1. Introduction

In 2021, China put forward the “30 and 60” double carbon development goals, accelerating the energy revolution focusing on carbon reduction [

1,

2]. As an important technology for integrating multiple types of energy resources such as electricity, heat, cooling and gas, and breaking the traditional single energy development, the integrated energy system realizes the complementarity, mutual assistance, coordination and optimization of multiple energy sources, and can also meet various load requirements [

3]. However, due to the complex multi-energy structure and the response rate of different energy sources, the coordinated operation and scheduling of integrated energy system (

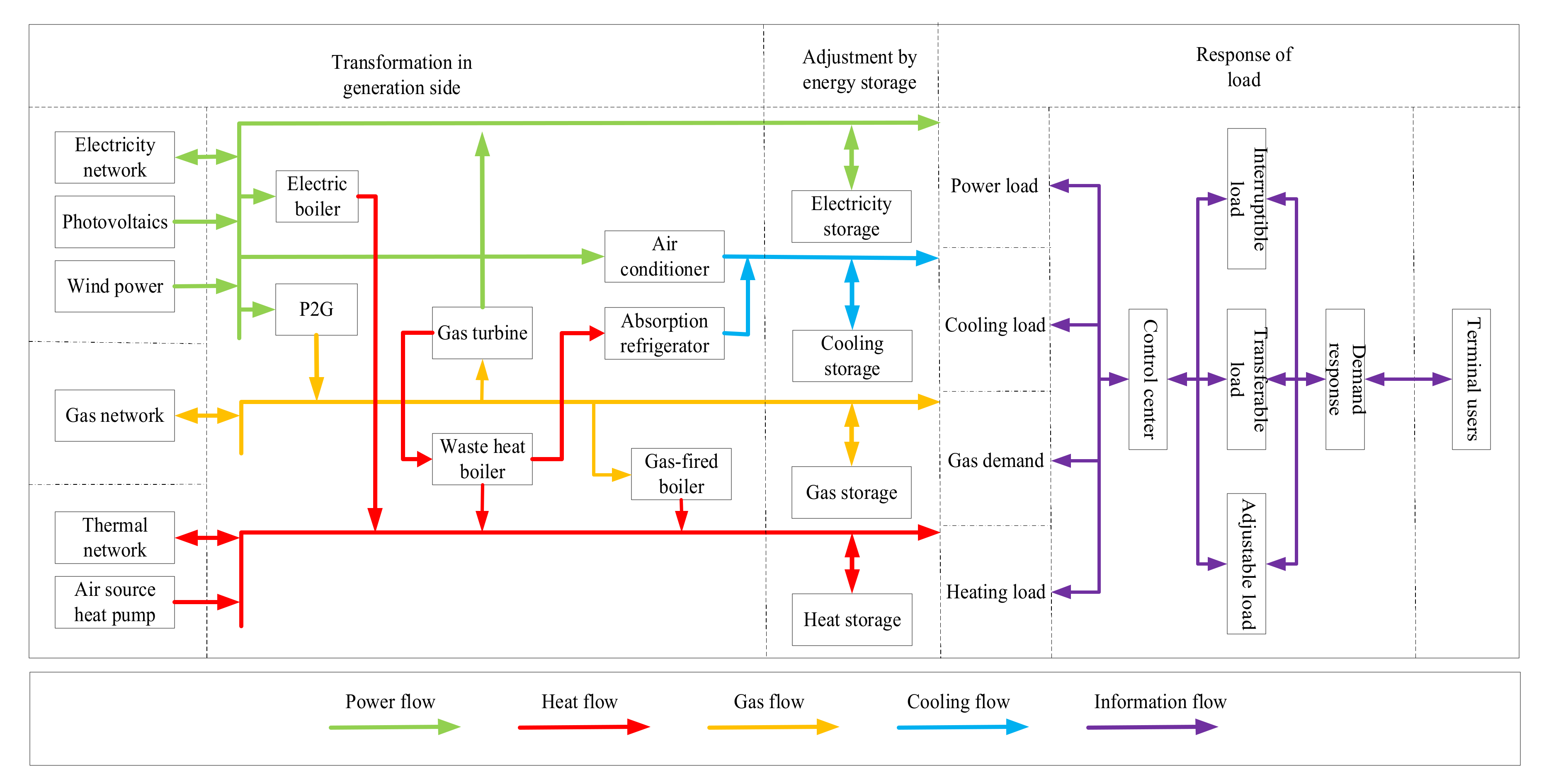

IES) is more difficult.

Since 2015, China has comprehensively promoted the pilot project of demand-side management and achieved remarkable results by adopting demand response technology and considering the load characteristics and energy storage technology of end-users [

4]. However, with the deep coupling development of electricity, heat, cooling and gas, demand response technology is not limited to the reduction or stabilization of electric load, but gradually transformed into the demand of electricity, heat, cooling and gas, which puts forward the concept of integrated demand response technology [

5]. Compared with the traditional demand response technology, the integrated demand response technology improves the interactive content, ability and benefit of the demand response of multiple loads by reducing or increasing the demand of electricity, heat, cooling and gas. When participating in the integrated demand response technology, various users adopt the incentive mechanism or energy price mechanism to guide various end users to change the energy consumption mode, improve the overall utilization rate of multi energy and reduce the operation cost [

6].

In this context, considering the multi-load demand response technology to participate in the coordinated optimal operation scheduling of the IES, and refining the energy demand of various users into interruptible load, transferable load and adjustable load, it is a direction to study the operation change of the system.

At present, many scholars have studied the collaborative optimal scheduling of the

IES, mainly aiming at the lowest total cost of the system [

7,

8,

9,

10,

11,

12,

13,

14], the maximum energy efficiency [

7,

11], the maximum user satisfaction [

9,

14], the minimum risk [

12], and the minimum carbon emission [

10,

13]. Amirmohammad Behzadi et al. [

7] considered photovoltaic equipment, double effect conversion equipment, absorption refrigerator, geothermal device and cooling equipment, and constructed a multi-objective optimization model of

IES with the lowest total operating cost and the highest energy efficiency, which was solved by genetic algorithm. Li Y. et al. [

8] analyzed the operation problem of community

IES in uncertain environments and established a hierarchical stochastic optimal scheduling model with the goal of minimizing the operation cost. Zhang N. et al. [

9] proposed a two-stage multi-objective optimization model for the

IES, in which the first stage focuses on the economic benefits of system operation and scheduling and user satisfaction, and the second stage focuses on reducing the impact of renewable energy prediction error, so as to ensure the real-time power balance of the system. Zhou, X.R. et al. [

10] aimed at the lowest carbon dioxide emission and economic cost, proposed an

IES optimal scheduling model considering the combination of low-carbon and economic operation, and used particle swarm optimization algorithm to solve the multi-objective optimization model. Wang, L.X. et al. [

11] established a two-level optimization model of

IES and optimized the operation scheduling strategy, based on the operation structure composed of energy conversion equipment, energy supply network and consumers. Wei. F. et al. [

12] introduced the interval variable method to deal with the uncertain problems caused by the grid connection of wind power and photovoltaic, established the regional

IES optimization model with the lowest investment cost and risk as the goal, and solved the multi-objective problem of the system under uncertainty by using the search optimization algorithm with adaptive covariance matrix and chaotic search. Shan, J.N. et al. [

13] aimed at the lowest daily power generation dispatching cost and daily environmental pollutant treatment cost and proposed a multi-objective optimization model of cogeneration microgrid, which balanced the economic benefits and environmental friendliness of the system. Chen, H.P. et al. [

14] proposed a multi-objective optimization model of microgrid system under opportunity constraint rules, aiming at minimizing system operation cost and maximizing user improvement. Although in the above works, multi-energy collaborative optimal scheduling models are constructed by analyzing the coupling relationship between various energy subsystems of comprehensive energy, few studies have discussed the refinement of various loads of users and the change of energy consumption habits.

Integrated demand response (IDR) is an extension of power demand response strategy [

14]. Sun et al. [

15] analyzed the problems of IDR technology participating in multi-energy system, based on the complementary relationship between energy subsystems and considering the comfort of end users. Yuan et al. [

16] considered the real-time electricity price, proposed a two-level optimization model of

IES with IDR technology, reduced the system operation cost and improved the user welfare, and obtained the optimal energy allocation strategy. Yang et al. [

17] introduced the IDR strategy into the optimal scheduling of

IES, which improved the economy and flexibility of the system. Chen, et al. [

18] considered the price-based demand response technology, analyzed the timing transmission and energy substitution of energy, established a general model of micro energy system, and verified that the energy substitution characteristics can reflect the consumption behavior of users. Liu, N. et al. [

19] integrated thermoelectric energy system based on cogeneration unit and demand response mechanism and proposed a hybrid energy sharing framework of multi-microgrid. However, the

IES involves multiple energy systems, which leads to different coordination strategies under different demand response mechanisms. Li et al. [

20] aimed at tapping the potential of source load interaction, considered the power consumption comfort of users and the actual schedulable margin in the dispatching interval of building system, and established the optimal dispatching model of energy storage and interruptible load. Zhao et al. [

21] established a demand response model considering transferable load to optimize the day-ahead, hour-ahead and real-time dispatches of power system, based on the uncertainty of flexible load response and consumer psychology. Wang et al. [

22] took the heating load as an adjustable load and applied it to the operation scheduling optimization of heating power plants under the environment of power market and established a two-stage optimal method for day-ahead and real-time scheduling with the participation of heat load in regulation. Xie et al. [

23] considered the characteristics of heat storage and release of pipe network, interruptible electric load and adjustable load of charged side boiler and constructed the source-network-load coordination optimization model of electric-heating system. The above research not only shows that the introduction of demand response strategy can reduce the operation cost of the system, but also change the energy consumption habits of users, but lacks the analysis and discussion under the condition of considering multiple types of loads.

To sum up, most of the existing research achievements focus on the coordinated operation and scheduling optimization of IES, and do not deeply consider the impact of various load demand response technologies of electricity, heat, cooling and gas. However, in the actual working conditions, the IES collaborative optimization scheduling under the IDR technology has more flexibility and space. Therefore, this paper refines the load type and studies the IDR technology in the collaborative optimal scheduling of IES. The specific innovations are represented as follows:

- (1)

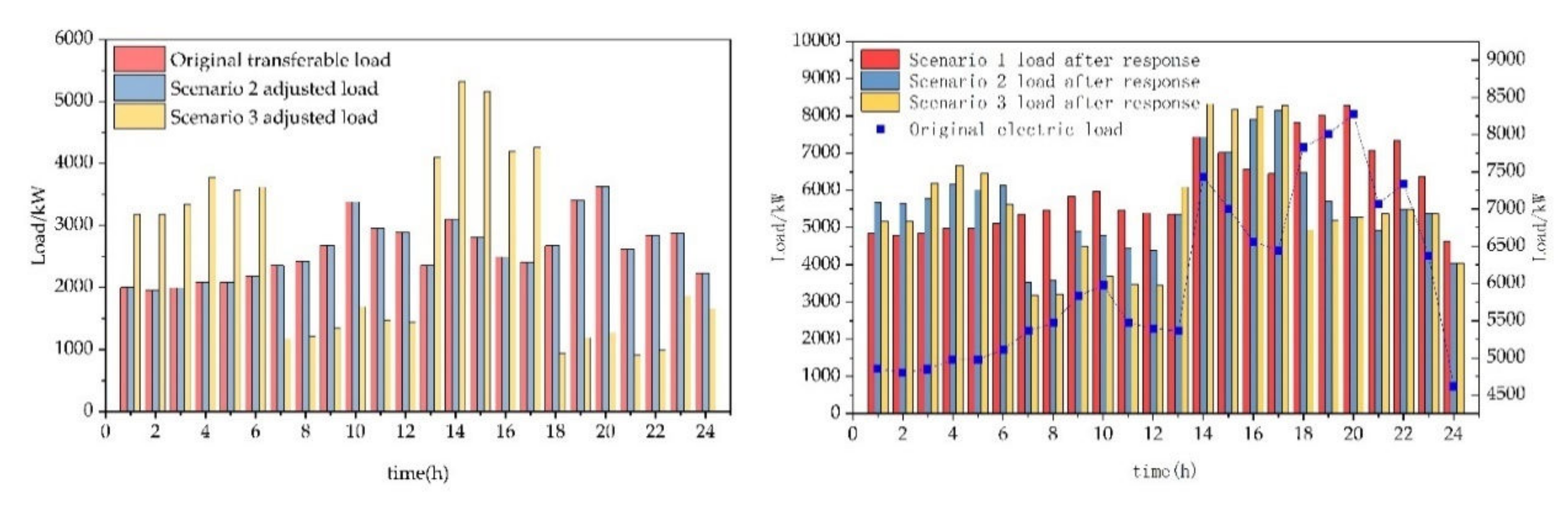

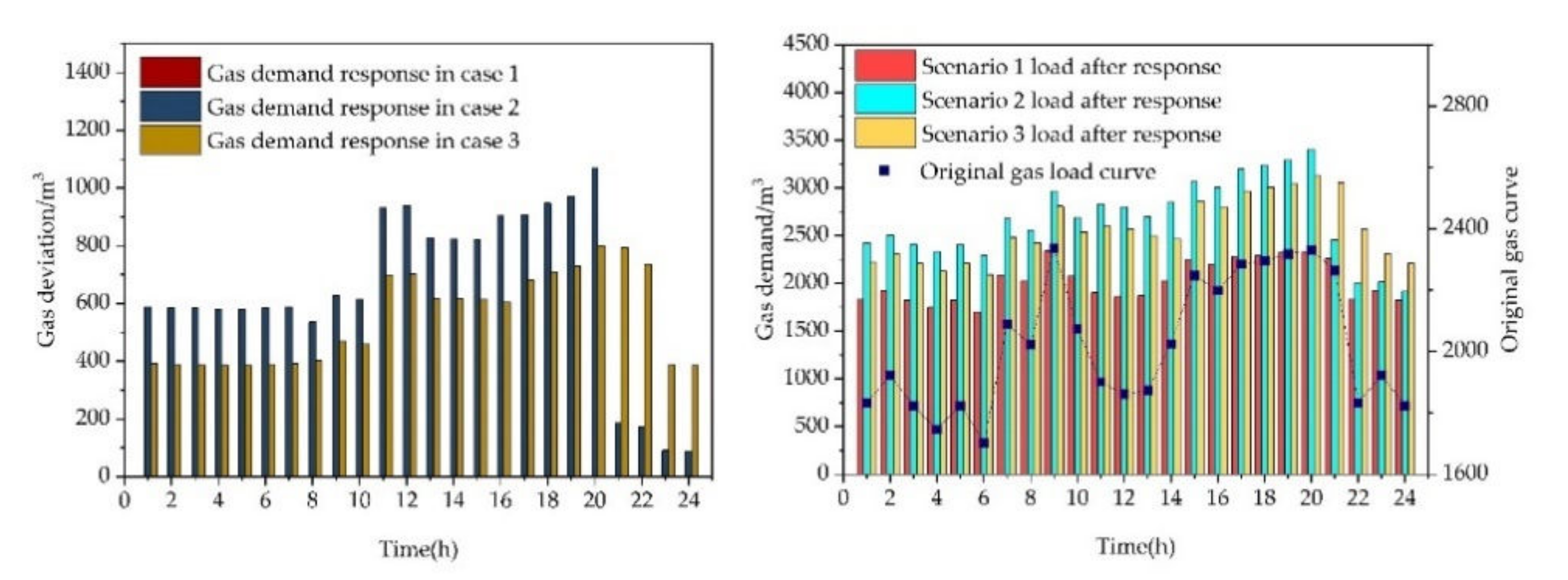

Based on the demands of multiple loads on the user side, this paper uses the IDR technology to participate in the coordinated and optimal dispatching operation of the IES, and uses interruptible, transferable and adjustable loads to change the energy load curve to maximize the satisfaction of energy consumption.

- (2)

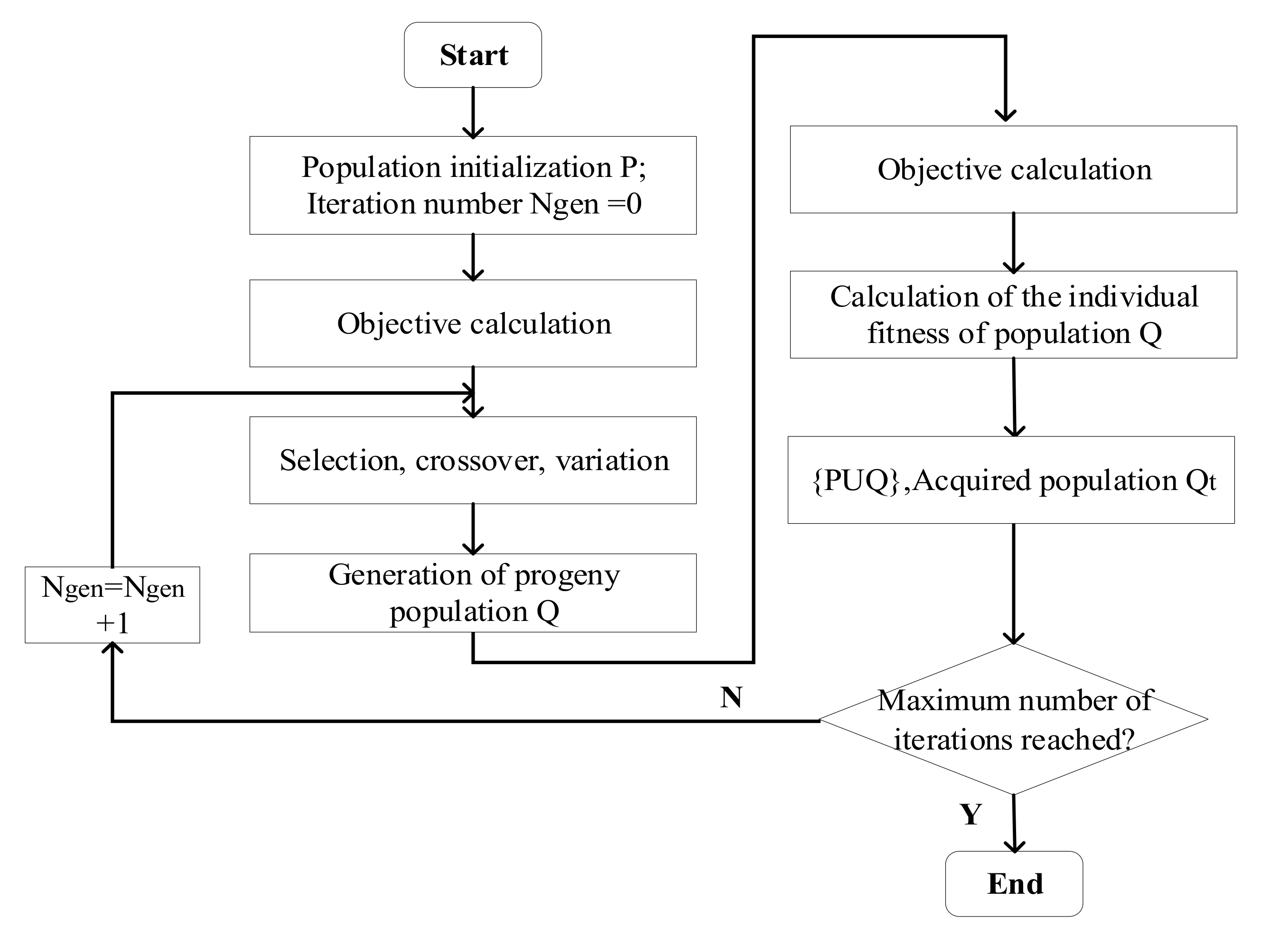

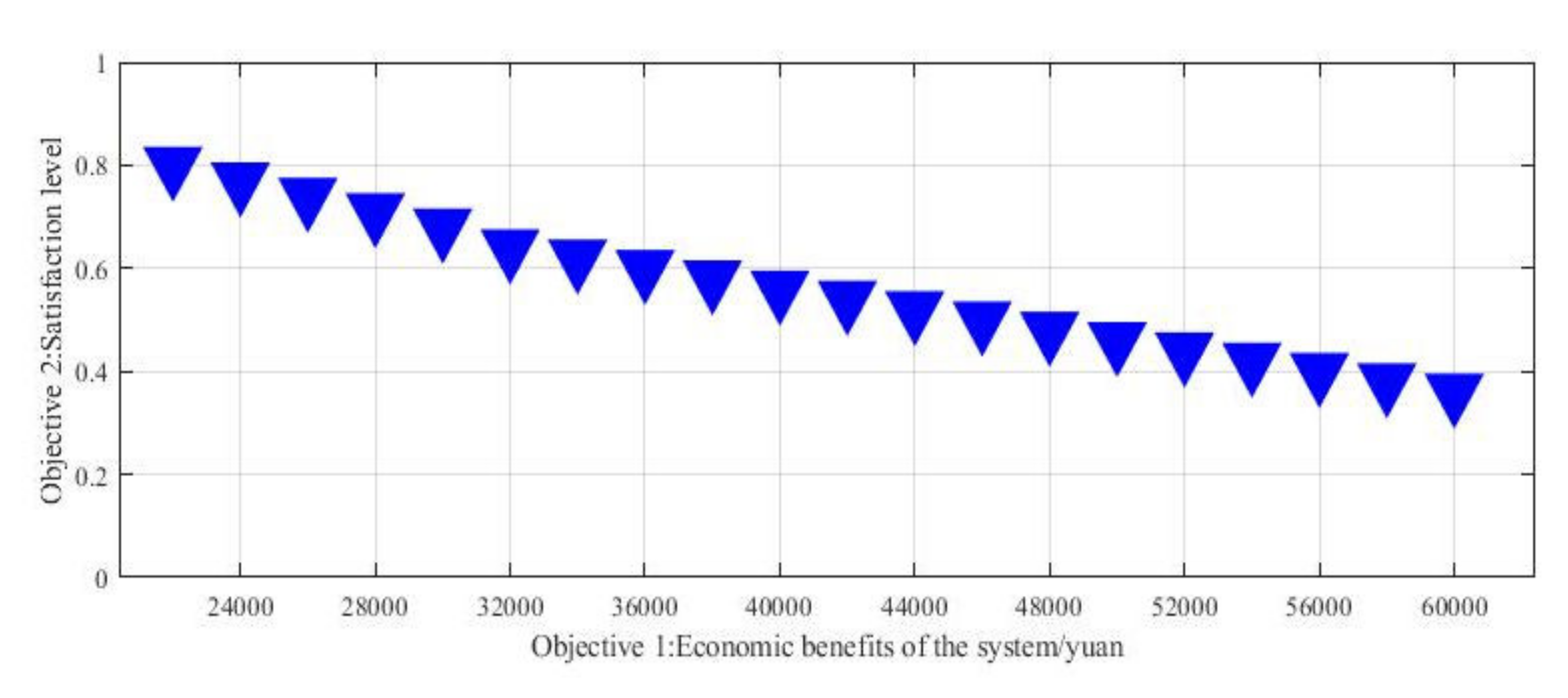

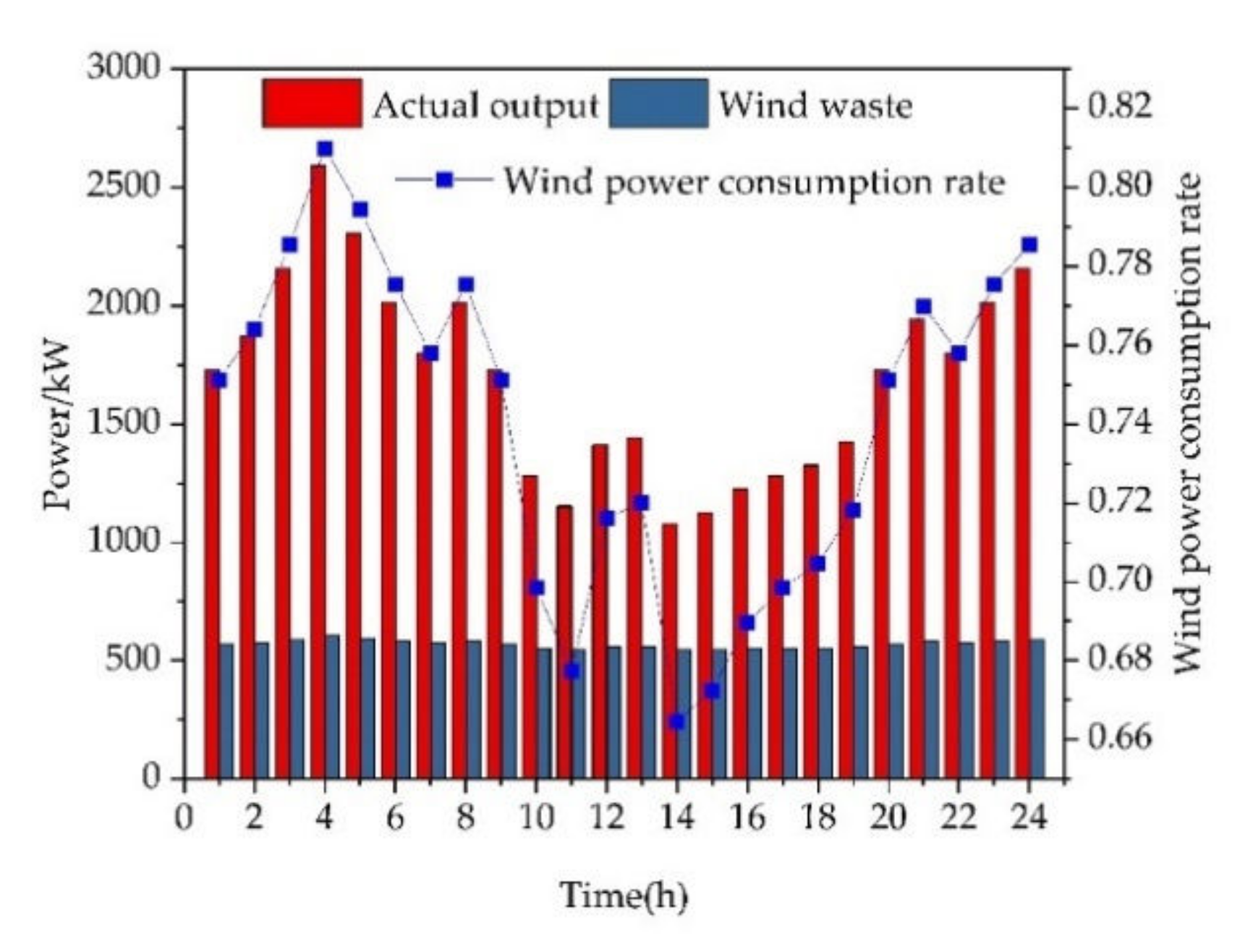

In this paper, a two-stage collaborative optimization model is established under the condition that the IDR technology participates in the collaborative optimization scheduling of IES. In the first stage of the daily dispatching model, according to the forecasted prices of daily electricity, heat, gas, user load and renewable energy power generation, the daily economic operation of the system is conducted, and the best output strategy for the system to respond to the power grid and heat supply network is established. In the second stage of the hour-ahead unit output scheduling model, based on the planned output curve of the day-ahead strategy, the real-time electricity price and the output of renewable energy units are predicted, and the day-ahead economic cooperative operation plan is adjusted in real time, so as to realize the system collaborative optimization and formulate the electric-heating demand response strategy, reduce the hour-ahead output deviation of the system and increase intermittent energy consumption.

- (3)

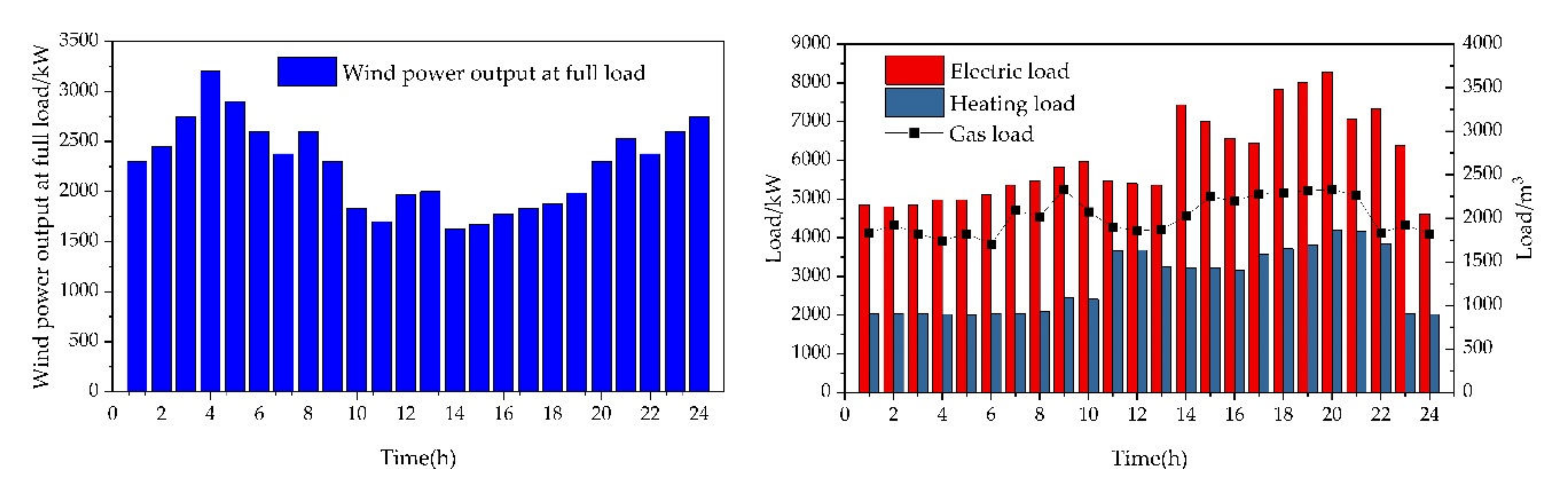

In this paper, a typical comprehensive energy demonstration base is selected for example analysis. The results show that under the multi-load of electricity, heat, cooling and gas, the IDR technology, which is involved in the collaborative optimization operation of the IES, can effectively improve the energy utilization efficiency and renewable energy utilization level of the system.

The rest of this paper is organized as follows. Analyzing the operation of

IES under multi-load response strategy in

Section 2; Considering the interactive relationship of

IES operation under multi-load demand response strategy and establishing a two-stage optimization model of

IES in

Section 3; According to the characteristics of the model, a two-stage collaborative optimization model solving method is proposed in

Section 4; Finally, example analysis and result discussion in

Section 5.