A Mini-Review on Straw Bale Construction

Abstract

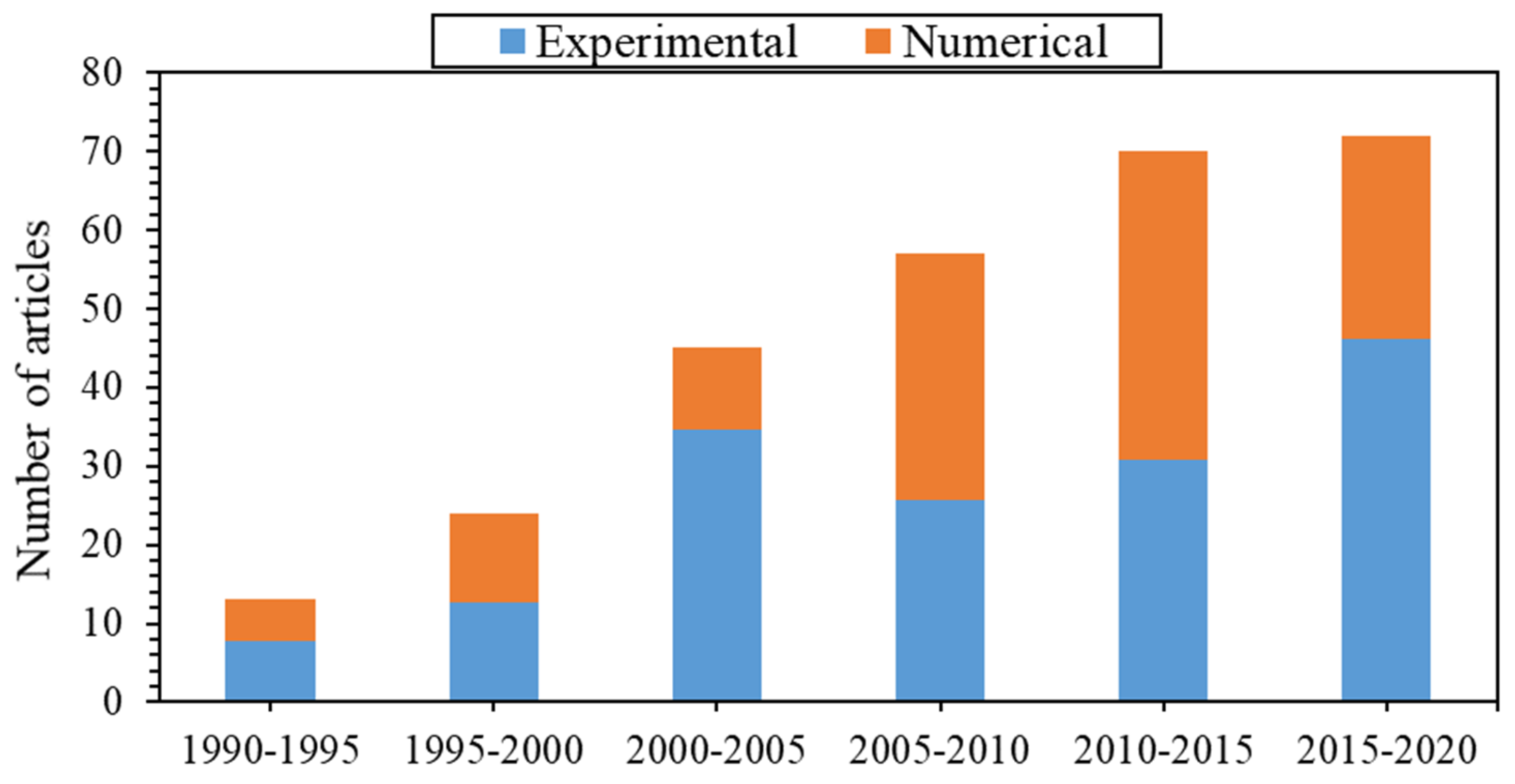

1. Introduction

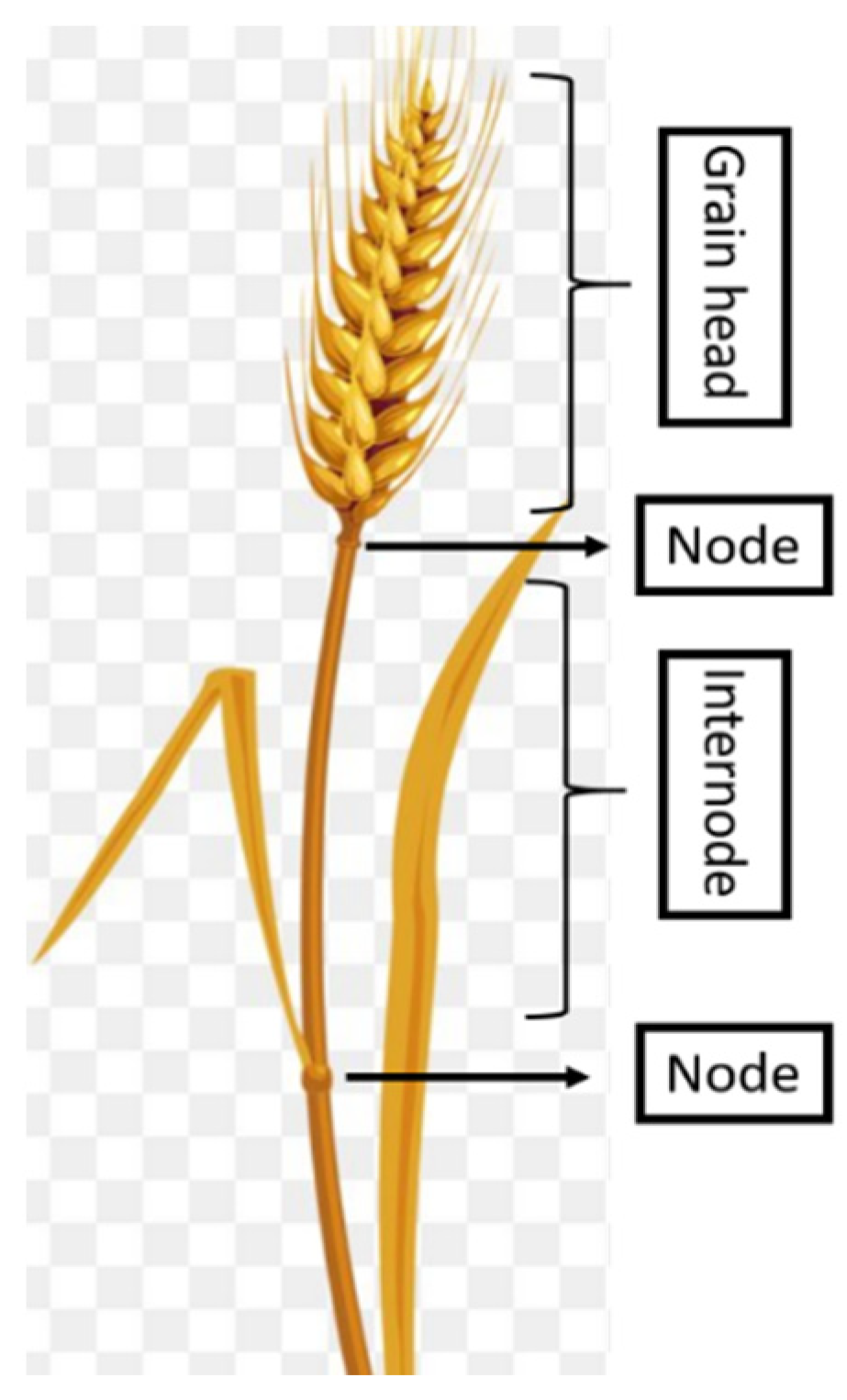

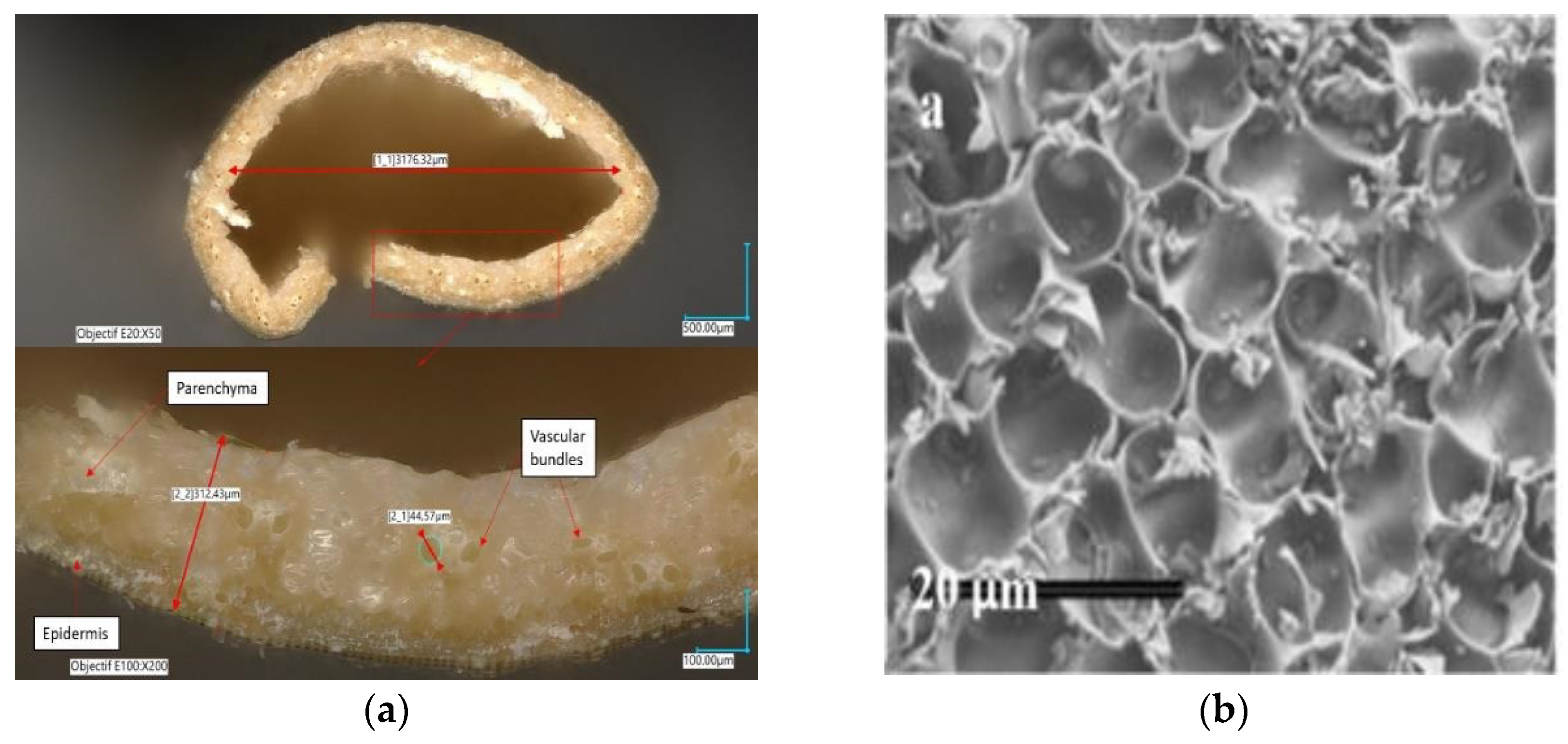

2. Straw Fibers and Bales

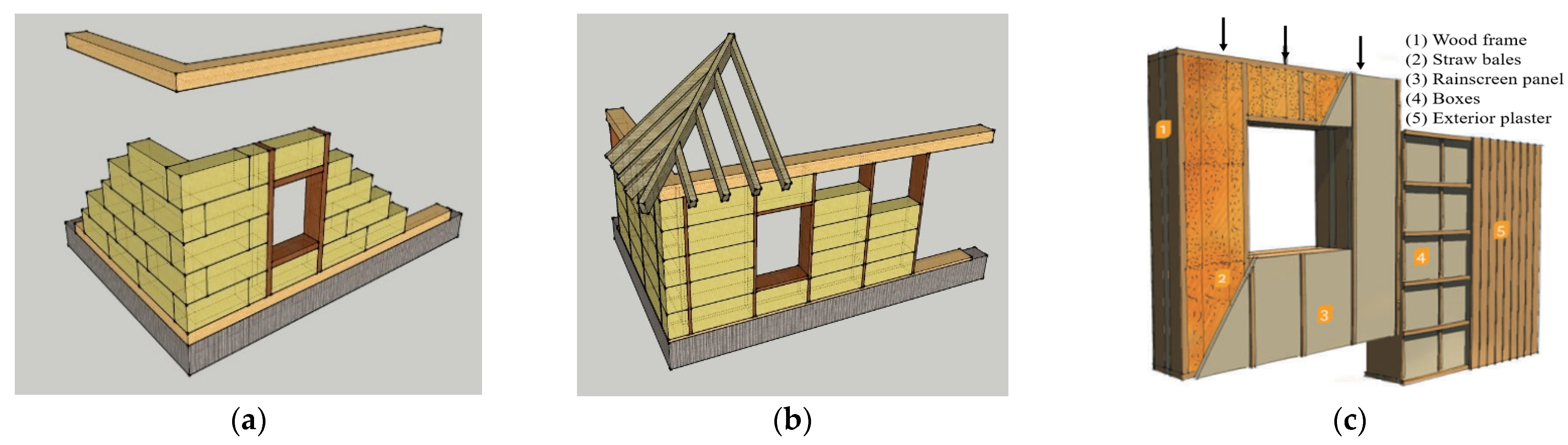

3. Straw Walls and Buildings

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- IEA—International Energy Agency. 2021. Available online: https://www.iea.org/ (accessed on 13 October 2022).

- SCM Lejeune, La Construction en Paille: Construire en Paille, Construire L’avenir, RFCP et SCM Lejeune. 2015. Available online: https://www.rfcp.fr/ (accessed on 1 September 2020).

- Tlaiji, G.; Ouldboukhitine, S.; Pennec, F.; Biwole, P. Thermal and mechanical behavior of straw-based construction: A review. Constr. Build. Mater. 2022, 316, 125915. [Google Scholar] [CrossRef]

- Cascone, S.; Rapisarda, R.; Cascone, D. Physical Properties of Straw Bales as a Construction Material: A Review. Sustainability 2019, 11, 3388. [Google Scholar] [CrossRef]

- Koh, C.H.; Kraniotis, D. A review of material properties and performance of straw bale as building material. Constr. Build. Mater. 2020, 259, 120385. [Google Scholar] [CrossRef]

- Ghaffar, S.H.; Fan, M. Revealing the morphology and chemical distribution of nodes in wheat straw. Biomass Bioenergy 2015, 77, 123–134. [Google Scholar] [CrossRef]

- Laborel-Préneron, A.; Magniont, C.; Aubert, J.-E. Characterization of Barley Straw, Hemp Shiv and Corn Cob as Resources for Bioaggregate Based Building Materials. Waste Biomass Valorization 2018, 9, 1095–1112. [Google Scholar] [CrossRef]

- Bouasker, M.; Belayachi, N.; Hoxha, D.; Al-Mukhtar, M. Physical Characterization of Natural Straw Fibers as Aggregates for Construction Materials Applications. Materials 2014, 7, 3034–3048. [Google Scholar] [CrossRef]

- Kurniati, A.; Darmokoesoemo, H.; Puspaningsih, N.N.T. Scanning Electron Microscope Analysis of Rice Straw Degradation by a Treatment with α-L-arabinofuranosidase. Procedia Chem. 2016, 18, 63–68. [Google Scholar] [CrossRef][Green Version]

- Halvarsson, S.; Edlund, H.; Norgren, M. Wheat Straw As Raw Material for Manufacture of Straw (Mdf). Bioresources 2010, 5, 1215–1231. [Google Scholar]

- Alpha Cellulose–CAMEO. 2016. Available online: http://cameo.mfa.org/wiki/Alpha_cellulose (accessed on 10 February 2021).

- Wang, D. Basic Lignin Chemistry. Available online: https://pdf4pro.com/view/basic-lignin-chemistry-59bdf9.html (accessed on 13 October 2020).

- Plazonić, I.; Barbarić-Mikočević, Z.; Antonović, A. Chemical Composition of Straw as an Alternative Material to Wood Raw Material in Fibre Isolation. Drv. Ind. 2016, 67, 119–125. [Google Scholar] [CrossRef]

- Comité National des Coproduits ADEME, Co-Produits Riches en Ligno-Cellulose, Paille de Céréale, Fiche 1. Available online: https://librairie.ademe.fr/ (accessed on 12 November 2020).

- Watts, K.C.; Wilkie, K.I.; Tompson, K.; Corson, J. Thermal and mechanical properties of straw bales as they relate to a straw house. In Proceedings of the agricultural institute of Canada Annual conference, Ottawa, ON, Canada, 9–12 July 1995; Agricultural Institute of Canada: Ottawa, ON, Canada, 1995; pp. 95–209. [Google Scholar]

- Wihan, J. Humidity in Straw Bale Walls and its Effect on the Decomposition of Straw; University of East London School of Computing and Technology: London, UK, 2007. [Google Scholar]

- JCostes, J.-P.; Evrard, A.; Biot, B.; Keutgen, G.; Daras, A.; Dubois, S.; Lebeau, F.; Courard, L. Thermal Conductivity of Straw Bales: Full Size Measurements Considering the Direction of the Heat Flow. Buildings 2017, 7, 11. [Google Scholar] [CrossRef]

- McCabe, J. The Thermal Resistivity of Straw Bale Construction. Master’s Thesis, The University of Arizona, Tucson, AZ, USA, 1993. [Google Scholar]

- Sabapathy, K.; Gedupudi, S. Straw bale based constructions: Measurement of effective thermal transport properties. Constr. Build. Mater. 2019, 198, 182–194. [Google Scholar] [CrossRef]

- JVėjelienė, J. Processed straw as effective thermal insulation for building envelope constructions. Eng. Struct. Technol. 2012, 4, 96–103. [Google Scholar]

- Solids, Liquids and Gases–Thermal Conductivities. Available online: https://www.engineeringtoolbox.com/thermal-conductivity-d_429.html (accessed on 13 October 2022).

- Goodhew, S.; Griffiths, R. Sustainable earth walls to meet the building regulations. Energy Build. 2005, 37, 451–459. [Google Scholar] [CrossRef]

- Marques, B.; Tadeu, A.; Almeida, J.; António, J.; de Brito, J. Characterisation of sustainable building walls made from rice straw bales. J. Build. Eng. 2019, 28, 101041. [Google Scholar] [CrossRef]

- Solids–Specific Heats. Available online: https://www.engineeringtoolbox.com/specific-heat-solids-d_154.html (accessed on 13 October 2022).

- Module 48: Simple Thermal Analysis for Buildings—CIBSE Journal. Available online: https://www.cibsejournal.com/cpd/modules/2013-01/ (accessed on 13 October 2022).

- Labat, M.; Magniont, C.; Oudhof, N.; Aubert, J.-E. From the experimental characterization of the hygrothermal properties of straw-clay mixtures to the numerical assessment of their buffering potential. Build. Environ. 2016, 97, 69–81. [Google Scholar] [CrossRef]

- Liuzzi, S.; Rubino, C.; Martellotta, F.; Stefanizzi, P.; Casavola, C.; Pappalettera, G. Characterization of biomass-based materials for building applications: The case of straw and olive tree waste. Ind. Crop. Prod. 2020, 147, 112229. [Google Scholar] [CrossRef]

- RFCP. Réseau Français de la Construction Paille|RFCP. Available online: https://www.rfcp.fr/ (accessed on 22 February 2022).

- LBN 002-01; Instruments Regulatory Codes and Standards, Regulations Regarding Latvian Construction Standard. Thermotechnics of Building Envelopes: Riga, Latvia, 2002.

- California Energy Commisio. CEC/ATI, Thermal Performance (ATI-20227); California Energy Commisio: Fresno, CA, USA, 1997.

- Ashour, T. The use of renewable agricultural by-products as building materials. Work 2003, 2, 013-2467034. [Google Scholar]

- Beck, A.; Heinemann, U.; Reidinger, M.; Fricke, J. Thermal Transport in Straw Insulation. J. Therm. Envel. Build. Sci. 2004, 27, 227–234. [Google Scholar] [CrossRef]

- Grelat, A. Utilisation de la Paille en Parois de Maisons Individuelles a Ossature Bois, Centre D’Expertise du Batiment et des Travaux Public 2004. Available online: https://amper.ped.muni.cz/~jhollan/letters/straw/pdfBwxFwYWDVG.pdf (accessed on 22 February 2022).

- FASBA. Thermal Performance: Strawbale Building, Research Development 2003–2009; FASBA: Norwalk, NY, USA, 2009.

- Shea, A.; Wall, K.; Walker, P. Evaluation of the thermal performance of an innovative prefabricated natural plant fibre building system. Build. Serv. Eng. Res. Technol. 2013, 34, 369–380. [Google Scholar] [CrossRef]

- Wei, K.; Lv, C.; Chen, M.; Zhou, X.; Dai, Z.; Shen, D. Development and performance evaluation of a new thermal insulation material from rice straw using high frequency hot-pressing. Energy Build. 2015, 87, 116–122. [Google Scholar] [CrossRef]

- Conti, L.; Barbari, M.; Monti, M. Steady-State Thermal Properties of Rectangular Straw-Bales (RSB) for Building. Buildings 2016, 6, 44. [Google Scholar] [CrossRef]

- Gallegos-Ortega, R.; Magaña-Guzmán, T.; Reyes-López, J.A.; Romero-Hernández, M.S. Thermal behavior of a straw bale building from data obtained in situ: A case in Northwestern México. Build. Environ. 2017, 124, 336–341. [Google Scholar] [CrossRef]

- D’Alessandro, F.; Bianchi, F.; Baldinelli, G.; Rotili, A.; Schiavoni, S. Straw bale constructions: Laboratory, in field and numerical assessment of energy and environmental performance. J. Build. Eng. 2017, 11, 56–68. [Google Scholar] [CrossRef]

- Cascone, S.; Evola, G.; Gagliano, A.; Sciuto, G.; Parisi, C.B. Laboratory and in-situ measurements for thermal and acoustic performance of straw bales. Sustainability 2019, 11, 5592. [Google Scholar] [CrossRef]

- Konečný, P.; Teslík, J.; Hamala, M. Mechanical and Physical Properties of Straw Bales. Adv. Mat. Res. 2013, 649, 250–253. [Google Scholar] [CrossRef]

- Ashour, T.; Georg, H.; Wu, W. Performance of straw bale wall: A case of study. Energy Build. 2011, 43, 1960–1967. [Google Scholar] [CrossRef]

- What Is the Modulus of Elasticity of Concrete? 9 Important Points. Available online: https://www.gcelab.com/blog/what-is-the-modulus-of-elasticity-of-concrete (accessed on 13 October 2022).

- Barbara. Information Guide to Straw Bale Building, for Self Builders and the Construction Industry; Amazon Nails: Todmorden, UK, 2001. [Google Scholar]

- Mesa, A.; Arenghi, A. Hygrothermal behaviour of straw bale walls: Experimental tests and numerical analyses. Sustain. Build. 2019, 4, 10. [Google Scholar] [CrossRef]

- Thomson, A.; Walker, P. Condition monitoring and durability assessment of straw bale construction. In Contribution of Sustainable Building to Meet EU 20-20-20 Targets, Design for Life Cycle and Reuse, Portugal; Braganca, L., Pinheiro, M., Mateus, R., Eds.; Elsevier: Guimaraes, Portugal, 2013; pp. 791–798. [Google Scholar]

- Robinson, J.; Aoun, H.K.; Davison, M. Determining Moisture Levels in Straw Bale Construction. Procedia Eng. 2017, 171, 1526–1534. [Google Scholar] [CrossRef]

- ODouzane, O.; Promis, G.; Roucoult, J.-M.; Le, A.-D.T.; Langlet, T. Hygrothermal performance of a straw bale building: In situ and laboratory investigations. J. Build. Eng. 2016, 8, 91–98. [Google Scholar] [CrossRef]

- Sabapathy, K.A.; Gedupudi, S. In situ thermal characterization of rice straw envelope of an outdoor test room. J. Build. Eng. 2020, 33, 101416. [Google Scholar] [CrossRef]

- Thomson, A.; Walker, P. Durability characteristics of straw bales in building envelopes. Constr. Build. Mater. 2014, 68, 135–141. [Google Scholar] [CrossRef]

- Tlaiji, G.; Pennec, F.; Ouldboukhitine, S.; Ibrahim, M.; Biwole, P. Hygrothermal performance of multilayer straw walls in different climates. Constr. Build. Mater. 2022, 326, 126873. [Google Scholar] [CrossRef]

- Džidić, S. Fire resistance of the straw bale walls. In Proceedings of the 5th International Conference, Contemporary Achievements in Civil Engineering, Subotica, Serbia, 21 April 2017. [Google Scholar]

- Theis, B. Straw Bale Fire Safety a review of testing and experience. In Ecological Building Network (EBNet); The Taunton Press: Newtown, NS, USA, 2003. [Google Scholar]

- Dalmeijer, R. Straw-bale Sound Isolation and Acoustics. Last Straw–Int. J. Straw Bale Nat. Build. 2006, 53. Available online: https://thelaststraw.org/strawbale-sound-isolation-acoustics/ (accessed on 20 October 2022).

- Trabelsi, A.; Kammoun, Z. Experimental evaluation of acoustic characteristics of straw walls. Can. Acoust. 2018, 46, 49–56. [Google Scholar]

- Wall, K.; Walker, P.; Gross, C.; White, C.; Mander, T. Development and testing of a prototype straw bale house. Proc. Inst. Civ. Eng. Constr. Mater. 2012, 165, 377–384. [Google Scholar] [CrossRef]

- CD2E Accelerateur de L’Eco-transition, Construction en Bottes de Paille: Performance Technique, Economique et Ecologique. Available online: https://cd2e.com/ (accessed on 9 September 2022).

- Ashour, T.; Wu, W. Using barley straw as building material. In Barley: Production, Cultivation and Uses; Elfson, S., Ed.; Nova Science Publishers, Inc.: Hauppauge, NY, USA, 2011. [Google Scholar]

- Techniques—A Travel in the Straw-Bale Buildings in Turkey. Available online: https://samanbalya.wordpress.com/building-techniques/ (accessed on 18 October 2021).

- Aznabaev, A.A.; Ovsyannikova, A.V.; Povzun, A.O.; Gaevskaya, Z.A. Assessment of straw construction technologies in terms of thermal efficiency of enclosing structures. Constr. Unique Build. Struct. 2016, 43, 104–116. [Google Scholar]

- Arnaud, L.; la Rosa, C.; Sallet, F. Mechanical behaviour of straw construction following the GREB technique. In Proceedings of the 11th International Conference on Non-Conventional Materials and Technologies (NOCMAT), Bath, UK, 6–9 September 2009; pp. 1–8. [Google Scholar]

- Egis-Straw: The Ultimate Green Building Solution? Available online: https://www.egis-group.com/all-insights/straw-the-ultimate-green-building-solution (accessed on 9 September 2022).

- Building with EcoCocon Straw Panels|EcoCocon. Available online: https://ecococon.eu/se/blog/2020/building-with-ecococon-panels (accessed on 9 September 2022).

- Chaussinand, A.; Scartezzini, J.L.; Nik, V. Straw bale: A waste from agriculture, a new construction material for sustainable buildings. Energy Procedia 2015, 78, 297–302. [Google Scholar] [CrossRef]

- Alcorn, A.; Donn, M. Life cycle potential of strawbale and timber for carbon sequestration in house construction. In Proceedings of the 2nd International Conference on Sustainable Construction Materials and Technologies, Ancona, Italy, 28–30 June 2010; pp. 885–895. [Google Scholar]

- European Straw Building Association. 7-Storey Modular Building in St. Die des Vosges. Available online: https://strawbuilding.eu/7-storey-modular-building-in-st-die-des-vosges/ (accessed on 18 October 2022).

| Ref. | Fiber’s Type | MC/RH (%) | T (°C) | (kg/m3) | Fiber’s Orientation | λ (W/m·K) | Cp (J/kg·K) | α (m2/s) |

|---|---|---|---|---|---|---|---|---|

| [18] | Wheat | MC 8.4 | 20 | 133 | perpendicular | 0.047 | 753.5 | |

| parallel | 0.06 | |||||||

| Rice | 123 | Random | 0.08 | |||||

| [30] | Rice | MC 11 | 23 | 107 | perpendicular | 0.0811 | ---- | ---- |

| parallel | 0.1471 | |||||||

| [31] | Wheat | ---- | ---- | 82–138 | ---- | 0.033 | 2000 | − |

| Barley | ---- | 69–98 | 0.034 | ---- | ---- | |||

| [32] | Barley | ---- | 40 | 80 | perpendicular | 0.041 | ---- | ---- |

| [33] | ---- | RH 50 | 23 | 77 | ---- | 0.066 | ---- | ---- |

| [34] | Wheat | 0 | ---- | 81–111 | perpendicular | 0.044 | ---- | ---- |

| 105 | parallel | 0.067 | ||||||

| [20] | Barley | RH 50 | 10 | 60–120 50–120 | parallel perpendicular | 0.0845–0.0875 0.04–0.075 | ---- | ---- |

| Barley chopped | 35–80 | random | 0.039–0.045 | |||||

| Barley defibered | 35–80 | random | 0.037–0.044 | |||||

| [35] | Wheat | RH 50 | ---- | 63–123 | random | 0.059–0.064 | ---- | ---- |

| ---- | ---- | 115 | 0.087 | |||||

| [36] | Rice | MC 10–18 | 30 | 200–350 | ---- | 0.051–0.053 | ---- | ---- |

| [37] | Wheat | MC 12.5 | 19 | 65.7 | parallel | 0.062 | ---- | ---- |

| MC 11.5 | 84.1 | 0.07 | ||||||

| [38] | ---- | RH 10 | 25 | 115 | ----- | 0.094 | ---- | ---- |

| [39] | ---- | RH 45 | 22 | 80 | ---- | 0.052 | ---- | ---- |

| [40] | Wheat | MC 8 | 35 | 78 | random | 0.069 | ---- | ---- |

| [23] | Rice | RH 0 | 0–40 | 80 | random | ---- | 1075–2025 | ---- |

| 23 | 0.042 | 3847 | ||||||

| RH 50 | 0–40 | 100 | ---- | 1075–2025 | ||||

| 23 | 0.047 | 2970 | ||||||

| [22] | ---- | ---- | --- | 60 | ------- | 0.067 | 600 | |

| [19] | Rice | RH 40 | 30 | 68 | random | 0.06 | ---- | |

| perpendicular | 0.057 | |||||||

| parallel | 0.15 | |||||||

| RH 60 | random | 0.07 | ||||||

| perpendicular | 0.08 | |||||||

| parallel | 0.17 | |||||||

| RH 80 | random | 0.07 | ||||||

| perpendicular | 0.075 | |||||||

| parallel | 0.19 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tlaiji, G.; Biwole, P.; Ouldboukhitine, S.; Pennec, F. A Mini-Review on Straw Bale Construction. Energies 2022, 15, 7859. https://doi.org/10.3390/en15217859

Tlaiji G, Biwole P, Ouldboukhitine S, Pennec F. A Mini-Review on Straw Bale Construction. Energies. 2022; 15(21):7859. https://doi.org/10.3390/en15217859

Chicago/Turabian StyleTlaiji, Ghadie, Pascal Biwole, Salah Ouldboukhitine, and Fabienne Pennec. 2022. "A Mini-Review on Straw Bale Construction" Energies 15, no. 21: 7859. https://doi.org/10.3390/en15217859

APA StyleTlaiji, G., Biwole, P., Ouldboukhitine, S., & Pennec, F. (2022). A Mini-Review on Straw Bale Construction. Energies, 15(21), 7859. https://doi.org/10.3390/en15217859