CO2 Emissions and Economy of Co-Firing Carbonized Wood Pellets at Coal-Fired Power Plants: The Case of Overseas Production of Pellets and Use in Japan

Abstract

:1. Introduction

2. Methodology

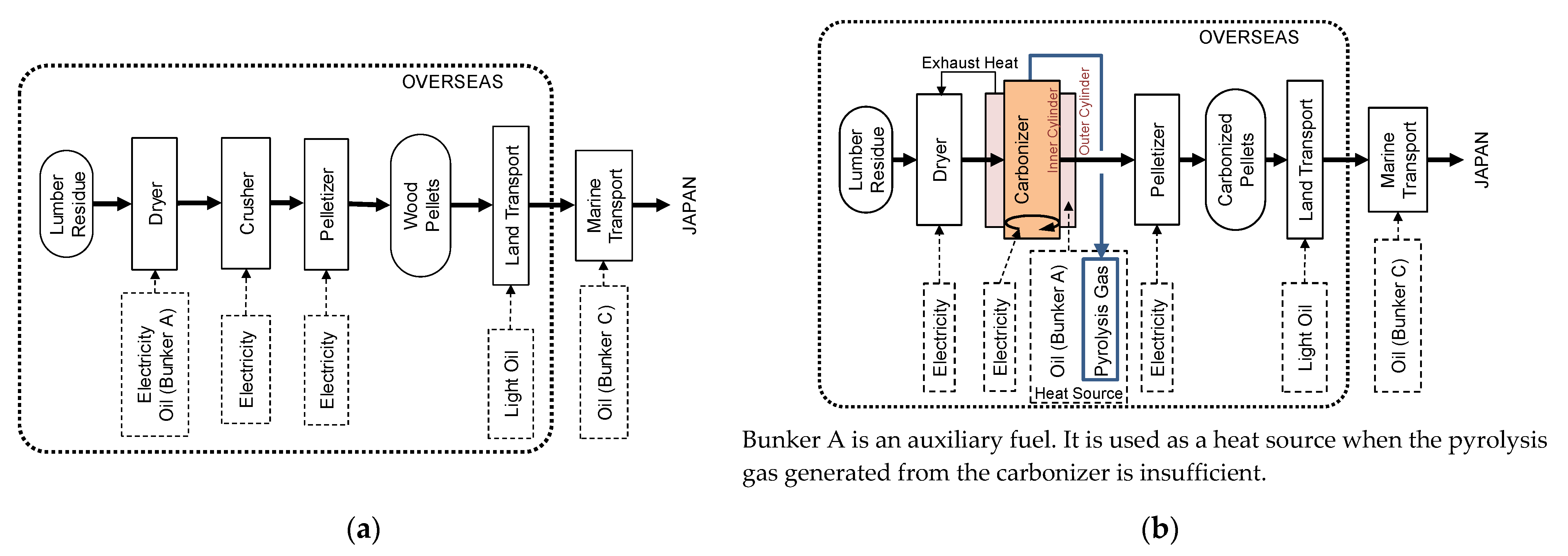

2.1. Assumptions of Fuel Production Process

2.2. Assumptions of Transportation Conditions of WP and CP

2.3. Cost Estimation

3. Results and Discussion

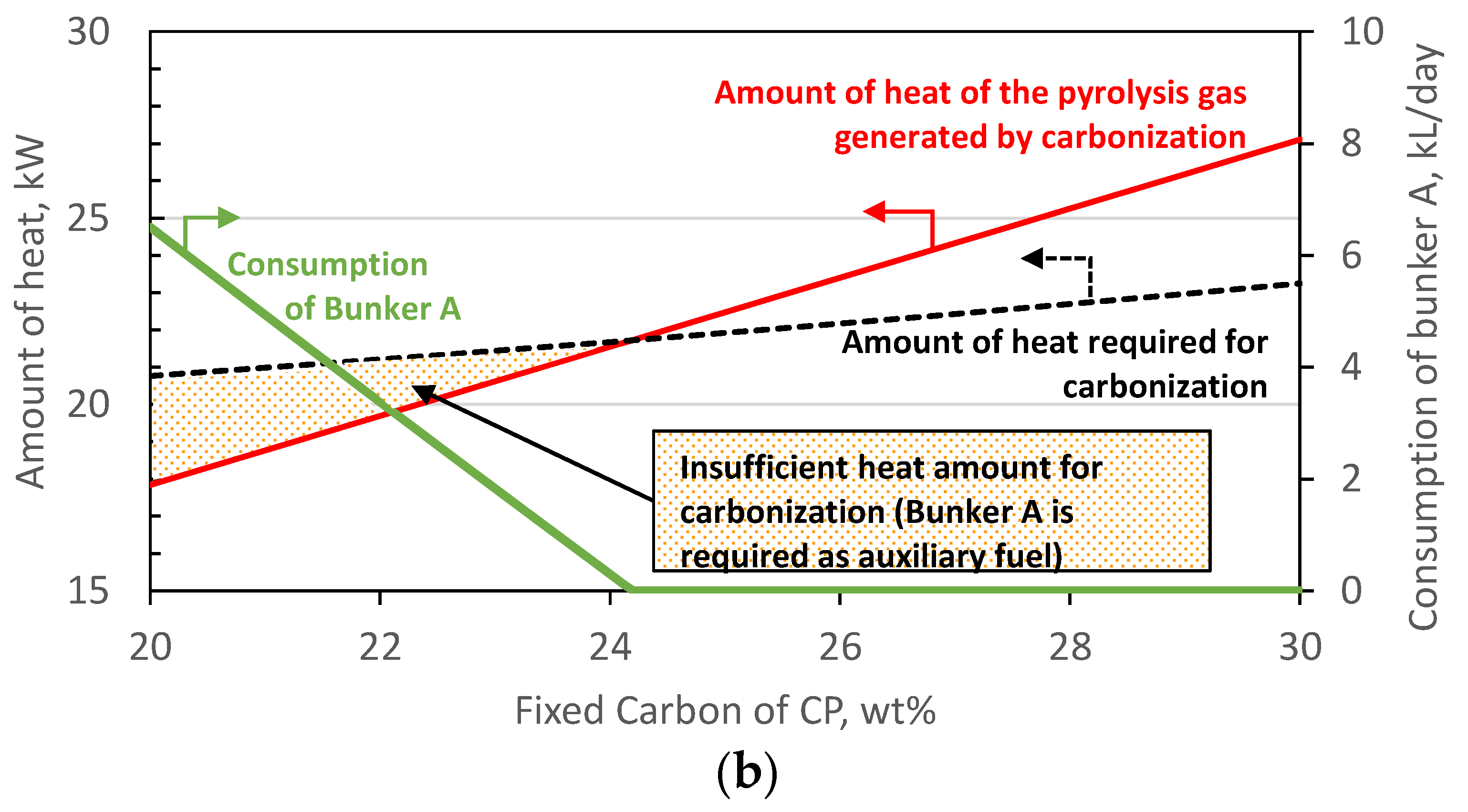

3.1. Estimation of Energy Consumption during Production of WP and CP

3.2. Estimation of Energy Consumption during Transportation

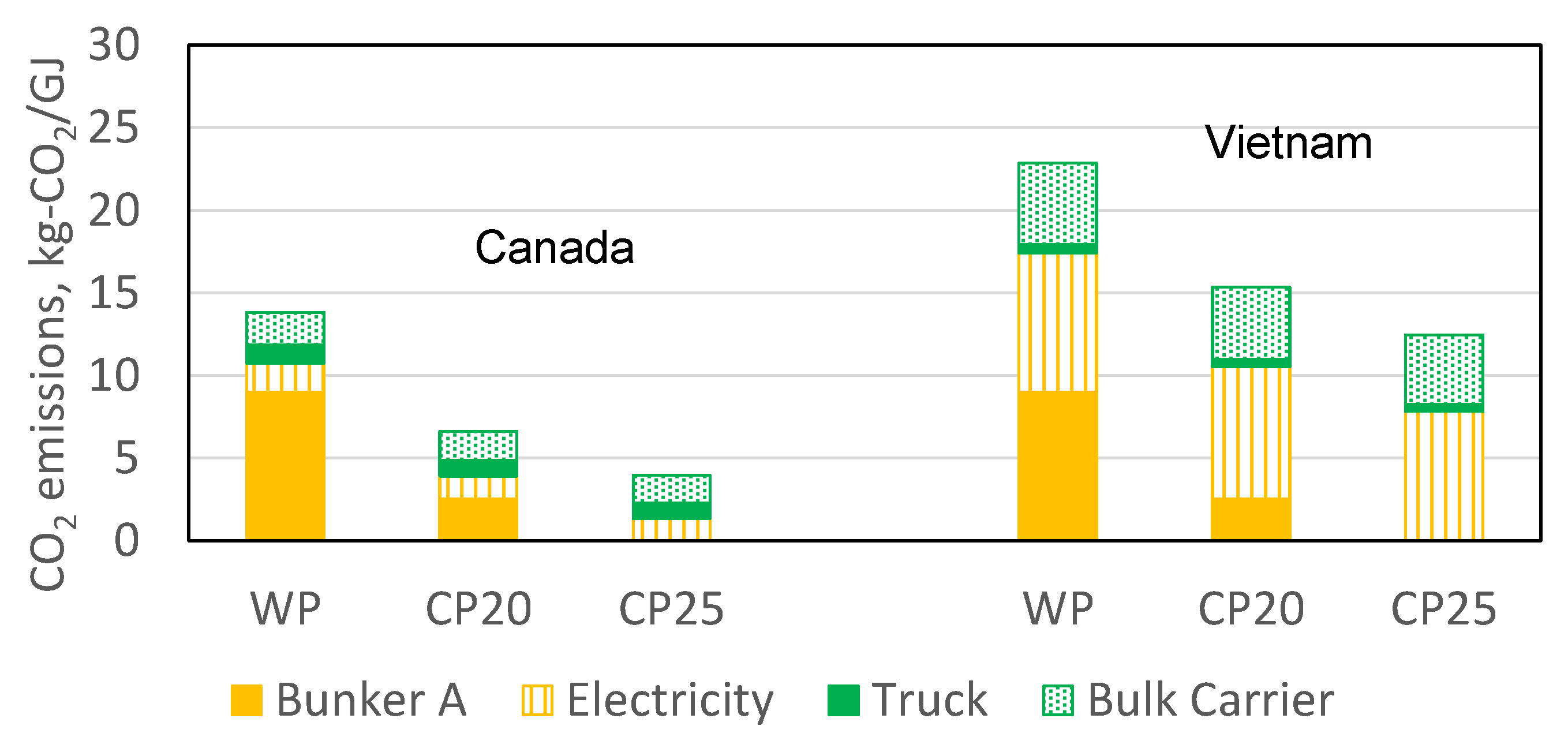

3.3. CO2 Emissions

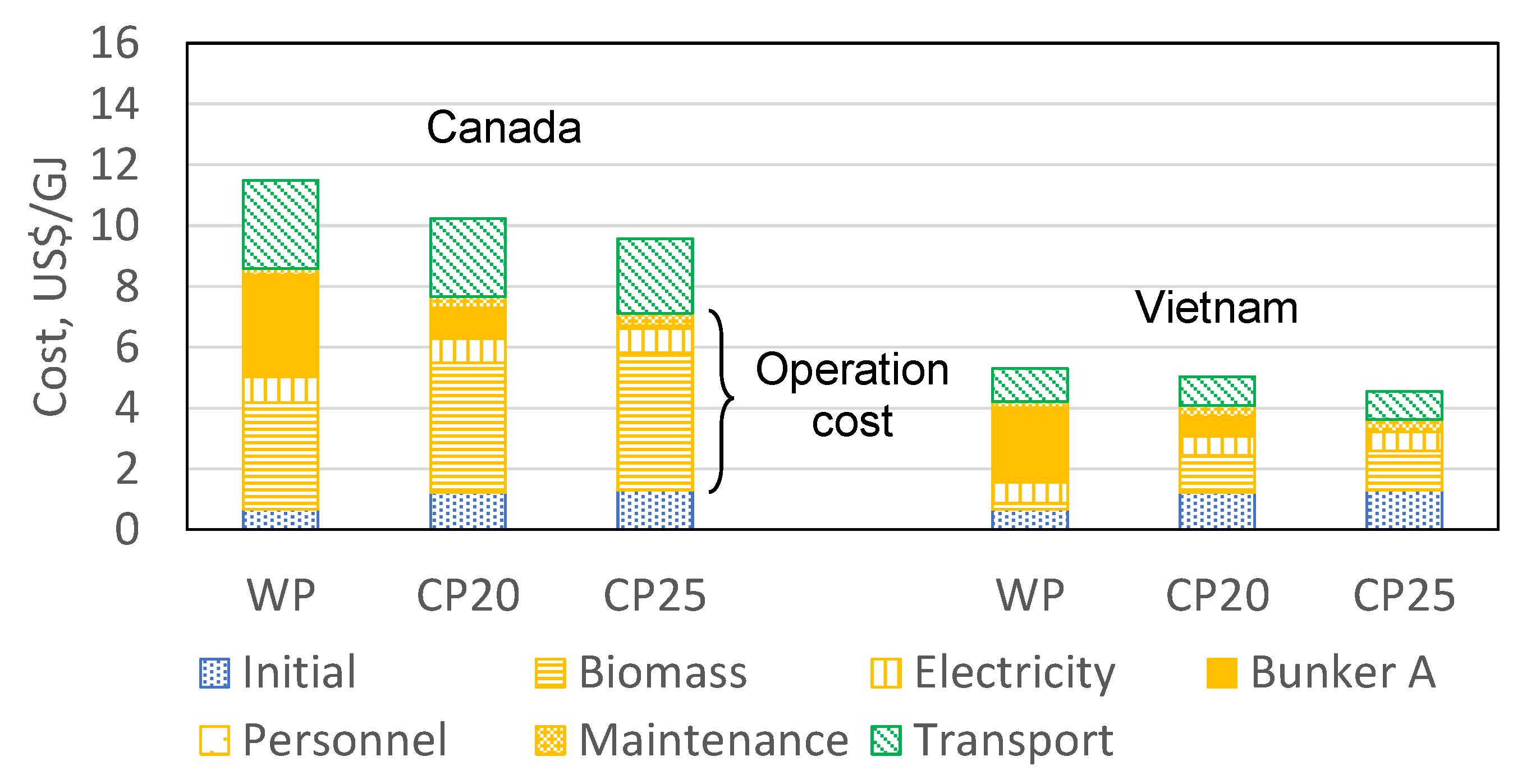

3.4. Economic Efficiency

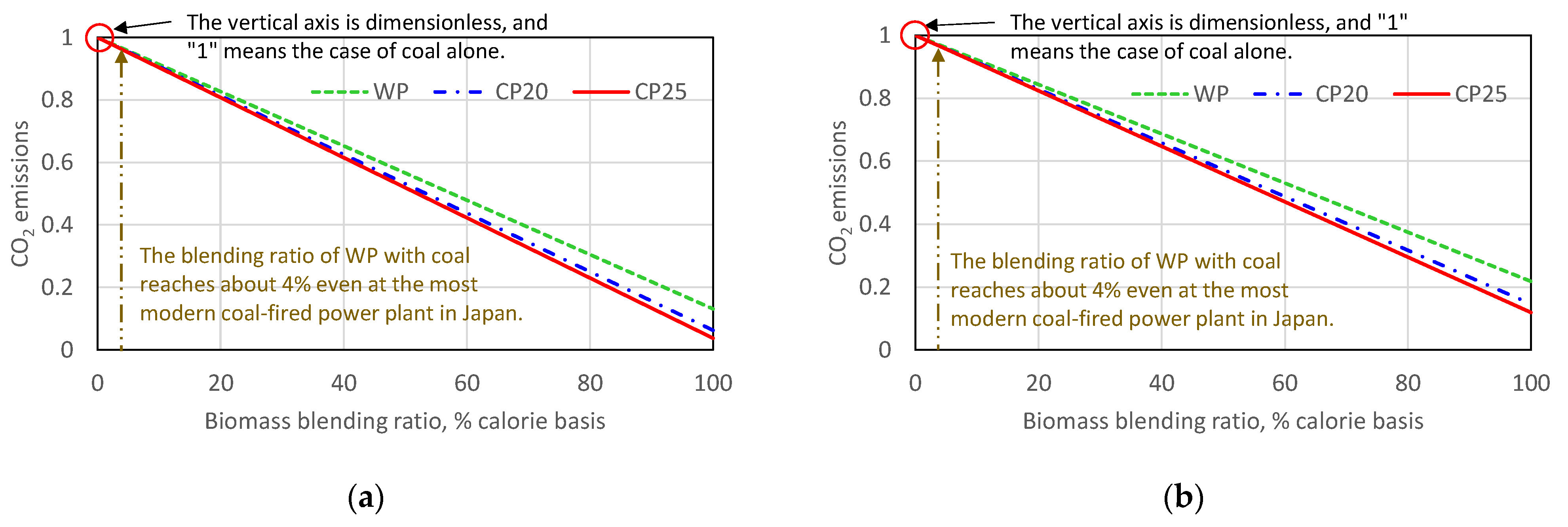

3.5. Co-Firing at a Coal-Fired Power Plant

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ministry of Economy, Trade and Industry; Agency for Natural Resources and Energy (METI/ANRE). Power Survey Statistics 2019. Available online: https://www.enecho.meti.go.jp/statistics/electric_power/ep002/pdf/2019/0-2019.pdf (accessed on 8 August 2021).

- Gil, M.V.; Rubiera, F. 5—Coal and biomass cofiring: Fundamentals and future trends. In New Trends in Coal Conversion; Suárez-Ruiz, I., Diez, M.A., Rubiera, F., Eds.; Woodhead Publishing: Sawston, Cambridge, UK, 2019; pp. 117–140. [Google Scholar]

- De, S.; Assadi, M. Impact of cofiring biomass with coal in power plants—A techno-economic assessment. Biomass Bioenergy 2009, 33, 283–293. [Google Scholar] [CrossRef]

- Narayanan, K.V.; Natarajan, E. Experimental studies on cofiring of coal and biomass blends in India. Renew. Energy 2007, 32, 2548–2558. [Google Scholar] [CrossRef]

- Demirbaş, A. Sustainable cofiring of biomass with coal. Energy Convers. Manag. 2003, 44, 1465–1479. [Google Scholar] [CrossRef]

- Holtmeyer, M.L.; Kumfer, B.M.; Axelbaum, R.L. Effects of biomass particle size during cofiring under air-fired and oxyfuel conditions. Appl. Energy 2012, 93, 606–613. [Google Scholar] [CrossRef]

- Loeffler, D.; Anderson, N. Emissions tradeoffs associated with cofiring forest biomass with coal: A case study in Colorado, USA. Appl. Energy 2014, 113, 67–77. [Google Scholar] [CrossRef]

- Mitsui & Co. Future Perspectives: Biomass Co-Firing in Coal-Fired Power Generation Attracting Domestic Attention, Global Strategic Studies Institute Monthly Report. Available online: https://www.mitsui.com/mgssi/en/report/detail/__icsFiles/afieldfile/2018/01/12/170703m_unokikuchi_e.pdf (accessed on 8 June 2021).

- Xue, J.; Chellappa, T.; Ceylan, S.; Goldfarb, J.L. Enhancing biomass + coal Co-firing scenarios via biomass torrefaction and carbonization: Case study of avocado pit biomass and Illinois No. 6 coal. Renew. Energy 2018, 122, 152–162. [Google Scholar] [CrossRef]

- Arias, B.; Pevida, C.; Fermoso, J.; Plaza, M.G.; Rubiera, F.; Pis, J.J. Influence of torrefaction on the grindability and reactivity of woody biomass. Fuel Process. Technol. 2008, 89, 169–175. [Google Scholar] [CrossRef] [Green Version]

- Phanphanich, M.; Mani, S. Impact of torrefaction on the grindability and fuel characteristics of forest biomass. Bioresour. Technol. 2011, 102, 1246–1253. [Google Scholar] [CrossRef] [PubMed]

- van der Stelt, M.J.C.; Gerhauser, H.; Kiel, J.H.A.; Ptasinski, K.J. Biomass upgrading by torrefaction for the production of biofuels: A review. Biomass Bioenergy 2011, 35, 3748–3762. [Google Scholar] [CrossRef]

- Ndibe, C.; Maier, J.; Scheffknecht, G. Combustion, cofiring and emissions characteristics of torrefied biomass in a drop tube reactor. Biomass Bioenergy 2015, 79, 105–115. [Google Scholar] [CrossRef]

- Huang, C.-W.; Li, Y.-H.; Xiao, K.-L.; Lasek, J. Cofiring characteristics of coal blended with torrefied Miscanthus biochar optimized with three Taguchi indexes. Energy 2019, 172, 566–579. [Google Scholar] [CrossRef]

- Yoshida, T. Production and Evaluation Method of Heat-Treated Biomass Pellet Fuels. J. Jpn. Soc. Exp. Mech. 2019, 19, 175–181. [Google Scholar]

- Nunes, L.J.R.; Matias, J.C.O.; Catalão, J.P.S. A review on torrefied biomass pellets as a sustainable alternative to coal in power generation. Renew. Sustain. Energy Rev. 2014, 40, 153–160. [Google Scholar] [CrossRef]

- Tabata, T.; Torikai, H.; Tsurumaki, M.; Genchi, Y.; Ukegawa, K. Life cycle assessment for co-firing semi-carbonized fuel manufactured using woody biomass with coal: A case study in the central area of Wakayama, Japan. Renew. Sustain. Energy Rev. 2011, 15, 2772–2778. [Google Scholar] [CrossRef] [Green Version]

- Kamimura, K.; Kuboyama, H.; Yamamoto, K. Wood biomass supply costs and potential for biomass energy plants in Japan. Biomass Bioenergy 2012, 36, 107–115. [Google Scholar] [CrossRef]

- Ashizawa, M.; Otaka, M.; Shoji, T.; Yamamoto, H. Carbonized characteristics of woody biomass, grindability and combustibility for carbonized woody biomass. J. Jpn. Sol. Energy Soc. 2021, 47, 49–56. Available online: https://www.jses-solar.jp/journal/backnumbers/j265/p49-56 (accessed on 24 January 2022).

- Japan Woody Bioenergy Association. Customs Statistics. Available online: https://www.jwba.or.jp/database/price-transition01/ (accessed on 8 June 2021).

- Ministry of Economy, Trade and Industry; Agency for Natural Resources and Energy (METI/ANRE). The Promotion of Energy Saving by Transportation 5th. Available online: https://www.enecho.meti.go.jp/category/saving_and_new/saving/ninushi/pdf/ninushitebiki_ver5.pdf (accessed on 8 June 2021).

- International Energy Agency; Nuclear Energy Agency; Organization for Economic Co-Operation and Development. Projected Costs of Generating Electricity 2015 Edition. Available online: https://www.oecd-nea.org/jcms/pl_14756/projected-costs-of-generating-electricity-2015-edition (accessed on 24 January 2022).

- Ministry of the Environment (MOE). List of Calculation Methods and Emission Factors in the Calculation/Reporting/Publication System. Available online: https://ghg-santeikohyo.env.go.jp/files/calc/itiran_2020_rev.pdf (accessed on 8 June 2021).

- Dehkordi, M.; Mahdi, M. On the Design and Analysis of Forest Biomass to Biofuel and Bioenergy Supply Chains, The University of British Columbia. 2015. Available online: https://open.library.ubc.ca/cIRcle/collections/ubctheses/24/items/1.0166110 (accessed on 8 June 2021).

- Alibaba.com. Biomass FOB Price. Available online: https://www.alibaba.com/product-detail/100-Pine-Wood-Sawdust_50039271188.html?spm=a2700.7724857.main07.3.189c198e979l2f (accessed on 8 June 2021).

- JETRO. Investment Cost Comparison of Vancouver in Canada/of Ho Chi Minh in Vietnam. Available online: https://www.jetro.go.jp/world/search/cost.html (accessed on 8 June 2021).

- Mitsubishi Heavy Industries Environmental & Chemical Engineering Co., Ltd. Development and Testing of Technologies to Further Reduce CO2 Emissions Commissioned by the Ministry of the Environment (MOE), Devising Processes to Produce Energy through Increased Use of Carbonized Biomass and Development of Firing Technologies for Use in 100% Pulverized Coal-Fired Boilers. 2017. Available online: https://id.ndl.go.jp/bib/029342406 (accessed on 8 June 2021).

- Iuchi, M. Evaluation of life cycle CO2 emissions of domestic and foreign biomass fuel for coal-fired power plant. CRIEPI Res. Rep. 2011, Y10010, 2. Available online: https://criepi.denken.or.jp/hokokusho/pb/reportDownload?reportNoUkCode=Y10010&tenpuTypeCode=30&seqNo=1&reportId=7739 (accessed on 24 January 2022).

- Japan Ship Technology Research Association. Research on Carbon Footprint Formulation in Ship Transportation, Research Report 2009. Available online: https://www.jstra.jp/html/PDF/2009_CFP_houkokusyo.pdf (accessed on 8 June 2021).

- JAERO. Comparison of CO2 Emission Factors (Power Generation Ends) in Each Country. Available online: http://www.ene100.jp/www/wp-content/uploads/zumen/2-1-18.pdf (accessed on 8 June 2021).

- Global Environment Centre Foundation (GEC). Electricity CO2 Emission Factor by Country Used in the 2019 JCM Equipment Subsidy Project. Available online: http://gec.jp/innovation/2019/S.2019JCM_emission_factor.pdf (accessed on 8 June 2021).

- Ministry of Economy, Trade and Industry; Agency for Natural Resources and Energy (METI/ANRE). Handbook of Electric Power Industry 2019; Research Institute of Economy, Trade and Industry (RIETI): Ginza, Chuo-ku, Tokyo, Japan, 2019. [Google Scholar]

- J-POWER. About the Start of Commercial Operation of the New No. 1 Takehara Thermal Power Station. Available online: https://www.jpower.co.jp/news_release/pdf/news200630.pdf (accessed on 8 June 2021).

| Country | Canada | Vietnam |

|---|---|---|

| Sawmill location | Merritt, British Columbia | Thanh Tam Commune Chon Thanh Dist., Binh Phuoc |

| Loading port | Vancouver | Cai Mep |

| Unloading port | Yokohama, Japan | |

| Land transportation distance, km | 274 | 128 |

| Marine transportation distance, km | 7912 | 4476 |

| Case Name | WP | CP20 and CP25 |

|---|---|---|

| Stockyard | 5 | 5 |

| Dryer | 4.5 | 3.6 |

| Carbonizing unit | - | 13 |

| Crusher | 2 | - |

| Pelletizer | 4 | 3.1 |

| Silo | 1 | - |

| Construction | 3 | 4.3 |

| Total | 19.5 | 29 |

| Country | Canada | Vietnam |

|---|---|---|

| Lumber residue, USD/t | 11.83 [24] | 2 [25] |

| Maintenance | 3%/year of plant cost | |

| Electricity, USD/kWh | 0.0875 [26] | 0.07 [26] |

| Oil bunker A, USD/L | 0.987 [26] | 0.74 [26] |

| Personnel expenses, USD/Month | 2817 [26] | 242 [26] |

| Case Name | WP | CP20 | CP25 |

|---|---|---|---|

| Production Fuel | Wood Pellet | Carbonized Wood Pellet | |

| Proximate Analysis (*1), Dry Basis | |||

| Ash, wt.% | 0.1 | 0.6 | 0.6 |

| Volatile matter, wt.% | 87.7 | 79.4 | 74.4 |

| Fixed carbon, wt.% | 12.2 | 20 | 25 |

| Fuel production rate, t/day | 464 | 336 | 305 |

| Moisture of fuel, wt.% (wet basis) | 8.0 | 5.0 | 5.0 |

| HHV of fuel, MJ/kg (dry basis) | 20.00 | 21.94 | 22.80 |

| Energy Consumption | |||

| Oil bunker A, L/day | 28,331 | 6513 | 0 |

| Electric power of dryer, kW | 338 | 338 | 338 |

| Electric power of carbonizing unit, kW | - | 211 | 204 |

| Electric power of pelletizer, kW | 3123 | 2147 | 1948 |

| Annual Energy Consumption | |||

| Availability, % | 90 | ||

| Fuel production rate, t/year | 152,467 | 110,327 | 100,087 |

| Oil bunker A, kL/year | 9307 | 2140 | 0 |

| Electric energy, MWh/year | 27,291 | 21,257 | 19,636 |

| Case Name | WP | CP20 | CP25 | |

|---|---|---|---|---|

| Canada | Land, kL/year | 1191 | 862 | 782 |

| Marine, kL/year | 1850 | 1338 | 1214 | |

| Vietnam | Land, kL/year | 556 | 402 | 365 |

| Marine, kL/year | 4618 | 3342 | 3031 |

| Items | Values | |

|---|---|---|

| Calorific value of fuel | Oil bunker A, MJ/L | 39.1 |

| Light oil, MJ/L | 37.7 | |

| Oil bunker C, MJ/L | 41.9 | |

| CO2 emission intensity | Oil bunker A, kg/L | 2.71 [23] |

| Light oil, kg/L | 2.58 [23] | |

| Oil bunker C, kg/L | 3.00 [23] | |

| Electricity in Canada, kg/kWh | 0.15 [30] | |

| Electricity in Vietnam, kg/kWh | 0.8649 [31] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ashizawa, M.; Otaka, M.; Yamamoto, H.; Akisawa, A. CO2 Emissions and Economy of Co-Firing Carbonized Wood Pellets at Coal-Fired Power Plants: The Case of Overseas Production of Pellets and Use in Japan. Energies 2022, 15, 1770. https://doi.org/10.3390/en15051770

Ashizawa M, Otaka M, Yamamoto H, Akisawa A. CO2 Emissions and Economy of Co-Firing Carbonized Wood Pellets at Coal-Fired Power Plants: The Case of Overseas Production of Pellets and Use in Japan. Energies. 2022; 15(5):1770. https://doi.org/10.3390/en15051770

Chicago/Turabian StyleAshizawa, Masami, Maromu Otaka, Hiromi Yamamoto, and Atsushi Akisawa. 2022. "CO2 Emissions and Economy of Co-Firing Carbonized Wood Pellets at Coal-Fired Power Plants: The Case of Overseas Production of Pellets and Use in Japan" Energies 15, no. 5: 1770. https://doi.org/10.3390/en15051770

APA StyleAshizawa, M., Otaka, M., Yamamoto, H., & Akisawa, A. (2022). CO2 Emissions and Economy of Co-Firing Carbonized Wood Pellets at Coal-Fired Power Plants: The Case of Overseas Production of Pellets and Use in Japan. Energies, 15(5), 1770. https://doi.org/10.3390/en15051770