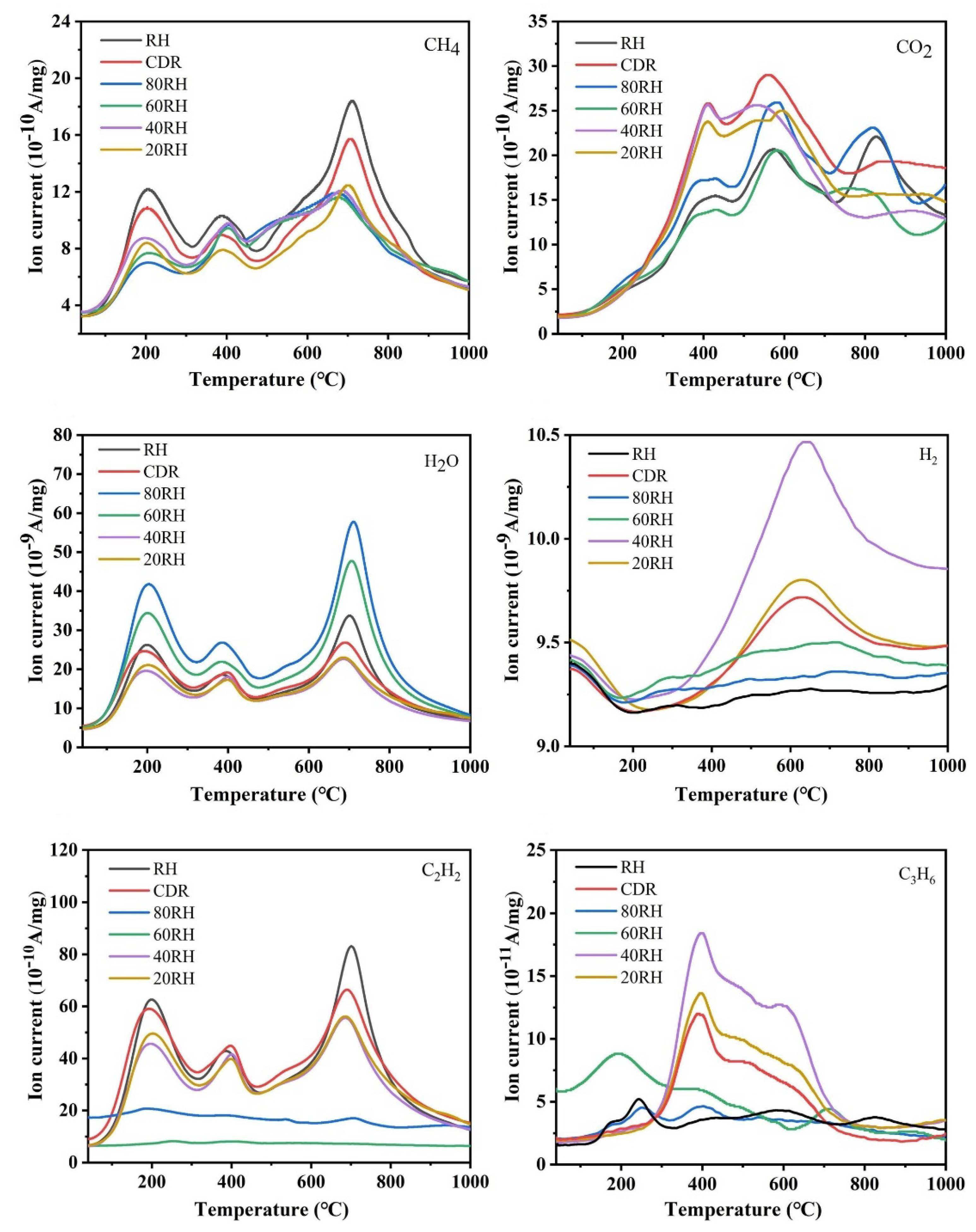

3.3. TG-MS Analysis

3.4. Kinetic Analysis

4. Discussions

- (a)

- Interaction: The deviation of weight loss TG (ΔW) demonstrated that there were synergistic interaction, no interaction and inhibitive interaction between RH and CDR at 76–374 °C, 374–455 °C and 455–1000 °C, respectively. Low temperatures favor synergistic interaction, which is consistent with some previous studies [26,59]. It is reported that the synergistic mechanism was mainly attributed to the catalytic effects of alkali and alkaline earth metals and the transfer of hydrogen and hydroxy radicals [60]. The phenomenon of no interaction generally occurs at the initial stage of pyrolysis due to the low temperature, at which the sample has not started to degrade yet [61]. It is a new discovery that there is no interaction in the middle temperature. This may be the reason for the temporary pause of the blends as the volatiles decrease. The inhibition mechanism was mainly attributed to the carbonization of biomass at high temperatures [62]. Further decomposition of CDR was hindered by a large number of carbonaceous deposits that covered and blocked the molecule pores of CDR residues.

- (b)

- Pyrolysis products: All co-pyrolysis products including CH4, H2O, CO2, H2 and light hydrocarbon were detected via MS. The addition of rice husk reduced the main gaseous products CH4 and CO2. For CH4, RH consistently produced more methane than CDR. This result was mainly attributed to the removal of methoxyl substituents of the lignin, cellulose and hemicellulose and the conversion of the alkyl chain of the lignin [63]. CDR was dominant during the pyrolysis of the blends, which reduced methane production. CDR produces a large amount of CO2 between 400 °C and 600 °C, indicating that a large number of aliphatic groups in CDR were produced by decarboxylation/decarbonylation reaction [64].

- (c)

- Kinetics data: The activation energy of RH in non-catalytic pyrolysis was 21.85 kJ/mol, which is far lower than the results of other studies. Balasundram et al. [65] revealed that the activation energy of RH under non-catalytic action was 49.78 kJ/mol, lower than 53.10 kJ/mol under catalytic action. The kinetic study of CDR has not been reported before this work. López-González et al. [66] reported activation energy of some biomass samples, such as Nannochloropsis gaditana, Scenedesmus almeriensis and Chlorella vulgaris, during pyrolysis in the range of 135–178 kJ/mol. Zhu et al. [26] reported an activation energy value of 71 kJ/mol for bio-oil distillation residue. Sanchez et al. [67] reported that the activation energy of animal manure, sewage sludge and municipal solid waste are 140, 143 and 173 kJ/mol. All samples studied in this paper have low activation energies, mainly due to the synergistic interaction at low temperatures. The synergistic interaction promoted the reaction process and resulted in a significant decrease in activation energy in corresponding conversion stages [62].

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclatures

| CDR | Cresol distillation residue |

| RH | Rice husk |

| TG-MS | thermogravimetry–mass spectrometry |

| ΔW | the deviation of weight loss TG |

| NIST | National Institute of Standards and Technology |

| TG | Thermogravimetric |

| DTG | Differential thermal gravity |

| A | Ash |

| VM | Volatile matter |

| FC | Fixed carbon |

| M | Moisture |

| Ti | the initial decomposition temperature (°C) |

| Tf | the final decomposition temperature (°C) |

| Tmax | the peak temperature (°C) |

| DTGmax | the maximum weight loss rate (wt.%/min) |

| Mf | the residue mass (%) |

| CPI | comprehensive pyrolysis index |

| x | the rate of conversion |

| β | heating rate |

| Ea | activation energy (kJ/mol) |

| A0 | pre-exponential factor (min−1) |

| R2 | linear correlation coefficient |

References

- Kiss, A.A.; Smith, R. Rethinking energy use in distillation processes for a more sustainable chemical industry. Energy 2020, 203, 117788. [Google Scholar] [CrossRef]

- Zhou, J.; Li, X.; Du, J.; He, L.; Wang, C.; Sui, H. Conversion of phenolic mixture to refractory resins: A resourcezation strategy for phenolic distillation residues. J. Hazard. Mater. 2021, 414, 125357. [Google Scholar] [CrossRef] [PubMed]

- Azinfar, B.; Zirrahi, M.; Hassanzadeh, H.; Abedi, J. Characterization of heavy crude oils and residues using combined Gel Permeation Chromatography and simulated distillation. Fuel 2018, 233, 885–893. [Google Scholar] [CrossRef]

- Liu, L.; Song, C.; Tian, S.; Zhang, Q.; Cai, X.; Liu, Y.; Liu, Z.; Wang, W. Structural characterization of sulfur-containing aromatic compounds in heavy oils by FT-ICR mass spectrometry with a narrow isolation window. Fuel 2019, 240, 40–48. [Google Scholar] [CrossRef]

- Stratiev, D.; Shishkova, I.; Tankov, I.; Pavlova, A. Challenges in characterization of residual oils. A review. J. Pet. Sci. Eng. 2019, 178, 227–250. [Google Scholar] [CrossRef]

- Fang, F.; Abbas, A.A.; Chen, Y.P.; Liu, Z.P.; Gao, X.; Guo, J.S. Anaerobic/aerobic/coagulation treatment of leachate from a municipal solid wastes incineration plant. Environ. Technol. 2012, 33, 927–935. [Google Scholar] [CrossRef]

- Frikha, Y.; Fellner, J.; Zairi, M. Leachate generation from landfill in a semi-arid climate: A qualitative and quantitative study from Sousse, Tunisia. Waste Manag. Res. 2017, 35, 940–948. [Google Scholar] [CrossRef]

- Naveen, B.P.; Mahapatra, D.M.; Sitharam, T.G.; Sivapullaiah, P.V.; Ramachandra, T.V. Physico-chemical and biological characterization of urban municipal landfill leachate. Environ. Pollut. 2017, 220, 1–12. [Google Scholar] [CrossRef]

- Iskander, S.M.; Zhao, R.; Pathak, A.; Gupta, A.; Pruden, A.; Novak, J.T.; He, Z. A review of landfill leachate induced ultraviolet quenching substances: Sources, characteristics, and treatment. Water Res. 2018, 145, 297–311. [Google Scholar] [CrossRef]

- Lee, C.C.; Huffman, G.L.; Oberacker, D.A. An Overview of Hazardous/Toxic Waste Incineration. J. Air Pollut. Control Assoc. 1986, 36, 922–931. [Google Scholar] [CrossRef]

- Hitchcock, D.A. Solid-waste disposal-incineration. Chem. Eng. 1979, 86, 185–194. [Google Scholar]

- Hu, X.; Zhang, Z.; Gholizadeh, M.; Zhang, S.; Lam, C.H.; Xiong, Z.; Wang, Y. Coke Formation during Thermal Treatment of Bio-oil. Energy Fuels 2020, 34, 7863–7914. [Google Scholar] [CrossRef]

- Su, T.; Jiang, H.; Sun, Z. Application of GC-FTIR and GC-MS to the Analysis of High Boiling Residue from the Dry Gas Synthesized Ethyl Benzene Distillation Tower Bottom. Pet. Sci. Technol. 2006, 24, 441–448. [Google Scholar] [CrossRef]

- Huang, L.; Xie, C.; Liu, J.; Zhang, X.; Chang, K.; Kuo, J.; Sun, J.; Xie, W.; Zheng, L.; Sun, S.; et al. Influence of catalysts on co-combustion of sewage sludge and water hyacinth blends as determined by TG-MS analysis. Bioresour. Technol. 2018, 247, 217–225. [Google Scholar] [CrossRef] [PubMed]

- Zhang, B.; Zhong, Z.; Min, M.; Ding, K.; Xie, Q.; Ruan, R. Catalytic fast co-pyrolysis of biomass and food waste to produce aromatics: Analytical Py–GC/MS study. Bioresour. Technol. 2015, 189, 30–35. [Google Scholar] [CrossRef] [PubMed]

- Fang, S.; Lin, Y.; Huang, Z.; Huang, H.; Chen, S.; Ding, L. Investigation of co-pyrolysis characteristics and kinetics of municipal solid waste and paper sludge through TG-FTIR and DAEM. Thermochim. Acta 2021, 700, 178889. [Google Scholar] [CrossRef]

- Lu, J.-S.; Chang, Y.; Poon, C.-S.; Lee, D.-J. Slow pyrolysis of municipal solid waste (MSW): A review. Bioresour. Technol. 2020, 312, 123615. [Google Scholar] [CrossRef]

- Mu, L.; Chen, J.; Yin, H.; Song, X.; Li, A.; Chi, X. Pyrolysis behaviors and kinetics of refining and chemicals wastewater, lignite and their blends through TGA. Bioresour. Technol. 2015, 180, 22–31. [Google Scholar] [CrossRef]

- Lin, Y.; Ma, X.; Ning, X.; Yu, Z. TGA–FTIR analysis of co-combustion characteristics of paper sludge and oil-palm solid wastes. Energy Convers. Manag. 2015, 89, 727–734. [Google Scholar] [CrossRef]

- Wang, T.; Fu, T.; Chen, K.; Cheng, R.; Chen, S.; Liu, J.; Mei, M.; Li, J.; Xue, Y. Co-combustion behavior of dyeing sludge and rice husk by using TG-MS: Thermal conversion, gas evolution, and kinetic analyses. Bioresour. Technol. 2020, 311, 123527. [Google Scholar] [CrossRef]

- Zhang, J.; Sun, G.; Liu, J.; Evrendilek, F.; Buyukada, M. Co-combustion of textile dyeing sludge with cattle manure: Assessment of thermal behavior, gaseous products, and ash characteristics. J. Clean. Prod. 2020, 253, 119950. [Google Scholar] [CrossRef]

- Cai, H.; Liu, J.; Kuo, J.; Buyukada, M.; Evrendilek, F. Thermal characteristics, kinetics, gas emissions and thermodynamic simulations of (co-)combustions of textile dyeing sludge and waste tea. J. Clean. Prod. 2019, 239, 118113. [Google Scholar] [CrossRef]

- Peng, X.; Ma, X.; Xu, Z. Thermogravimetric analysis of co-combustion between microalgae and textile dyeing sludge. Bioresour. Technol. 2015, 180, 288–295. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; Wang, S.; Ma, X.; Tian, Y. Interaction between coal and distillation residues of coal tar during co-pyrolysis. Fuel Process. Technol. 2015, 138, 221–227. [Google Scholar] [CrossRef]

- Li, H.; Xia, S.; Ma, P. Thermogravimetric investigation of the co-combustion between the pyrolysis oil distillation residue and lignite. Bioresour. Technol. 2016, 218, 615–622. [Google Scholar] [CrossRef]

- Zhu, X.; Li, K.; Zhang, L.; Wu, X.; Zhu, X. Synergistic effects on thermochemical behaviors of co-pyrolysis between bio-oil distillation residue and bituminous coal. Energy Convers. Manag. 2017, 151, 209–215. [Google Scholar] [CrossRef]

- Diao, R.; Wang, C.; Luo, Z.; Zhu, X. The valorization of co-pyrolysis bio-oil derived from bio-oil distillation residue and walnut shell via coupling fractional condensation and lyophilization. J. Clean. Prod. 2021, 294, 126263. [Google Scholar] [CrossRef]

- Sad, M.E.; Padró, C.L.; Apesteguía, C.R. Selective synthesis of p-cresol by methylation of phenol. Appl. Catal. A Gen. 2008, 342, 40–48. [Google Scholar] [CrossRef]

- Lv, W.; Wu, J.; He, X.; Lv, J.; Yang, X.; Tang, R. A New High Decorative Phenolic-Polyurethane High Temperature Resistant Paint Prepared by Paracresol Waste Residue. CHN. Bldg. Mater. Sci. Technol. 2012, 21, 13–16. [Google Scholar]

- Miranda, T.; Esteban, A.; Rojas, S.; Montero, I.; Ruiz, A. Combustion analysis of different olive residues. Int. J. Mol. Sci. 2008, 9, 512–525. [Google Scholar] [CrossRef]

- Idris, S.S.; Rahman, N.A.; Ismail, K. Combustion characteristics of Malaysian oil palm biomass, sub-bituminous coal and their respective blends via thermogravimetric analysis (TGA). Bioresour. Technol. 2012, 123, 581–591. [Google Scholar] [CrossRef] [PubMed]

- Coats, A.W.; Redfern, J.P. Kinetic Parameters from Thermogravimetric Data. Nature 1964, 201, 68–69. [Google Scholar] [CrossRef]

- Damartzis, T.; Vamvuka, D.; Sfakiotakis, S.; Zabaniotou, A. Thermal degradation studies and kinetic modeling of cardoon (Cynara cardunculus) pyrolysis using thermogravimetric analysis (TGA). Bioresour. Technol. 2011, 102, 6230–6238. [Google Scholar] [CrossRef] [PubMed]

- Xiao, H.; Ma, X.; Lai, Z. Isoconversional kinetic analysis of co-combustion of sewage sludge with straw and coal. Appl. Energy 2009, 86, 1741–1745. [Google Scholar] [CrossRef]

- Vyazovkin, S.; Burnham, A.K.; Criado, J.M.; Pérez-Maqueda, L.A.; Popescu, C.; Sbirrazzuoli, N. ICTAC Kinetics Committee recommendations for performing kinetic computations on thermal analysis data. Thermochim. Acta 2011, 520, 1–19. [Google Scholar] [CrossRef]

- Loy, A.C.M.; Yusup, S.; Lam, M.K.; Chin, B.L.F.; Shahbaz, M.; Yamamoto, A.; Acda, M.N. The effect of industrial waste coal bottom ash as catalyst in catalytic pyrolysis of rice husk for syngas production. Energy Convers. Manag. 2018, 165, 541–554. [Google Scholar] [CrossRef]

- Gao, W.; Li, H.; Song, B.; Zhang, S. Integrated Leaching and Thermochemical Technologies for Producing High-Value Products from Rice Husk: Leaching of Rice Husk with the Aqueous Phases of Bioliquids. Energies 2020, 13, 6033. [Google Scholar] [CrossRef]

- Ledakowicz, S.; Stolarek, P.; Malinowski, A.; Lepez, O. Thermochemical treatment of sewage sludge by integration of drying and pyrolysis/autogasification. Renew. Sustain. Energy Rev. 2019, 104, 319–327. [Google Scholar] [CrossRef]

- Zhang, J.; Zhao, Q.H.; Wang, X.; Chen, F. In Retroreflector Calibration Method and Uncertainty Evaluation. CHN. Meet. 2021, 266–268. [Google Scholar]

- Buratti, C.; Barbanera, M.; Bartocci, P.; Fantozzi, F. Thermogravimetric analysis of the behavior of sub-bituminous coal and cellulosic ethanol residue during co-combustion. Bioresour. Technol. 2015, 186, 154–162. [Google Scholar] [CrossRef]

- Chen, C.; Ma, X.; He, Y. Co-pyrolysis characteristics of microalgae Chlorella vulgaris and coal through TGA. Bioresour. Technol. 2012, 117, 264–273. [Google Scholar] [CrossRef] [PubMed]

- Xie, Z.; Ma, X. The thermal behaviour of the co-combustion between paper sludge and rice straw. Bioresour. Technol. 2013, 146, 611–618. [Google Scholar] [CrossRef] [PubMed]

- Aboulkas, A.; El Harfi, K.; El Bouadili, A. Pyrolysis of olive residue/low density polyethylene mixture: Part I Thermogravimetric kinetics. J. Fuel Chem. Technol. 2008, 36, 672–678. [Google Scholar] [CrossRef]

- Aboulkas, A.; El harfi, K.; Nadifiyine, M.; El bouadili, A. Investigation on pyrolysis of Moroccan oil shale/plastic mixtures by thermogravimetric analysis. Fuel Processing Technol. 2008, 89, 1000–1006. [Google Scholar] [CrossRef]

- Lee, J.-Y.; Yoo, C.; Jun, S.-Y.; Ahn, C.-Y.; Oh, H.-M. Comparison of several methods for effective lipid extraction from microalgae. Bioresour. Technol. 2010, 101, S75–S77. [Google Scholar] [CrossRef]

- Zhu, J.; Zhu, L.; Guo, D.; Chen, Y.; Wang, X.; Zhu, Y. Co-pyrolysis of petrochemical sludge and sawdust for syngas production by TG-MS and fixed bed reactor. Int. J. Hydrogen Energy 2020, 45, 30232–30243. [Google Scholar] [CrossRef]

- Wu, Z.; Yang, W.; Tian, X.; Yang, B. Synergistic effects from co-pyrolysis of low-rank coal and model components of microalgae biomass. Energy Convers. Manag. 2017, 135, 212–225. [Google Scholar] [CrossRef]

- Cong, K.; Han, F.; Zhang, Y.; Li, Q. The investigation of co-combustion characteristics of tobacco stalk and low rank coal using a macro-TGA. Fuel 2019, 237, 126–132. [Google Scholar] [CrossRef]

- Peng, X.; Ma, X.; Lin, Y.; Guo, Z.; Hu, S.; Ning, X.; Cao, Y.; Zhang, Y. Co-pyrolysis between microalgae and textile dyeing sludge by TG–FTIR: Kinetics and products. Energy Convers. Manag. 2015, 100, 391–402. [Google Scholar] [CrossRef]

- Wang, M.; Li, Z.; Huang, W.; Yang, J.; Xue, H. Coal pyrolysis characteristics by TG–MS and its late gas generation potential. Fuel 2015, 156, 243–253. [Google Scholar] [CrossRef]

- Blanco López, M.C.; Blanco, C.G.; Martínez-Alonso, A.; Tascón, J.M.D. Composition of gases released during olive stones pyrolysis. J. Anal. Appl. Pyrolysis 2002, 65, 313–322. [Google Scholar] [CrossRef]

- Li, T.; Guo, F.; Li, X.; Liu, Y.; Peng, K.; Jiang, X.; Guo, C. Characterization of herb residue and high ash-containing paper sludge blends from fixed bed pyrolysis. Waste Manag. 2018, 76, 544–554. [Google Scholar] [CrossRef] [PubMed]

- Arenillas, A.; Rubiera, F.; Pis, J.J. Simultaneous thermogravimetric–mass spectrometric study on the pyrolysis behaviour of different rank coals. J. Anal. Appl. Pyrolysis 1999, 50, 31–46. [Google Scholar] [CrossRef] [Green Version]

- Zou, C.; Ma, C.; Zhao, J.; Shi, R.; Li, X. Characterization and non-isothermal kinetics of Shenmu bituminous coal devolatilization by TG-MS. J. Anal. Appl. Pyrolysis 2017, 127, 309–320. [Google Scholar] [CrossRef]

- Luo, L.; Liu, J.; Zhang, H.; Ma, J.; Wang, X.; Jiang, X. TG-MS-FTIR study on pyrolysis behavior of superfine pulverized coal. J. Anal. Appl. Pyrolysis 2017, 128, 64–74. [Google Scholar] [CrossRef]

- Yu, D.; Chen, M.; Wei, Y.; Niu, S.; Xue, F. An assessment on co-combustion characteristics of Chinese lignite and eucalyptus bark with TG–MS technique. Powder Technol. 2016, 294, 463–471. [Google Scholar] [CrossRef]

- Arenillas, A.; Rubiera, F.; Pis, J.J.; Cuesta, M.J.; Iglesias, M.J.; Jiménez, A.; Suárez-Ruiz, I. Thermal behaviour during the pyrolysis of low rank perhydrous coals. J. Anal. Appl. Pyrolysis 2003, 68, 371–385. [Google Scholar] [CrossRef]

- Mishra, R.K.; Mohanty, K. Pyrolysis kinetics and thermal behavior of waste sawdust biomass using thermogravimetric analysis. Bioresour. Technol. 2018, 251, 63–74. [Google Scholar] [CrossRef]

- Zhang, X.; Lei, H.; Zhu, L.; Zhu, X.; Qian, M.; Yadavalli, G.; Wu, J.; Chen, S. Thermal behavior and kinetic study for catalytic co-pyrolysis of biomass with plastics. Bioresour. Technol. 2016, 220, 233–238. [Google Scholar] [CrossRef]

- Wu, Z.; Wang, S.; Zhao, J.; Chen, L.; Meng, H. Thermochemical behavior and char morphology analysis of blended bituminous coal and lignocellulosic biomass model compound co-pyrolysis: Effects of cellulose and carboxymethylcellulose sodium. Fuel 2016, 171, 65–73. [Google Scholar] [CrossRef]

- Fang, S.; Yu, Z.; Lin, Y.; Lin, Y.; Fan, Y.; Liao, Y.; Ma, X. A study on experimental characteristic of co-pyrolysis of municipal solid waste and paper mill sludge with additives. Appl. Therm. Eng. 2017, 111, 292–300. [Google Scholar] [CrossRef]

- Wang, C.; Bi, H.; Lin, Q.; Jiang, X.; Jiang, C. Co-pyrolysis of sewage sludge and rice husk by TG–FTIR–MS: Pyrolysis behavior, kinetics, and condensable/non-condensable gases characteristics. Renew. Energy 2020, 160, 1048–1066. [Google Scholar] [CrossRef]

- Özsin, G.; Pütün, A.E. Kinetics and evolved gas analysis for pyrolysis of food processing wastes using TGA/MS/FT-IR. Waste Manag. 2017, 64, 315–326. [Google Scholar] [CrossRef] [PubMed]

- Yu, J.; Lucas, J.A.; Wall, T.F. Formation of the structure of chars during devolatilization of pulverized coal and its thermoproperties: A review. Prog. Energy Combust. Sci. 2007, 33, 135–170. [Google Scholar] [CrossRef]

- Balasundram, V.; Ibrahim, N.; Kasmani, R.M.; Hamid, M.K.A.; Isha, R.; Hasbullah, H.; Ali, R.R. Thermogravimetric catalytic pyrolysis and kinetic studies of coconut copra and rice husk for possible maximum production of pyrolysis oil. J. Clean. Prod. 2017, 167, 218–228. [Google Scholar] [CrossRef]

- López-González, D.; Fernandez-Lopez, M.; Valverde, J.L.; Sanchez-Silva, L. Kinetic analysis and thermal characterization of the microalgae combustion process by thermal analysis coupled to mass spectrometry. Appl. Energy 2014, 114, 227–237. [Google Scholar] [CrossRef]

- Sanchez, M.E.; Otero, M.; Gómez, X.; Morán, A. Thermogravimetric kinetic analysis of the combustion of biowastes. Renew. Energy 2009, 34, 1622–1627. [Google Scholar] [CrossRef]

| Samples | Ultimate Analysis (%) | Proximate Analysis (%) | H/C | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| C | N | H | S | O | A | VM | FC | M | ||

| RH | 42.68 | 0.54 | 5.26 | 0.06 | 37.78 | 13.68 | 70.45 | 9.45 | 6.42 | 0.1232 |

| CDR | 64.12 | 0 | 6.23 | 3.57 | 25.53 | 0.55 | 60.00 | 29.45 | 10.00 | 0.0972 |

| Samples | Content(%) | |||||||

|---|---|---|---|---|---|---|---|---|

| Ca | Mg | K | Fe | Cu | Zn | Ni | Si | |

| RH | 0.1222 | 0.0708 | 0.6647 | 0.0279 | 0.0014 | 0.0038 | 0.0022 | 6.0389 |

| CDR | 0.0025 | 0.0215 | 0.0021 | 0.0012 | 0.0814 | |||

| Samples | Ti (°C) | Tf (°C) | Tmax (°C) | DTGmax (wt.%/min) | Mf % |

|---|---|---|---|---|---|

| RH | 274.20 | 983 | 350 | 19.16 | 26.66 |

| 80 RH | 249.03 | 982 | 320 | 9.06 | 25.21 |

| 60 RH | 222.54 | 978 | 298 | 8.37 | 25.44 |

| 40 RH | 222.11 | 975 | 288 | 8.80 | 26.09 |

| 20 RH | 194.09 | 973 | 270 | 9.46 | 26.97 |

| CDR | 177.24 | 965 | 268 | 11.84 | 17.58 |

| Samples | Equation | Ea (kJ/mol) | A0 (min−1) | R2 |

|---|---|---|---|---|

| RH | y = −2628.6x − 9.8112 | 21.85 | 42.25 | 0.9918 |

| 80 RH | y = −1852.8x − 9.9077 | 15.40 | 27.04 | 0.9530 |

| 60 RH | y = −1805.5x − 9.8152 | 15.01 | 28.91 | 0.9845 |

| 40 RH | y = −2015.3x − 9.3487 | 16.76 | 51.46 | 0.9774 |

| 20 RH | y = −2223x − 8.9758 | 18.48 | 82.38 | 0.9597 |

| CDR | y = −2887.8x − 8.0009 | 24.00 | 283.62 | 0.9649 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, N.; Cui, M.; Zhang, Z.; Tang, J.; Qiao, X. Quest for the Co-Pyrolysis Behavior of Rice Husk and Cresol Distillation Residue: Interaction, Gas Evolution and Kinetics. Energies 2022, 15, 2130. https://doi.org/10.3390/en15062130

Xu N, Cui M, Zhang Z, Tang J, Qiao X. Quest for the Co-Pyrolysis Behavior of Rice Husk and Cresol Distillation Residue: Interaction, Gas Evolution and Kinetics. Energies. 2022; 15(6):2130. https://doi.org/10.3390/en15062130

Chicago/Turabian StyleXu, Na, Mifen Cui, Zhuxiu Zhang, Jihai Tang, and Xu Qiao. 2022. "Quest for the Co-Pyrolysis Behavior of Rice Husk and Cresol Distillation Residue: Interaction, Gas Evolution and Kinetics" Energies 15, no. 6: 2130. https://doi.org/10.3390/en15062130

APA StyleXu, N., Cui, M., Zhang, Z., Tang, J., & Qiao, X. (2022). Quest for the Co-Pyrolysis Behavior of Rice Husk and Cresol Distillation Residue: Interaction, Gas Evolution and Kinetics. Energies, 15(6), 2130. https://doi.org/10.3390/en15062130