Study on Stability and Control of Surrounding Rock in the Stopping Space with Fully Mechanized Top Coal Caving under Goaf

Abstract

1. Introduction

2. Engineering Geological Conditions

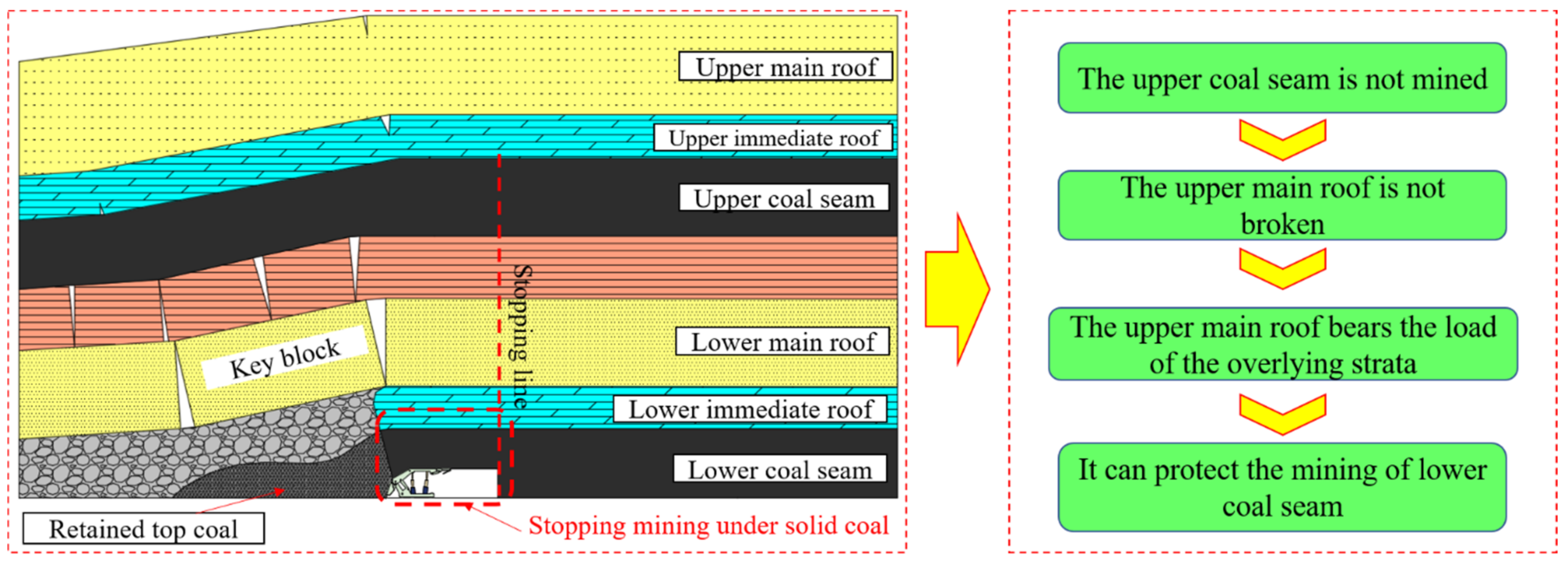

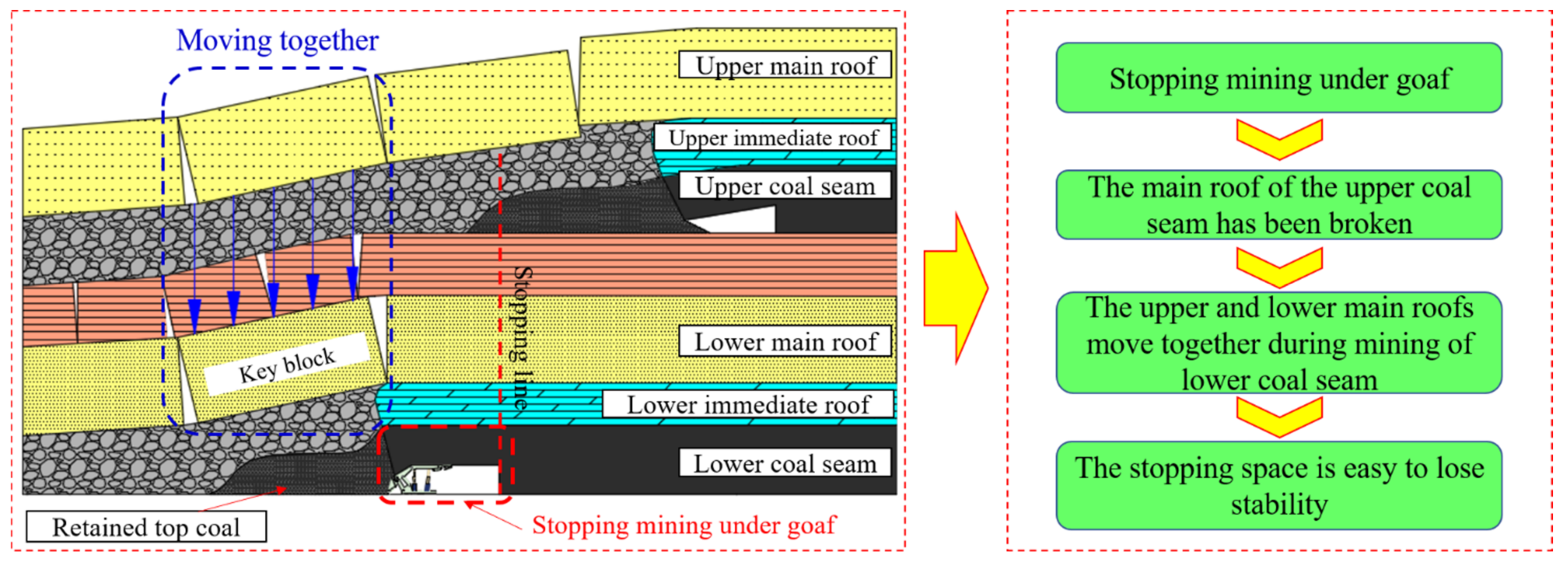

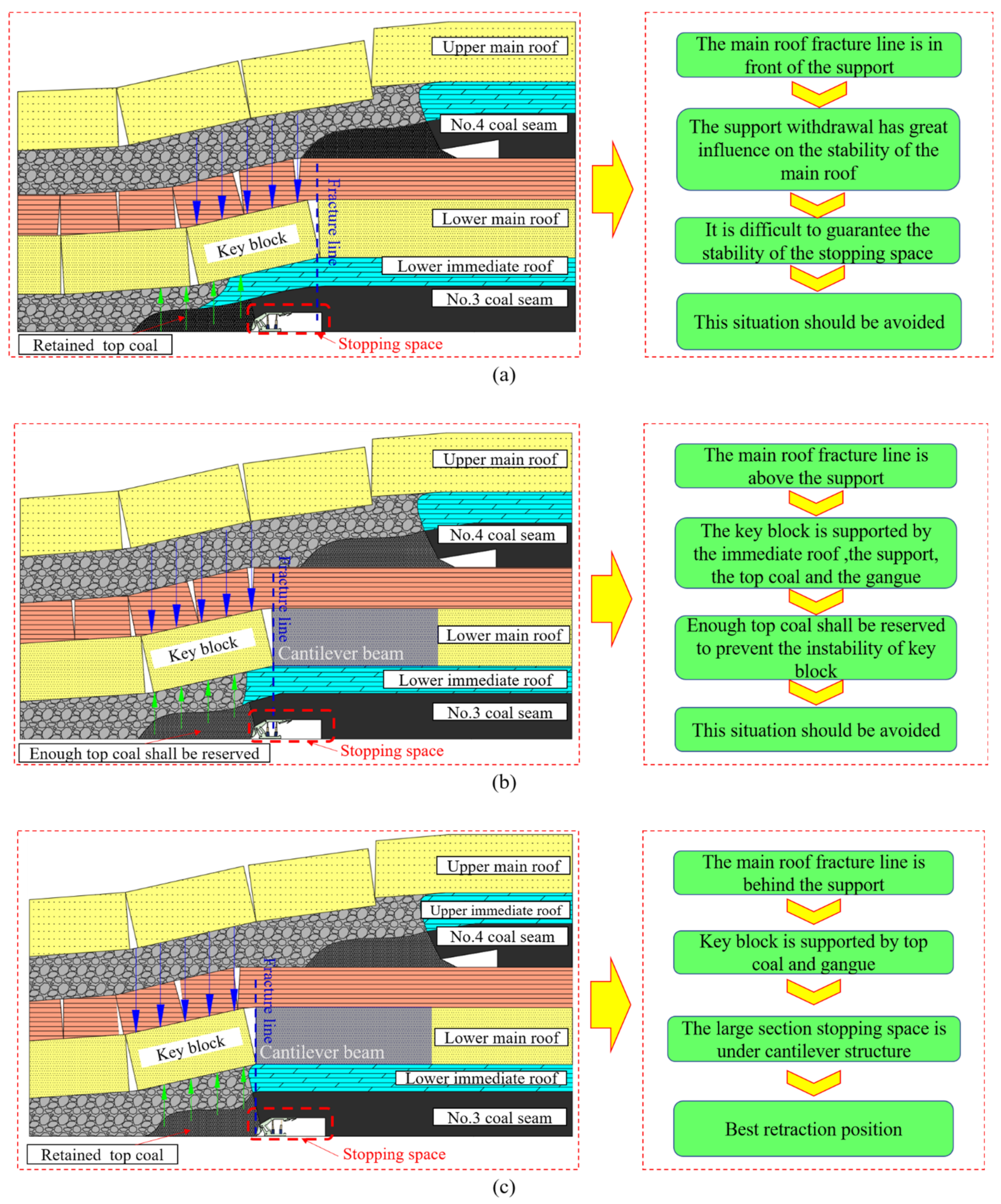

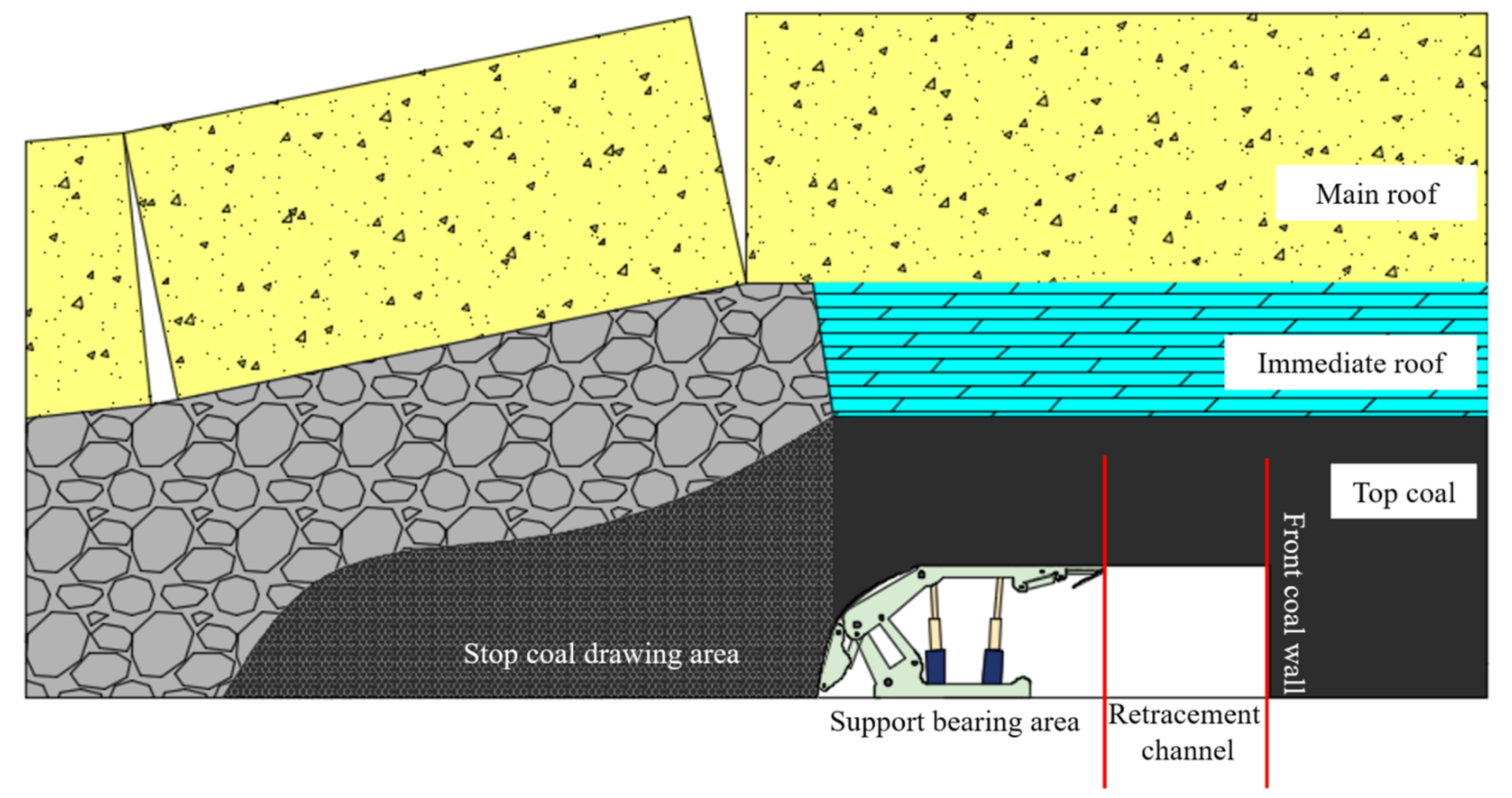

3. Analysis of Stopping Position under Goaf

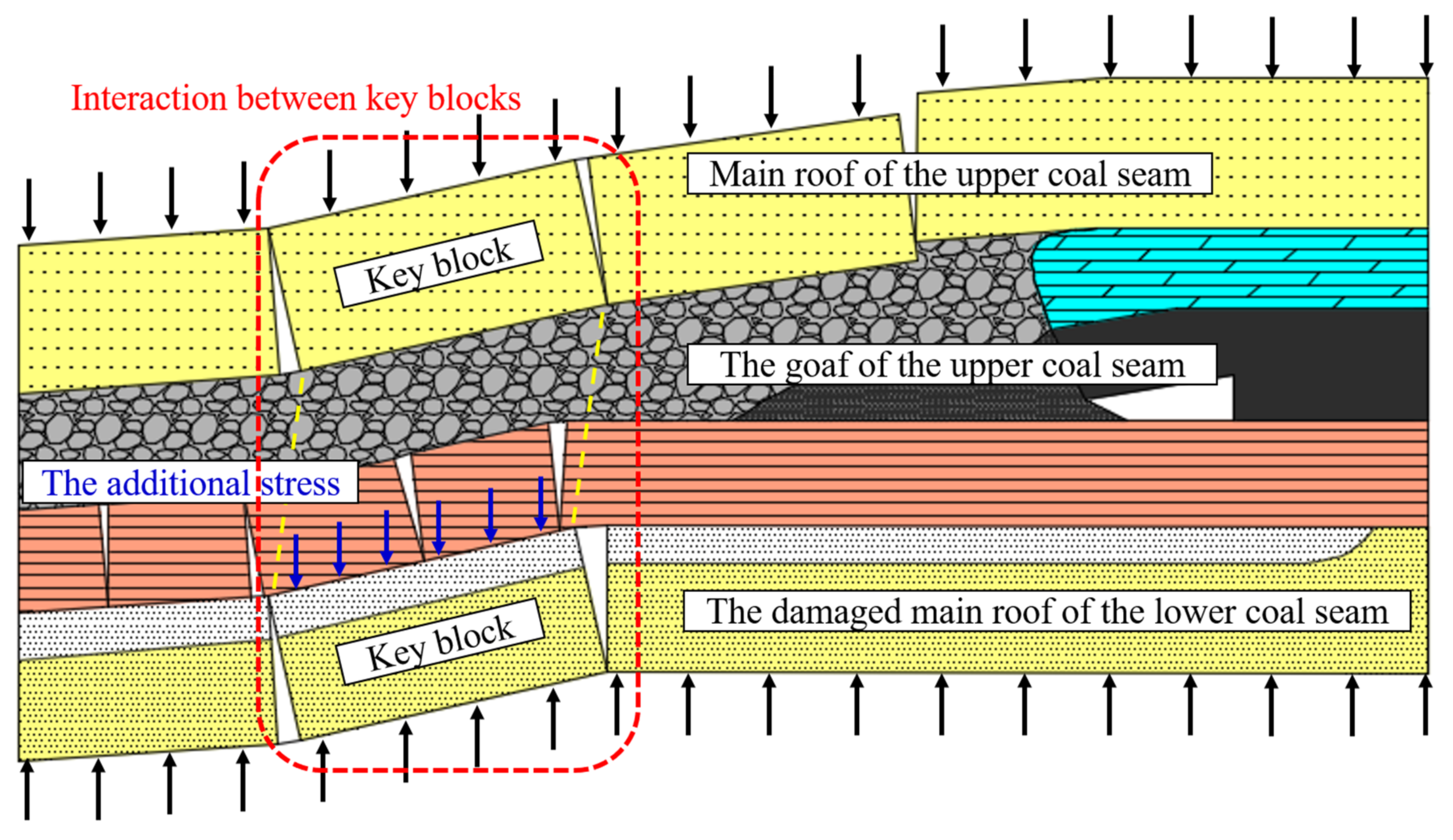

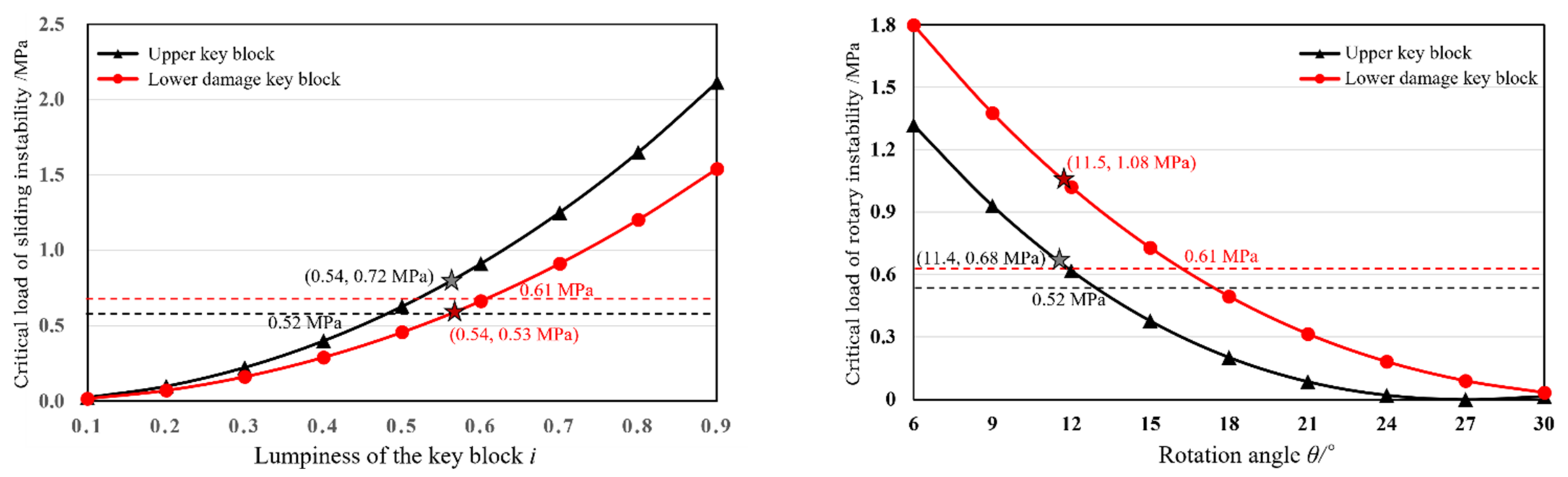

4. Stability Analysis of Key Blocks in Close Distance Coal Seam Mining

- iu is the lumpiness of the key block in the upper coal seam;

- iuh is the critical lumpiness for sliding instability of the key block;

- θ1 is the rotating angle of the key block, °;

- [σc] is the ultimate compressive of rock mass, MPa;

- [σt] is the ultimate tensile strength of rock mass, MPa;

- tanφ and η are the friction coefficient between rock blocks, taken as 0.3.

- il is the lumpiness of the key block in the lower coal seam;

- ilh is the critical lumpiness of the key block for sliding instability;

- θ2 is the rotation angle of the key block, °;

- ψ is sequence degree, and its value is 0.77.

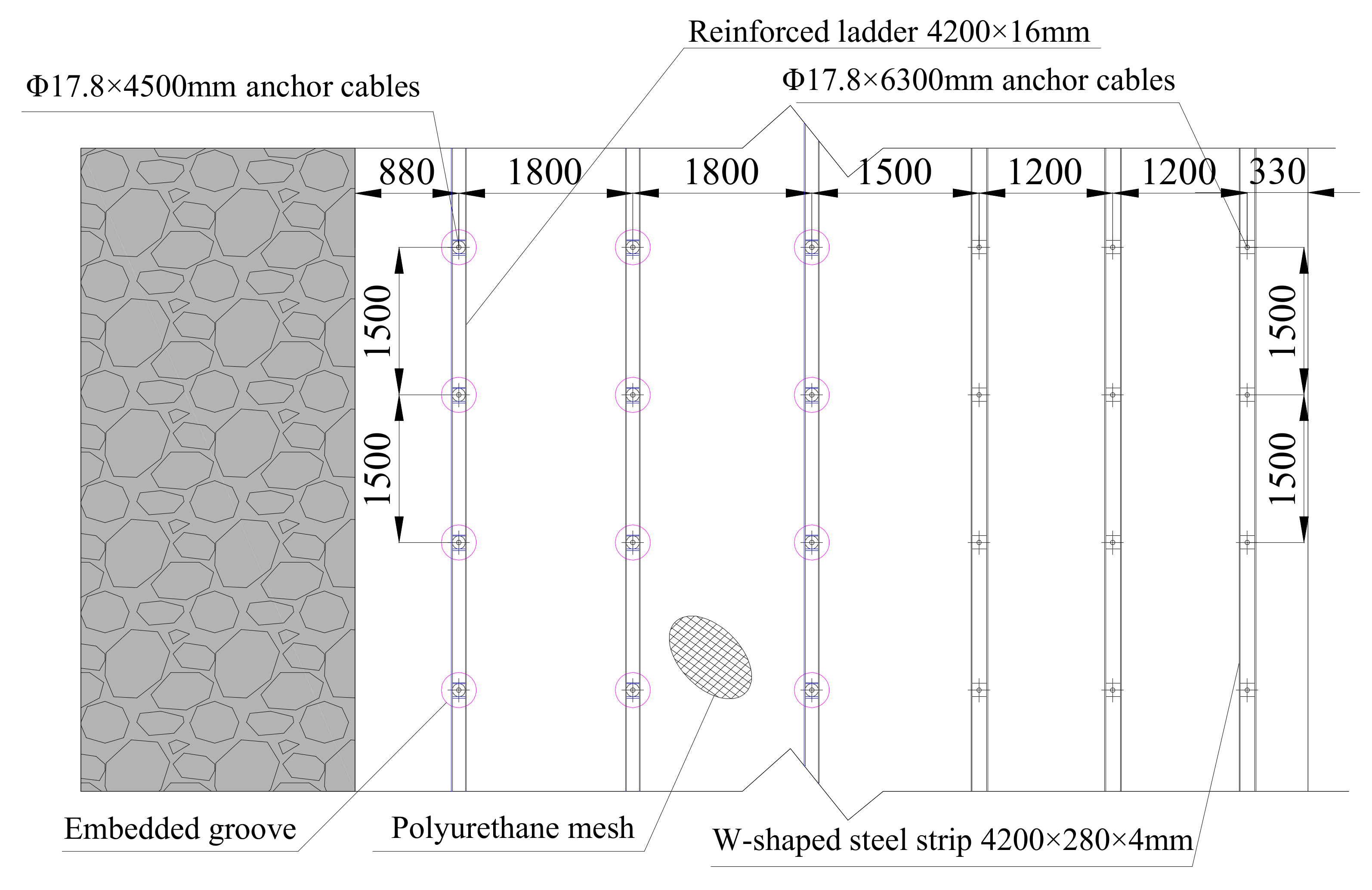

5. “Anchorage with Push and Pull Equipment-Embedded Anchorages and Trays” Integral Anchoring Technology

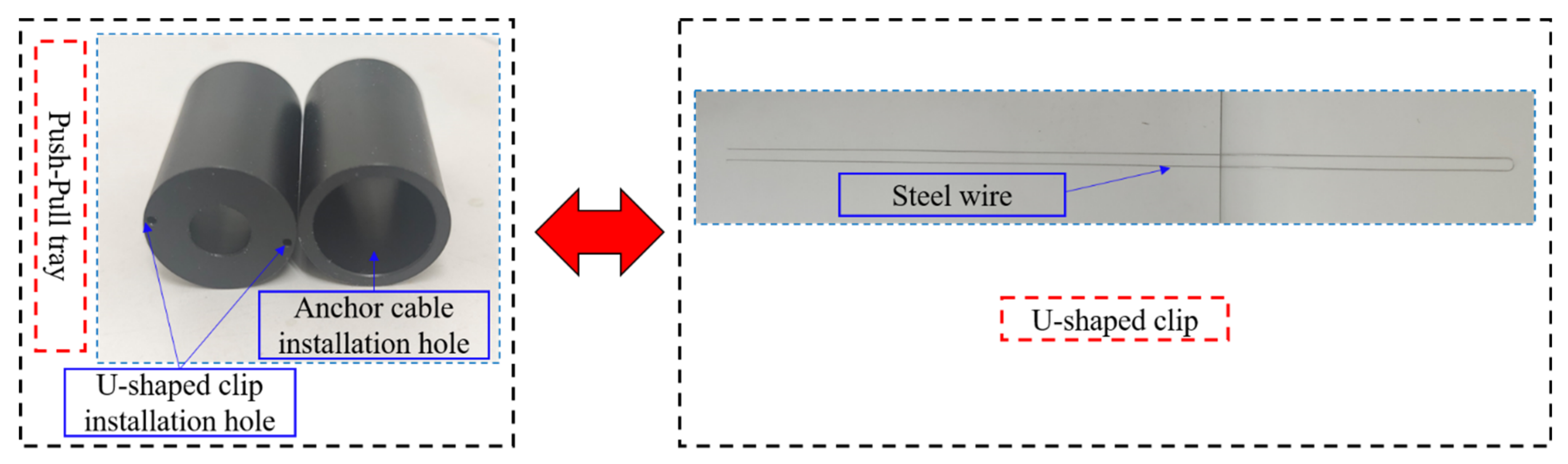

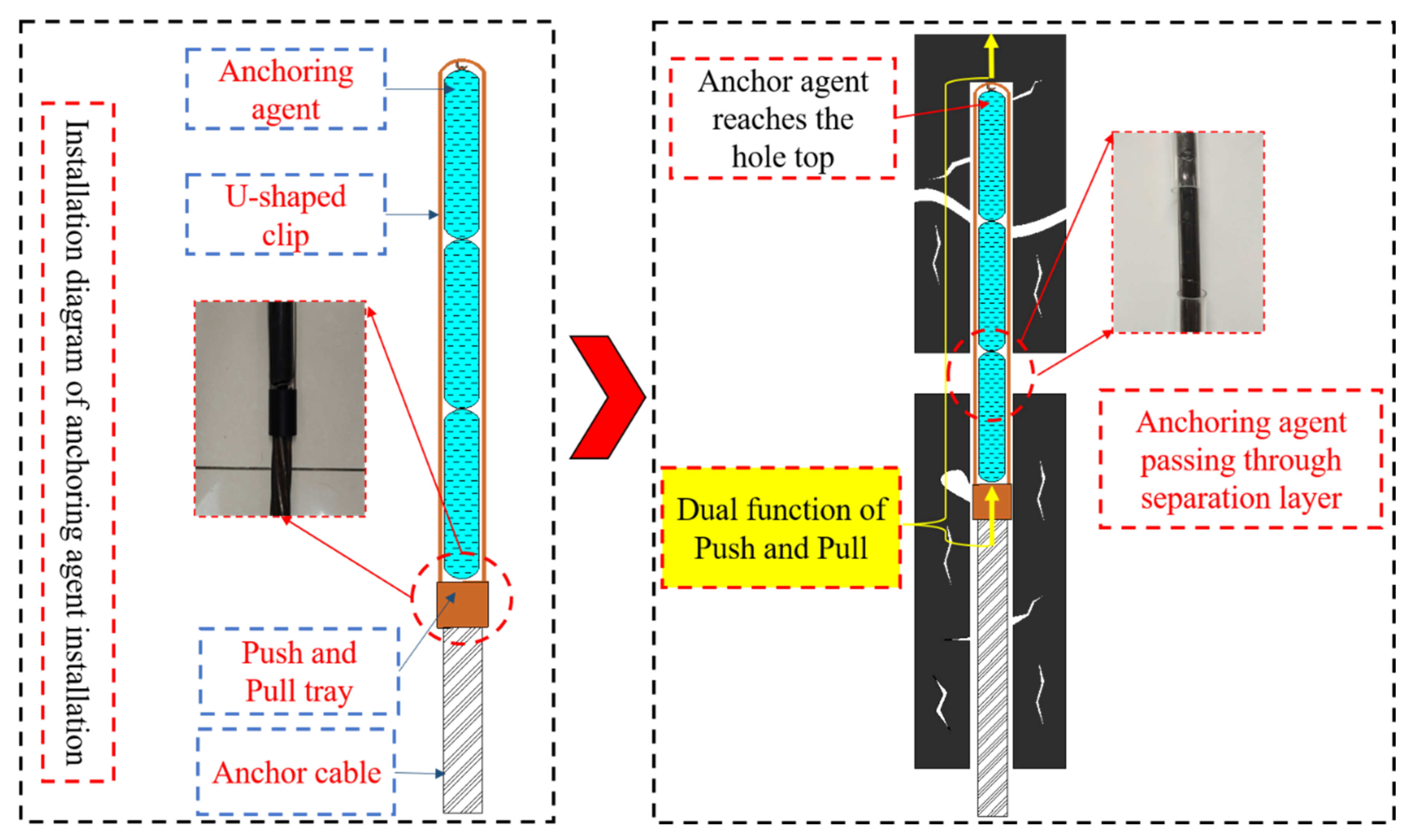

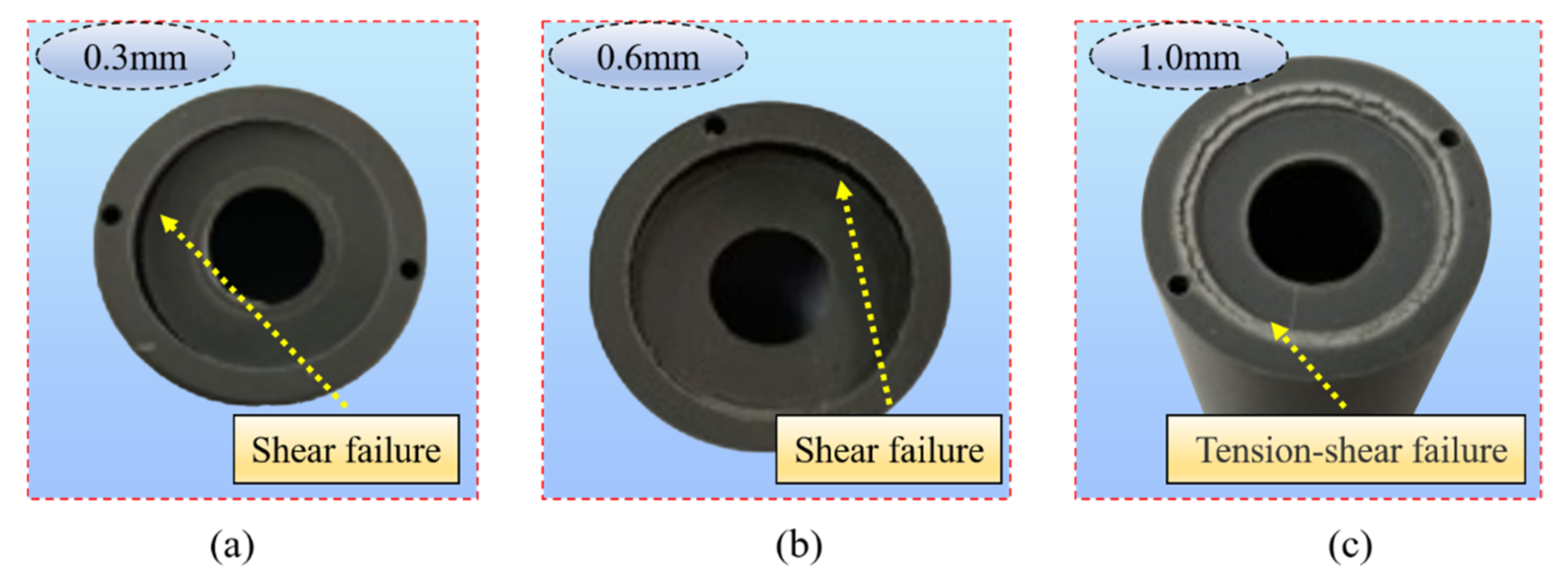

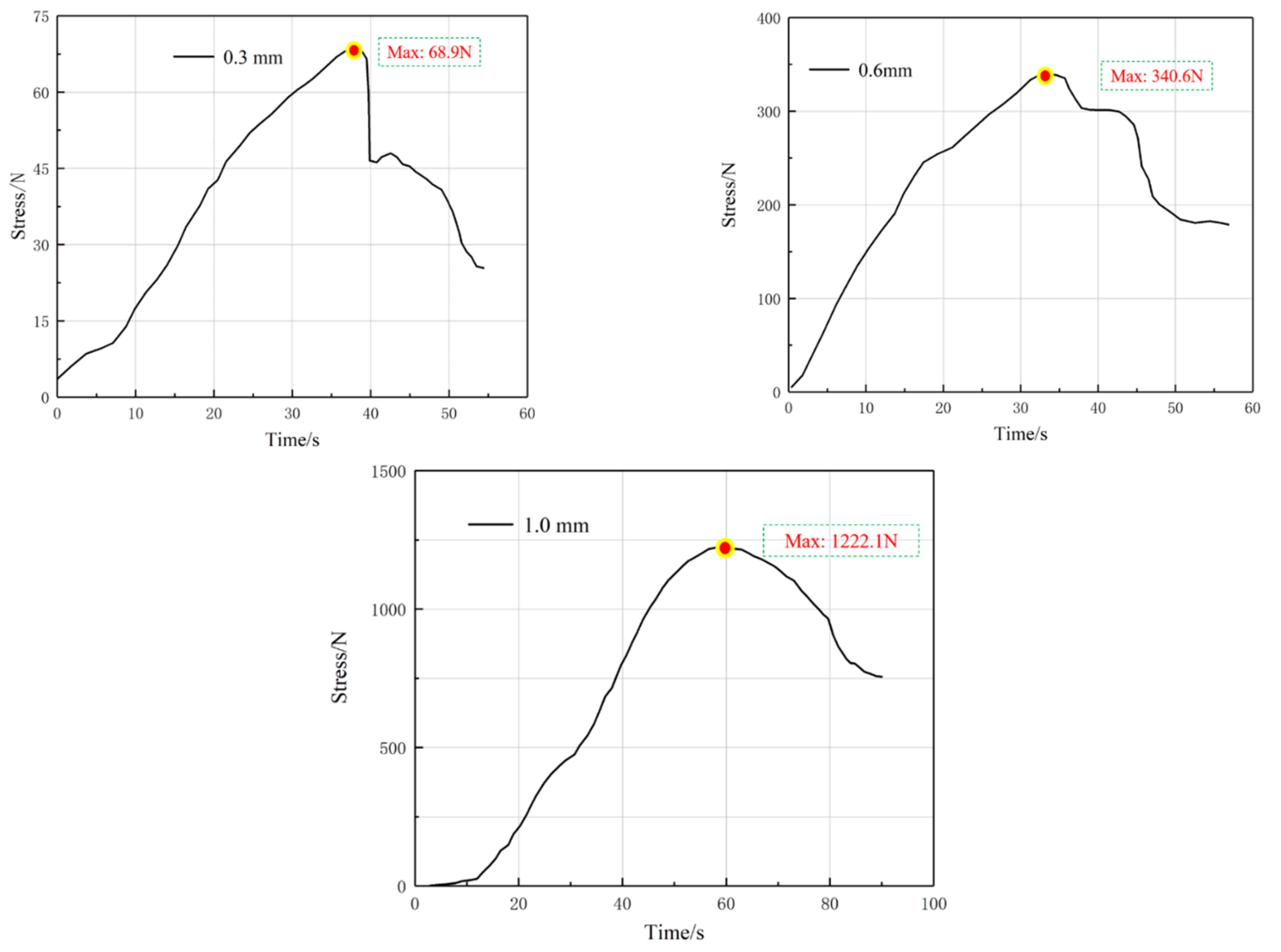

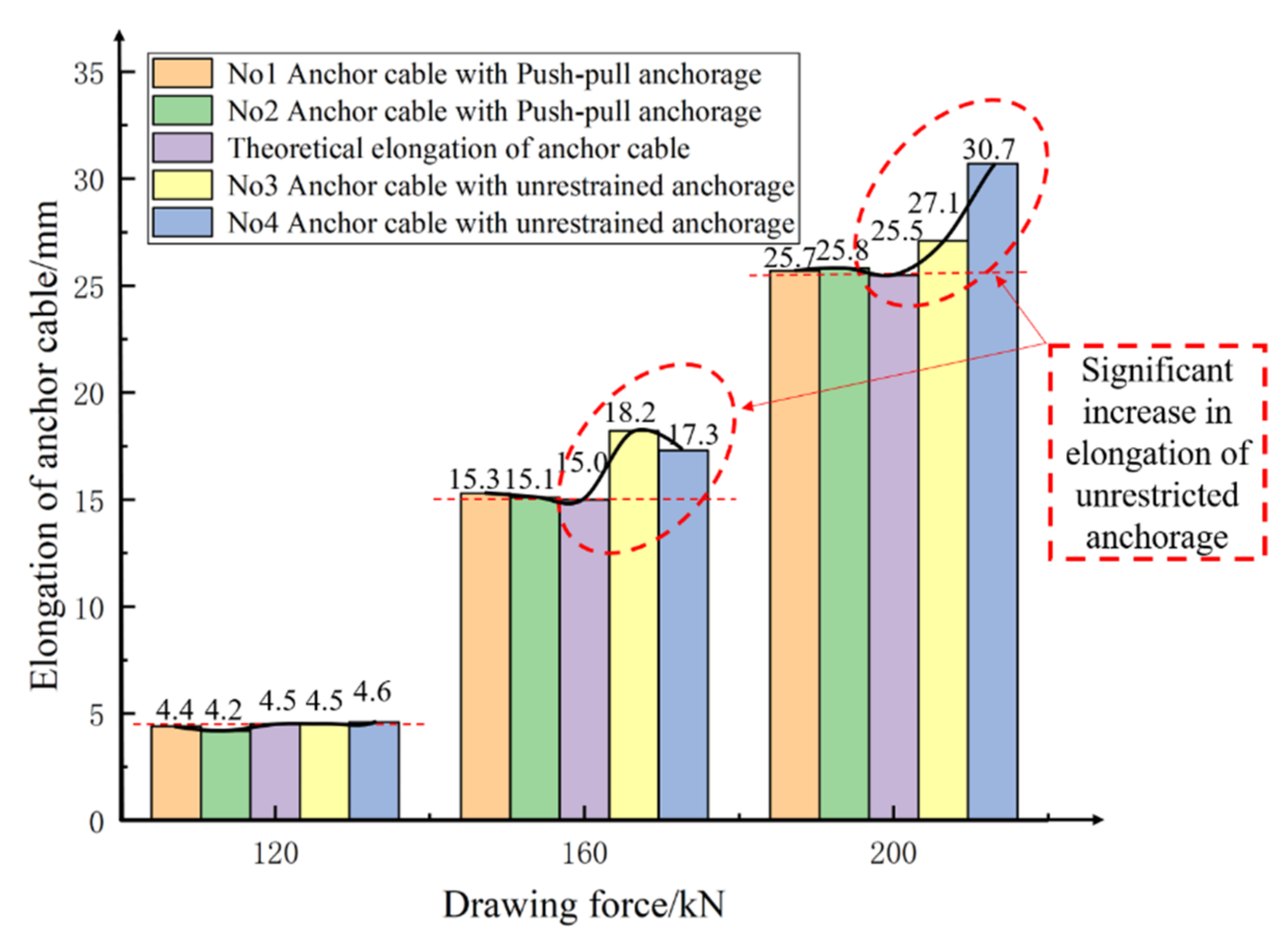

5.1. Development of Anchorage with Push and Pull Equipment

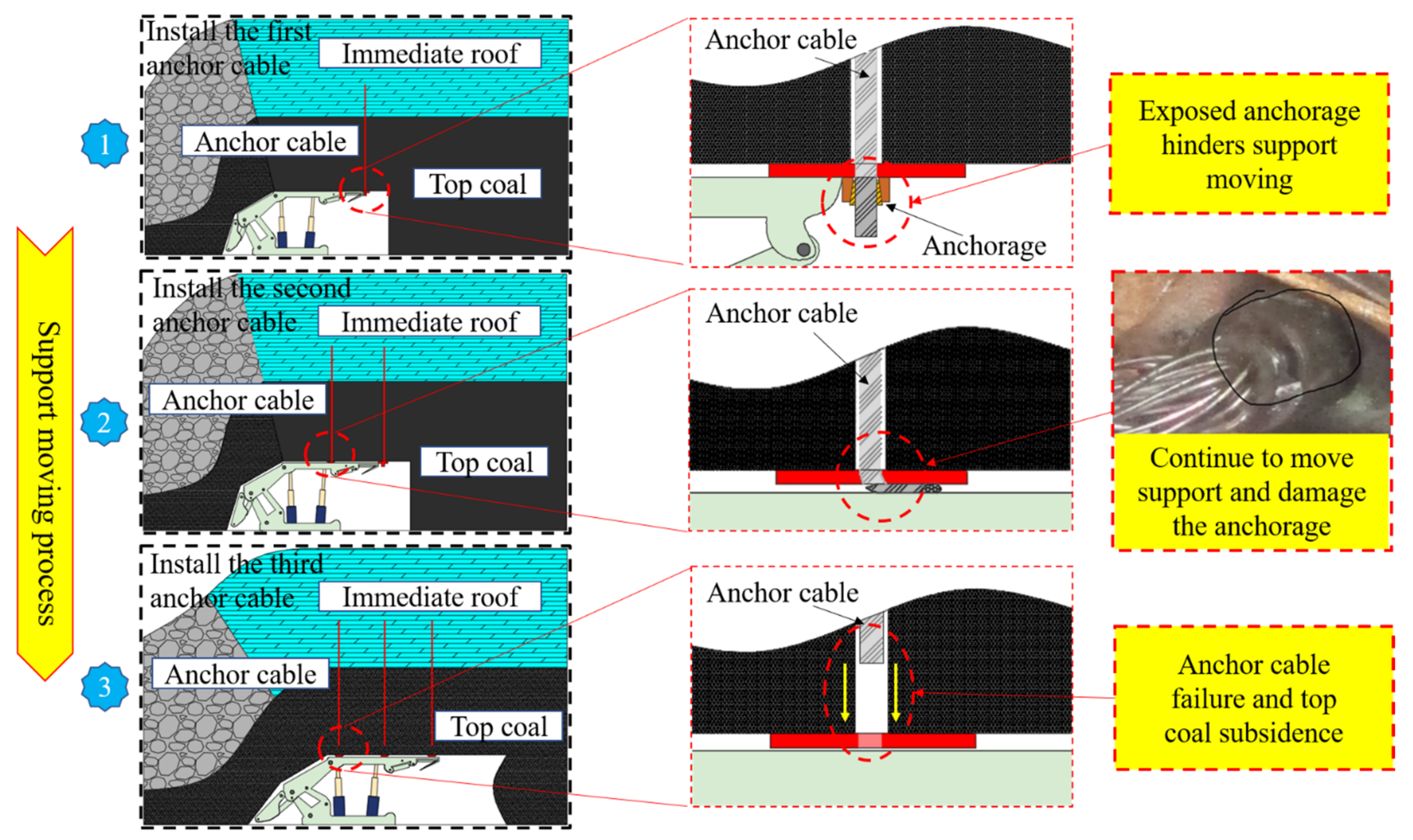

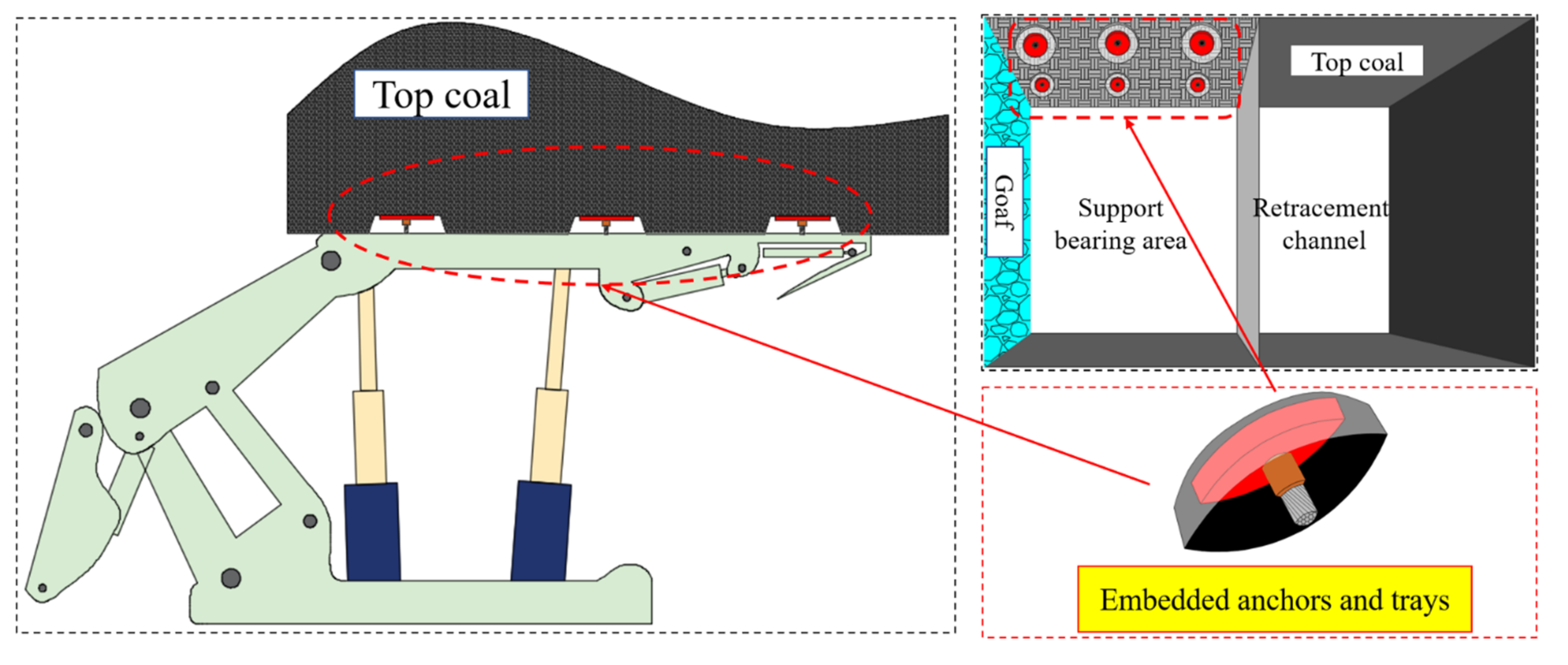

5.2. Anchoring Technology with Embedded Anchorages and Trays

6. Support Schemes for Stopping Space

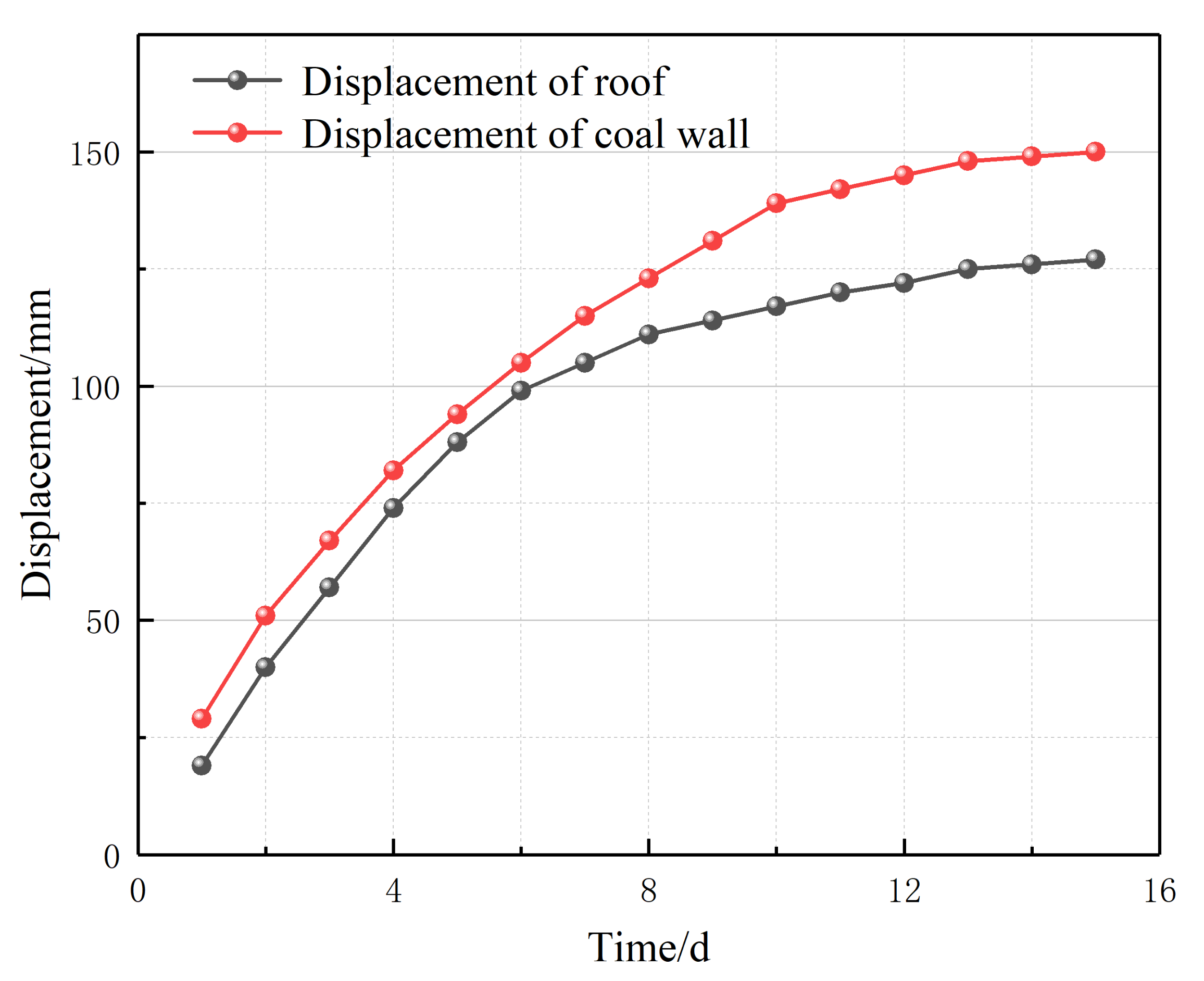

7. Industrial Test

8. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Shang, Y.Q.; Kong, D.Z.; Pu, S.J.; Xiong, Y.; Li, Q.; Cheng, Z.B. Study on Failure Characteristics and Control Technology of Roadway Surrounding Rock under Repeated Mining in Close-Distance Coal Seam. Mathematics 2022, 10, 2166. [Google Scholar] [CrossRef]

- Chen, D.; Guo, F.; Li, Z.; Ma, X.; Xie, S.; Wu, Y.; Wang, Z. Study on the Influence and Control of Stress Direction Deflection and Partial-Stress Boosting of Main Roadways Surrounding Rock and under the Influence of Multi-Seam Mining. Energies 2022, 15, 8257. [Google Scholar] [CrossRef]

- Bhattacharya, M.; Rafiq, S.; Bhattacharya, S. The role of technology on the dynamics of coal consumption–economic growth: New evidence from China. Appl. Energy 2015, 154, 686–695. [Google Scholar] [CrossRef]

- Xie, S.; Wang, E.; Chen, D.; Jiang, Z.; Li, H.; Liu, R. Collaborative Control Technology of External Anchor-Internal Unloading of Surrounding Rock in Deep Large-Section Coal Roadway under Strong Mining Influence. J. China Coal Soc. 2022, 47, 1946–1957. [Google Scholar]

- Zhang, B.S.; Yang, Z.P.; Ji, C.X.; Guo, Z.F.; Li, H.Y. Research on the Influence of the Key Stratum Position on the Support Working Resistance during Large Mining Height Top-Coal Caving Mining. Adv. Civ. Eng. 2021, 2021, 6690280. [Google Scholar] [CrossRef]

- Wang, B.N.; Mu, L.; He, M.M.; Gu, S.C. Mechanism Analysis of Roof Deformation in Pre-Driven Longwall Recovery Rooms Considering Main Roof Failure Form. Sustainability 2022, 14, 9093. [Google Scholar] [CrossRef]

- Zhu, C.; Yuan, Y.; Chen, Z.S.; Liu, Z.H.; Yuan, C.F. Study of the Stability Control of the Rock Surrounding Double-Key Strata Recovery Roadways in Shallow Seams. Adv. Civ. Eng. 2019, 2019, 9801637. [Google Scholar] [CrossRef]

- Wang, B.N.; Dang, F.N.; Gu, S.C.; Huang, R.B.; Miao, Y.P.; Chao, W. Method for determining the width of protective coal pillar in the pre-driven longwall recovery room considering main roof failure form. Int. J. Rock. Mech. Min. 2020, 130, 104340. [Google Scholar] [CrossRef]

- Kang, H.P.; Lv, H.W.; Zhang, X.; Gao, F.Q.; Wu, Z.G.; Wang, Z.C. Evaluation of the Ground Response of a Pre-driven Longwall Recovery Room Supported by Concrete Cribs. Rock. Mech. Rock. Eng. 2016, 49, 1025–1040. [Google Scholar] [CrossRef]

- Fei, L.; Jiang, Z.X. Research on Deformation Mechanism of Retracement Channel during Fully Mechanized Caving Mining in Superhigh Seam. Adv. Civ. Eng. 2018, 2018, 1368965. [Google Scholar] [CrossRef]

- Xu, J.H.; Miao, X.X.; Pu, H.; Cao, S.G. Determination of reasonable position and stability analysis of finishing cut in fully-mechanized coal face with topped caving. Chin. J. Rock Mech. Eng. 2004, 23, 1981–1985. [Google Scholar]

- Yang, R.S.; Li, Y.L.; Zhu, Y.; Xiao, C.L.; Zhao, Y.; Shi, G.L. Study on stability control of equipment removal channel for high cutting mining face under special condition. Coal Sci. Technol. 2017, 45, 10–15. [Google Scholar]

- Song, B. Instant Removal Gateway for Large Height Working Face in Soft Coal Seam. Saf. Coal Mines 2014, 45, 136–139. [Google Scholar]

- Chen, Z.S.; Yuan, Y.; Zhu, C.; Wang, W.M. Stability Mechanism and Control Factors on Equipment Removal Area under “Goaf-Roof-Coal” Structure. Adv. Civ. Eng. 2021, 2021, 6628272. [Google Scholar] [CrossRef]

- Wu, J.N.; Feng, X.W.; Liu, B.K. Rapid removing technology of heavy fully mechanized top coal caving mining face without preset removing gateway. Coal Sci. Technol. 2008, 36, 14–17. [Google Scholar]

- Liu, Y.M.; Liu, Y.H.; Gao, M.S. Roof Fracture Characteristics of Deep Mining-pause Space Without Pre-excavation Roadway. Saf. Coal Mines 2016, 47, 197–199. [Google Scholar]

- Wang, X.; Ji, W.P.; Li, X.M.; Liu, F.; Zhang, N.B. Study on Position of Withdrawal Entry in Fully Mechanized Caving Face of Extremely Thick Coal Seam. Coal Technol. 2010, 29, 63–65. [Google Scholar]

- Ning, J.G.; Wang, J.; Tan, Y.L.; Xu, Q. Mechanical mechanism of overlying strata breaking and development of fractured zone during close-distance coal seam group mining. Int. J. Min. Sci. Technol. 2020, 30, 207–215. [Google Scholar] [CrossRef]

- Guo, G.C.; Yang, Y.K. The study of key stratum location and characteristics on the mining of extremely thick coal seam under goaf. Adv. Civ. Eng. 2021, 2021, 8833822. [Google Scholar] [CrossRef]

- Xie, S.; Wu, Y.; Guo, F.; Zou, H.; Chen, D.; Zhang, X.; Ma, X.; Liu, R.; Wu, C. Application of Pre-Splitting and Roof-Cutting Control Technology in Coal Mining: A Review of Technology. Energies 2022, 15, 6489. [Google Scholar] [CrossRef]

- Pan, W.D.; Zhang, S.P.; Liu, Y. Safe and efficient coal mining below the goaf: A case study. Energies 2020, 13, 864. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, D.S.; Qi, D.H.; Hu, W.M.; He, Z.M.; Zhang, W.S. Floor failure depth of upper coal seam during close coal seams mining and its novel detection method. Energy Explor. Exploit. 2018, 36, 1265–1278. [Google Scholar] [CrossRef]

- Vu, T.T. Solutions to prevent face spall and roof falling in fully mechanized longwall at underground mines, Vietnam. Min. Min. Dep. 2022, 16, 127–134. [Google Scholar] [CrossRef]

- Małkowski, P.; Niedbalski, Z.; Majcherczyk, T.; Bednarek, Ł. Underground monitoring as the best way of roadways support design validation in a long time period. Min. Min. Dep. 2020, 14, 1–14. [Google Scholar] [CrossRef]

- Zhu, C.; Xu, Y.Z.; Wu, Y.X.; He, M.C.; Zhu, C.Q.; Meng, Q.X.; Lin, Y. A hybrid artifi cial bee colony algorithm and support vector machine for predicting blast-induced ground vibration. Earthq. Eng. Eng. Vib. 2022, 21, 861–876. [Google Scholar]

- Xie, S.R.; Wu, Y.Y.; Ma, X.; Chen, D.D.; Guo, F.F.; Jiang, Z.S.; Li, H.; Zou, H.; Liu, R.P.; Zhang, X. Reasonable stopping method and retracement channel support at fully mechanized top coal caving working face of 15 m extra-thick coal seam: A case study. Energy Sci. Eng. 2022. [Google Scholar] [CrossRef]

- Chen, D.; Wu, Y.; Xie, S.; Guo, F.; He, F.; Liu, R. Reasonable Location of Stopping Line in Close-Distance Underlying Coal Seam and Partition Support of Large Cross-Section Roadway. Int. J. Coal Sci. Technol. 2022, 9, 55. [Google Scholar] [CrossRef]

- Singh, G.S.P.; Singh, U.K. Assessment of goaf characteristics and compaction in longwall caving. Min. Technol. 2011, 120, 222–232. [Google Scholar] [CrossRef]

- Alehossein, H.; Poulsen, B.A. Stress analysis of longwall top coal caving. Int. J. Rock Meck. Min. 2010, 47, 30–41. [Google Scholar] [CrossRef]

- Klishin, V.I.; Fryanov, V.N.; Pavlova, L.D.; Opruk, G.Y. Modeling top coal disintegration in thick seams in longwall top coal caving. J. Min. Sci. 2019, 55, 247–256. [Google Scholar] [CrossRef]

- Wang, X.Z.; Ju, J.F.; Xu, J.L. Theory and applicable of yield mining at ending stage of fully-mechanized face in shallow seam at Shendong mine area. J. Min. Saf. Eng. 2012, 3, 151–156. [Google Scholar]

- Qian, M.G.; Miao, X.X.; Xu, J.L. Theoretical Study of Key Sratum in Ground Control. J. China Coal Soc. 1996, 21, 2–7. [Google Scholar]

- Xie, S.R.; Wu, Y.Y.; Guo, F.F.; Chen, D.D.; Wang, E.; Zhang, X.; Zou, H.; Liu, R.P.; Ma, X.; Li, S.J. Interaction Mechanism of the Upper and Lower Main Roofs with Different Properties in Close Coal Seams: A Case Study. Energies 2022, 15, 5533. [Google Scholar] [CrossRef]

- He, S.S.; Xie, S.R.; Song, B.H.; Zhou, D.Q.; Sun, Y.D.; Han, S. Breaking laws and stability analysis of damage main roof in close distance hypogynous seams. J. China Coal Soc. 2016, 41, 2596–2605. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, F.; Liu, B.; Wang, D.; Chen, D.; Wu, Y.; Song, L.; Ma, X.; Ye, Q.; Jiang, Z.; Guo, F.; et al. Study on Stability and Control of Surrounding Rock in the Stopping Space with Fully Mechanized Top Coal Caving under Goaf. Energies 2022, 15, 8498. https://doi.org/10.3390/en15228498

He F, Liu B, Wang D, Chen D, Wu Y, Song L, Ma X, Ye Q, Jiang Z, Guo F, et al. Study on Stability and Control of Surrounding Rock in the Stopping Space with Fully Mechanized Top Coal Caving under Goaf. Energies. 2022; 15(22):8498. https://doi.org/10.3390/en15228498

Chicago/Turabian StyleHe, Fulian, Bingquan Liu, Deqiu Wang, Dongdong Chen, Yanhao Wu, Liming Song, Xiang Ma, Qiucheng Ye, Zaisheng Jiang, Fangfang Guo, and et al. 2022. "Study on Stability and Control of Surrounding Rock in the Stopping Space with Fully Mechanized Top Coal Caving under Goaf" Energies 15, no. 22: 8498. https://doi.org/10.3390/en15228498

APA StyleHe, F., Liu, B., Wang, D., Chen, D., Wu, Y., Song, L., Ma, X., Ye, Q., Jiang, Z., Guo, F., Wang, W., & Wu, Y. (2022). Study on Stability and Control of Surrounding Rock in the Stopping Space with Fully Mechanized Top Coal Caving under Goaf. Energies, 15(22), 8498. https://doi.org/10.3390/en15228498