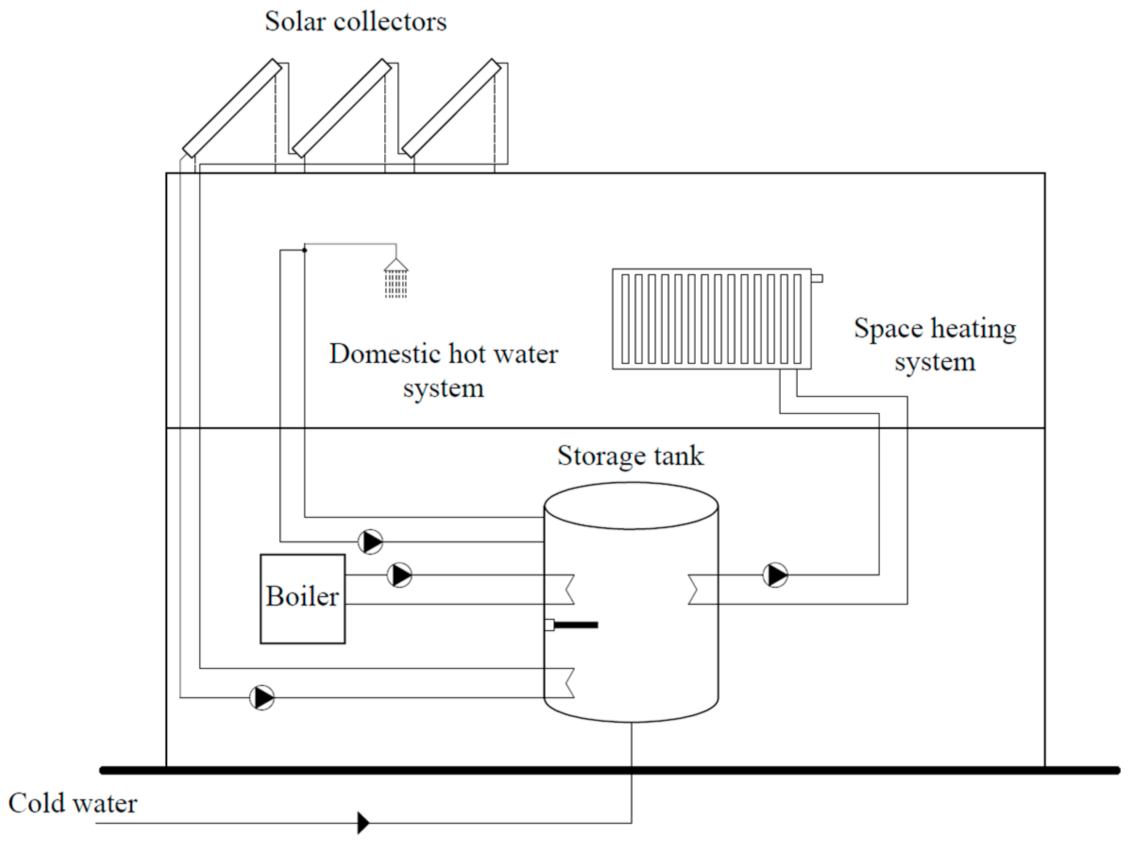

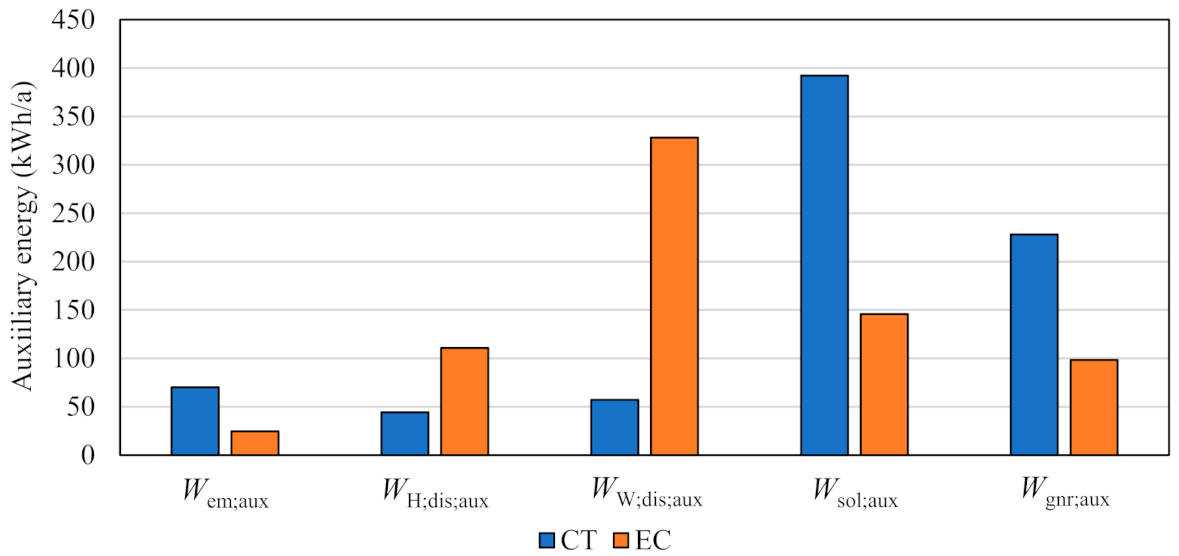

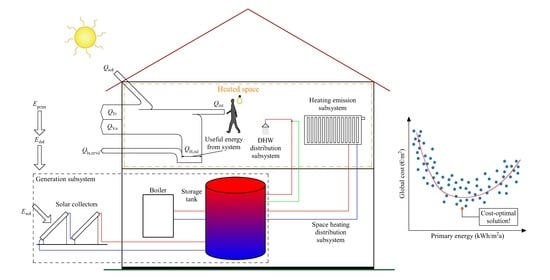

This chapter provides an overview of the calculation methods based on the set of EPB standards EN 15316:2017 for assessing the energy performance of a solar hot water system used for SH and DHW needs, as shown in

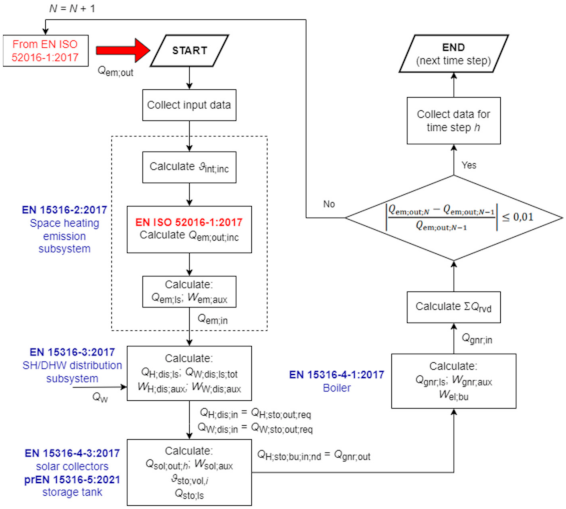

Figure 1. The calculation procedure starts with the calculation of energy at the output from the subsystem and ends with the calculation of energy input to the subsystem. Each standard describes the method for calculating the heat losses and auxiliary energy consumption of a particular subsystem, according to which the delivered and primary energy of the building are ultimately determined. The calculation flow is shown in

Figure 2. The main input data are the energy output from the space heating emission subsystem

Qem;out determined according to the standard EN ISO 52016-1:2017 [

26] and the energy need for DHW

QW determined according to EN 12831-3:2017 [

27]. In the following text, basic principles of each standard with proposals to overcome found ambiguities and shortcomings are described.

2.1.1. Space Heating Emission Subsystem

The calculation of the space emission subsystem is performed according to the standard EN 15316-2:2017 [

28], which replaces the standard EN 15316-2-1:2007 [

29]. Unlike EN 15316-2-1:2007, where the heat losses of the emission subsystem are calculated using the efficiencies method, the calculation procedure in the new version of the standard is based on the calculation of increased indoor air temperature (Equation (1)):

where

ϑint;ini is initial internal set-point temperature and Δ

ϑint;inc is internal set-point temperature variation calculated as:

which takes into account the impact of heat loss due to temperature variation that occurs as a result of non-uniform space temperature distribution

ϑstr, control accuracy of indoor temperature

ϑctr, radiation

ϑrad, hydronic balancing of system

ϑhydr and operation of control system

ϑroomaut. Calculated

ϑint;inc is then used to determine the modified energy at the output from space heating emission subsystem

Qem;out;inc, according to [

26].

The impact of temperature variation based on additional heating losses of embedded emitters in the building envelope

ϑemb is used to calculate the embedded losses

Qemb;ls, according to:

where

ϑe;comb is equal to average outdoor air temperature in observed time step

ϑe,avg. Together,

Qem;out,

Qem;out;inc and

Qemb;ls are used to calculate the total heat loss of the emission subsystem:

The standard recommends that the operating duration of the fans (operation at nominal power), as well as the operating duration of the control system, should be equal to the operating time of the heating system. The authors of this paper recommend that the fans operating time be calculated as:

This approach, considering only nominal power, does not take into consideration the modulation of the fans’ power. Such an upgrade can be a further improvement of the calculation procedure. Furthermore, the present authors recommend that the auxiliary energy of the control system should be calculated for each hour of the year.

2.1.2. Distribution Subsystem

The calculation of the SH and DHW distribution subsystem is performed according to the standard EN 15316-3:2017 [

30], which is a replacement for the standards EN 15316-2-3:2007 [

31] and EN 15316-3-2:2007 [

32]. The main input data for the SH distribution system is

Qem;in (energy input to the emission module) and the main input data for the DHW distribution system is the energy need for DHW

QW. The heat loss calculation of a distribution subsystem is based on the mean water temperature, the temperature of space surrounding the pipe section, the thermal transmittance of the pipes, the length of the pipes and the operation time. For the SH distribution system, only heat losses that occur in the circulation loop during the heating system operation are taken into account. For the DHW distribution system, heat losses in the circulation loop are separately calculated for the time when the circulation pump is ON and OFF (if there is a hot water recirculation system), as well as heat losses that occur in open-circuited stubs between subsequent tappings.

According to [

30], the heat losses of the SH and DHW circulation loops during circulation pump operating time are calculated according to the same equation:

where

j is an index representing pipeline section (zone), Ψ

j is linear thermal transmittance,

ϑX;mean is mean water temperature in the SH/DHW distribution system,

ϑX;amb,j is an ambient temperature surrounding the section,

L is the length of the pipe section,

Lequi is the equivalent length of the pipe section for fittings (valves, tees, bends, etc.),

tci is time step of the calculation, and

tX;op is the circulation pump operating time. Index X is replaced by H or W in the case of calculating SH or DHW distribution system, respectively.

If the

tatap, i.e., time after the last tapping in the tapping profile, or last pump operation in the DHW circulation loop, is known, it is possible to calculate the temperature after the last tapping or last pump operation according to:

where

ϑW is the design hot water temperature,

VW,j is the volume of water in pipe section

j,

cW is the specific heat capacity of water,

ρW is the density of water,

cp is the specific heat capacity of the pipes, and

mp,j is the mass of pipes. By knowing

ϑW;atap,j, the heat loss of the open-circuited stubs, or heat loss of the DHW circulation loop when the pump is not operating, can be calculated as:

where the average water temperature is:

If only the number of tapping’s

ntap and the volume of water within the pipes is known, the heat loss of the open-circuited stubs

QW;dis;stub per time step during tapping can be calculated under the assumption that, between the tappings, the hot water temperature drops to the ambient air temperature according to:

where the mass flow of hot water in open-circuited stubs during tapping is given by:

If neither the tapping profile nor the pipe dimensions are known, the heat loss of the open-circuited stubs is calculated according to Equation (8), using the simplified method for determining mean water temperature:

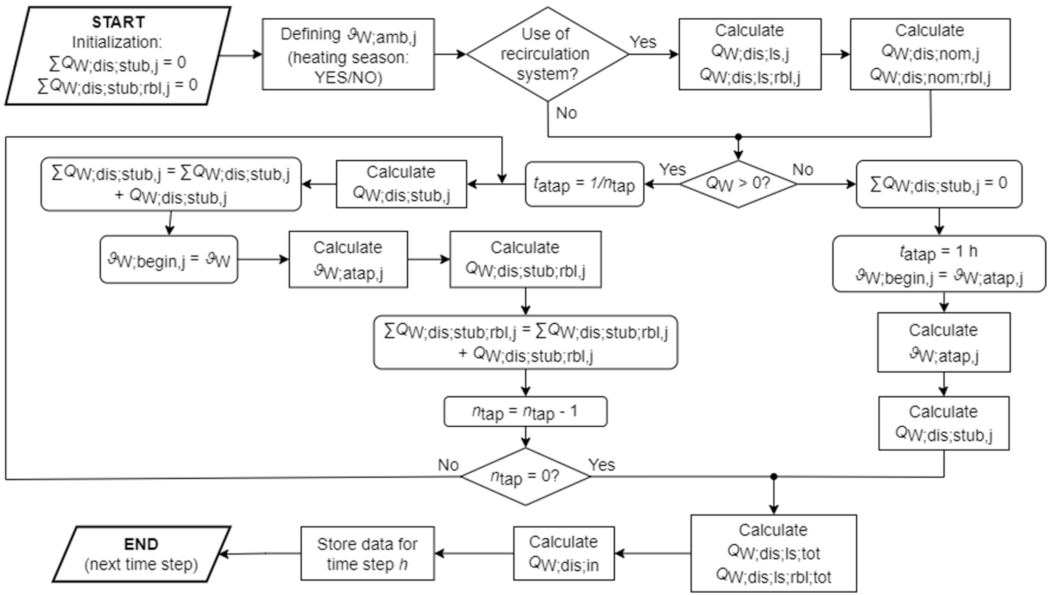

The calculation method of the DHW distribution system heat losses is not clearly described, and it also contains certain shortcomings. According to Equation (8), heat losses of the open-circuited stubs and heat losses of the DHW circulation loop when the pump is not operating are calculated for the period when the pump operates (

tW;op). Furthermore, the procedure for obtaining

ϑW;atap,j yields questionable results. So, in this paper, a new approach for calculating the heat loss of open-circuited stubs, and the heat loss of the DHW circulation loop when the pump is not operating, is implemented. The calculation flowchart is shown in

Figure 3. This method is based on the equality of the heat transfer rate between water and the environment, and the heat transfer rate through the pipe wall. The water temperature after the last pump operation is then calculated according to:

and the water temperature after the last tapping is calculated as:

where the amount of hot water in section

j in the observed time step is given by:

and

ϑW;begin,j is the water temperature in the pipes at the beginning of the cooling period. If calculated

ϑW;atap,j is lower than

ϑW;amb,j, then

ϑW;atap,j is equal to

ϑW;amb,j. If there is tapping in the observed time step,

ϑW;begin,j is equal to

ϑW, whereas in the case where there is no tapping in the observed time step,

ϑW;begin,j is equal to the water temperature at the end of the previous time step

ϑW;atap,j;h−1. In this method, time after the last tapping

tatap is determined by:

where

ntap represents the number of tappings in the observed time step. Therefore, this method can be used when only the tapping profile is known. Heat losses of the open-circuited stubs during tapping, and heat losses of the DHW circulation loop when the pump is not operating, are calculated according to:

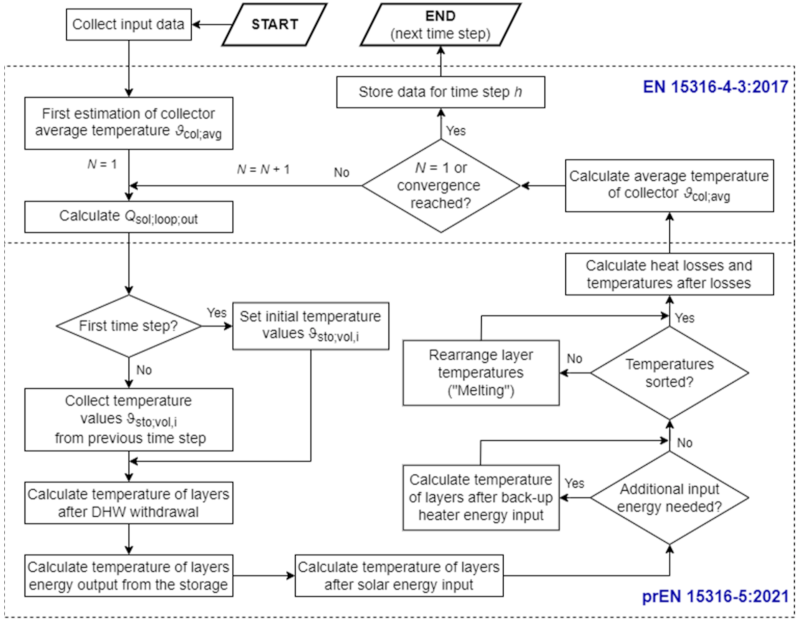

2.1.3. Thermal Solar Collectors and Storage Tank

The standard EN 15316-4-3:2017 [

33], which supersedes the standards EN 15316-4-3:2007 [

34] and EN 15316-4-6:2007 [

35], deals with the energy performance calculation of thermal solar collectors and a photovoltaic generation subsystem. Photovoltaic panels were not used in this case study. The standard EN 15316-4-3:2007 describes two methods of monthly calculation of solar thermal system: Method A, which uses system data, and method B (based on the

f-chart method), which uses component data. A new dynamic hourly calculation method, based on the energy balance of the solar collector, has been added to the new standard. The new calculation procedure works in conjunction with the storage module (calculation according to the standard prEN 15316-5:2021 [

36]). prEN 15316-5:2021 describes two calculation methods. Method A takes into account temperature stratification inside the tank, and it is recommended to use it when analyzing systems with solar collectors. Method B models the storage tank with a uniform temperature and is generally used in all other cases. Temperatures in the storage tank influence the calculation of the heat losses in the solar collectors. This necessitates the iterative calculation in which the convergence condition is described as:

where

Qsol;loop;out is the heat output of collector loop to the storage tank and

N is the iteration step. The iteration is executed until the condition is met, or for four times, whereby the fourth iteration is final.

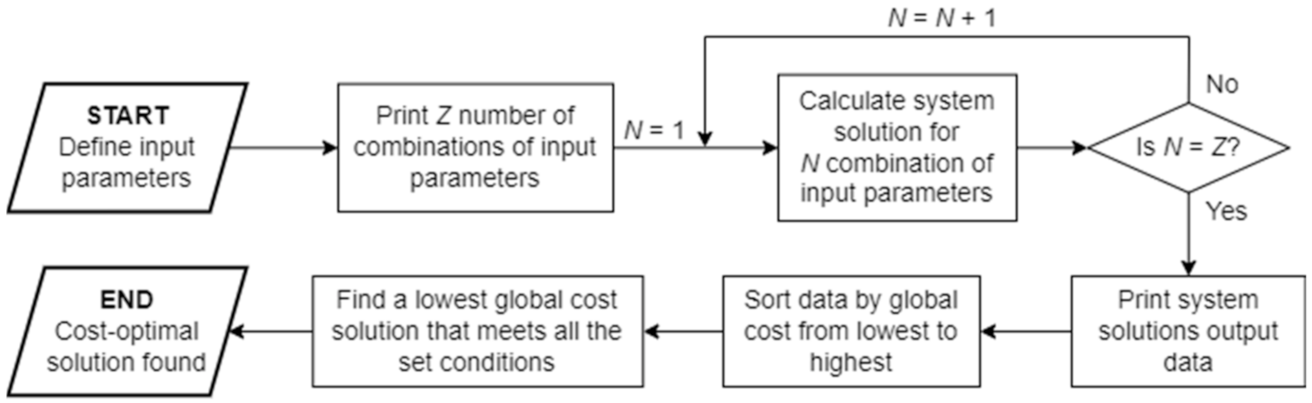

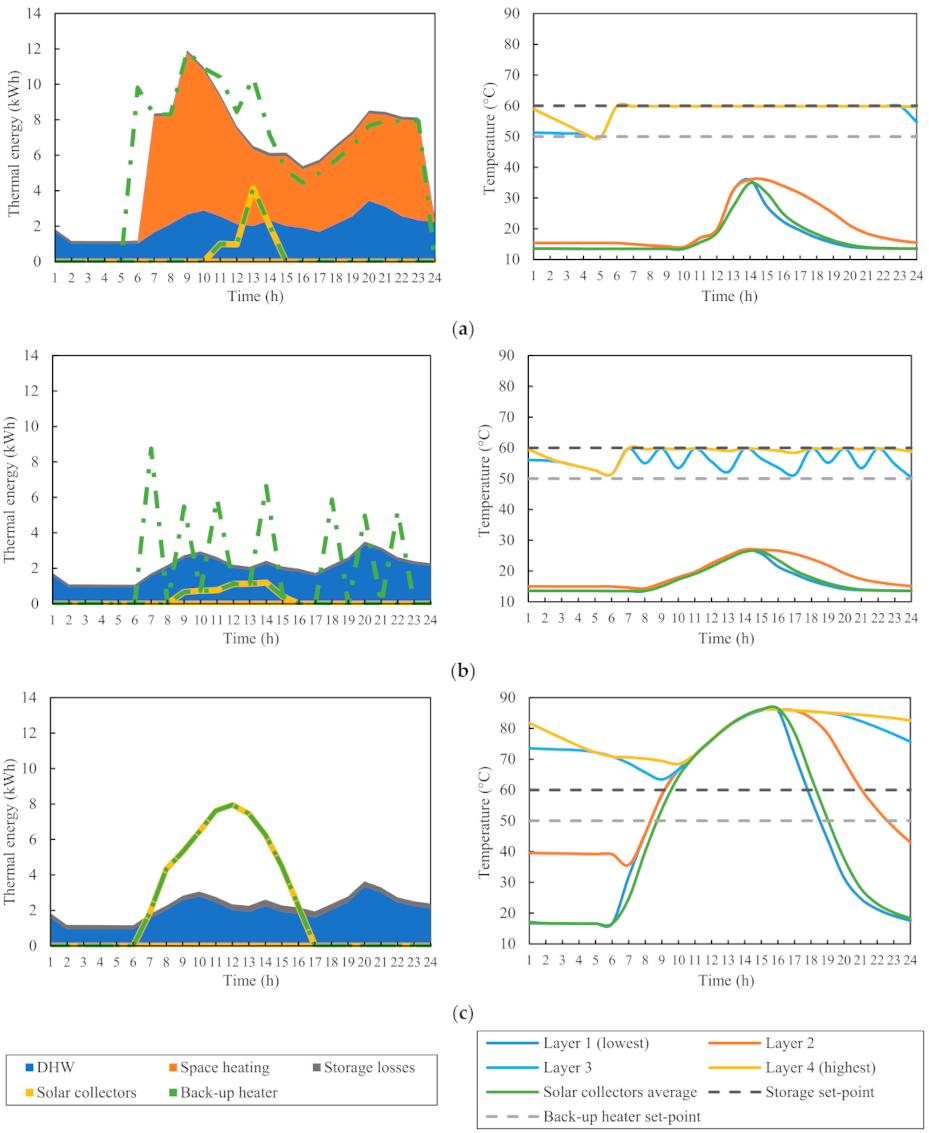

After gathering all the necessary input data, such as meteorological data, hourly loads

QH;dis;in and

QW;dis;in (output from the distribution module), technical data about solar collectors and storage tanks, and the type of application (SH and/or DHW), the calculation is performed as shown in

Figure 4. For each time step, in the initial calculation step, the collector efficiency of 40% is assumed. In the following iteration steps, the collector efficiency

ηcol;h is calculated based on the obtained average temperature of the working medium in collector loop

ϑcol;avg;h according to:

where

η0 is the zero-loss efficiency of the solar collector,

Khem(50°) is the incidence angle modifier,

a1 and

a2 are the first- and second-order heat loss coefficients and

is the reduced temperature difference in the collector. Afterwards, the collector output energy is calculated as:

where

Isol;h is the solar irradiance on the collector plane, and

Asol is the installed collector area. Finally, the energy output of the collector loop to the storage is calculated by:

where

Qsol;loop;ls;h is heat loss of the collector loop piping. It is important to note that in the case where

Qsol;loop;out;h is less than or equal to the power of the collector loop pump multiplied by 3,

Qsol;loop;out;h is equal to 0. This takes into account that the working medium temperature in the solar collectors has to rise sufficiently in order for the pump to start.

Qsol;loop;out;h is used as input to calculate the storage module.

In addition to the described procedure, the present authors propose a simplified method for checking whether the collector output temperature

ϑcol;out;h is equal to or higher than the stagnation set-point temperature

ϑstag (e.g., 90 °C). In stagnation, the temperature of the working medium can be calculated as:

with collector stagnation output defined as:

and collector losses calculated as:

where

Mcol is the mass of the working medium in the collector,

CW is the specific heat of working medium, and

ϑe;h is outside air temperature in considered time step. If collector output temperature in the previous time step reaches

ϑstag, the pump in the collector loop is switched off, i.e.,

Qsol;loop;out is equal to 0 in all subsequent time steps, until

ϑcol;out;h drops below

ϑstag.

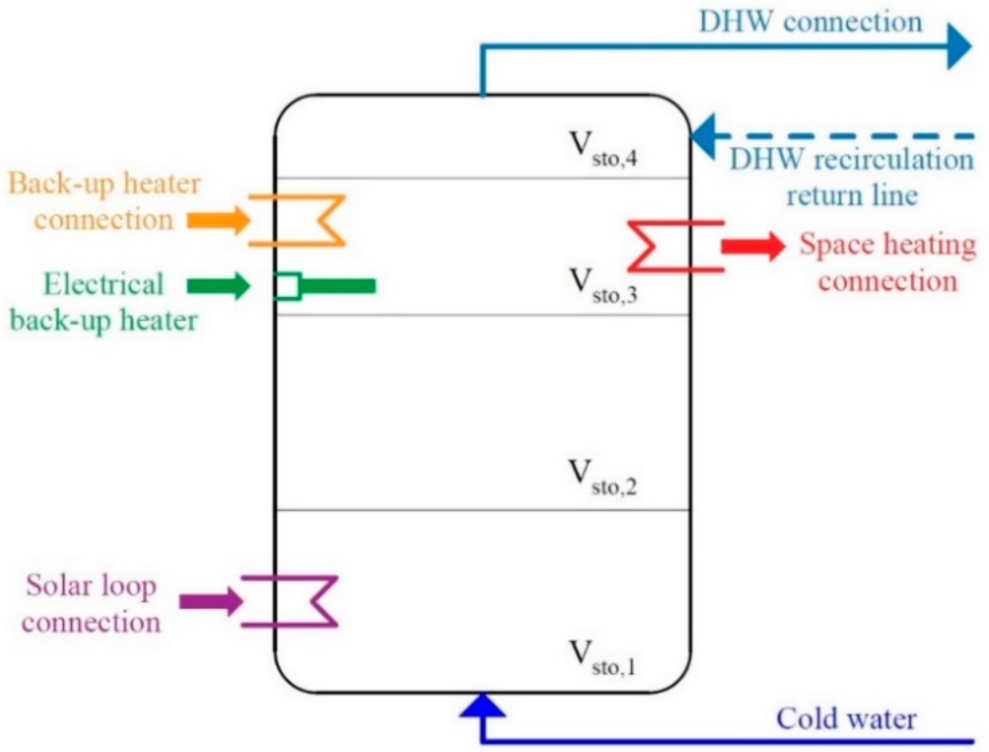

In the case of the solar thermal system with a back-up heater, authors propose using Method A from prEN 15316-5:2021 [

36] and dividing the storage unit volume into a minimum of four layers. The schematic of the storage model, including its connections to the rest of the system, is shown in

Figure 5. It is important to emphasize that this model, like many others commonly used, assumes that the thickness of the thermocline is zero, to simplify the calculation procedure. Of course, in reality, the thermocline has a certain thickness that changes during operation. A more detailed presentation of the tank model is given in [

37]. The calculation method for the storage tank covers the calculation of energy delivered to the storage, i.e., energy delivered by solar collectors and energy delivered by a back-up heater (e.g., combustion boiler, electric heater), energy delivered from the storage to the SH and DHW distribution subsystem, outlet/inlet temperatures from the storage and storage tank heat losses.

The revised standard prEN 15316-5:2021 resolves the ambiguities and shortcomings found in the 2017 version of the standard. This includes the correction of basic energy balances and the ability to define layers of arbitrary volumes. Furthermore, the new version takes into account the contribution of the back-up heater when determining the energy output from the storage, and takes into account the temperature difference between the storage water content temperature, and the working medium temperature in the heat exchanger (if present). The new version of the standards also contains a more precise description of how to consider DHW system losses, the calculation of additional heat losses due to the thermosyphon circulation, and a more accurate definition of heat losses through the envelope of each layer.

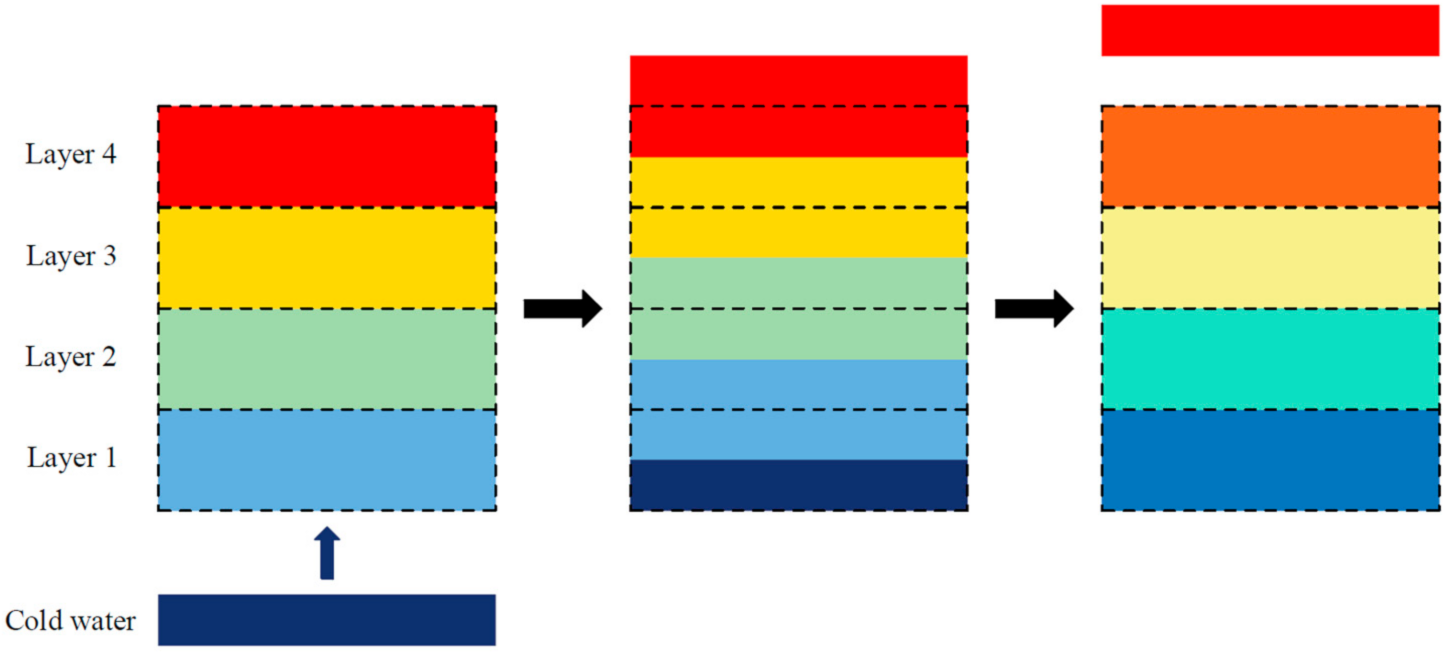

The calculation, based on the energy balance of each layer, is performed by determining the accumulated energy in each layer, defined by the volume of contained water and the temperature difference between the layer temperature and the required temperature. The calculation of the considered time step starts with collecting the temperatures of all layers in the previous time step. After that, the volume withdrawn from storage for DHW service is calculated. Withdrawal is assumed to occur from the top of the storage, while an equal volume of cold water enters the bottom of the storage. All this causes the transport of water through the layer’s boundaries. It is assumed that the water of the upper module is ideally mixed with the quantity of withdrawn water at the temperature of the lower module. This “piston movement” of volume is graphically shown in

Figure 6. In the next step, energy withdrawn for the DHW circulation loop is calculated. This is followed by a calculation of the energy withdrawn for SH service. The calculation of energy delivered to the storage by collector loop

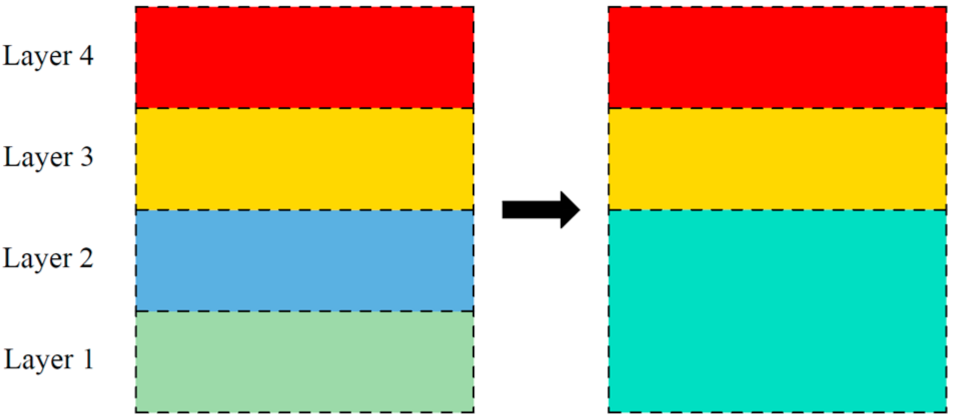

Qsol;loop;out and back-up heater

QH;sto;bu;in;vol,Nvol,bu is then performed. It is important to emphasize that the temperature of each layer is determined after every aforementioned step. When the temperature of the considered layer is higher than the upper layer, then these two layers are melted, as shown in

Figure 7. This iterative calculation procedure, according to [

36], is maintained until the temperature of the considered layer is lower than or equal to the temperature of the upper layer, i.e., if

ϑsto;vol,i >

ϑsto;vol,i+1 then:

where

ϑsto;vol is the temperature of the layer,

Vsto;vol is the volume of layer,

i is the considered layer, and

i + 1 is the layer above the considered layer. Standard also describes an alternative approach given in Annex C [

36], according to which melting is solved in a defined number of steps (no need for an iterative calculation procedure). After the re-arrangement of the temperatures, thermal losses of each layer and final temperatures are calculated. In the last step, the inlet temperature to the collector loop

ϑsol;loop;in and heat generator loop

ϑHc;RT are calculated. The calculated

ϑsol;loop;in is used to determine

ϑcol;avg;h, with which the solar collector is recalculated and the new value of

Qsol;loop;out is determined.

It is assumed that the back-up heater in storage operates in ON/OFF mode, and is only turned ON if the temperature of the layer where the heater is placed

ϑsto;vol,Nvol,bu is equal to or lower than the defined heater switch-on temperature set-point

ϑsto;set;on;bu. Once the heater is turned ON, it should run until all the layers affected by the heater have reached the storage set-point temperature

ϑsto;set;on. According to the current procedure within the standard, the heater is turned OFF, even if

ϑsto;set;on was not reached in the previous time step. Therefore, the authors of this paper propose an additional condition (condition A) to the equation for determining the total energy need in each layer affected by the back-up heater to increase their temperature to the

ϑsto;set;on:

with:

where

QH;sto;nd;in;vol,i is the energy to be delivered to each layer to make their temperature equal to

ϑsto;set;on, and

Nvol is the number of layers used in the model. The notation

h represents the observed time step and

h − 1 the previous time step. According to this condition, it is checked whether the heater was operational and whether

ϑsto;set;on was not achieved in the previous time step. If these two conditions are met, the heater continues to operate in all subsequent time steps until

ϑsto;set;on is achieved.

2.1.4. Heat Generation by Fuel Combustion (Boilers)

The standard EN 15316-4-1:2017 [

38], which replaces the standards EN 15316-4-1:2008 [

39], EN 15316-4-7:2008 [

40], and EN 15316-3-3:2007 [

41], deals with the energy performance calculation of the water-based heat generation subsystem based on the combustion of fuels (boilers). The new standard unifies the calculation of fossil fuels and renewable fuel boilers and, in addition, redefines the calculation of boilers used for combined service (SH and DHW). In the 2008 version of the standard, calculation of the combined service generator is generally performed for the summed load

QHW;gen;out. This increased load

QHW:gen;out is then used to determine the generator load factor

βgnr which is used to calculate the generator heat losses and auxiliary energy consumption. The calculation can also be performed independently for the two operating modes, but the procedure by which the

βgnr is determined for each mode is not well explained. The new standard [

38] extends on this and proposes a more precise procedure for the calculation of combined service, which is still not sufficiently explained. First, the operating time of the boiler is determined for each service according to:

and:

where

Pn is generator output at full load,

QH;gen;out is heat output to the connected SH distribution subsystem, and

QW;gen;out is heat output to the connected DHW distribution subsystem. After that, the boiler usage period for each service can be determined according to

Table 1, as proposed by the authors of this paper.

Finally, load factors

βH and

βW can be determined according to:

and

It is important to emphasize that if the usage period for a particular service is equal to zero, then the load factor for that service is equal to zero.

The method for calculating generator heat losses still remains based on the same procedure of determining corrected generator heat losses at full, intermediate and zero loads, which are then used to determine the generator heat loss at an actual load. In addition to the new standard is a new procedure, according to which the temperature corrected efficiency at full load for the condensing boilers is calculated:

where

ηgnr;Pn is generator efficiency at full load,

ϑgen;test;Pn is return temperature to the generator at the full load during the test, and

ϑXc;RT is return temperature to the generator as a function of the specific operating conditions. Indices 30 and 60 indicate the return temperature of 30 °C and 60 °C, respectively. The disadvantage of the new version of the standard is the lack of minimum temperature at which a certain type of boiler can operate. These temperatures can be taken from the old version.

In a case where the boiler is connected to the storage tank, the energy output from the boiler can be calculated, as in the case of the boiler used only for SH service (QH;gen;out = QH;sto;bu;in;nd). In this case, heat losses of the boiler are not calculated using water temperatures in the SH or DWH distribution systems. Instead, heat losses of the boiler are calculated using temperature in the primary circulation loop between the boiler and the storage. Furthermore, a condition is added to the equation for calculating the corrected generator heat loss at zero load Pgnr;ls;P0;corr, where the mean water temperature in primary circulation loop ϑc;mn is replaced with the minimum operating temperature of the boiler ϑgnr;min in the case the boiler is not running (Qgnr;out = 0). Additionally, the boiler minimum operating temperature ϑgnr;min, in the case of condensing and combination boilers of 20 °C and 35 °C, is replaced with ϑbrm (installation room temperature). This enables a more precise determination of boiler standby heat losses.