Thermodynamic Analysis and Working Fluid Selection of a Novel Cogeneration System Based on a Regenerative Organic Flash Cycle

Abstract

1. Introduction

2. Methodology

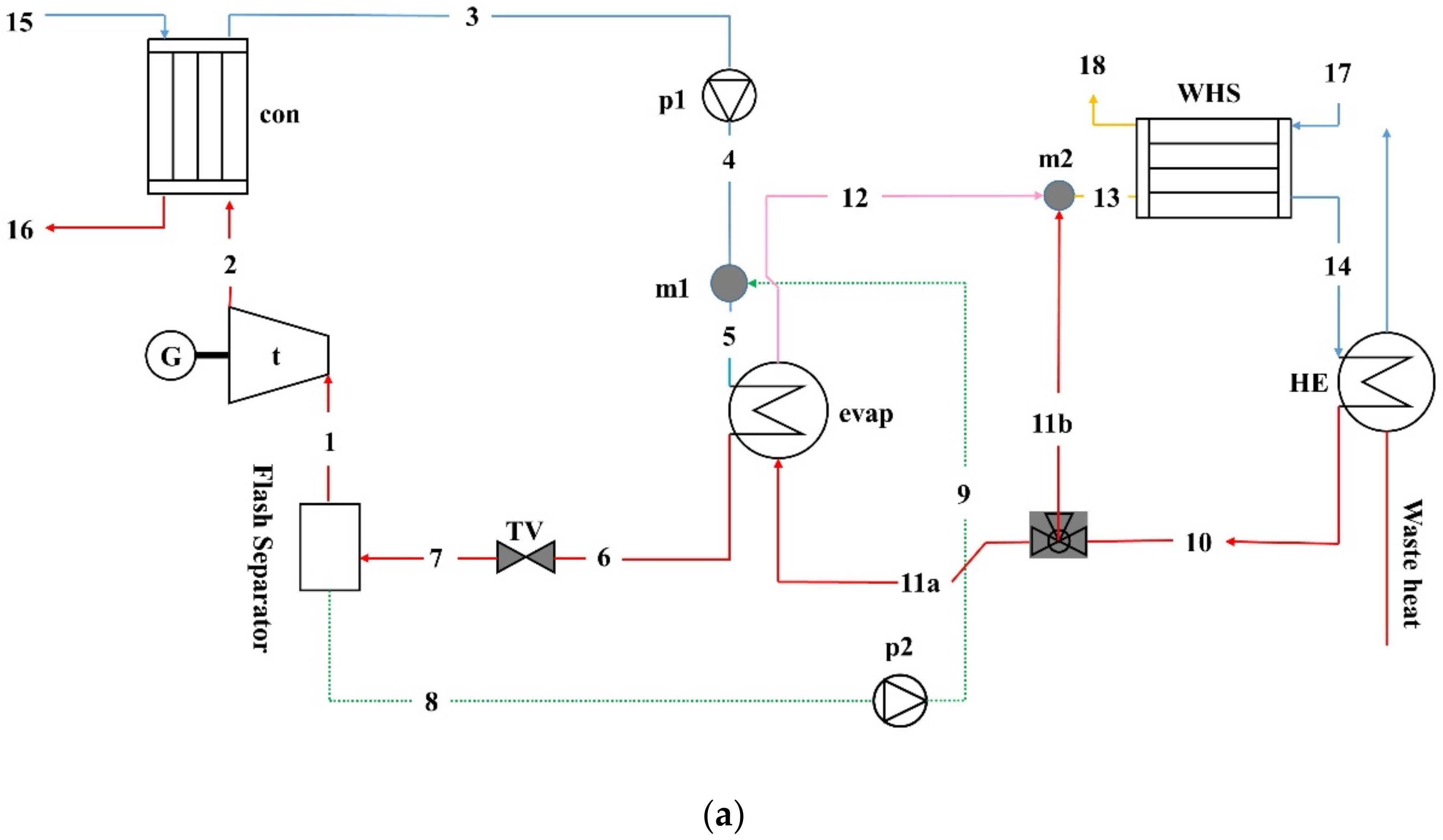

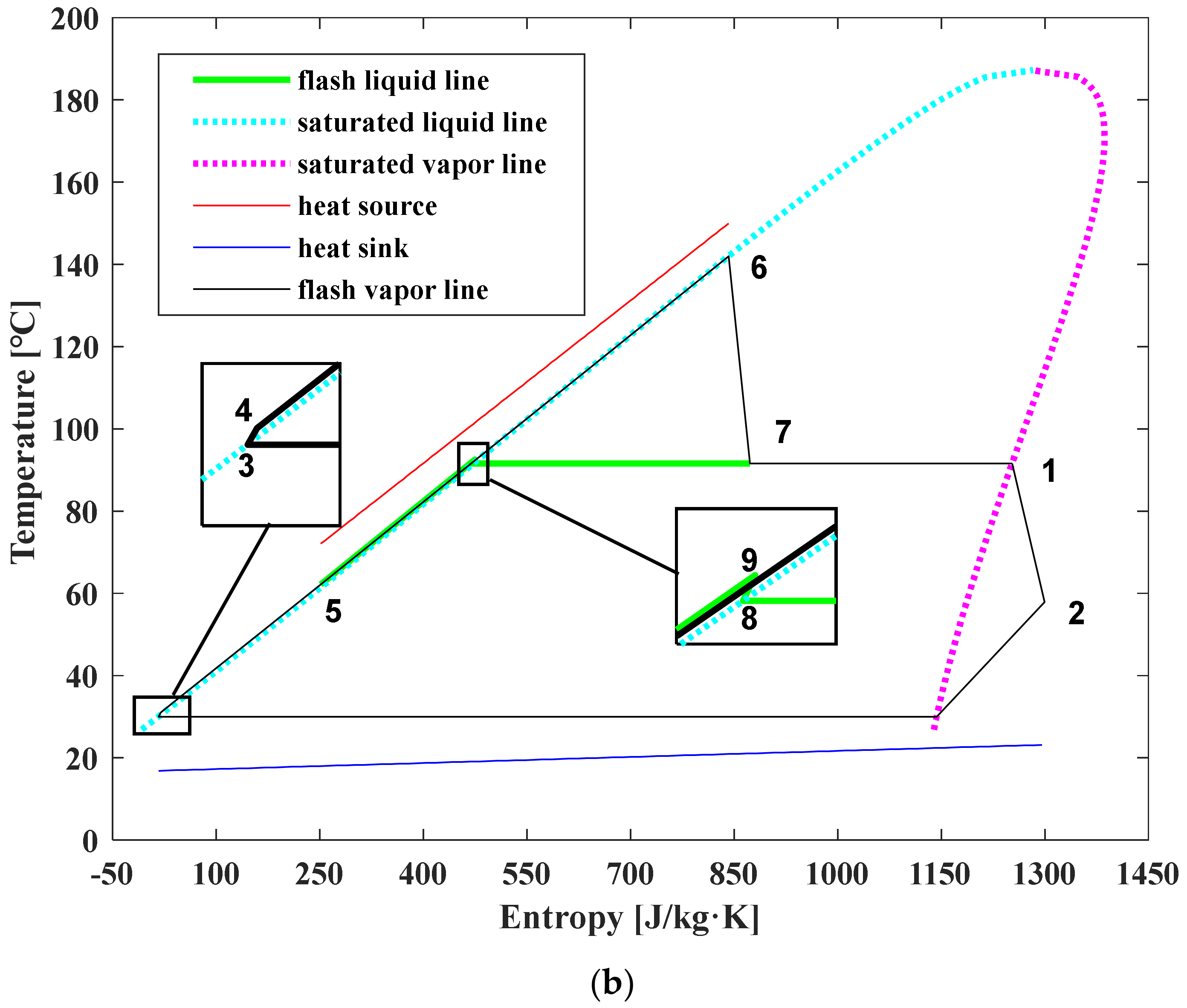

2.1. System Description

2.2. Energy Analysis

- (1)

- Pressure drops during every process were considered zero.

- (2)

- This cycling process was a steady flow process.

- (3)

- Heat losses from the components were negligible.

- (4)

- The kinetic and potential energies were to be zero.

- (5)

- The working fluids flowed into the pumps in the saturated state.

- (6)

- The efficiencies of pumps, turbines, and generators were unchanged.

2.3. Exergy Analysis

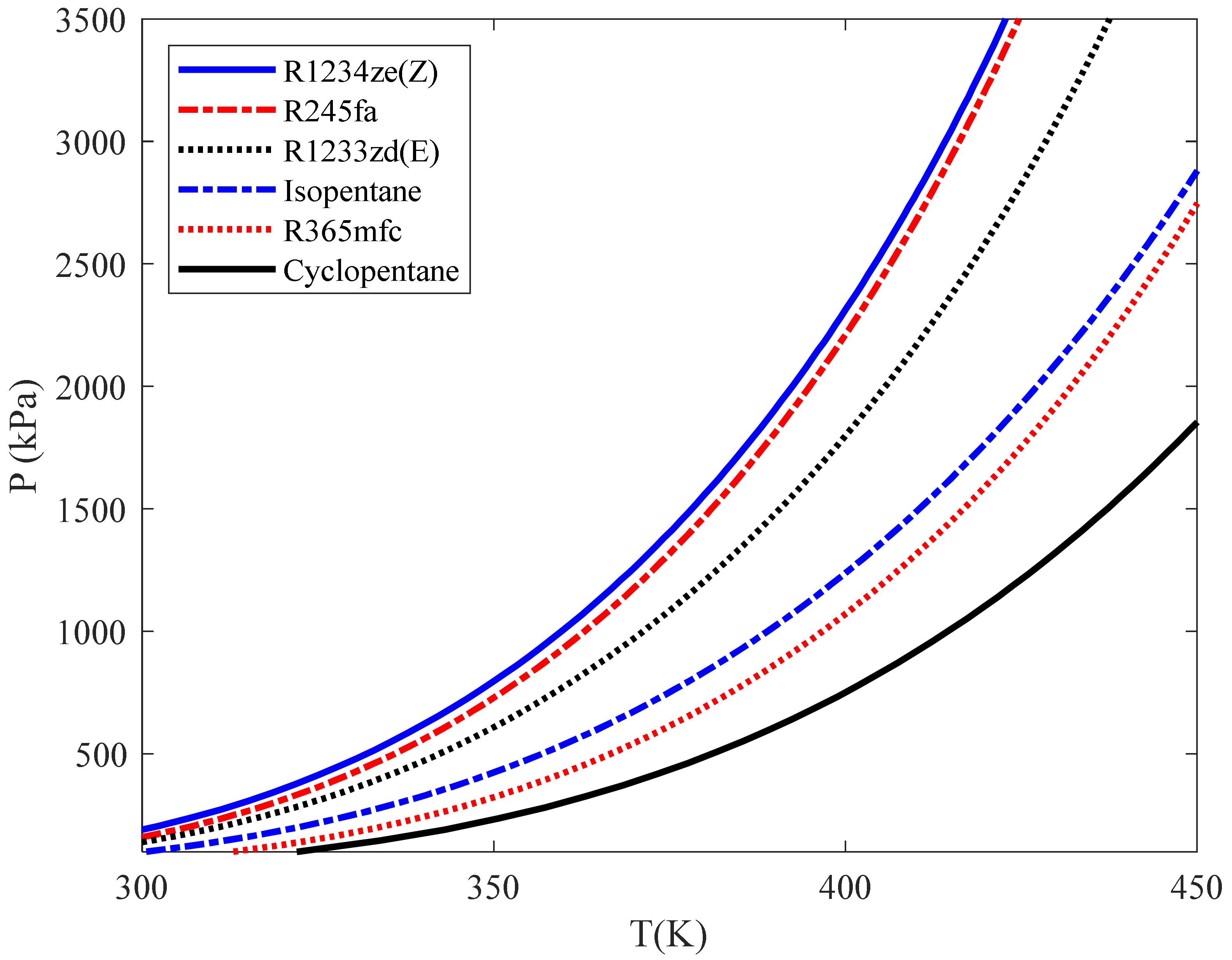

2.4. Model Validation and Working Fluid Selection

3. Results and Discussion

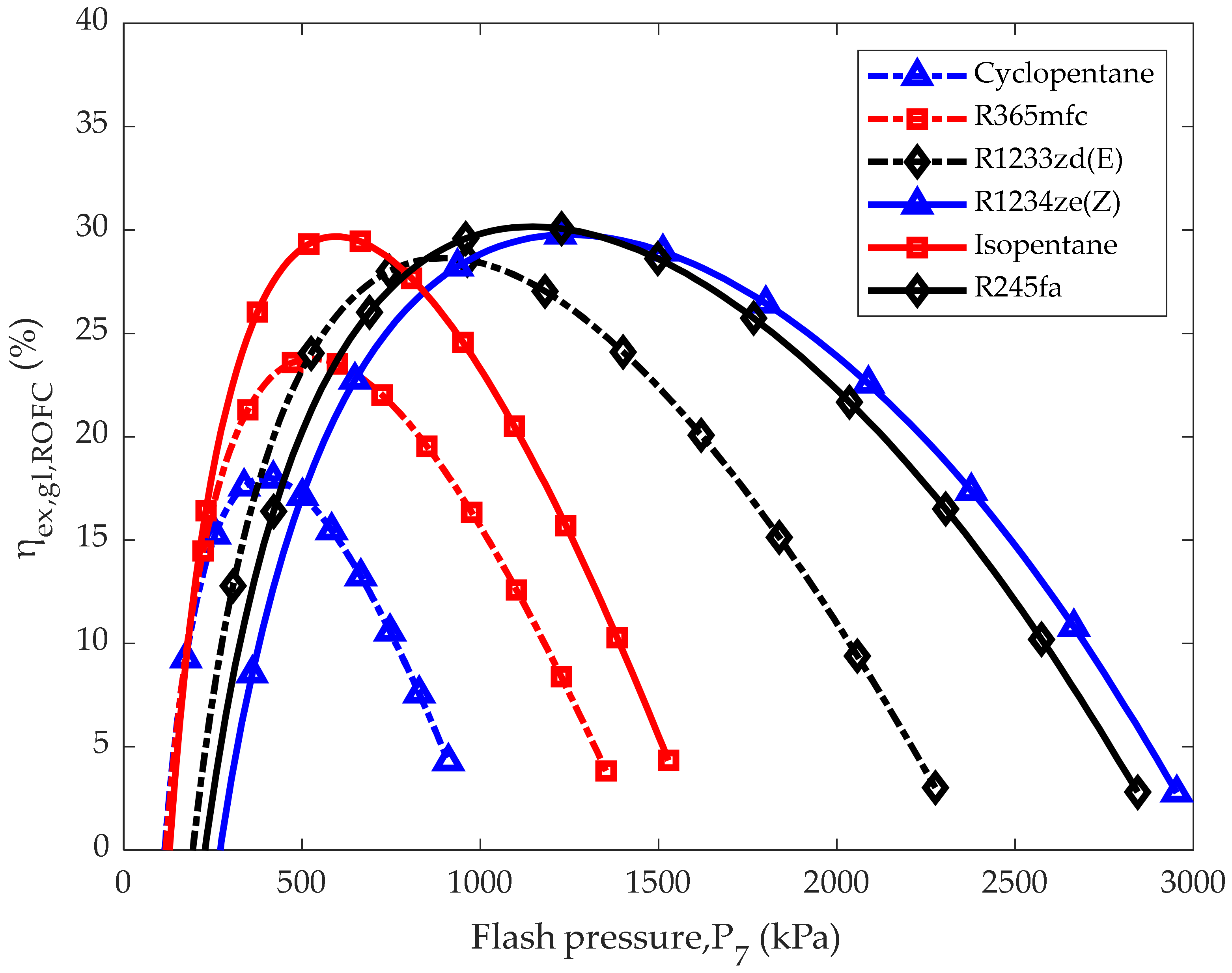

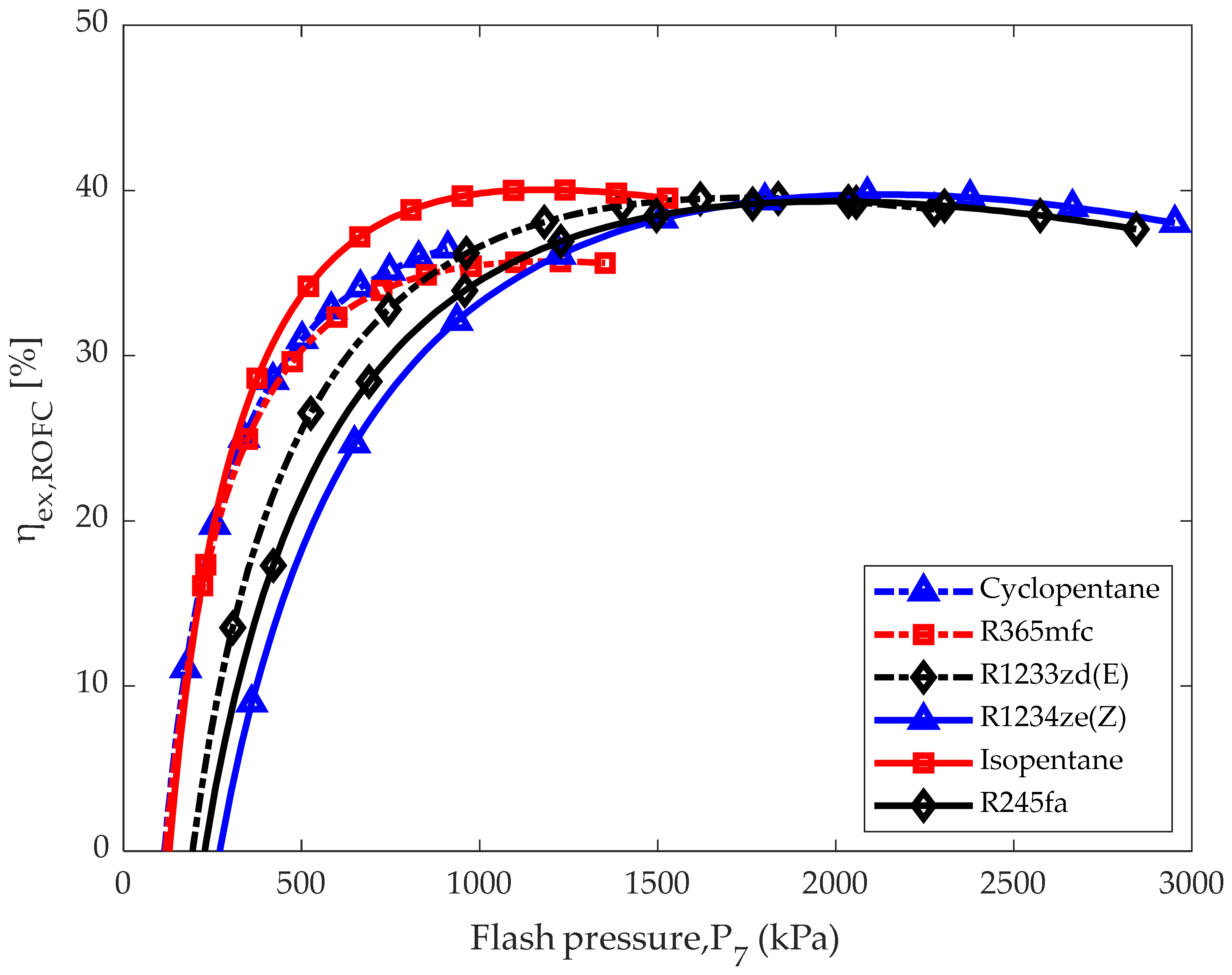

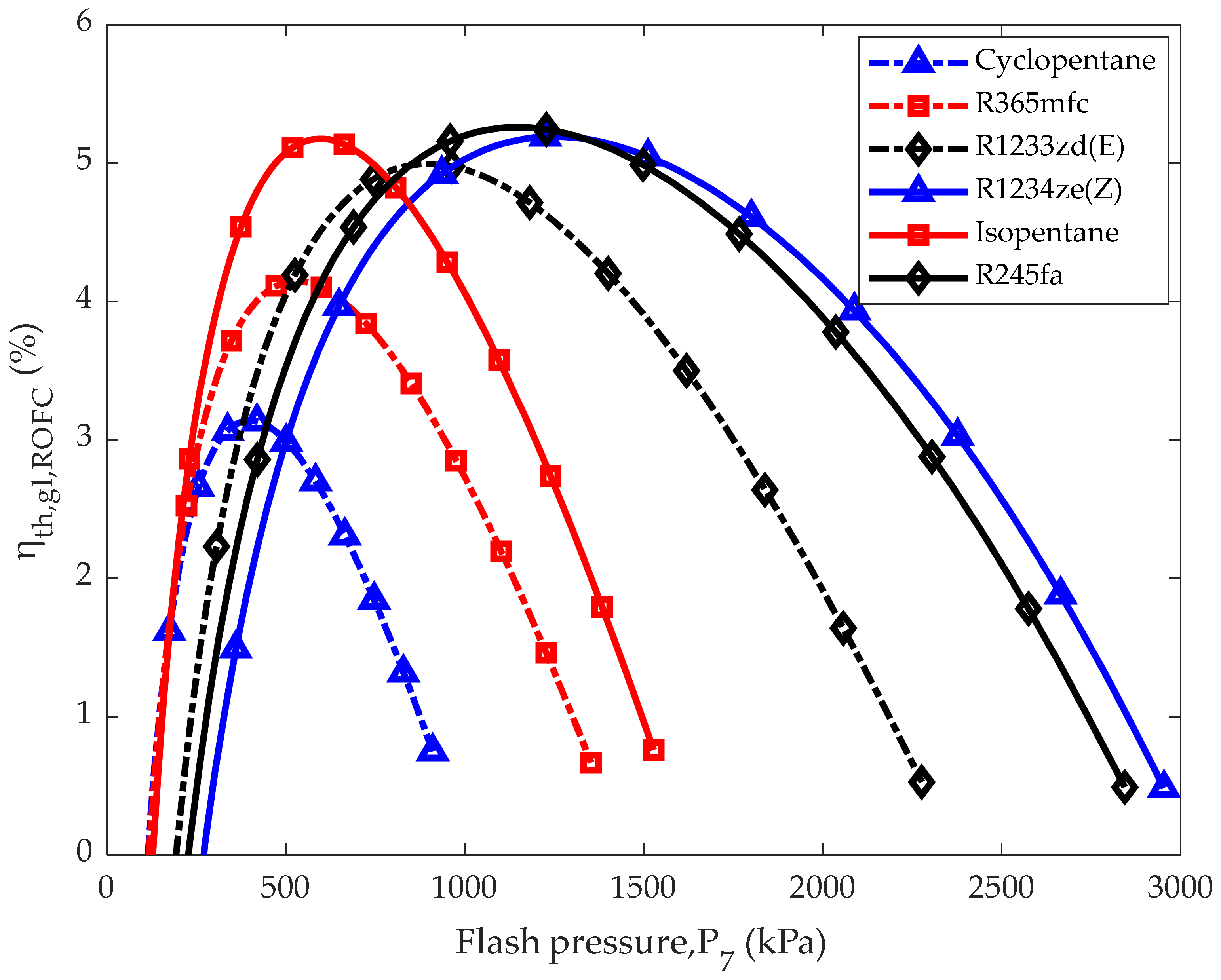

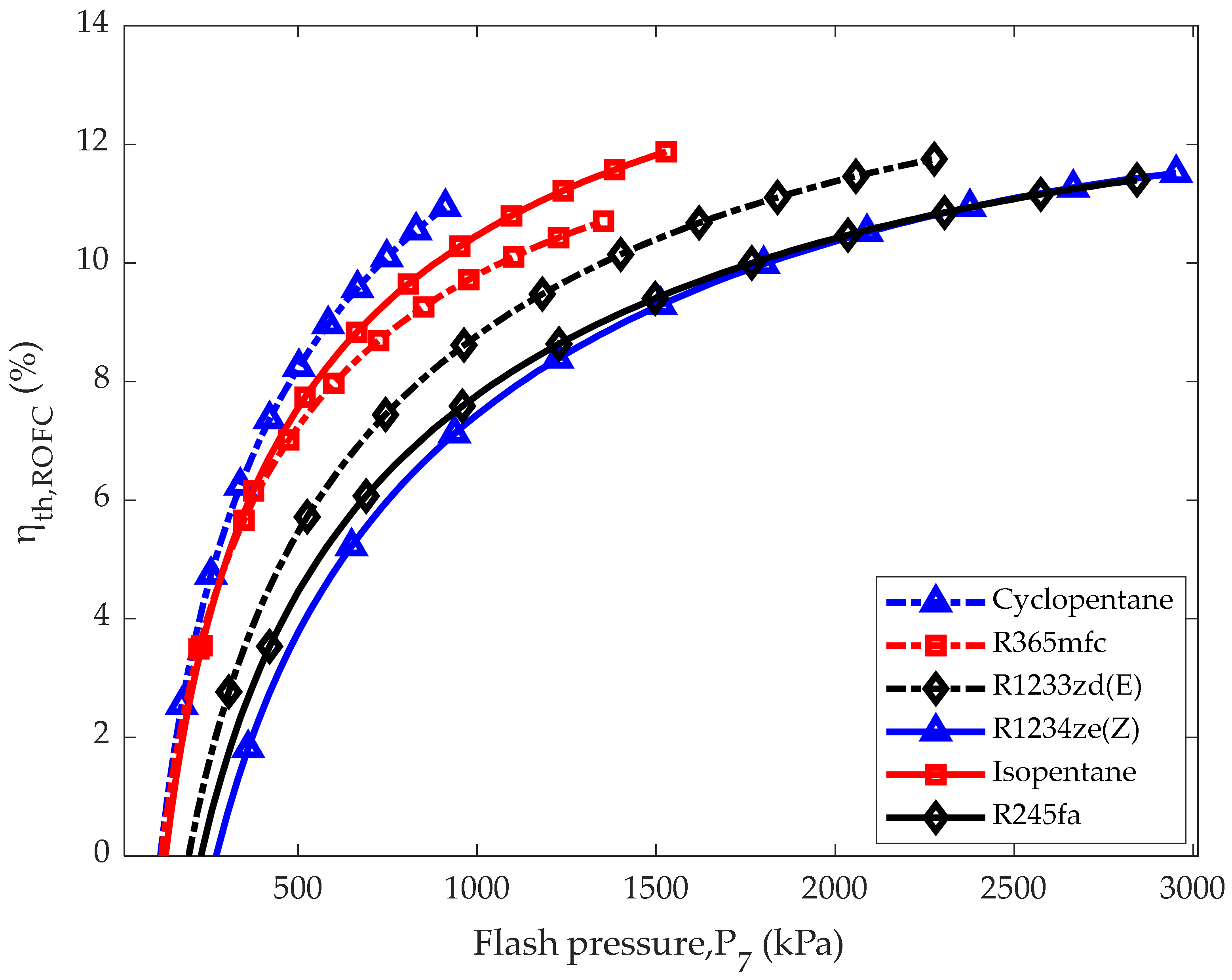

3.1. The Effect of Flash Pressure on ROFC Performance

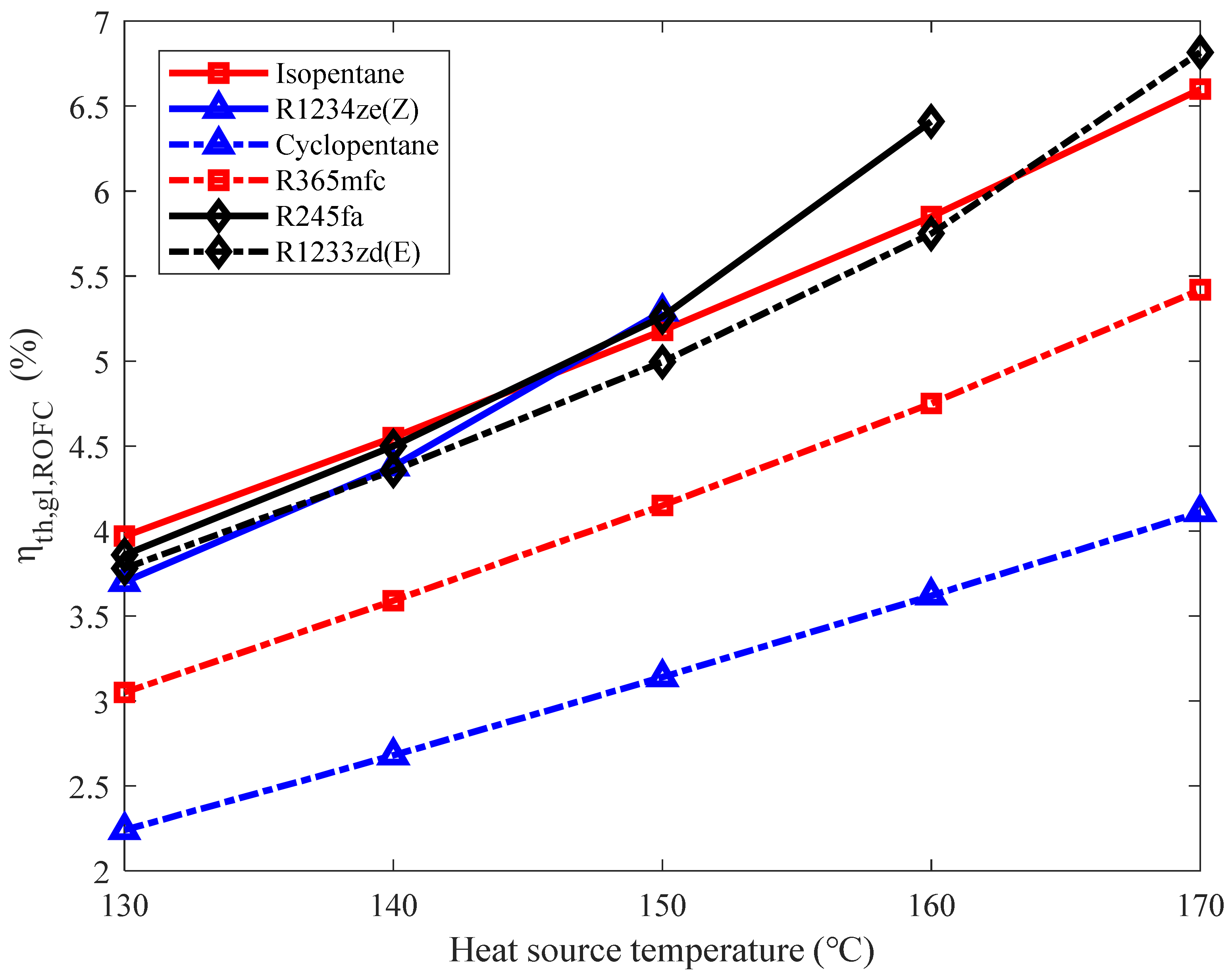

3.2. The Optimal Working Fluid for ROFC

3.3. The Effect of Heat Source Temperature on ROFC Performance

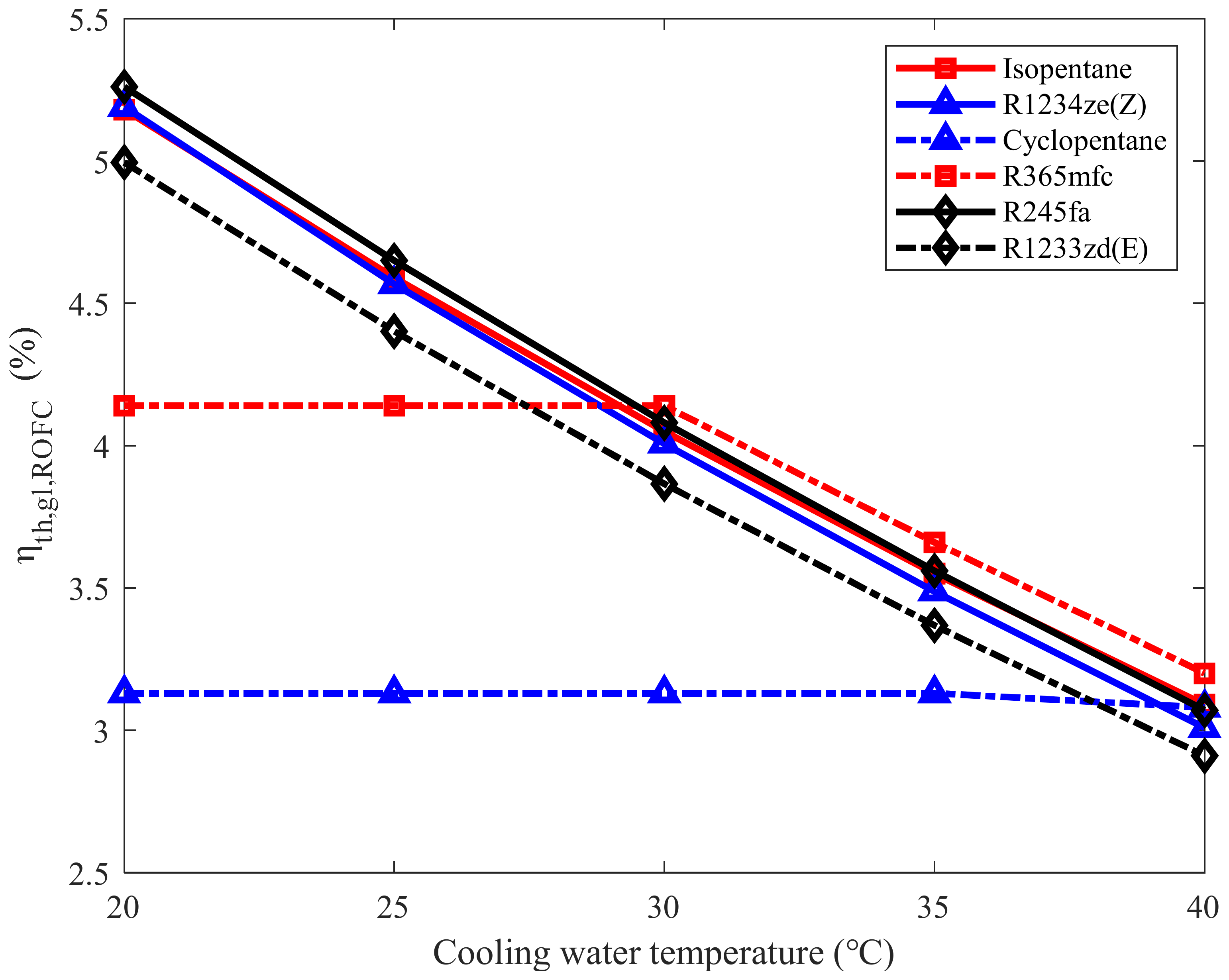

3.4. The Effect of Cooling Water Temperature on ROFC Performance

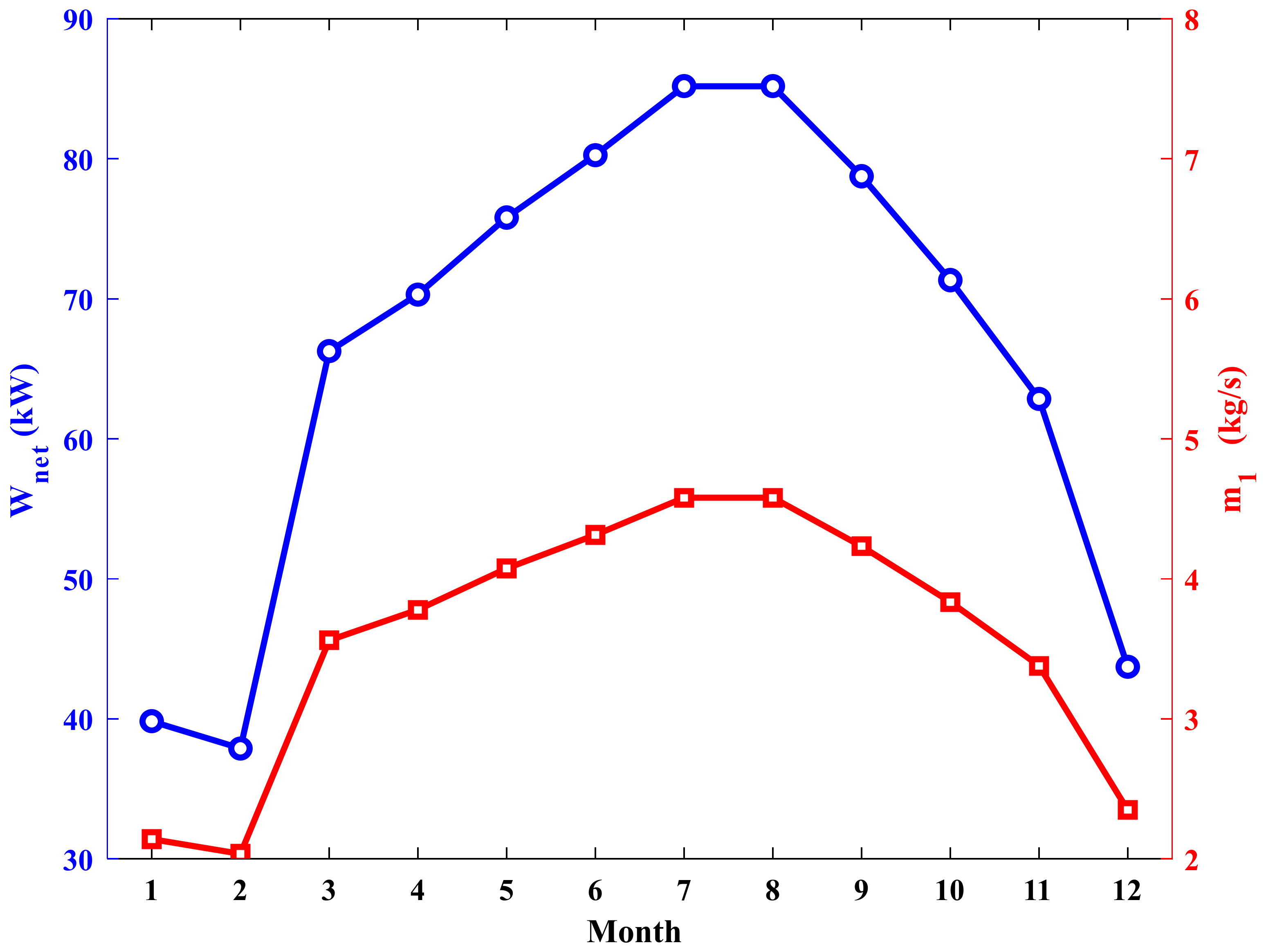

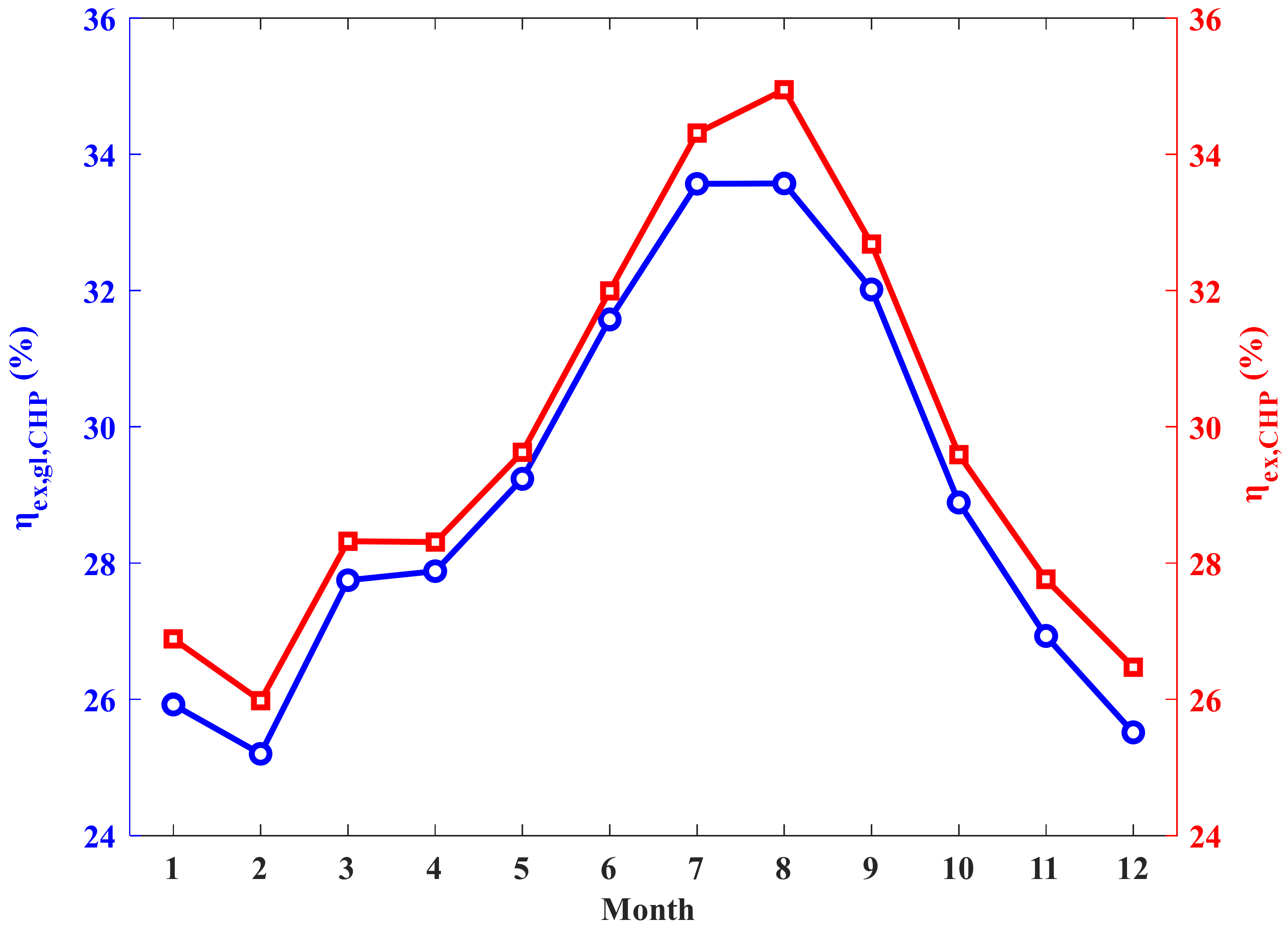

3.5. The Performance of the CHP System Using Isopentane as the Working Fluid throughout a Year

4. Conclusions

- For each working fluid, the flash pressure affected the ROFC’s performance. The net power output increased, and then decreased rapidly as the flash pressure increased; the best net power output was obtained at an optimal flash pressure.

- The results regarding the quantitative analysis of the effects of a heat source and cooling water temperature on the ROFC’s performance revealed that the ROFC performed better as the heat source temperature increased, and as the cooling water temperature declined. Furthermore, with a 10 °C increase in the heat source temperature, the global exergy efficiency increased by around 2.5%. In contrast, with a 10 °C increase in the cooling water temperature, the global exergy efficiency decreased by around 2.5%.

- The optimal working fluid for the ROFC was affected by the heat source and cooling water temperature. At a constant cooling water temperature of 20 °C, isopentane and R245fa were the two best working fluids for the ROFC. R245fa performed better when the heat source temperature was ≥ 150 °C and ≤ 160 °C. At a constant heat source temperature of 150 °C, R365mfc was superior to the other working fluids for the ROFC, when the cooling water temperature was 30–40 °C.

- The following conclusions were reached, in terms of the proposed CHP system’s simulation results throughout a year:

- -

- In February, exergy destruction mainly occurred at the WHS, accounting for 65.0%. The mixer, condenser and throttling valve accounted for 7.80%, 7.64%, and 7.33%, respectively. A more effective system layout of the ROFC-based CHP system can be investigated to further improve system efficiency in the future.

- -

- In August, exergy destruction occurred on the throttling valve, WHS, and turbine, accounting for 28.46%, 21.30%, and 20.98%, respectively.

- -

- Compared to the thermal efficiency of 8.37% of the ROFC, the thermal efficiency of the CHP system improved to 32.80% in August, and greatly improved to 74.34% in February.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| specific heat [kJ/(kg·K)] | |

| specific exergy [kJ/kg] | |

| specific enthalpy [kJ/kg] | |

| exergy destruction rate [kW] | |

| mass flow rate [kg/s] | |

| pressure [kPa] | |

| heat transfer rate [kW] | |

| specific entropy [kJ/kg·K] | |

| temperature [°C] | |

| power [kW] | |

| efficiency [%] | |

| quality | |

| Abbreviations | |

| BOFC | basic organic flash cycle |

| CHP | combined heat and power |

| CCHP | combined cooling, heating, and power |

| GWP | global warming potential |

| HTF | heat transfer fluid |

| HTX | external heat exchanger |

| HE | heat exchanger |

| IEA | international energy agency |

| IHE | internal heat exchanger |

| KC | Kalina cycle |

| Mtoe | million tonnes of oil equivalent |

| MOFC | modified organic flash cycle |

| ORC | organic Rankine cycle |

| OFC | organic flash cycle |

| OFCT | organic flash cycle with a two-phase expander |

| ODP | ozone depletion potential |

| ROFC | organic flash cycle with a regenerator |

| SCBC | supercritical carbon dioxide Brayton cycle |

| ST | split turbine |

| TFC | trilateral flash cycle |

| WHS | water heating system |

| Subscripts | |

| 0, 1, 2, …18 | state points |

| a, b | state points at the three-direction valve |

| con | condenser |

| evap | evaporator |

| g | generator |

| gl | global |

| m1 | mixer1 |

| m2 | mixer2 |

| p1 | pump1 |

| p2 | pump2 |

| t | turbine |

| TV | throttling valve |

References

- Kim, M.-H.; Pettersen, J.; Bullard, C.W. Fundamental process and system design issues in CO2 vapor compression systems. Prog. Energy Combust. Sci. 2004, 30, 119–174. [Google Scholar] [CrossRef]

- Kim, M.-H.; Lee, S.Y.; Mehendale, S.S.; Webb, R.L. Microchannel Heat Exchanger Design for Evaporator and Condenser Applications. Adv. Heat Transf. 2003, 37, 297–429. [Google Scholar]

- Khatoon, S.; Kim, M.-H. Performance analysis of carbon dioxide based combined power cycle for concentrating solar power. Energy Convers. Manag. 2020, 205, 112416. [Google Scholar] [CrossRef]

- Khatoon, S.; Kim, M.-H. Potential improvement and comparative assessment of supercritical Brayton cycles for arid climate. Energy Convers. Manag. 2019, 200, 112082. [Google Scholar] [CrossRef]

- Sung, T.; Kim, S.; Kim, K.C. Thermoeconomic analysis of a biogas-fueled micro-gas turbine with a bottoming organic Rankine cycle for a sewage sludge and food waste treatment plant in the Republic of Korea. Appl. Therm. Eng. 2017, 127, 963–974. [Google Scholar] [CrossRef]

- Ahmadi, A.; El Haj Assad, D.; Jamali, D.H.; Kumar, R.; Li, Z.; Salameh, T.; Al-Shabi, M.; Ehyaei, M. Applications of geothermal organic Rankine Cycle for electricity production. J. Clean. Prod. 2020, 274, 122950. [Google Scholar] [CrossRef]

- Muhammad, U.; Imran, M.; Lee, D.H.; Park, B.S. Design and experimental investigation of a 1kW organic Rankine cycle system using R245fa as working fluid for low-grade waste heat recovery from steam. Energy Convers. Manag. 2015, 103, 1089–1100. [Google Scholar] [CrossRef]

- Liu, C.; Gao, T. Off-design performance analysis of basic ORC, ORC using zeotropic mixtures and composition-adjustable ORC under optimal control strategy. Energy 2019, 171, 95–108. [Google Scholar] [CrossRef]

- Bianchi, G.; Kennedy, S.; Zaher, O.; Tassou, S.; Miller, J.; Jouhara, H. Numerical modeling of a two-phase twin-screw expander for Trilateral Flash Cycle applications. Int. J. Refrig. 2018, 88, 248–259. [Google Scholar] [CrossRef]

- Wang, L.; Li, H.; Bu, X. Thermo-economic investigation of binary flashing cycle for enhanced geothermal system. Geothermics 2021, 89, 101951. [Google Scholar] [CrossRef]

- Pan, M.; Zhu, Y.; Bian, X.; Liang, Y.; Lu, F.; Ban, Z. Theoretical analysis and comparison on supercritical CO2 based combined cycles for waste heat recovery of engine. Energy Convers. Manag. 2020, 219, 113049. [Google Scholar] [CrossRef]

- Chen, H.; Goswami, D.Y.; Stefanakos, E.K. A review of thermodynamic cycles and working fluids for the conversion of low-grade heat. Renew. Sustain. Energy Rev. 2010, 14, 3059–3067. [Google Scholar] [CrossRef]

- Li, Y.-R.; Du, M.-T.; Wu, C.-M.; Wu, S.-Y.; Liu, C. Potential of organic Rankine cycle using zeotropic mixtures as working fluids for waste heat recovery. Energy 2014, 77, 509–519. [Google Scholar] [CrossRef]

- Smith, I.K. Development of the Trilateral Flash Cycle System: Part 1: Fundamental Considerations. Proc. Inst. Mech. Eng. Part A J. Power Energy 1993, 207, 179–194. [Google Scholar] [CrossRef]

- DiPippo, R. Ideal thermal efficiency for geothermal binary plants. Geothermics 2007, 36, 276–285. [Google Scholar] [CrossRef]

- Baccioli, A.; Antonelli, M.; Desideri, U. Technical and economic analysis of organic flash regenerative cycles (OFRCs) for low temperature waste heat recovery. Appl. Energy 2017, 199, 69–87. [Google Scholar] [CrossRef]

- Baccioli, A.; Antonelli, M. Organic Flash Cycles: Off-design behavior and control strategies of two different cycle architectures for Waste Heat Recovery applications. Energy Convers. Manag. 2018, 157, 176–185. [Google Scholar] [CrossRef]

- Lee, H.Y.; Park, S.H.; Kim, K.H. Comparative analysis of thermodynamic performance and optimization of organic flash cycle (OFC) and organic Rankine cycle (ORC). Appl. Therm. Eng. 2016, 100, 680–690. [Google Scholar] [CrossRef]

- Wang, Q.; Wu, W.; Li, D.; Wang, J.; He, Z. Thermodynamic analysis and optimization of four organic flash cycle systems for waste heat recovery. Energy Convers. Manag. 2020, 221, 113171. [Google Scholar] [CrossRef]

- Meng, D.; Liu, Q.; Ji, Z. Performance analyses of regenerative organic flash cycles for geothermal power generation. Energy Convers. Manag. 2020, 224, 113396. [Google Scholar] [CrossRef]

- Chen, L.X.; Hu, P.; Sheng, C.C.; Zhang, N.; Xie, M.N.; Wang, F.X. Thermodynamic analysis of three ejector based organic flash cycles for low grade waste heat recovery. Energy Convers. Manag. 2019, 185, 384–395. [Google Scholar] [CrossRef]

- Mondal, S.; De, S. Ejector based organic flash combined power and refrigeration cycle (EBOFCP&RC)—A scheme for low grade waste heat recovery. Energy 2017, 134, 638–648. [Google Scholar] [CrossRef]

- Van Erdeweghe, S.; Van Bael, J.; Laenen, B.; D’haeseleer, W. Optimal combined heat-and-power plant for a low-temperature geothermal source. Energy 2018, 150, 396–409. [Google Scholar] [CrossRef]

- Prando, D.; Renzi, M.; Gasparella, A.; Baratieri, M. Monitoring of the energy performance of a district heating CHP plant based on biomass boiler and ORC generator. Appl. Therm. Eng. 2015, 79, 98–107. [Google Scholar] [CrossRef]

- Liao, G.; Liu, L.; Zhang, F.; Jiaqiang, E.; Chen, J. A novel combined cooling-heating and power (CCHP) system integrated organic Rankine cycle for waste heat recovery of bottom slag in coal-fired plants. Energy Convers. Manag. 2019, 186, 380–392. [Google Scholar] [CrossRef]

- Wang, Q.; Wu, W.; He, Z. Thermodynamic analysis and optimization of a novel organic Rankine cycle-based micro-scale cogeneration system using biomass fuel. Energy Convers. Manag. 2019, 198, 111803. [Google Scholar] [CrossRef]

- Arabkoohsar, A.; Nami, H. Thermodynamic and economic analyses of a hybrid waste-driven CHP–ORC plant with exhaust heat recovery. Energy Convers. Manag. 2019, 187, 512–522. [Google Scholar] [CrossRef]

- Rostamzadeh, H.; Ebadollahi, M.; Ghaebi, H.; Shokri, A. Comparative study of two novel micro-CCHP systems based on organic Rankine cycle and Kalina cycle. Energy Convers. Manag. 2019, 183, 210–229. [Google Scholar] [CrossRef]

- Aghahosseini, S.; Dincer, I. Comparative performance analysis of low-temperature Organic Rankine Cycle (ORC) using pure and zeotropic working fluids. Appl. Therm. Eng. 2013, 54, 35–42. [Google Scholar] [CrossRef]

- Tabrizi, K.M.; Bonalumi, D. Techno-economic performance of the 2-propanol/1-butanol zeotropic mixture and 2-propanol/water azeotropic mixture as a working fluid in Organic Rankine Cycles. Energy 2022, 246, 123316. [Google Scholar] [CrossRef]

- Bahrami, M.; Pourfayaz, F.; Kasaeian, A. Low global warming potential (GWP) working fluids (WFs) for Organic Rankine Cycle (ORC) applications. Energy Rep. 2022, 8, 2976–2988. [Google Scholar] [CrossRef]

- Scharrer, D.; Bazan, P.; Pruckner, M.; German, R. Simulation and analysis of a Carnot Battery consisting of a reversible heat pump/organic Rankine cycle for a domestic application in a community with varying number of houses. Energy 2022, 261, 125166. [Google Scholar] [CrossRef]

- Feili, M.; Rostamzadeh, H.; Ghaebi, H. Thermo-mechanical energy level approach integrated with exergoeconomic optimization for realistic cost evaluation of a novel micro-CCHP system. Renew. Energy 2022, 190, 630–657. [Google Scholar] [CrossRef]

- Peris, B.; Navarro-Esbrí, J.; Molés, F.; Mota-Babiloni, A. Experimental study of an ORC (organic Rankine cycle) for low grade waste heat recovery in a ceramic industry. Energy 2015, 85, 534–542. [Google Scholar] [CrossRef]

- Blondel, Q.; Tauveron, N.; Caney, N.; Voeltzel, N. Experimental Study and Optimization of the Organic Rankine Cycle with Pure NovecTM649 and Zeotropic Mixture NovecTM649/HFE7000 as Working Fluid. Appl. Sci. 2019, 9, 1865. [Google Scholar] [CrossRef]

- Cedar Laker Ventures, Inc. Data of Ambient Temperature in Daegu, Korea n.d. Available online: https://ko.weatherspark.com/y/142569/ (accessed on 17 January 2021).

- Aziz, F.; Salim, M.S.; Kim, M.-H. Performance analysis of high temperature cascade organic Rankine cycle coupled with water heating system. Energy 2019, 170, 954–966. [Google Scholar] [CrossRef]

- Aziz, F.; Mudasar, R.; Kim, M.-H. Exergetic and heat load optimization of high temperature organic Rankine cycle. Energy Convers. Manag. 2018, 171, 48–58. [Google Scholar] [CrossRef]

- Kim, M.-H. Energy and Exergy Analysis of Solar Organic Rankine Cycle Coupled with Vapor Compression Refrigeration Cycle. Energies 2022, 15, 5603. [Google Scholar] [CrossRef]

- Lemmon, E.W.; Bell, I.H.; Huber, M.L.; McLinden, M.O. NIST Standard Reference Database 23: Reference Fluid Thermodynamic and Transport Properties-REFPROP. Version 10.0. Standard Reference Data Program. National Institute of Standards and Technology: Gaithersburg, MD, USA, 2018.

- Khatoon, S.; Almefreji, N.M.A.; Kim, M.-H. Thermodynamic Study of a Combined Power and Refrigeration System for Low-Grade Heat Energy Source. Energies 2021, 14, 410. [Google Scholar] [CrossRef]

- Wu, C.; Xu, X.; Li, Q.; Li, X.; Liu, L.; Liu, C. Performance assessment and optimization of a novel geothermal combined cooling and power system integrating an organic flash cycle with an ammonia-water absorption refrigeration cycle. Energy Convers. Manag. 2021, 227, 113562. [Google Scholar] [CrossRef]

- ASHRAE. ANSI/ASHRAE Addendum f to ANSI/ASHRAE. Standard 34-2019; ASHRAE: Atlanta, GA, USA, 2019. [Google Scholar]

| Month | Ambient Temperature (°C) | Median Water Temperature (°C) | Water Flow Rate in WHS (kg/s) | Heat Transfer Rate in WHS (kW) | ||

|---|---|---|---|---|---|---|

| Max. | Min. | Avg. | ||||

| January | 5.00 | −3.00 | 1.00 | 13.50 | 8.50 | 1124.55 |

| February | 7.50 | −2.00 | 2.75 | 12.50 | 8.50 | 1160.25 |

| March | 13.00 | 3.50 | 8.25 | 12.25 | 6.00 | 825.30 |

| April | 19.00 | 9.50 | 14.25 | 14.00 | 5.80 | 755.16 |

| May | 24.00 | 14.50 | 19.25 | 16.50 | 5.50 | 658.35 |

| June | 27.00 | 19.00 | 23.00 | 19.50 | 5.30 | 567.63 |

| July | 29.50 | 22.50 | 26.00 | 23.00 | 4.80 | 443.52 |

| August | 29.50 | 22.50 | 26.00 | 25.50 | 4.50 | 368.55 |

| September | 26.00 | 18.00 | 22.00 | 24.00 | 6.00 | 529.20 |

| October | 21.00 | 11.50 | 16.25 | 21.00 | 6.50 | 655.20 |

| November | 13.50 | 5.00 | 9.25 | 18.00 | 7.00 | 793.80 |

| December | 7.50 | −1.00 | 3.25 | 15.50 | 8.50 | 1053.15 |

| Working Fluids | Chemical Formula | Molar Mass (g/mol) | Critical Pressure (kPa) | ODP/GWP | Safety Group | |

|---|---|---|---|---|---|---|

| Cyclopentane | 70.13 | 4583 | 238.6 | 0/11 | A3 | |

| R1234ze(Z) | 114.00 | 3530 | 150.1 | 0/6 | A2L | |

| R365mfc | 148.07 | 3266 | 186.9 | 0/804 | - | |

| Isopentane | 72.15 | 3378 | 187.2 | 0/11 | A3 | |

| R1233zd(E) | 130.50 | 3570 | 165.6 | 0/1 | A1 | |

| R245fa | 134.05 | 3651 | 153.9 | 0/858 | B1 |

| Parameters (Unit) | Given Conditions |

|---|---|

| Pressure of the hot water (kPa) | 1000 |

| Heat transfer fluid (HTF) | Water |

| Inlet temperature of the HTF (°C) | 150 |

| Mass flow rate of the HTF (kg/s) | 5 |

| OFC working fluid | Isopentane |

| Minimum temperature difference at condenser (°C) | 10 |

| Minimum temperature difference at evaporator (°C) | 8 |

| Ambient temperature (°C) | 20 |

| Condensation temperature (°C) | 30 |

| Efficiency of the generator (%) | 90 |

| Efficiency of the turbine (%) | 75 |

| Efficiency of the pump (%) | 70 |

| State Point | Working Fluid | T [°C] | P [kPa] | h [kJ/kg] | s [kJ/(kg·K)] | [kg/s] |

|---|---|---|---|---|---|---|

| 1 | Isopentane | 91.6 | 600 | 1.25 | 442.59 | 3.92 |

| 2 | Isopentane | 57.9 | 109 | 1.30 | 396.23 | 3.92 |

| 3 | Isopentane | 30.0 | 109 | 0.02 | 5.00 | 3.92 |

| 4 | Isopentane | 31.02 | 1628 | 0.02 | 8.55 | 3.92 |

| 5 | Isopentane | 62.1 | 1628 | 0.25 | 82.56 | 7.63 |

| 6 | Isopentane | 142.0 | 1628 | 0.84 | 304.24 | 7.63 |

| 7 | Isopentane | 91.6 | 600 | 0.87 | 304.24 | 7.63 |

| 8 | Isopentane | 91.6 | 600 | 0.47 | 158.05 | 3.71 |

| 9 | Isopentane | 92.5 | 1628 | 0.47 | 160.77 | 3.71 |

| 10 | Water | 150.0 | 1000 | 1.84 | 632.50 | 5.00 |

| 11a | Water | 150.0 | 1000 | 1.84 | 632.50 | 0.00 |

| 11b | Water | 150.0 | 1000 | 1.84 | 632.50 | 5.00 |

| 12 | Water | 70.1 | 1000 | 0.96 | 294.20 | 5.00 |

| 13 | Water | 70.1 | 1000 | 0.96 | 294.20 | 5.00 |

| 14 | Water | 70.1 | 1000 | 0.96 | 294.20 | 5.00 |

| 15 | Water | 18.0 | 101 | 0.27 | 75.64 | 18.16 |

| 16 | Water | 23.2 | 101 | 0.34 | 97.18 | 18.16 |

| Working Fluids | Evaporation Pressure (kPa) | Flash Pressure (kPa) | Condensation Pressure (kPa) | Net Power Output (kW) | Global Exergy Efficiency (%) |

|---|---|---|---|---|---|

| Cyclopentane | 973.01 | 395.60 | 101.33 | 86.11 | 18.01 |

| R365mfc | 1452.90 | 531.10 | 101.33 | 113.72 | 23.78 |

| R1233zd(E) | 2376.60 | 897.60 | 154.00 | 136.99 | 28.64 |

| Isopentane | 1628.07 | 600.00 | 109.17 | 141.97 | 29.68 |

| R1234ze(Z) | 3052.90 | 1253.00 | 209.00 | 142.41 | 29.78 |

| R245fa | 2943.60 | 1148.60 | 178.08 | 144.00 | 30.16 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, H.; Kim, M.-H. Thermodynamic Analysis and Working Fluid Selection of a Novel Cogeneration System Based on a Regenerative Organic Flash Cycle. Energies 2022, 15, 7843. https://doi.org/10.3390/en15217843

Chen H, Kim M-H. Thermodynamic Analysis and Working Fluid Selection of a Novel Cogeneration System Based on a Regenerative Organic Flash Cycle. Energies. 2022; 15(21):7843. https://doi.org/10.3390/en15217843

Chicago/Turabian StyleChen, Haojie, and Man-Hoe Kim. 2022. "Thermodynamic Analysis and Working Fluid Selection of a Novel Cogeneration System Based on a Regenerative Organic Flash Cycle" Energies 15, no. 21: 7843. https://doi.org/10.3390/en15217843

APA StyleChen, H., & Kim, M.-H. (2022). Thermodynamic Analysis and Working Fluid Selection of a Novel Cogeneration System Based on a Regenerative Organic Flash Cycle. Energies, 15(21), 7843. https://doi.org/10.3390/en15217843