Geomechanical and Petrophysical Assessment of the Lower Turonian Tight Carbonates, Southeastern Constantine Basin, Algeria: Implications for Unconventional Reservoir Development and Fracture Reactivation Potential

Abstract

1. Introduction

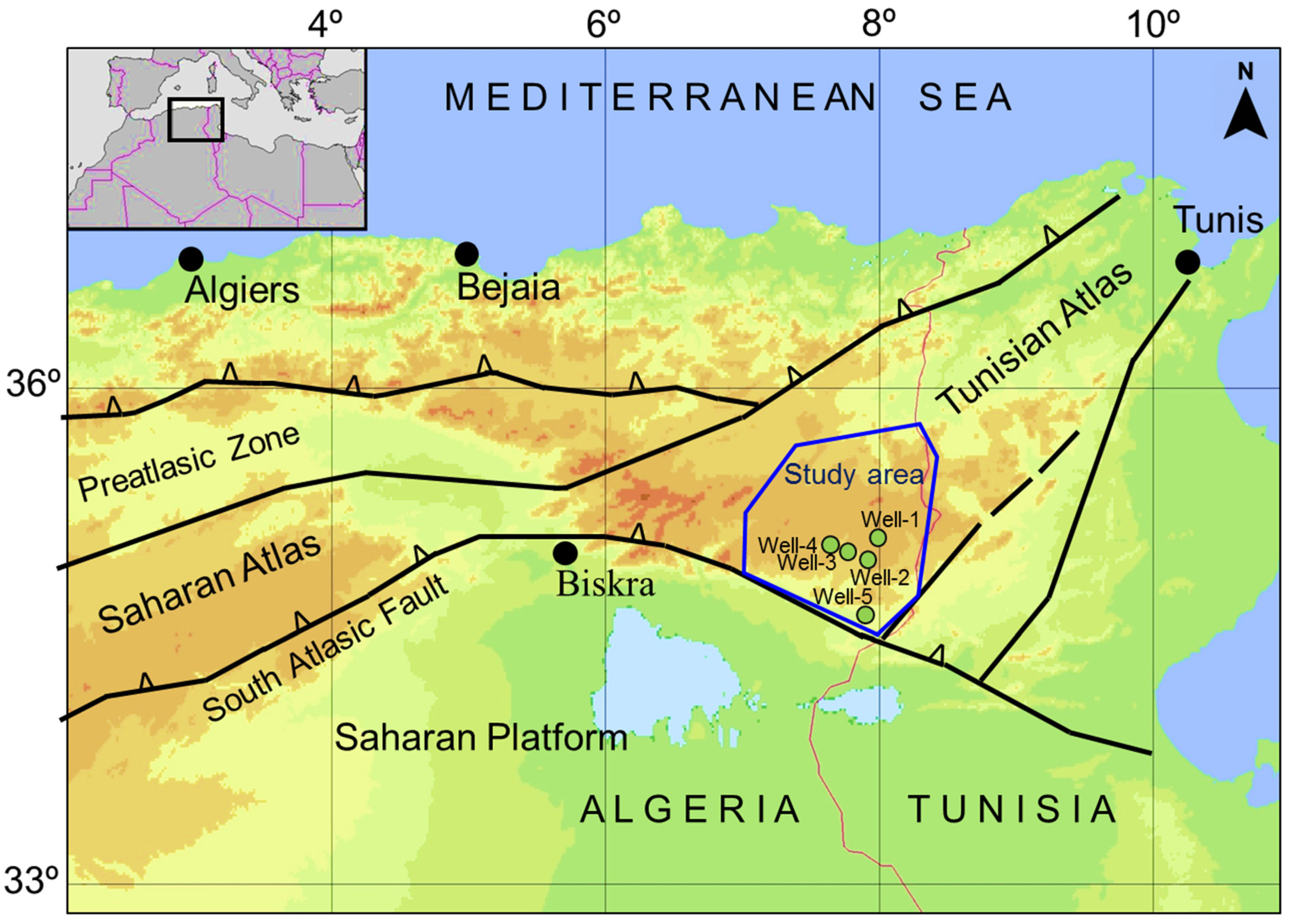

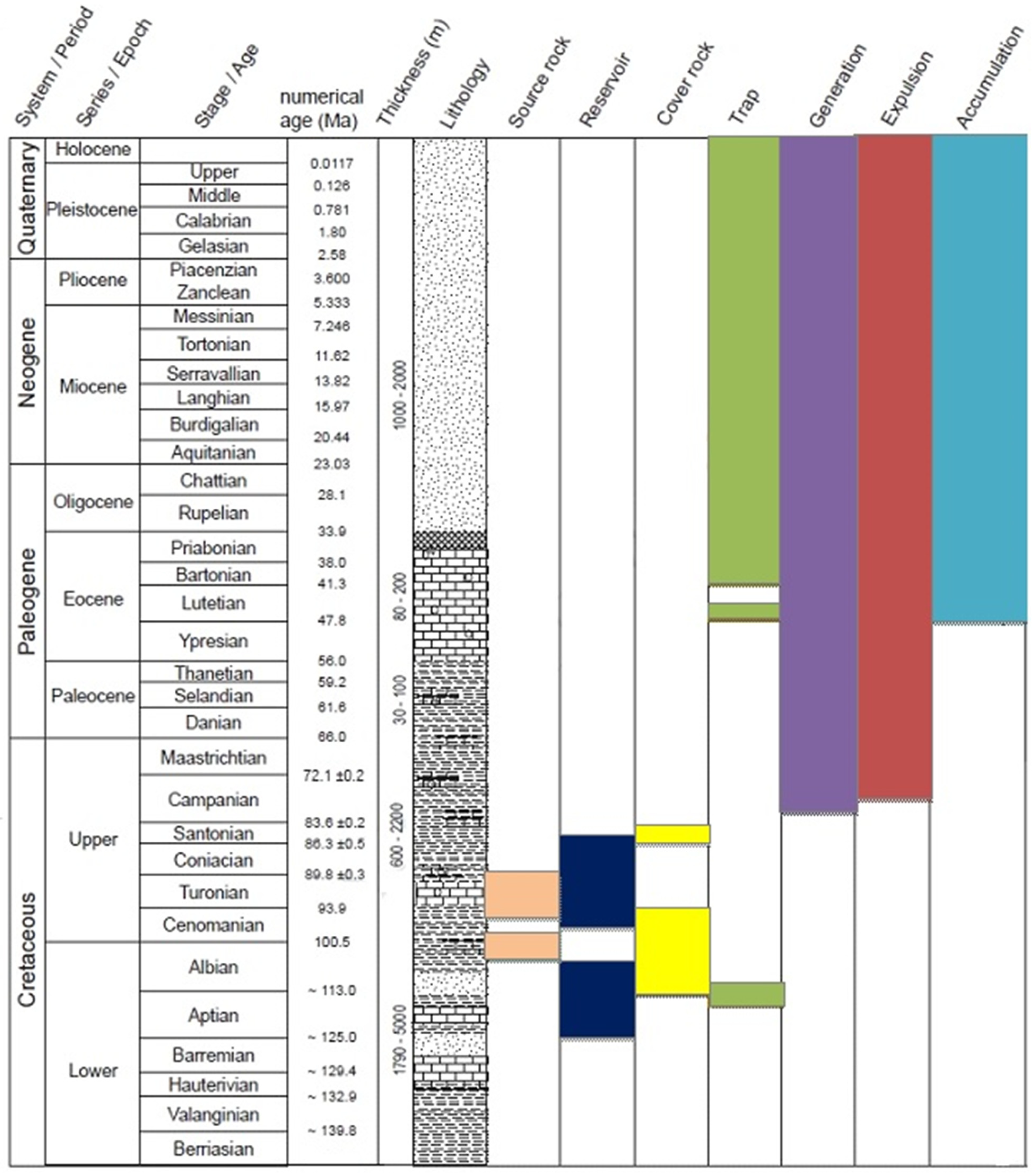

2. Geological Setting

3. Materials and Methods

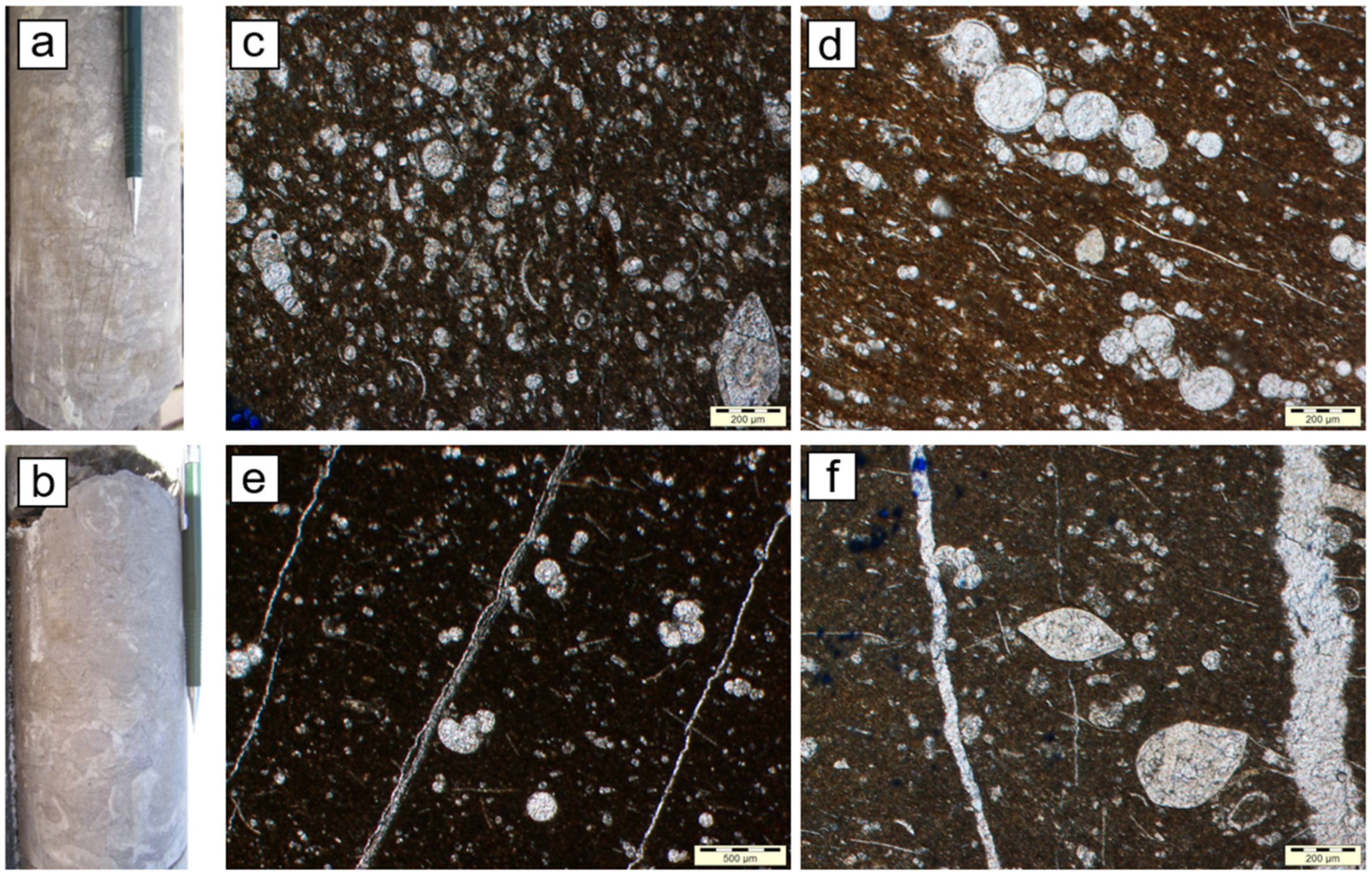

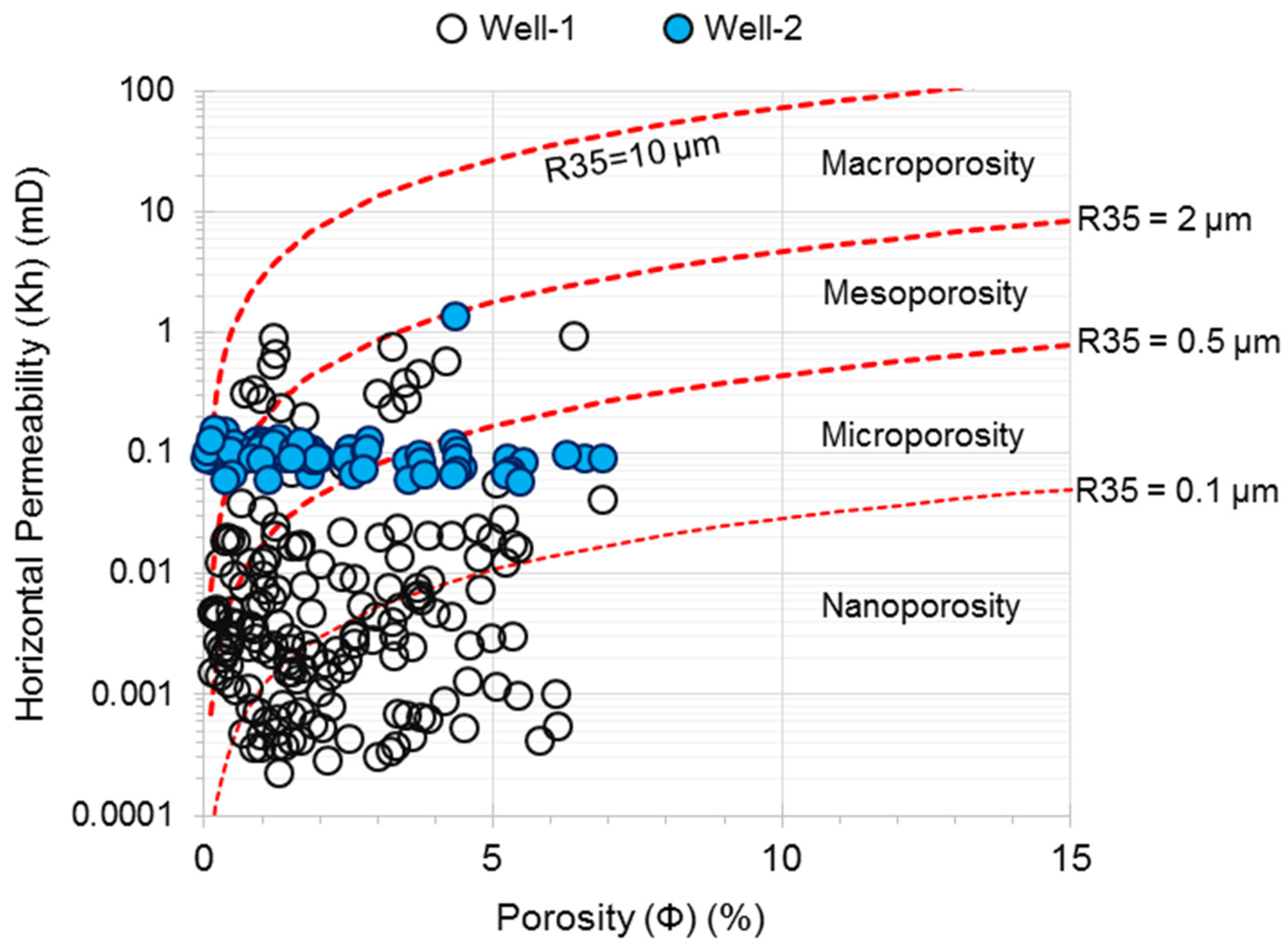

3.1. Petrographic and Petrophysical Analysis

3.2. Geomechanical Analysis

4. Results and Discussions

4.1. Petrographical and Petrophysical Characteristics

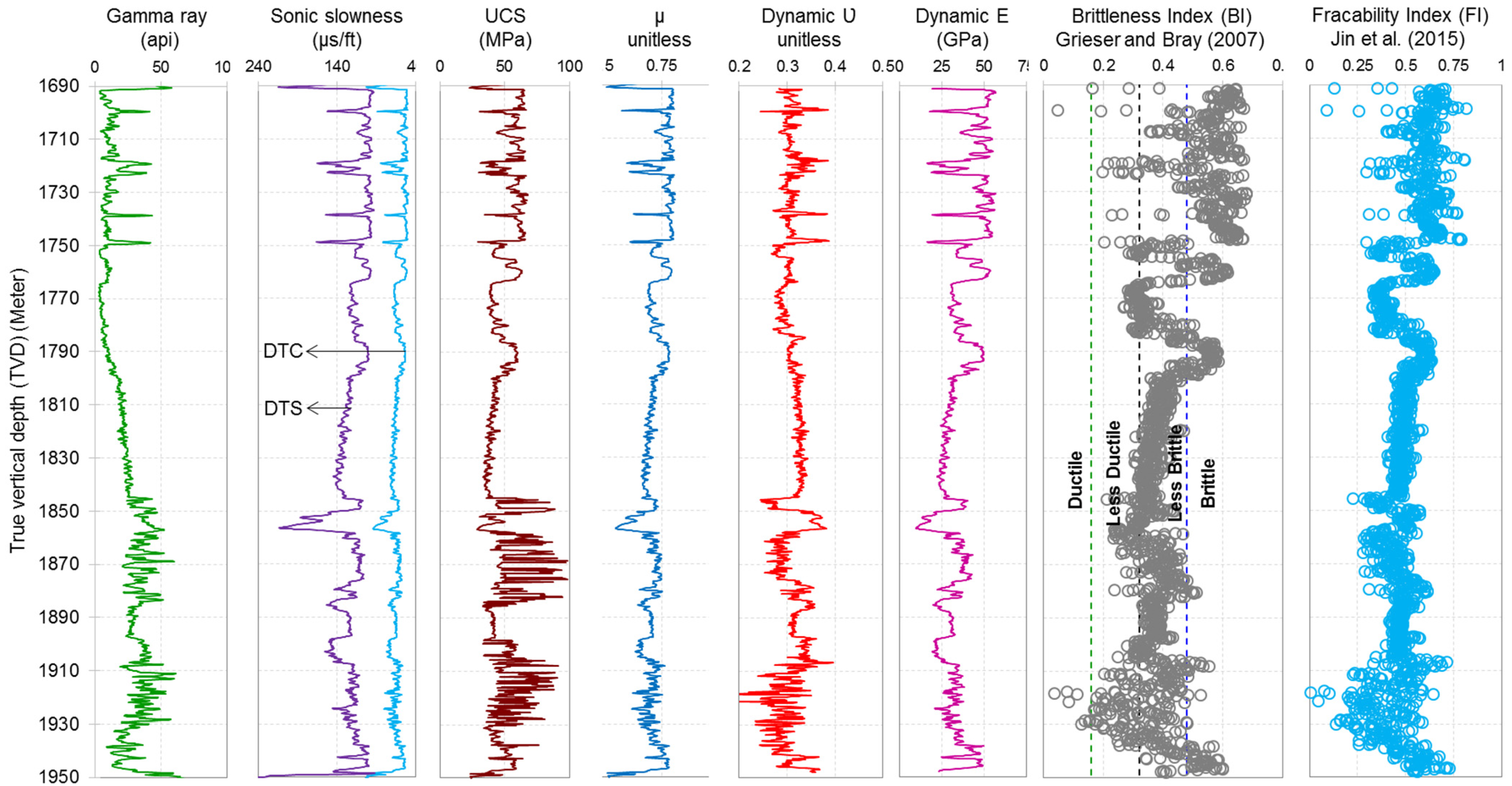

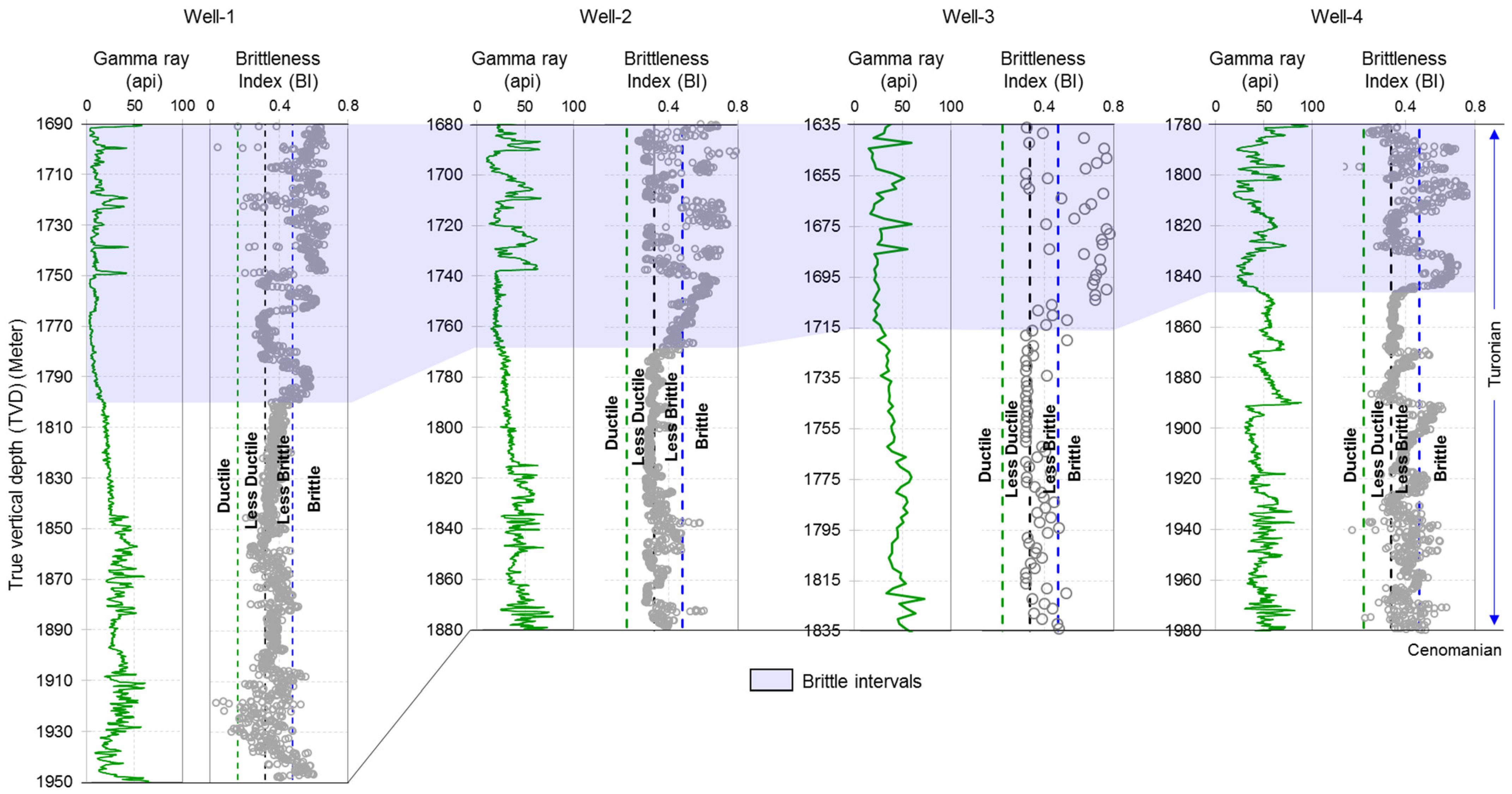

4.2. Rock-Mechanical Properties

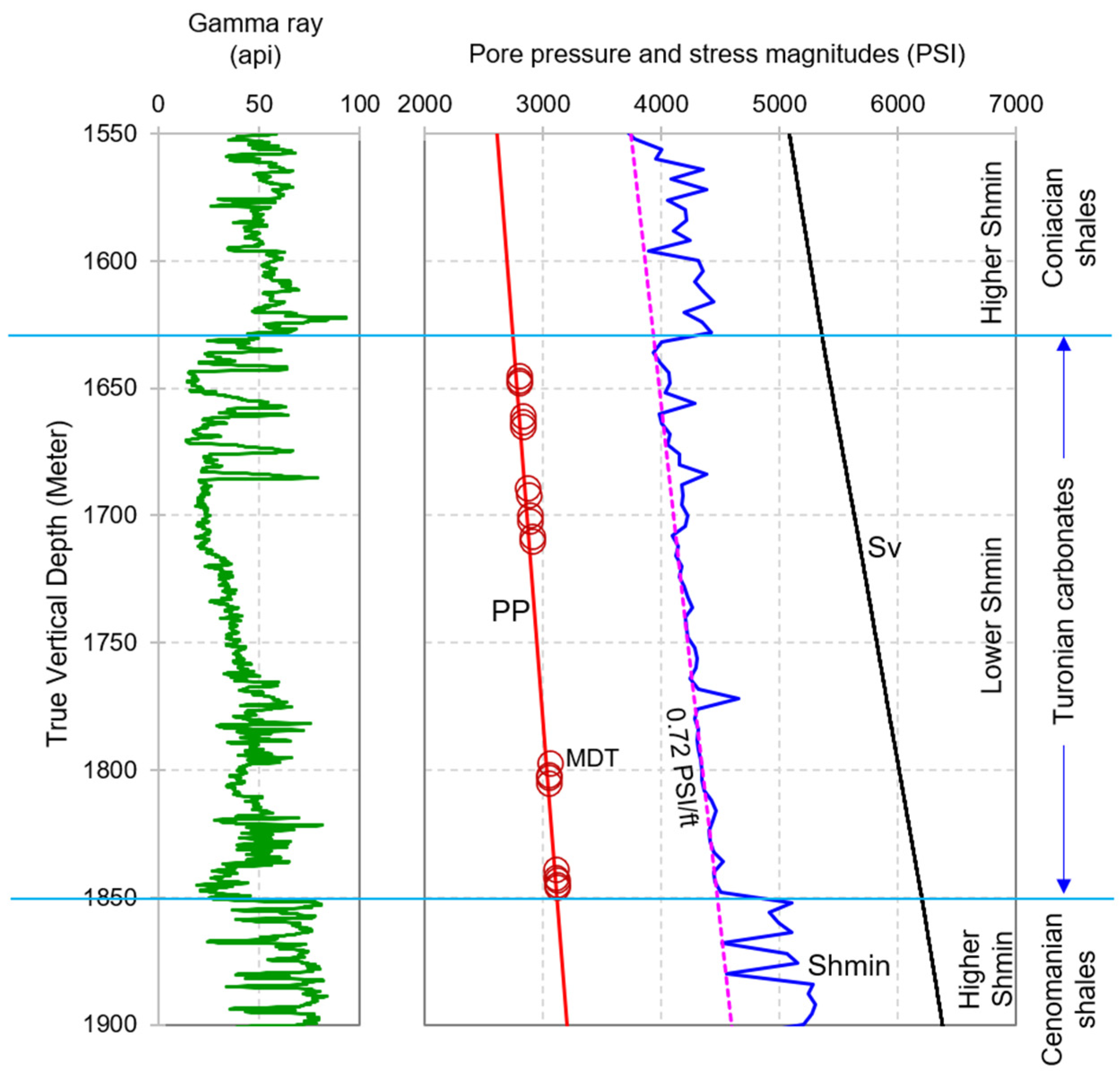

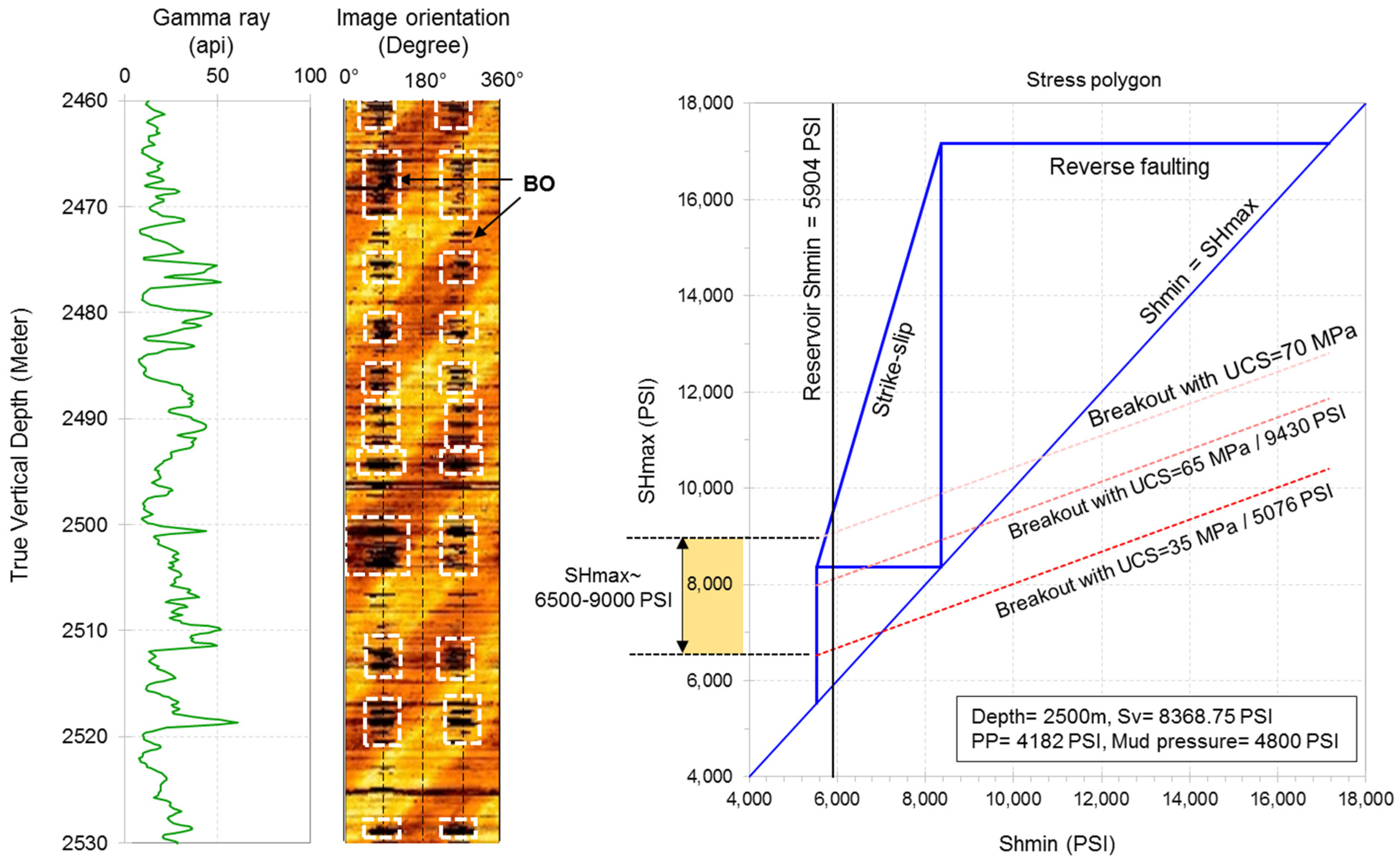

4.3. In-Situ Stress State

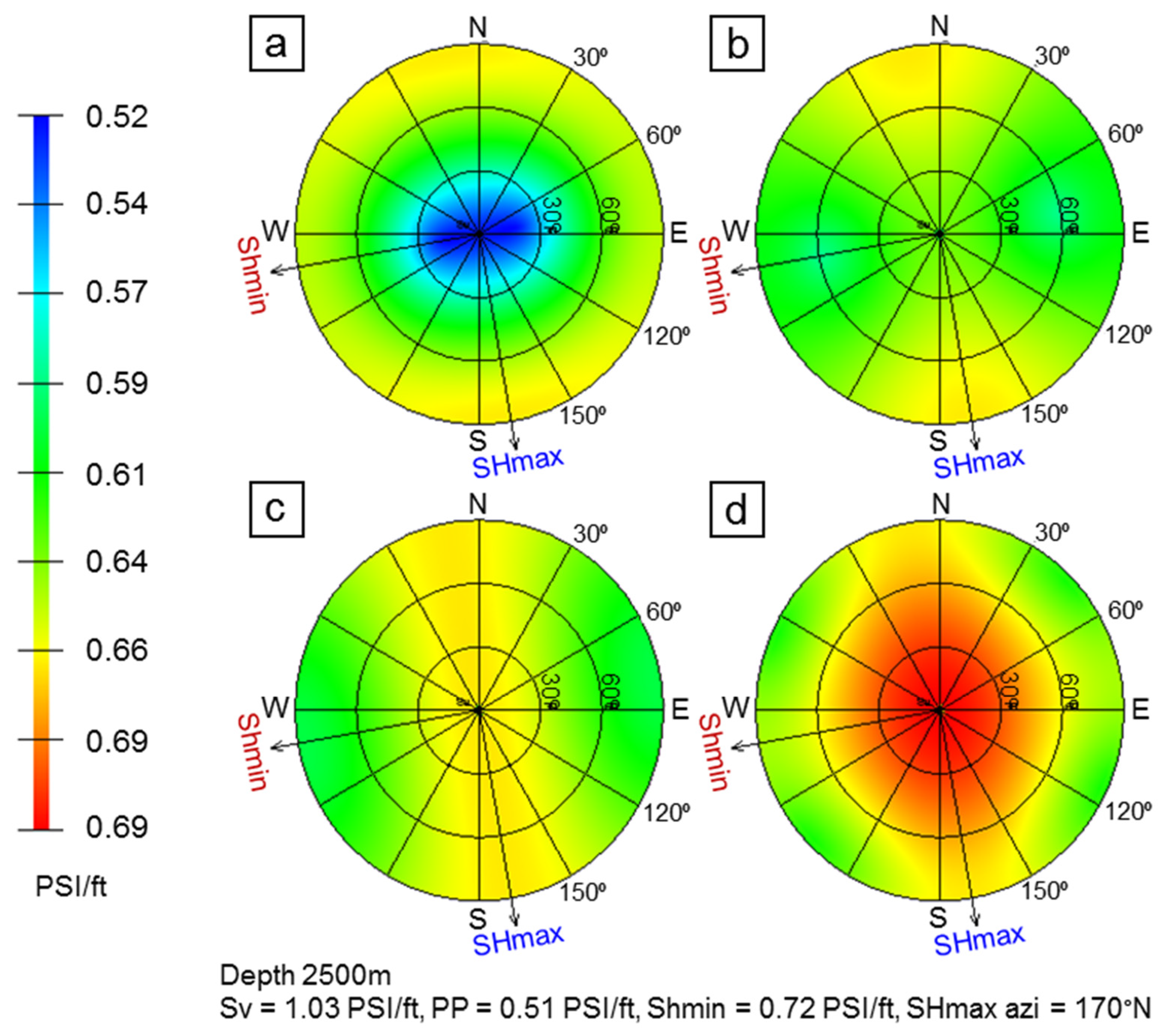

4.4. Safe Wellbore Trajectory Analysis

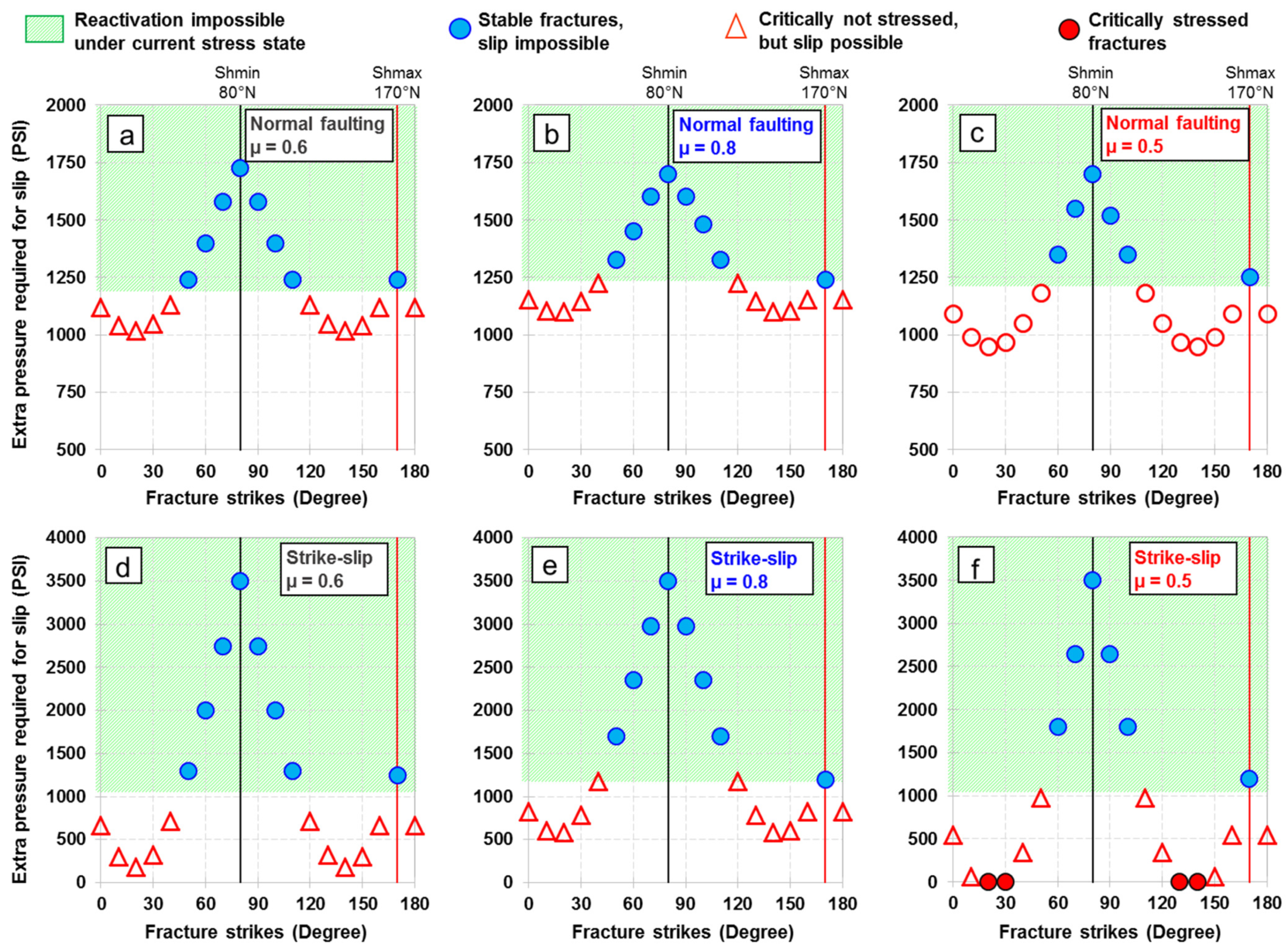

4.5. Fracture Reactivation Potential

4.6. Inferences on Unconventional Reservoir Development

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Herbin, J.P.; Montadert, L.; Muller, C.; Gomez, R.; Thurow, J.; Wiedmann, J. Organic-Rich Sedimentation at the Cenomanian-Turonian Boundary in Oceanic and Coastal Basins in the North Atlantic and Tethys. Geol. Soc. Lond. Spec. Publ. 1986, 21, 389–422. [Google Scholar] [CrossRef]

- Klemme, H.D.; Ulmishek, G.F. Effective petroleum source rocks of the world: Stratigraphic distribution and controlling depositional factors. AAPG Bull. 1991, 75, 1809–1851. [Google Scholar] [CrossRef]

- Lüning, S.; Kolonic, S.; Belhadj, E.M.; Belhadj, Z.; Cota, L.; Barić, G.; Wagner, T. Integrated depositional model for the Cenomanian–Turonian organic-rich strata in North Africa. Earth-Sci. Rev. 2004, 64, 51–117. [Google Scholar] [CrossRef]

- Boutaleb, K.; Baouche, R.; Sadaoui, M.; Radwan, A.E. Sedimentological, petrophysical, and geochemical controls on deep marine unconventional tight limestone and dolostone reservoir: Insights from the Cenomanian/Turonian oceanic anoxic event 2 organic-rich sediments, Southeast Constantine Basin, Algeria. Sediment. Geol. 2022, 429, 106072. [Google Scholar] [CrossRef]

- Farouk, S.; Sen, S.; Ganguli, S.S.; Ahmed, F.; Abioui, M.; Al-Kahtany, K.; Gupta, P. An integrated petrographical, petrophysical and organic geochemical characterization of the Lower Turonian Abu Roash-F carbonates, Abu Gharadig field, Egypt—Inferences on self-sourced unconventional reservoir potential. Mar. Pet. Geol. 2022, 145, 105885. [Google Scholar] [CrossRef]

- Zobaa, M.K.; Oboh-Ikuenobe, F.E.; Ibrahim, M.I.; Arneson, K.K.; Browne, C.M.; Kholeif, S. The Cenomanian/Turonian oceanic anoxic event in the Razzak #7 oil well, north Western Desert, Egypt: Palynofacies and isotope analyses. In Proceedings of the 2009 GSA Annual Meeting 2009, Abstracts with Programs, Portland, OR, USA, 19 October 2009; p. 513. [Google Scholar]

- Dokka, A.M.; Guellati, N.; Hamel, A. Cenomanian–Turonian carbonate reservoirs of Guerguett-El-Kihal, a new discovery in the Southeast Constantine Basin, Algeria. In Proceedings of the AAPG Annual Convention and Exposition, San Francisco, CA, USA, 3–6 June 1990. [Google Scholar]

- Boudjema, A.; Rahmani, A.; Belhadj, E.M.; Hamel, M.; Bourmouche, R. Source rock identification and oil generation related to trap formation: Southeast Constantine Oil Field. In Proceedings of the Annual Convention, AAPG Annual Convention, San Francisco, CA, USA, 3–6 June 1990. [Google Scholar]

- Baouche, R.; Sen, S.; Ganguli, S.S.; Boutaleb, K. Petrophysical and geomechanical characterization of the Late Cretaceous limestone reservoirs from the Southeastern Constantine Basin, Algeria. Interpretation 2021, 9, SH1. [Google Scholar] [CrossRef]

- Askri, H.; Belmecheri, A.; Benrabah, B.; Boudjema, A.; Boumendjel, K.; Daoudi, M.; Drid, M.; Ghalem, T.; Docca, A.M.; Ghandriche, H.; et al. Geology of Algeria. In Well Evaluation Conference Algeria; Schlumberger: Houston, TX, USA, 1995; pp. 1–93. [Google Scholar]

- Bentaalla-Kaced, S.; Aïfa, T.; Deramchi, K. Organic-rich Albian deposits as the origin of hydrocarbons-contaminated phosphates, southeast Constantine Basin, Algeria. J. Pet. Sci. Eng. 2017, 157, 680–695. [Google Scholar] [CrossRef]

- Choquette, P.W.; Pray, L.C. Geologic nomenclature and classification of porosity in sedimentary carbonates. AAPG Bull. 1970, 54 (Suppl. 2), 207–250. [Google Scholar]

- Dunham, R.J. Classification of carbonate rocks according to depositional texture. Am. Assoc. Pet. Geol. Mem. 1962, 1, 108–121. [Google Scholar]

- Embry, A.F.; Klovan, J.E. Absolute water depth limits of Late Devonian paleoecological zones. Geol. Rundsch. 1972, 61 (Suppl. 2), 672–686. [Google Scholar] [CrossRef]

- Flügel, E. Carbonate Rocks. Analysis, Interpretation and Application, 2nd ed.; Springer: Berlin/Heidelberg, Germany; New York, NY, USA, 2010. [Google Scholar] [CrossRef]

- Jannot, Y.; Lasseux, D. A new quasi-steady method to measure gas permeability of weakly permeable porous media. Rev. Sci. Instrum. 2012, 83 (Suppl. 1), 015113. [Google Scholar] [CrossRef] [PubMed]

- Zoback, M.D. Reservoir Geomechanics; Stanford University: Stanford, CA, USA, 2007. [Google Scholar]

- Abdelghany, W.K.; Radwan, A.E.; Elkhawaga, M.A.; Wood, D.A.; Sen, S.; Kassem, A.A. Geomechanical modeling using the depth-of-damage approach to achieve successful underbalanced drilling in the Gulf of Suez Rift Basin. J. Pet. Sci. Eng. 2021, 202, 108311. [Google Scholar] [CrossRef]

- Radwan, A.; Sen, S. Stress path analysis for characterization of in situ stress state and effect of reservoir depletion on present-day stress magnitudes: Reservoir geomechanical modeling in the Gulf of Suez Rift Basin, Egypt. Nat. Resour. Res. 2021, 30, 463–478. [Google Scholar] [CrossRef]

- Radwan, A.E.; Sen, S. Characterization of in-situ stresses and its implications for production and reservoir stability in the depleted El Morgan hydrocarbon field, Gulf of Suez Rift Basin, Egypt. J. Struct. Geol. 2021, 148, 104355. [Google Scholar] [CrossRef]

- Militzer, H.; Stoll, R. Einige Beitrage der geophysik zur primadatenerfassung im Bergbau. Neue Bergbautech. 1973, 3, 21–25. [Google Scholar]

- Grieser, W.V.; Bray, J.M. Identification of production potential in unconventional reservoirs. In Proceedings of the Production and Operations Symposium 2007, Oklahoma City, OK, USA, 31 March 2007. [Google Scholar] [CrossRef]

- Jin, X.; Shah, S.N.; Roegiers, J.-C.; Zhang, B. An integrated petrophysics and geomechanics approach for fracability evaluation in shale reservoirs. SPE J. 2015, 20, 518–526. [Google Scholar] [CrossRef]

- Enderlin, M.B.; Alsleben, H. A method for evaluating the effects of confining stresses and rock strength on fluid flow along the surfaces of mechanical discontinuities in low-permeability rocks. In Shale Reservoirs—Giant Resources for the 21st Century: AAPG Memoir 97; Breyer, J.A., Ed.; APPG: Tulsa, OK, USA, 2012. [Google Scholar]

- Zoback, M.D.; Lund Snee, J.-E. Predicted and observed shear on preexisting faults during hydraulic fracture stimulation. SEG Tech. Program Expand. Abstr. 2018, 239, 3588–3592. [Google Scholar]

- Almalikee, H.; Sen, S. Rock-mechanical properties and in situ stress state of the Upper Cenomanian Mishrif limestone reservoir, Zubair oil field, southern Iraq. Interpretation 2022, 10, T521–T529. [Google Scholar] [CrossRef]

- Agbasi, O.E.; Sen, S.; Inyang, N.J.; Etuk, S.E. Assessment of pore pressure, wellbore failure and reservoir stability in the Gabo field, Niger Delta, Nigeria—Implications for drilling and reservoir management. J. Afr. Earth Sci. 2021, 173, 104038. [Google Scholar] [CrossRef]

- Kassem, A.; Sen, S.; Radwan, A.E.; Abdelghany, W.K.; Abioui, M. Effect of depletion and fluid injection in the Mesozoic and Paleozoic sandstone reservoirs of the October oil field, Central Gulf of Suez Basin: Implications on drilling, production and reservoir stability. Nat. Resour. Res. 2021, 30, 2587–2606. [Google Scholar] [CrossRef]

- Radwan, A.E. A multi-proxy approach to detect the pore pressure and the origin of overpressure: An example from the Gulf of Suez Rift Basin. Front. Earth Sci. 2022, 1607. [Google Scholar] [CrossRef]

- Bashmagh, N.M.; Lin, W.; Murata, S.; Yousefi, F.; Radwan, A.E. Magnitudes and Orientations of Present-Day In-Situ Stresses in the Kurdistan Region of Iraq: Insights into combined strike-slip and reverse faulting stress regimes. J. Asian Earth Sci. 2022, 147, 105398. [Google Scholar] [CrossRef]

- Radwan, A.E.; Abdelghany, W.K.; Elkhawaga, M.A. Present-day in-situ stresses in Southern Gulf of Suez, Egypt: Insights for stress rotation in an extensional rift basin. J. Struct. Geol. 2021, 147, 104334. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baouche, R.; Sen, S.; Radwan, A.E. Geomechanical and Petrophysical Assessment of the Lower Turonian Tight Carbonates, Southeastern Constantine Basin, Algeria: Implications for Unconventional Reservoir Development and Fracture Reactivation Potential. Energies 2022, 15, 7901. https://doi.org/10.3390/en15217901

Baouche R, Sen S, Radwan AE. Geomechanical and Petrophysical Assessment of the Lower Turonian Tight Carbonates, Southeastern Constantine Basin, Algeria: Implications for Unconventional Reservoir Development and Fracture Reactivation Potential. Energies. 2022; 15(21):7901. https://doi.org/10.3390/en15217901

Chicago/Turabian StyleBaouche, Rafik, Souvik Sen, and Ahmed E. Radwan. 2022. "Geomechanical and Petrophysical Assessment of the Lower Turonian Tight Carbonates, Southeastern Constantine Basin, Algeria: Implications for Unconventional Reservoir Development and Fracture Reactivation Potential" Energies 15, no. 21: 7901. https://doi.org/10.3390/en15217901

APA StyleBaouche, R., Sen, S., & Radwan, A. E. (2022). Geomechanical and Petrophysical Assessment of the Lower Turonian Tight Carbonates, Southeastern Constantine Basin, Algeria: Implications for Unconventional Reservoir Development and Fracture Reactivation Potential. Energies, 15(21), 7901. https://doi.org/10.3390/en15217901