Study on Flow Characteristics and Mass Transfer Mechanism of Kettle Taylor Flow Reactor

Abstract

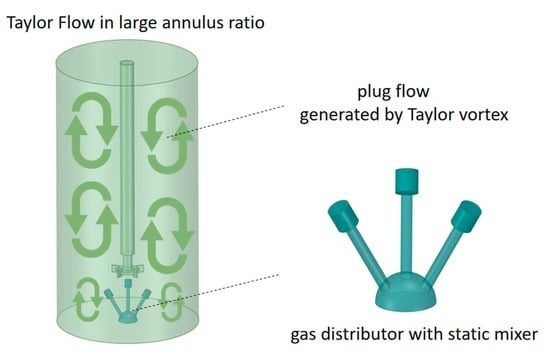

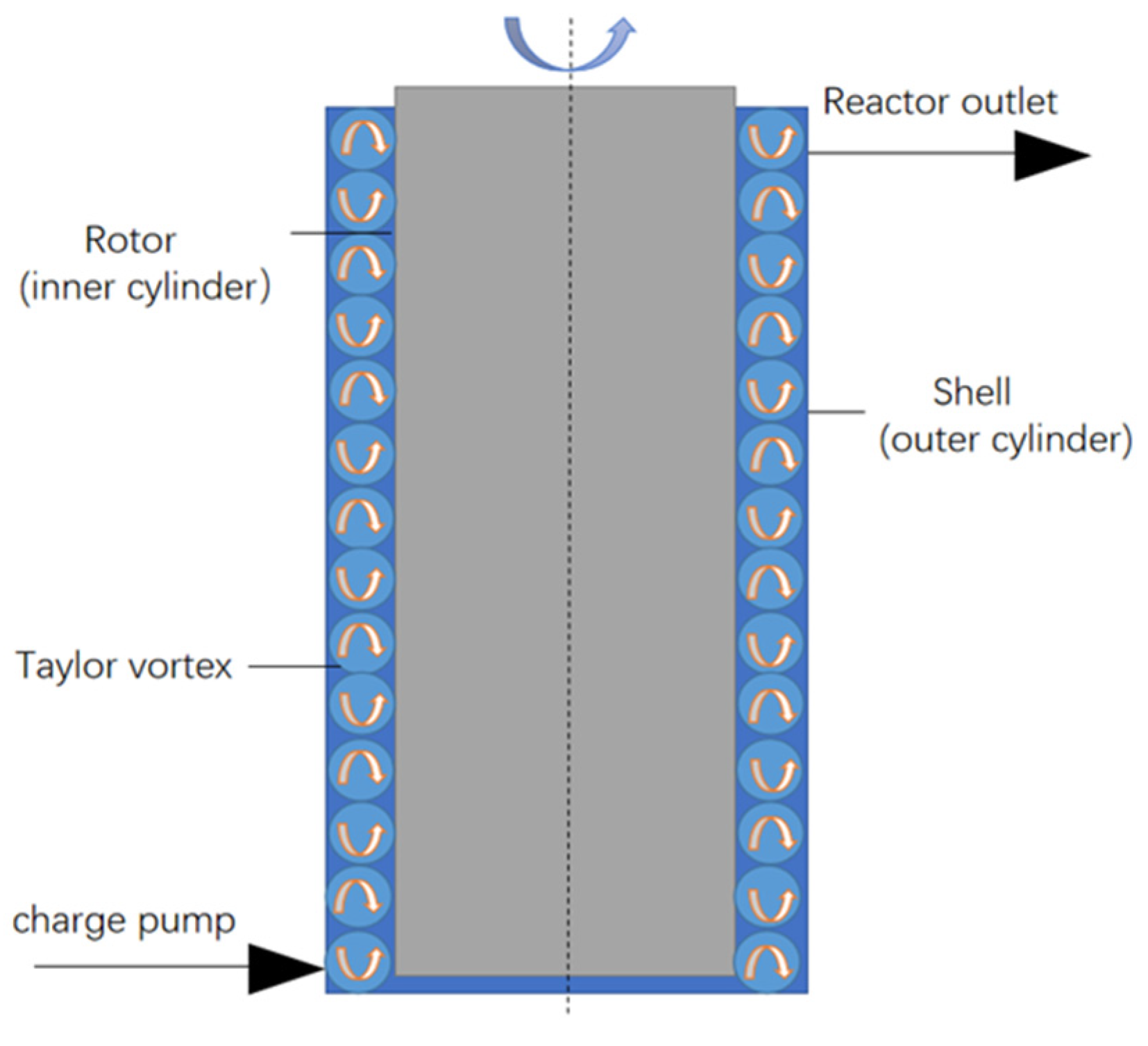

:1. Introduction

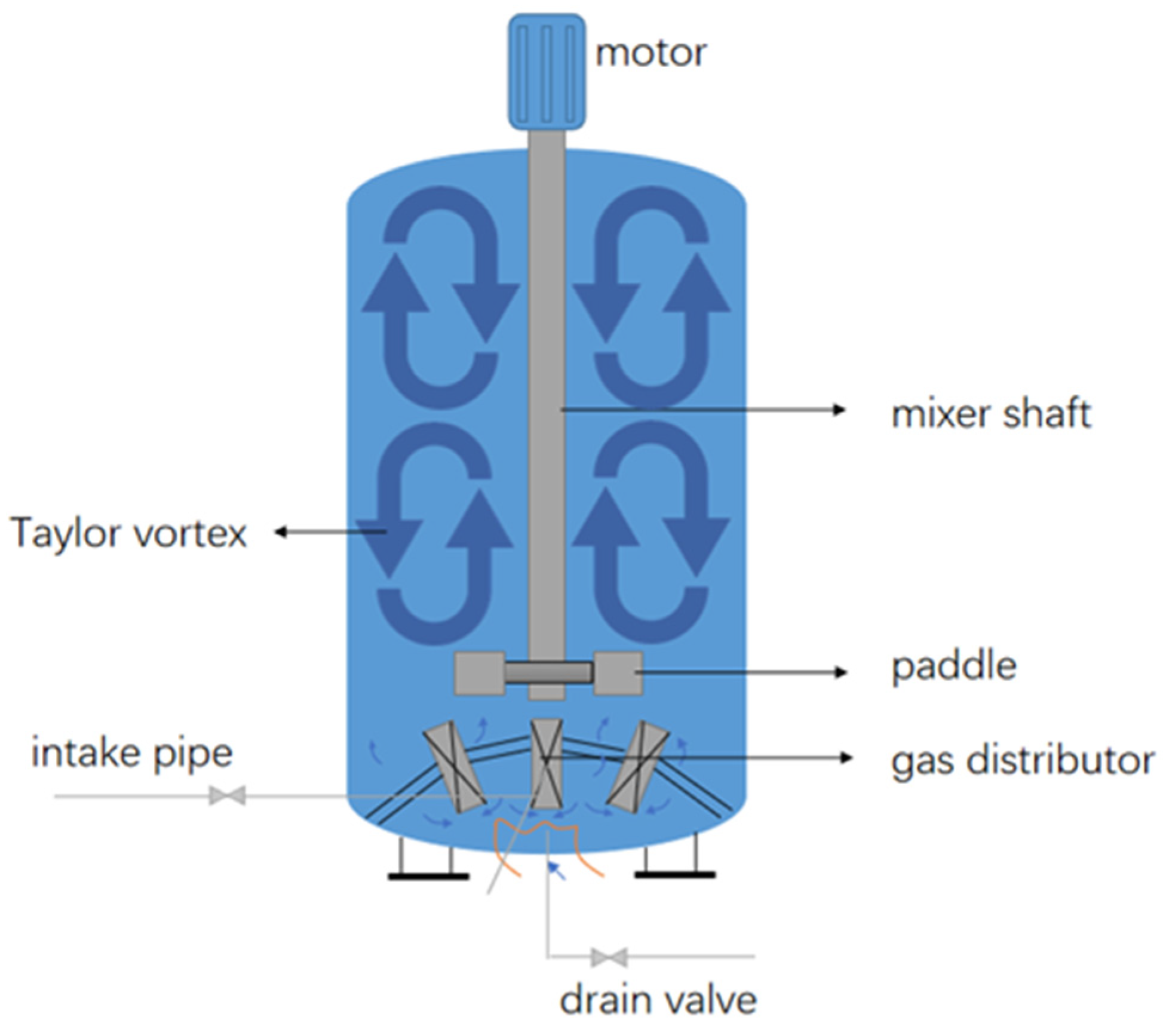

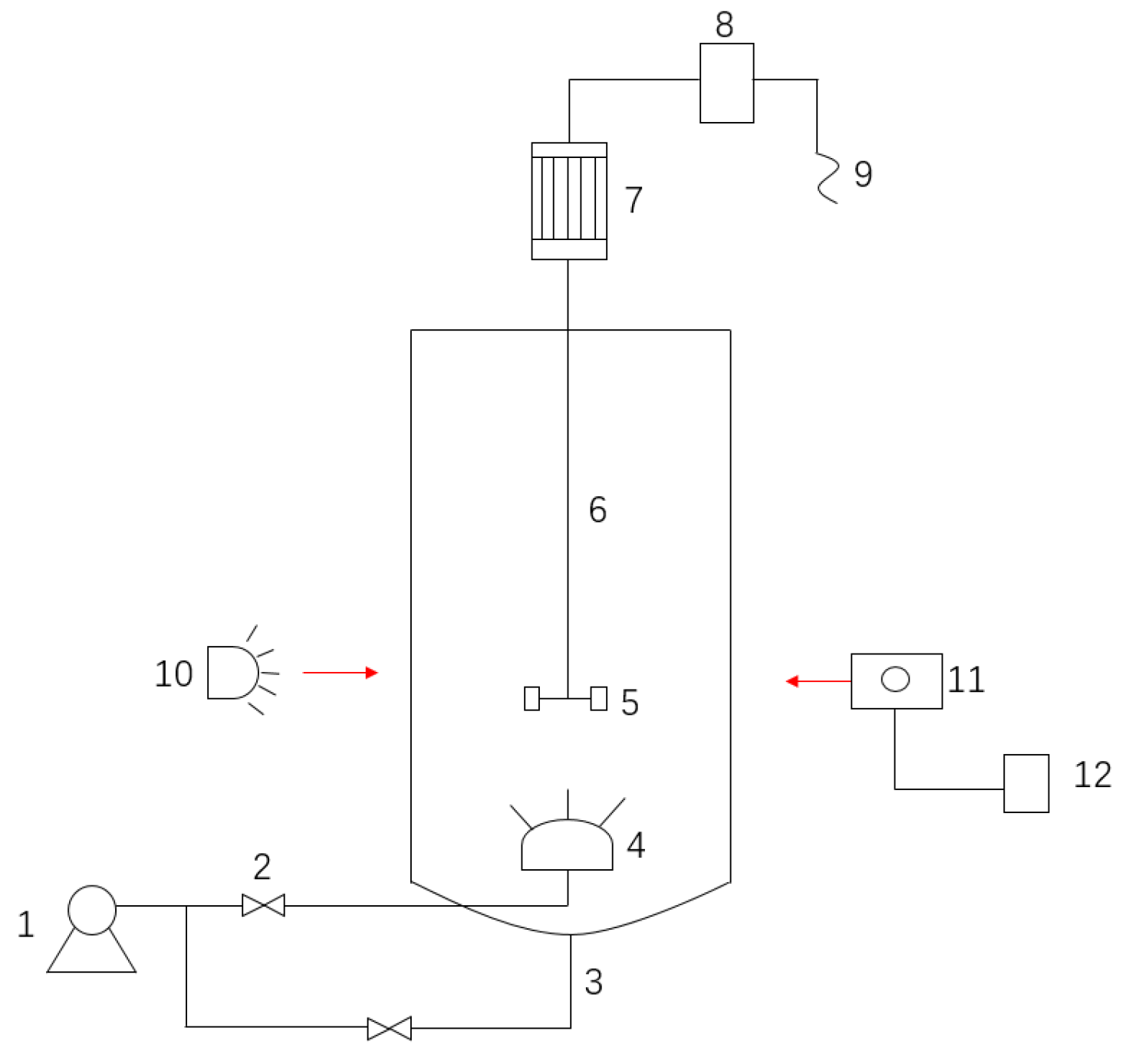

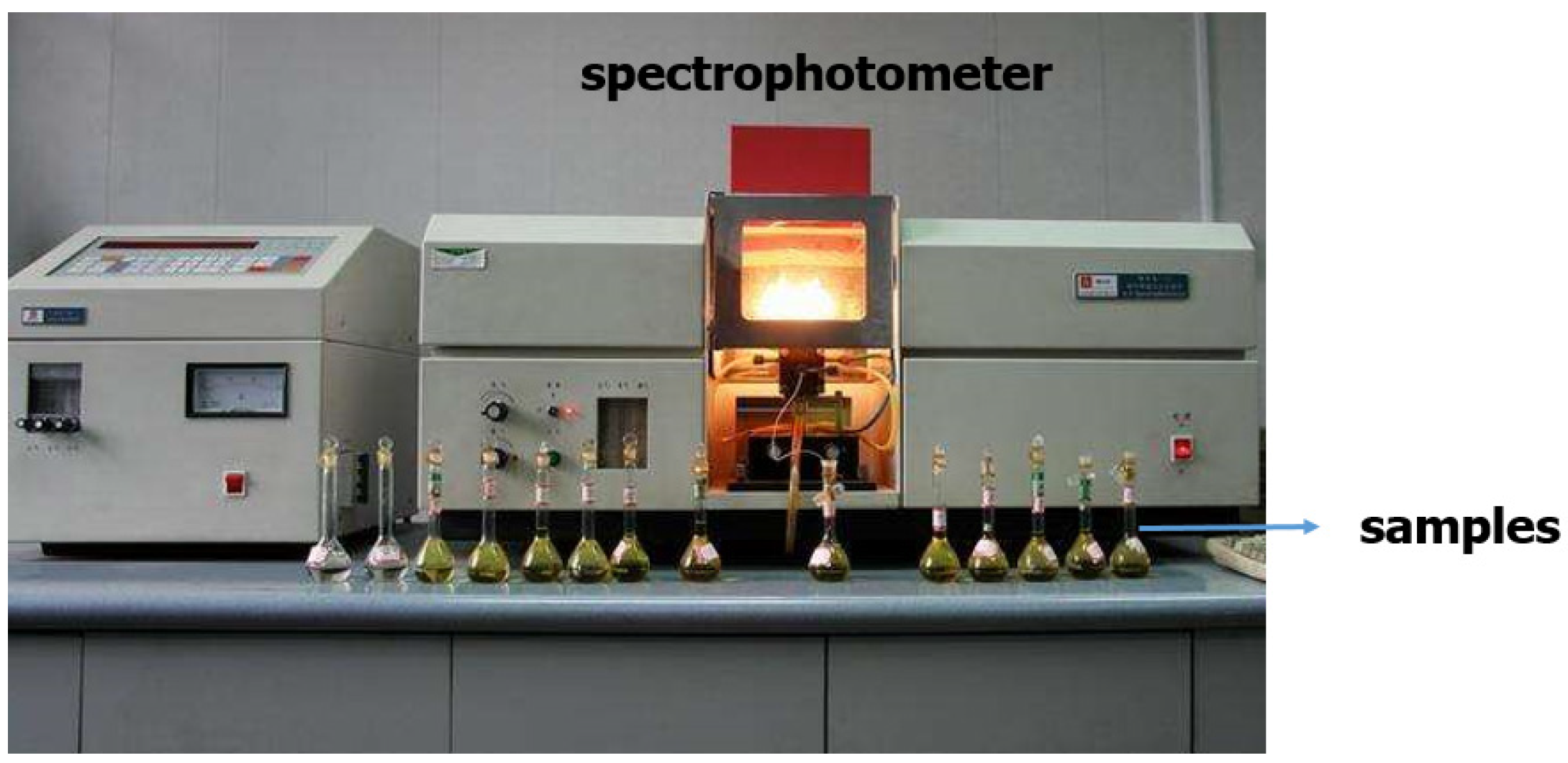

2. Experimental Equipment and Procedures

3. Numerical Simulation

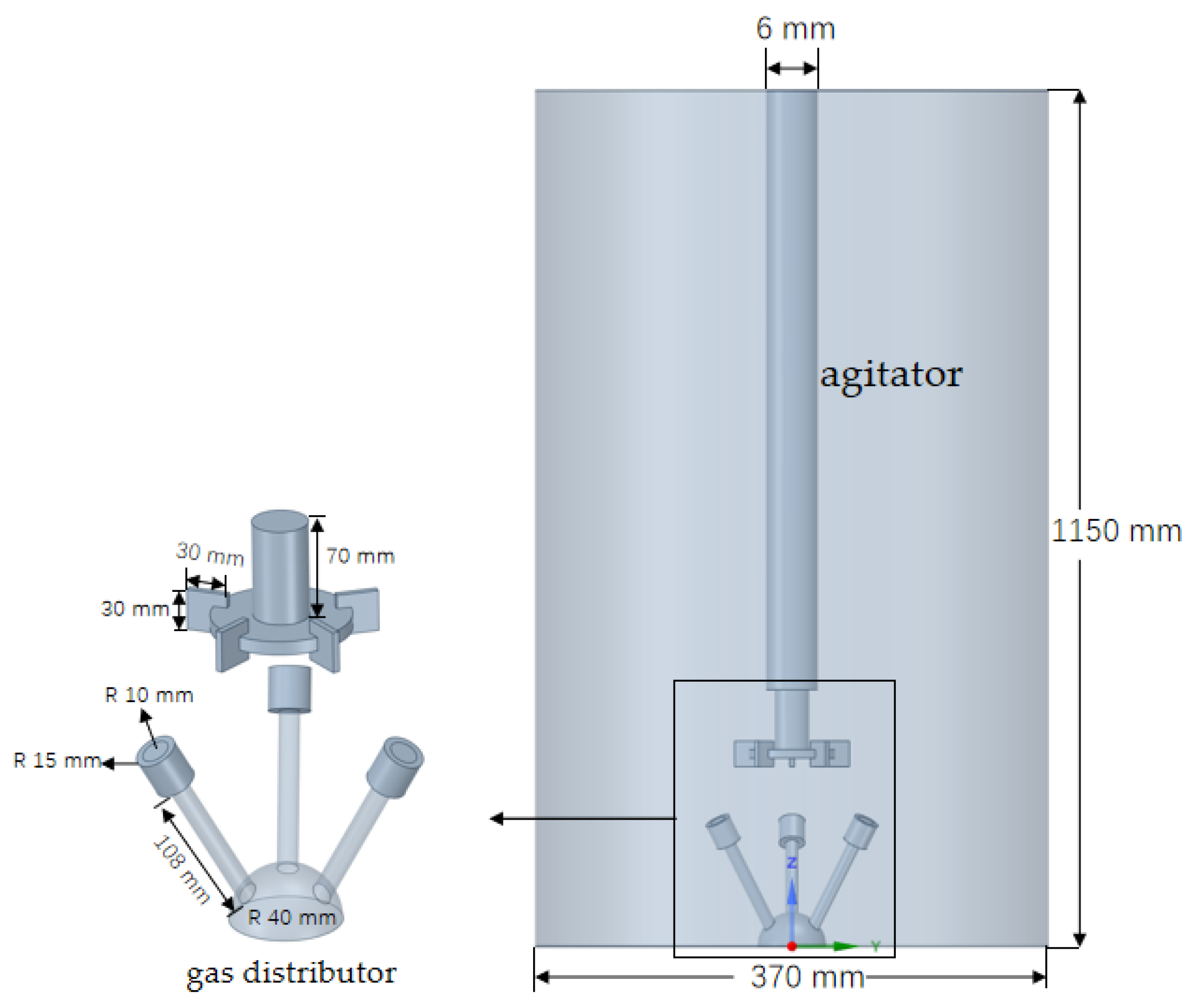

3.1. Geometric Model

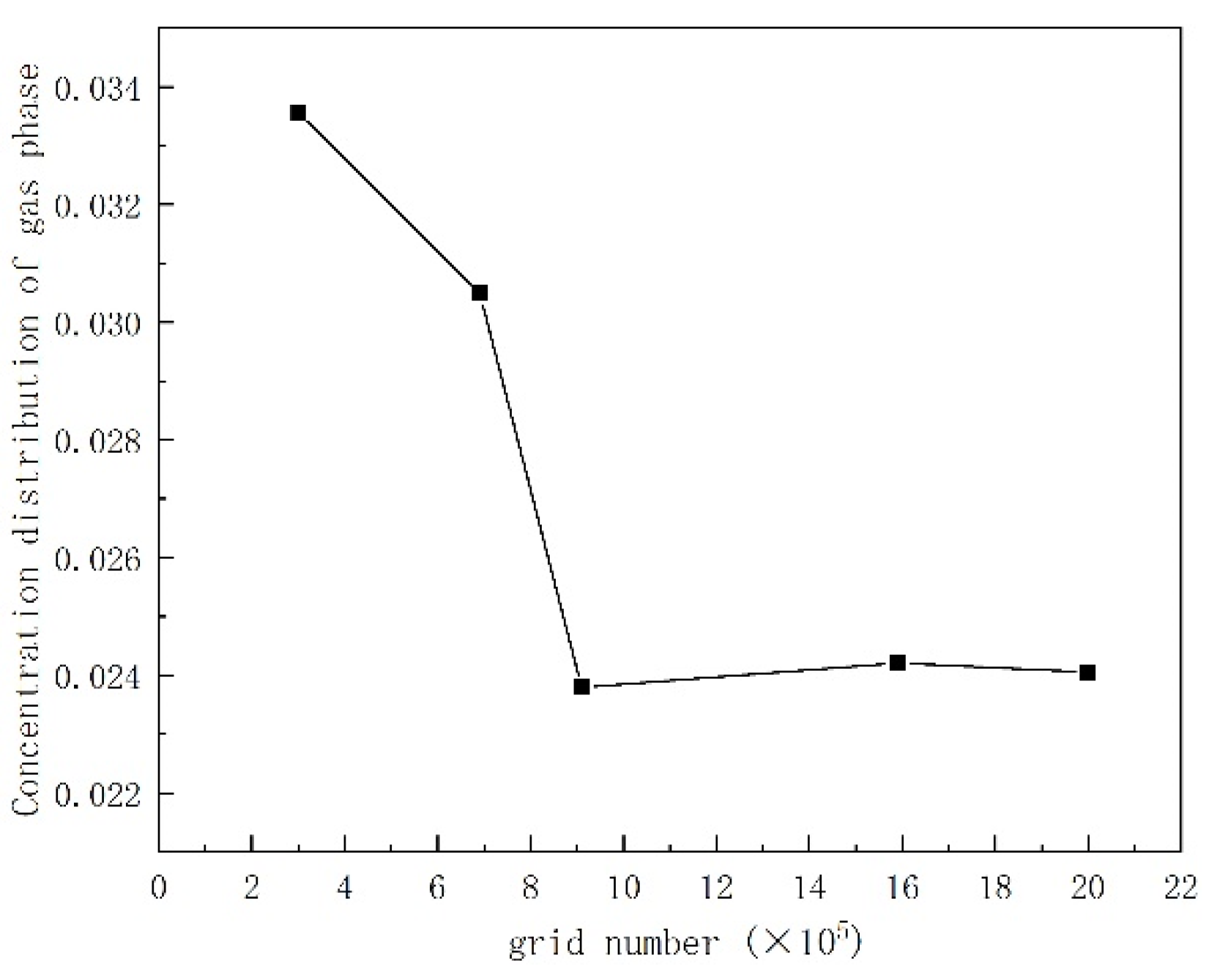

3.2. Grid Division and Grid Independence Verification

3.3. Physical Model and Boundary Conditions

4. Simulation Results and Analysis

4.1. Comparative Analysis of Simulation Results and Experimental Results

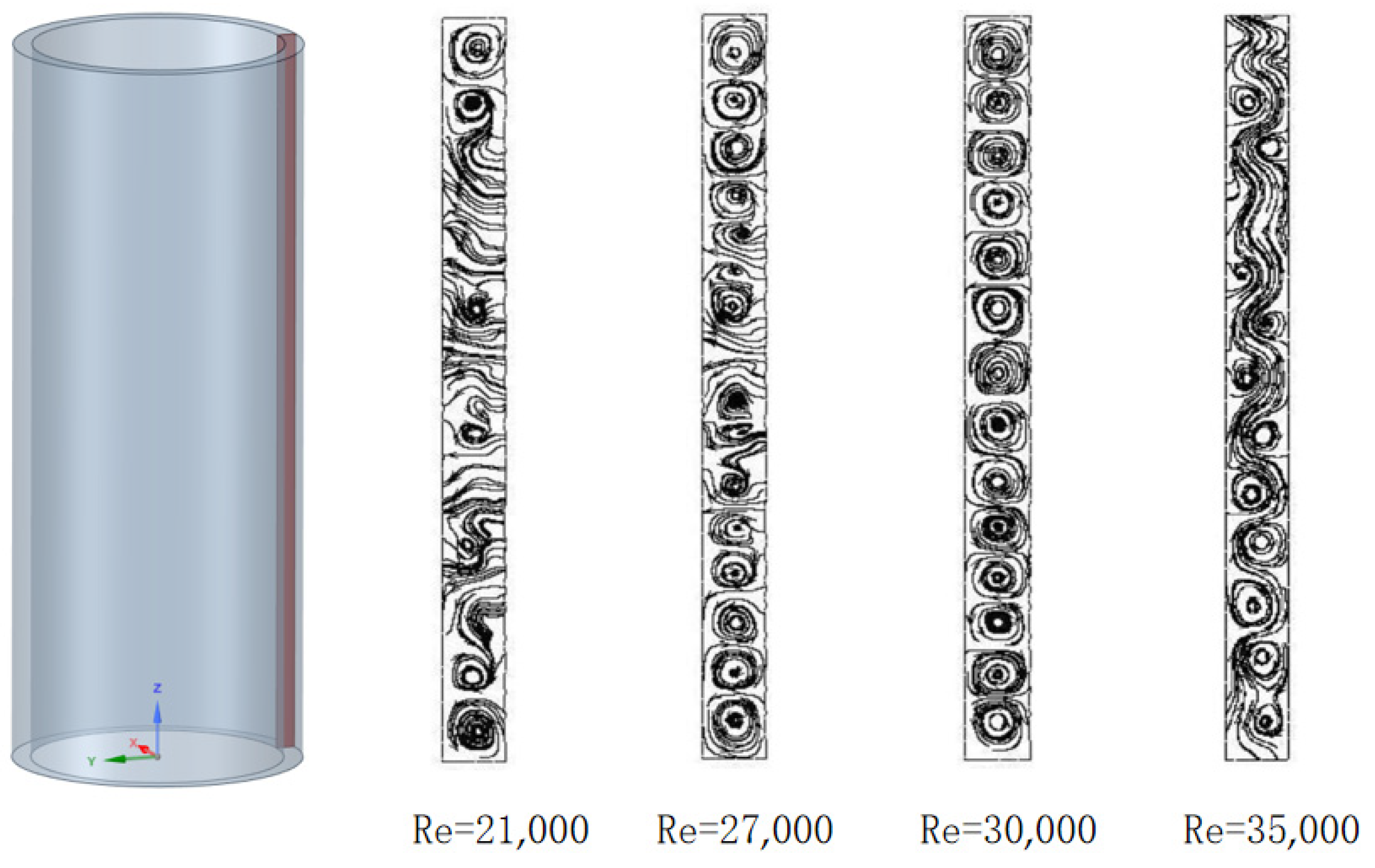

4.2. Influence of Taylor Vortex on Flow Field

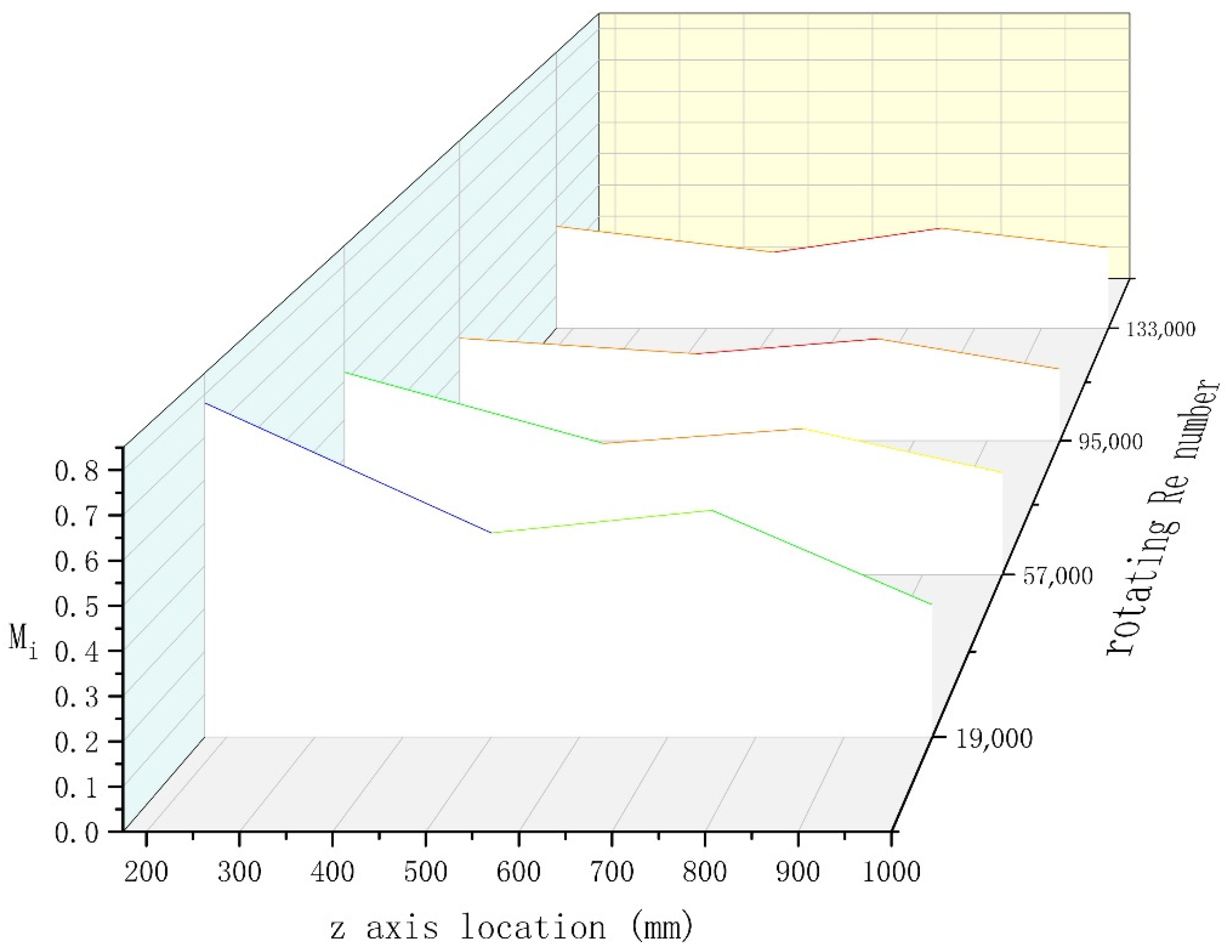

4.3. Influence of Taylor Vortex on Flow Model

4.4. Influence of Taylor Vortex on Mass Transfer

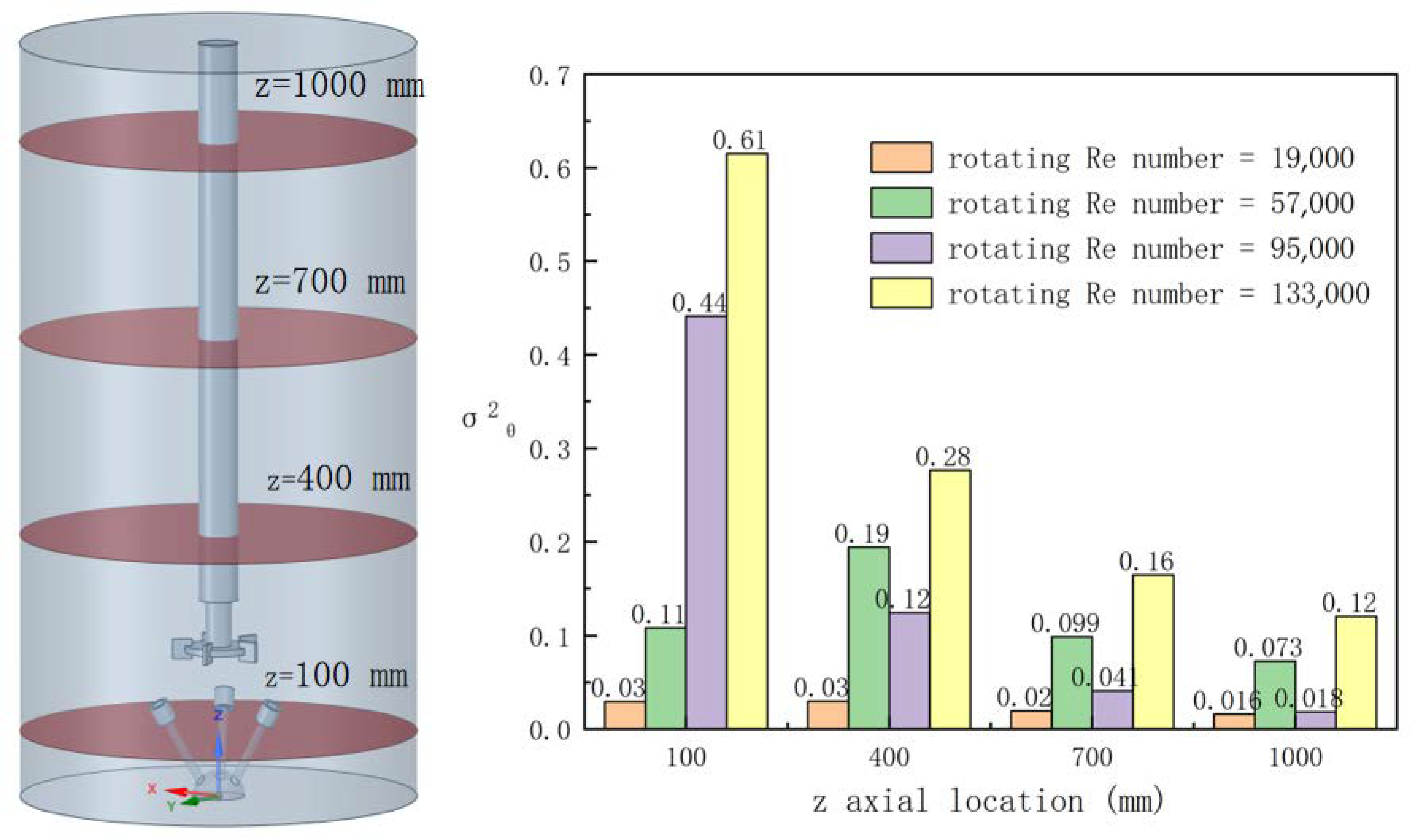

4.4.1. Influence of Taylor Vortex on Gas Phase Homogeneity

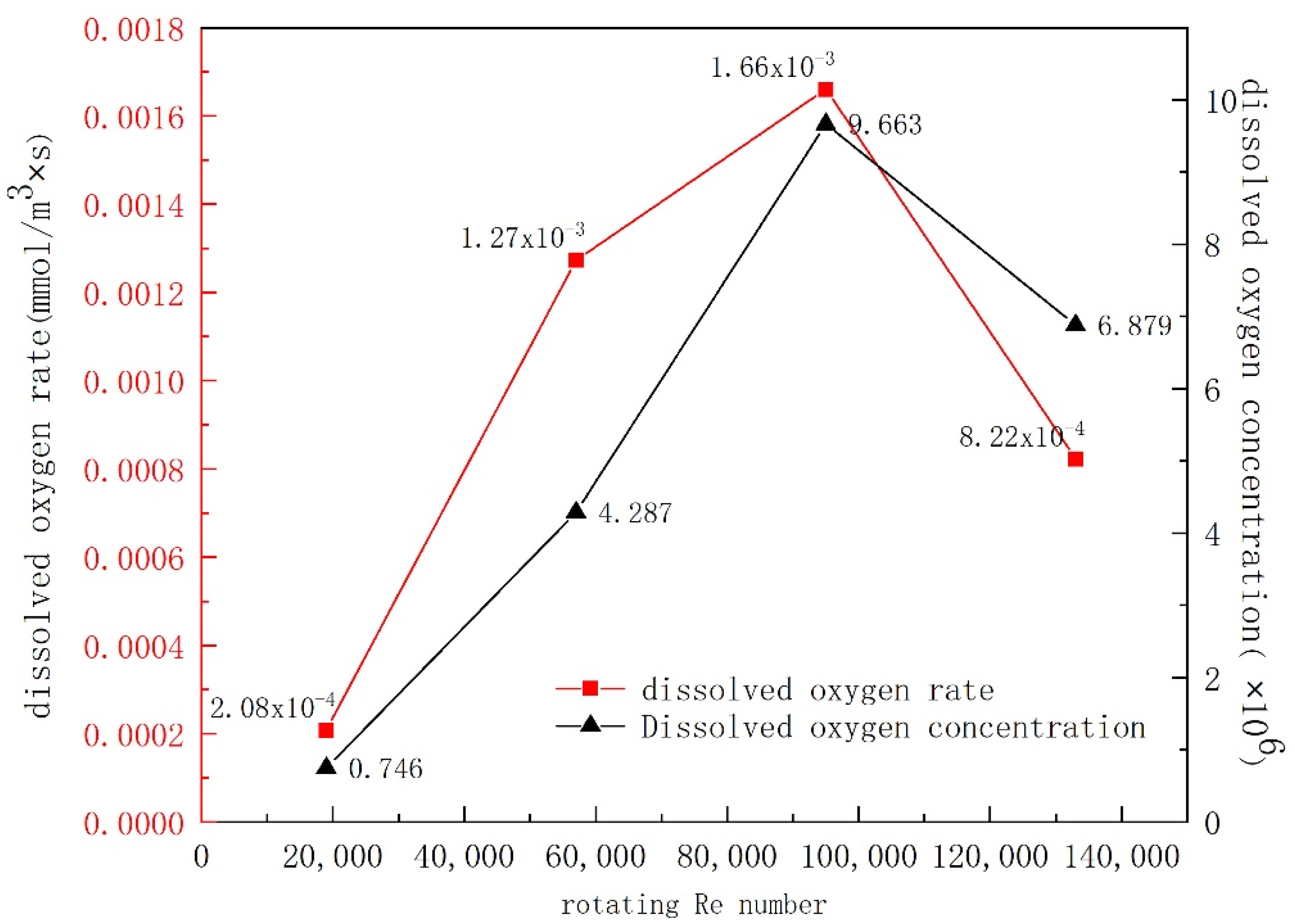

4.4.2. Influence of Taylor Vortex on Dissolved Oxygen

5. Conclusions

- (1)

- Taylor vortex is formed in stirred tank Taylor reactor by gas distributor and its evolution law is consistent with that in conventional Taylor flow reactor.

- (2)

- The effect of increasing rotation Reynolds number on the difference eigenvalue variance θ2 is different in the region above the outlet of the gas distributor and in the region at the bottom of the reactor. The stirring action of the impeller leads to the enhancement of backmixing, while the Taylor vortex will build up a local plug flow area in the reactor, which reduces backmixing.

- (3)

- Under the critical Reynolds number Recr, the gas phase homogeneity of the reactor is increased by about 28% compared with the low rotation Reynolds number and the dissolved oxygen rate is increased by about 5 times, which effectively improves the flow condition in the reactor and strengthens the mass transfer efficiency between gas and liquid.

- (4)

- The variation trend of residence time distribution curves obtained by experiment and numerical simulation is consistent and the error between experimental data and simulated data is no more than 8.2%, which verifies the correctness of the numerical model.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Singh, R.S.; Singh, T.; Pandey, A. Production of fungal endoinulinase in a stirred tank reactor and fructooligosaccharides preparation by crude endoinulinase. Bioresour. Technol. Rep. 2021, 15, 388–395. [Google Scholar] [CrossRef]

- Wang, Z.; Zeng, J. Application of moving horizon estimation in continuous stirred tank reactors. Comput. Appl. Softw. 2021, 38, 67–71. [Google Scholar]

- Abiev, R.S. Gas-liquid and gas-liquid-solid mass transfer model for Taylor flow in micro (milli) channels: A theoretical approach and experimental proof. Chem. Eng. J. Adv. 2020, 4, 1875–1882. [Google Scholar] [CrossRef]

- Dong, S.; Ji, X.-Y.; Li, C.-X. Large eddy simulation of Taylor-Couette turbulent flow under transverse magnetic field. Acta Phys. Sin. 2021, 70, 216–224. [Google Scholar] [CrossRef]

- Lim, J.G.; Yoon, S.H.; Hong, J.; Choi, J.B.; Kim, M.K.; Lee, T.R. Continuous synthesis of nickel/cobalt/manganese hydroxide microparticles in Taylor–Couette reactors. J. Ind. Eng. Chem. 2021, 99, 388–395. [Google Scholar] [CrossRef]

- Hosoya, M.; Manaka, A.; Nishijima, S.; Tsuno, N. Development of a Liquid-Liquid Biphasic Reaction Using a Taylor Vortex Flow Reactor. Asian J. Org. Chem. 2021, 10, 1414–1418. [Google Scholar] [CrossRef]

- Kaye, J.; Elgar, E. Modes of adiabatic and diabatic fluid flow in an annulus with an inner rotating cylinder. Trans. ASME 1958, 80, 753–765. [Google Scholar] [CrossRef]

- Gil, L.V.G.; Singh, H.; da Silva, J.D.S.; dos Santos, D.P.; Covas, D.T.; Swiech, K.; Suazo, C.A.T. Feasibility of the taylor vortex flow bioreactor for mesenchymal stromal cell expansion on microcarriers. Biochem. Eng. J. 2020, 162, 107710. [Google Scholar]

- Sha, Y.; Fritz, J.; Klemm, T.; Ripperger, S. Untersuchung der Strömung im Taylor-Couette-System bei geringen Spaltbreiten. Chem. Ing. Tech. 2016, 88, 640–647. [Google Scholar] [CrossRef]

- Yin, J.; Liu, X.; Zhou, C.; Zhu, Z. Analysis and measurement of mixing flow field on side wall of large-scale mixing tank. Chem. Eng. 2021, 49, 73–78. [Google Scholar]

- Zhu, J.; Liu, D.; Tang, C.; Chao, C.Q.; Wang, C.L. Study of Slit Wall Aspect Ratio Effect on the Taylor Vortex Flow. J. Eng. Thermophys. 2016, 37, 1208–1211. [Google Scholar]

- Lei, M.; Li, M. High-Performance Manufacturing Principle and Application of Thrust Bearings of Primary Pump in Nuclear Power Plant. China Nucl. Power 2020, 13, 592–598. [Google Scholar]

- Giordano, R.C.; Giordano, R.L.C.; Prazeres, D.M.F.; Cooney, C.L. Analysis of a Taylor–Poiseuille vortex flow reactor—I: Flow patterns and mass transfer characteristics. Chem. Eng. Sci. 1998, 53, 3635–3652. [Google Scholar] [CrossRef]

- Giordano, R.L.C.; Giordano, R.C.; Prazeres, D.M.F.; Cooney, C.L. Analysis of a Taylor–Poiseuille vortex flow reactor—II: Reactor modeling and performance assessment using glucose-fructose isomerization as test reaction. Chem. Eng. Sci. 2000, 55, 3611–3626. [Google Scholar] [CrossRef]

- Resende, M.M.; Tardioli, P.W.; Fernandez, V.M.; Ferreira, A.L.O.; Giordano, R.L.C.; Giordano, R.C. Distribution of suspended particles in a Taylor–Poiseuille vortex flow reactor. Chem. Eng. Sci. 2001, 56, 755–761. [Google Scholar] [CrossRef]

- Resende, M.M.; Vieira, P.G.; Sousa, R., Jr.; Giordano, R.L.C.; Giordano, R.C. Estimation of mass transfer parameters in a Taylor-Couette-Poiseuille heterogeneous reactor. Braz. J. Chem. Eng. 2004, 21, 175–184. [Google Scholar] [CrossRef]

- Ostilla-Mónico, R.; Van der Poel, E.; Verzicco, R.; Grossmann, S.; Lohse, D. Exploring the phase diagram of fully turbulent Taylor–Couette flow. J. Fluid Mech. 2014, 761, 1–26. [Google Scholar] [CrossRef] [Green Version]

- Richter, O.; Menges, M.; Kraushaar-Czarnetzki, B. Investigation of mixing in a rotor shape modified Taylor-vortex reactor by the means of a chemical test reaction. Chem. Eng. Sci. 2009, 64, 2384–2391. [Google Scholar] [CrossRef]

- Deng, R.; Arifin, D.Y.; Chyn, M.Y.; Wang, C.H. Taylor vortex flow in presence of internal baffles. Chem. Eng. Sci. 2010, 65, 4598–4605. [Google Scholar] [CrossRef]

- Carlos Álvarez, M.; Vicente, W.; Solorio, F.; Mancilla, E.; Salinas, M.; Zenit, V.R. A study of the Taylor-Couette flow with finned surface rotation. J. Appl. Fluid Mech. 2019, 12, 1371–1382. [Google Scholar] [CrossRef]

- Yang, G.; Wang, M. Numerical simulation and performance analysis of flow field in coaxial contra-rotating bioreactor. CIESC J. 2020, 71, 5188–5199. [Google Scholar]

- Berghout, P.; Dingemans, R.J.; Zhu, X.; Verzicco, R.; Stevens, R.J.; Van Saarloos, W.; Lohse, D. Direct numerical simulations of spiral Taylor–Couette turbulence. J. Fluid Mech. 2020, 887, 18. [Google Scholar] [CrossRef] [Green Version]

- Bakhuis, D.; Ezeta, R.; Berghout, P.; Bullee, P.A.; Tai, D.; Chung, D.; Verzicco, R.; Lohse, D.; Huisman, S.G.; Sun, C. Controlling secondary flow in Taylor–Couette turbulence through spanwise-varying roughness. J. Fluid Mech. 2019, 883, 654–662. [Google Scholar] [CrossRef] [Green Version]

- Qin, Z.; Zhang, Q.; Liu, Y.; Guo, J.; Shi, Y. PIV measurement and CFD simulation of flow characteristic in a spinning disc reactor. Chem. Eng. 2019, 47, 44–49. [Google Scholar]

- Hiroyuki, F.; Noritaka, S. Velocity Component Comparison between CFD and EFD in Taylor Vortex Flow. J. Mech. Eng. Autom. 2017, 7, 327–334. [Google Scholar] [CrossRef] [Green Version]

- Ma, R.-X.; Wang, Y.-M.; Zhang, S.-H.; Wu, C.-H.; Wang, X.-N. Numerical investigation of scale effect on acoustic scattering by vortex. Acta Phys. Sin. 2021, 70, 184–193. [Google Scholar] [CrossRef]

- Ye, L.; Li, L.N.; Chen, D.; Xie, F. Flow and reaction performance of Taylor-vortex flow reactor. CIESC J. 2013, 64, 2058–2064. [Google Scholar]

- Karen, L.; Henderson, D.; Rhys, G. Limiting behavior of particles in Taylor-Couette flow. J. Eng. Math. 2010, 67, 85–94. [Google Scholar]

- Hiroyuki, F. Interactive Visualization System of Taylor Vortex Flow Using Stokes’ Stream Function. World J. Mech. 2012, 2, 188–196. [Google Scholar]

| Parameter | Reactor Diameter | Reactor Height | Agitator Diameter | Static Distributor Diameter | Nozzle Length | Annulus Ratio |

|---|---|---|---|---|---|---|

| Dimensions (mm) | 370 | 1150 | 6 | 30 | 108 | 7.42 |

| Grid Quantity | Y+ |

|---|---|

| 301,545 | 34.28 |

| 693,835 | 37.51 |

| 914,523 | 32.15 |

| 1,593,471 | 30.16 |

| 2,664,228 | 31.31 |

| Inlet Mass Flow Velocity | Static Distributor Speed | Stirring Speed | Rotating Re Number |

|---|---|---|---|

| 0.001 kg/s | 200 rpm | 50 rpm | 19,000 |

| 150 rpm | 57,000 | ||

| 250 rpm | 95,000 | ||

| 350 rpm | 133,000 |

| t/s | 50 | 55 | 60 | 65 | 70 | 75 | 80 | 85 | 90 | 95 | 100 |

| (c)p | 1.25 | 4.73 | 66.13 | 44.67 | 101.58 | 100.42 | 77.50 | 73.38 | 55.88 | 37.38 | 17.23 |

| E(t) × 104 | 0.01 | 0.19 | 2.49 | 3.92 | 6.93 | 9.70 | 11.70 | 11.60 | 11.20 | 10.80 | 9.68 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ye, L.; Wan, T.; Xie, X.; Hu, L. Study on Flow Characteristics and Mass Transfer Mechanism of Kettle Taylor Flow Reactor. Energies 2022, 15, 2028. https://doi.org/10.3390/en15062028

Ye L, Wan T, Xie X, Hu L. Study on Flow Characteristics and Mass Transfer Mechanism of Kettle Taylor Flow Reactor. Energies. 2022; 15(6):2028. https://doi.org/10.3390/en15062028

Chicago/Turabian StyleYe, Li, Tengfei Wan, Xiaohui Xie, and Lin Hu. 2022. "Study on Flow Characteristics and Mass Transfer Mechanism of Kettle Taylor Flow Reactor" Energies 15, no. 6: 2028. https://doi.org/10.3390/en15062028

APA StyleYe, L., Wan, T., Xie, X., & Hu, L. (2022). Study on Flow Characteristics and Mass Transfer Mechanism of Kettle Taylor Flow Reactor. Energies, 15(6), 2028. https://doi.org/10.3390/en15062028