The Transient Thermal Disturbance in Surrounding Formation during Drilling Circulation

Abstract

1. Introduction

2. Methodology

2.1. Governing Equations

- (1)

- Incompressible single-phase fluid (i.e., oil, no free gas);

- (2)

- Constant heat properties;

- (3)

- No reservoir flow;

- (4)

- Negligible Joule–Thomson effect;

- (5)

- The heated mud through deep formation is sufficiently cooled to the injecting temperature. The circulating mud is often observed to be heated by the circulation through the deep formation in the drilling practice; this phenomenon becomes more distinct when the circulation time gets longer.

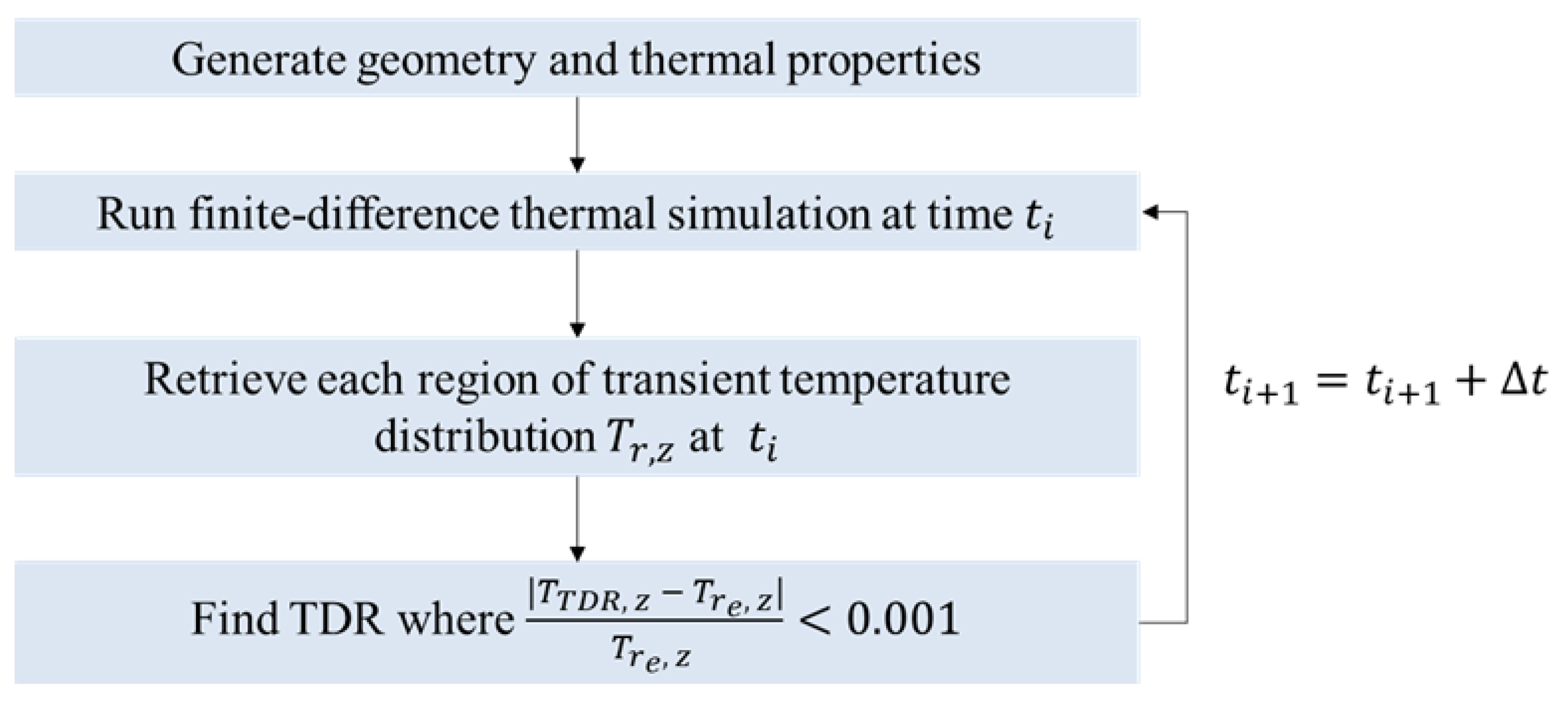

2.2. Numerical Scheme

3. Results

3.1. Validation

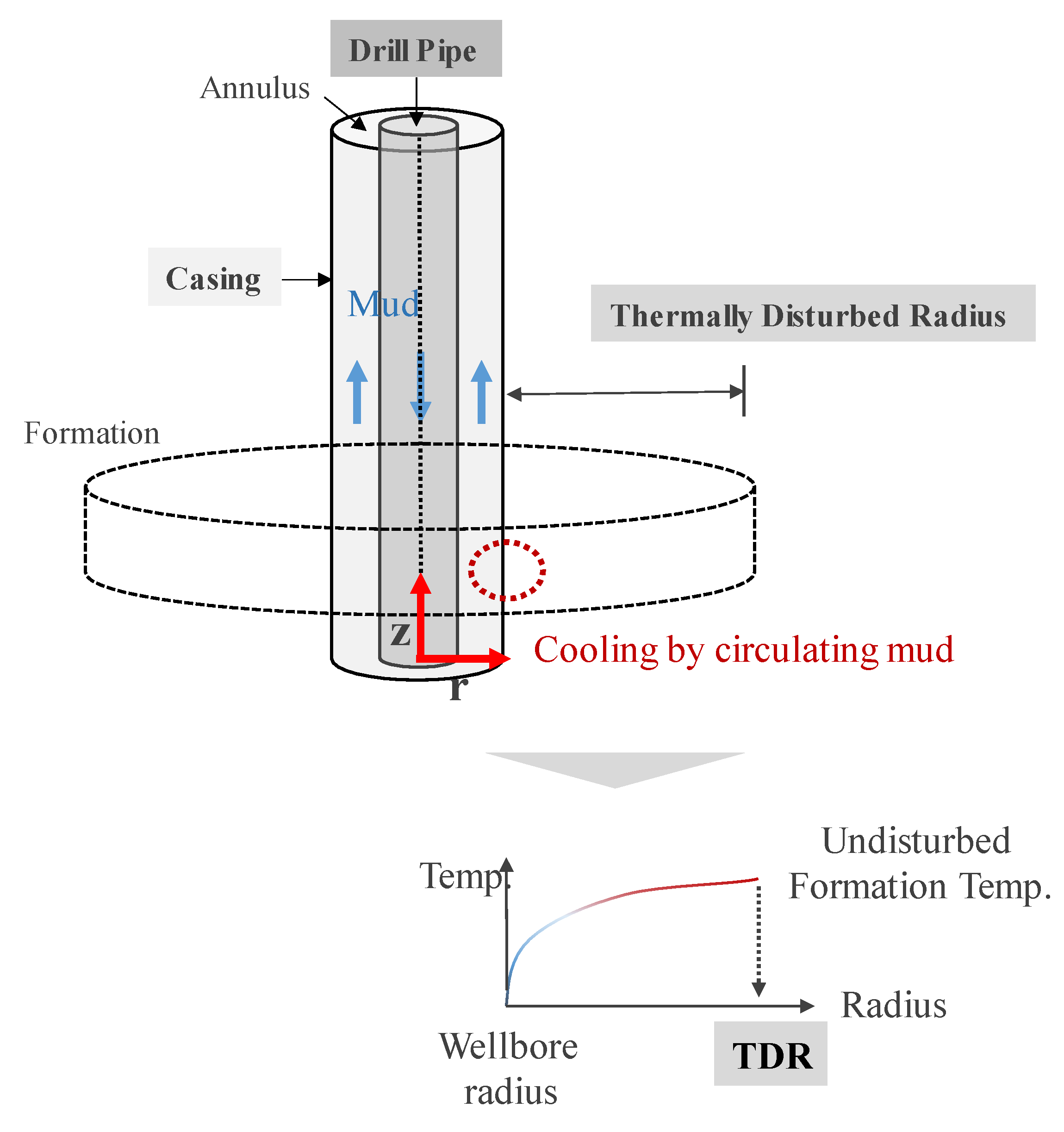

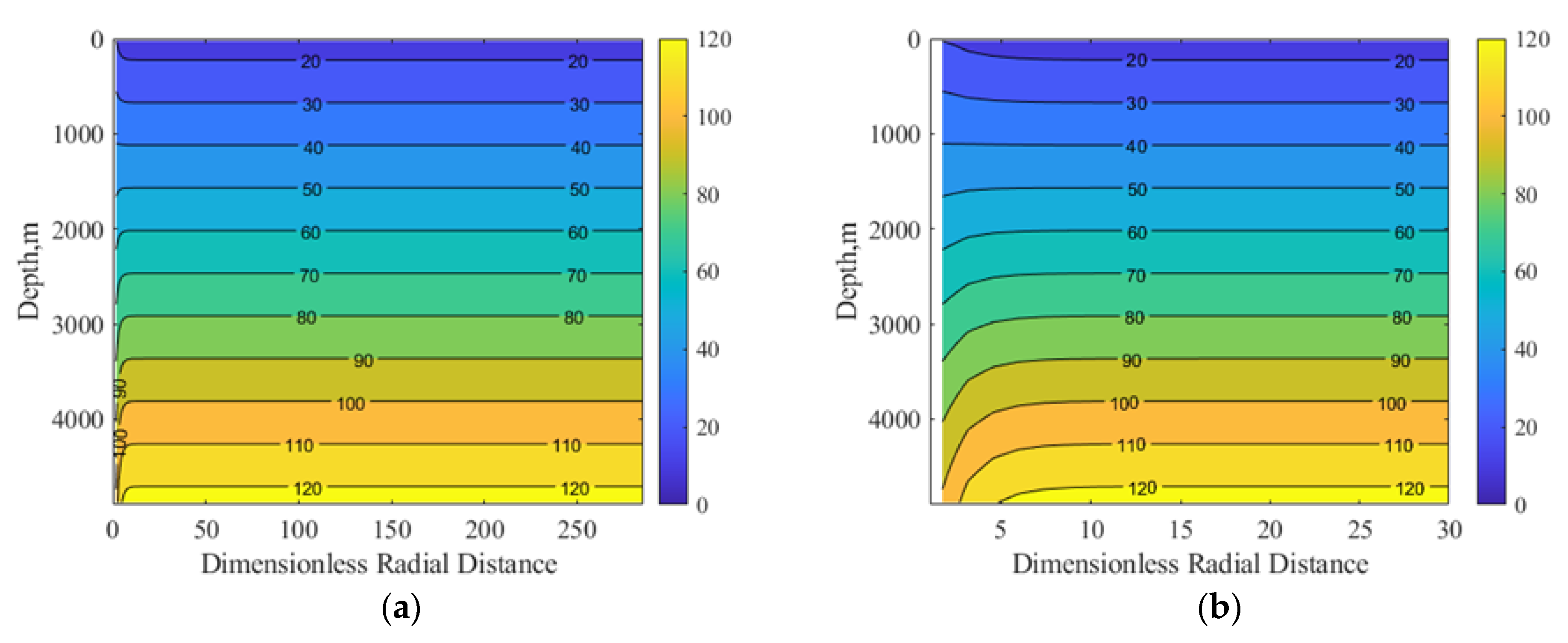

3.2. Identification of Thermal Disturbance

4. Sensitivity Analysis

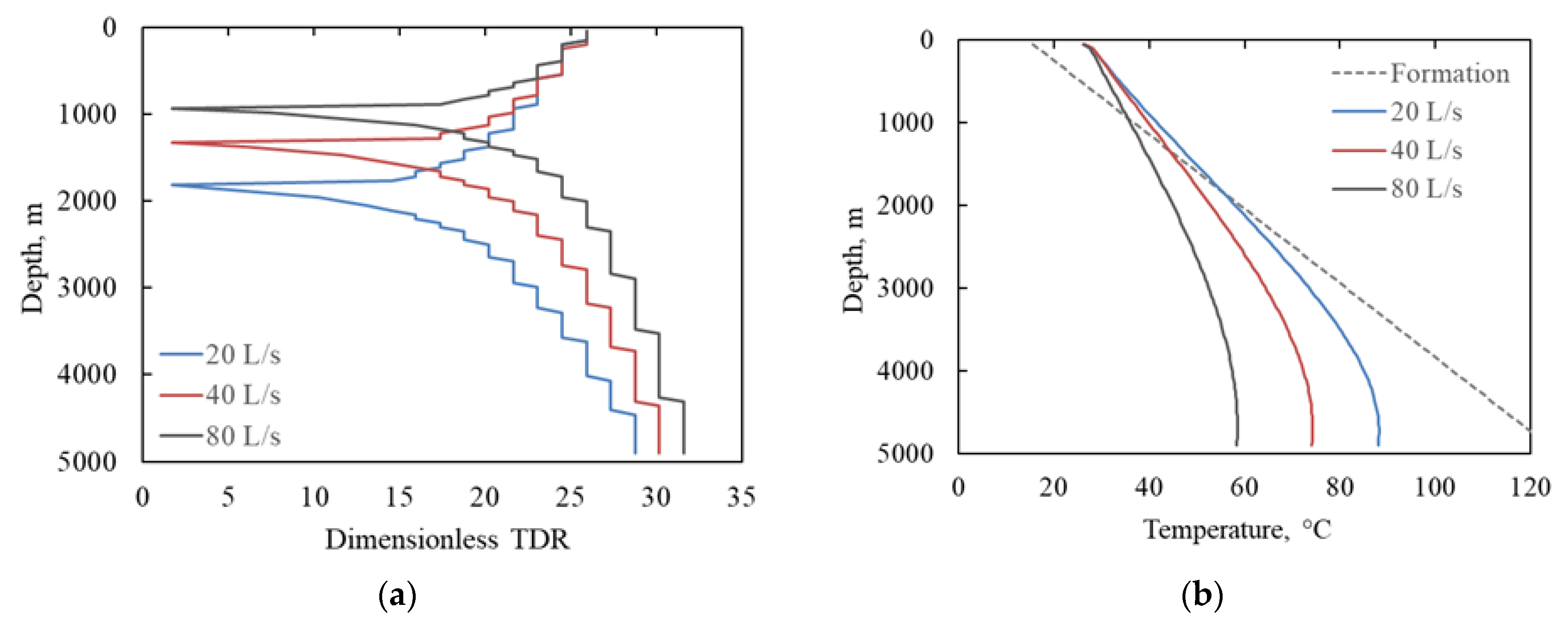

4.1. Circulation Rate

4.2. Circulation Time

4.3. Injecting Temperature

4.4. Mud Density

5. Conclusions

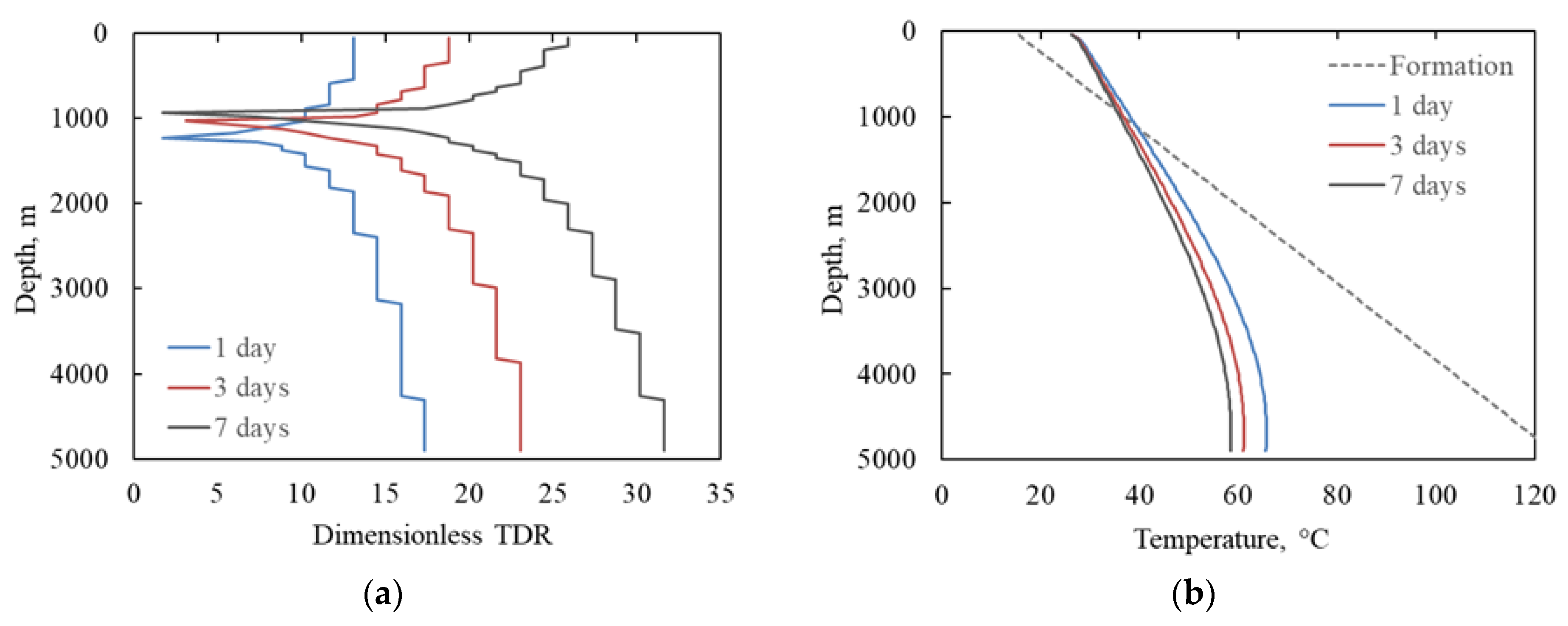

- The circulating mud cools down the formation near the wellbore during drilling, causing the thermal disturbance in the formation. The TDR is the radial distance where the thermal disturbance occurs. Thus, the TDR acts as a quantified indicator of thermal disturbance.

- The TDR tends to increase with the temperature difference between the fluids in the annulus and the formation, evidenced by the largest TDR being observed at the bottom hole.

- Among the operational parameters, circulation time is the most influential factor in changing TDR, meaning measured temperature data may be inaccurate if the drilling operation time lasts longer. Meanwhile, other parameters (i.e., circulation rate, injecting temperature, and mud density) have insignificant effects.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| A | horizontal cross-sectional area, |

| c | specific heat capacity, |

| d | hydraulic diameter, |

| geothermal gradient, | |

| convection heat transfer coefficient between sections x and y, | |

| intersection length between sections x and y, | |

| total number of grid cells in r direction | |

| total number of grid cells in z direction | |

| total number of time steps | |

| Nu | Nusselt number |

| Prandtl number | |

| well flow rate, | |

| heat flux per unit depth from section x to section y, | |

| radius, | |

| Reynolds number | |

| time, | |

| temperature, | |

| depth, | |

| thermal conductivity, | |

| radial discretization size, | |

| temporal discretization size, | |

| vertical discretization size, | |

| average temperature gradient, | |

| viscosity, | |

| density, | |

| Subscript | |

| a | annulus |

| bot | bottom |

| bth | bottom hole |

| c | casing |

| circ | circulation |

| D | dimensionless |

| f | formation |

| e | reservoir boundary |

| h | drilling hole |

| i | r-index |

| j | z-index |

| inj | injection |

| m | drilling mud |

| p | drill pipe |

| surf | surface |

| top | top |

| Superscript | |

| n | t-index |

References

- Wu, B.; Zhang, X.; Jeffrey, R.G. A Model for Downhole fluid and Rock Temperature Prediction during Circulation. Geothermics 2014, 50, 202–212. [Google Scholar] [CrossRef]

- Yang, M.; Luo, D.; Chen, Y.; Li, G.; Tang, D.; Meng, Y. Establishing a Practical Method to Accurately Determine and Manage Wellbore Thermal Behavior in High-Temperature Drilling. Appl. Energy 2019, 238, 1471–1483. [Google Scholar] [CrossRef]

- Dirksen, R. Upgrading Formation-Evaluation Electronics for High-Temperature Drilling Environments. J. Pet. Technol. 2011, 63, 24–26. [Google Scholar] [CrossRef]

- Bullard, E.C. The Time Necessary for a Bore Hole to Attain Temperature Equilibrium. Geophys. J. Int. 1947, 5, 127–130. [Google Scholar] [CrossRef]

- Shen, P.Y.; Beck, A.E. Stabilization of Bottom Hole Temperature with Finite Circulation Time and Fluid Flow. Geophys. J. Int. 1986, 86, 63–90. [Google Scholar] [CrossRef]

- Edwardson, M.J.; Girner, H.M.; Parkison, H.R.; Williams, C.D.; Matthews, C.S. Calculation of Formation Temperature Disturbances Caused by Mud Circulation. J. Pet. Technol. 1962, 14, 416–426. [Google Scholar] [CrossRef]

- Luheshi, M.N. Estimation of Formation Temperature from Borehole Measurements. Geophys. J. R. Astron. Soc. 1983, 74, 747–776. [Google Scholar] [CrossRef]

- Espinosa-Paredes, G.; Espinosa-Martínez, E.G. A Feedback-Based Inverse Heat Transfer Method to Estimate Unperturbed Temperatures in Wellbores. Energy Convers. Manag. 2009, 50, 140–148. [Google Scholar] [CrossRef]

- Abdelhafiz, M.M.; Hegele, L.A.; Oppelt, J.F. Numerical Transient and Steady State Analytical Modeling of the Wellbore Temperature during Drilling Fluid Circulation. J. Pet. Sci. Eng. 2020, 186, 106775. [Google Scholar] [CrossRef]

- Kutasov, I.M.; Eppelbaum, L.V. Wellbore and Formation Temperatures During Drilling, Cementing of Casing and Shut-In. In Proceedings of the World Geothermal Congress, Melbourne, Australia, 19–25 April 2015; International Geothermal Association: Den Haag, The Netherlands, 2015. [Google Scholar]

- Gorman, J.M.; Abraham, J.P.; Sparrow, E.M. A novel, Comprehensive Numerical Simulation for Predicting Temperatures within Boreholes and the Adjoining Rock Bed. Geothermics 2014, 50, 213–219. [Google Scholar] [CrossRef]

- Yang, H.; Li, J.; Liu, G.; Wang, J.; Luo, K.; Wang, B. Development of Transient Heat Transfer Model for Controlled Gradient Drilling. Appl. Therm. Eng. 2019, 148, 331–339. [Google Scholar] [CrossRef]

- Ouyang, L.B.; Belanger, D. Flow Profiling by Distributed Temperature Sensor (DTS) System—Expectation and Reality. SPE Prod. Oper. 2006, 21, 269–281. [Google Scholar] [CrossRef]

- Jang, M. Wellbore and Near-Wellbore Heat Transfer: General Theory and Practical Application. Ph.D. Thesis, Texas A&M University, College Station, TX, USA, 2021. [Google Scholar]

- Palabiyik, Y.; Onur, M.; Tureyen, O.I.; Cinar, M. Transient Temperature Behavior and Analysis of Single-Phase Liquid-Water Geothermal Reservoirs during Drawdown and Buildup Tests: Part I. Theory, New Analytical and Approximate Solutions. J. Pet. Sci. Eng. 2016, 146, 637–656. [Google Scholar] [CrossRef]

- Jang, M.; Chun, T.S.; An, J. An Analytical Heat Transfer Model in Oil Reservoir during Long-Term Production. Energies 2022, 15, 2544. [Google Scholar] [CrossRef]

- Eppelbaum, L.V.; Kutasov, I.M. Pressure and Temperature Drawdown Well Testing: Similarities and Differences. J. Geophys. Eng. 2006, 3, 12–20. [Google Scholar] [CrossRef]

- Yang, M.; Tang, D.; Chen, Y.; Li, G.; Zhang, X.; Meng, Y. Determining Initial Formation Temperature Considering Radial Temperature Gradient and Axial Thermal Conduction of the Wellbore Fluid. Appl. Therm. Eng. 2019, 147, 876–885. [Google Scholar] [CrossRef]

- Bridges, S.; Robinson, L. A Practical Handbook for Drilling Fluids Processing, 1st ed.; Gulf Professional Publishing: Houston, TX, USA, 2020. [Google Scholar]

- Pwaga, S.; Iluore, C.; Hundseth, Ø.; Perales, F.J.; Idrees, M.U. Comparative Study of Different EOR Methods; Technical report; Norwegian University of Science & Technology: Trondheim, Norway, 2010. [Google Scholar]

- Alajmi, A.F. Heat Loss Effect on Oil Bank Formation during Steam Flood. J. Pet. Sci. Eng. 2021, 199, 108262. [Google Scholar] [CrossRef]

- Askarova, A.; Turakhanov, A.; Markovic, S.; Popov, E.; Maksakov, K.; Usachev, G.; Karpov, V.; Cheremisin, A. Thermal Enhanced Oil Recovery in Deep Heavy Oil Carbonates: Experimental and Numerical Study on a Hot Water Injection Performance. J. Pet. Sci. Eng. 2020, 194, 107456. [Google Scholar] [CrossRef]

- Schubert, J.J.; Juvkam-Wold, H.C.; Choe, J. Well Control Procedures for Dual Gradient Drilling as Compared to Conventional Riser Drilling. SPE Drill. Complet. 2006, 21, 287–295. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Circulation rate, , L/s | 18 |

| Circulation time, , h | 24 |

| Inlet temperature, , °C | 25 |

| Surface temperature, , °C | 15 |

| Density of the drilling mud, , kg/m3 | 1200 |

| Density of the formation, , kg/m3 | 2640 |

| Thermal conductivity of the drilling mud, , W/m. °C | 1.25 |

| Thermal conductivity of the formation, , W/m. °C | 1.75 |

| Specific heat of the drilling fluid, , J/kg. °C | 1600 |

| Specific heat of the formation, , J/kg. °C | 800 |

| Well depth, , m | 4900 |

| Geothermal gradient, , °C /100 m | 2.23 |

| Wellbore diameter, , mm | 210 |

| Inner diameter of the drill pipe, , mm | 121.4 |

| Outer diameter of the drill pipe, , mm | 139.7 |

| Discretization levels ) | (200, 100, 7) |

| Section | 4.1 | 4.2 | 4.3 | 4.4 |

|---|---|---|---|---|

| Circulation rate, q, L/s | 20, 40, 80 | 80 | 80 | 80 |

| Circulation time, , h | 168 | 24, 72, 168 | 168 | 168 |

| Injecting temperature, , °C | 25 | 25 | 25, 50, 75 | 25 |

| Mud density, , 1000 kg/m3 | 1.2 | 1.2 | 1.2 | 1.0, 1.2, 1.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jang, M.; Chun, T.S.; An, J. The Transient Thermal Disturbance in Surrounding Formation during Drilling Circulation. Energies 2022, 15, 8052. https://doi.org/10.3390/en15218052

Jang M, Chun TS, An J. The Transient Thermal Disturbance in Surrounding Formation during Drilling Circulation. Energies. 2022; 15(21):8052. https://doi.org/10.3390/en15218052

Chicago/Turabian StyleJang, Minsoo, Troy S. Chun, and Jaewoo An. 2022. "The Transient Thermal Disturbance in Surrounding Formation during Drilling Circulation" Energies 15, no. 21: 8052. https://doi.org/10.3390/en15218052

APA StyleJang, M., Chun, T. S., & An, J. (2022). The Transient Thermal Disturbance in Surrounding Formation during Drilling Circulation. Energies, 15(21), 8052. https://doi.org/10.3390/en15218052