Contamination Level Monitoring Techniques for High-Voltage Insulators: A Review

Abstract

1. Introduction

- To prevent disastrous flashovers and decreases compulsory outage period by providing correct and precise information about the pollution level ahead of time;

- To decrease maintenance costs and enable effective maintenance planning (specify the optimal time for washing);

- To improve the general dependability of the electrical system;

- To enable effective utilization of limited resources, such as workforce and time, by creating priorities for the upkeep of insulators.

2. The Insulator Contamination and Source of Contaminants

3. Industry Experience in Improving Insulator Performance

3.1. Coating of Insulator

3.2. Optimization of Electric Field Distribution

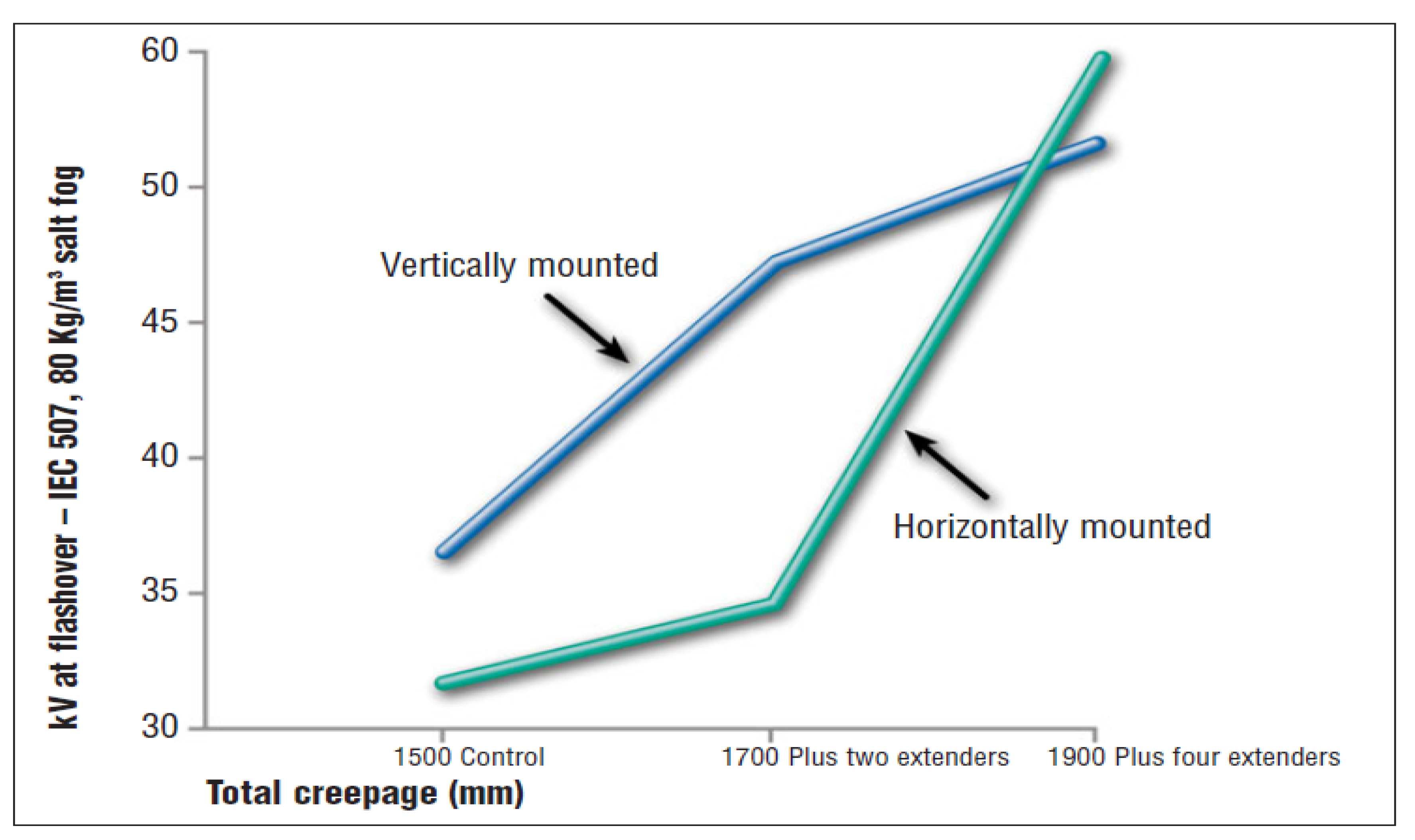

3.3. Creepage Extenders

3.4. Washing of Insulator (Cleaning)

3.5. The Saudi Electricity Company (SEC) Experience

- Zone 1—Washing every month: line insulators near major generating plants, such as Ghazlan Power Plant, and in close proximity to the Arabian Gulf;

- Zone 2—Washing every 2–3 months: line insulators near major generating plants, such as Berri Power Plant, but not too close to the Arabian Gulf;

- Zone 3—Washing every 6–12 months: line insulators at a distance of 20–50 km from the Arabian Gulf;

- Zone 4—No washing: Lines located more than 50 km from the Arabian Gulf.

4. Contamination Indicators & Signal Processing Techniques

4.1. Leakage Current

4.1.1. Fast Fourier Transform (FFT)

4.1.2. Time Domain analysis of LC

4.1.3. Wavelet Transform

4.1.4. S Transform

| Reference | Insulator Type | Preprocessing Stage | Metrics | Accuracy |

|---|---|---|---|---|

| [75] | Porcelain | Time domain analysis and discrete wavelet transform | Out-of-bag (OOB) error rate and identification rate | The identification rate is 98% |

| [33] | Porcelain | Autocorrelation | Accuracy | 90.7% |

| [76] | Polymer | stepwise regression | Accuracy | KNN is 57.5%, polynomial is 65%, and fuzzy is 56.3% |

| [77] | Porcelain | Discrete S transform | Accuracy | 95% to 97% |

| [2] | Silicone rubber | stepwise regression, PCA, and moving average filter | Accuracy, RMSE | 68% for four classes and 95% for two |

| [78] | Porcelain | STMHT and FLDA | Accuracy | 90% |

| [79] | Porcelain | Extract distortions | Error | 4% to 7% |

| [80] | Porcelain | Mathematical morphological function and statistical operations | Precision | 100% |

| [81] | Glass | Data augmented using: Gaussian, Salt and Pepper, Poisson, and Speckle noise. | Accuracy | 99.76% |

| [82] | Ceramic | Modelling current equation | MAPE | MAPE= 0.4%, for Imax = 1.292 mA |

| [83] | Ceramic | GLCM and Tamura features of the spectrograms | Accuracy and computational time | 90.6% |

| [84] | Polymeric | Hyperbolic window Stockwell transform | Accuracy, sensitivity, and specificity | RF (=97.5%) |

| [85] | Porcelain | Data are standardized using the KMO test and Bartlett spherical test | MAE, RMSE, MAPE, mean squared percentage error (MSPE), Theil inequality coefficient (TIC), coefficient of determination (R2), modeling time (TM), and prediction time (TP) | MAPE is 1.567 |

| [86] | Porcelain, glass, and polymer | FFT | Error | 2% |

4.2. The Imaging Method

4.2.1. Digital Imaging Method

4.2.2. Thermal Image (Infrared, Thermal Vision)

4.2.3. Ultraviolet Image

4.2.4. Hyperspectral Images

| Reference | Insulator Type | Input Signal | Preprocessing Stage | Test Type (Dataset) | Metrics | Accuracy |

|---|---|---|---|---|---|---|

| [21] | Ceramic | IR and UV image | Fisher criterion and KPCA | Experiment-Field (120 samples for testing and 280 for training) | Accuracy | 96.67% |

| [10] | Porcelain | Images | Matrix manipulation and edge-based segmentation | Experiment-Field (51 samples: 36 for training and 15 for testing) | Mean absolute error (MAE), predicting rate | MAE: 0–0.045 and predicting rate is 80% |

| [90] | Porcelain | Images | Denoising, image segmentation, and PCA | Experiment-Field (40 groups of samples) | Probability density | - |

| [103] | Porcelain | IR images | Flat shot to image test pieces, grayscale | Experiment-Lab (700 images: 560 for training and 140 for testing) | Accuracy | 93% |

| [94] | Porcelain | IR image | Denoising technique based on MAP segmentation, estimation, and wavelet generic Gaussian distribution | Experiment-Lab | Accuracy and time | 97.31% |

| [1] | Glass and porcelain | Images | RGB to grey, RGB to HSV, and SVD | Experiment-Lab (40 for training and 19 for testing) | MSE and accuracy | 84.2% |

| [77] | Porcelain | Leakage current | Discrete S transform | Experiment-Lab | Accuracy | 95% to 97% |

| [91] | Ceramic | Images | Template matching and grayscale histogram | Experiment-Lab (96 images: 24 for each level) | Accuracy | ANN = 93.75% |

| [101] | Silicone rubber | Hyperspectral images | multiplicative scatter correction and black-and-white correction | Experiment-Lab (120 sets for training and 120 sets for testing) | Accuracy | From 87.5% to 90% |

| [104] | Porcelain | IR images | Denoising and enhancing contrast | Experiment-field (300 frames) | Accuracy | 100% |

| [92] | Silicone rubber | RGB and HSV images | Segmentation method based on randomized Hough transform, and Fisher criterion | Experiment-Lab (65 samples for light and 59 for heavy, and the ratio is 2:1 for training and testing) | Accuracy, precision, recall, and f-measure | 97.5% |

| [97] | Ceramic | UV discharge images | The grayscale images were converted to binary images, all set to black, excluding the white pixels. | Experiment-Lab (320 samples for training and 160 for testing) | Accuracy | 92% |

| [95] | Ceramic | Images | PCA | Experiment-Field (frame size of 640 × 512 pixels) | Accuracy | 90% |

| [102] | Silicone rubber | Hyperspectral image | MSC, PCA, SPA | Experiment-Lab (176 variables) | Accuracy and Kappa | LDA (=97.5%) |

| [105] | Ceramic | Images | Bounding box | Experiment-Field (2973 images) | Mean average precision (mAP) and processing time | onshore: mAP is 0.67 and processing time is 0.55 s, onboard: mAP is 0.26 and processing time is 1.27 s |

| [106] | Polymeric | Audible (ultrasound) signal | wavelet transform (WT), filtering, and noise reduction | Experiment-Lab (20,000 samples: 70% for training and 30% for testing) | RMSE, MAPE, MAE, and R2 | R2 is 0.9982 |

| [107] | Porcelain | Discharge image | Grayscale, binarization, and main spot feature extraction on the image | Experiment-Field (1243 pictures: 994 for training and 249 for testing) | Accuracy | 84.8% |

| [99] | Porcelain | Hyperspectral image | GGCM, color feature, and KPCA | Experiment-Lab (Ten sets for each pollution level: 20 for training and 20 for testing) | Accuracy | 95.0% |

| [108] | Porcelain | Images | Gaussian filtering, Canny algorithm, edge location, and multiplicative scatter correction | Experiment-Lab (1200 samples with ratio of 7:3 for training and testing) | Accuracy | 96.9% |

4.3. Acoustic Emission (AE), Microwave & Ultrasonic

4.4. Contact Angle

4.5. Partial Discharge (PD)

5. HV Insulator Contamination Level Classification Techniques

5.1. Machine Learning

5.1.1. Backpropagations Neural Network (BPNN)

5.1.2. Support Vector Machine (SVM)

5.1.3. The k-Nearest Neighbours (KNN) Algorithm

5.1.4. Random Forests (RF)

5.1.5. Ensemble Learning (EL)

5.1.6. Convolutional Neural Network (CNN)

5.2. Fuzzy

5.3. Nero Fuzzy

5.4. Detrended Fluctuation Analysis (DFA)

5.5. Miscellaneous Techniques

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Maraaba, L.; Alhamouz, Z.; Alduwaish, H. A neural network-based estimation of the level of contamination on high-voltage porcelain and glass insulators. Electr. Eng. 2018, 100, 1545–1554. [Google Scholar] [CrossRef]

- Abouzeid, A.K.; El-Hag, A.; Assaleh, K. Equivalent salt deposit density prediction of silicone rubber insulators under simulated pollution conditions. Electr. Power Compon. Syst. 2018, 46, 1123–1133. [Google Scholar] [CrossRef]

- Kim, T.; Yi, J. Application of hydrophobic coating to reduce leakage current through surface energy control of high voltage insulator. Appl. Surf. Sci. 2022, 578, 151820. [Google Scholar] [CrossRef]

- Kalla, U.K.; Suthar, R.; Sharma, K.; Singh, B.; Ghotia, J. Power quality investigation in ceramic insulator. IEEE Trans. Ind. Appl. 2017, 54, 121–134. [Google Scholar] [CrossRef]

- Gençoğlu, M.T. The comparison of ceramic and non-ceramic insulators. Eng. Sci. 2007, 2, 274–294. [Google Scholar]

- Patel, C.R.; Patel, N.; Patel, R. Condition Assessment of Silicon Rubber Insulator used in Overhead Systems. In Proceedings of the 2020 21st National Power Systems Conference (NPSC), Gandhinagar, India, 17–19 December 2020; pp. 1–5. [Google Scholar]

- Rajini, H.; Ballaji, A.; Saahithi, S.; Bharat, M.; Ashwini Kumari, P.; Raghu, C. Comparative performance of insulating materials used in high voltage insulators. AIP Conf. Proc. 2022, 2461, 040001. [Google Scholar]

- Saleem, M.Z.; Akbar, M. Review of the performance of high-voltage composite insulators. Polymers 2022, 14, 431. [Google Scholar] [CrossRef] [PubMed]

- Maraaba, L.S.F. Image Processing Based Contamination Level Monitdoring of High Voltage Insulator; King Fahd University of Petroleum and Minerals: Dhahran, Saudi Arabia, 2013. [Google Scholar]

- Maraaba, L.; Al-Hamouz, Z.; Al-Duwaish, H. Prediction of the levels of contamination of HV insulators using image linear algebraic features and neural networks. Arab. J. Sci. Eng. 2015, 40, 2609–2617. [Google Scholar] [CrossRef]

- Gorur, R.; Sivasubramaniyam, S. Computation of defect-induced electric fields on outdoor high voltage ceramic and non-ceramic insulators. In Proceedings of the Annual Report Conference on Electrical Insulation and Dielectric Phenomena, Cancun, Mexico, 20–24 October 2002; pp. 319–322. [Google Scholar]

- Kiessling, F.; Nefzger, P.; Nolasco, J.F.; Kaintzyk, U. Overhead Power Lines: Planning, Design, Construction; Springer: Berlin/Heidelberg, Germany, 2003; Volume 759. [Google Scholar]

- Baker, A.; Farzaneh, M.; Gorur, R.; Gubanski, S.; Hill, R.; Karady, G.; Schneider, H. Insulator selection for AC overhead lines with respect to contamination. IEEE Trans. Power Deliv. 2009, 24, 1633–1641. [Google Scholar] [CrossRef]

- Rizk, F.A.; Trinh, G.N. High Voltage Engineering; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Alyousef, Y.; Varnham, A. Saudi Arabia’s National Energy Efficiency Programme: Description, achievements and way forward. Int. J. Low Carbon Technol. 2010, 5, 291–297. [Google Scholar] [CrossRef]

- Maraaba, L.S.; Al Soufi, K.Y.; Alhems, L.M.; Hassan, M.A. Performance evaluation of 230 kV polymer insulators in the coastal area of Saudi Arabia. IEEE Access 2020, 8, 164292–164303. [Google Scholar] [CrossRef]

- Khattak, A.; Alahamdi, A.A.; Iqbal, M.B. Degradation Performance Investigation of Hydrothermally Stressed Epoxy Micro and Nanocomposites for High Voltage Insulation. Polymers 2022, 14, 1094. [Google Scholar]

- Sk, M.H.; Ardila-Rey, J.A.; Umar, Y.; Mas’ud, A.A.; Muhammad-Sukki, F.; Jume, B.H.; Rahman, H.; Bani, N.A. Application and Suitability of Polymeric Materials as Insulators in Electrical Equipment. Energies 2021, 14, 2758. [Google Scholar]

- Abedini-Livari, A.; Eshaghi-Maskouni, M.; Vakilian, M.; Firuzi, K. Line Composite Insulators Condition Monitoring through Partial Discharge Measurement. In Proceedings of the 2019 International Power System Conference (PSC), Tehran, Iran, 9–11 December 2019; pp. 595–600. [Google Scholar]

- Arief, S.; Abral, H.; Hazmi, A.; Waldi, E.; Ahmad, M. Estimated leakage current based on the thermal image of the polymer insulator using the color detection method. J. Physics Conf. Ser. 2019, 1317, 012025. [Google Scholar]

- Jin, L.; Zhang, D. Contamination grades recognition of ceramic insulators using fused features of infrared and ultraviolet images. Energies 2015, 8, 837–858. [Google Scholar] [CrossRef]

- Han, S.; Hao, R.; Lee, J. Inspection of insulators on high-voltage power transmission lines. IEEE Trans. Power Deliv. 2009, 24, 2319–2327. [Google Scholar] [CrossRef]

- Kunicki, M.; Cichoń, A. Application of a phase resolved partial discharge pattern analysis for acoustic emission method in high voltage insulation systems diagnostics. Arch. Acoust. 2018, 43, 235–243. [Google Scholar]

- Pernebayeva, D.; Irmanova, A.; Sadykova, D.; Bagheri, M.; James, A. High voltage outdoor insulator surface condition evaluation using aerial insulator images. High Volt. 2019, 4, 178–185. [Google Scholar] [CrossRef]

- de Santos, H.; Sanz-Bobi, M.Á. A Cumulative Pollution Index for the Estimation of the Leakage Current on Insulator Strings. IEEE Trans. Power Deliv. 2020, 35, 2438–2446. [Google Scholar] [CrossRef]

- Salem, A.A.; Abd-Rahman, R.; Al-Gailani, S.A.; Kamarudin, M.S.; Ahmad, H.; Salam, Z. The leakage current components as a diagnostic tool to estimate contamination level on high voltage insulators. IEEE Access 2020, 8, 92514–92528. [Google Scholar] [CrossRef]

- Salam, M.A.; Aamer, K.; Hamdan, A.; Hamdan, N. Study the Relationship between the Resistance and ESDD of A Contaminated insulator A Laboratory Approach. In Proceedings of the Proceedings of the 7th International Conference on Properties and Applications of Dielectric Materials (Cat. No. 03CH37417), Nagoya, Japan, 1–5 June 2003; pp. 1032–1034. [Google Scholar]

- Ren, A.; Li, Q.; Xiao, H. Influence analysis and prediction of ESDD and NSDD based on random forests. Energies 2017, 10, 878. [Google Scholar] [CrossRef]

- Montoya, G.; Ramirez, I.; Montoya, J. Correlation among ESDD, NSDD and leakage current in distribution insulators. IEE Proc. Gener. Transm. Distrib. 2004, 151, 334–340. [Google Scholar] [CrossRef]

- Gorur, R.S.; Cherney, E.A.; Burnham, J.T. Outdoor Insulators; Ravi S. Gorur: Phoenix, AZ, USA,, 1999. [Google Scholar]

- IEC TS 60815-1; Selection and Dimensioning of High-voltage Insulators Intended for Use in Polluted Conditions-Part 1: Definitions, Information and General Principles. International Electrotechnical Commission: Worcester, MA, USA,, 2008.

- Banik, A.; Pradhan, A.; Ghosh, R.; Dalai, S.; Chaterjee, B. A comparative study on leakage current harmonics of porcelain disc insulator contaminated with NaCl and KCl. In Proceedings of the 2015 1st Conference on Power, Dielectric and Energy Management at NERIST (ICPDEN), Arunachal Pradesh, India, 10–11 January 2015; pp. 1–4. [Google Scholar]

- Banik, A.; Dalai, S.; Chatterjee, B. Autocorrelation aided rough set based contamination level prediction of high voltage insulator at different environmental condition. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 2883–2891. [Google Scholar] [CrossRef]

- Slama, M.E.A.; Krzma, A.; Albano, M.; Haddad, A.M. Experimental study and modeling of the effect of ESDD/NSDD on AC flashover of SiR outdoor insulators. Energies 2022, 15, 3782. [Google Scholar] [CrossRef]

- Salem, A.A.; Lau, K.Y.; Abdul-Malek, Z.; Al-Gailani, S.A.; Tan, C.W. Flashover voltage of porcelain insulator under various pollution distributions: Experiment and modeling. Electr. Power Syst. Res. 2022, 208, 107867. [Google Scholar] [CrossRef]

- Volpov, E.; Kishcha, P. Advanced modeling and mapping of severe pollution stress required for outdoor insulation coordination. Electr. Eng. 2022, 104, 741–752. [Google Scholar] [CrossRef]

- Liu, L.W.; Thành, S.N. Towards the Feasibility of Long Range Wireless Power Transfer over an Ocean Surface. Appl. Sci. 2022, 12, 8751. [Google Scholar] [CrossRef]

- Ullah, I.; Akbar, M.; Khan, H.A. Degradation analysis of RTV-SiR based composites under both polarities DC voltage for insulators coating. Mater. Today Commun. 2021, 29, 102890. [Google Scholar] [CrossRef]

- Cherney, E.; Gorur, R. RTV silicone rubber coatings for outdoor insulators. IEEE Trans. Dielectr. Electr. Insul. 1999, 6, 605–611. [Google Scholar] [CrossRef]

- Suwarno; Basuki, A. Mitigation of outdoor insulators failure using silicone coating. In Proceedings of the 2011 International Conference on Electrical Engineering and Informatics, Bandung, Indonesia, 17–19 July 2011. [Google Scholar]

- Siderakis, K.; Pylarinos, D.; Thalassinakis, E.; Vitellas, I.; Pyrgioti, E. Pollution maintenance techniques in coastal high voltage installations. Eng. Technol. Appl. Sci. Res. 2011, 1, 1–7. [Google Scholar] [CrossRef]

- Qing, Y.; Sima, W.; Jiazhuo, D.; Tao, Y.; Lin, C. New optimization method on electric field distribution of composite insulator. In Proceedings of the 2010 Annual Report Conference on Electrical Insulation and Dielectic Phenomena, West Lafayette, IN, USA, 17–20 October 2010; pp. 1–4. [Google Scholar]

- Karady, G.G.; Shah, M.; Brown, R. Flashover mechanism of silicone rubber insulators used for outdoor insulation-I. IEEE Trans. Power Deliv. 1995, 10, 1965–1971. [Google Scholar] [CrossRef]

- Vlastos, A.E.; Sherif, E. Natural ageing of EPDM composite insulators. IEEE Trans. Power Deliv. 1990, 5, 406–414. [Google Scholar] [CrossRef]

- Al-Hamoudi, I.Y.; Al-Hamouz, Z.M. Field and laboratory performance evaluation of SiR insulators in the eastern coastal area of Saudi Arabia. In Proceedings of the 2004 IEEE International Conference on Solid Dielectrics, ICSD 2004, Toulouse, France, 5–9 July 2004; pp. 359–362. [Google Scholar]

- Al-Hamoudi, I.; Al-Hamouz, Z. Reliability and cost effectiveness of silicone rubber insulators in the eastern coastal industrial area of Saudi Arabia. In Proceedings of the 2003 IEEE 10th International Conference on Transmission and Distribution Construction, Operation and Live-Line Maintenance, 2003 IEEE ESMO, Orlando, FL, USA, 6–10 April 2003; pp. 156–168. [Google Scholar]

- Maraaba, L.; Al-Hamouz, Z.; Al-Duwaish, H. Estimation of high voltage insulator contamination using a combined image processing and artificial neural networks. In Proceedings of the 2014 IEEE 8th International Power Engineering and Optimization Conference (PEOCO2014), Langkawi, Malaysia, 24–25 March 2014; pp. 214–219. [Google Scholar]

- Sopelsa Neto, N.F.; Stefenon, S.F.; Meyer, L.H.; Ovejero, R.G.; Leithardt, V.R.Q. Fault prediction based on leakage current in contaminated insulators using enhanced time series forecasting models. Sensors 2022, 22, 6121. [Google Scholar] [CrossRef]

- Ghiasi, Z.; Faghihi, F.; Shayegani-Akmal, A.A. Artificial Neural Network Approach for Prediction of Leakage Current of polymeric insulator under Non-Uniform Fan-shaped Contamination. Electr. Power Syst. Res. 2022, 209, 107920. [Google Scholar] [CrossRef]

- Richards, C.; Renowden, J. Development of a remote insulator contamination monitoring system. IEEE Trans. Power Deliv. 1997, 12, 389–397. [Google Scholar] [CrossRef]

- Li, J.; Sun, C.; Sebo, S. Humidity and contamination severity impact on the leakage currents of porcelain insulators. IET Gener. Transm. Distrib. 2011, 5, 19–28. [Google Scholar] [CrossRef]

- Mizuno, Y.; Nakamura, H.; Naito, K. Dynamic simulation of risk of flashover of contaminated ceramic insulators. IEEE Trans. Power Deliv. 1997, 12, 1292–1298. [Google Scholar] [CrossRef]

- Jolly, D. Dynamic Theory of Discharge Growth over Contaminated Insulator Surfaces; IEEE Paper C; IEEE: New York, NY, USA, 1974. [Google Scholar]

- Pei, C.; Shu, N.; Li, L.; Wang, D.; Li, Z. An acoustic emission method for on-line monitoring the contamination-causing flashover of insulator. In Proceedings of the 2008 International Conference on Electrical Machines and Systems, Vilamoura, Portugal, 6–9 September 2008; pp. 817–822. [Google Scholar]

- Ibrahim, M.E.; Abd-Elhady, A.M. Rogowski Coil Transducer-Based Condition Monitoring of High Voltage Insulators. IEEE Sens. J. 2020, 20, 13694–13703. [Google Scholar] [CrossRef]

- Jin, L.; Xu, Z.; Zhang, S. A pre-warning method of contamination flashover based on the leakage current of insulators in dry condition. In Proceedings of the 2017 International Symposium on Electrical Insulating Materials (ISEIM), Toyohashi City, Japan, 11–15 September 2017; pp. 757–760. [Google Scholar]

- Deb, S.; Ghosh, R.; Dutta, S.; Dalai, S.; Chatterjee, B. Effect of humidity on leakage current of a contaminated 11 kV Porcelain Pin Insulator. In Proceedings of the 2017 6th International Conference on Computer Applications In Electrical Engineering-Recent Advances (CERA), Roorkee, India, 5–7 October 2017; pp. 215–219. [Google Scholar]

- Chakraborty, S.; Podder, S.; Deb, S.; Nath, S. Qualitative Analysis of Contamination Severity between NaCl and CuSO 4 for Outdoor Insulator. In Proceedings of the 2018 IEEE Applied Signal Processing Conference (ASPCON), Kolkata, India, 7–9 December 2018; pp. 342–345. [Google Scholar]

- Kordkheili, H.H.; Abravesh, H.; Tabasi, M.; Dakhem, M.; Abravesh, M.M. Determining the probability of flashover occurrence in composite insulators by using leakage current harmonic components. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 502–512. [Google Scholar] [CrossRef]

- Patel, K.; Parekh, B. Prediction of flashover of silicone rubber insulator under different contaminated surface conditions. In Proceedings of the 2013 IEEE 1st International Conference on Condition Assessment Techniques in Electrical Systems (CATCON), Kolkata, India, 6–8 December 2013; pp. 358–361. [Google Scholar]

- Zhengfa, L.; Qing, Z.; Wuyang, Z.; Shimian, L.; Gaolin, W.; Jianlin, H.; Maoqiang, B. Study on leakage current characteristics and influence factors of 110kV polluted composite insulators. In Proceedings of the 2018 12th International Conference on the Properties and Applications of Dielectric Materials (ICPADM), Xi’an, China, 20–24 May 2018; pp. 896–900. [Google Scholar]

- Wang, J.; Gubanski, S.M.; Blennow, J.; Atarijabarzadeh, S.; Stromberg, E.; Karlsson, S. Influence of biofilm contamination on electrical performance of silicone rubber based composite materials. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 1690–1699. [Google Scholar] [CrossRef]

- Li, J.; Sun, C.; Sima, W.; Yang, Q. Stage pre-warning based on leakage current characteristics before contamination flashover of porcelain and glass insulators. IET Gener. Transm. Distrib. 2009, 3, 605–615. [Google Scholar] [CrossRef]

- Li, J.; Sima, W.; Sun, C.; Sebo, S.A. Use of leakage currents of insulators to determine the stage characteristics of the flashover process and contamination level prediction. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 490–501. [Google Scholar] [CrossRef]

- Um, C.-G.; Jung, C.-G.; Han, B.-G.; Song, Y.-C.; Choi, D.-H. A fuzzy framework for flashover monitoring. In Proceedings of the International Conference on Fuzzy Systems and Knowledge Discovery, Changsha, China, 27–29 August 2005; pp. 989–993. [Google Scholar]

- Mao, Y.; Guan, Z.; Wang, L. Analysis of the leakage current pulses of outdoor insulators in different relative humidity. In Proceedings of the 2007 Annual Report-Conference on Electrical Insulation and Dielectric Phenomena, Vancouver, BC, Canada, 14–17 October 2007; pp. 400–403. [Google Scholar]

- Wang, J.; Xi, Y.; Fang, C.; Cai, L.; Wang, J.; Fan, Y. Leakage current response mechanism of insulator string with ambient humidity on days without rain. IEEE Access 2019, 7, 55229–55236. [Google Scholar] [CrossRef]

- Amini, M.A.; Sedighi, A.R. A new procedure for determination of insulators contamination in electrical distribution networks. Int. J. Electr. Power Energy Syst. 2014, 61, 380–385. [Google Scholar] [CrossRef]

- Amini, M.; Anaraki, A.S.; Sadeghi, M. High frequency components of feeder current as diagnostic tool to study contamination conditions of outdoor insulators in power distribution networks. In Proceedings of the 2013 21st Iranian Conference on Electrical Engineering (ICEE), Mashhad, Iran, 14–16 May 2013; pp. 1–6. [Google Scholar]

- Algeelani, N.A.; Piah, M.A.M. Characterization of leakage current on high voltage glass insulators using wavelet transform technique. In Proceedings of the 2012 4th International Conference on Intelligent and Advanced Systems (ICIAS2012), Kuala Lumpur, Malaysia, 12–14 June 2012; pp. 882–885. [Google Scholar]

- Kumagai, S.; Yoshimura, N. Leakage current characterization for estimating the conditions of ceramic and polymeric insulating surfaces. IEEE Trans. Dielectr. Electr. Insul. 2004, 11, 681–690. [Google Scholar] [CrossRef]

- Du, B.; Liu, Y.; Liu, H.; Yang, Y. Recurrent plot analysis of leakage current for monitoring outdoor insulator performance. IEEE Trans. Dielectr. Electr. Insul. 2009, 16, 139–146. [Google Scholar] [CrossRef]

- Hui, A.; Zheng, J.; Lin, H.; He, B. Wavelet-fractal characteristics of leakage current on HV insulators. In Proceedings of the 2008 Third International Conference on Electric Utility Deregulation and Restructuring and Power Technologies, Nanjing, China, 6–9 April 2008; pp. 732–736. [Google Scholar]

- Natarajan, A.; Narayanan, S. S-transform based time-frequency analysis of leakage current signals of transmission line insulators under polluted conditions. J. Electr. Eng. Technol. 2015, 10, 616–624. [Google Scholar] [CrossRef][Green Version]

- Kannan, K.; Shivakumar, R.; Chandrasekar, S. A Random Forest Model Based Pollution Severity Classification Scheme of High Voltage Transmission Line Insulators. J. Electr. Eng. Technol. 2016, 11, 951–960. [Google Scholar] [CrossRef]

- Khaled, A.; El-Hag, A.; Assaleh, K. Equivalent salt deposit density prediction of outdoor polymer insulators during salt fog test. In Proceedings of the 2016 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Toronto, ON, Canada, 16–19 October 2016; pp. 786–789. [Google Scholar]

- Xia, Y.; Song, X.; Jia, Z.; Wang, X.; Li, Y. Applying S-transform and SVM to evaluate insulator’s pollution condition based on leakage current. In Proceedings of the 2018 12th International conference on the properties and applications of dielectric materials (ICPADM), Xi’an, China, 20–24 May 2018; pp. 742–747. [Google Scholar]

- Deb, S.; Choudhury, N.R.; Ghosh, R.; Chatterjee, B.; Dalai, S. Short time modified Hilbert transform-aided sparse representation for sensing of overhead line insulator contamination. IEEE Sens. J. 2018, 18, 8125–8132. [Google Scholar] [CrossRef]

- Deb, S.; Das, S.; Pradhan, A.K.; Banik, A.; Chatterjee, B.; Dalai, S. Estimation of contamination level of overhead insulators based on surface leakage current employing detrended fluctuation analysis. IEEE Trans. Ind. Electron. 2019, 67, 5729–5736. [Google Scholar] [CrossRef]

- Sit, K.; Chakraborty, A.; Dalai, S.; Chatterjee, B.; Pradhan, A.K. Mathematical Morphology aided Random Forest Classifier based High Voltage Porcelain Insulator Contamination level Classification. In Proceedings of the 2020 IEEE Region 10 Symposium (TENSYMP), Dhaka, Bangladesh, 5–7 June 2020; pp. 98–101. [Google Scholar]

- Mussina, D.; Irmanova, A.; Jamwal, P.K.; Bagheri, M. Multi-Modal Data Fusion Using Deep Neural Network for Condition Monitoring of High Voltage Insulator. IEEE Access 2020, 8, 184486–184496. [Google Scholar] [CrossRef]

- Castillo-Sierra, R.; Oviedo-Trespalacios, O.; Candelo-Becerra, J.E.; Soto, J.D.; Calle, M. A novel method for prediction of washing cycles of electrical insulators in high pollution environments. Int. J. Electr. Power Energy Syst. 2021, 130, 107026. [Google Scholar] [CrossRef]

- Ma, D.; Jin, L.; He, J.; Gao, K. Classification of partial discharge severities of ceramic insulators based on texture analysis of UV pulses. High Volt. 2021, 6, 986–996. [Google Scholar] [CrossRef]

- Sit, K.; Das, A.K.; Mukherjee, D.; Haque, N.; Deb, S.; Pradhan, A.K.; Dalai, S.; Chatterjee, B. Condition Monitoring of Overhead Polymeric Insulators Employing Hyperbolic Window Stockwell Transform of Surface Leakage Current Signals. IEEE Sens. J. 2021, 21, 10957–10964. [Google Scholar] [CrossRef]

- Sun, J.; Zhang, H.; Li, Q.; Liu, H.; Lu, X.; Hou, K. Contamination degree prediction of insulator surface based on exploratory factor analysis-least square support vector machine combined model. High Volt. 2020, 6, 264–277. [Google Scholar] [CrossRef]

- Palangar, M.F.; Mohseni, S.; Mirzaie, M.; Mahmoudi, A. Designing an Automatic Detector Device to Diagnose Insulator State on Overhead Distribution lines. IEEE Trans. Ind. Inf. 2021, 18, 1072–1082. [Google Scholar] [CrossRef]

- Hui, L.; Qinghe, S.; Jun, Y.; Hailei, M. Detection and processing for±660 composite insulator abnormal discharge. In Proceedings of the 2014 International Conference on Power System Technology, Chengdu, China, 20–22 October 2014; pp. 1404–1409. [Google Scholar]

- Tian, Z.; Jin, L.; Peng, C.; Duan, W.; Gao, K. Discrimination of transmission line insulator contamination grades using visible light images. In Proceedings of the 2016 IEEE 16th International Conference on Environment and Electrical Engineering (EEEIC), Florence, Italy, 7–10 June 2016; pp. 1–5. [Google Scholar]

- Jarrar, I.; Assaleh, K.; El-Hag, A.H. Using a pattern recognition-based technique to assess the hydrophobicity class of silicone rubber materials. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 2611–2618. [Google Scholar] [CrossRef]

- Yao, X.; Zhang, Y.; Gao, Y.; Pan, Y.; Liu, L. Research on technology of contact insulator pollution classification and pollution level division based on machine vision. In Proceedings of the 2017 IEEE 3rd Information Technology and Mechatronics Engineering Conference (ITOEC), Chongqing, China, 3–5 October 2017; pp. 1264–1268. [Google Scholar]

- Patel, I.; Maarouf, I.; Soltan, S.; Saad, A.; Al-Taher, A.; El-Hag, A.; Assaleh, K. Image processing based estimation of ceramic insulator pollution levels. In Proceedings of the 2018 5th International Conference on Electric Power and Energy Conversion Systems (EPECS), Kitakyushu, Japan, 23–25 April 2018; pp. 1–4. [Google Scholar]

- Chen, T.; Li, F.; Wei, Z.; Li, Z. Contamination Identification and Classification on Composite Insulator by Visible Light Images. In Proceedings of the 2020 IEEE International Conference on High Voltage Engineering and Application (ICHVE), Beijing, China, 6–10 September 2020; pp. 1–4. [Google Scholar]

- Yan, S.J.; Duan, W.S.; Shan, H.T.; Tong, M.S. Insulator Contamination Measurement Based on Infrared Thermal and Visible Image Information Fusion. In Proceedings of the 2019 PhotonIcs & Electromagnetics Research Symposium-Spring (PIERS-Spring), Rome, Italy, 17–20 June 2019; pp. 1006–1011. [Google Scholar]

- He, H.; Luo, D.; Lee, W.-J.; Zhang, Z.; Cao, Y.; Lu, T. A contactless insulator contamination levels detecting method based on infrared images features and RBFNN. IEEE Trans. Ind. Appl. 2018, 55, 2455–2463. [Google Scholar] [CrossRef]

- Liu, L.; Mei, H.; Guo, C.; Tu, Y.; Wang, L. Pixel-Level Classification of Pollution Severity on Insulators Using Photothermal Radiometry and Multiclass Semisupervised Support Vector Machine. IEEE Trans. Ind. Inf. 2020, 17, 441–449. [Google Scholar] [CrossRef]

- Suhaimi, S.M.I.; Bashir, N.; Muhamad, N.A.; Rahim, N.N.A.; Ahmad, N.A.; Rahman, M.N.A. Surface discharge analysis of high voltage glass insulators using ultraviolet pulse voltage. Energies 2019, 12, 204. [Google Scholar] [CrossRef]

- Zhang, D.; Chen, S. Intelligent Recognition of Insulator Contamination Grade Based on the Deep Learning of Ultraviolet Discharge Image Information. Energies 2020, 13, 5221. [Google Scholar] [CrossRef]

- Lu, F.; Wang, S.; Li, H. Insulator pollution grade evaluation based on ultraviolet imaging and fuzzy logic inference. In Proceedings of the 2010 Asia-Pacific Power and Energy Engineering Conference, Chengdu, China, 28–31 March 2010; pp. 1–4. [Google Scholar]

- Yin, C.; Xiao, Z.; Guo, Y.; Shi, C.; Zhang, X.; Wu, G. Method for detecting the pollution degree of naturally contaminated insulator based on hyperspectral characteristics. High Volt. 2021, 6, 1031–1039. [Google Scholar] [CrossRef]

- Tian, Z.; Jin, L.; Zhang, Y.; Ai, J.; Peng, C.; Duan, W. Discrimination of insulator contamination grades using information fusion of multi-light images. In Proceedings of the 2015 IEEE 11th International Conference on the Properties and Applications of Dielectric Materials (ICPADM), Sydney, Australia, 19–22 July 2015; pp. 967–970. [Google Scholar]

- Qiu, Y.; Wu, G.; Xiao, Z.; Guo, Y.; Zhang, X.; Liu, K. An extreme-learning-machine-based hyperspectral detection method of insulator pollution degree. IEEE Access 2019, 7, 121156–121164. [Google Scholar] [CrossRef]

- Xia, C.; Ren, M.; Wang, B.; Dong, M.; Song, B.; Hu, Y.; Pischler, O. Acquisition and analysis of hyperspectral data for surface contamination level of insulating materials. Measurement 2021, 173, 108560. [Google Scholar] [CrossRef]

- Liu, Y.; Pei, S.; Fu, W.; Zhang, K.; Ji, X.; Yin, Z. The discrimination method as applied to a deteriorated porcelain insulator used in transmission lines on the basis of a convolution neural network. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 3559–3566. [Google Scholar] [CrossRef]

- Tao, G.; Lianggang, X.; Hongyun, S.; Fengxiang, C.; Shichun, W.; Xiaowei, L. Research on Zero-Sequence Insulator Detection Technology Based on Deep Learning. J. Physics Conf. Ser. 2019, 1325, 012011. [Google Scholar] [CrossRef]

- Waleed, D.; Mukhopadhyay, S.; Tariq, U.; El-Hag, A.H. Drone-Based Ceramic Insulators Condition Monitoring. IEEE Trans. Instrum. Meas. 2021, 70, 6007312. [Google Scholar] [CrossRef]

- Stefenon, S.F.; Ribeiro, M.H.D.M.; Nied, A.; Mariani, V.C.; Coelho, L.D.S.; Leithardt, V.R.Q.; Silva, L.A.; Seman, L.O. Hybrid Wavelet Stacking Ensemble Model for Insulators Contamination Forecasting. IEEE Access 2021, 9, 66387–66397. [Google Scholar] [CrossRef]

- Liu, Y.; Lai, T.; Liu, J.; Li, Y.; Pei, S.; Yang, J. Insulator Contamination Diagnosis Method Based on Deep Learning Convolutional Neural Network. In Proceedings of the 2021 3rd Asia Energy and Electrical Engineering Symposium (AEEES), Chengdu, China, 26–29 March 2021; pp. 184–188. [Google Scholar]

- Zhao, Y.; Yan, J.; Wang, Y.; Jing, Q.; Liu, T. Porcelain Insulator Crack Location and Surface States Pattern Recognition Based on Hyperspectral Technology. Entropy 2021, 23, 486. [Google Scholar] [CrossRef]

- He, Y.; Li, M.; Meng, Z.; Chen, S.; Huang, S.; Hu, Y.; Zou, X. An overview of acoustic emission inspection and monitoring technology in the key components of renewable energy systems. Mech. Syst. Sig. Process. 2021, 148, 107146. [Google Scholar] [CrossRef]

- Pei, C.; Shu, N.; Li, L.; Li, Z.; Peng, H. On-line monitoring of insulator contamination causing flashover based on acoustic emission. In Proceedings of the 2008 Third International Conference on Electric Utility Deregulation and Restructuring and Power Technologies, Nanjing, China, 6–9 April 2008; pp. 1667–1671. [Google Scholar]

- Li, H.; Wen, X.; Shu, N.; Pei, C. Application of Acoustic Emission Technology on Monitoring of Polluted Insulator Discharge. In Proceedings of the 2009 Asia-Pacific Power and Energy Engineering Conference, Wuhan, China, 28–30 March 2009; pp. 1–4. [Google Scholar]

- Jiang, Y.; McMeekin, S.G.; Reid, A.J.; Nekahi, A.; Judd, M.D.; Wilson, A. Monitoring insulator contamination level under dry condition with a microwave reflectometer. In Proceedings of the 2015 IEEE 11th International Conference on the Properties and Applications of Dielectric Materials (ICPADM), Sydney, Australia, 19–22 July 2015; pp. 959–962. [Google Scholar]

- Yi, M.C.; Fang, J.; Wang, Y.; Li, Z.N.; Gu, C.H.; Shu, N.Q.; Li, Z.P. A Method for Extracting Acoustic Emission Signal Frequency Characteristics of Polluted-Insulator Discharge. Appl. Mech. Mater. 2014, 494–495, 1513–1516. [Google Scholar] [CrossRef]

- Al-geelani, N.A.; Piah, M.A.M.; Abdul-Malek, Z. Identification of acoustic signals of corona discharges under different contamination levels using wavelet transform. Electr. Eng. 2018, 100, 1059–1067. [Google Scholar] [CrossRef]

- El-Hag, A.H. Promoting condition monitoring and diagnostics of electrical insulation in undergraduate capstone graduation projects. IEEE Electr. Insul. Mag. 2015, 31, 8–15. [Google Scholar] [CrossRef]

- Qaddoumi, N.N.; El-Hag, A.H.; Saker, Y. Outdoor insulators testing using artificial neural network-based near-field microwave technique. IEEE Trans. Instrum. Meas. 2013, 63, 260–266. [Google Scholar] [CrossRef]

- Stefenon, S.F.; Grebogi, R.B.; Freire, R.Z.; Nied, A.; Meyer, L.H. Optimized ensemble extreme learning machine for classification of electrical insulators conditions. IEEE Trans. Ind. Electron. 2019, 67, 5170–5178. [Google Scholar] [CrossRef]

- Frizzo Stefenon, S.; Zanetti Freire, R.; dos Santos Coelho, L.; Meyer, L.H.; Bartnik Grebogi, R.; Gouvêa Buratto, W.; Nied, A. Electrical insulator fault forecasting based on a wavelet neuro-fuzzy system. Energies 2020, 13, 484. [Google Scholar] [CrossRef]

- Su, H.; Jia, Z.; Guan, Z.; Li, L. Mechanism of contaminant accumulation and flashover of insulator in heavily polluted coastal area. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 1635–1641. [Google Scholar] [CrossRef]

- Yang, S.; Jia, Z.; Ouyang, X.; Bai, H.; Zhang, X. Effects of algae contamination on composite insulator hydrophobic property. In Proceedings of the 2017 1st International Conference on Electrical Materials and Power Equipment (ICEMPE), Xi’an, China, 14–17 May 2017; pp. 667–670. [Google Scholar]

- Yang, S.; Jia, Z.; Ouyang, X. Effects of algae contamination on the hydrophobicity of high-voltage composite insulators. High Volt. 2019, 4, 234–240. [Google Scholar] [CrossRef]

- Dave, V.; Gupta, H.; Chandra, R. Nanostructured hydrophobic DC sputtered inorganic oxide coating for outdoor glass insulators. Appl. Surf. Sci. 2014, 295, 231–239. [Google Scholar] [CrossRef]

- Zeng, X.; Wang, X.; Cheng, L.; Zhang, S.; Liao, R. A Research on the Super-hydrophobic Surface Constructing Method for the Out-door Insulator Based on the Recycling of Composite. In Proceedings of the 2018 IEEE International Conference on High Voltage Engineering and Application (ICHVE), Athens, Greece, 10–13 September 2018; pp. 1–4. [Google Scholar]

- Bala, P.; Bose, R.; Chatterjee, S. Electric stress analysis of a 11kV RTV silicone rubber coated porcelain insulator. In Proceedings of the 2016 Biennial International Conference on Power and Energy Systems: Towards Sustainable Energy (PESTSE), Bengaluru, India, 21–23 January 2016; pp. 1–6. [Google Scholar]

- Yang, Z.; Jia, Z.; Chen, C.; Zhang, X.; Liu, L.; Zhu, R.; Xie, Q. Hydrophobicity distribution analysis of DC composite insulators. In Proceedings of the 2014 IEEE Electrical Insulation Conference (EIC), Philadelphia, PA, USA, 8–11 June 2014; pp. 465–468. [Google Scholar]

- Chandrasekar, S.; Kalaivanan, C.; Montanari, G.C.; Cavallini, A. Partial discharge detection as a tool to infer pollution severity of polymeric insulators. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 181–188. [Google Scholar] [CrossRef]

- Liu, Y.; Du, B. Energy eigenvector analysis of surface discharges for evaluating the performance of polymer insulator in presence of water droplets. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 2438–2447. [Google Scholar] [CrossRef]

- Hussain, M.M.; Farokhi, S.; McMeekin, S.; Farzaneh, M. Prediction of surface degradation of composite insulators using PD measurement in cold fog. In Proceedings of the 2016 IEEE International Conference on Dielectrics (ICD), Montpellier, France, 3–7 July 2016; pp. 697–700. [Google Scholar]

- Al Khafaf, N.; El-Hag, A. Bayesian regularization of neural network to predict leakage current in a salt fog environment. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 686–693. [Google Scholar] [CrossRef]

- Jinlei, H.; Chao, S.; Zhenxing, K.; Xiaobo, Z.; Yunpeng, J. Insulator Contamination Prediction Model Based on BP Neural Network Optimized by Genetic Algorithm. In Proceedings of the 2018 International Conference on Power System Technology (POWERCON), Guangzhou, China, 6–8 November 2018; pp. 3166–3172. [Google Scholar]

- Yan, S.; Gang, H.; Jiafu, Z. The Monitoring Interface of Insulator’s State Based on the Leakage Characteristics. In Proceedings of the 2020 IEEE International Conference on High Voltage Engineering and Application (ICHVE), Beijing, China, 6–10 September 2020; pp. 1–4. [Google Scholar]

- Liu, Y.; Yang, J.; Li, Y.; Pei, S.; Liu, J.; Lai, T. Research on Diagnosis Device of Insulator Pollution Degree Based on BP Neural Network. In Proceedings of the 2021 3rd Asia Energy and Electrical Engineering Symposium (AEEES), Chengdu, China, 26–29 March 2021; pp. 166–169. [Google Scholar]

- Zhao, S.; Jiang, X.; Xie, Y. Evaluating the contamination level of polluted insulators based on the characteristics of leakage current. Int. Trans. Electr. Energy Syst. 2015, 25, 2109–2123. [Google Scholar] [CrossRef]

- Mahdjoubi, A.; Zegnini, B.; Belkheiri, M.; Seghier, T. Fixed least squares support vector machines for flashover modelling of outdoor insulators. Electr. Power Syst. Res. 2019, 173, 29–37. [Google Scholar] [CrossRef]

- Zhou, H.; Chen, Y. Prediction of Insulator Pollution Flashover Voltage Based on Data Mining Technology. IOP Conf. Series Earth Environ. Sci. 2021, 692, 022070. [Google Scholar] [CrossRef]

- Chaou, A.K.; Mekhaldi, A.; Teguar, M. Recurrence quantification analysis as a novel LC feature extraction technique for the classification of pollution severity on HV insulator model. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 3376–3384. [Google Scholar] [CrossRef]

- Corso, M.P.; Perez, F.L.; Stefenon, S.F.; Yow, K.-C.; García Ovejero, R.; Leithardt, V.R.Q. Classification of Contaminated Insulators Using k-Nearest Neighbors Based on Computer Vision. Computers 2021, 10, 112. [Google Scholar] [CrossRef]

- Feng, H.; Xuran, H.; Bin, L.; Haipeng, W.; Decai, Z. Infrared Image Recognition Technology Based on Visual Processing and Deep Learning. In Proceedings of the 2020 Chinese Automation Congress (CAC), Shanghai, China, 6–8 November 2020; pp. 641–645. [Google Scholar]

- Vigneshwaran, B.; Maheswari, R.; Kalaivani, L.; Shanmuganathan, V.; Rho, S.; Kadry, S.; Lee, M.Y. Recognition of pollution layer location in 11 kV polymer insulators used in smart power grid using dual-input VGG Convolutional Neural Network. Energy Rep. 2021, 7, 7878–7889. [Google Scholar] [CrossRef]

- Wang, Y.-C.; Lin, Y.-T.; Chang, H.-C.; Kuo, C.-C. Contamination assessment of insulators using microsystem technology with fuzzy-based approach. Microsyst. Technol. 2019, 27, 1759–1772. [Google Scholar] [CrossRef]

- Petri, L.d.P.S.; Moutinho, E.A.; Silva, R.P.; Capelini, R.M.; Salustiano, R.; Ferraz, G.M.F.; Neto, E.T.W.; Villibor, J.P.; Pinto, S.S. A Portable System for the Evaluation of the Degree of Pollution of Transmission Line Insulators. Energies 2020, 13, 6625. [Google Scholar] [CrossRef]

- Lu, Y.-P.; Yu, M.; Lai, L.; Lin, X. A new fuzzy neural network based insulator contamination detection. In Proceedings of the 2006 International Conference on Machine Learning and Cybernetics, Dalian, China, 13–16 August 2006; pp. 4099–4104. [Google Scholar]

- Salem, A.A.; Abd Rahman, R.; Kamarudin, M.; Othman, N.; Jamail, N.; Hamid, H.; Ishak, M. An alternative approaches to predict flashover voltage on polluted outdoor insulators using artificial intelligence techniques. Bull. Electr. Eng. Inform. 2020, 9, 533–541. [Google Scholar] [CrossRef]

- Singh, P.; Dutta, S.; Baral, A.; Chakravorti, S. Contamination Level Assessment in Porcelain Disc Insulator using Detrended Fluctuation Analysis. In Proceedings of the 2019 IEEE 4th International Conference on Condition Assessment Techniques in Electrical Systems (CATCON), Chennai, India, 21–23 November 2019; pp. 1–5. [Google Scholar]

- Dey, J.; Dutta, S.; Baral, A.; Chakravorti, S. Leakage Current Monitoring of Suspension Insulator for Effective Determination of ESDD. In Proceedings of the 2019 8th International Conference on Power Systems (ICPS), Jaipur, India, 20–22 December 2019; pp. 1–6. [Google Scholar]

- Liao, Y.; Li, Y.; Zhang, F.; Zhang, X.; Wang, T.; Guo, Y.; Xiao, Z.; Wang, Y. Study on evaluation method of insulator surface contamination level based on LIBS technology and PCA algorithm. In Proceedings of the 2019 2nd International Conference on Electrical Materials and Power Equipment (ICEMPE), Guangzhou, China, 7–10 April 2019; pp. 512–517. [Google Scholar]

- Ahmad, J.; Tahir, A.; Stewart, B.G.; Nekahi, A. Forecasting Flashover Parameters of Polymeric Insulators under Contaminated Conditions Using the Machine Learning Technique. Energies 2020, 13, 3889. [Google Scholar]

- Palangar, M.; Mirzaie, M. Predicting Critical Conditions in Polluted Insulators Using Phase Angle Index of Leakage Current. In Proceedings of the 2020 IEEE International Conference on High Voltage Engineering and Application (ICHVE), Beijing, China, 6–10 September 2020; pp. 1–4. [Google Scholar]

- Salem, A.A.; Abd-Rahman, R.; Al-Gailani, S.A.; Salam, Z.; Kamarudin, M.S.; Zainuddin, H.; Yousof, M.F.M. Risk assessment of polluted glass insulator using leakage current index under different operating conditions. IEEE Access 2020, 8, 175827–175839. [Google Scholar] [CrossRef]

- Wahyudi, M.; Setiawan, N.A.; Pambudi, K.; Saputra, D. Severity Level of An Insulator in Polluted and Dry Conditions Based on Ultraviolet Emission. In Proceedings of the 2020 2nd International Conference on Smart Power & Internet Energy Systems (SPIES), Bangkok, Thailand, 2–4 June 2020; pp. 457–462. [Google Scholar]

- Banik, A.; Nielsen, S.; Nourbakhsh, G. A crest factor-based technique for the analysis of polluted insulator leakage current under harmonically distorted supply voltage. Electr. Eng. 2021, 103, 1823–1836. [Google Scholar] [CrossRef]

| IEC 60815 Standards | ||

|---|---|---|

| Leakage Distance (kV/l mm) | ESDD (mg/cm2) | Site Severity |

| 2.11 | >0.40 | Very Heavy |

| 1.70 | 0.15–0.40 | Heavy |

| 1.37 | 0.04–0.15 | Medium |

| 1.09 | 0.01–0.04 | Light |

| 0.87 | <0.01 | Very Light |

| ESDD, mg/cm2 | Site Severity | |

|---|---|---|

| IEEE | CIGRE | |

| - | >0.48 | Exceptional |

| - | 0.24–0.48 | Very heavy |

| >0.10 | 0.12–0.24 | Heavy |

| 0.06–0.10 | 0.06–0.12 | Average/Moderate |

| 0.03–0.06 | 0.03–0.06 | Light |

| 0–0.03 | 0.015–0.03 | Very light |

| - | 0.0075–0.015 | None |

| Leakage Current (mA) RTV Coated | Leakage Current (mA) Noncoated | Voltage (kV) |

|---|---|---|

| 0.811 | - | 45 |

| 0.705 | - | 40 |

| 0.580 | Flashover | 35 |

| 0.478 | - | 30 |

| 0.394 | 1.601 | 25 |

| 0.305 | 0.695 | 20 |

| 0.224 | 0.371 | 15 |

| 0.151 | 0.358 | 10 |

| 0.073 | 0.226 | 5 |

| n | 4 | 3 | 2 | 1 | 0 |

|---|---|---|---|---|---|

| Voltage of 20% distance in high voltage end % | 38.36 | 41.61 | 45.44 | 51.75 | 63.5 |

| Maximum electric field Strength (kV/mm) | 0.39 | 0.536 | 0.65 | 1.01 | 2.0 |

| % Voltage of composite insulator | 53.26 | 57.91 | 63.76 | 73.62 | 100 |

| Cleaning Method | Deposit | Comments | |

|---|---|---|---|

| Insulator washing | High-pressure washing | Deposits with poor adhesion | Time of washing Live washing? Work hours cost if power interruptions are required |

| Insulator cleaning | Dry cleaning | Cement fertilizers | Time of cleaning Dry material deposits Cost Glaze damage and insulator shattering |

| Visible Light | Infrared | Ultraviolet | |

|---|---|---|---|

| Temperature | - | ≥5 °C 5 °C or higher | - |

| Relative humidity | - | ≤85% 85% or less | - |

| Wind speed | ≤5 m/s | ≤0.5 m/s | ≤1.5 m/s |

| Weather | The weather is sunny and should not be thunder, rain, fog, snow, etc. | The weather is cloudy, and it is advisable to avoid thunder, rain, fog, snow, etc. | Should not be thunder or heavy rain |

| Visibility | High | Relatively high | Relatively high |

| Best time | Daytime for surface shape test, night for partial discharge detection | At night, two hours after sunset | At night |

| Electromagnetic interference | - | Avoiding | Avoiding |

| Heat source radiation | - | Avoiding | - |

| Background radiation | - | Balance | - |

| Reference | Insulator Type | Preprocessing Stage | Metrics | Accuracy |

|---|---|---|---|---|

| [117] | - | Bottom-Up segmentation, wavelet energy coefficient, principal component analysis, | Recall, precision, accuracy, time, and F-measure | 98% |

| [118] | Glass | WPT | RMSE, MAE, R2 | R2 for testing in grid partition is 0.9592 |

| [106] | Polymeric | wavelet transform (WT), filtering, and noise reduction | RMSE, MAPE, MAE, and R2 | R2 is 0.9982 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maraaba, L.; Al-Soufi, K.; Ssennoga, T.; Memon, A.M.; Worku, M.Y.; Alhems, L.M. Contamination Level Monitoring Techniques for High-Voltage Insulators: A Review. Energies 2022, 15, 7656. https://doi.org/10.3390/en15207656

Maraaba L, Al-Soufi K, Ssennoga T, Memon AM, Worku MY, Alhems LM. Contamination Level Monitoring Techniques for High-Voltage Insulators: A Review. Energies. 2022; 15(20):7656. https://doi.org/10.3390/en15207656

Chicago/Turabian StyleMaraaba, Luqman, Khaled Al-Soufi, Twaha Ssennoga, Azhar M. Memon, Muhammed Y. Worku, and Luai M. Alhems. 2022. "Contamination Level Monitoring Techniques for High-Voltage Insulators: A Review" Energies 15, no. 20: 7656. https://doi.org/10.3390/en15207656

APA StyleMaraaba, L., Al-Soufi, K., Ssennoga, T., Memon, A. M., Worku, M. Y., & Alhems, L. M. (2022). Contamination Level Monitoring Techniques for High-Voltage Insulators: A Review. Energies, 15(20), 7656. https://doi.org/10.3390/en15207656