Hybrid Solar-Driven Desalination/Cooling Systems: Current Situation and Future Trend

Abstract

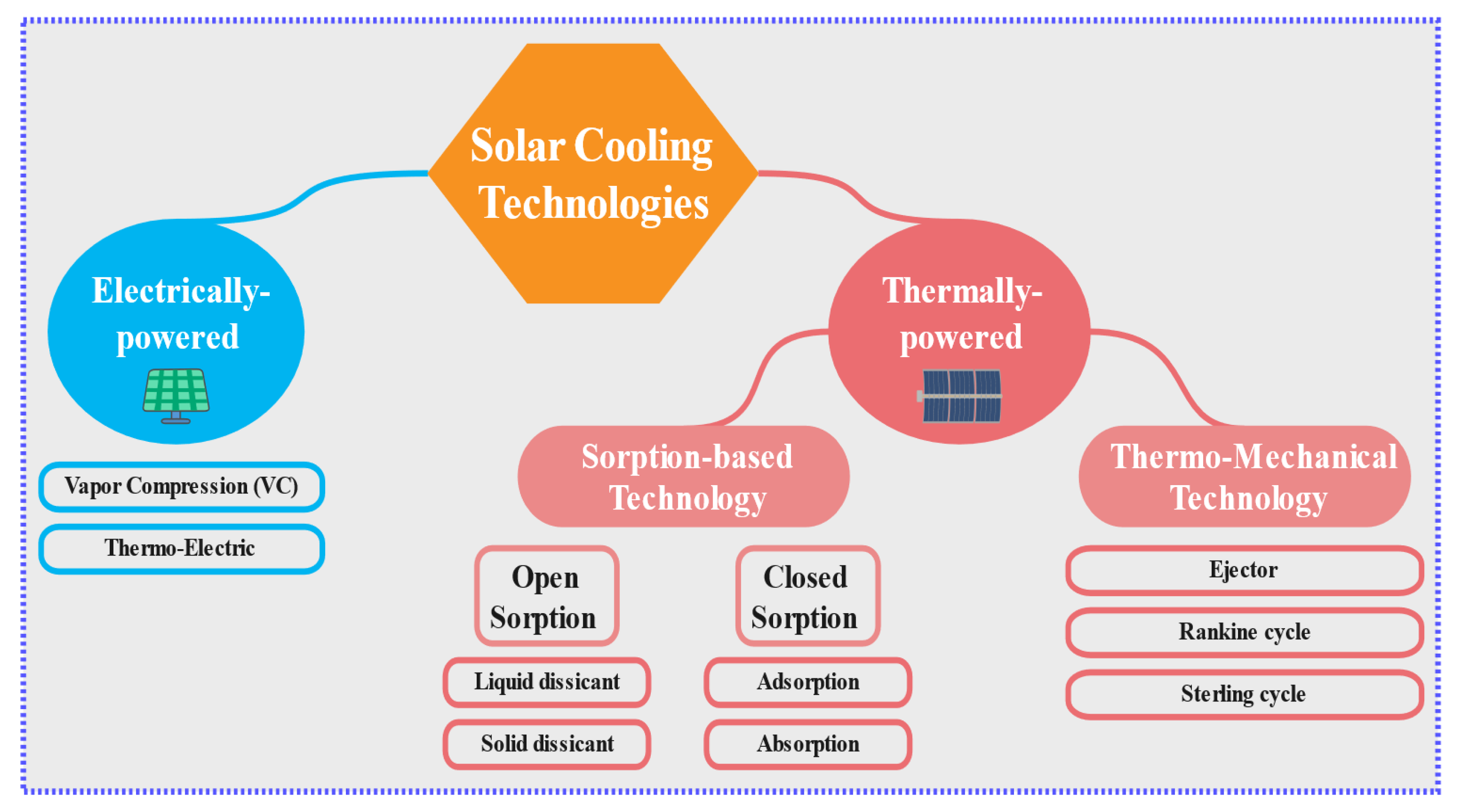

1. Introduction

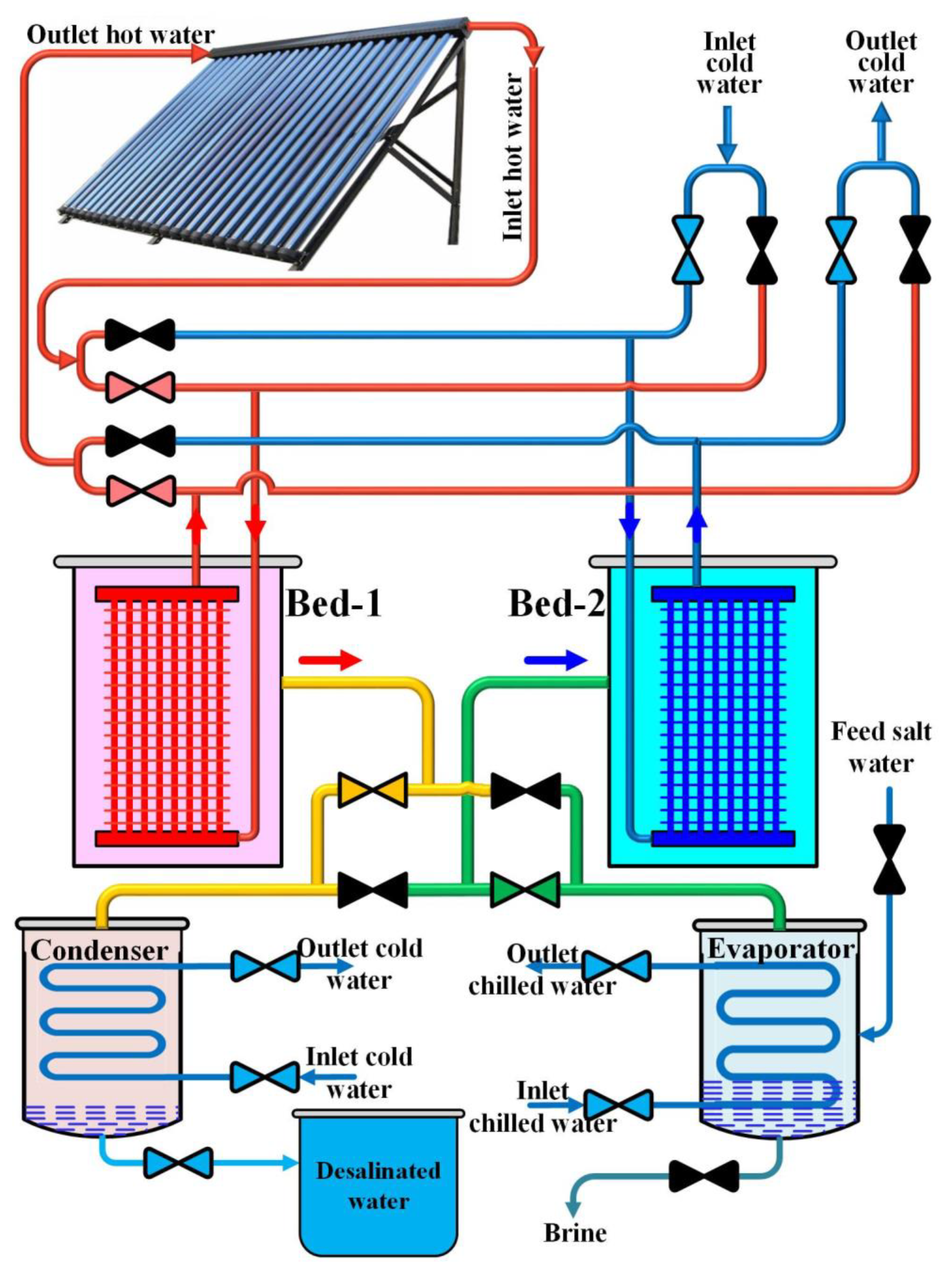

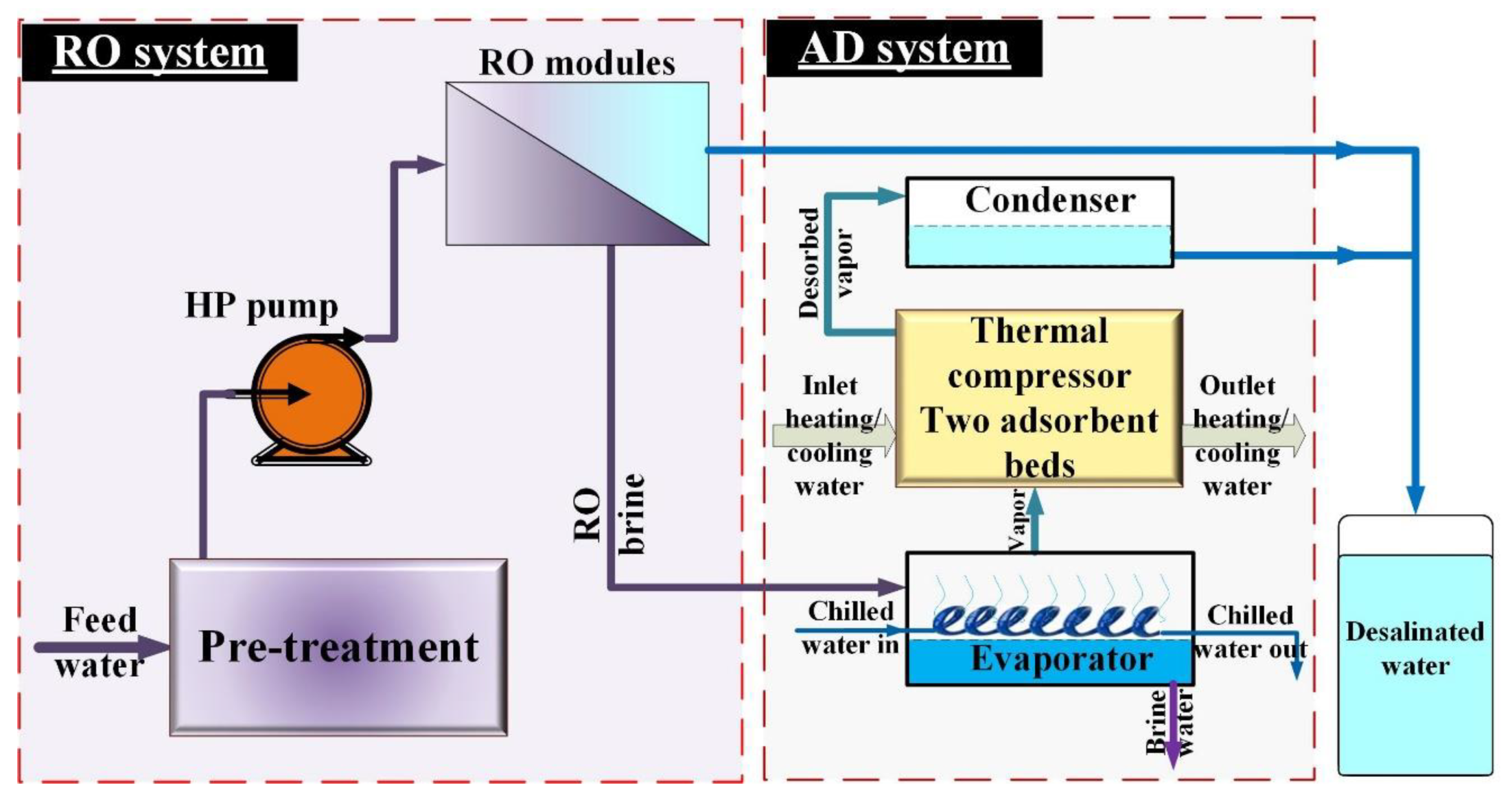

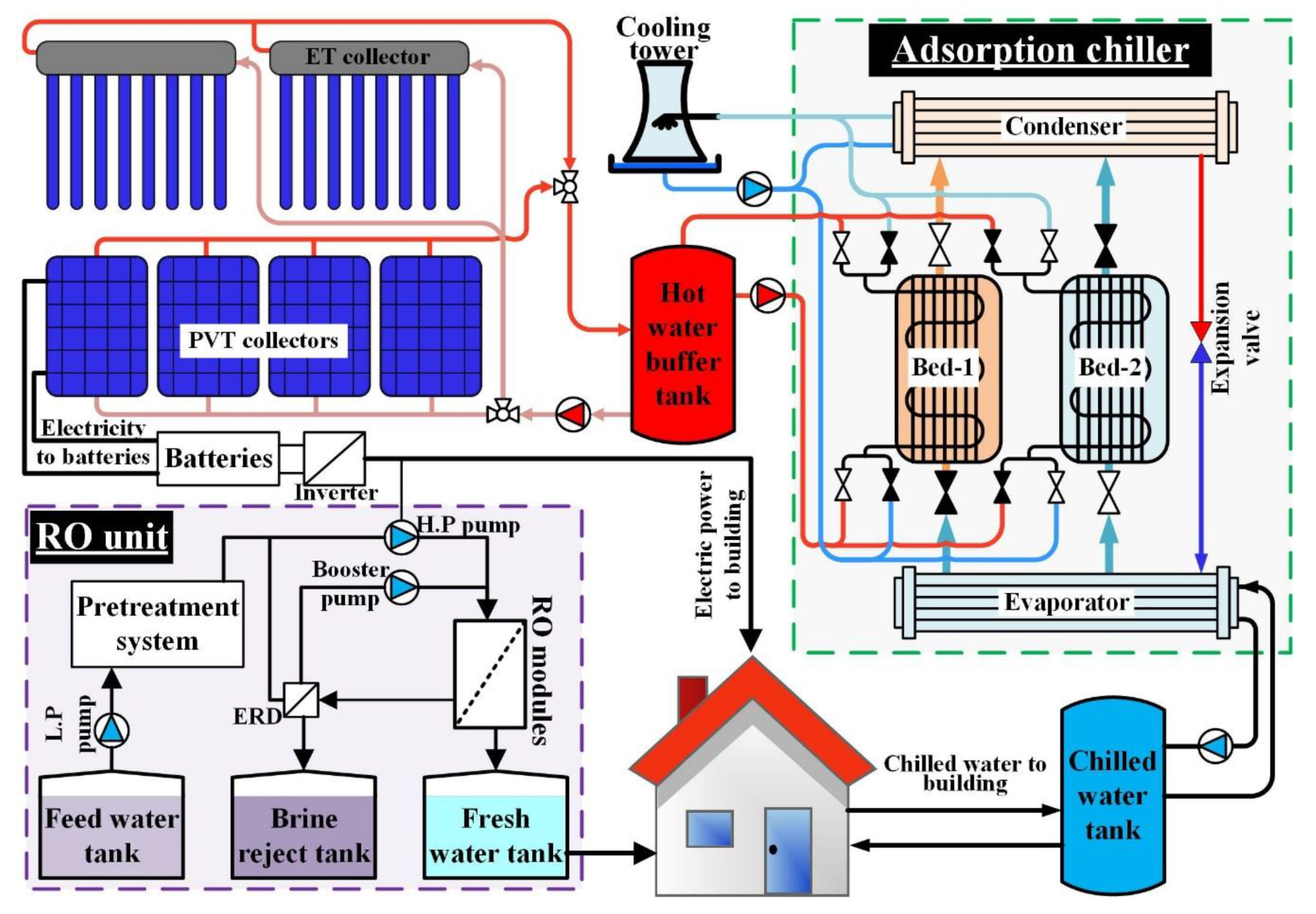

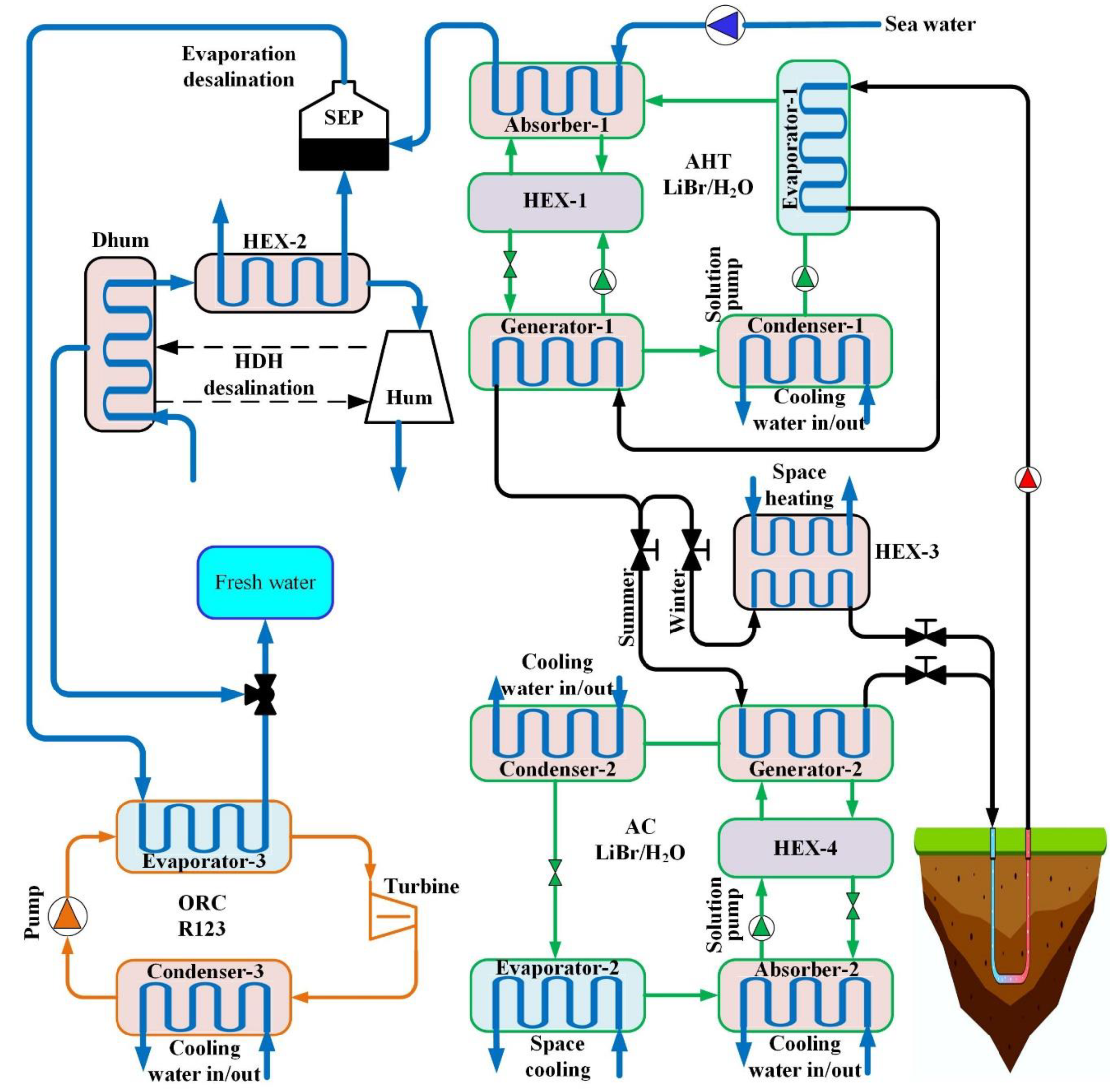

2. Solar Sorption Desalination/Cooling (SSDC) Systems

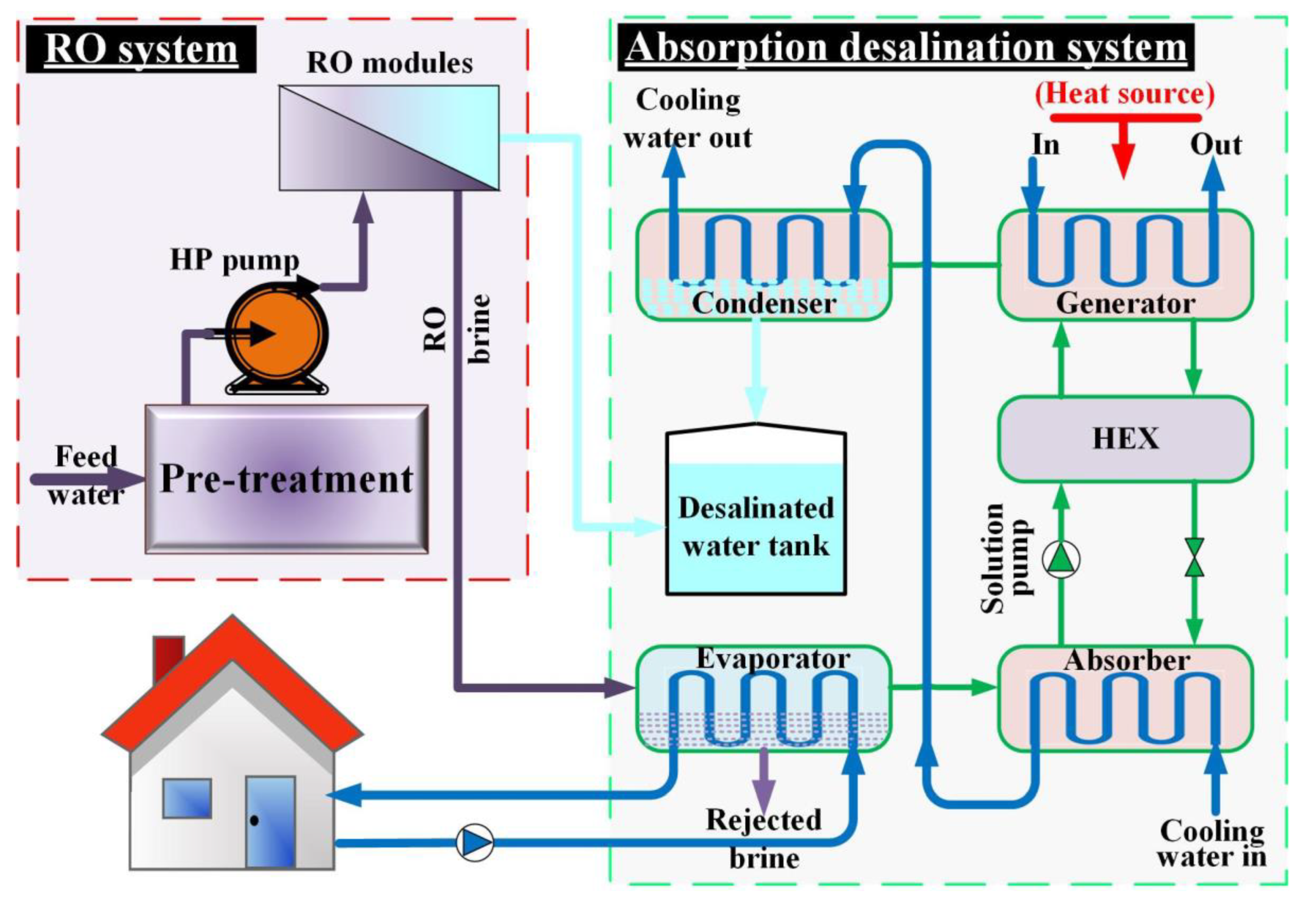

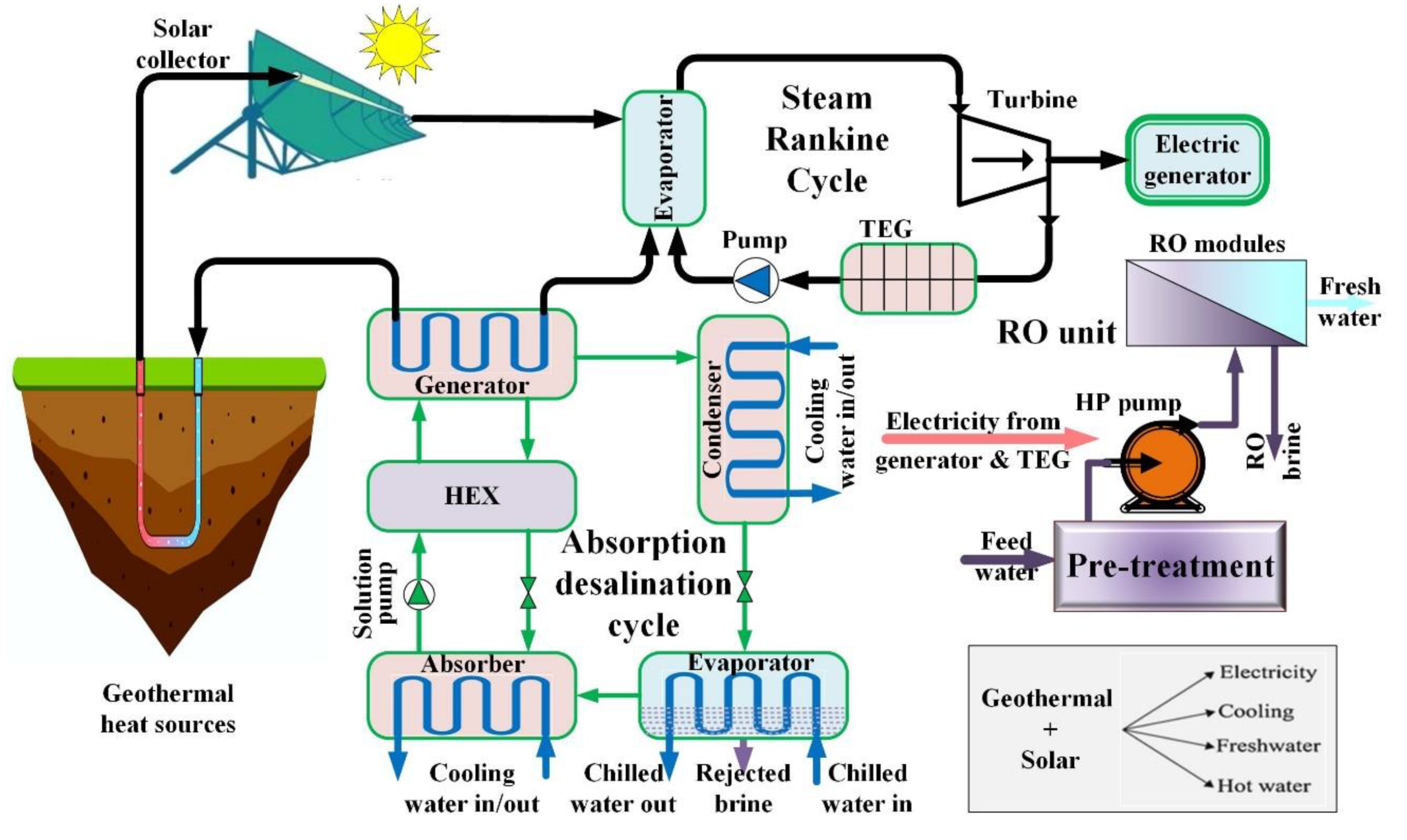

3. Solar Reverse Osmosis/Cooling (SROC) Systems

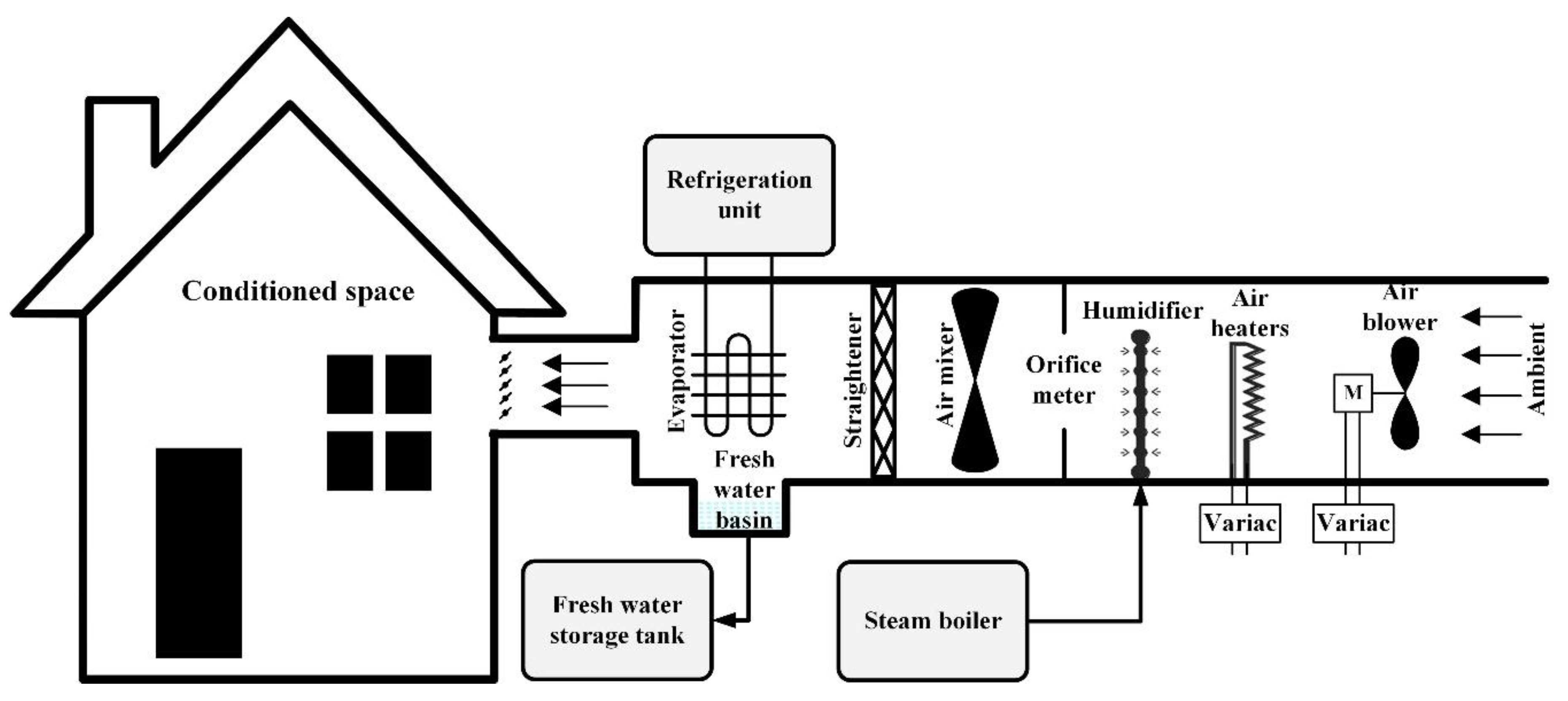

4. Solar Humidification-Dehumidification/Cooling (SHDC) Systems

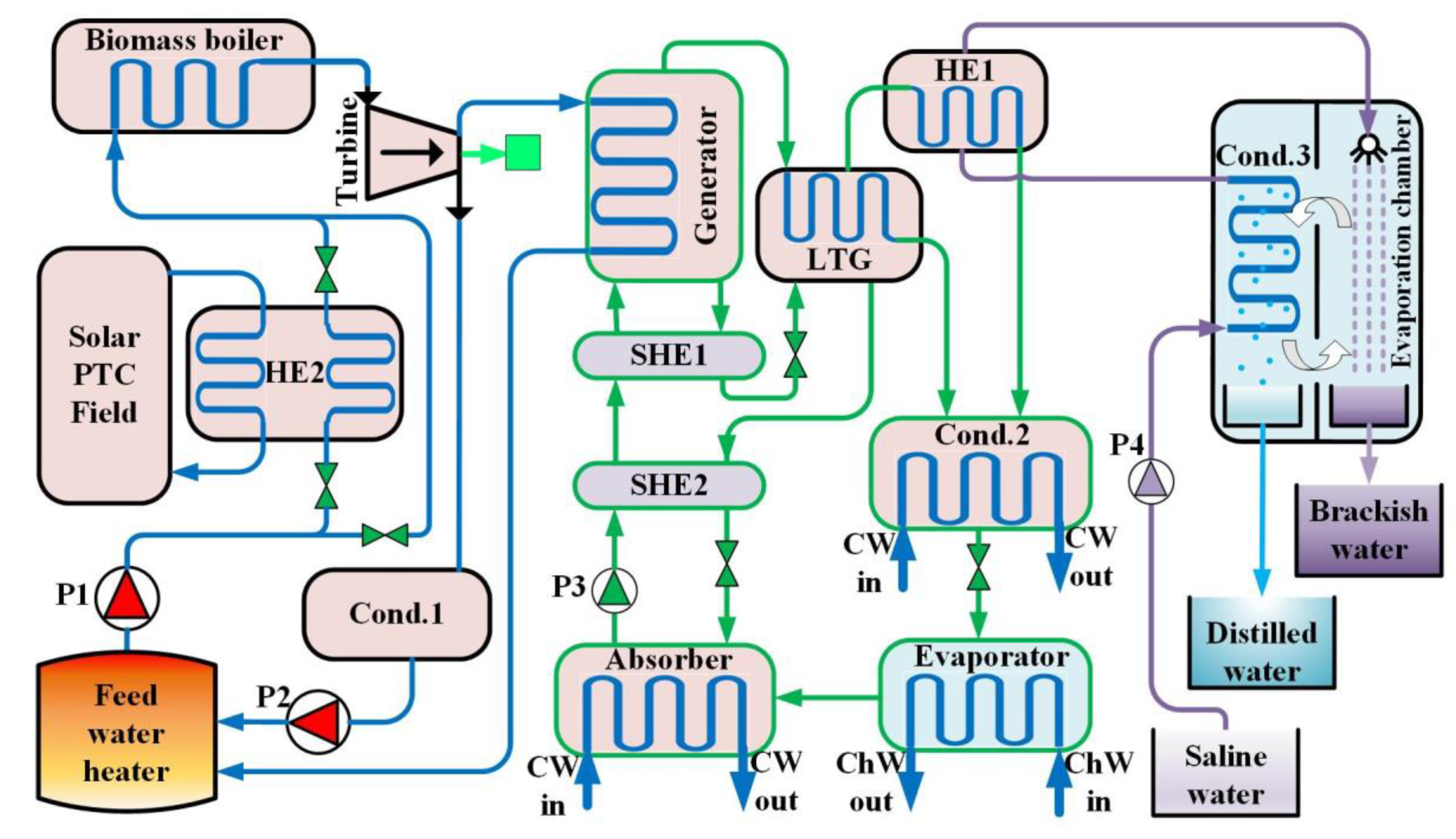

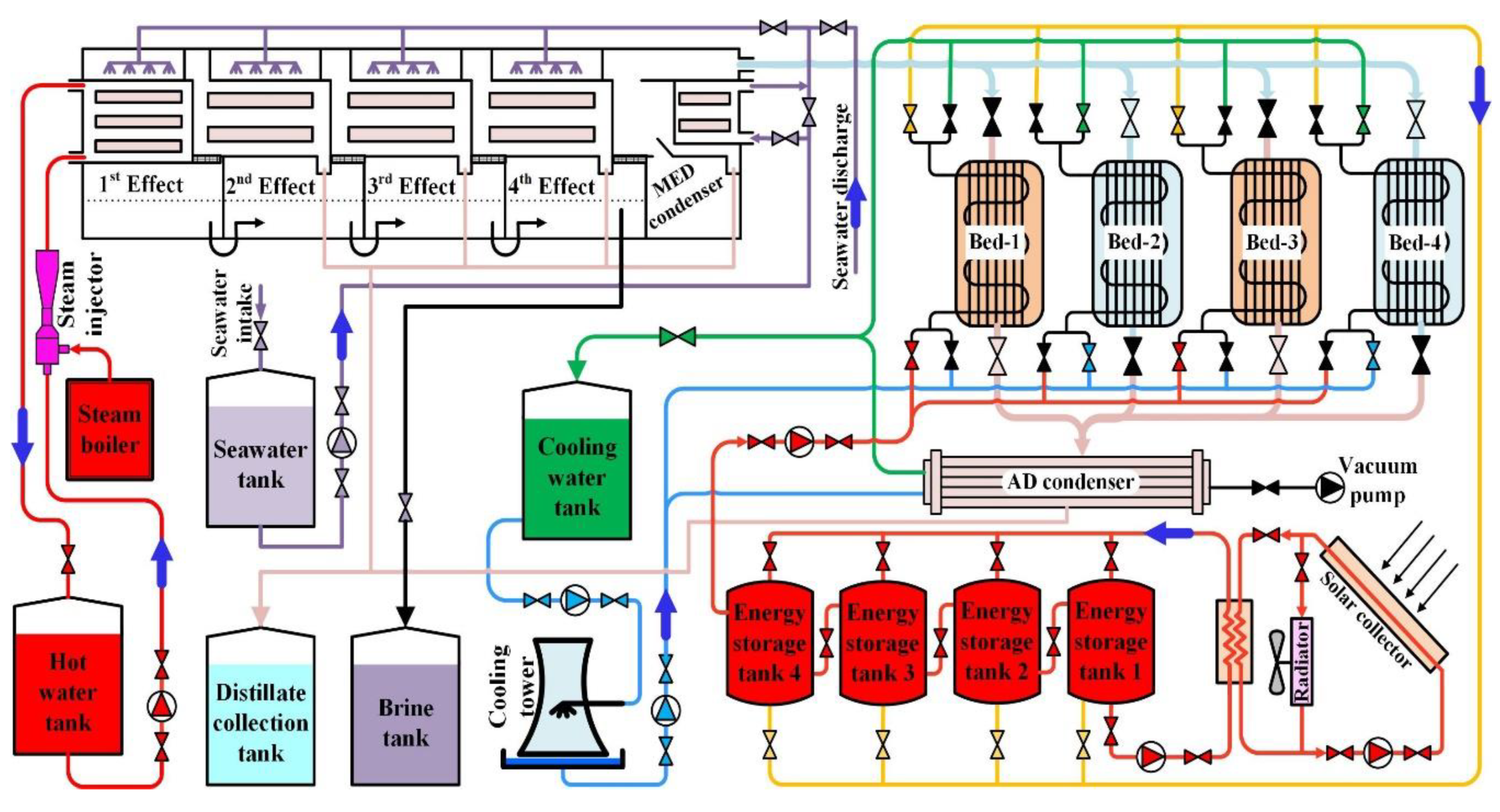

5. Solar Multi-Effect Distillation/Cooling (SMEDC) Systems

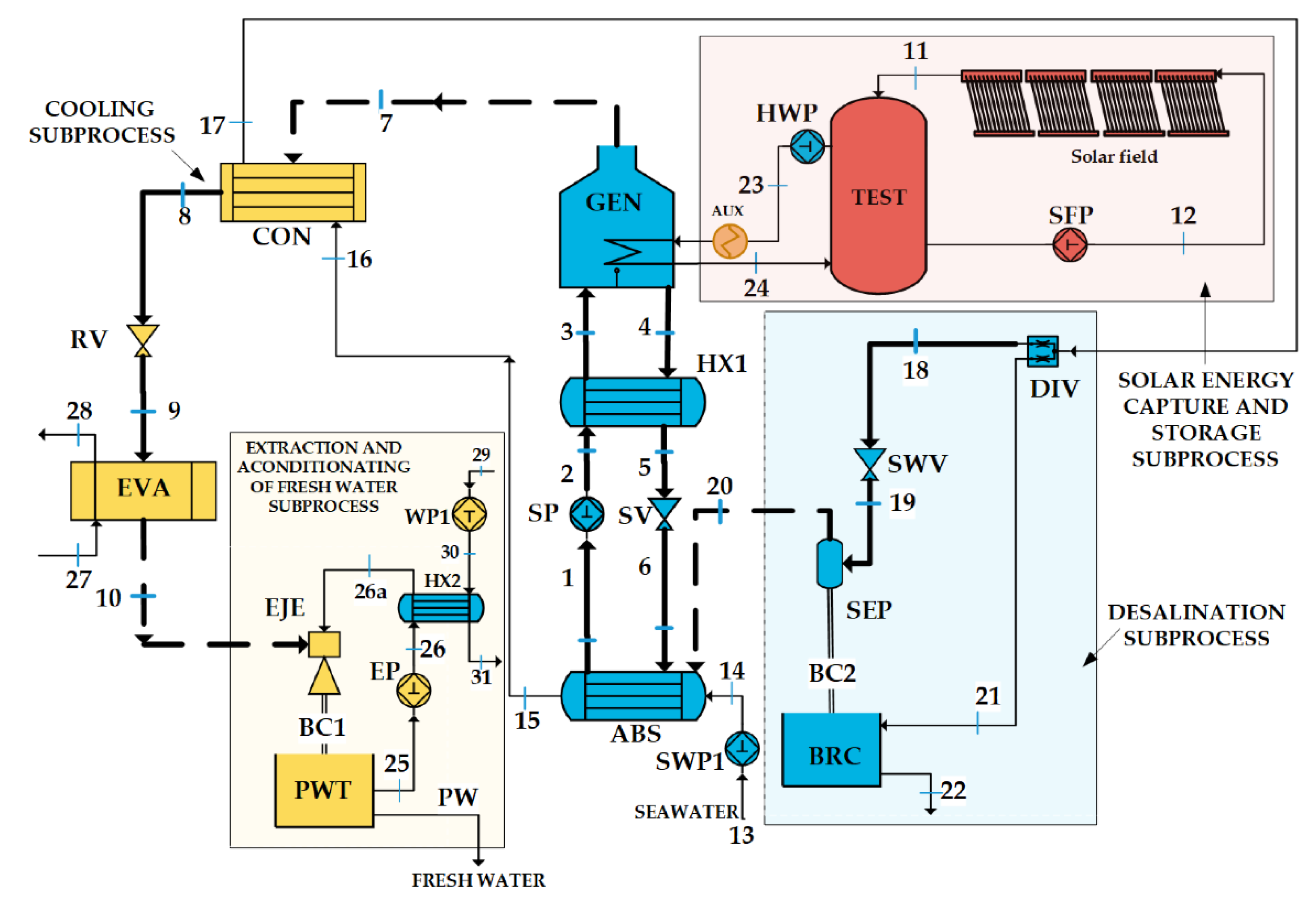

6. Solar Single-Stage Flash/Cooling (SSSFC) Systems

7. Solar Membrane Distillation/Cooling (SMDC) Systems

8. Comparison between Different Reported Hybrid Desalination/Cooling Systems

9. Conclusions and Future Recommendations

Funding

Conflicts of Interest

Abbreviations

| ABR | Absorption Refrigeration |

| ABDC | Absorption Desalination and Cooling |

| AC | Air Conditioning |

| AD | Adsorption Desalination |

| ADC | Adsorption Desalination Cooling |

| Al-Fum | Aluminum Fumarate |

| AWH | Atmospheric Water Harvesting |

| CC | Cooling Capacity |

| COP | Coefficient of Performance |

| EC | Electrical Consumption |

| EEF | Exergy Efficiency |

| ERC | Ejector Refrigeration Cycle |

| EJ | Ejector |

| GT | Gas Turbine |

| GW | Global Warming |

| GOR | Gained Output Ratio |

| HDH | Humidification-Dehumidification |

| HP | Heat Pump |

| HVAC | Heating, Ventilation and Air Conditioning |

| HWT | Hot Water Temperature |

| MD | Membrane Distillation |

| MED | Multi-Effect Distillation |

| MOF | Metal-Organic Frameworks |

| MSF | Multi-Effect Flash |

| MWCNT | Multi-Walled Carbon Nanotube |

| NF | Nano Filtration |

| ORC | Organic Rankine Cycle |

| PCM | Phase Change Material |

| PR | Performance Ratio |

| PTC | Parabolic Trough Collector |

| PV | Photovoltaic |

| PVT | Photovoltaic/Thermal |

| RO | Reverse Osmosis |

| RT | Refrigeration Ton |

| SADDC | Solar Adsorption Desalination/Cooling |

| SDWP | Specific Daily Water Production |

| SC | Solar Collector |

| SCP | Specific Cooling Capacity |

| SEC | Specific Energy Consumption |

| SG | Silica gel |

| SGT | Solar-Driven Gas Turbine |

| SHDC | Solar Humidification-Dehumidification/Cooling |

| SMDC | Solar Membrane Distillation/Cooling |

| SMEDC | Solar Multi-Effect Distillation/Cooling |

| SP | Separate Production |

| SROC | Solar Reverse Osmosis/Cooling |

| SPS | Solar Power System |

| SSF | Single Stage Flash |

| SSDC | Solar Sorption Desalination/Cooling |

| SSSFC | Solar Single-Stage Flash/Cooling |

| SWAC | Seawater Air Conditioning |

| TDS | Total Dissolved Solids |

| TEG | Thermoelectric generator |

| TVC | Thermal Vapor Compression |

| VC | Vapor Compression |

| WP | Water Production |

References

- Aghahosseini, A.; Bogdanov, D.; Breyer, C. Towards Sustainable Development in the MENA Region: Analysing the Feasibility of a 100% Renewable Electricity System in 2030. Energy Strategy Rev. 2020, 28, 100466. [Google Scholar] [CrossRef]

- Al-Ghussain, L. Global Warming: Review on Driving Forces and Mitigation. Environ. Prog. Sustain. Energy 2019, 38, 13–21. [Google Scholar] [CrossRef]

- Wuebbles, D.J.; Jain, A.K. Concerns about Climate Change and the Role of Fossil Fuel Use. Fuel Process. Technol. 2001, 71, 99–119. [Google Scholar] [CrossRef]

- Randazzo, T.; De Cian, E.; Mistry, M.N. Air Conditioning and Electricity Expenditure: The Role of Climate in Temperate Countries. Econ. Model. 2020, 90, 273–287. [Google Scholar] [CrossRef]

- Gleick, P.H. Water in Crisis: A Guide to the World’s Freshwater Resources; Oxford University Press: New York, NY, USA, 1993; Volume 100. [Google Scholar]

- Sosnowski, M.; Krzywanski, J.; Skoczylas, N. Adsorption Desalination and Cooling Systems: Advances in Design, Modeling and Performance. Energies 2022, 15, 4036. [Google Scholar] [CrossRef]

- Ejeian, M.; Wang, R.Z. Adsorption-Based Atmospheric Water Harvesting. Joule 2021, 5, 1678–1703. [Google Scholar] [CrossRef]

- Gado, M.G.; Nasser, M.; Hassan, A.A.; Hassan, H. Adsorption-Based Atmospheric Water Harvesting Powered by Solar Energy: Comprehensive Review on Desiccant Materials and Systems. Process Saf. Environ. Prot. 2022, 160, 166–183. [Google Scholar] [CrossRef]

- Ng, K.C.; Thu, K.; Oh, S.J.; Ang, L.; Shahzad, M.W.; Ismail, A. Bin Recent Developments in Thermally-Driven Seawater Desalination: Energy Efficiency Improvement by Hybridization of the MED and AD Cycles. Desalination 2015, 356, 255–270. [Google Scholar] [CrossRef]

- Qasim, M.; Badrelzaman, M.; Darwish, N.N.; Darwish, N.A.; Hilal, N. Reverse Osmosis Desalination: A State-of-the-Art Review. Desalination 2019, 459, 59–104. [Google Scholar] [CrossRef]

- Shahzad, M.W.; Burhan, M.; Ang, L.; Ng, K.C. Energy-Water-Environment Nexus Underpinning Future Desalination Sustainability. Desalination 2017, 413, 52–64. [Google Scholar] [CrossRef]

- Byrne, P.; Fournaison, L.; Delahaye, A.; Ait Oumeziane, Y.; Serres, L.; Loulergue, P.; Szymczyk, A.; Mugnier, D.; Malaval, J.L.; Bourdais, R.; et al. A Review on the Coupling of Cooling, Desalination and Solar Photovoltaic Systems. Renew. Sustain. Energy Rev. 2015, 47, 703–717. [Google Scholar] [CrossRef]

- Hassan, A.A.; Elwardany, A.E.; Ookawara, S.; Sekiguchi, H.; Hassan, H. Energy, Exergy, Economic and Environmental (4E) Assessment of Hybrid Solar System Powering Adsorption-Parallel/Series ORC Multigeneration System. Process Saf. Environ. Prot. 2022, 164, 761–780. [Google Scholar] [CrossRef]

- Hassan, A.A.; Elwardany, A.E.; Ookawara, S.; El-Sharkawy, I.I. Performance Investigation of a Solar-Powered Adsorption-Based Trigeneration System for Cooling, Electricity, and Domestic Hot Water Production. Appl. Therm. Eng. 2021, 199, 117553. [Google Scholar] [CrossRef]

- Hosenuzzaman, M.; Rahim, N.A.; Selvaraj, J.; Hasanuzzaman, M.; Malek, A.B.M.A.; Nahar, A. Global Prospects, Progress, Policies, and Environmental Impact of Solar Photovoltaic Power Generation. Renew. Sustain. Energy Rev. 2015, 41, 284–297. [Google Scholar] [CrossRef]

- Rahman, A.; Farrok, O.; Haque, M.M. Environmental Impact of Renewable Energy Source Based Electrical Power Plants: Solar, Wind, Hydroelectric, Biomass, Geothermal, Tidal, Ocean, and Osmotic. Renew. Sustain. Energy Rev. 2022, 161, 112279. [Google Scholar] [CrossRef]

- Hassan, A.A.; Elwardany, A.E.; Ookawara, S.; El-Sharkawy, I.I. Performance Investigation of Integrated PVT/Adsorption Cooling System under the Climate Conditions of Middle East. Energy Rep. 2020, 6, 168–173. [Google Scholar] [CrossRef]

- Hassan, A.A.; Elwardany, A.E.; Ookawara, S.; Ahmed, M.; El-Sharkawy, I.I. Integrated Adsorption-Based Multigeneration Systems: A Critical Review and Future Trends. Int. J. Refrig. 2020, 116, 129–145. [Google Scholar] [CrossRef]

- Zaki, O.M.; Mohammed, R.H.; Abdelaziz, O. Separate Sensible and Latent Cooling Technologies: A Comprehensive Review. Energy Convers. Manag. 2022, 256, 115380. [Google Scholar] [CrossRef]

- Ghazy, M.; Ibrahim, E.M.M.; Mohamed, A.S.A.; Askalany, A.A. Cooling Technologies for Enhancing Photovoltaic–Thermal (PVT) Performance: A State of the Art. Int. J. Energy Environ. Eng. 2022. [Google Scholar] [CrossRef]

- She, X.; Cong, L.; Nie, B.; Leng, G.; Peng, H.; Chen, Y.; Zhang, X.; Wen, T.; Yang, H.; Luo, Y. Energy-Efficient and -Economic Technologies for Air Conditioning with Vapor Compression Refrigeration: A Comprehensive Review. Appl. Energy 2018, 232, 157–186. [Google Scholar] [CrossRef]

- Harby, K.; Gebaly, D.R.; Koura, N.S.; Hassan, M.S. Performance Improvement of Vapor Compression Cooling Systems Using Evaporative Condenser: An Overview. Renew. Sustain. Energy Rev. 2016, 58, 347–360. [Google Scholar] [CrossRef]

- Cai, Y.; Wang, Y.; Liu, D.; Zhao, F.Y. Thermoelectric Cooling Technology Applied in the Field of Electronic Devices: Updated Review on the Parametric Investigations and Model Developments. Appl. Therm. Eng. 2019, 148, 238–255. [Google Scholar] [CrossRef]

- Pourkiaei, S.M.; Ahmadi, M.H.; Sadeghzadeh, M.; Moosavi, S.; Pourfayaz, F.; Chen, L.; Pour Yazdi, M.A.; Kumar, R. Thermoelectric Cooler and Thermoelectric Generator Devices: A Review of Present and Potential Applications, Modeling and Materials. Energy 2019, 186, 115849. [Google Scholar] [CrossRef]

- Chauhan, P.R.; Kaushik, S.C.; Tyagi, S.K. Current Status and Technological Advancements in Adsorption Refrigeration Systems: A Review. Renew. Sustain. Energy Rev. 2022, 154, 111808. [Google Scholar] [CrossRef]

- Hara Chakravarty, K.; Sadi, M.; Chakravarty, H.; Sulaiman Alsagri, A.; James Howard, T.; Arabkoohsar, A. A Review on Integration of Renewable Energy Processes in Vapor Absorption Chiller for Sustainable Cooling. Sustain. Energy Technol. Assess. 2022, 50, 101822. [Google Scholar] [CrossRef]

- Kasaeian, A.; Shamaeizadeh, A.; Jamjoo, B. Combinations of Rankine with Ejector Refrigeration Cycles: Recent Progresses and Outlook. Appl. Therm. Eng. 2022, 211, 118382. [Google Scholar] [CrossRef]

- Braimakis, K. Solar Ejector Cooling Systems: A Review. Renew Energy 2021, 164, 566–602. [Google Scholar] [CrossRef]

- Mohammed, R.H.; Ibrahim, M.M.; Abu-Heiba, A. Exergoeconomic and Multi-Objective Optimization Analyses of an Organic Rankine Cycle Integrated with Multi-Effect Desalination for Electricity, Cooling, Heating Power, and Freshwater Production. Energy Convers. Manag. 2021, 231, 113826. [Google Scholar] [CrossRef]

- Elsayed, M.L.; Mesalhy, O.; Mohammed, R.H.; Chow, L.C. Exergy and Thermo-Economic Analysis for MED-TVC Desalination Systems. Desalination 2018, 447, 29–42. [Google Scholar] [CrossRef]

- Shemer, H.; Semiat, R. Sustainable RO Desalination—Energy Demand and Environmental Impact. Desalination 2017, 424, 10–16. [Google Scholar] [CrossRef]

- Sztekler, K.; Kalawa, W.; Mika, L.; Lis, L.; Radomska, E.; Nowak, W. The Effects of Using Steam to Preheat the Beds of an Adsorption Chiller with Desalination Function. Energies 2021, 14, 6454. [Google Scholar] [CrossRef]

- Pan, Q.; Peng, J.; Wang, R. Experimental Study of an Adsorption Chiller for Extra Low Temperature Waste Heat Utilization. Appl. Therm. Eng. 2019, 163, 114341. [Google Scholar] [CrossRef]

- Saha, B.B.; El-Sharkawy, I.I.; Shahzad, M.W.; Thu, K.; Ang, L.; Ng, K.C. Fundamental and Application Aspects of Adsorption Cooling and Desalination. Appl. Therm. Eng. 2016, 97, 68–76. [Google Scholar] [CrossRef]

- Makhanya, N.; Oboirien, B.; Ren, J.; Musyoka, N.; Sciacovelli, A. Recent Advances on Thermal Energy Storage Using Metal-Organic Frameworks (MOFs). J. Energy Storage 2021, 34, 102179. [Google Scholar] [CrossRef]

- Ali, E.S.; Muhammad Asfahan, H.; Sultan, M.; Askalany, A.A. A Novel Ejectors Integration with Two-Stages Adsorption Desalination: Away to Scavenge the Ambient Energy. Sustain. Energy Technol. Assess. 2021, 48, 101658. [Google Scholar] [CrossRef]

- Zohir, A.E.; Ali, E.S.; Farid, A.M.; Elshaer, R.N.; Mohammed, R.H.; Alsaman, A.S.; El-Ghetany, H.H.; Askalany, A.A. A State-of-the-Art of Experimentally Studied Adsorption Water Desalination Systems. Int. J. Energy Environ. Eng. 2022. [Google Scholar] [CrossRef]

- Sztekler, K.; Siwek, T.; Kalawa, W.; Lis, L.; Mika, L.; Radomska, E.; Nowak, W. CFD Analysis of Elements of an Adsorption Chiller with Desalination Function. Energies 2021, 14, 7804. [Google Scholar] [CrossRef]

- Sztekler, K.; Kalawa, W.; Mika, Ł.; Sowa, M. Effect of Metal Additives in the Bed on the Performance Parameters of an Adsorption Chiller with Desalination Function. Energies 2021, 14, 7226. [Google Scholar] [CrossRef]

- Sztekler, K.; Mika, Ł. Increasing the Performance of an Adsorption Chiller Operating in the Water Desalination Mode. Energies 2021, 14, 7743. [Google Scholar] [CrossRef]

- Sztekler, K. Optimisation of Operation of Adsorption Chiller with Desalination Function. Energies 2021, 14, 2668. [Google Scholar] [CrossRef]

- Sztekler, K.; Kalawa, W.; Nowak, W.; Mika, L.; Gradziel, S.; Krzywanski, J.; Radomska, E. Experimental Study of Three-Bed Adsorption Chiller with Desalination Function. Energies 2020, 13, 5827. [Google Scholar] [CrossRef]

- Younes, M.M.; El-Sharkawy, I.I.; Kabeel, A.E.; Saha, B.B. A Review on Adsorbent-Adsorbate Pairs for Cooling Applications. Appl. Therm. Eng. 2017, 114, 394–414. [Google Scholar] [CrossRef]

- Alsaman, A.S.; Ibrahim, E.M.M.; Ahmed, M.S.; Askalany, A.A. Composite Adsorbent Materials for Desalination and Cooling Applications: A State of the Art. Int. J. Energy Res. 2022, 46, 10345–10371. [Google Scholar] [CrossRef]

- Alsaman, A.S.; Ibrahim, E.M.M.; Askalany, A.A.; Farid, A.M.; Ali, E.S.; Ahmed, M.S. Composite Material-Based a Clay for Adsorption Desalination and Cooling Applications. Chem. Eng. Res. Des. 2022, 188, 417–432. [Google Scholar] [CrossRef]

- Alsaman, A.S.; Ibrahim, E.M.M.; Salem Ahmed, M.; Ali, E.S.; Farid, A.M.; Askalany, A.A. Experimental Investigation of Sodium Polyacrylate-Based Innovative Adsorbent Material for Higher Desalination and Cooling Effects. Energy Convers. Manag. 2022, 266, 115818. [Google Scholar] [CrossRef]

- Alsaman, A.S.; Askalany, A.A.; Ibrahim, E.M.M.; Farid, A.M.; Ali, E.S.; Ahmed, M.S. Characterization and Cost Analysis of a Modified Silica Gel-Based Adsorption Desalination Application. J. Clean. Prod. 2022, 379, 134614. [Google Scholar] [CrossRef]

- Rocky, K.A.; Pal, A.; Rupam, T.H.; Palash, M.L.; Saha, B.B. Recent Advances of Composite Adsorbents for Heat Transformation Applications. Therm. Sci. Eng. Prog. 2021, 23, 100900. [Google Scholar] [CrossRef]

- Mohammed, R.H.; Rezk, A.; Askalany, A.; Ali, E.S.; Zohir, A.E.; Sultan, M.; Ghazy, M.; Abdelkareem, M.A.; Olabi, A.G. Metal-Organic Frameworks in Cooling and Water Desalination: Synthesis and Application. Renew. Sustain. Energy Rev. 2021, 149, 111362. [Google Scholar] [CrossRef]

- Ali, E.S.; Mohammed, R.H.; Zohir, A.E.; Farid, A.M.; Elshaer, R.N.; El-Ghetany, H.H.; Askalany, A.A. Novel Ultrasonic Dynamic Vapor Sorption Apparatus for Adsorption Drying, Cooling and Desalination Applications. Energy Rep. 2022, 8, 8798–8804. [Google Scholar] [CrossRef]

- Sztekler, K.; Mlonka-Mędrala, A.; Khdary, N.H.; Kalawa, W.; Nowak, W.; Mika, Ł. Possibility of Advanced Modified-Silica-Based Porous Materials Utilisation in Water Adsorption Processes—A Comparative Study. Energies 2022, 15, 368. [Google Scholar] [CrossRef]

- Solovyeva, M.; Krivosheeva, I.; Gordeeva, L.; Aristov, Y. MIL-160 as an Adsorbent for Atmospheric Water Harvesting. Energies 2021, 14, 3586. [Google Scholar] [CrossRef]

- Ng, K.C.; Thu, K.; Chakraborty, A.; Saha, B.B.; Chun, W.G. Solar-Assisted Dual-Effect Adsorption Cycle for the Production of Cooling Effect and Potable Water. Int. J. Low-Carbon Technol. 2009, 4, 61–67. [Google Scholar] [CrossRef]

- Alsaman, A.S.; Askalany, A.A.; Harby, K.; Ahmed, M.S. Performance Evaluation of a Solar-Driven Adsorption Desalination-Cooling System. Energy 2017, 128, 196–207. [Google Scholar] [CrossRef]

- Ali, E.S.; Harby, K.; Askalany, A.A.; Diab, M.R.; Alsaman, A.S. Weather Effect on a Solar Powered Hybrid Adsorption Desalination-Cooling System: A Case Study of Egypt’s Climate. Appl. Therm. Eng. 2017, 124, 663–672. [Google Scholar] [CrossRef]

- Elsheniti, M.B.; Rezk, A.; Shaaban, M.; Roshdy, M.; Nagib, Y.M.; Elsamni, O.A.; Saha, B.B. Performance of a Solar Adsorption Cooling and Desalination System Using Aluminum Fumarate and Silica Gel. Appl. Therm. Eng. 2021, 194, 117116. [Google Scholar] [CrossRef]

- Raj, R.; Baiju, V. Thermodynamic Analysis of a Solar Powered Adsorption Cooling and Desalination System. Energy Procedia 2019, 158, 885–891. [Google Scholar] [CrossRef]

- Ng, K.C.; Thu, K.; Saha, B.B.; Chakraborty, A. Study on a Waste Heat-Driven Adsorption Cooling Cum Desalination Cycle. Int. J. Refrig. 2012, 35, 685–693. [Google Scholar] [CrossRef]

- Olkis, C.; Brandani, S.; Santori, G. Cycle and Performance Analysis of a Small-Scale Adsorption Heat Transformer for Desalination and Cooling Applications. Chem. Eng. J. 2019, 378, 122104. [Google Scholar] [CrossRef]

- Olkis, C.; Brandani, S.; Santori, G. Design and Experimental Study of a Small Scale Adsorption Desalinator. Appl. Energy 2019, 253, 113584. [Google Scholar] [CrossRef]

- Ghaffour, N.; Lattemann, S.; Missimer, T.; Ng, K.C.; Sinha, S.; Amy, G. Renewable Energy-Driven Innovative Energy-Efficient Desalination Technologies. Appl. Energy 2014, 136, 1155–1165. [Google Scholar] [CrossRef]

- Mitra, S.; Srinivasan, K.; Kumar, P.; Murthy, S.S.; Dutta, P. Solar Driven Adsorption Desalination System. Energy Procedia 2014, 49, 2261–2269. [Google Scholar] [CrossRef]

- Youssef, P.G.; Al-Dadah, R.K.; Mahmoud, S.M.; Dakkama, H.J.; Elsayed, A. Effect of Evaporator and Condenser Temperatures on the Performance of Adsorption Desalination Cooling Cycle. Energy Procedia 2015, 75, 1464–1469. [Google Scholar] [CrossRef]

- Youssef, P.G.; Mahmoud, S.M.; AL-Dadah, R.K. Performance Analysis of Four Bed Adsorption Water Desalination/Refrigeration System, Comparison of AQSOA-Z02 to Silica-Gel. Desalination 2015, 375, 100–107. [Google Scholar] [CrossRef]

- Wang, X.; Ng, K.C. Experimental Investigation of an Adsorption Desalination Plant Using Low-Temperature Waste Heat. Appl. Therm. Eng. 2005, 25, 2780–2789. [Google Scholar] [CrossRef]

- Ali, E.S.; Mohammed, R.H.; Askalany, A. A Daily Freshwater Production of 50 M3/Ton of Silica Gel Using an Adsorption-Ejector Combination Powered by Low-Grade Heat. J. Clean. Prod. 2021, 282, 124494. [Google Scholar] [CrossRef]

- Li, M.; Zhao, Y.; Long, R.; Liu, Z.; Liu, W. Field Synergy Analysis for Heat and Mass Transfer Characteristics in Adsorption-Based Desalination and Cooling Systems. Desalination 2021, 517, 115244. [Google Scholar] [CrossRef]

- Naeimi, A.; Nowee, S.M.; Akhlaghi Amiri, H.A. Numerical Simulation and Theoretical Investigation of a Multi-Cycle Dual-Evaporator Adsorption Desalination and Cooling System. Chem. Eng. Res. Des. 2020, 156, 402–413. [Google Scholar] [CrossRef]

- Woo, S.Y.; Lee, H.S.; Ji, H.; Moon, D.S.; Kim, Y.D. Silica Gel-Based Adsorption Cooling Cum Desalination System: Focus on Brine Salinity, Operating Pressure, and Its Effect on Performance. Desalination 2019, 467, 136–146. [Google Scholar] [CrossRef]

- Albaik, I.; Al-Dadah, R.; Mahmoud, S.; Solmaz, İ. Non-Equilibrium Numerical Modelling of Finned Tube Heat Exchanger for Adsorption Desalination/Cooling System Using Segregated Solution Approach. Appl. Therm. Eng. 2021, 183, 116171. [Google Scholar] [CrossRef]

- Li, M.; Zhao, Y.; Long, R.; Liu, Z.; Liu, W. Computational Fluid Dynamic Study on Adsorption-Based Desalination and Cooling Systems with Stepwise Porosity Distribution. Desalination 2021, 508, 115048. [Google Scholar] [CrossRef]

- Thu, K.; Saha, B.B.; Chua, K.J.; Ng, K.C. Performance Investigation of a Waste Heat-Driven 3-Bed 2-Evaporator Adsorption Cycle for Cooling and Desalination. Int. J. Heat Mass Transf. 2016, 101, 1111–1122. [Google Scholar] [CrossRef]

- Elsayed, E.; AL-Dadah, R.; Mahmoud, S.; Anderson, P.; Elsayed, A. Experimental Testing of Aluminium Fumarate MOF for Adsorption Desalination. Desalination 2020, 475, 114170. [Google Scholar] [CrossRef]

- Albaik, I.; Badawy Elsheniti, M.; Al-Dadah, R.; Mahmoud, S.; Solmaz, İ. Numerical and Experimental Investigation of Multiple Heat Exchanger Modules in Cooling and Desalination Adsorption System Using Metal Organic Framework. Energy Convers. Manag. 2022, 251, 114934. [Google Scholar] [CrossRef]

- Youssef, P.G.; Dakkama, H.; Mahmoud, S.M.; AL-Dadah, R.K. Experimental Investigation of Adsorption Water Desalination/Cooling System Using CPO-27Ni MOF. Desalination 2017, 404, 192–199. [Google Scholar] [CrossRef]

- Shaaban, M.; Elsheniti, M.B.; Rezk, A.; Elhelw, M.; Elsamni, O.A. Performance Investigation of Adsorption Cooling and Desalination Systems Employing Thermally Enhanced Copper Foamed Bed Coated with SAPO-34 and CPO-27(Ni). Appl. Therm. Eng. 2022, 205, 118056. [Google Scholar] [CrossRef]

- Ghazy, M.; Askalany, A.A.; Ibrahim, E.M.M.; Mohamed, A.S.A.; Ali, E.S.; AL-Dadah, R. Solar Powered Adsorption Desalination System Employing CPO-27(Ni). J. Energy Storage 2022, 53, 105174. [Google Scholar] [CrossRef]

- Ghazy, M.; Ibrahim, E.M.M.; Mohamed, A.S.A.; Askalany, A.A. Experimental Investigation of Hybrid Photovoltaic Solar Thermal Collector (PV/T)-Adsorption Desalination System in Hot Weather Conditions. Energy 2022, 254, 124370. [Google Scholar] [CrossRef]

- Woo, S.Y.; Lee, H.S.; Kim, J.S.; Kim, K.H.; Ji, H.; Kim, Y.D. Applicability Assessment of Functional Adsorption Zeolite Materials in Adsorption Desalination Cum Cooling Systems Driven by Low-Grade Heat Source. Chem. Eng. J. 2022, 430, 131375. [Google Scholar] [CrossRef]

- Ali, S.M.; Chakraborty, A. Adsorption Assisted Double Stage Cooling and Desalination Employing Silica Gel + Water and AQSOA-Z02 + Water Systems. Energy Convers. Manag. 2016, 117, 193–205. [Google Scholar] [CrossRef]

- Bai, S.; Ho, T.C.; Ha, J.; An, A.K.; Tso, C.Y. Study of the Salinity Effects on the Cooling and Desalination Performance of an Adsorption Cooling Cum Desalination System with a Novel Composite Adsorbent. Appl. Therm. Eng. 2020, 181, 115879. [Google Scholar] [CrossRef]

- Ali, E.S.; Askalany, A.A.; Harby, K.; Diab, M.R.; Hussein, B.R.M.; Alsaman, A.S. Experimental Adsorption Water Desalination System Utilizing Activated Clay for Low Grade Heat Source Applications. J. Energy Storage 2021, 43, 103219. [Google Scholar] [CrossRef]

- Mito, M.T.; Ma, X.; Albuflasa, H.; Davies, P.A. Reverse Osmosis (RO) Membrane Desalination Driven by Wind and Solar Photovoltaic (PV) Energy: State of the Art and Challenges for Large-Scale Implementation. Renew. Sustain. Energy Rev. 2019, 112, 669–685. [Google Scholar] [CrossRef]

- Ali, E.S.; Alsaman, A.S.; Harby, K.; Askalany, A.A.; Diab, M.R.; Ebrahim Yakoot, S.M. Recycling Brine Water of Reverse Osmosis Desalination Employing Adsorption Desalination: A Theoretical Simulation. Desalination 2017, 408, 13–24. [Google Scholar] [CrossRef]

- Hassan, A.A.; Elwardany, A.E.; Ookawara, S.; Sekiguchi, H.; Hassan, H. Performance and Economic Analysis of Hybrid Solar Collectors-Powered Integrated Adsorption/Reverse Osmosis Multigeneration System. Int. J. Energy Res. 2022, 46, 19414–19437. [Google Scholar] [CrossRef]

- Harby, K.; Ali, E.S.; Almohammadi, K.M. A Novel Combined Reverse Osmosis and Hybrid Absorption Desalination-Cooling System to Increase Overall Water Recovery and Energy Efficiency. J. Clean. Prod. 2021, 287, 125014. [Google Scholar] [CrossRef]

- Hunt, J.D.; Weber, N.d.A.B.; Zakeri, B.; Diaby, A.T.; Byrne, P.; Filho, W.L.; Schneider, P.S. Deep Seawater Cooling and Desalination: Combining Seawater Air Conditioning and Desalination. Sustain. Cities Soc. 2021, 74, 103257. [Google Scholar] [CrossRef]

- Hussain, J. HUSSAIN Development of a Hybrid Powerplant for Kuwait: The Simultaneous Production of Power, Fresh Water and Cooling; Cranfield University: Bedford, UK, 2006. [Google Scholar]

- Assareh, E.; Alirahmi, S.M.; Ahmadi, P. A Sustainable Model for the Integration of Solar and Geothermal Energy Boosted with Thermoelectric Generators (TEGs) for Electricity, Cooling and Desalination Purpose. Geothermics 2021, 92, 102042. [Google Scholar] [CrossRef]

- Abbasi, H.R.; Pourrahmani, H. Multi-Objective Optimization and Exergoeconomic Analysis of a Continuous Solar-Driven System with PCM for Power, Cooling and Freshwater Production. Energy Convers. Manag. 2020, 211, 112761. [Google Scholar] [CrossRef]

- Faegh, M.; Behnam, P.; Shafii, M.B. A Review on Recent Advances in Humidification-Dehumidification (HDH) Desalination Systems Integrated with Refrigeration, Power and Desalination Technologies. Energy Convers. Manag. 2019, 196, 1002–1036. [Google Scholar] [CrossRef]

- Giwa, A.; Akther, N.; Al Housani, A.; Haris, S.; Hasan, S.W. Recent Advances in Humidification Dehumidification (HDH) Desalination Processes: Improved Designs and Productivity. Renew. Sustain. Energy Rev. 2016, 57, 929–944. [Google Scholar] [CrossRef]

- Nada, S.A.; Elattar, H.F.; Fouda, A. Experimental Study for Hybrid Humidification-Dehumidification Water Desalination and Air Conditioning System. Desalination 2015, 363, 112–125. [Google Scholar] [CrossRef]

- Elattar, H.F.; Fouda, A.; Nada, S.A. Performance Investigation of a Novel Solar Hybrid Air Conditioning and Humidification-Dehumidification Water Desalination System. Desalination 2016, 382, 28–42. [Google Scholar] [CrossRef]

- Fouda, A.; Nada, S.A.; Elattar, H.F. An Integrated A/C and HDH Water Desalination System Assisted by Solar Energy: Transient Analysis and Economical Study. Appl. Therm. Eng. 2016, 108, 1320–1335. [Google Scholar] [CrossRef]

- Nada, S.A.; Elattar, H.F.; Fouda, A. Performance Analysis of Proposed Hybrid Air Conditioning and Humidification-Dehumidification Systems for Energy Saving and Water Production in Hot and Dry Climatic Regions. Energy Convers. Manag. 2015, 96, 208–227. [Google Scholar] [CrossRef]

- Chiranjeevi, C.; Srinivas, T. Combined Two Stage Desalination and Cooling Plant. Desalination 2014, 345, 56–63. [Google Scholar] [CrossRef]

- Chiranjeevi, C.; Srinivas, T. Experimental and Simulation Studies on Two Stage Humidification-Dehumidification Desalination and Cooling Plant. Desalination 2015, 376, 9–16. [Google Scholar] [CrossRef]

- Chiranjeevi, C.; Srinivas, T. Influence of Vapor Absorption Cooling on Humidification-Dehumidification (HDH) Desalination. Alex. Eng. J. 2016, 55, 1961–1967. [Google Scholar] [CrossRef]

- Chiranjeevi, C.; Srinivas, T. Dessalement Augmenté Avec Refroidissement. Int. J. Refrig. 2017, 80, 106–119. [Google Scholar] [CrossRef]

- Picinardi, A. Cogeneration of Cooling Energy and Fresh Water; University of Bergamo: Bergamo, Italy, 2011. [Google Scholar]

- Almahmoud, H.A.; Al-Sulaiman, F.A.; Ibrahim, N.I.; Ben Mansour, R.; Alkhulaifi, Y.M. Energetic Performance Analysis of a Solar-Driven Hybrid Ejector Cooling and Humidification-Dehumidification Desalination System. Energy 2021, 230, 120849. [Google Scholar] [CrossRef]

- Elbassoussi, M.H.; Mohammed, R.H.; Zubair, S.M. Thermoeconomic Assessment of an Adsorption Cooling/Desalination Cycle Coupled with a Water-Heated Humidification-Dehumidification Desalination Unit. Energy Convers. Manag. 2020, 223, 113270. [Google Scholar] [CrossRef]

- Ali, E.S.; Mohammed, R.H.; Qasem, N.A.A.; Zubair, S.M.; Askalany, A. Solar-Powered Ejector-Based Adsorption Desalination System Integrated with a Humidification-Dehumidification System. Energy Convers. Manag. 2021, 238, 114113. [Google Scholar] [CrossRef]

- Al-Mahmoud, H.A.; Ibrahim, N.I.; Al-Sulaiman, F.A.; Zubair, S.M. Thermodynamic Performance Evaluation of a Hybrid Ejector Cooling and Humidification-Dehumidification Desalination System. Energy Convers. Manag. 2020, 225, 113450. [Google Scholar] [CrossRef]

- Ghiasirad, H.; Asgari, N.; Khoshbakhti Saray, R.; Mirmasoumi, S. Thermoeconomic Assessment of a Geothermal Based Combined Cooling, Heating, and Power System, Integrated with a Humidification-Dehumidification Desalination Unit and an Absorption Heat Transformer. Energy Convers. Manag. 2021, 235, 113969. [Google Scholar] [CrossRef]

- Sadeghi, M.; Yari, M.; Mahmoudi, S.M.S.; Jafari, M. Thermodynamic Analysis and Optimization of a Novel Combined Power and Ejector Refrigeration Cycle—Desalination System. Appl. Energy 2017, 208, 239–251. [Google Scholar] [CrossRef]

- Habeebullah, B. Performance Analysis of a Combined Heat Pump-Dehumidifying System. J. King Abdulaziz Univ. Eng. Sci. 2010, 21, 97–114. [Google Scholar] [CrossRef]

- Nada, S.A.; Fouda, A.; Mahmoud, M.A.; Elattar, H.F. Experimental Investigation of Air-Conditioning and HDH Desalination Hybrid System Using New Packing Pad Humidifier and Strips-Finned Helical Coil. Appl. Therm. Eng. 2021, 185, 116433. [Google Scholar] [CrossRef]

- Xu, H.; Zhao, Y.; Jia, T.; Dai, Y.J. Experimental Investigation on a Solar Assisted Heat Pump Desalination System with Humidification-Dehumidification. Desalination 2018, 437, 89–99. [Google Scholar] [CrossRef]

- Lawal, D.U.; Antar, M.A.; Khalifa, A.; Zubair, S.M.; Al-Sulaiman, F. Experımental Investigation of Heat Pump Driven Humidification-Dehumidification Desalination System for Water Desalination and Space Conditioning. Desalination 2020, 475, 114199. [Google Scholar] [CrossRef]

- El-Dessouky, H.T.; Ettouney, H.M. Fundamentals of Salt Water Desalination; Elsevier: Amsterdam, The Netherlands, 2002; ISBN 9780444508102. [Google Scholar]

- Abdelhay, A.O.; Fath, H.E.S.; Nada, S.A. Solar Driven Polygeneration System for Power, Desalination and Cooling. Energy 2020, 198, 117341. [Google Scholar] [CrossRef]

- Kerme, E.D.; Orfi, J.; Fung, A.S.; Salilih, E.M.; Khan, S.U.D.; Alshehri, H.; Ali, E.; Alrasheed, M. Energetic and Exergetic Performance Analysis of a Solar Driven Power, Desalination and Cooling Poly-Generation System. Energy 2020, 196, 117150. [Google Scholar] [CrossRef]

- Mehrpooya, M.; Ghorbani, B.; Hosseini, S.S. Thermodynamic and Economic Evaluation of a Novel Concentrated Solar Power System Integrated with Absorption Refrigeration and Desalination Cycles. Energy Convers. Manag. 2018, 175, 337–356. [Google Scholar] [CrossRef]

- Sahoo, U.; Kumar, R.; Pant, P.C.; Chaudhury, R. Scope and Sustainability of Hybrid Solar-Biomass Power Plant with Cooling, Desalination in Polygeneration Process in India. Renew. Sustain. Energy Rev. 2015, 51, 304–316. [Google Scholar] [CrossRef]

- Sahoo, U.; Kumar, R.; Pant, P.C.; Chaudhary, R. Development of an Innovative Polygeneration Process in Hybrid Solar-Biomass System for Combined Power, Cooling and Desalination. Appl. Therm. Eng. 2017, 120, 560–567. [Google Scholar] [CrossRef]

- Aly, S.; Jawad, J.; Manzoor, H.; Simson, S.; Lawler, J.; Mabrouk, A.N. Pilot Testing of a Novel Integrated Multi Effect Distillation—Absorber Compressor (MED-AB) Technology for High Performance Seawater Desalination. Desalination 2022, 521, 115388. [Google Scholar] [CrossRef]

- Son, H.S.; Shahzad, M.W.; Ghaffour, N.; Ng, K.C. Pilot Studies on Synergetic Impacts of Energy Utilization in Hybrid Desalination System: Multi-Effect Distillation and Adsorption Cycle (MED-AD). Desalination 2020, 477, 114266. [Google Scholar] [CrossRef]

- Raluy, G.; Serra, L.; Uche, J. Life Cycle Assessment of MSF, MED and RO Desalination Technologies. Energy 2006, 31, 2361–2372. [Google Scholar] [CrossRef]

- Elsaid, K.; Kamil, M.; Sayed, E.T.; Abdelkareem, M.A.; Wilberforce, T.; Olabi, A. Environmental Impact of Desalination Technologies: A Review. Sci. Total Environ. 2020, 748, 141528. [Google Scholar] [CrossRef]

- Joseph, J.; Saravanan, R.; Renganarayanan, S. Studies on a Single-Stage Solar Desalination System for Domestic Applications. Desalination 2005, 173, 77–82. [Google Scholar] [CrossRef]

- Maroo, S.C.; Goswami, D.Y. Theoretical Analysis of a Single-Stage and Two-Stage Solar Driven Flash Desalination System Based on Passive Vacuum Generation. Desalination 2009, 249, 635–646. [Google Scholar] [CrossRef]

- Hogerwaard, J.; Dincer, I.; Naterer, G.F. Solar Energy Based Integrated System for Power Generation, Refrigeration and Desalination. Appl. Therm. Eng. 2017, 121, 1059–1069. [Google Scholar] [CrossRef]

- Velázquez-Limón, N.; López-Zavala, R.; Hernández-Callejo, L.; Aguilar-Jiménez, J.A.; Ojeda-Benítez, S.; Ríos-Arriola, J. Study of a Hybrid Solar Absorption-Cooling and Flash-Desalination System. Energies 2020, 13, 3943. [Google Scholar] [CrossRef]

- Yadav, A.; Labhasetwar, P.K.; Shahi, V.K. Membrane Distillation Using Low-Grade Energy for Desalination: A Review. J. Environ. Chem. Eng. 2021, 9, 105818. [Google Scholar] [CrossRef]

- Ma, Q.; Xu, Z.; Wang, R. Distributed Solar Desalination by Membrane Distillation: Current Status and Future Perspectives. Water Res. 2021, 198, 117154. [Google Scholar] [CrossRef] [PubMed]

- Mohan, G.; Kumar, U.; Pokhrel, M.K.; Martin, A. A Novel Solar Thermal Polygeneration System for Sustainable Production of Cooling, Clean Water and Domestic Hot Water in United Arab Emirates: Dynamic Simulation and Economic Evaluation. Appl. Energy 2016, 167, 173–188. [Google Scholar] [CrossRef]

- Byrne, P.; Ait Oumeziane, Y.; Serres, L.; Mare, T. Study of a Heat Pump for Simultaneous Cooling and Desalination. Appl. Mech. Mater. 2016, 819, 152–159. [Google Scholar] [CrossRef]

- Shafieian, A.; Khiadani, M. A Multipurpose Desalination, Cooling, and Air-Conditioning System Powered by Waste Heat Recovery from Diesel Exhaust Fumes and Cooling Water. Case Stud. Therm. Eng. 2020, 21, 100702. [Google Scholar] [CrossRef]

- Ayou, D.S.; Zaragoza, G.; Coronas, A. Small-Scale Renewable Polygeneration System for off-Grid Applications: Desalination, Power Generation and Space Cooling. Appl. Therm. Eng. 2021, 182, 116112. [Google Scholar] [CrossRef]

| Refs. | Adsorbent Material | No. of Beds | HWT (°C) | SDWP (m3/ton) | SCP (W/kg) | COP (-) |

|---|---|---|---|---|---|---|

| Ng et al. [53] | SG | 4 | 85 | 7.2 | 168 | 0.62 |

| Alsaman et al. [54] | SG | 2 | 85 | 4 | 112 | 0.45 |

| Ali et al. [55] | SG | 2 | 85 | 10 | 134 | 0.5 |

| Ng et al. [58] | SG | 4 | 85 | 8 | 181 | - |

| Olkis et al. [59,60] | SG | 2 | 80 | 7.7 | 80 | 0.6 |

| Ghaffour et al. [61] | SG | 2 | 85 | 12 | 88 | - |

| Mitra et al. [62] | SG | 4 | 85 | 2.3 | 63 | 0.5 |

| Youssef et al. [63] | SG | 2 | 85 | 10 | 270 | 0.52 |

| Youssef et al. [64] | SG | 4 | 85 | 3.5 | 53 | - |

| Wang et al. [65] | SG | 4 | 85 | 4.7 | - | 0.34 |

| Ali et al. [66] | SG | 2 | 85 | 12 | 220 | 0.29 |

| Ali et al. [36] | SG | 4 | 85 | 9 | 200 | 0.58 |

| Li et al. [67] | SG | 2 | 85 | 12.5 | 363 | - |

| Naeimi et al. [68] | SG | 8 | 85 | 9.6 | 88 | - |

| Woo et al. [69] | SG | 2 | 85 | 6.76 | 130 | - |

| Albaik et al. [70] | SG | 2 | 85 | 23 | 1322.6 | - |

| Li et al. [71] | SG RD | 2 | 85 | 7.5 | 219 | 0.7 |

| Thu et al. [72] | SG A++ | 3 | 85 | 6.5 | 110 | 0.84 |

| Elsheniti et al. [56] | Aluminum fumarate | 2 | 85 | 2.2 | 185 | 0.65 |

| Elsayed et al. [73] | Aluminum fumarate | 2 | 90 | 8.5 | 250 | 0.13 |

| Albaik et al. [74] | Aluminum fumarate | 2 | 85 | 8.7 | 226 | 0.5 |

| Youssef et al. [75] | CPO-27(Ni) | 1 | 110 | 6.9 | 200 | - |

| Shaaban et al. [76] | CPO-27(Ni) | 2 | 70–100 | 4.7–29.3 | 132–821 | 0.2–0.421 |

| Ghazy et al. [77,78] | CPO-27(Ni) | 2 | 5–6.3 | 152.2 | 0.25 | |

| Woo et al. [79] | FAM-Z02 | 2 | 80 | 10 | 265 | 0.4 |

| Youssef et al. [64] | AQSOA-Z02 | 4 | 85 | 6.2 | 188 | - |

| Ali and Chakraborty [80] | AQSOA-Z02 | 4 | 85 | 7.88 | 168 | - |

| Bai et al. [81] | MWCNT embedded zeolite 13X/CaCl2 | 2 | 85 | 18 | 490 | 0.3 |

| Shaaban et al. [76] | SAPO-34 | 2 | 70–100 | 14–31 | 393–855 | 0.378–0.388 |

| Ali et al. [82] | Montmorillonite | 2 | 85 | 4.4 | 110 | 0.41 |

| Alsaman et al. [45] | Bentonite/CaCl2 | 2 | 85 | 11.5 | 326 | 0.52 |

| Alsaman et al. [46] | Sodium polyacrylate/CaCl2 | 2 | 85 | 15 | 425 | 0.71 |

| Alsaman et al. [47] | SG/CaCl2 | 2 | 85 | 23.3 | 660 | 0.71 |

| Refs. | System | WP | CC | COP | GOR | EC | WP Cost |

|---|---|---|---|---|---|---|---|

| Ng et al. [53] | SADDC | 3–5 m3/tonSG.day | 25–35 RT/tonSG | 1.5 kWh/m3 | 0.489 $/m3 | ||

| Alsaman et al. [54] | SADDC | 4 m3/tonSG.day | 112 W/kgSG | 0.45 | |||

| Ali et al. [55] | SADDC | 10 m3/tonSG.day | 134 W/kgSG | 0.5 | |||

| Ali et al. [84] | RO-ADC | 25% improvement | 100 W/kgSG | 0.46 | |||

| Harby et al. [86] | RO-ABDC | 13.89 m3/day | 0.346 kW | 0.77 | 2.75 kWh/m3 | ||

| Hunt et al. [87] | RO-SWAC | 1 m3/s | 49 MW | 12 MW | |||

| Assareh et al. [89] | RO-ABR | 240.23 m3 | |||||

| Abbasi et al. [90] | RO-ABR | 5209.5 m3/day | 1.62 MW | 31.008 ¢/m3 | |||

| Almahmoud et al. [102] | HDH-ERC | 245–270 L/day | 0.55 | 2.76 | |||

| Elbassoussi et al. [103] | HDH-AD | 21.75 kg/h | 2.53 kW | 0.46 | 2.5 | 1.15 ¢/m3 | |

| Ali et al. [66,104] | HDH-AD2EJ | 83.1 m3/tonSG.day | 220 W/kgSG | 1.47 | 2.76 | 1.49 $/m3 | |

| Ghiasirad et al. [106] | HDH-ABR | 92.1 m3/day | 4991 kW | 0.476 | 0.6072 $/m3 | ||

| Sadeghi et al. [107] | HDH-ERC | 120.4 kW | 1.9 | ||||

| Habeebullah [108] | HDH-HP | 0.618–2.23 m3/day | 23 $/m3 | ||||

| Nada et al. [109] | HDH-AC | 17.42 kg/h | 3.9 kW | 4.35 | 0.7 ¢/kg | ||

| Xu et al. [110] | HDH-HP | 12.75 kg/h | 1.24 | 1.03 kW | 29.78 $/ton | ||

| Lawal et al. [111] | HDH-HP | 287.8 L/day | 3.07 kW | 4.85 | 4.07 | 160.16 kWh/m3 | 10.68–20.39 $/m3 |

| Abdelhay et al. [113] | SPS-ABR-MED | 550 m3/day | 7737 kW | 0.77 | 1.247 $/m3 | ||

| Mehrpooya et al. [115] | MED-ABR | 22.79 kg/s | 820.8 kW | 0.611 | |||

| Aly et al. [118] | MED-ABR | 25 m3/day | 4.8 kWh/m3 | 0.455 $/m3 | |||

| Ghaffour et al. [61] | MD-AD | 8 m3/day | 1.5 kWh/m3 | ||||

| Shafieian et al. [130] | MD-ABR | 160 kW | 0.83–0.88 | ||||

| Ayou et al. [131] | MD-ABR | 41.4 m3/day | 130 kW |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alsaman, A.S.; Hassan, A.A.; Ali, E.S.; Mohammed, R.H.; Zohir, A.E.; Farid, A.M.; Eraqi, A.M.Z.; El-Ghetany, H.H.; Askalany, A.A. Hybrid Solar-Driven Desalination/Cooling Systems: Current Situation and Future Trend. Energies 2022, 15, 8099. https://doi.org/10.3390/en15218099

Alsaman AS, Hassan AA, Ali ES, Mohammed RH, Zohir AE, Farid AM, Eraqi AMZ, El-Ghetany HH, Askalany AA. Hybrid Solar-Driven Desalination/Cooling Systems: Current Situation and Future Trend. Energies. 2022; 15(21):8099. https://doi.org/10.3390/en15218099

Chicago/Turabian StyleAlsaman, Ahmed S., Ahmed A. Hassan, Ehab S. Ali, Ramy H. Mohammed, Alaa E. Zohir, Ayman M. Farid, Ayman M. Zakaria Eraqi, Hamdy H. El-Ghetany, and Ahmed A. Askalany. 2022. "Hybrid Solar-Driven Desalination/Cooling Systems: Current Situation and Future Trend" Energies 15, no. 21: 8099. https://doi.org/10.3390/en15218099

APA StyleAlsaman, A. S., Hassan, A. A., Ali, E. S., Mohammed, R. H., Zohir, A. E., Farid, A. M., Eraqi, A. M. Z., El-Ghetany, H. H., & Askalany, A. A. (2022). Hybrid Solar-Driven Desalination/Cooling Systems: Current Situation and Future Trend. Energies, 15(21), 8099. https://doi.org/10.3390/en15218099