Abstract

Battery electric tractors (BETs) demonstrate considerable advantages over diesel-fueled tractors, including higher conversion efficiency, higher torque, less maintenance, and no tailpipe emissions. Converting to BETs also requires tradeoffs in the form of the batteries’ high cost, increased weight, limited energy capacity, finite charging cycles, and lengthy charging time. The extent to which small-scale organic vegetable, fruit and cut-flower growers are aware of these tradeoffs is unknown. Little research exists examining these growers’ perceptions, concerns, and willingness to pay for or adopt BETs. Here, we address that gap by conducting qualitative semi-structured interviews with 14 organic growers in the US Midwest, most operating in Michigan. We focus our questions on growers’ motivations, existing tractor-use patterns, and the evaluation of different configurations of a belly-mount open-station cultivating BET. Our results suggest interest in and potential for growers to transition to BETs, including an estimated willingness to pay 14 percent more for a BET compared to a diesel-fueled alternative. This premium is driven by most growers’ preferences for reduced noise, fumes, fuel, and greenhouse gases, as well as beliefs about BETs ultimately being a more sustainable long-term option than diesel-fueled tractors. Growers also identify significant concerns and uncertainty about the long-term performance, maintenance, storage, cost, safety, and weight of the tractors’ battery systems. While growers linked some environmental values and motivations to their interest in BETs, altruistic value signaling was absent, and growers focused considerably more on financial and instrumental concerns and motivations for BET adoption.

1. Introduction

Agriculture accounts for 3 percent of industrial energy consumption in the US [1], and the agriculture and transportation sectors make up 11 and 27 percent of total US greenhouse gas (GHG) emissions [2], and 24 and 14 percent of total global GHGs, respectively [3]. While tractors make up a small portion of each sector’s energy consumption and emissions, nearly all existing tractors in the world rely on internal combustion engines (ICE) and diesel for fuel. In this study, we examined the extent to which growers are willing to adopt battery electric tractors (BETs) in place of ICE tractors. We focused specifically on small-scale organic vegetable, fruit, and cut-flower growers in the US.

Few studies report ICE tractors’ contribution to on-farm energy use or emissions, but those that do suggest that their contribution to farms’ total carbon footprint can be sizeable, i.e., 20 and 25 percent for maize and wheat in China, respectively [4], 7 percent for cotton production in Australia [5], and 10 percent for on-farm fieldwork in Canada [6]—even 1 percent for paddy rice production in Egypt [7]. These carbon footprints increase if vehicles have been poorly maintained and lack pollution control equipment [8]. In addition to high GHG emissions, ICE tractors also suffer from low conversion efficiency, increased and complex maintenance [8,9], diesel fuel costs that outpace inflation [10], oil and fuel spills, and unreliable fuel supplies [9,11].

Compared to ICE tractors, BETs demonstrate considerable advantages. These include reduced noise [12], higher conversion efficiency as a result of removing or reducing non-propulsive loads (e.g., radiator fans, water pumps, and air compressors) [13], higher torque and more flexible torque-speed control, greater maneuverability and potentially all-wheel steering [14], no tailpipe emissions [8,9], and improved safety due to eliminating high hydraulic pressure and excessive heat [14]. Additionally, pairing BETs with renewable energy like on-farm solar can reduce GHGs and ultimately fuel costs entirely. In developing countries, on-farm solar, both grid-connected and stand-alone systems, have generated considerable economic and environmental benefits [9,15]. And pairing BETs with on-farm solar can aid in decentralizing electric power generation [8], improve stability for farms on unstable power grids [14], and provide extra income and autonomy to farmers who can sell their surplus energy, even after regularly charging their own BETs [16].

Converting to BETs is not without its drawbacks, the majority of which come as a result of batteries’ high cost, increased weight, limited energy capacity, finite charging cycles, lengthy charging time, and concerns about safety [8]. Batteries have lower energy density than diesel, so BETs with the same rated power will require greater volume and weigh more than their ICE counterparts [17]. Batteries often also make up 30–50 percent of the BET’s total capital investment, which can be 2–3 times higher than ICE tractors [8,17]. Electric transformations of ICE tractors can be costly as well [17], prohibitively expensive in some regions and as tractors’ power increases, though BET life-cycle costs can be lower than ICE tractors with the right electricity and diesel price [12]. Other limitations of BETs include a lack of charging infrastructure and a lack of growers’ skills or experience with advanced electronics [14].

Despite the known tradeoffs of BETs, few researchers [18,19] have examined current growers’ knowledge, perceptions, concerns or willingness to pay (WTP) for this technology using interviews or surveys. Research examining consumers’ motivations for adopting battery electric vehicles (BEVs) can inform our understanding, but significant gaps remain regarding BET attributes, demographics of potential adopters, and the types of values and motivations that inform that adoption. Here, we help address that gap by conducting semi-structured qualitative interviews with 14 mostly organic small-scale vegetable, fruit and cut-flower growers from the US Midwest and Mid-Atlantic. We ask growers to assess BET technology, and compare different BET prototypes and configurations to their current ICE tractors and use patterns.

This work was not only intended to identify how small-scale growers perceive tradeoffs associated with BETs and their motivations for potential adoption, but also to inform and optimize development of an open-source ICE–BET transformation currently under development by the authors’ research team. We thus focus our analysis on a belly-mount open-station cultivating tractor, similar to the $22,000 USD 22 hp Oggun II [20] and $29,500 USD 22 hp Tilmor 520 [21], both of which are commonly operated by smaller organic vegetable growers. We also expect these results to inform a host of other BETs currently under development or in production, including Fendt’s 50 kW/100 kWh e100 Vario, Escorts’ 19 kW/21 kWh Farmtrac 26E, and Rigitrac’s 50 kW/80 kWh SKE 50 [14]—for a more in-depth review of the evolution of electric tractor technology, see [8,13].

The literature reviewed above and iterative discussions amongst the research team regarding the BET prototype’s budget and potential configuration ultimately led to the development of three research questions (RQs). These questions guided development of our interview protocol and overall study:

- RQ1:

- What motivations for adoption and willingness to pay do growers provide for BETs?

- RQ2:

- What advantages and concerns of BETs are most likely to promote or constrain adoption?

- RQ3:

- What specific BET configurations best align with current growers’ use patterns and preferences, and thus optimize BET performance and value?

2. Materials and Methods

2.1. Interview Sample

In Fall 2021, a non-probability convenience sample of 25 mostly organic vegetable, fruit and cut-flower farms or growers was identified based on (i) existing relationships with the research team, (ii) growers’ attendance at university training and extension workshops, (iii) Internet search, and (iv) snowball sampling, i.e., study participants recommending other growers we should contact. Twenty-one farms were located in Michigan. Ultimately, 12 of those 25 farms (46 percent) agreed to participate and 14 growers were interviewed during the winter of 2021–2022. Two growers were interviewed in person, and 12 were interviewed via telephone or Zoom, primarily due to concerns regarding the COVID-19 pandemic. Twelve growers lived in Michigan, one lived in Maryland, and one in Ohio. While our sample should not be considered representative of small-scale growers, it does target growers who we believe to be most likely in the market for a cultivating BET, or at least test the BET transformation developed by the research team.

2.2. Interview Protocol

The interview protocol (see Supplementary Material) focused on five areas: (i) farm characteristics (e.g., farm size, revenues, varieties of crops grown); (ii) farmer characteristics (e.g., growers’ experience, goals, decision-making strategies; (iii) on-farm solar (e.g., existing systems installed, interest in and constraints of adoption); (iv) current tractor use patterns, experience and preferences (e.g., length and time of use, maintenance, cost, age, etc.); and (v) electric tractor knowledge, attitudes and preferences (e.g., knowledge of BETs, their perceived costs and benefits, WTP for BETs and several unique configurations). Interviews lasted between 60 and 90 min and were conducted by the lead author, a trained social scientist with 8 years’ experience conducting interviews. The University’s Office of Regulatory Affairs: Human Research and Protection Program approved this research study and interview protocol, study ID: STUDY00006596, determining it to be exempt under 45 CFR 46.104(d) 2ii.

2.3. Research Questions

To answer RQ1: “What motivations for adoption and willingness to pay do growers provide for BETs?”, we compared growers’ responses to questions about their farm, their long-term goals, their fuel costs, interest in or experience with on-farm solar, and their potential motivations for adopting, WTP for, and concerns regarding the BET prototype and BETs more generally. To answer RQ2: “What advantages and concerns of BETs are most likely to promote or constrain adoption?”, we prompted growers to think about and respond to some known tradeoffs of BETs including noise, exhaust fumes, GHG emissions, and the increased weight of batteries, and we asked open-ended questions about their most serious concerns and what motivated them to potentially adopt BETs. Finally, to answer RQ3: What specific BET configurations best align with current growers’ use patterns and preferences, and thus optimize BET performance and value?”, we included a battery of questions aimed at capturing growers’ interest in and WTP for different configurations of, or specific improvements on, a prototype BET. We compared those configurations to farmers’ own ICE tractor use patterns.

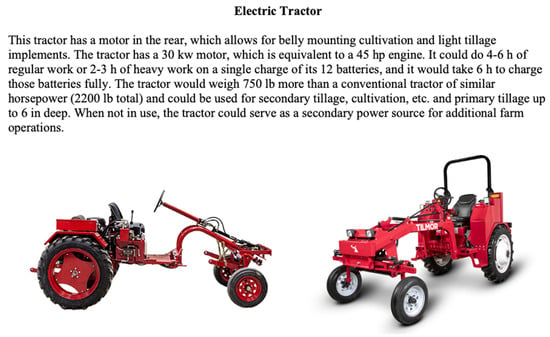

The description of our prototype BET is provided in Figure 1, along with a photograph of Horace Clemmons’ Oggun Tractor and the Tilmor 520, which served as the base of the research team’s ICE–BET transformation.

Figure 1.

BET prototype as described and shown to participants. Photos c/o Ronnie Baugh Iron Horse Tractors (https://ronnietractors.com/, accessed on 14 November 2022) and Tilmor (https://www.tilmor.com/en-us/products/33/tilmor-tractor?sc=46-11105, accessed on 14 November 2022).

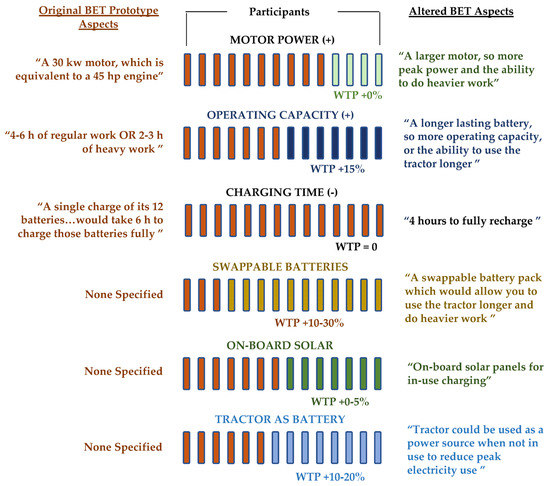

After describing the prototype BET and allowing growers to respond, we then altered 6 elements of design including (i) motor power, (ii) operating capacity, (iii) charging time, (iv) battery pack, (v) on-board solar, and (vi) tractor as supplemental power, asking growers how much more (or less) they were willing to pay for that alteration and why. This allowed us to examine growers’ interest (or lack thereof) in specific improvements to the BET, most of which would increase the cost or complexity of the BET’s design.

2.4. Data Analyis

All interviews were recorded, and upon completion were transcribed by either the first author or an undergraduate researcher. Written responses were transferred to Microsoft Excel and were analyzed using thematic analysis, which involves systematically organizing, identifying, and deriving themes to provide meaning across participant responses [22]. Certain questions and responses did allow for simple quantitative analysis (e.g., medians, ranges), which are presented to help frame our sample and provide a preliminary understanding of majority opinions, concerns, or WTP preferences. These descriptive statistics are not to be considered representative, and it is important to note that participants often used different formats to frame costs, prices, and WTP (i.e., qualitatively, e.g., “a little bit more”, percentages, or dollars). In these cases, we used the average price of a new ICE alternative ($23,500) to estimate and transform participants’ responses. The themes identified and discussed here capture a wide range of small-scale organic growers’ perceived tradeoffs regarding values and motivations for pursuing BETs.

3. Results

3.1. Grower Demographics

Participants, including 10 men and 4 women, worked 12 farms ranging between 4 and 46 worked acres (median = 13 acres), with some managing upwards of 100 varieties (median = 60 varieties) of vegetables (e.g., greens and salad mixes, tomatoes, carrots, potatoes, and garlic), fruit (e.g., strawberries), and/or cut flowers. Eight of the 12 farms were certified organic, with the remaining 4 farms practicing organically, but not having received certification. Growers all had at least 10 years’ experience working on farms (median = 16 years), and participants’ farms employed between 2 and 22 full-time seasonal workers (median = 9). Annual revenue ranged between $12,000 and $1.4 million USD, with a median of $270,000.

Growers relied on 17 different tractors, with six growers relying on more than one tractor. The most common tractor manufacturers (types) were Kubota (L245; L245H; 130; M60), John Deere (2640; 5103; 1070; 4720; 5075E), Allis Chalmers (G) Farmall (130; Super A), Tilmor (520) and Massey Ferguson (165; 180). Growers reported paying between $2500 and $39,000 for both new and used tractors, with a median cost of $6000. The horsepower (hp) of these models ranged considerably, from 24 to 76 hp with a median of 42.5 hp. Growers’ annual fuel costs ranged between $200 and $8000 per year, with a median annual fuel cost of $1090.

3.2. RQ1: What Motivations for Adoption and Willingness to Pay Do Growers Provide for BETs?

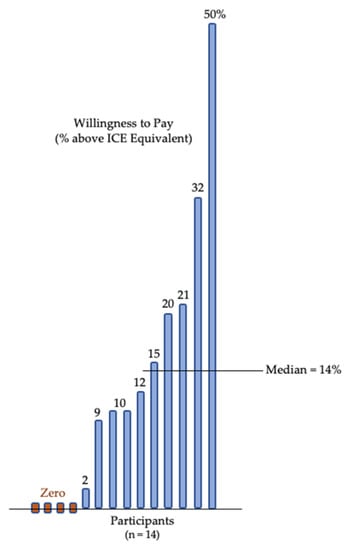

Environmental values and sustainability goals were articulated by most growers in reference to why BETs were of interest; however, the premiums growers were willing to pay varied considerably. Growers reported the premium they would pay for the BET prototype, compared to an equivalently powered ICE alternative, either in percentages or dollars (6 used percentages; 4 used dollars; 4 were unwilling to pay more for a BET). Responses provided as a percentage ranged between 2 and 50 percent and responses provided as dollars ranged between $5000 and 10,000. If asked, growers were instructed that a new ICE alternative would cost between $18,000 and $29,000. Using the ICE alternative cost range and average ($23,500), the median BET premium of those willing to purchase a BET amounted to approximately $2900, or a WTP between 10 and 16 percent (median = 14 percent) above the price of an ICE alternative (see Figure 2).

Figure 2.

Premium each of 14 participants were willing to pay for a BET over an ICE-tractor alternative, represented as a percentage of the average ICE-tractor cost. Median premium is provided only for those participants willing to purchase a BET.

Below we describe five growers who identified a high WTP for BETs and three who demonstrated a low or zero WTP.

3.2.1. Growers Providing High WTP for BETs

Two growers from one farm (11 acres, 12 employees, $600 k in annual revenues, henceforth 11 ac/12 emp/$600 k), who had already purchased a 20 kW on-farm solar energy system, were willing to pay up to 25–50 percent more for the BET (over an ICE alternative) based on the BET prototype’s ultimate configuration. They identified “fuel and environmental impacts” as the key advantages of a BET, having reported $8000 in annual fuel costs (the highest in our sample).

A no-till permanent bed grower in Grand Traverse County (14 ac/7 emp/$180 k) identified a WTP of $5000 for the BET, identifying that “it would be intrinsically better technology for the environment”. He was attracted to the reduced pollution and fumes of a BET and saw them as a “better long-term solution”. He had expressed a willingness and history of financing purchases on the farm and reported $5000 in annual fuel costs.

Another grower (27 ac/22 emp/$1.4 million) who was looking to “automate the farm as much as possible”, and identified the problems inherent in “not having the right equipment and resources to finish [a] job efficiently”, identified a WTP of up to $10,000 for the BET, despite having concerns about what he might do if he were forced to cultivate for long hours one day due to weather constraints. He noted annual fuel costs of $750.

A certified organic grower in Gratiot County, MI (13 ac/8 emp/$260 k), qualified his estimated WTP for a BET of 10 to 20 percent with questions about the cost of replacing batteries, the cost of electricity needed to charge those batteries (compared to diesel), and the money saved from no longer needing to change the motor oil. He spoke of the potential advantages of a BET, particularly one that lacked gear-shifting, preferring a less “jerkier operation” and fewer of the training and safety headaches that accompany a gearbox. He reported annual fuel costs of $800.

3.2.2. Growers Providing Low or Zero WTP

Three growers were comparatively less enthusiastic about BETs. One organic grower in Maryland (46 ac/10 emp/$375 k), who had installed 25–26 kW of on-farm solar, spoke about the prototype’s limited operating time as a significant barrier:

So if…you want to replace your diesel power tractor that can go all day long without a hiccup…and you want to replace it with a tractor that costs more money and it’s going to take six hours to recharge if you use it for four to six hours. I’m already going okay… I’m gonna need to have two of these things…(later) I know more than one person that converted [Allis Chalmers Gs] to electric and they had regrets about doing that because they lost…downtime with the charging process.

Two others, both in Michigan, argued that the BET prototype’s configuration was not appropriate for their farm. One, who used a no-till permanent bed system (5 ac/15 emp/$550 k), argued that the belly-mount open-station configuration was not attractive; he preferred “a workhorse” arguing that “if we ever got to that scale”, he’d replace his loader tractor with a 60–75 hp equivalent electric loader that could also do field work. He and his partner had installed 21 kW of on-farm solar, and had previously purchased a Tuff-Bilt cultivating tractor that had been converted to electric. Another grower (5 ac/5 emp/$200 k), when asked about her long-term goals, expressed a strong interest in on-farm solar, but was concerned about “the potential for messing something up or not understanding the barrier to entry”. All growers, excepting those who had already installed solar energy systems, expressed interest in pursuing on-farm solar, identifying the high installation cost, lack of available grants, insufficient information, and other farm infrastructure and investments taking priority, as barriers to investment. She wanted less power out of a BET, arguing that the prototype BET was “overbuilt” for what she needed. She also identified concerns about the “longevity of batteries”, “costs if the batteries were not reliable” and the availability of replacement parts. She reported $500 in annual fuel costs.

3.3. RQ2: What Advantages and Concerns of BETs Are Most Likely to Promote or Constrain Adoption?

3.3.1. Advantages of BETs

Growers consistently identified reductions in noise, exhaust fumes, GHGs, and fuel costs as advantages of BETs. All but one grower identified the silence of BETs as a significant advantage. Many spoke of the perils of farm noise, not only the damage previously or currently done to their own or others’ hearing by ICEs and loud farm equipment, but also the extent to which the noise of ICE tractors impacts farm safety and limits communication. A grower from Gratiot County, MI (13 ac/8 emp/$260 k), argued that “when we have people actually behind the tractor, something with less noise would be a little more safe and allow a little more, a little better, communication”. A grower from Washtenaw County, MI (5 ac/15 emp/$550 k), agreed, “What a joy to not have to be yelling, you know, for both safety and for operator comfort”. An organic grower from Allegan County, MI (12 ac/9 emp/$300 k), was particularly enthusiastic about the silence of BETs:

I love it…knowing old farmers, they’re all deaf from farm equipment, from running farm equipment. It’s [expletive] loud and it destroys your hearing…all of my old mentors, they’re all [expletive] deaf as a door nail.

Many growers were excited about BETs eliminating exhaust fumes, preferring to avoid the smells that accompany ICE tractors and their health implications. A grower from Grand Traverse County, MI (14 ac/7 emp/$180 k), urged, “that would be very valuable, being trapped inside of the plastic bubble with those fumes is not great”. Another (4 ac/7 emp/$280 k) mentioned, “it’s smelly, it’s not fun…if you’d be putting on an implement, you’re like, ‘let’s get this over with as quick as possible,’ because you’re right in the path”. Another (5 ac/15 emp/$550 k) added “you definitely feel it at the end of the day, and it stinks”.

With respect to one of the most commonly discussed advantages of electrification, i.e., reducing GHGs, growers were unanimous in identifying GHG mitigation as a clear and considerable advantage of and motivation for adopting BETs. Even one grower in Maryland (46 ac/10 emp/$375 k) who expressed reluctance at being identified a “tree hugger” urged,

I think that’s in line with sort of the holistic approach to growing vegetables organically. So while I’m not particularly overly concerned about particulate matter or, you know, the emissions, I know it’s the right side of the equation, to be on the right side of history, so I’m interested in it.

Finally, growers were interested in BETs reducing fuel costs and some noted how electric motors require less maintenance. An owner of a CSA and market farm in Ionia County, MI (4 ac/7 emp/$280 k), identified, “I don’t have to go to a gas station you know, or get a tank filled”, as an advantage. Another, a small grower in Genesee County (8 ac/0 emp/$12 k in unrealized sales), when asked to summarize what interests him about BETs, urged “doing the same work with a format that’s more dependable…Electric motors don’t break down like gas motors do…there’s no moving parts, so…a whole lot less can go wrong with them”.

3.3.2. Concerns Regarding BETs

Despite growers identifying a lack of familiarity with BET technology—all but one replied 5 or below on a scale of 1 to 10 (with 10 being extremely knowledgeable) regarding their knowledge of electric tractors, many growers noted serious concerns regarding BETs’ long-term battery performance, the safety and weight of batteries, and the potentially high and unpredictable cost of maintaining and replacing batteries as their performance degrades. Some growers urged that the long-term cost of replacing batteries could ultimately make BETs unaffordable, with one (4 ac/7 emp/$280 k) asking, “What’s gonna be the annual maintenance or every couple-year maintenance? It just seems like that could be something that could make it really expensive for me”. Another agreed (5 ac/5 emp/$200 k), “my concern would be longevity of batteries, I know batteries cost a lot of money. We have a Prius, and so my concern would be, yeah, longevity of the battery”, before adding that she was also concerned about the “availability of parts and access to regular maintenance stuff”. A grower in Ingham County, MI (35 ac/10 emp/$250 k), described her concerns regarding the safety of batteries, before her partner added that he was concerned about unexpected maintenance costs as well:

I’m always afraid of batteries exploding. I’m still that person that’s like what if it got too hot? Or like if I’m sitting on it will it ever catch on fire, or if it does catch on fire, can I just use a random fire extinguisher or do we need something like special to like put the fire out?...[she added] The same issues that you have with gas though.

Others too identified concerns about maintenance, a grower in Gratiot County, MI (13 ac/8 emp/$260 k), asked, “what if it breaks? How do you fix electric things?” He was not alone in expressing concerns about battery upkeep and maintenance. A grower in Ionia County, MI (4 ac/7 emp/$280 k), voiced concerns:

You know you have a gas tractor, ok, you do a couple of things maintenance wise, it’s not that expensive…if you leave old gas in it, it’s not gonna like destroy the tractor…but if you don’t charge the batteries properly, you know, or keep them topped off…that could be a pretty expensive thing…You do all the things you’re supposed to do, and you still have to replace them in three years.

Nearly every grower identified the importance of being able to do routine maintenance on a BET, while some acknowledged that computerized or mechanized components may require a specialist. A grower from Maryland (46 ac/10 emp/$375 k) identified that “if it’s one of those situations where, you know, the tractor shuts down and the display throws a code and says call the dealer, that’s not going to work”. Another in Ottawa County (7 ac/16 emp/$150 k) explained, “the last thing you want is to have to call a technician when you have a breakdown or something simple…now you’re dealing with downtime again. And extra cost”.

3.4. RQ3: What Specific BET Configurations Best Align with Current Growers’ Use Patterns and Preferences, and Thus Optimize BET Performance and Value?

3.4.1. Current ICE Tractor-Use Patterns

Most growers (unsurprisingly) identified the primary time of use for their current tractors as either morning, mid-morning or afternoon, identifying soil moisture, weed pressure, time of year, or seasonal responsibilities and workload as ultimately driving that decision. Nearly all growers identified a typical maximum duration of approximately 3 h of use per day, with some regularly using their tractor only 1 h per day. In certain seasons, some farmers identified that they may rely on their tractor for up to 6 h per day. A grower in Ottawa County, MI (7 ac/16 emp/$150 k), described his use this way:

If it’s hot out or something I might wanna be on it in the morning, um, get things done- knocked out…but again it depends—it depends on where you are in the season, and in the early part of the season where you’re breaking up the ground and everything, I go ahead and use it at all times of the day… it’s all over the place, you know?

Most farmers were happy with their existing tractors, quantifying their level of happiness as either an 8 or 9 on a scale of 1 to 10 (with 10 being extremely happy).

3.4.2. Optimal BET Configurations

Similar to their WTP for the original BET prototype, the premium each grower placed on different configurations of that prototype varied considerably. Some participants provided their WTP as a percentage, dollar figure, or qualitatively (e.g., a lot, little, nothing, “more than that”, etc.), and we report them here using similar units. See Figure 3 for a summary of the alternate configurations and growers’ preferences.

Figure 3.

Preferences for BET Prototype Aspects. Six BET prototype aspects as described to the 14 participants, descriptions of the altered BET aspects, and a summary of participants’ preferences (No. of participants preferring either aspect is color-coordinated) and estimated WTP for the altered BET aspects.

Power and Capacity

The majority of growers were satisfied with the original prototype’s motor power, i.e., 30 kW (45 hp equivalent), with 10 of 14 growers either not interested in adding power or seeing a more powerful motor as a drawback. One (4 ac/7 emp/$280 k) identified that a larger motor would only be beneficial if the operating capacity that accompanied it was improved as well, “I just know that the tractor we use for heavier work we’re going to use it for longer. I mean if I could use it for six hours that would probably be sufficient, but if it was only three, that wouldn’t be enough”. Other growers were split on the prototype’s operating capacity, i.e., 4 to 6 h of regular work or 2 to 3 h of heavy work, with half preferring additional capacity and growers at two farms identifying a WTP of 15 percent and up to 20 percent more, respectively, relative to the original prototype. The former, a couple operating an organic farm in Ingham County, MI (35 ac/10 emp/$250 k), responded this way:

If this was a primary tractor. To be able to actually use it…to use it a full day…yeah, for up to eight hours for even moderate work. We’re a quarter mile back when we’re at the furthest field, we’re a quarter mile from any sort of infrastructure. So…yeah…it would never be a primary tractor unless I could use it for more than four hours, I would say, five hours.

The latter, a grower in Allegan County, MI (12 ac/9 emp/$300 k), qualified his response, urging the importance of how the electricity was generated,

If I was able to produce electricity from a renewable source and it could last me a full day’s work whenever I wanted it to...then I would pay 20–30 percent extra above what I would pay for a diesel.

Charging

The original prototype required 6 h for a full recharge. No grower was willing to pay more for a 2 h improvement in charging time. A grower from Ionia County, MI’s (4 ac/7 emp/$280 k) comments summarized most participants’ responses: “four hours and six hours for me seems about the same. At that point I’d be like ‘okay it’s done for the day, [I’ll] plug it in to tomorrow”. Rather than simply decrease recharging time, we asked participants about swappable batteries. The majority of growers were interested in this technology and willing to pay more (10–30 percent) for a prototype with swappable batteries. A grower in Grand Traverse County, MI (14 ac/7 emp/$180 k), identified that having a second battery pack would allow him to take advantage of net metering and provide secondary storage for his on-farm solar, while also improving battery maintenance down the road. Others voiced concerns however about the weight of the batteries, the time required and the safety and difficulty in swapping out the batteries. For example, a grower in Maryland (46 ac/10 emp/$375 k) said, “As long as there’s a way to physically move those battery packs that wouldn’t be really hard or onerous, that would be appealing”.

Others worried about the added cost and the impact of weather and temperature on the batteries’ lifespan and long-term performance. A grower in Washtenaw County, MI (5 ac/15 emp/$550 k), discussed the risk associated with lead acid batteries, “You don’t take them inside in winter because the tractor lives outside and like, you know, pretty soon you trash those batteries…I’d rather not have to deal with a swappable battery and just have more run time because there’s a bigger capacity to start with”. Another means of increasing run time would be to install a solar canopy that could recharge the battery during operation. When asked about that feature, approximately half of the growers were interested, but primarily in the canopy’s ability to protect them from the sun, rather than believing it a meaningful way to recharge the battery. Amongst those interested, few were willing to pay more for it.

One of the potential advantages of an electric tractor with a significant battery pack would be its ability to provide emergency or temporary power for other on-farm uses. When asked about potentially using the tractor’s battery as a power source for other farm operations, more than half of our growers were interested, particularly in the alternate prototype’s ability to provide storage for energy generated using on-farm solar, emergency backup power generation (as opposed to purchasing a diesel generator), or as a grower in Gratiot County, MI (13 ac/8 emp/$260 k), put it:

If we need some random power to repair something like far away from a power source, or if I don’t have to put in as many electric lines to go to hoop houses and stuff…if I could just park the tractor there and plug it in, like plug a power tool in, that actually would be a big benefit.

Others were less interested, noting that the battery capacity would likely be insufficient for most on-farm uses (e.g., running coolers).

4. Discussion

Our results suggest interest in and potential for small-scale growers transitioning to BETs, driven by personal and pro-environmental values around reduced noise, fumes, fuel, and the greenhouse gases caused by ICE tractors, as well as beliefs about BETs ultimately being a more sustainable long-term option than diesel-fueled ICE tractors. Growers also voiced considerable worry and uncertainty about the long-term performance, maintenance, cost, safety, and weight of the tractors’ battery systems, along with concerns about the BET’s high up-front cost and the lack of experience, both their own and of growers more generally, with new BETs and BET transformations. Perhaps surprisingly, growers demonstrated little to no concern regarding differences in the performance of electric motors and diesel engines, including differences in the tractors’ overall weight. Finally, the WTP figures estimated here, i.e., a median BET premium of $2900, or 14 percent more than the cost of a comparable ICE alternative, align with known previous efforts, specifically work gauging Italian nursery farms’ WTP for solar electric tractors (1000 to 5000 Euros) [19].

Previous studies of BETs [19] and battery electric vehicles (BEVs) [23,24,25] more generally suggested that growers’ values and motivations associated with sustainability and the environment would correlate with growers’ interest in and WTP for BETs. While such values were evinced, and sometimes plainly linked to growers’ interest, explicit concerns about how BETs may impact farms’ long-term financial sustainability were more prominent. Growers were concerned about unpredictable battery maintenance and replacement costs, also noting the uncertain impact of weather and storage conditions on battery performance. In this way, growers’ concerns were unique from those more commonly associated with BEVs around range levels [26] and range anxiety [27], likely a result of growers operating BETs in a single location. Though, a few growers did identify the potential inconvenience associated with having to return a BET to an electric connection, or a BET becoming stranded in a field.

These results support earlier work showing that instrumental motivations and attributes are more important predictors of consumers’ intentions to adopt BEVs than are hedonic, altruistic, or symbolic motivations [28,29,30]. Here, growers rarely voiced motivations of the latter type, i.e., joy, pride, excitement, shame, or embarrassment, with respect to BET adoption—or disinterest, instead focusing on instrumental concerns and constraints. Nowhere did participants signal altruistic motives for adopting worse-performing BETs over ICE alternatives [29]. For example, no one identified BETs’ potential prosocial impact, i.e., increased sales via improved customer perceptions [31]. There was also no mention of how other growers, family, or friends might perceive their decision to adopt BETs, despite studies showing that organic growers rely heavily on these networks to test unfamiliar or uncertain practices and technology [32]. Many of our growers identified that they relied on YouTube and Instagram to learn about alternate practices and technology. Organic growers focusing on the instrumental and financial concerns associated with BETs should not be surprising, as studies have shown that organic growers and transitioning growers are often focused more on financial motives, i.e., securing the farm, solving existing financial problems, and saving costs, than they are regarding general concerns about conservation, stewardship, and soil quality [33].

Growers’ concerns over long-term battery costs and maintenance may also be in part due to high satisfaction with their current tractors’ performance. Despite research and advocates demonstrating the benefit of BETs in terms of reduced maintenance, growers identified few maintenance costs or concerns related to their existing tractors. Previous work also demonstrated that farms already relying on multiple tractors may demonstrate a higher WTP for BETs because they would be less impacted by their technical limitations [19]; a phenomena common for BEVs as well. Many of our growers owned more than one tractor—some owned three or more, yet these growers’ concerns remained centered on battery cost and performance of BETs more generally, rather than specific limitations associated with BETs’ motor power, operating capacity or recharging time. It should be noted that one way of providing long-term certainty regarding battery cost and performance would be via a manufacturers’ warranty or maintenance contract [34].

Our results suggest that predicting the rate of BET adoption in the near term may be difficult and the rate itself may be slow. Early attempts to predict BEV adoption suffered from a lack of sales data, difficulty in predicting consumer behavior change, few studies examining consumers’ preferences, and uncertainty in how or whether consumers might compare energy consumption (i.e., BEV) and fuel consumption (i.e., ICE) [35,36]. While BEV modeling and the data it relies upon has improved substantially [37], BETs remain in a similar position with few sales, little known outside a few studies regarding growers’ WTP or intentions to change behavior, and difficulty in calculating on-farm energy and fuel costs. These attributes make applying innovation theories difficult. Rogers’ [38] diffusion theory requires historical sales data, analogs, or surveys. Ajzen’s [39] theory of planned behavior requires at least some grower knowledge and experience, and data regarding subjective norms, which is currently absent. Consumer choice modeling requires either purchaser demographic data and past sales data—both absent with regard to BETs, or the estimation of a host of attributes like cost, battery replacement, recharging time, maintenance cost, and range—all of which were notable concerns identified by our growers. And finally, agent-based models require a host of demographics and preferences to define consumer agents, the latter of which include safety, reliability, and performance—again all noted here, but missing more representative surveys and an existing pool of BET adopters [35]. In this study, only one grower owned and operated a BET and, due to adopting no-till practices, was less interested in a cultivator and more interested in a high-clearance, light-weight BET with a PTO or a high-powered loader.

Even if BET adoption continues to remain associated with instrumental values and concerns, improving our understanding of growers’ interest in BETs will require eliciting and examining a host of sociotechnical, i.e., social, cultural, and environmental costs, benefits and attributes. These have long been associated not only with innovative technologies like electric vehicles [34], but also sustainable farm practices like ecological weed management (EWM) [32,40]. Even though growers did not speak of social norms influencing BET adoption here, such norms may become more prominent and impactful as BET adoption increases, and value signaling may become more important in maintaining or improving one’s reputation as an environmental steward. Branding and marketing opportunities may accompany BET adoption, and organic certification could even someday require it.

5. Conclusions

Most of our growers demonstrated interest in BETs, driven primarily by their pro-environmental values and BETs’ advantages with respect to individual health and safety. Yet, growers also identified significant concerns centering on BETs’ long-term battery performance and cost, maintenance, and the impacts of weather and storage conditions on battery life. In describing their preferences, growers tended to evince instrumental motivations, rather than altruistic or symbolic motivations, suggesting that efforts to promote BET adoption should focus on addressing performance concerns, perhaps via extended battery warranties, rather than emphasizing BETs’ impact on reducing GHGs. Most growers also demonstrated high satisfaction with their existing ICE tractors and a reliance on used tractors, suggesting that BET adoption by small-scale growers may be slow without sufficient financial incentives.

This study relied on a convenience sample of only 14 growers, most in Michigan, who owned and operated tractors of different ages, power ratings, and costs. The small number of participants, the lack of precision in their cost estimates, and high variability in the types of tractors owned may limit the representativeness of our results. At the same time, our study was one of the first to focus on small-scale growers, and they provided clear preferences with respect to the six aspects of the BET prototype examined, which will directly influence our BET transformation. Nevertheles, additional research, particularly more representative surveys of small-scale organic growers and work examining the preferences of large-scale conventional growers, is crucial for both identifying and instituting proper BET incentive amounts and programs, and for ultimately reducing BET costs through more widespread adoption.

Finally, our study focused on a subset of small-scale US growers, but BETs hold considerable promise for small-holder farmers and the successful creation of sustainable agri-food chains in other nations as well. Greater resources, including increased automation and mechanization, are likely necessary to improve agricultural production, income, and food security [8]. Doing so will require the expanded use of tractors and their corresponding energy use and GHG emissions. However, electrifying tractors can utilize off-grid power, renewable power like the sun, and can eliminate unstable fossil fuel supply chains, making BETs an even more attractive long-term solution in those regions.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/en15228648/s1, Table S1: Semi-structured grower interview protocol.

Author Contributions

Conceptualization, D.L.B., D.C.B., A.K.S., W.L. and S.G.; methodology, D.L.B., D.C.B., A.K.S., W.L. and S.G.; formal analysis, D.L.B.; resources, D.C.B., A.K.S., W.L. and S.G.; writing—original draft preparation, D.L.B.; writing—review and editing, D.L.B., D.C.B. and A.K.S.; project administration, D.C.B.; funding acquisition, D.C.B., A.K.S. and W.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by MSU AgBioResearch Project GREEEN Proposal #GR21-070.

Data Availability Statement

Not applicable.

Acknowledgments

We would like to thank Edie Carney for transcribing the interviews.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- EIA. Use of Energy in Industry. Available online: https://www.eia.gov/energyexplained/use-of-energy/industry.php (accessed on 30 August 2022).

- US EPA. Inventory of U.S. Greenhouse Gas Emissions and Sinks: 1990–2020. Available online: https://www.epa.gov/ghgemissions/inventory-us-greenhouse-gas-emissions-and-sinks-1990-2020 (accessed on 15 August 2022).

- IPCC. AR5 Climate Change 2014: Mitigation of Climate Change; Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2014.

- Zhang, D.; Shen, J.; Zhang, F.; Li, Y.; Zhang, W. Carbon Footprint of Grain Production in China. Sci. Rep. 2017, 7, 4126. [Google Scholar] [CrossRef] [PubMed]

- Hedayati, M.; Brock, P.M.; Nachimuthu, G.; Schwenke, G. Farm-Level Strategies to Reduce the Life Cycle Greenhouse Gas Emissions of Cotton Production: An Australian Perspective. J. Clean. Prod. 2019, 212, 974–985. [Google Scholar] [CrossRef]

- Dyer, J.A.; Desjardins, R.L. A Simple Meta-Model for Assessing the Contribution of Liquid Fossil Fuel for On-Farm Fieldwork to Agricultural Greenhouse Gases in Canada. J. Sustain. Agric. 2005, 27, 71–90. [Google Scholar] [CrossRef]

- Farag, A.; Radwan, H.; Abdrabbo, M.; Heggi, M.; McCarl, B. Carbon Footprint for Paddy Rice Production in Egypt. Nat. Sci. 2013, 11, 36–45. [Google Scholar]

- Gorjian, S.; Ebadi, H.; Trommsdorff, M.; Sharon, H.; Demant, M.; Schindele, S. The Advent of Modern Solar-Powered Electric Agricultural Machinery: A Solution for Sustainable Farm Operations. J. Clean. Prod. 2021, 292, 126030. [Google Scholar] [CrossRef]

- Redpath, D.A.G.; McIlveen-Wright, D.; Kattakayam, T.; Hewitt, N.J.; Karlowski, J.; Bardi, U. Battery Powered Electric Vehicles Charged via Solar Photovoltaic Arrays Developed for Light Agricultural Duties in Remote Hilly Areas in the Southern Mediterranean Region. J. Clean. Prod. 2011, 19, 2034–2048. [Google Scholar] [CrossRef]

- Langemeier, M. Trends in General Inflation and Farm Input Prices. Farmdoc Dly. 2022, 12, 56. [Google Scholar]

- Chipman, K.; Durisin, M. Diesel’s 100% Surge and Scarcity Deny Farmers Their ‘Lifeblood’. Bloomberg.com. 2022. Available online: https://www.bloomberg.com/news/articles/2022-05-19/diesel-s-100-surge-and-scarcity-deny-farmers-their-lifeblood (accessed on 14 November 2022).

- Gao, H.; Xue, J. Modeling and Economic Assessment of Electric Transformation of Agricultural Tractors Fueled with Diesel. Sustain. Energy Technol. Assess. 2020, 39, 100697. [Google Scholar] [CrossRef]

- Khatawkar, D.S.; James, P.S.; Dhalin, D. Modern Trends in Farm Machinery-Electric Drives: A Review. Int. J. Curr. Microbiol. App. Sci. 2019, 8, 83–98. [Google Scholar] [CrossRef]

- Malik, A.; Kohli, S. Electric Tractors: Survey of Challenges and Opportunities in India. Mater. Today Proc. 2020, 28, 2318–2324. [Google Scholar] [CrossRef]

- Maammeur, H.; Hamidat, A.; Loukarfi, L.; Missoum, M.; Abdeladim, K.; Nacer, T. Performance Investigation of Grid-Connected PV Systems for Family Farms: Case Study of North-West of Algeria. Renew. Sustain. Energy Rev. 2017, 78, 1208–1220. [Google Scholar] [CrossRef]

- Vogt, H.H.; de Melo, R.R.; Daher, S.; Schmuelling, B.; Antunes, F.L.M.; dos Santos, P.A.; Albiero, D. Electric Tractor System for Family Farming: Increased Autonomy and Economic Feasibility for an Energy Transition. J. Energy Storage 2021, 40, 102744. [Google Scholar] [CrossRef]

- Melo, R.R.; Antunes, F.L.M.; Daher, S.; Vogt, H.H.; Albiero, D.; Tofoli, F.L. Conception of an Electric Propulsion System for a 9 KW Electric Tractor Suitable for Family Farming. IET Electr. Power Appl. 2019, 13, 1993–2004. [Google Scholar] [CrossRef]

- Caban, J.; Vrabel, J.; Šarkan, B.; Zarajczyk, J.; Marczuk, A. Analysis of the Market of Electric Tractors in Agricultural Production. MATEC Web Conf. 2018, 244, 03005. [Google Scholar] [CrossRef]

- Lombardi, G.V.; Berni, R. Renewable Energy in Agriculture: Farmers Willingness-to-Pay for a Photovoltaic Electric Farm Tractor. J. Clean. Prod. 2021, 313, 127520. [Google Scholar] [CrossRef]

- Oggun. Oggún Tractor|Think Oggún. 2022. Available online: https://ronnietractors.com/ (accessed on 14 November 2022).

- Tilmor. Tilmor—Tilmor Tractor. 2022. Available online: https://www.tilmor.com/en-us/products/33/tilmor-tractor?sc=46-11105 (accessed on 14 November 2022).

- Kiger, M.E.; Varpio, L. Thematic Analysis of Qualitative Data: AMEE Guide No. 131. Med. Teach. 2020, 42, 846–854. [Google Scholar] [CrossRef] [PubMed]

- Hahnel, U.J.J.; Gölz, S.; Spada, H. How Does Green Suit Me? Consumers Mentally Match Perceived Product Attributes with Their Domain-Specific Motives When Making Green Purchase Decisions. J. Consum. Behav. 2014, 13, 317–327. [Google Scholar] [CrossRef]

- Hahnel, U.J.J.; Ortmann, C.; Korcaj, L.; Spada, H. What Is Green Worth to You? Activating Environmental Values Lowers Price Sensitivity towards Electric Vehicles. J. Environ. Psychol. 2014, 40, 306–319. [Google Scholar] [CrossRef]

- Heffner, R.R.; Kurani, K.S.; Turrentine, T.S. Symbolism in California’s Early Market for Hybrid Electric Vehicles. Transp. Res. Part D Transp. Environ. 2007, 12, 396–413. [Google Scholar] [CrossRef]

- Franke, T.; Krems, J.F. Interacting with Limited Mobility Resources: Psychological Range Levels in Electric Vehicle Use. Transp. Res. Part A Policy Pract. 2013, 48, 109–122. [Google Scholar] [CrossRef]

- Rauh, N.; Franke, T.; Krems, J.F. Understanding the Impact of Electric Vehicle Driving Experience on Range Anxiety. Hum. Factors 2015, 57, 177–187. [Google Scholar] [CrossRef]

- Dittmar, H. The Social Psychology of Material Possessions: To Have Is to Be; Palgrave MacMillan: London, UK, 1992; ISBN 0-312-08538-9. [Google Scholar]

- Griskevicius, V.; Tybur, J.M.; Van den Bergh, B. Going Green to Be Seen: Status, Reputation, and Conspicuous Conservation. J. Personal. Soc. Psychol. 2010, 98, 392. [Google Scholar] [CrossRef]

- Schuitema, G.; Anable, J.; Skippon, S.; Kinnear, N. The Role of Instrumental, Hedonic and Symbolic Attributes in the Intention to Adopt Electric Vehicles. Transp. Res. Part A Policy Pract. 2013, 48, 39–49. [Google Scholar] [CrossRef]

- Van Vugt, M.; Roberts, G.; Hardy, C. Competitive Altruism: Development of Reputation-Based Cooperation in Groups. In Handbook of Evolutionary Psychology; Oxford University Press: Oxford, UK, 2007; pp. 531–540. [Google Scholar]

- Bessette, D.; Wilson, R.; Beaudrie, C.; Schroeder, C. An Online Decision Support Tool to Evaluate Ecological Weed Management Strategies. Weed Sci. 2019, 67, 463–473. [Google Scholar] [CrossRef]

- Padel, S. Conversion to Organic Farming: A Typical Example of the Diffusion of an Innovation? Sociol. Rural. 2001, 41, 40–61. [Google Scholar] [CrossRef]

- Egbue, O.; Long, S. Barriers to Widespread Adoption of Electric Vehicles: An Analysis of Consumer Attitudes and Perceptions. Energy Policy 2012, 48, 717–729. [Google Scholar] [CrossRef]

- Al-Alawi, B.M.; Bradley, T.H. Review of Hybrid, Plug-in Hybrid, and Electric Vehicle Market Modeling Studies. Renew. Sustain. Energy Rev. 2013, 21, 190–203. [Google Scholar] [CrossRef]

- Lee, J.H.; Hardman, S.J.; Tal, G. Who Is Buying Electric Vehicles in California? Characterising Early Adopter Heterogeneity and Forecasting Market Diffusion. Energy Res. Soc. Sci. 2019, 55, 218–226. [Google Scholar] [CrossRef]

- Rietmann, N.; Hügler, B.; Lieven, T. Forecasting the Trajectory of Electric Vehicle Sales and the Consequences for Worldwide CO2 Emissions. J. Clean. Prod. 2020, 261, 121038. [Google Scholar] [CrossRef]

- Rogers, E.M.; Singhal, A.; Quinlan, M.M. Diffusion of Innovations. In An Integrated Approach to Communication Theory and Research; Routledge: Abingdon, UK, 2014; pp. 432–448. ISBN 0-203-88701-8. [Google Scholar]

- Ajzen, I. The Theory of Planned Behavior. Organ. Behav. Hum. Decis. Processes 1991, 50, 179–211. [Google Scholar] [CrossRef]

- Zwickle, S.; Wilson, R.; Doohan, D. Identifying the Challenges of Promoting Ecological Weed Management (EWM) in Organic Agroecosystems through the Lens of Behavioral Decision Making. Agric. Hum. Values 2014, 31, 355–370. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).