Abstract

Hydrogen is becoming an increasingly important energy carrier in sector integration for fuel cell transportation, heat and electricity. Underground salt caverns are one of the most promising ways to store the hydrogen obtained from water electrolysis using power generation from renewable energy sources (RES). At the same time, the production of hydrogen can be used to avoid energy curtailments during times of low electricity demand or low prices. The stored hydrogen can also be used during times of high energy demand for power generation, e.g., with fuel cells, to cover the fluctuations and shortages caused by low RES generation. This article presents an overview of the techniques that were used and proposed for using excess energy from RES for hydrogen production from water and its storage techniques, especially in underground salt caverns, for the aforementioned purpose, and its feasibility. This paper compares and summarizes the competing technologies based on the current state-of-the-art, identifies some of the difficulties in hydrogen production and storage, and discusses which technology is the most promising. The related analysis compares cost and techno-economic feasibility with regard to hydrogen production and storage systems. The paper also identifies the potential, technical challenges and the limitations associated with hydrogen integration into the power grid.

1. Introduction

We are witnessing changes in all energy sectors. Strong decarbonization and defossilization is necessary to realize the set climate targets by 2050 [1]. An example of these challenges is the “European Green Deal”, a strategy that aims to transform the European Union (EU) into a society with no net greenhouse gas emissions in 2050 [1]. This is where renewable energy sources (RES) play a leading role. Within this framework of energy transition, hydrogen was identified as an important energy carrier for coupling the transportation, heating and electricity sectors [2,3,4,5,6,7,8,9,10,11,12,13,14,15,16,17,18,19,20,21,22,23,24,25,26].

Hydrogen can be produced from water in an electrolyzer using electric energy coming from different RES, such as solar or wind [3,4,5,6,7,8,9,10,11,12,13,14,15,16,17,18,19,20,21,22,27,28,29,30]. This can be applied in residential and industrial sectors [24]. In recent years, a lot of research was conducted in the field of hydrogen storage. One possible way of storing hydrogen is using salt caverns, as they proved to be an excellent reserve system for crude oil and natural gas [5,6,7,8,9,29,30,31,32,33,34,35]. The main goal of storing hydrogen in underground salt caverns is to compensate for seasonal fluctuations in electrical energy, which increase the reliability of the future energy systems, which mostly rely on the RES [5,6,8,13,14,15,16,17,29,30,31,32,33,36,37].

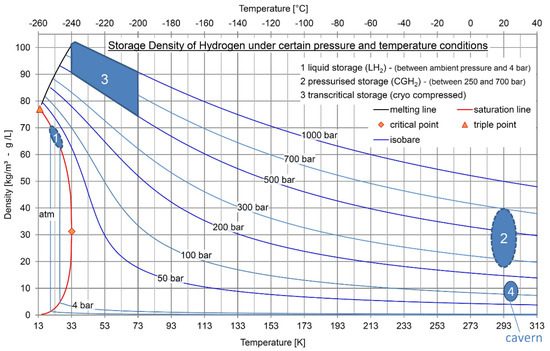

Conventional power plant capacity will decrease in the next years. This leads to a reduction in fossil fuel usage, implying the need to find and implement other ways to produce electricity. RES could solve this problem and reduce CO2 emissions [36]. Hydrogen is the first storage candidate, a non-fossil fuel option for fulfilling the current demand of primary or secondary energy sources. To provide a rough idea of the feasibility of hydrogen storage, the temperature of a salt cavern to store hydrogen is around 25 °C/km−1 with respect to depth [5]. Considering the test cavern, which has a depth of 1000 m below the surface, and a volume of 500 m3, which is being investigated within the project called Hydrogen Caverns for Mobility (HyCAVmobil) at the German Aerospace Center (DLR), the temperature then is assumed to be around 25 °C. Based on Figure 1, below, the hydrogen density at this temperature and under the atmospheric pressure (1 Bar) is between 7 kg/m3 and 12 kg/m3. This implies the need to compress hydrogen into a higher pressure to increase the density and make it a usable medium to store a large amount of energy. The typical cavern pressure for this depth is from approximately 70 to 180 Bar, as shown by Area 4 in Figure 1 [5].

Figure 1.

Density of hydrogen under different pressures and temperatures (reprinted with permission from Ref. [38]. Copyright 2012 ILK Dresden, Moritz Kuhn. CC BY-SA 4.0).

Water is the only product resulting from the hydrogen–oxygen reaction [24]. The produced water could be liquid or water vapor or a mixture of both, depending on the fuel cell or combustion process.

Considering this, two main ideas are going to be discussed in this article. The first idea is the techniques that other researchers have used and proposed regarding the use of excess energy from the RES for hydrogen production and storage technologies. The second aim is to provide an overview of how the electric system can benefit from hydrogen storage in underground salt caverns for a better integration of RES. The techno-economic feasibility will be shown, as well as the advantages and constraints of the integration of such storage systems into the power grid.

The paper is organized into seven sections. Section 2 provides a description of ways of producing hydrogen using energy from renewable energy sources. Section 3 focuses on the techniques of storing hydrogen with a focus on underground salt caverns. Section 4 discusses the hydrogen storage abilities for daily and seasonal energy shifting. Section 5 analyses the techno-economic feasibility of hydrogen production and storage. Section 6 discusses the integration of hydrogen system with the power grid and their technical limitations. Section 7 concludes the paper.

2. Hydrogen Production Techniques from Renewable Energies

Electricity production from most renewables depends on the weather conditions: when power generation exceeds the demand or the grid transportation capacity, wind parks, for example, are either curtailed or shut down. To avoid losing the surplus of produced energy, it could be stored in hydrogen, which is one of the most promising energy carriers, due to its long-term storage capabilities [5,6,10,36].

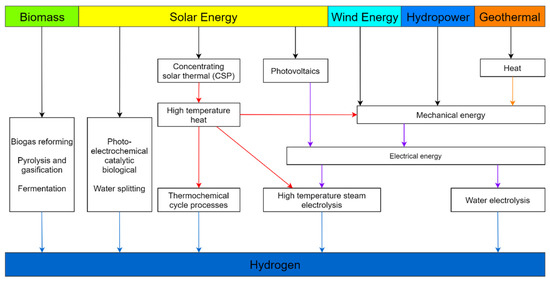

Hydrogen has a high gravimetric power density and various production methods through water-splitting, as shown in Figure 2 [39]. Electrolysis for hydrogen production is the most mature technology and the only technology that is available at the market scale. However, the concentrating solar thermal energy (CSP) can be used to provide high-temperature thermochemical water splitting, which is used instead of electricity to split water. Thermochemical cycle processes are expected to have higher efficiencies, which can turn it into a long-term solution to hydrogen production. However, thermochemical cycle processes have a larger footprint. Photo-electrochemical processes use the semiconductor material to absorb sunlight and the resulting photovoltage to directly split water. In contrast, photo-catalytic processes use only one semiconductor-based photocatalyst or a photocatalyst suspension. Due to their simple design, an efficient, large-scale deployment is anticipated [40]. However, recent test systems demonstrated [41] only low efficiencies to date [42,43,44]. Research efforts include the development of new photocatalysts, especially organics, and catalyst combinations, which use a two-step excitation process (a so-called Z-scheme). Photobiological water-splitting makes use of microorganisms such as green algae, which have a high photon conversion efficiency but are hindered by the presence of oxygen [45]. The current research approaches are two-step processes and the use of the hydrogen-producing enzyme hydrogenase from green algae in a cell-free system [46]. All three hydrogen production pathways from solar radiation rely on long-known mechanisms but are currently at an early stage of development. Further pathways use organic matter to produce hydrogen from hydrocarbons. This can be conducted via steam reformation applied on biogas, pyrolysis or fermentation, which all require a high-temperature supply. To reduce the carbon footprint, the integration of heat from CSP is proposed. Pyrolysis and gasification produce a mix of mainly hydrogen, CO and methane in the absence of oxygen. The methane can be further cracked to hydrogen and carbon at 1200 °C. [39] Possible feedstocks include organic wastes which would enable these technologies to reduce waste streams. However, the commercial applications of these processes, producing different fuels, have faced operational and economical challenges in the past [47].

Figure 2.

The various paths for hydrogen production from renewable energies (reprinted with permission from Ref. [39]). Copyright 2020 DLR.

Fermentative hydrogen production is a microbial process under anaerobic conditions. In addition to dark fermentation, which is the most promising approach, there are also photo-fermentative processes [48]. At the German Aerospace Center (DLR), Cologne, Germany, intensive research is being conducted on the development of the previously mentioned hydrogen production methods [39].

The components [4] needed for hydrogen production through water electrolysis and storage system are as follows: wind or solar parks that generate electric energy, electrolyzers that produce hydrogen and oxygen from water, compressors that compress produced hydrogen to store it in the cavern and a combustion power plant that generates electricity using hydrogen as an energy source.

A suitable method to produce hydrogen, especially using excess energy from RES to avoid losing potential energy by water electrolysis, providing clean and pollution-free “green” hydrogen, is presented in [6]. The use of a hybrid combination of RES, together with a battery and an alkaline water electrolysis system, to enhance hydrogen production, is presented in [12].

The following hydrogen production methods presented in [12,15,49] are usually integrated in a multi-energy system or other applications, such as power-to-gas (P2G) or distributed generation (DG).

The potential of implementing P2G to meet the industrial or fueling stations hydrogen demands using electrolysers in Ontario is analyzed in [12]. The authors examined the excess power from the off-peak net exports and curtailed power from wind and nuclear with the surplus forecast. The analysis showed that the energy storage has the potential to supply industrial users.

The idea of using a wind–hydrogen–heat-storage (WHHS) as an integrated energy network based on a complementary multi-energy concept is presented in [15]. The designed integrated energy network is composed of three main systems: P2G where the electricity is the input to produce hydrogen, oxygen and methane as outputs; power to heat (P2H) also uses electricity as an input to produce heat. The third system is gas to power (G2P), where the gases produced from P2G are used to produce electric power.

The concept of (DG) is presented in [49]. This uses on-site, small-scale RES generation methods such as wind and PV systems coupled with hydrogen storage to store the excess electrical energy. During this process, the stored energy will be used by the fuel cell to reduce the peak power demand. This reduces power losses and increases the voltage in grid.

3. Hydrogen Storage Techniques and Capacities from Renewable Energies

Electricity storage provides a wide variety of beneficial services to the power system, providing flexibility to balance services and maximizes the use of RES [34]. It allows the storage operator to capture the benefit of price arbitrage and avoid wind-power curtailment. Curtailment is a response to preserve the system stability at times of excess production [23]. As an example of curtailed energy, in 2012, Germany had a 16 GWh curtailment from solar generation and 358 GWh from wind generation [23]. In 2019, there was a 177 GWh curtailment from solar generation and 6272 GWh from wind generation in 2019 [50].

The study described in [33] focuses on hydrogen storage at a large scale and studies the possibility and feasibility of different types of storage where salt cavern storage is not possible due to the geological situation. Hydrogen can be stored in different forms, such as liquid hydrogen or chemically bound, e.g., in methanol or ammonia. This can be cost-effective having a good energy storage density coupled with safety. However, the costs will be reasonable when producing and storing hydrogen during periods of low electricity prices. The transition to renewables presents the need to store energy and control the renewable generation fluctuation. Hydrogen density is low (0.09 kg/m3); this means that hydrogen density needs to be increased for use as a storage solution. Constraints for hydrogen storages can differ from one application to another due to their differing requirements. Some applications require fast storage and withdrawal of hydrogen, while others need the hydrogen to be very pure. The authors in [33] compare the different storage technologies and requirements, taking their applications into consideration. Aboveground storages on a large scale have high investment costs, while costs are lower for underground storage in a salt cavern. Aboveground tank storages have lower pressure limits (typically up to 100 bar) compared to the underground salt cavern (~200 bar) [5]. For this reason, underground salt caverns have a significantly smaller surface space requirement compared to aboveground tank storages for the same amount of stored hydrogen. A higher storage pressure is accompanied by a higher energy need for compression to the intended pressure and, consequently, higher relative operating costs. Aboveground tanks can, in principle, be placed at any location, while underground salt caverns require the presence of suitable geological salt formations. Underground salt caverns are significantly less susceptible to unwanted release of hydrogen, while aboveground tanks have a higher risk of hazards and accidents due to their higher exposure to weather changes and external impacts [33]. Other advantages of salt caverns include: fast charge and discharge, low construction cost, low leakage rates, and a potential clean storage.

The integrated energy network using the wind–hydrogen–heat-storage (WHHS) discussed in [15] solved the wind power curtailment by converting electricity into non-electrical energy storage. The hydrogen and oxygen produced from water electrolysis are first stored in the tank for utilization in a vehicle, hospital, laboratories, etc. If the storage ability is not enough, hydrogen can immediately be injected into the natural gas pipeline. A combined gas with 5–20% hydrogen could meet the requirements of the gas standard. Methanation is a final alternative method to improve the storage capacity of the curtailed wind power. Whenever possible, P2H should aim to accomplish peak load shifting and use electricity for heating.

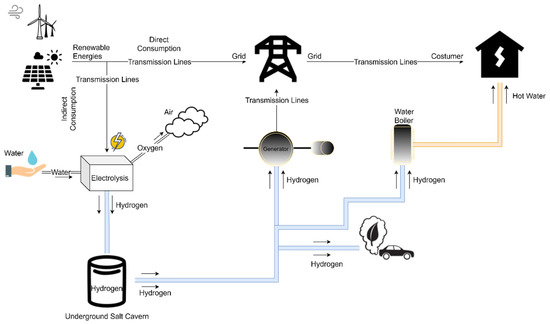

The authors in [8] discussed the potential of hydrogen and fuel cell technologies to support the German Energiewende (energy transition). An example of a possible future wind–hydrogen-system is given in [8]. Hydrogen could be produced from excess wind-power and stored in caverns. This method would for allow the storage of hydrogen for later use. The main components of the wind–hydrogen-system are an electrolysis unit with 500 MW of capacity, a combined cycle plant with 270 MW of total power, which can be used for re-electrification to supply the power grid, and a filling station with 500 bar trailers for transporting hydrogen fuel, compressors, and an underground salt cavern with volume for 4.000 tons of hydrogen, as shown in Figure 3.

Figure 3.

Hydrogen production, storage and its applications integrated to the energy system.

In the Hydrogen Cavern for Mobility (HyCAVmobil) project, the German Aerospace Center (DLR) is researching and evaluating how hydrogen can be stored in salt caverns and then used in vehicles with fuel cells [51,52]. Tests at laboratory scale are followed by tests on a test cavern operated by the energy company EWE. In Rüdersdorf (Brandenburg) near Berlin, the EWE gas storage company is building a small cavern storage facility in the salt rock at a depth of around 1000 m. The volume of this cavern is 500 cubic meters. Only pure hydrogen is going to be stored there. Construction will begin in early 2021.

According to [2], there were 671 underground gas storage facilities in the world in 2017, with a total capacity of 417 billion cubic meters, of which 70% are in the USA, Russia, Ukraine, Canada and Germany. By 2035, it is estimated that the volume in underground gas storage will increase by up to 54%. The authors in [4] conducted a pre-evaluation of hydrogen storage in salt cavern in Turkey. They stated that the hydrogen storage at this location has a technical potential for large-scale storage systems with a range of 100 GWh.

According to [5], at present, only a few sites for hydrogen storage in salt caverns are in use. Known to the authors: in the United Kingdom and the United States. Based on [26], when considering both offshore and onshore salt caverns, the storage potential in Europe is 84.800 TWhH2 (42% of which belongs to Germany). The overall onshore-only potential is 23.200 TWhH2 (41% of which belongs to Germany). The potential storage capacity of the salt caverns in European countries, based on the cavern location, is presented in Table 1 [5]. To account for the economic and ecological aspects of brine disposal pipelines, a restriction of a maximum distance of 50 km is applied to the onshore salt caverns. In this case, onshore potential decreases to 7300 TWhH2 (60% of which belongs to Germany).

Table 1.

Cavern storage potential for European countries onshore, offshore, and within 50 km of shore (based on Figure 7 from [5]).

Authors in [32] stated that Germany has around 170 caverns for the storage of natural gas, with a typical volume of 700.000 m3, with 20 MPa maximum pressure. The maximum pressure is 80% of initial formation pressure and the minimum pressure is around 30% of the maximum pressure.

4. Daily and Seasonal Shifting Using Stored Hydrogen

In situations where electric power generation varies, mechanical energy storage methods, such as pumped hydro and compressed air energy storage, can help overcome this variation. These technologies are still not suitable for large-scale implementation and for seasonal storage, because of the compressed air and water’s low storage density. In contrast to mechanical energy storage, chemical energy storage, such as using hydrogen, can provide up to 100 times more energy density for the same storage volume than compressed air energy storage [5]. Pumped hydro- and compressed air are the most cost-effective storage technologies for deployment in short-term (STS) or medium-term (MTS) storage [53]. The cost of hydrogen storage is not competitive in these deployment scenarios. In terms of long-term storage (LTS), the most expensive form of energy storage in this dispatch scenario is pumped hydro. This is followed by compressed air, then hydrogen storage [53]. Based on [53], short-term storage (STS) has 300 MWh storage capacity, medium-term storage (MTS) has 2100 MWh storage capacity and long-term storage (LTS) has 60,000 MWh storage capacity. These scenarios have 7 working hours per day with a full load. They operate in 7 cycles per day for STS, 1 cycle per day for MTS and 0.033 cycle per day for LTS.

The daily load shifting is tested in [6]. The authors were able to compare the compressed-air energy-storage system (CAS) to the compressed-hydrogen storage system to cover the large deficiency in wind power on the 5th of October, 2006. The comparison criteria are the variations in pressure and temperature in the storage system and how much wind energy is curtailed for the available excess energy during the testing week (from the 2nd to the 8th of October). The results show, for CAS, that around 40% of excess of wind energy is curtailed while, for compressed-hydrogen storage, all the power is stored. On the day (5th of October) of a large decrease in wind power, CAS covered only 14.2 h of the necessary power, while the compressed-hydrogen storage supplied all the needed power. In addition, there was a strong drop in the cavern pressure, to its minimum pressure and temperature, with CAS while less sharp fluctuations occurred, and the values stayed within the maximum and minimum, for compressed hydrogen storage. Hence, hydrogen has a higher energy density, leading to the fact that compressed-hydrogen storage system is better for daily load shifting using a fixed cavern size. The same study [6] also compares compressed-air energy storage and compressed-hydrogen energy storage systems for seasonal load-shifting analyses. The models used for this test are identical, with 200 wind turbines, a salt cavern of 3.8 million m3 and a 50% filled cavern. The authors in [6] simulated three cases with different levels of peak demand for the entire year of operation (2006): 600 MW, 800 MW and 1000 MW (see Table 2 for details). These demands are scaled-down versions from the demand profile on the entire Electric Reliability Council of Texas (ERCOT) region in Texas U.S in 2006. The electricity in this region has a seasonal variation in demand and generation. The peak in demand occurs in summer and the minima in occurs in the spring and fall. However, the peak in generation occurs in winter and fall and the minima occurs in summer. In the 600 MW peak demand scenario, the curtailment begins after 72 days when using compressed-hydrogen energy storage system, while, for the compressed-air energy storage, it starts after only 27 h. Only 12.6% of the wind energy was curtailed in the compressed-hydrogen energy storage system, compared to 53.5% due to lack of capacity in the case of compressed-air energy storage. In the 800 MW peak scenario, 0.69% of the wind energy is curtailed after 100 days when using the compressed-hydrogen energy storage system, compared to 38.9% after around 1 day in the case of compressed-air storage system. In the 1000 MW peak scenario, 27.4% wind energy is curtailed after 1 day when using the compressed-air system. However, no wind energy is curtailed for compressed-hydrogen energy storage.

Table 2.

Seasonal load-shifting comparison between compressed-air energy storage and compressed-hydrogen energy storage systems [6].

The authors in [6] also performed simulations that mimic the event of catastrophic interruptions, such as tornados, when the wind farms completely stop working. The simulations showed that the hydrogen-energy storage system was able to provide emergency backup power for almost seven times longer (57.7 days) than the compressed-air energy system (8.7 days). The authors in [30] addressed the possible issue for a longer hydrogen storage period, as this can increase the loss of hydrogen and vice versa.

5. The Techno-Economic Feasibility and Cost Comparison of the Hydrogen Production and Storage

The authors in [28] performed a comparison between the economic, social and environmental impacts of production of hydrogen using the RES (wind and solar energies, biomass gasification), nuclear energy sources (thermochemical water-splitting, high-temperature electrolysis), and fossil fuels (natural gas steam reforming, coal gasification). In this way, a reference was created for later knowledge of production costs, energy and exergy efficiencies for different hydrogen production methods.

As the authors have stated in [28], natural gas steam reforming (or steam methane reforming, SMR) is the most well-established and cheapest method of hydrogen production at a large scale. In addition, SMR uses already existing infrastructure, which leads to a secure supply of hydrogen. The problem of hydrogen production by electrolysis is its high capital cost and energy compared to fossil fuels. Electrolysis costs are between 6 and 25 times higher compared to production from fossil fuels, e.g., by steam methane reformation [28].

A comparative assessment of hydrogen production methods was performed in [28] and these were the outcomes:

- Regarding the environmental impact comparison based on the global warming potential (GWP) and acidification potential (AP), fossil fuel is the most harmful method. Biomass has the highest AP but a relatively low GWP. The most environmentally friendly is hydrogen production using thermochemical cycles.

- Criteria of the social cost of carbon comparison (SCC) were considered. SCC measures the marginal external cost of a unit of CO2 emissions, due to the environmental damage caused by that emission. From this criteria, natural gas steam reforming and coal gasification are the most harmful, where the most beneficial are thermochemical cycles.

- The authors conducted a financial comparison based on the current state of production technology development, infrastructure accessibility, and the price of the raw materials. Steam methane reformation, coal and biomass gasification are the most economically viable methods of hydrogen production. The most expensive production costs are for wind and solar power. Thermochemical cycles seem to be competitive. However, the lowest capital cost is steam methane reformation, while the highest is water electrolysis. However, at a small production scale the capital costs of water electrolysis and steam reformation are close to each other, which leads to more competition at this level of production.

- Energy and exergy efficiency comparisons show that the lowest efficiency is for solar-based electrolysis and the most advantageous method is biomass gasification.

According to [4], an electrolyzer currently requires between 39 kWh and 48 kWh of electric energy per 1 kg of hydrogen, which has a chemical energy density of ~33 kWh/kg. The most-used electrolysis technologies are alkaline, polymer electrolyte membrane (PEM) and high-temperature water electrolysis [39]. PEM electrolyzers with up to 200 kWel are mainly used for low-scale systems or plants due to their high cost and shorter lifetime. Alkaline electrolyzers (AEL) with up to 3000 kWel rated power are used for large-scale systems, as they are cheaper at the commercial level, easy to implement and have a long lifetime (Table 3 and Table 4).

Table 3.

Electrolyzer types [39].

Table 4.

Comparison between PEM and AEL electrolyzers [3,13,39].

The feasibility of the power-to-gas technology in the future Swiss low-voltage grid is analyzed in [19]. A model is established with hydrogen and methane production using PV surplus energy and additional energy from the grid. The goal of this study was the investigation of the feasibility of the power-to-gas plant to produce hydrogen as the main product. The production of oxygen and heat as by-products is analyzed. The use of the biogas plant as a source of CO2 is investigated for methanation to ensure that the power-to-gas system economically viable.

According to [17], the authors evaluated whether a decrease in off-peak electricity prices would lead to a lower electrolytic hydrogen costs. The authors split the daily timings during the day into five time intervals:

- Off-peak (0:00–5:00 and 22:00–5:00);

- High on-peak (6:00–10:00 and 17:00–21:15);

- On-peak (11:00–16:00).

As discussed in [17], there are three options when running the electrolyzers:

- Standard Continuous, in which the price remains constant at 12 p/kWh (0.137 €/kWh by multiplying it with 1.138 mid-exchange rate in 2017);

- Off-Peak Only, in which the price only falls to 0.057 €/kWh during off-peak hours;

- 2-Tier Continuous, in which a low price is maintained during off-peak hours, and a high price is maintained otherwise.

According to the findings, the lowest electricity cost per kilogram of hydrogen is produced in Scenario 2 (3.3 €/kg H2), followed by Scenario 3 at 4.32 €/kg H2, and Scenario 1 at 7.85 €/kg H2.

The equipment costs (electrolyzer, storage, compressor, dispenser and control system) and electricity cost are the two main factors that affect the cost of electrolytic hydrogen. Note that the electricity costs are more significant than equipment costs in large-scale systems.

The authors in [9] analyzed a large-scale hydrogen underground storage in France based on the techno-economic feasibility and business case. The economic case of salt caverns storage facility was assessed for 2025 and 2050. The cavern was modelled based on hourly cavern operation, and restricted to only wind and grid electricity.

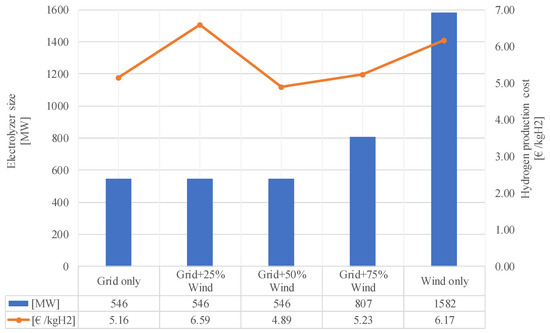

Based on five study cases that simulated and analyzed the electricity supply options in [9], we gathered the results of those studies, which are displayed in Figure 4. The Grid-only solution (which serves as a reference case) does not require any storage capacity since the electrolyzers can be turned on as needed to meet the hydrogen demand. Other cases are: wind-only and grid with wind solution, which requires different wind rates (25 percent, 50 percent, 75 percent, respectively).

Figure 4.

Hydrogen production cost (orange line) in comparison to the electrolyzer size required to meet peak demand (blue bar) based on the results of study cases in [9].

In case of grid-only, a high-capacity electrolyzer is needed to meet peak demand, which happens only once a year. In this case, a 546 MW electrolyzer is required and hydrogen is produced at 5.16 euros per kilogram. When compared to other power supply options, hydrogen produced against a wind-only source is the most expensive. Furthermore, the installed electrolysis capacity is oversized (1582 MW versus 535 MW) and 620 new wind turbines with 3 MW installed power are needed. The hydrogen production cost in this case is 6.59 euros per kilogram.

The grid + wind turbine solution shows that the storage requirements start to appear at around 30% wind rate and become massive between 50% and 75% wind rate. Investing in storage is more economical than building more renewable capacity to meet demand when there is a high proportion of renewables. At 25% wind, the hydrogen production cost is 4.89 €/kg; at 50% wind, it is 5.23 €/kg; at 75% wind, it is 6.17 €/kg. The size of electrolyzers is 546 MW for the 25% and 50% wind cases, and 807 MW for 75% wind cases.

In the study, we discovered that storage is essential when the share of renewables is so large (over 50% wind-power).

For the maximum exploitation of renewable generation, this paper [23] investigates hydrogen energy storage sizing and control. This paper proposes a means of controlling the instability when including renewable energy in power systems, by implementing a hydrogen energy storage system of a suitable size. A total of 87 TWh worth of energy was generated by renewable sources, including 70 percent wind and 30 percent solar. They evaluated three case studies:

- In case 1, hydrogen storage capacity does not align with demand response and is optimized to accommodate renewable production.

- In Case 2, hydrogen energy storage is sized using domestic thermal storage for a demand response scenario (100% enrollment).

- In Case 3, hydrogen energy storage is sized for a system with 25 percent base load generation.

The hydrogen storage capacity was:

- 67 TWh in the first case;

- 58 TWh in the second case;

- 46 TWh in the third case.

In addition, oversizing generation from renewables reduces the required size of hydrogen storage.

The authors in [12] established a multi-objective optimization model of a combined heat and power for minimum operating cost of the micro-grid and maximizing the wind 421 accommodation. The flexibility of grid scheduling was considered, and a micro-grid autonomous-control scheduling strategy was proposed. The authors in [12] present an electro-thermal hybrid energy storage model based on electricity, hydrogen and thermal energy conversion on a micro-grid autonomous operational strategy. The energy storage model presented in this paper is based on an electro-hydrogen unit (EHU), micro-turbine cogeneration unit (MCU), electric boiler unit (EBU), hydrogen energy storage unit (HSU) and thermal storage unit (TSU). The EHU produces hydrogen and oxygen without polluting gas. The HSU has a high energy density, low investment costs and non-polluting storage process. It is a high-potential energy storage technology. The authors propose a hydrogen power generation technology that uses hydrogen as a gas turbine fuel, which will contribute to zero-emission power generation.

Among the possible solutions for the large-scale storage of energy, storing hydrogen in a salt cavern is the most promising solution due to its low cost, high sealing potential, and lack of cushion gas requirement [5]. Based on the study in [7], demand side management, interconnectors and energy storage are important for a future renewable-only power grid network. The authors in [7] show that the hydrogen storage in a cavern has an increased storage capacity and lower cost for combined offshore wind and storage.

According to [34], underground salt caverns or depleted gas fields are the cheapest option for underground storage. The overall costs depend upon the initial cost of preparing the underground cavern. Based on [54], hydrogen storage costs are about 12.4 €/kWh (17 $/kWh) for aboveground storage. Regarding hydrogen storage in different underground formations, the authors in [55] stated that the costs vary from 0.002 €/kWh to 0.41 €/kWh. These values are based on the Euro (€) currency rate from 2014. For example, solution-mined salt caverns have a storage cost of 0.02 €/kWh, and dry-mined salt caverns have a storage cost of 0.14 €/kWh [55].

6. Technical Challenges of the Hydrogen Systems Integration into the Power Grid

The grid stability at the connection point of the hydrogen cavern may affect the allowable storage capacity. The connection point (node) could be weak from the electrical perspective and unable to handle the storage system energy demands. In addition to the connection point restriction, the power grid itself should be able to handle the extra feed-in power coming from the hydrogen system to feed loads located far from the node. This implies a need to investigate the grid infrastructure and check whether it needs further reinforcements, such as building new lines, using a bigger transformer or adding some reinforcement equipment, such as Flexible AC Transmission System (FACTS) devices.

The authors in [56] mentioned the main factors that affect the integration of renewable system to the grid in China. The first factor considers the necessity of transmitting the electrical energy, since the generation and consumption of energy do not always occur in same place. The underdeveloped transmission infrastructure should be also taken into consideration prior to any integration of a new system. The second factor is the operational flexibility of the current grid. It should be more able to adapt the fluctuations in the RES and, therefore, regulate the frequency, voltage and peak-load. With that said, power-to-gas systems can be a solution to the above-mentioned problems, leading to more flexibility in the grid and higher efficiency for energy conversion, while having a big storage capacity compared to other storage solutions. The authors in [56] mark the necessity of an in-depth study of power-to-gas system integration and the operation of a power grid that not only considers the influence of the power-to-gas on the active power flow but also considers the reactive power and voltage regulation at different working scenarios.

The need for an electricity–hydrogen integrated energy system model (EH-IES) was analyzed in [57]. The authors analyzed the potential of hydrogen production and its storage, while considering the excessive integration of RES. The lack of long-term storage capacity and short-term operation flexibility with the IES is going to be solved by the integration of hydrogen with the (EH-IES). The EH-IES is complicated because the hydrogen capacity allocation is directly impacted by the RES’ variation. The optimal EH-IES model given by the authors in [57] attempts to solve the abovementioned planning problems using the following methodology: a beneficial and profitable planning model for EH-IES system by considering the N-1 criterion (an acceptable reliability level is when a system can withstand any unplanned loss of a single component at any time) and the generation-load uncertainties. In addition, the seasonal hydrogen storage (SHS) and power-to-heat and hydrogen (P2HH) models can help optimize the EH-IES from the economic perspective and address the uncertainty associated with renewable energy.

For use as a storage solution, hydrogen storage density needs to be increased [33]. Hydrogen storage constraints vary from one application to another based on the requirements. Some applications need the fast charge and discharge of hydrogen, while others need the hydrogen to be pure.

The authors in [58] described the main three hydrogen challenges, including hydrogen production, storage, and end use. These three topics are intricately linked by the closed hydrogen cycle, by related scientific fundamentals, and by conditions and safety concerns. All three of these topics have clearly defined targets: high hydrogen production efficiency and hydrogen-use efficiency, and a high hydrogen storage density at an economically reasonable cost. The performance of the hydrogen cycle, however, is based on the sequential functioning of all the steps as a whole, rather than specific challenges. Hydrogen storage, for example, could not be used in low-temperature fuel cells if hydrogen is combined with CO2-producing hydrocarbons. Only high-temperature fuel cells can meet this requirement. An internal or external combustion engine, high-temperature fuel cells and heat devices may be preferable end uses for the fuel. However, these devices will exhibit a lower efficiency than pure-hydrogen conversion devices. Despite the fact that hydrogen storage has technically been solved, the system generally performs less than that of pure-hydrogen systems with pressurized cylinders (which have other critical issues). In other words, both the atomistic phenomena in the material and the system level define the performance of the system. Using metal hydrides as hydrogen storage is another interesting example given by this author. The operating temperatures for high-capacity materials such as borohydrides are 300–500 °C at 100 bar of pressure. A high-pressure, high-temperature hydrogen vessel requires thick walls made of special stainless-steel, heat insulation, and special heat-exchangers, so the overall system capacity of hydrogen decreases. MgH2 is the only common hydrogen storage in metal hydrides, so its applications are rare.

The researchers at the DLR Institute for Networked Energy Systems are examining the purity of the hydrogen before and after storage with the help of trace gas analysis [51]. It is important that the hydrogen meets the high quality and purity requirements for fuel cell mobility after it is stored in the cavern. Further research questions are which systems and regulations are necessary to feed the hydrogen in and out under pressure in the cavern and how stably the RES can continuously supply the electricity required for this system. They also aim to produce and store hydrogen directly on-site using electrolysis. The research questions are related to researching the power grids at the cavern location and determining the requirements and operating concepts in order to integrate the underground hydrogen cavern into the existing energy system. The scientific findings can be transferred to caverns with a large-as-possible volume.

7. Conclusions and Discussion

Using current state-of-the-art technology, this paper analyzed, compared and summarized the competing hydrogen production and storage technologies. It also identified some of the challenges, as well as suggesting which technology is the most promising. This study examines the feasibility of relying on stored hydrogen for daily and seasonal shifts. An analysis of both hydrogen production and storage systems from the perspective of cost and techno-economic feasibility is also included. This paper outlines the technical challenges related to hydrogen integration into the power grid. This article presented an overview of the techniques that other researchers used and proposed for the use of excess energy produced from the RES in hydrogen production by water-splitting and its storage, especially in underground salt caverns, including challenges in their integration into the power grid. The key findings of the reviewed papers and techniques for hydrogen storing systems, along with their integration into the power grid, are as follows:

- Hydrogen is produced by electrolyzing water using the excess energy produced from the RES and will be used as fuel in transportation or to generate electricity for power grid integration. Hydrogen production techniques are diversified. As a market-scale technology, electrolysis for hydrogen production is the most mature technology. Hydrogen as an energy carrier solution promises cuts in green-house and other emissions to meet the climate targets by 2050.

- In terms of flexibility and reliability, electrical energy storage has the highest potential to compensate for the gaps between generation and consumption [56]. The high cost of energy storage is still the main obstacle concerning its availability on the market. Salt caverns are the most promising and cheapest option for large-scale storage. They have fast storage and extraction rates, and relatively low construction costs. DLR researchers examine the purity of hydrogen before and after storage through gas analysis at the Institute for Networked Energy Systems. Researchers are trying to confirm the claims of the low leakage and contamination rates in the salt cavern that contains hydrogen.

- The storage of hydrogen in underground salt caverns makes it more adaptable and scalable. Hydrogen storage in a cavern is a more capable backup than compressed air energy storage because hydrogen has a higher energy density. Simulated results showed that the hydrogen energy storage system could provide emergency backup power for almost seven times longer (57.7 days) than the compressed-air energy system (8.7 days).

- The benefit of hydrogen storage in salt caverns for daily and seasonal shifting is that it reduces the curtailed energy when extra power could be generated from renewables, thus creating a balance between the generation and demand in a power system [57] when a deficiency of electricity occurs due to inconvenient weather conditions. The use of power-to-hydrogen technology and seasonal hydrogen storage plays a major role in reaching a complimentary energy security approach.

- Electricity storage provides a wide variety of beneficial services to the power system, providing flexibility for balancing services, and maximizes the use of RES. Otherwise, the electricity coming from wind farms could have a negative impact on the power grid, affecting its regulation, load flow and scheduling. This allows for the storage operator to capture the benefit of price arbitrage and to avoid wind-power curtailment.

- Electrically speaking, the connection point (node) may be weak and unable to handle the energy demands of the storage system. Additionally, the power grid should be able to handle the extra feed-in power from the hydrogen system to feed loads that are located far from the system. The power grid infrastructure should be assessed and further reinforced if required, for example by building new lines, adding a bigger transformer, or adding some reinforcement equipment, such as FACTS devices. Hence, grid stability is an important factor to investigate.

- Another factor that needs further investigation is the operational flexibility of the current grid. The system should be able to adapt to the fluctuations in the RES and, therefore, control the frequency, voltage and peak load. An analysis of the active power flow and reactive power in different working scenarios, together with voltage regulation, should be conducted.

- There is a need for an electricity–hydrogen integrated energy system model (EH-IES) to solve the lack of long-term storage capacity and short-term operation flexibility that occurs with the IES when considering the excessive integration of the RES. For profitable planning, the model can incorporate the N-1 criterion and generation-load uncertainty.

- The production, storage, and use of hydrogen are the three main challenges facing the hydrogen industry. There are defined targets in all three of these areas: high hydrogen-production efficiency and hydrogen-use efficiency, and high hydrogen-storage density at an economically reasonable cost. Rather than specific challenges, the performance of the hydrogen cycle depends on all steps working together sequentially. Thus, a system’s performance is determined by both the atomistic phenomena occurring within it and its structure as a whole.

The future of green energy production and its storage is prosperous. RES ia a great candidate to replace fossil fuel energy sources. A lot of effort and money have been invested in hydrogen-related research. Hydrogen energy is one of the most promising green solutions, because of its global abundancy and possible green generation. Hydrogen storage in salt caverns could dominate the market, with large-scale application in areas where salt layers are geographically available. The lack of salt layers in some areas implies the need for further research and solutions to efficient hydrogen storage long-term storage. Further research projects could use energy system analysis to study how much of the existing storage potential can be used and where to locate the possible cavern sites. Locations with high demand and RES generation profiles should be found prior to the utilization of salt caverns. When considering the utilization scenarios of a hydrogen storage, it can be seen that hydrogen storage is far better to overcome the seasonal shifting problem and can almost remove any RES curtailment. Furthermore, the coupling between the RES and grid power to produce hydrogen is the most feasible and cheapest solution. In addition, the electrolysis operation time plays a major role in defining the price of the hydrogen produced. Electrolyzers only operate during off-peak hours, resulting in the lowest prices for producing hydrogen, at under 3.4 €/kg H2. Electrolysis efficiency is expected to reach around 75% for PEM and 90% for high-temperature water electrolysis by 2050 [29]. The prospected increase in efficiency will introduce a huge step towards relying on hydrogen technology, especially when the price of modern electrolysis significantly drops when entering the mass production phase. Thus, the cost of hydrogen systems will drop as well. In summary, the key findings of the article confirm that hydrogen production and storage have many useful applications, introducing flexibility and reliability to a renewable energy-based system. Storing the green hydrogen in a salt cavern is a great way to bridge the gap between the production and consumption of energy, especially for seasonal shifting. This can help avoid curtailment. However, it can be a costly and uncompetitive solution, especially for short-term storage. The future of hydrogen is promising; therefore, further research should be conducted to cut costs and make it a competitive technology with increasing efficiency. This could decrease the capital costs of the hydrogen plant system. Reinforcements are also needed, and a hydrogen plant introduces potential challenges to the grid system, which are currently being investigated in the Hydrogen Caverns for Mobility (HyCAVmobil) project at the German Aerospace Center (DLR) to research and evaluate the possibility of storing hydrogen in salt caverns, where the plant is connected to the power grid and the hydrogen will be used in vehicles to produce electricity using fuel cells.

Author Contributions

Conceptualization M.S. and M.T.; Writing—original draft preparation M.S. and M.T.; Writing—review and editing M.S., M.T., D.P., M.K., F.S. and K.v.M. All authors have read and agreed to the published version of the manuscript.

Funding

The project HyCavMobil is funded by the German Federal Ministry for Digital and Transport (BMDV) under grant no. 03B10902B within the National Innovation Programme for Hydrogen and Fuel Cell Technology (NIP 2) coordinated by NOW GmbH (National Organisation Hydrogen and Fuel Cell Technology).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- European Commission. Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions: The European Green Deal; European Comission: Brussels, Belgium, 2019. [Google Scholar]

- Saeedmanesh, A.; Mac Kinnon, M.A.; Brouwer, J. Hydrogen is essential for sustainability. Curr. Opin. Electrochem. 2018, 12, 166–181. [Google Scholar] [CrossRef]

- Ursua, A.; Gandia, L.M.; Sanchis, P. Hydrogen Production from Water Electrolysis: Current Status and Future Trends. Proc. IEEE 2012, 100, 410–426. [Google Scholar] [CrossRef]

- Ozarslan, A. Large-scale hydrogen energy storage in salt caverns. Int. J. Hydrogen Energy 2012, 37, 14265–14277. [Google Scholar] [CrossRef]

- Caglayan, D.G.; Weber, N.; Heinrichs, H.U.; Linßen, J.; Robinius, M.; Kukla, P.A.; Stolten, D. Technical potential of salt caverns for hydrogen storage in Europe. Int. J. Hydrogen Energy 2019, 45, 6793–6805. [Google Scholar] [CrossRef]

- Maton, J.-P.; Zhao, L.; Brouwer, J. Dynamic modeling of compressed gas energy storage to complement renewable wind power intermittency. Int. J. Hydrogen Energy 2013, 38, 7867–7880. [Google Scholar] [CrossRef] [Green Version]

- Alexander, M.J.; James, P.; Richardson, N. Energy storage against interconnection as a balancing mechanism for a 100% renewable UK electricity grid. IET Renew. Power Gener. 2015, 9, 131–141. [Google Scholar] [CrossRef] [Green Version]

- Ehret, O.; Bonhoff, K. Hydrogen as a fuel and energy storage: Success factors for the German Energiewende. Int. J. Hydrogen Energy 2015, 40, 5526–5533. [Google Scholar] [CrossRef]

- Le Duigou, A.; Bader, A.-G.; Lanoix, J.-C.; Nadau, L. Relevance and costs of large scale underground hydrogen storage in France. Int. J. Hydrogen Energy 2017, 42, 22987–23003. [Google Scholar] [CrossRef]

- Simon, J.; Ferriz, A.; Correas, L. HyUnder–Hydrogen Underground Storage at Large Scale: Case Study Spain. Energy Procedia 2015, 73, 136–144. [Google Scholar] [CrossRef] [Green Version]

- Rivard, E.; Trudeau, M.; Zaghib, K. Hydrogen Storage for Mobility: A Review. Materials 2019, 12, 1973. [Google Scholar] [CrossRef] [Green Version]

- Teng, Y.; Sun, P.; Hui, Q.; Li, Y.; Chen, Z. A model of electro-thermal hybrid energy storage system for autonomous control capability enhancement of multi-energy microgrid. CSEE J. Power Energy Syst. 2019, 5, 489–497. [Google Scholar] [CrossRef]

- Gillessen, B.; Heinrichs, H.; Stenzel, P.; Linssen, J. Hybridization strategies of power-to-gas systems and battery storage using renewable energy. Int. J. Hydrogen Energy 2017, 42, 13554–13567. [Google Scholar] [CrossRef]

- Cai, G.; Northeast Dianli University; Kong, L. Techno-economic analysis of wind curtailment/hydrogen production/fuel cell vehicle system with high wind penetration in China. CSEE J. Power Energy Syst. 2017, 3, 44–52. [Google Scholar] [CrossRef]

- Shujun, M.; You, Z.; Ye, Y.; Ding, Z.; Jin, L.; Kai, S. A curtailed wind power accommodation strategy based on wind-hydrogen-heat-storage integrated energy network. In Proceedings of the Chinese Automation, Congress (CAC), Jinan, China, 20–22 October 2017; pp. 6146–6150. [Google Scholar] [CrossRef]

- Harrison, G.; Sun, W. Active operation of hydrogen fuelling stations to support renewable integration. In Proceedings of theIEEE PES Innovative Smart Grid Technologies Conference Europe, ISGT-Europe 2017, Torino, Italy, 26–29 September 2017; pp. 1–6. [Google Scholar] [CrossRef]

- Rahil, A.; Gammon, R. Dispatchable Hydrogen Production at the Forecourt for Electricity Demand Shaping. Sustainability 2017, 9, 1785. [Google Scholar] [CrossRef] [Green Version]

- Al-Subaie, A.; Elkamel, A.; Mukherjee, U.; Fowler, M. Exploring the potential of power-to-gas concept to meet Ontario’s industrial demand of hydrogen. In Proceedings of the 5th IEEE International Conference on Smart Energy Grid Engineering (SEGE) UOIT, Oshawa, ON, Canada, 14–17 August 2017; pp. 336–340. [Google Scholar] [CrossRef]

- Park, C.; Bigler, F.; Knazkins, V.; Kienzle, F. Feasibility analysis of the power-to-gas concept in the future Swiss distribution grid. CIRED–Open Access Proc. J. 2017, 2017, 1768–1772. [Google Scholar] [CrossRef]

- Lazarou, S.; Makridis, S. Hydrogen Storage Technologies for Smart Grid Applications. Challenges 2017, 8, 13. [Google Scholar] [CrossRef] [Green Version]

- Alkano, D.; Scherpen, J.M. Distributed Supply Coordination for Power-to-Gas Facilities Embedded in Energy Grids. IEEE Trans. Smart Grid 2018, 9, 1012–1022. [Google Scholar] [CrossRef]

- Mirzaei, M.A.; Yazdankhah, A.S.; Mohammadi-Ivatloo, B. Integration of Demand Response and Hydrogen Storage System in Security Constrained Unit Commitment with High Penetration of Wind Energy. In Proceedings of the 26th Iranian Conference on Electrical Engineering (ICEE), Mashhad, Iran, 8–10 May 2018; pp. 1203–1208. [Google Scholar] [CrossRef]

- Ali, M.; Ekstrom, J.; Lehtonen, M. Sizing Hydrogen Energy Storage in Consideration of Demand Response in Highly Renewable Generation Power Systems. Energies 2018, 11, 1113. [Google Scholar] [CrossRef] [Green Version]

- Srinivasan, S.S.; Stefanakos, E.K. Clean Energy and Fuel Storage. Appl. Sci. 2019, 9, 3270. [Google Scholar] [CrossRef] [Green Version]

- Ge, P.; Hu, Q.; Wu, Q.; Dou, X.; Wu, Z.; Ding, Y. Increasing operational flexibility of integrated energy systems by introducing power to hydrogen. IET Renew Power Gener. 2020, 14, 372–380. [Google Scholar] [CrossRef]

- Zhang, Y.; Wei, W. Decentralised coordination control strategy of the PV generator, storage battery and hydrogen production unit in islanded AC microgrid. IET Renew. Power Gener. 2020, 14, 1053–1062. [Google Scholar] [CrossRef]

- Melo, D.F.R.; Chang-Chien, L.-R. Synergistic Control between Hydrogen Storage System and Offshore Wind Farm for Grid Operation. IEEE Trans. Sustain. Energy 2014, 5, 18–27. [Google Scholar] [CrossRef]

- Acar, C.; Dincer, I. Comparative assessment of hydrogen production methods from renewable and non-renewable sources. Int. J. Hydrogen Energy 2014, 39, 1–12. [Google Scholar] [CrossRef]

- Michalski, J.; Bünger, U.; Crotogino, F.; Donadei, S.; Schneider, G.-S.; Pregger, T.; Cao, K.-K.; Heide, D. Hydrogen generation by electrolysis and storage in salt caverns: Potentials, economics and systems aspects with regard to the German energy transition. Int. J. Hydrogen Energy 2017, 42, 13427–13443. [Google Scholar] [CrossRef]

- Hemme, C.; Van Berk, W. Hydrogeochemical Modeling to Identify Potential Risks of Underground Hydrogen Storage in Depleted Gas Fields. Appl. Sci. 2018, 8, 2282. [Google Scholar] [CrossRef] [Green Version]

- Lerch, E. Storage of fluctuating wind energy. In Proceedings of the European Conference on Power Electronics and Applications, Aalborg, Denmark, 2–5 September 2007; pp. 1–8. [Google Scholar] [CrossRef]

- Crotogino, F.; Donadei, S.; Bünger, U.; Landinge, H. Large-Scale Hydrogen Underground Storage for Securing Future Energy Supplies. In Proceedings of the 18th World Hydrogen Energy Conference (WHEC), Essen, Germany, 16–21 May 2010; pp. 37–45. [Google Scholar]

- Andersson, J.; Grönkvist, S. Large-scale storage of hydrogen. Int. J. Hydrogen Energy 2019, 44, 11901–11919. [Google Scholar] [CrossRef]

- Loisel, R.; Mercier, A.; Gatzen, C.; Elms, N.; Petric, H. Valuation framework for large scale electricity storage in a case with wind curtailment. Energy Policy 2010, 38, 7323–7337. [Google Scholar] [CrossRef]

- Gabrielli, P.; Poluzzi, A.; Kramer, G.J.; Spiers, C.; Mazzotti, M.; Gazzani, M. Seasonal energy storage for zero-emissions multi-energy systems via underground hydrogen storage. Renew. Sustain. Energy Rev. 2020, 121, 109629. [Google Scholar] [CrossRef]

- Schiebahn, S.; Grube, T.; Robinius, M.; Tietze, V.; Kumar, B.; Stolten, D. Power to gas: Technological overview, systems analysis and economic assessment for a case study in Germany. Int. J. Hydrogen Energy 2015, 40, 4285–4294. [Google Scholar] [CrossRef]

- de Cerio Mendaza, I.D.; Bak-Jensen, B.; Chen, Z. Alkaline electrolyzer and V2G system DIgSILENT models for demand response analysis in future distribution networks. In Proceedings of the 2013 IEEE Grenoble Conference, Grenoble, France, 16–20 June 2013; pp. 1–8. [Google Scholar] [CrossRef]

- Klier, J.; Rattey, M.; Kaiser, G.; Klupsch, M.; Kade, A.; Schneider, M.; Herzog, R. A new cryogenic high-pressure H2 test area: First results. In Proceedings of the 12th Cryogenics 2012 IIR International Conference, Dresden, Germany, 11–14 September 2012. [Google Scholar]

- Roeb, M.; Brendelberger, S.; Rosenstiel, A.; Agrafiotis, C.; Monnerie, N.; Budama, V.; Jacobs, N. Wasserstoff als ein Fundament der Energiewende, Teil 1: Technologien und Perspektiven für eine nachhaltige und ökonomische Wasserstoffversorgung; Deutsches Zentrum für Luft- und Raumfahrt (DLR) Institut für Solarforschung: Köln, Germany, 2020. [Google Scholar]

- Bai, Y.; Nakagawa, K.; Cowan, A.J.; Aitchison, C.M.; Yamaguchi, Y.; Zwijnenburg, M.A.; Kudo, A.; Sprick, R.S.; Cooper, A.I. Photocatalyst Z-scheme system composed of a linear conjugated polymer and BiVO4 for overall water splitting under visible light. J. Mater. Chem. A 2020, 8, 16283–16290. [Google Scholar] [CrossRef]

- Nishiyama, H.; Yamada, T.; Nakabayashi, M.; Maehara, Y.; Yamaguchi, M.; Kuromiya, Y.; Nagatsuma, Y.; Tokudome, H.; Akiyama, S.; Watanabe, T.; et al. Photocatalytic solar hydrogen production from water on a 100-m2 scale. Nature 2021, 598, 304–307. [Google Scholar] [CrossRef] [PubMed]

- Tahir, M.; Asiri, A.M.; Nawaz, T. A perspective on the fabrication of heterogeneous photocatalysts for enhanced hydrogen production. Int. J. Hydrogen Energy 2020, 45, 24544–24557. [Google Scholar] [CrossRef]

- Lakhera, S.K.; Rajan, A.; Rugma, T.P.; Bernaurdshaw, N. A review on particulate photocatalytic hydrogen production system: Progress made in achieving high energy conversion efficiency and key challenges ahead. Renew. Sustain. Energy Rev. 2021, 152, 111694. [Google Scholar] [CrossRef]

- Özen, C.; Obata, K.; Bogdanoff, P.; Yulianto, N.; Wasisto, H.S.; Abdi, F.F. Transparent porous polymer sheets for efficient product separation in solar water splitting. Sustain. Energy Fuels 2021, 6, 377–385. [Google Scholar] [CrossRef]

- Melis, A.; Happe, T. Hydrogen Production. Green Algae as a Source of Energy. Plant Physiol. 2001, 127, 740–748. [Google Scholar] [CrossRef]

- Happe, T.; Müllner, K. Biokraftstoffe aus Algen: Photobiologische Wasserstoffproduktion und CO2-Fixierung; German Physical Society (DPG): Munich, Germany, 2004. [Google Scholar]

- Tangri, N.; Wilson, M.; Waste Gasification & Pyrolysis: High Risk, Low Yield Processes for Waste Management. A Technology Risk Analysis. Report, 2017, GAIA.. Available online: https://www.no-burn.org/wp-content/uploads/Waste-Gasification-and-Pyrolysis-high-risk-low-yield-processes-march-2017.pdf (accessed on 10 January 2022).

- Antonopoulou, G.; Ntaikou, I.; Stamatelatou, K.; Lyberatos, G. Biological and fermentative production of hydrogen. In Handbook of Biofuels Production; Woodhead Publishing: Swaston, UK, 2011; pp. 305–346. [Google Scholar] [CrossRef]

- Doumbia, M.L.; Agbossou, K.; Dostie, M. Power Transfer Analysis in a Utility-Interconnected Fuel Cell Distributed Generator. In Proceedings of the 32nd Annual Conference on IEEE Industrial Electronics (IECON), Paris, France, 7–10 November 2006; pp. 4331–4336. [Google Scholar] [CrossRef]

- Monitoring Report Bundesnetzagentur: 2020, Bonn, Germany. 2020. Available online: https://www.bundesnetzagentur.de/SharedDocs/Downloads/EN/Areas/ElectricityGas/CollectionCompanySpecificData/Monitoring/MonitoringReport2020.pdf;jsessionid=7F81839719C525FD3D40E1C5D7A3C460?__blob=publicationFile&v=2 (accessed on 10 January 2022).

- Hoidis, J.; Kröner, M.; Agert, C. Salzkavernen Speichern Wasserstoff für Mobilitätsswende; Deutsches Zentrum für Luft- und Raumfahrt (DLR): Cologne, Germany, 2020. [Google Scholar]

- Sarajlic, M.; Takach, M.; Kroener, M.; Derendorf, K.; Beckmann, R.; Liere-Netheler, I.; Schuldt, F.; Maydell, K. Utilizing Un-derground Caverns as Energy Storage for Future Energy Systems: Challenges for Grid Integration. In Proceedings of the 41. CIGRE International Symposium, Ljubljana, Slovenia, 21–24 November 2021. [Google Scholar]

- Klumpp, F. Comparison of pumped hydro, hydrogen storage and compressed air energy storage for integrating high shares of renewable energies—Potential, cost-comparison and ranking. J. Energy Storage 2016, 8, 119–128. [Google Scholar] [CrossRef]

- Rahman, M.; Oni, A.O.; Gemechu, E.; Kumar, A. Assessment of energy storage technologies: A review. Energy Convers. Manag. 2020, 223, 113295. [Google Scholar] [CrossRef]

- Zakeri, B.; Syri, S. Electrical energy storage systems: A comparative life cycle cost analysis. Renew. Sustain. Energy Rev. 2015, 42, 569–596, Erratum in Renew. Sustain. Energy Rev. 2016, 53, 1634–1635. [Google Scholar] [CrossRef]

- Hartmann, B.; Liptak, S. Development of steady state and dynamic energy storage models for DIgSILENT PowerFactory. In Proceedings of the IEEE Eindhoven PowerTech, Eindhoven, The Netherlands, 29 June–2 July 2015; pp. 1–6. [Google Scholar] [CrossRef]

- Pan, G.; Gu, W.; Lu, Y.; Qiu, H.; Lu, S.; Yao, S. Optimal Planning for Electricity-Hydrogen Integrated Energy System Considering Power to Hydrogen and Heat and Seasonal Storage. IEEE Trans. Sustain. Energy 2020, 11, 2662–2676. [Google Scholar] [CrossRef]

- Borgschulte, A. The Hydrogen Grand Challenge. Front. Energy Res. 2016, 4, 11. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).