Study on Critical Parameters of Nitrogen Injection during In Situ Modification in Oil Shale

Abstract

:1. Introduction

2. The Critical Injection of Nitrogen

3. Model for Critical Nitrogen Injection

- (1)

- Steam parameter prediction modelIn order to simplify the model calculation, the basic assumptions of the steam parameter prediction model are:

- a.

- b.

- The velocity, pressure, and temperature of steam in the insulated pipe only change along the axial direction, which is one-dimensional steady flow and heat transfer;

- c.

- Neglecting formation heat conduction;

- d.

- Ignoring the variation of geothermal gradient along the well depth direction;

- e.

- The sealing condition of the heat insulation pipe is intact and the coupling is free of leakage.

- (2)

- The pressure change of steam from the wellhead to the bottom of the well were calculated by the two-phase flow pressure drop calculation method of Beggs–Brill method. At the same time, the temperature distribution of the inner and outer walls of the insulation pipe along the wellbore direction, the temperature, and dryness of the inner wall of the casing can be obtained by combining with the wellbore heat transfer calculation. Nitrogen parameter prediction model

- (3)

- Prediction model of critical nitrogen injection displacement

4. Influencing Factors of Critical Nitrogen Injection

4.1. Influence of Wellhead Steam Injection Parameters

4.2. Effect of Thermal Insulation Pipe Performance

4.3. Effect of Annulus Sealing

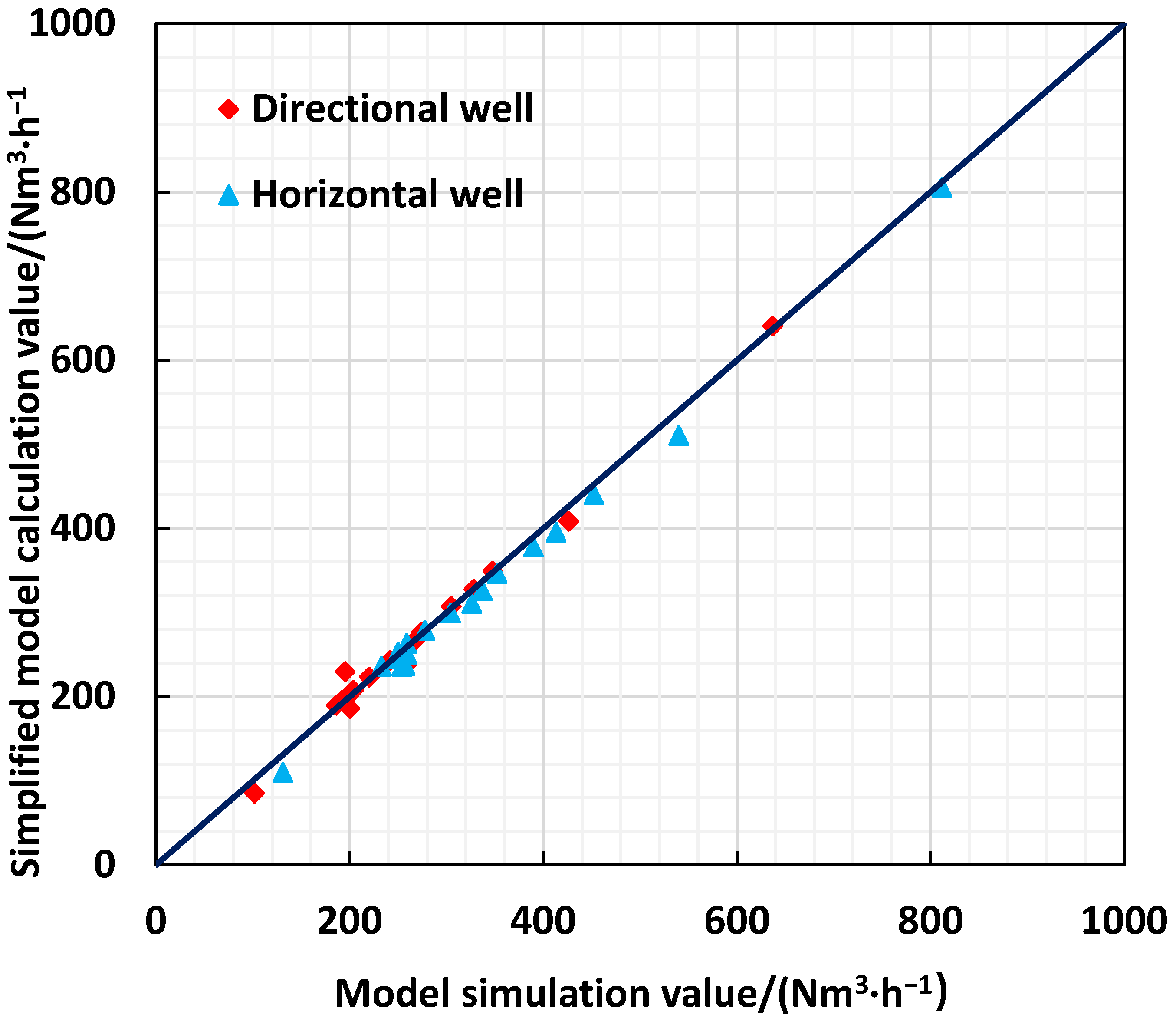

5. Simplified Model of Critical Nitrogen Injection Rate

6. Conclusions

- (1)

- The steam parameter prediction model in the insulated pipe string and the nitrogen parameter prediction model in the casing annulus were constructed, which according to the completion structure characteristics of thermal injection wells were based on the basic principles of heat transfer and fluid mechanics. According to the modified model of field test data, the influence of different well types, reservoir parameters, steam parameters, and annulus sealing conditions on the critical nitrogen injection rate was studied.

- (2)

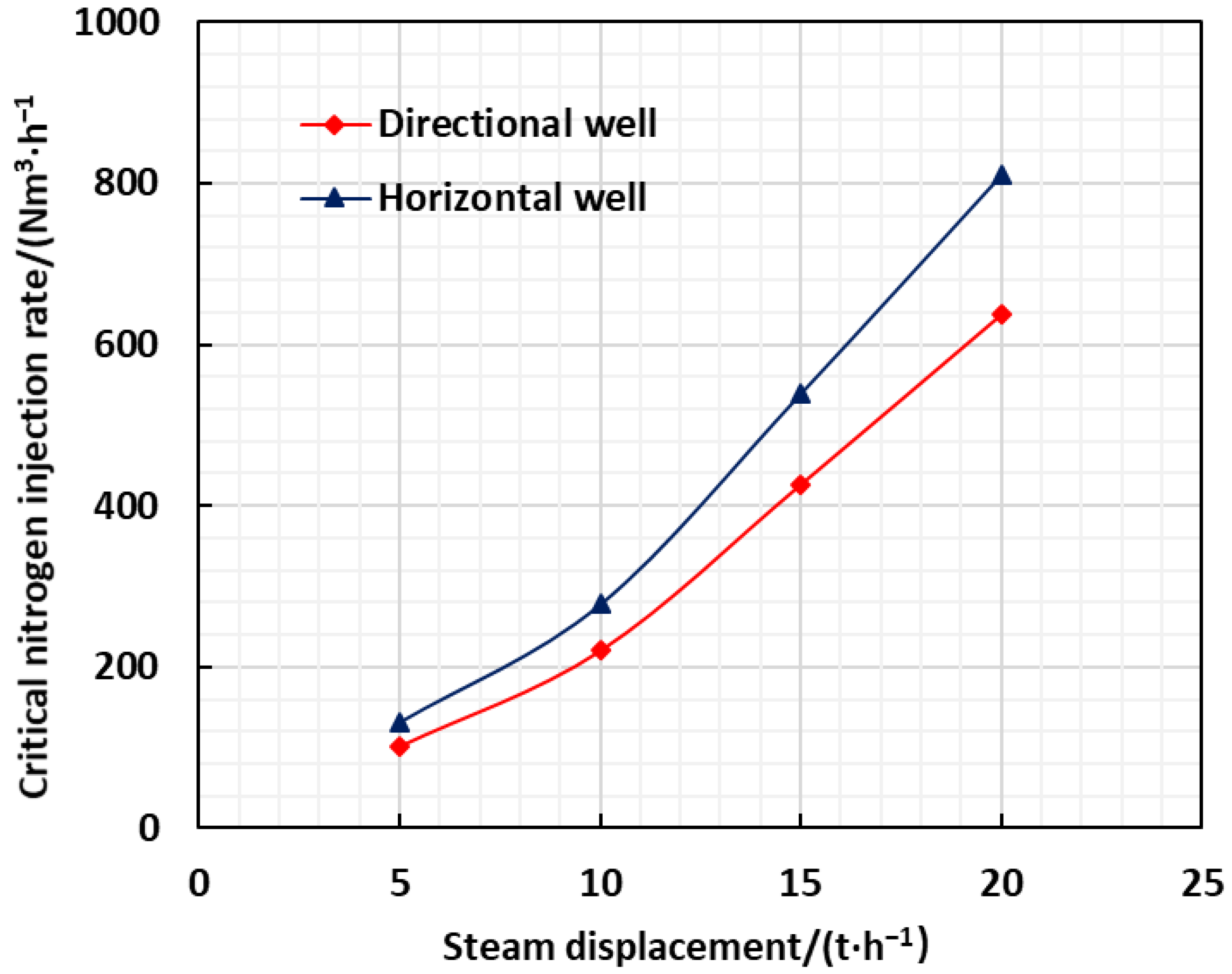

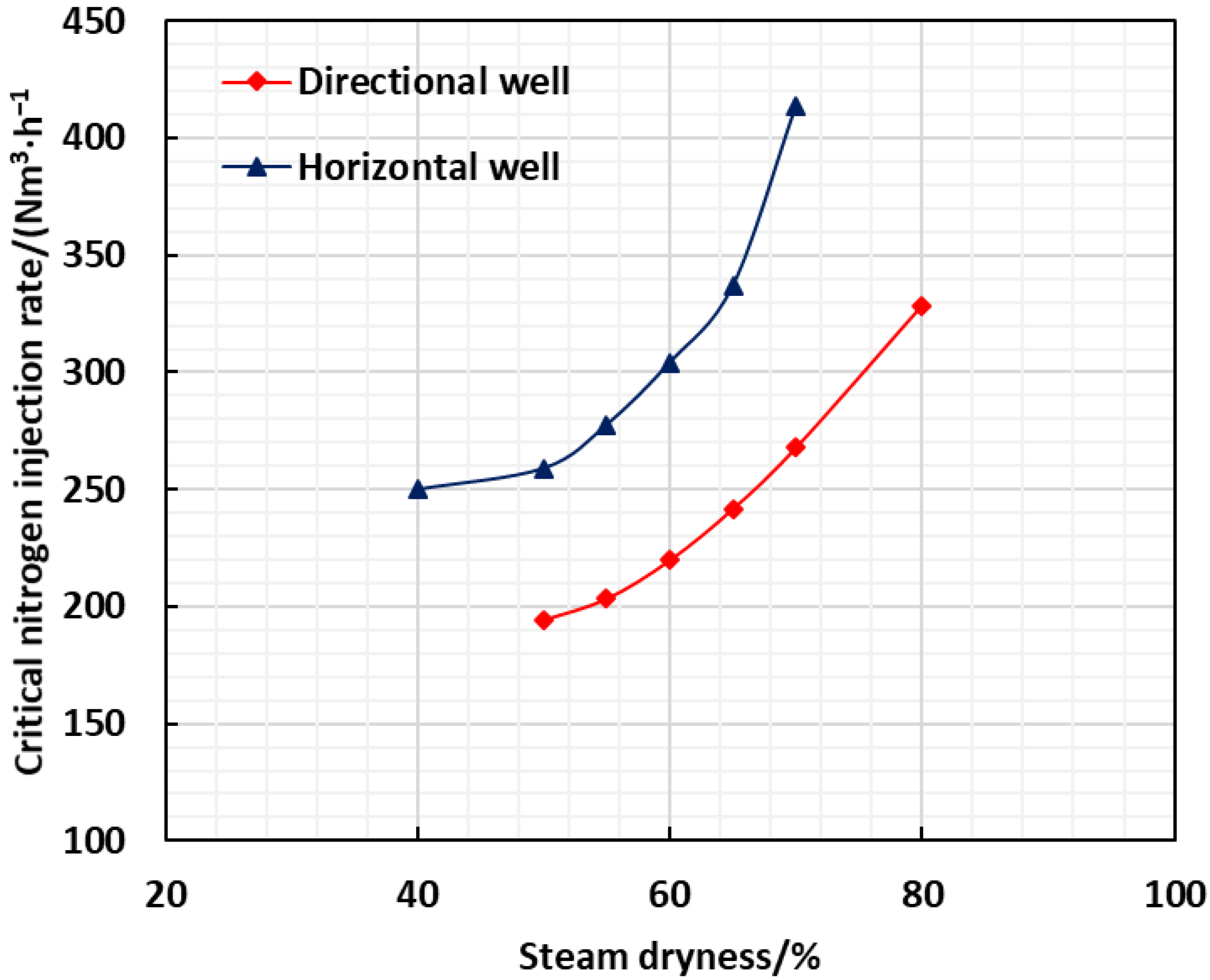

- Under the different well type conditions, the annulus thermal resistance of horizontal wells is larger than that of directional wells, and the critical nitrogen injection displacement required is higher accordingly. The analysis of influencing factors shows that with the increase of pressure, steam displacement, and steam dryness, the required critical nitrogen injection displacement increases at a quadratic function rate.

- (3)

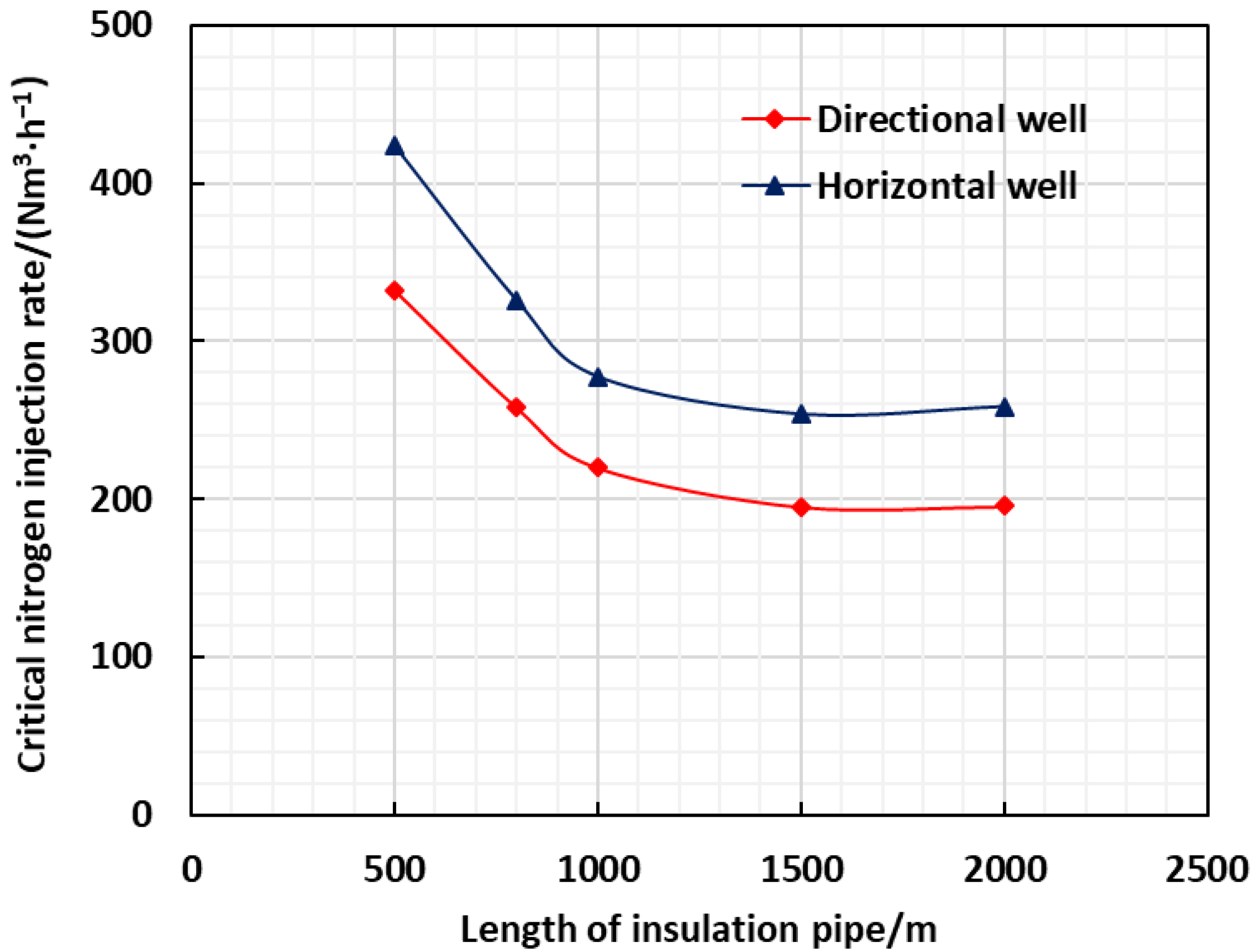

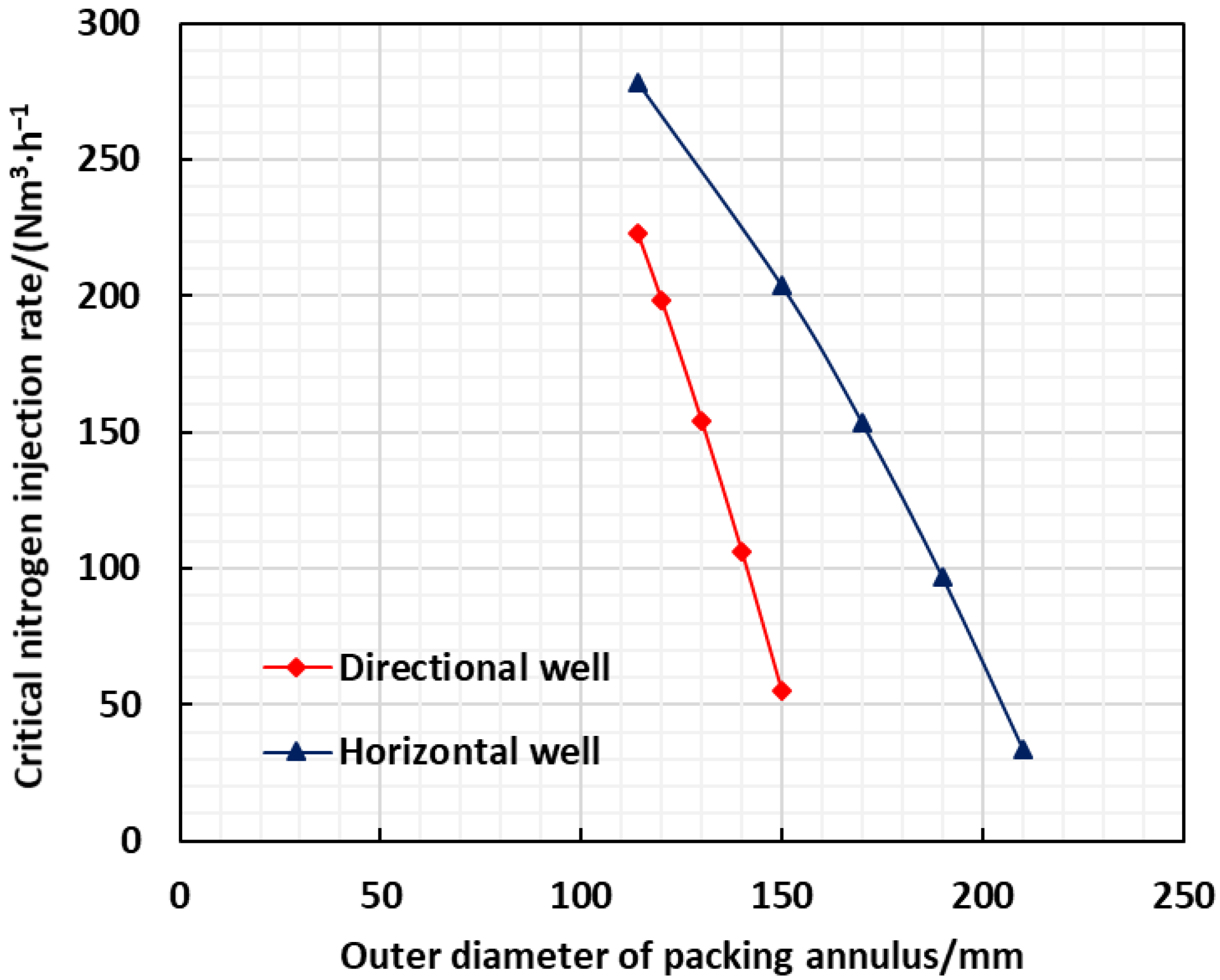

- With the increase of the length and thermal conductivity of the insulated pipe, the required critical nitrogen injection rate decreases cubically. However, with the increase of annulus sealing, the required critical nitrogen injection displacement decreases linearly. The research results are of great significance for improving steam quality and string life in thermal injection wells.

Author Contributions

Funding

Conflicts of Interest

References

- Han, X.; Zhong, L.; Liu, Y.; Wang, Q.; Chen, C.; Wu, X. Study and Optimization of the First Horizontal Well Steam flooding Pilot for Offshore Oilfield. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 4–7 May 2020. [Google Scholar]

- Vargo, R.F.; Payne, M.; Faul, R.; LeBlanc, J.; Griffith, J.E. Practical and Successful Prevention of Annular Pressure Buildup on the Marlin Project. Spe Drill. Complet. 2003, 18, 228–234. [Google Scholar] [CrossRef]

- Zou, J.; Han, X.; Liu, Y.; Wang, Q.; Zhang, H.; Liu, H.; Wang, H.; Han, C. Research and Application of the Optical Fiber Technology for Real-time Temperature Test of Offshore Thermal Wells. In Proceedings of the Abu Dhabi International Petroleum Exhibition & Conference, Abu Dhabi, United Arab Emirates, 11–14 November 2019. [Google Scholar]

- Xu, A.; Mu, L.; Fan, Z.; Zhao, L. New findings on heatloss of superheated steam transmitted along the wellbore and heating enhancement in heavy oil reservoirs. In Proceedings of the IPTC 2013: International Petroleum Technology Conference, Beijing, China, 26–28 March 2013. [Google Scholar]

- Xu, A.; Mu, L.; Fan, Z.; Zhao, L.; Bo, B. Mechanism of heavy oil recovery by cyclic superheated steam stimulation. J. Petro. Sci. Eng. 2013, 111, 197–207. [Google Scholar] [CrossRef]

- Zheng, S.; Li, W.; Cao, C.; Wang, C. Prediction of the wellhead uplift caused by HT–HP oil and gas production in deep-water wells. Energy Rep. 2021, 7, 740–749. [Google Scholar] [CrossRef]

- Zheng, S.; Zhang, C. Influence of Cement Return Height on the Wellhead Uplift in Deep-Water High-Pressure–High-Temperature Wells. ACS Omega 2021, 6, 2990–2998. [Google Scholar] [CrossRef] [PubMed]

- Hu, Y.I.N.; Menghan, S.I.; Qian, L.I.; Hongwei, J.A.N.G.; Liming, D.A.I. Mechanism and prevention method of drill string uplift during shut-in after overflow in an ultra-deep well. Pet. Explor. Dev. 2018, 45, 1139–1145. [Google Scholar]

- Kaldal, G.S.; Jónsson, M.Þ.; Pálsson, H.; Karlsdottir, S.N. Using Probabilistic Analysis with Finite Element Modeling of High Temperature Geothermal Well Casings. In Proceedings of the Sims Conference, Bergen, Norway, 16–18 October 2013. [Google Scholar]

- Kaldal, G.S.; Jonsson, M.T.; Palsson, H.; Karlsdottir, S.N. Structural modeling of the casings in the IDDP-1 well: Load history analysis. Geothermics 2016, 62, 1–11. [Google Scholar] [CrossRef]

- Case, R.; Mahajanam, S.; Dunn, J.; Joosten, M.; Achour, M.; Marchebois, H.; Bonis, M. Evaluation of corrosivity of produced fluids during SAGD operations. In Proceedings of the Nace International Corrosion Conference, San Antonio, TX, USA, 9–13 March 2014. [Google Scholar]

- Wen, X.; Bai, P.; Luo, B.; Zheng, S.; Chen, C. Review of recent progress in the study of corrosion products of steels in a hydrogen sulphide environment. Corros. Sci. 2018, 139, 124–140. [Google Scholar] [CrossRef]

- Valbuena, E.; Bashbush, J.L.; Rincon, A.C. Energy Balance in Steam Injection Projects Integrating Surface-Reservoir Systems. In Proceedings of the SPE Latin American and Caribbean Petroleum Engineering Conference, Cartagena, Colombia, 31 May–3 June 2009. [Google Scholar]

- Teodoriu, C.; Falcone, G. Labyrinth Packer Lowers the Costs for Steam Injections Wells: Theoretical and Experimental Results. In Proceedings of the SPE/DOE Improved Oil Recovery Symposium, Tulsa, OK, USA, 3–5 April 2008. [Google Scholar]

- Sun, F.; Yao, Y.; Li, X.; Tian, J.; Zhu, G.; Chen, Z. The flow and heat transfer characteristics of superheated steam in concentric dual-tubing wells. Int. J. Heat Mass Transf. 2017, 115 Pt B, 1099–1108. [Google Scholar] [CrossRef]

- Cao, R.; Gu, H. A comprehensive mathematical model for predicting thermophysical properties of superheated steamin horizontal injection wells considering phase change. In Proceedings of the SPE Latin American and Caribbean Petroleum Engineering Conference, Quito, Ecuador, 18–20 November 2015. [Google Scholar]

- Zhang, B.; Guan, Z.; Wang, Q.; Xuan, L.; Liu, Y.; Sheng, Y. Appropriate Completion To Prevent Potential Damage of Annular Pressure Buildup in Deepwater Wells. In Proceedings of the IADC/SPE Asia Pacific Drilling Technology Conference, Singapore, 22–24 August 2016. [Google Scholar]

- Ju, N. A Calculation Model for Steam Property Variation Along Wellbore Trajectory in SAGD Process. In Proceedings of the SPE Latin American and Caribbean Petroleum Engineering Conference, Lima, Peru, 19–20 October 2016. [Google Scholar]

- Gu, H.; Cheng, L.; Huang, S.; Zhang, H.; Lin, M.; Hu, C. A New Semi-analytical Model for Predicting Steam Pressure and Temperature in Annuli. In Proceedings of the SPE Latin American and Caribbean Petroleum Engineering Conference, Maracaibo, Venezuela, 21–23 May 2014. [Google Scholar]

- Sagar, R.; Doty, D.R.; Schmidt, Z. Predicting Temperature Profiles in a Flowing Well. SPE Reserv. Eng. Novemb. 1991, 6, 441–448. [Google Scholar] [CrossRef]

- Alves, I.N.; Alhanatl, F.J.S.; Shoham, O. A Unified Model for Predicting Flowing Temperature Distribution in Wellbores and Pipelines. SPE Prod. Eng. Novemb. 1992, 7, 363–367. [Google Scholar] [CrossRef]

- Hasan, A.R.; Kabir, C.S. A Basic Approach to Wellbore Two-phase Flow Modeling. Paper SPE 109868. In Proceedings of the SPE Annual Technical Conference and Exhibition, Anaheim, CA, USA, 11–14 November 2007. [Google Scholar]

- Ramey, H.J. Wellbore Heat Transmission. J. Pet. Technol. 1962, 14, 427–435. [Google Scholar] [CrossRef]

- Satter, A. Heat Losses During Flow of Steam Down a Wellbore. J. Pet. Technol. 1965, 17, 845–851. [Google Scholar] [CrossRef]

- Beggs, D.H.; Brill, J.P. A Study of Two-Phase Flow in Inclined Pipes. J. Pet. Technol. 1973, 25, 607–617. [Google Scholar] [CrossRef]

- Kretzschmar, H.J. Mollier h-s Diagram for Water and Steam: Calculated from the IAPWS Industrial Formulation 1997 for the Thermodynamic Properties of Water and Steam IAPWS-IF97, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2008; ISBN 10:3642033210. [Google Scholar]

- Hussein, I.B.; Owen, I.; Amini, A.M. Energy metering system for high quality saturated steam. Flow Meas. Instrum. 1992, 3, 235–240. [Google Scholar] [CrossRef]

- Aziz, K. Calculation of Bottom-Hole Pressure in Gas Wells. J. Pet. Technol. 1967, 19, 897–899. [Google Scholar] [CrossRef]

| Influence Factors | Directional Well | Horizontal Well | |

|---|---|---|---|

| Reservoir parameters | Pressure/MPa | 5–20 | 5–20 |

| Depth/m | 500–2000 | 500–2000 | |

| Steam parameters | Displacement/(t·h−1) | 5–20 | 5–20 |

| Dryness/% | 50–80 | 50–80 | |

| Insulation pipe parameters | Thermal conductivity/(w·m−1·K−1) | 0.01–0.10 | 0.01–0.10 |

| Influence Factors | Well Types | Fitting Formula | ||

|---|---|---|---|---|

| Wellhead steam parameters | Pressure/MPa | Directional well | Q = 0.3959 P2 + 0.8807 P + 171.81 | R2 = 1 |

| Horizontal well | Q = 0.551 P2 + 0.8866 P + 214.36 | R2 = 1 | ||

| Displacement, t/h | Directional well | Q = 0.92 q2 + 13.244 q + 8.06 | R2 = 0.9979 | |

| Horizontal well | Q = 1.2512 q2 + 14.797 q + 20.43 | R2 = 0.9979 | ||

| Dryness/% | Directional well | Q = 0.0874 X2 − 6.8416 X + 316.91 | R2 = 0.9994 | |

| Horizontal well | Q = 0.1223 X2 − 10.368 X + 461 | R2 = 0.9992 | ||

| Insulation pipe parameters | Thermal conductivity, w/(m·K) | Directional well | Q = −4 × 106 α3 + 526,000α2 − 21,459α+ 470.7 | R2 = 1 |

| Horizontal well | Q = −8 × 106 α3 + 864,750α2 − 31,910α+ 629.9 | R2 = 1 | ||

| Length/m | Directional well | Q = −7 × 108 L3 + 0.0004 L2 − 0.6473 L + 574.49 | R2 = 0.9982 | |

| Horizontal well | Q = −107 L3 + 0.0005 L2 − 0.9096 L + 759.06 | R2 = 0.9977 | ||

| Parameters | Value | Parameters | Value |

|---|---|---|---|

| Formation thermal conductivity/[w·(m·°C)−1] | 1.73 | Inner diameter of insulated pipe/m | 0.076 |

| Thermal conductivity of cement/[w·(m·°C)−1] | 0.993 | Outer diameter of inner pipe of heat insulation pipe/m | 0.0889 |

| Geothermal gradient/[°C·(100 m)−1] | 3.8 | Inner diameter of outer pipe of heat insulation pipe/m | 0.1016 |

| Outer diameter of technical casing/m | 0.1778 | Outer diameter of outer pipe of heat insulation pipe/m | 0.1143 |

| Inside diameter of technical casing/m | 0.159 | Outer diameter of packer/m | 0.155 |

| Depth of heat insulation pipe of Shu 1-X well/m | 852.7 | Gas injection velocity/(t·h−1) | 5 |

| Depth of heat insulation pipe of Shu 1-Y well/m | 860.9 | Steam injection time/d | 15 |

| Depth of heat insulation pipe of Shu 1-Z well/m | 869.6 | Nitrogen concentration/% | 99.9 |

| Wellhead steam dryness/% | 65 | Nitrogen velocity/(Nm3/h) | 35 |

| Well No. | Before optimization | After optimization | ||||||

|---|---|---|---|---|---|---|---|---|

| Injection Pressure/ MPa | Bottom Hole Pressure/ MPa | Bottom Hole Dryness/ % | Injection Pressure/ MPa | Bottom Hole Pressure Prediction/MPa | Measured Bottom Hole Pressure/MPa | Bottom Hole Dryness Prediction/% | Measurement of Bottom Hole Dryness/% | |

| Shu1-X | 7.58 | 4.13 | 47.3 | 7.97 | 4.72 | 4.60 | 49.5 | 50.5 |

| Shu1-Y | 6.15 | 4.27 | 55.2 | 7.03 | 5.35 | 5.13 | 58.1 | 59.3 |

| Shu1-Z | 5.84 | 3.52 | 58.3 | 6.13 | 4.22 | 4.09 | 62.9 | 63.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tao, S.; Cen, X.; Yu, X.; Hu, J.; Kan, C. Study on Critical Parameters of Nitrogen Injection during In Situ Modification in Oil Shale. Energies 2022, 15, 8034. https://doi.org/10.3390/en15218034

Tao S, Cen X, Yu X, Hu J, Kan C. Study on Critical Parameters of Nitrogen Injection during In Situ Modification in Oil Shale. Energies. 2022; 15(21):8034. https://doi.org/10.3390/en15218034

Chicago/Turabian StyleTao, Shilin, Xueqi Cen, Xiaocong Yu, Junqing Hu, and Changbin Kan. 2022. "Study on Critical Parameters of Nitrogen Injection during In Situ Modification in Oil Shale" Energies 15, no. 21: 8034. https://doi.org/10.3390/en15218034

APA StyleTao, S., Cen, X., Yu, X., Hu, J., & Kan, C. (2022). Study on Critical Parameters of Nitrogen Injection during In Situ Modification in Oil Shale. Energies, 15(21), 8034. https://doi.org/10.3390/en15218034