Corona Characteristics of a Large-Sized AC Grading Ring and Prediction of Corona Onset Field Intensity

Abstract

:1. Introduction

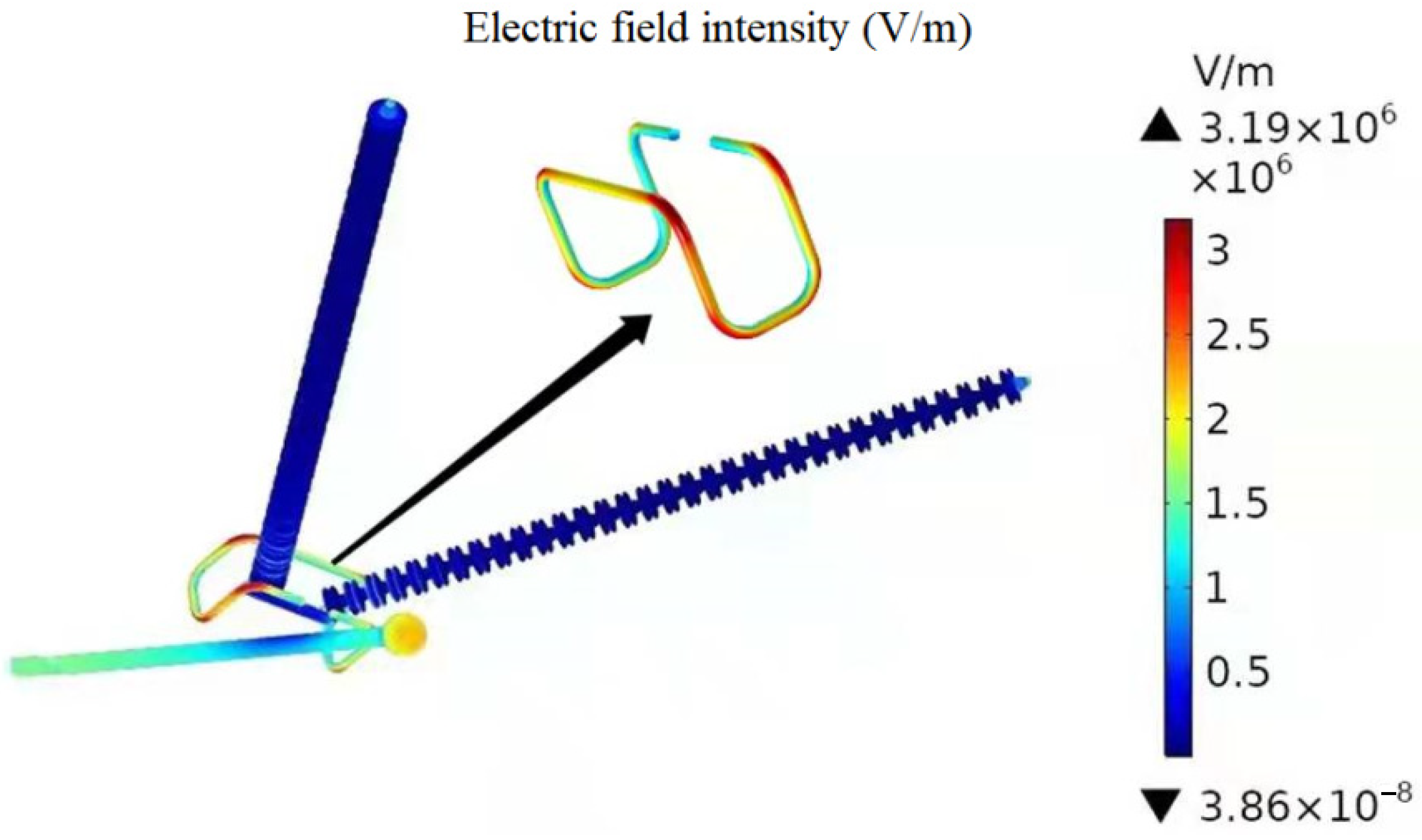

2. Calculation of Electric Field Distribution on the Grading Ring Surface and Study on Its Influence Law

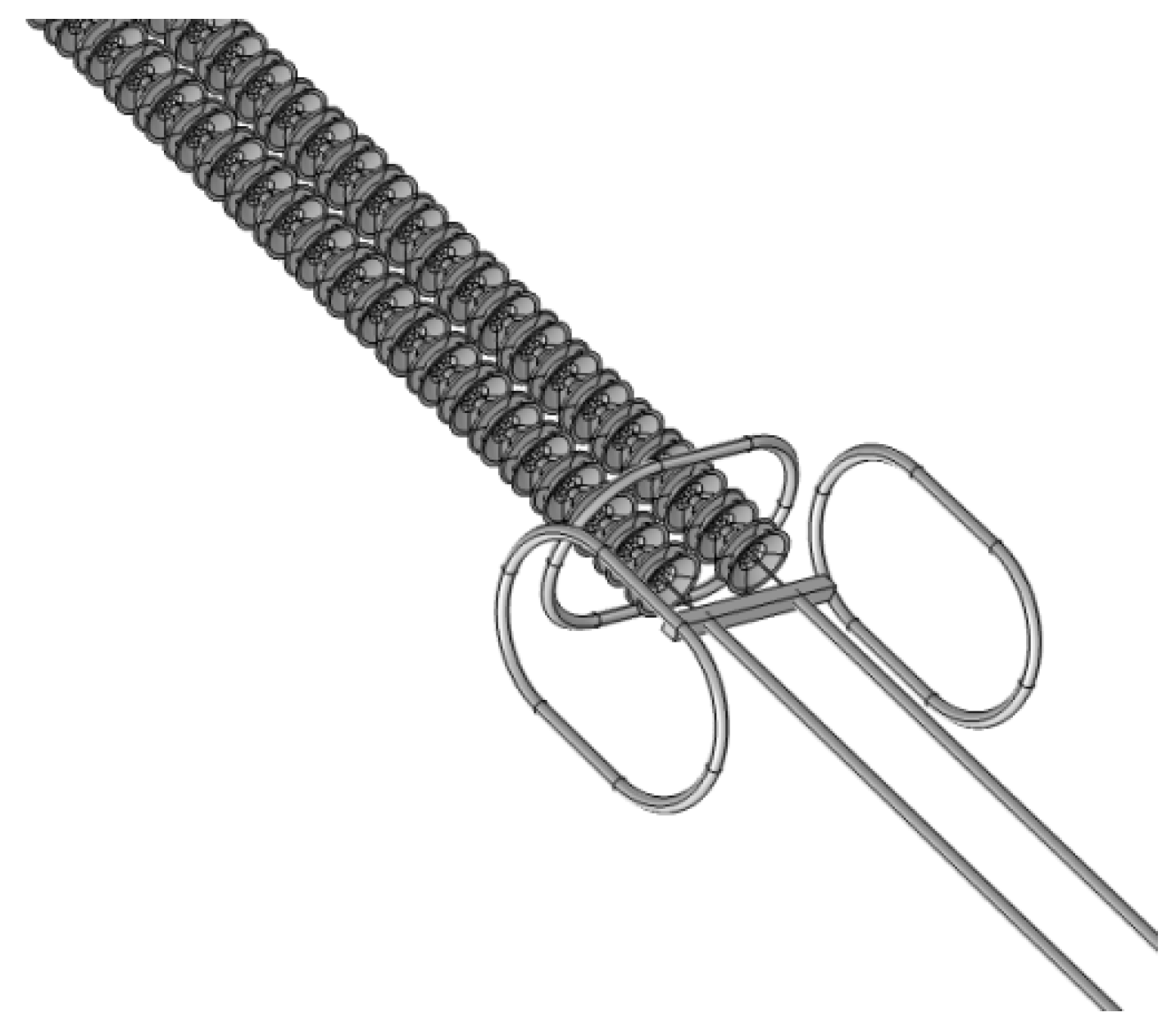

2.1. The Saddle Type Grading Ring

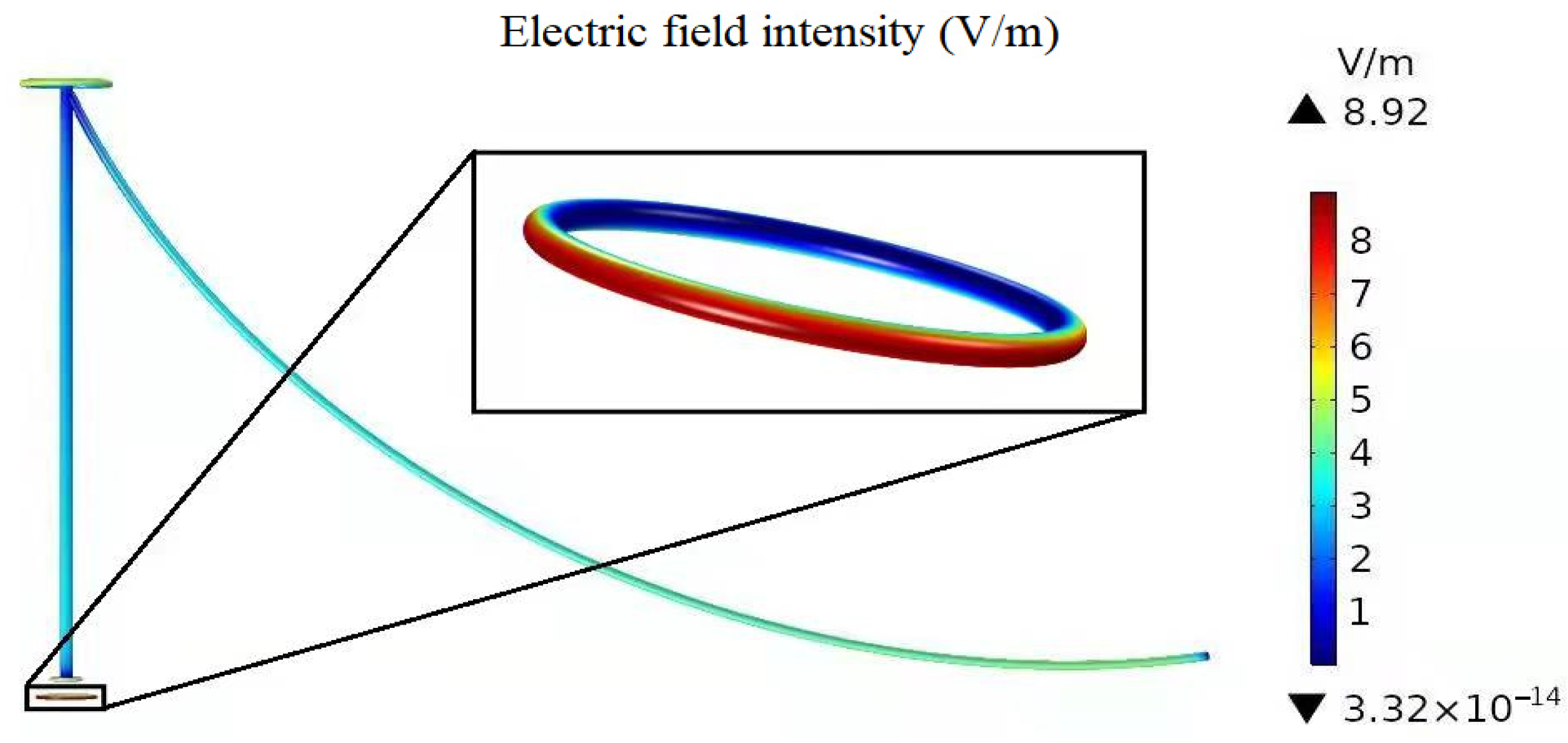

2.1.1. Calculation of Electric Field Distribution

2.1.2. Influence Law of Electric Field Distribution

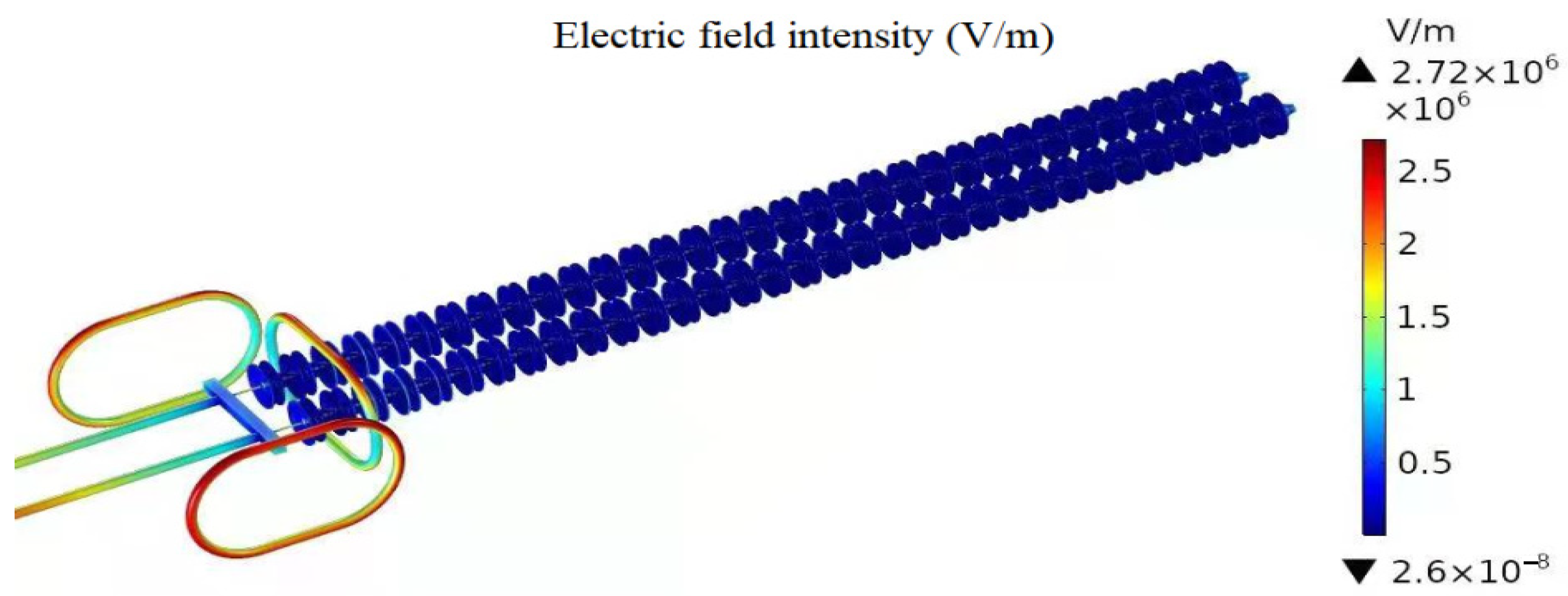

2.2. The Elliptical and Circular Grading Ring

2.2.1. Calculation of Electric Field Distribution

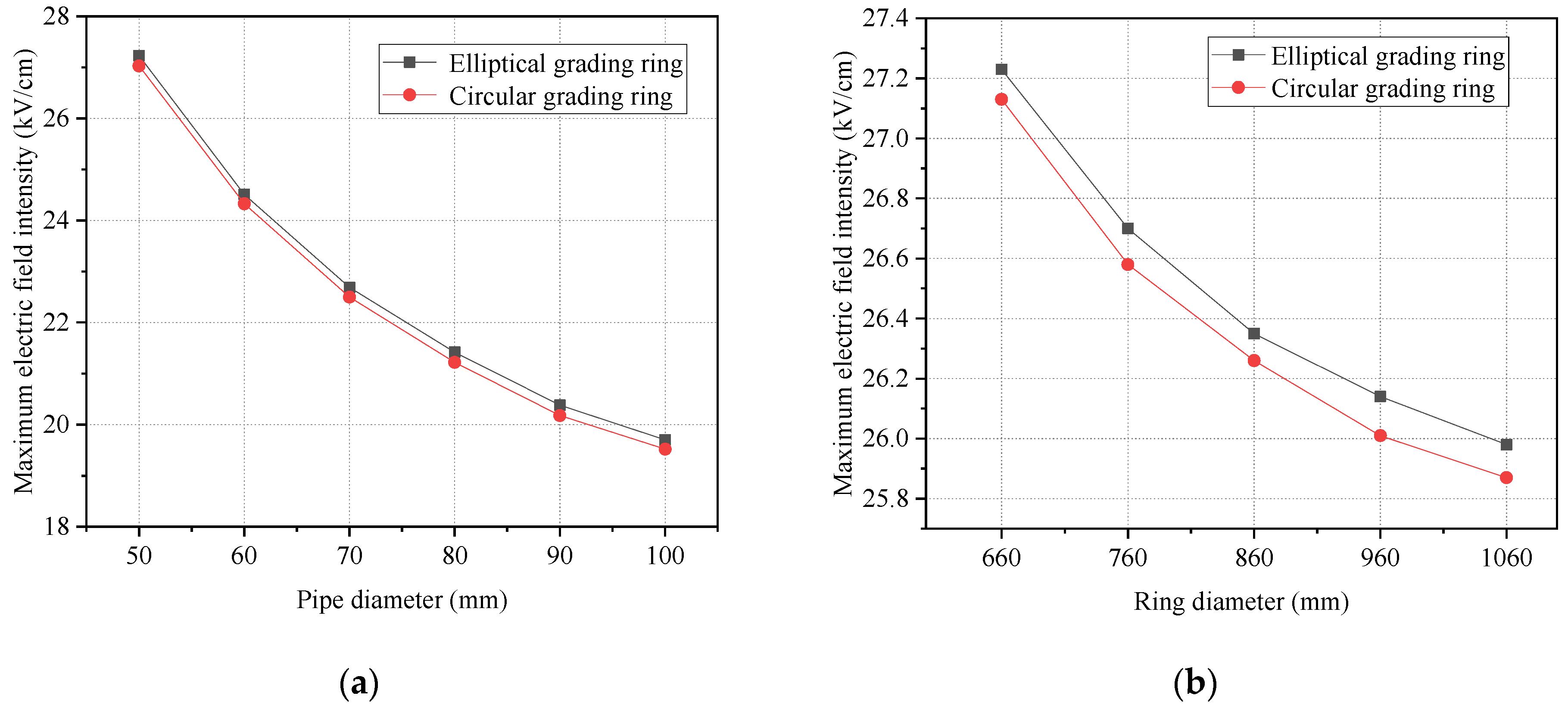

2.2.2. Influence Law of Electric Field Distribution

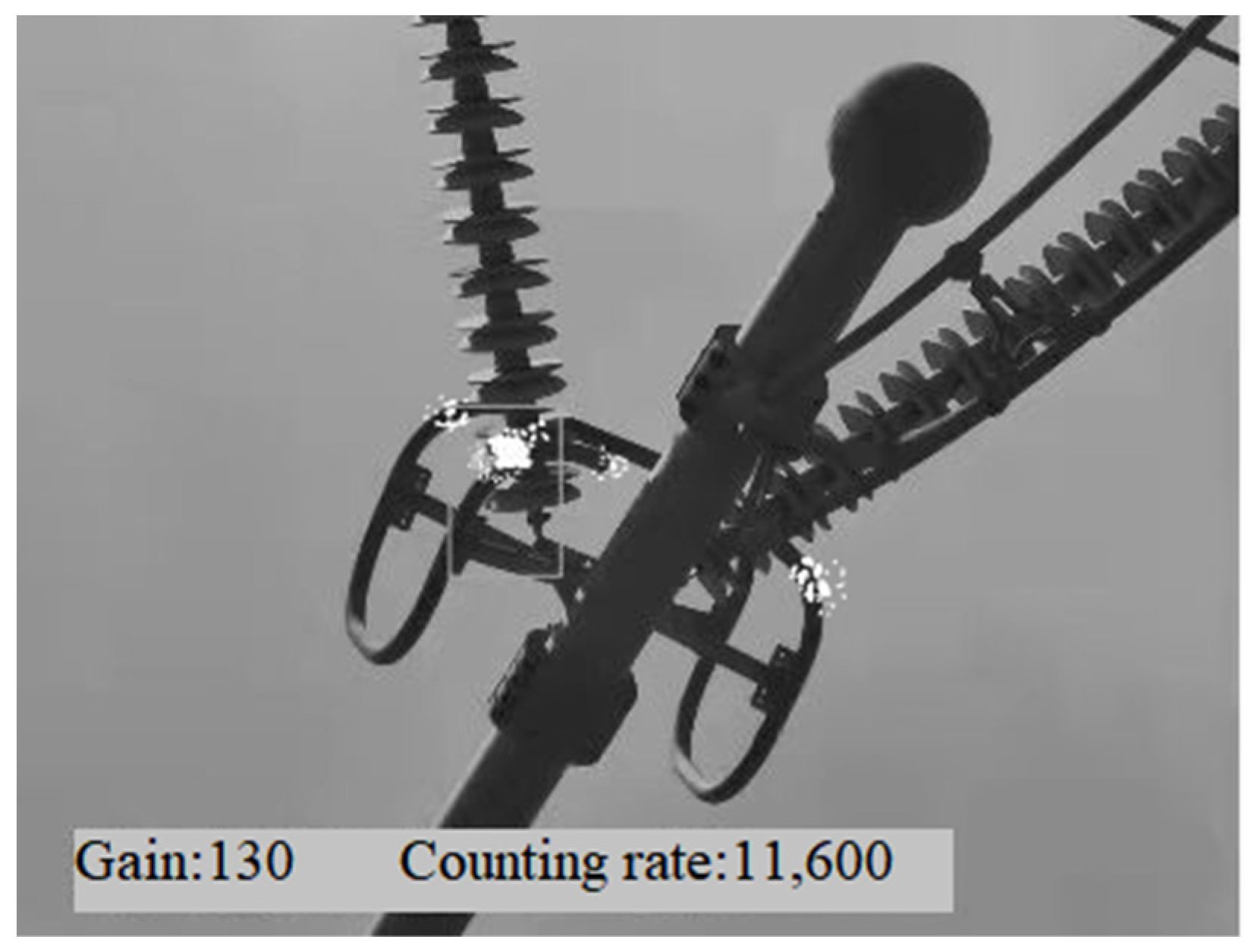

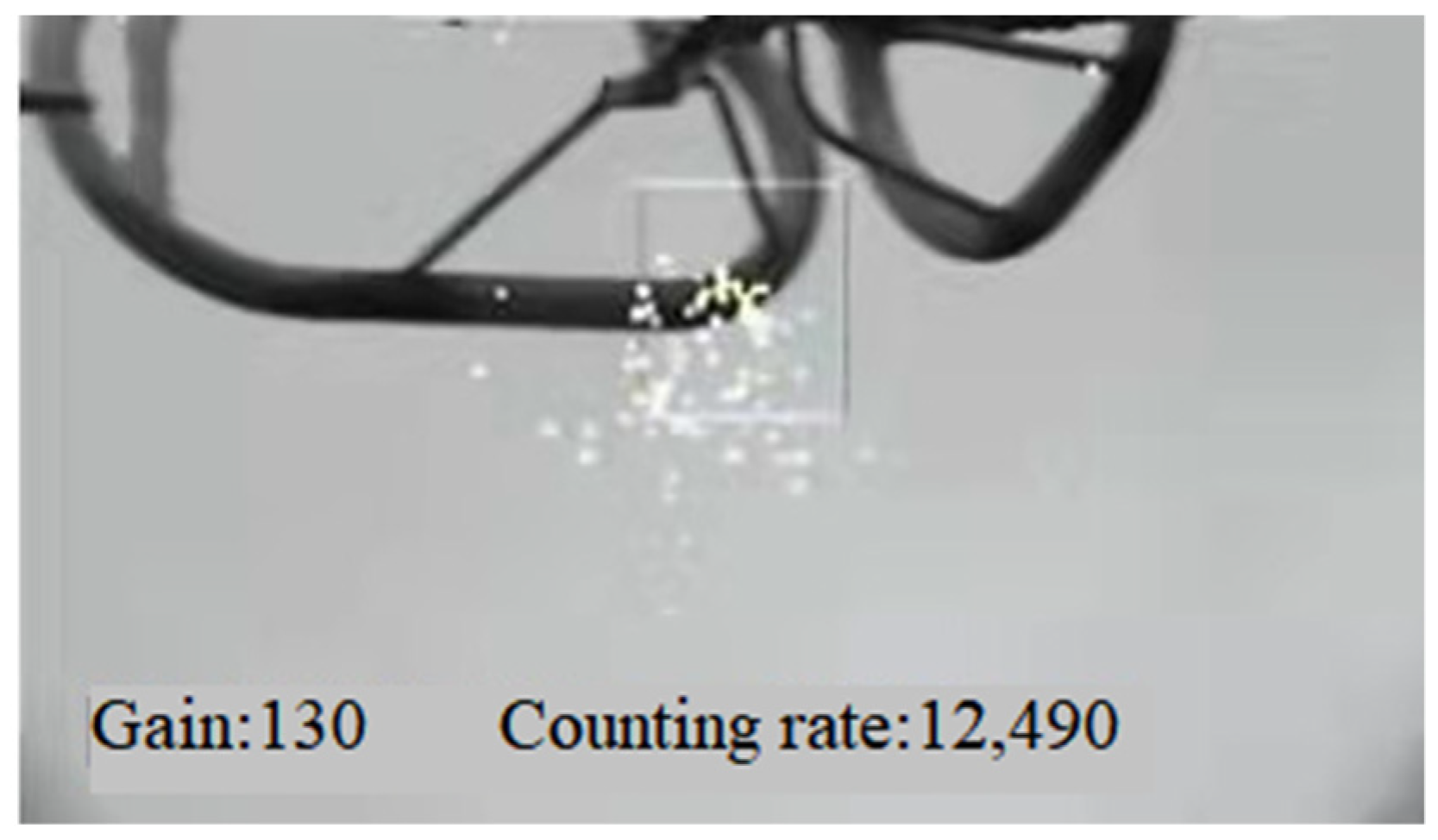

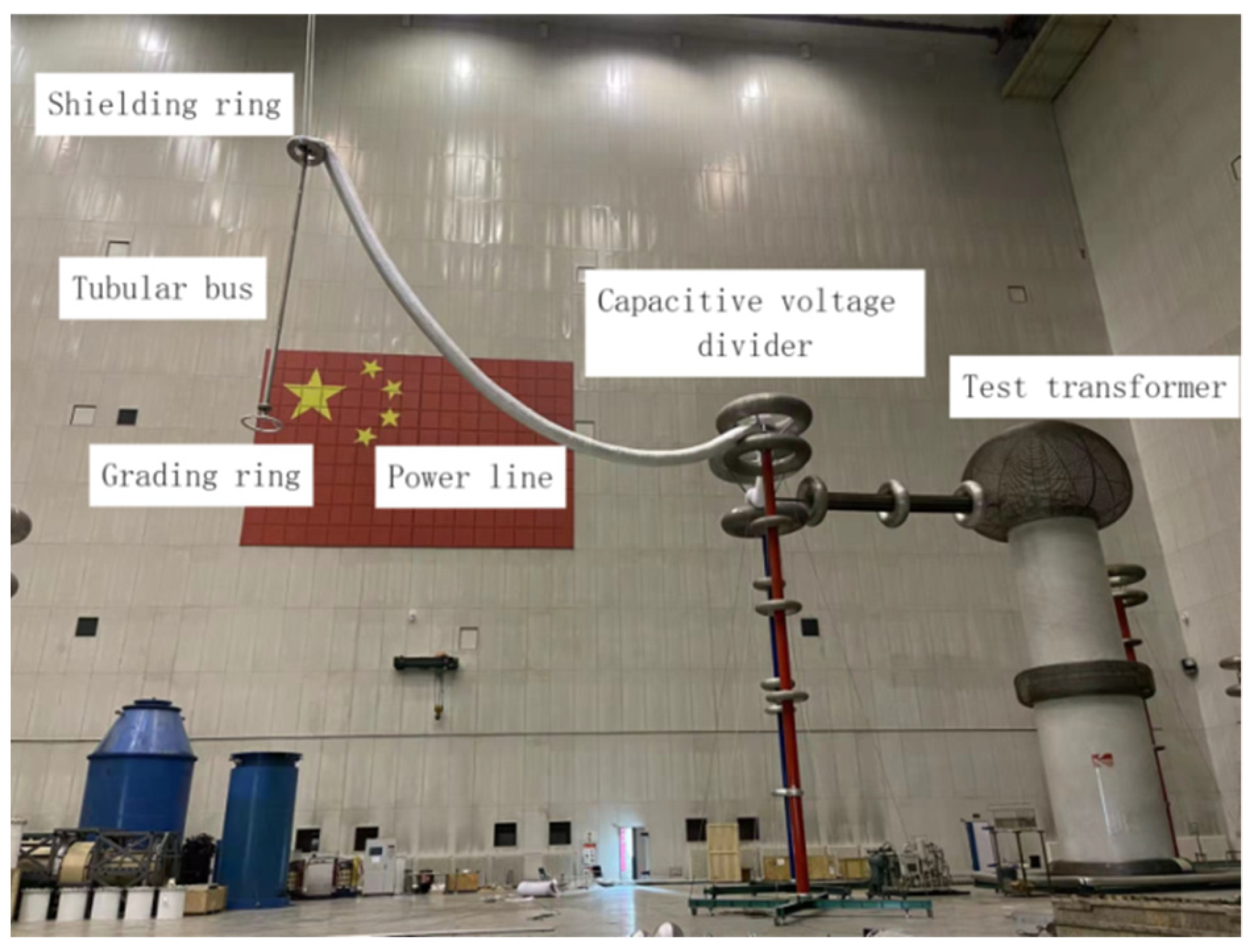

3. The COI Tests of Grading Rings

3.1. The COI Test Results

3.2. The COI Test and Calculation Results Analysis

4. Prediction Method of the COI of an AC Grading Ring

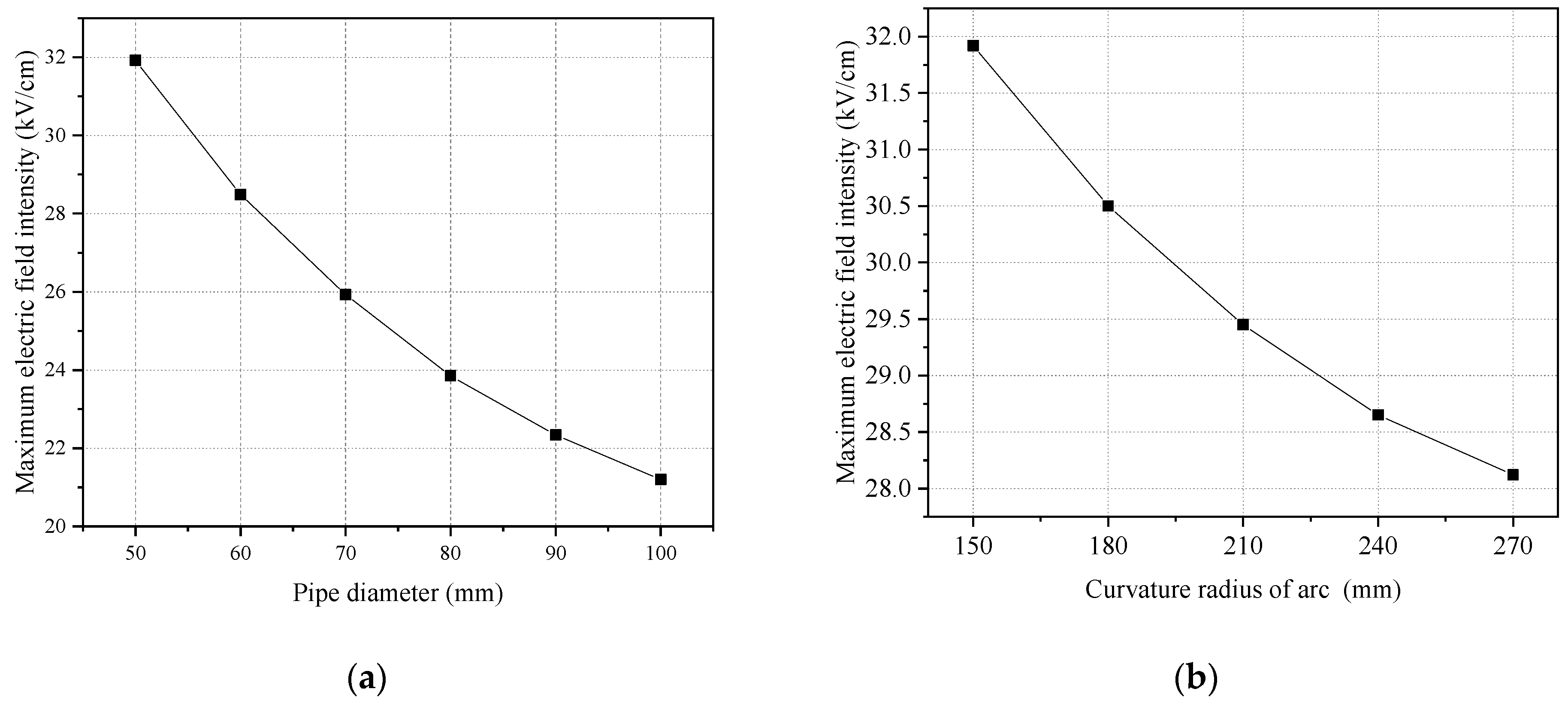

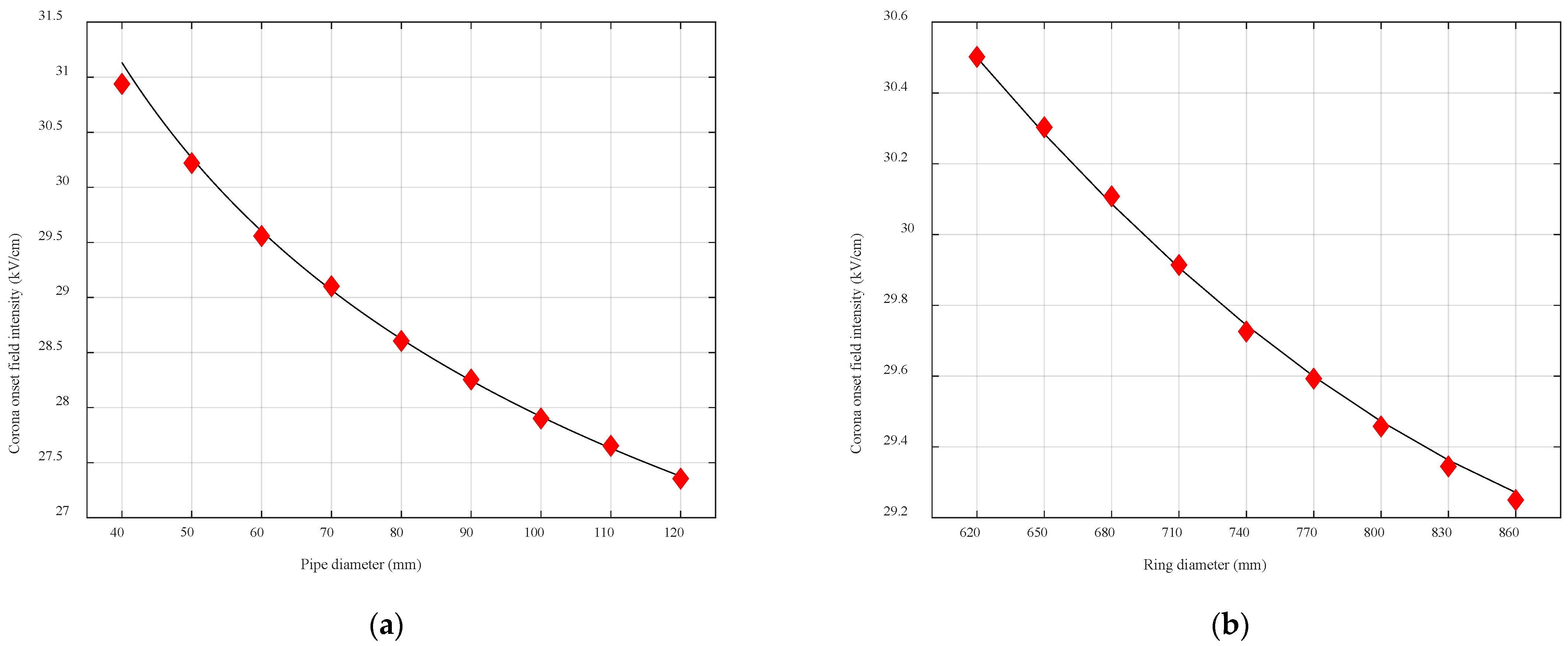

4.1. Influence of Pipe Diameter on the COI of a Grading Ring

4.2. Influence of Ring Diameter on the COI of a Grading Ring

4.3. Prediction Formula of the COI

4.4. Verification of Prediction Formula

5. Conclusions

- (1)

- The calculation results of the MEI on the surface of saddle type and elliptical (circular) grading rings show that pipe diameter is the main factor affecting the MEI of grading rings with different structures. With continuous increase in pipe diameter, the MEI of the grading ring is gradually saturated.

- (2)

- The COI tests of grading rings are carried out in the UHV AC test base, and test results are compared with calculation results obtained based on the Peek formula, which shows that the Peek formula has a large error in predicting the COI of an AC grading ring.

- (3)

- Based on test results of the COI, a formula for predicting the COI of an AC grading ring in a plain area with an altitude of 100 m is proposed by considering the effect of both the pipe diameter and the ring diameter.

- (4)

- The COI of circular and elliptical grading rings with the same pipe diameter and ring diameter remains basically unchanged. Compared with pipe diameter, which has a more significant distortion effect on the COI of the grading ring, the ring diameter has less distortion effect on the COI of the grading ring.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhou, H.; Yu, Y.H. Discussion on some important issues in the development of UHV transmission in China. Power Grid Technol. 2005, 29, 1–9. [Google Scholar]

- Zhang, G.Z.; Cheng, L.G.; Wan, B.Q. Electromagnetic environment and corona control measures of UHV Substation. High Volt. Technol. 2010, 36, 109–115. [Google Scholar]

- Wan, B.Q.; Xie, H.C.; Fan, L. Study on electromagnetic environment of AC UHV test section. High Volt. Technol. 2008, 34, 438–441. [Google Scholar]

- Liu, Z.Y. UHV Power Grid, 2nd ed.; China Economic Publishing House: Beijing, China, 2005; pp. 10–52. [Google Scholar]

- Shu, Y.B. Research and application of 1000kV UHV AC transmission technology. Power Grid Technol. 2005, 29, 1–6. [Google Scholar]

- Deng, T.; Su, Z.Y.; Fan, J.B. Optimal design of grading ring of composite insulator for ±800 kV UHV DC line. Power Grid Technol. 2010, 34, 31–35. [Google Scholar]

- Chen, Y.; Xie, X.J.; Xie, L. Optimization of voltage equalizing ring for 750 kV double circuit compact line on the same tower. High Volt. Technol. 2008, 34, 2390–2394. [Google Scholar]

- Peek, F.W. Dielectric Phenomena in High Voltage Engineering, 1st ed.; McGraw-Hill: New York, NY, USA, 1929; pp. 1–328. [Google Scholar]

- Whitehead, J.B. High-Voltage Corona, 1st ed.; McGraw-Hill: New York, NY, USA, 1929; pp. 107–108. [Google Scholar]

- Lowke, J.J.; D’Alessandro, F. Onset corona fields and electrical breakdown criteria. J. Phys. D Appl. Phys. 2003, 36, 2673–2682. [Google Scholar] [CrossRef]

- Robinson, M. The corona threshold for coaxial cylinders in air at high pressures. IEEE Trans. Power Appl. Syst. 1967, PAS-86, 185–189. [Google Scholar] [CrossRef]

- Waters, R.T.; Stark, B. Characteristics of stabilized glow discharge in air. J. Phys. D Appl. Phys. 1975, 8, 416–426. [Google Scholar] [CrossRef]

- Huang, S.L.; Liu, Y.P.; Chen, S.S. Corona onset voltage gradient of bundle conductors for EHV/UHV AC power lines in corona cages considering altitude correction. CSEE J. Power Energy Syst. 2020, 6, 693–703. [Google Scholar] [CrossRef]

- Chang, J.L.; Xu, G.H.; Xu, J.T. Calculation of electric field on the surface of ±1100 kV UHV valve hall fittings and corona check. High Volt. Appar. 2018, 54, 87–92, 100. [Google Scholar]

- Hu, R.; Jin, S. Calculation and analysis of electric field of fittings for four valve hall of ±500 kV converter station. High Volt. Appar. 2014, 50, 49–55. [Google Scholar]

- Wang, H.Y.; Xia, J.X.; Huang, D.C. Corona characteristics of insulator string grading ring in ultra-high altitude 500 kV substation. High Volt. Eng. 2013, 39, 661–667. [Google Scholar]

- Zhou, T.T.; Ruan, J.J.; Du, Z.Y. Corona characteristics of HVDC shielding fittings at high altitude. High Volt. Technol. 2017, 43, 3036–3041. [Google Scholar]

- Wan, B.Q.; Xie, H.C.; Fan, L. Electromagnetic environment and corona control measures of UHV Substation. High Volt. Eng. 2010, 36, 109–115. [Google Scholar]

- GB/T2317.2-2008; Test Methods for Power Fittings Part 2: Corona and Radio Interference Test. China Standards Press: Beijing, China, 2009.

- Jin, X.; Du, Z.Y.; Qiu, Z.B. Corona characteristics and corona onset voltage prediction of large diameter shielding ball. High Volt. Eng. 2019, 45, 4079–4087. [Google Scholar]

- Li, M.; Liu, L.; Yu, Z.Q. Prediction and correction method of corona field intensity of DC line fittings at an altitude of 2 km. South. Power Syst. Technol. 2016, 10, 55–60. [Google Scholar] [CrossRef] [Green Version]

| Pipe Diameter (mm) | COV (kV) | COI (kV/cm) | Environmental Parameters | ||

|---|---|---|---|---|---|

| Atmospheric Pressure (kPa) | Temperature (°C) | Humidity (%) | |||

| 40 | 347 | 30.939 | 101.5 | 13.2 | 32 |

| 50 | 385 | 30.196 | 100.9 | 13.1 | 32 |

| 60 | 423 | 29.458 | 102.1 | 13.0 | 32 |

| 70 | 453 | 29.002 | 102.5 | 12.9 | 32 |

| 80 | 485 | 28.605 | 101.9 | 12.7 | 32 |

| 90 | 515 | 28.255 | 102.0 | 13.0 | 32 |

| 100 | 541 | 27.901 | 101.7 | 12.7 | 32 |

| 110 | 568 | 27.653 | 101.8 | 12.5 | 32 |

| 120 | 589 | 27.455 | 102.0 | 12.5. | 32 |

| Ring Diameter (mm) | COV (kV) | COI (kV/cm) | Environmental Parameters | ||

|---|---|---|---|---|---|

| Atmospheric Pressure (kPa) | Temperature (°C) | Humidity (%) | |||

| 620 | 391 | 30.502 | 101.3 | 12.5 | 32 |

| 650 | 398 | 30.303 | 101.0 | 12.0 | 32 |

| 680 | 404 | 30.108 | 101.3 | 12.5 | 32 |

| 710 | 410 | 29.914 | 100.9 | 12.5 | 32 |

| 740 | 415 | 29.726 | 101.9 | 12.0 | 32 |

| 770 | 420 | 29.593 | 101.5 | 12.7 | 32 |

| 800 | 423 | 29.458 | 102.1 | 13.0 | 32 |

| 830 | 428 | 29.345 | 102.0 | 12.5 | 32 |

| 860 | 431 | 29.250 | 102.0 | 12.1 | 32 |

| Length (mm) | COV (kV) | COI (kV/cm) | Environmental Parameters | ||

|---|---|---|---|---|---|

| Atmospheric Pressure (kPa) | Temperature (°C) | Humidity (%) | |||

| 1250 | 425 | 29.441 | 101.3 | 12.5 | 32 |

| 1450 | 427 | 29.409 | 101.0 | 12.5 | 32 |

| Size of Grading Ring | COI (kV/cm) | |||

|---|---|---|---|---|

| Pipe Diameter (mm) | Ring Diameter (mm) | Test Data | Fitting Formula | Peek Formula |

| 80 | 680 | 28.82 | 28.47 | 25.30 |

| 80 | 820 | 28.47 | 28.21 | 25.30 |

| 50 | 800 | 30.23 | 29.85 | 26.19 |

| 70 | 800 | 28.87 | 28.68 | 25.53 |

| 90 | 800 | 28.19 | 27.87 | 25.10 |

| Size of Grading Ring | Relative Error (%) | ||

|---|---|---|---|

| Pipe Diameter (mm) | Ring Diameter (mm) | Test Data and Fitting Formula | Test Data and Peek Formula |

| 80 | 680 | 1.21 | 12.21 |

| 80 | 820 | 0.91 | 11.13 |

| 50 | 800 | 1.26 | 13.36 |

| 70 | 800 | 0.66 | 11.57 |

| 90 | 800 | 1.14 | 10.96 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Zhang, Z.; Jia, B.; Yan, X.; Wang, P.; Geng, J. Corona Characteristics of a Large-Sized AC Grading Ring and Prediction of Corona Onset Field Intensity. Energies 2022, 15, 2041. https://doi.org/10.3390/en15062041

Liu J, Zhang Z, Jia B, Yan X, Wang P, Geng J. Corona Characteristics of a Large-Sized AC Grading Ring and Prediction of Corona Onset Field Intensity. Energies. 2022; 15(6):2041. https://doi.org/10.3390/en15062041

Chicago/Turabian StyleLiu, Jie, Zhimeng Zhang, Boyan Jia, Xiaoliang Yan, Ping Wang, and Jianghai Geng. 2022. "Corona Characteristics of a Large-Sized AC Grading Ring and Prediction of Corona Onset Field Intensity" Energies 15, no. 6: 2041. https://doi.org/10.3390/en15062041

APA StyleLiu, J., Zhang, Z., Jia, B., Yan, X., Wang, P., & Geng, J. (2022). Corona Characteristics of a Large-Sized AC Grading Ring and Prediction of Corona Onset Field Intensity. Energies, 15(6), 2041. https://doi.org/10.3390/en15062041