Abstract

The production of olive oil involves the sustainable management of the waste produced along the entire production chain. This review examines the developments regarding cultivation techniques, production technologies, and waste management, highlighting the goals to be achieved and the most reasonable prospects. The results show that cultivation and production technology have evolved to an almost final solution to meet economic feasibility, keeping the oil’s high quality. Continuous horizontal decanters will coexist with traditional mills in many countries with old olive oil production and consumption traditions. High-quality products have conquered markets, especially in the wealthiest countries. At the same time, the exploitation of dried pomace by solvent extraction is increasingly an obsolete practice. However, waste management is still looking for one or a few reasonable solutions that meet modern society’s constraints. The enhancement of some experienced technologies and the full-scale application of emerging technologies and strategies should solve this problem in the short–medium term. A short discussion is reported on the possibility of unifying the nature and the quality of the waste, whatever the olive oil production method is. Furthermore, modern thermochemical treatment for solid wet organic waste disposal is examined and discussed.

1. Introduction

The production, packaging, distribution, and consumption of food and beverages give rise to relevant production surpluses, by-products, and waste rich in valuable organic compounds. Additional organic waste derives from forestry and urban green maintenance. Regardless of the biological stability and the great variety of substances, much of this material must be removed from the environment and possibly enhanced through the production of renewable energy and usable materials, coherently with sustainability, circular economy, biorefinery, and waste hierarchy [1,2,3,4,5,6,7]. Among the various branches of agro-industry, the olive oil production sector plays a role of primary importance for many Mediterranean countries. Olive oil is the organic fraction of the juice of the fruit produced by the olive tree (Olea europaea L.), amongst the oldest known cultivated trees in the world [8,9,10,11,12].

Olive trees have been grown around the Mediterranean since the 8th millennium BC. However, since the beginning of the sixteenth century the cultivation of the olive tree for the production of olive oil has gradually spread to all continents, except for the Antarctic [13,14,15,16].

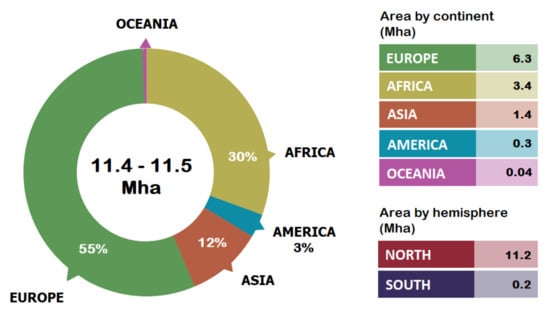

The total area of olive production exceeds 11.5 Mha, distributed in 58 countries [17]. Against this internationalization, it is worth highlighting the decrease caused by Italy, Spain, Greece, Jordan, and Syria in the cultivated area after 22 years of uninterrupted growth. In all these countries, this phenomenon was accompanied by a decrease in the internal consumption of olive oil and the adoption of intensive (HD) and super-intensive (SHD) cultivation systems. Furthermore, by the end of the following year, the number of countries affected had risen to 65 [18,19]. Olive fruit’s growth and ripening take about five months in usual climatic conditions and even more in cold climatic conditions [20]. The density of planting, productivity per tree, productivity per hectare, irrigation methods, mechanized harvesting of olives from the tree, and production costs differ depending on the cultivation system adopted. For instance, the planting density ranges from 200 to over 1500 trees per hectare for a traditional olive grove and an SHD olive farming, respectively [10]. On average, the annual yield of fresh olives per tree is about 3.5 kg, corresponding to about 10–12.5 t/ha/a of fresh olive [21,22]. The most reliable estimates give a global production of olives which currently amounts to about 23 Mt/a. Approximately 20 Mt/a is used to produce olive oil and 3 Mt/a to produce table olives [23].

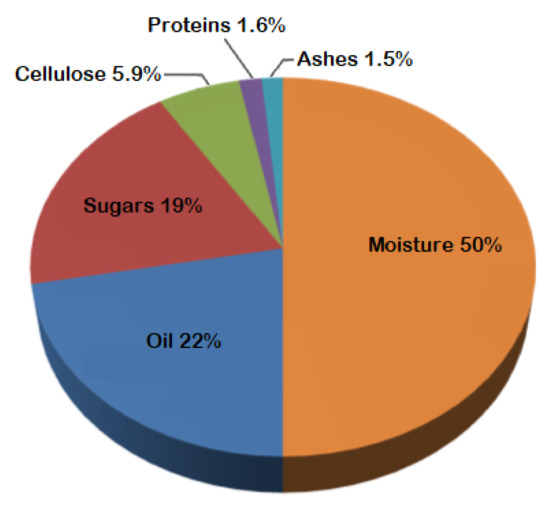

The composition of the olives depends on the cultivar, the meteorological conditions that characterized the different stages of flowering, as well as the growth and maturation of the fruit, the degree of ripeness at the time of harvest, the harvesting techniques, the duration and conditions of temporary storage, the cultivation practice, the location of the olive grove, the harvest time, the existence of any irrigation systems in traditional systems, and the fertilization. Figure 1 shows olive fruit’s average composition, including water, protein, oil, carbohydrate, cellulose, and inorganic substances. Table 1 [24,25] also gives the percentages of phenolic compounds and other essential compounds (pectin, organic acids, and pigments) in olive fruit.

Figure 1.

Chemical Composition of Olive Fruit.

Table 1.

Composition of Parts of the Olive Fruit.

The estimated production of olive oil for the current campaign is equal to 3.2 Mt/a [26]. Therefore, the average yield equals 14%, with considerable variations concerning production technologies, cultivar, and maturation. A current and reliable estimate for olive oil mill waste (OMW) is at least 16.8 Mt/a from the data reported. To this amount, one must add the water necessary for continuous processes, leaves, and pruning waste (TCW), which have an average ground humidity of about 22% [26].

Overall, a reasonable estimate of the global world biomass waste resulting from virgin olive oil production is at least 40 Mt/a which corresponds to over 20 Mt/a of dry biomass. It is a material rich in organic substances, mostly humid and very humid, partly woody, and partly biodegradable even if polyphenols are present in the pulp, which have a bactericidal power [27,28,29]. This enormous amount of material has a high energy content [30]. However, olive availability is unevenly distributed throughout the year. Pruning occurs after harvesting and processing of the olives in the mill. Furthermore, the OMW must be disposed of quickly to prevent the onset of severe olfactory phenomena, whatever the strategy adopted. This practice also happens in the case of pomace’s valorization to prevent its degradation with adverse effects, in both the yield and quality of the products in each subsequent processing.

On the contrary, woody material TCW degrades very slowly without causing pollution of the atmosphere, soil, surface, and groundwater. The fact remains that they must still be removed from the olive grove to prevent them from becoming unusable. In the past, TCW were harvested, generally by hand, and accumulated in the surrounding areas for natural drying. Later, they were burned on the spot or used as fuel for domestic use: heating and cooking food. In other cases, and in more recent times, after harvesting, the TCW were finely chopped and overthrown in the ground with negative repercussions in terms of costs, energy, and environmental sustainability and, no less critical, microbiological damage to the tree roots. Currently, especially in the new intensive or SHD, mechanized harvesting of TCW is practiced, which is eliminated from the olive groves and, generally, destined for the industrial production of wood pellets [27]. From the data and considerations reported so far, the importance of this agro-industrial activity is clear, especially for the countries of the Mediterranean area. In particular, Spain, Italy, and Greece produce over 60% of all olive oil produced globally [18].

For this reason, in 1956, the International Council of Olives and Oil (IOOC) was established among the countries most concerned with headquarters in Madrid. Subsequently, this body changed its name (IOC), and the number of adhering countries increased. The primary purpose of the IOC is to stimulate the adaptation of sector regulations through proposals and advice addressed to the legislative bodies of the adhering countries. At the same time, it annually carries out and disseminates the monitoring of other issues concerning the production of olives and olive oil and those concerning the management of processing waste [31].

Over the past 60 years, dozens of books, manuals, and reports by public and private entities dedicated to olive cultivation and elaiotechnics have been published, simultaneous with the publication of thousands of scientific articles. As an example, it is worth mentioning that, in the last 40 years, more than 1000 articles and about 500 patents were published on the disposal of vegetation water (VW) produced before the introduction of the two-stage decanter [9,32,33,34,35,36,37,38,39,40,41,42]. In addition, a census carried out as part of this work shows that about 1.5–2 reviews dedicated to the topic in question have been published in the last ten years. Some of these are very recent [28,29,43,44,45,46,47,48,49,50,51,52,53,54,55]. However, they did not consider at all or underestimated the potential of emerging strategies and technologies already applicable at full scale for both olive oil production and related waste management.

The first purpose of this additional review is updating the state of the art at a global level, to reasonably configurate the final landing of the olive oil production sector. The second purpose is to evaluate the most modern options for the sustainable management of the wetted pomace and other waste derived from the olive oil production chain.

2. Methodology

The methodology used for this review consists of retracing the profound changes that have affected the production of olive oil in the last fifty years, splitting the whole production chain into three segments: production and harvesting of olives, making virgin and extra virgin olive oil, and managing by-products and waste. This approach makes it possible to understand the irreversibility of the changes that have taken place, estimate the speed of these changes, and make a reasonable forecast for the sector’s future. A possible strategy and one or more technologies for disposal of the new pomace derives are identified from the critical review of the technologies traditionally used and the emerging ones, accounting for the evolution of the legislation to safeguard the environment and health from the waste management hierarchy perspective.

3. Production Technologies

3.1. Production of Olives for the Oil Supply Chain

The production of olives destined for the oil supply chain has undergone profound changes over the years, which mainly concern:

- The increase in production yields per unit area.

- The reduction of unit production costs through mechanization.

- The need to adapt to changes in the collection and cultivation by-products.

- The trend towards industrialization of the sector.

Currently, the olive cultivation systems for the oil supply chain divides into traditional and modern. The density in traditional systems does not exceed 200 trees/ha, while in modern ones, it can reach up to 2000 trees/ha [56]. A further difference is that traditional olive groves are on marginal lands or in the edges of lands intended for other crops. In contrast, modern systems are dedicated plantations, equipped with irrigation systems, and designed to mechanize harvesting, pruning, and residual biomass collection [35,36,37,40,55,56,57]. The usual classification considers high density (HD) and super high density (SHD) systems.

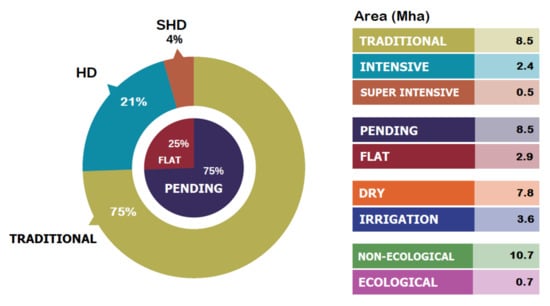

Traditional olive groves cover an area of 8–9 Mha worldwide, while modern ones cover just over 3 Mha [58]. Of these, 82% is covered by HD cultivation systems and the remainder, about 0.5 Mha, by SHD systems [59]. Faced with this situation, modern olive groves’ production per unit area is considerably higher.

The new plants built outside Europe are all modern, HD and SHD. In Europe, the conversion is also proceeding with public contributions. In Portugal, modern systems now account for 64% of the total. At the same time, in Morocco, about 46% of traditional olive groves are being transformed into modern HD and more than 9% into SHD orchards. Overall, the transformation of traditional olive groves into modern ones is proceeding at a rate of 1.5% per year of the area concerned (Olive Time 2020). Figure 2 and Figure 3 show this situation related to 2016/2017 campaign with more additional information.

Figure 2.

Total area planted with olive groves by continent and hemispheres.

Figure 3.

Traditional and modern systems of olive groves.

As already mentioned, details on the arrangement of plants in HD and SHD olives growth are given in many books and manuals while the most used cultivars are reported, among others, by Paul Vossen [10]. Before concluding this paragraph, it is worth citing and briefly discussing two recent publications on the ongoing research activities. One of these [60] examines a new type of intensive olive grove called pedestrian orchards, proposed as an alternative to current HD and SHD systems since it could further reduce production costs and enhance the quality, functional properties, and typicality of the oil produced, simultaneously reducing environmental impact. The other [56] examines the problem of mulching with lignocellulosic material (leaves and pruning) resulting from the maintenance of modern SHD plants. The experimentation activity implies high costs and long times for both these aspects. Furthermore, the validation of the results is possible after an adequate number of oil campaigns.

3.2. Processing Olives into Oil

In order to produce high-quality oil, the olives must be harvested without breaking the skin, and the fruit should be processed within 12 to 24 h. Fruit should be separated by quality, with each grade processed separately [57,61]. Oil from olives is separated mechanically, unlike what happens for other fruits, seeds, and vegetables in general. First, however, it is necessary to carry out some of the upstream operations, in particular:

- Washing, carried out with water to remove any residues of pesticides and woody and inorganic debris. Leaves, dust, and other light debris are removed in advance by blowing air.

- Grinding, generally carried out discontinuously with stone crushers or continuously, using modern hammer mills, toothed discs, and cylindrical or roller crushers. The grinding aims to break and crush the fruit to allow the separation of liquids trapped in the solid matrix [57,62,63,64].

- Malaxation, consisting in stirring, slowly and gently, the material obtained from the grinding to aggregate the oil dispersed between the aqueous and solid phases in drops for subsequent separation. Malaxation lasts about an hour, during which it is necessary to avoid the oxidation of polyphenols and control the release of volatile compounds that affect the olfactory quality of the final product [65]. For this purpose, modern machines are hermetic and allowed to operate in a controlled atmosphere or under a vacuum. Other modern measures concern light and rapid heating of the dough with non-traditional technologies and possibly the preventive de-stoning of the olives [66,67,68,69,70].

Once completed upstream treatments, the paste is sent to the plants to separate the oily phase from the solids and VW. The traditional technologies used for this operation are the traditional press and, rarely, selective filtration or percolation (Sinolea process), which are discontinuous processes [57,71], now used only for small productions or for lots of precious olives destined for the production, in limited quantities, of oils with special characteristics and very high costs. Numerous texts and manuals concerning the production of olive oil describe the details of this process and related equipment used. Percolation has meagre extraction yields. It is strongly dependent on the percolation duration and the ratio between oil and water, typical of processed olives [10,57]. For the sake of completeness, it is worth mentioning another technology considered at the laboratory level to separate oil from olive paste after all upstream treatments. This technology, widely used in the food industry, employs supercritical CO2 as a separation medium [72,73]. Strictly speaking, the oil obtained in this way could not be labelled as virgin or extra virgin oil, but it would have all the characteristics of such oil as the non-toxic CO2 is entirely removable by decompression of the supercritical phase.

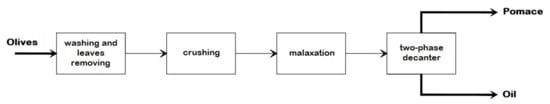

Since the early 1960s, continuous separation by centrifugation has been placed on the market and adopted at an increasing rate. For about 30 years, the three-phase decanter has been used to separate the pulp from the malaxation process into three phases: a wet solid (pomace), an aqueous phase, VW, and the organic liquid phase (virgin olive oil or extra virgin olive oil). This technology involves adding hot water to the olive paste with the inevitable consequence of increasing the flow of VW and the complex environmental problems associated with the difficulty of purifying this aqueous waste. At the beginning of the 1990s, the marketing and use of the two-phase decanter began at an increasing rate. In this case, it is not necessary to add water to the pasta fed to the decanter. The heart of both these technologies lies in the horizontal decanter, where the upstreamed olives undergo centrifugal action at about 3000 rpm [74].

In the three-phase system, the added water washes away some of the flavours and antioxidants and results in lower polyphenol content in the oil. In a two-phase system, the decanter has only two outlets: one for the oil and one for the wetted pomace. With the two-phase decanter, it is possible to reduce drastically or eliminate the production of the very polluting wastewater, thus solving the significant problem of the disposal of VW that has afflicted the olive oil industry for so many years. Furthermore, the extraction yield is improved compared to the batch mills, while the oil quality is comparable or even better [75]. The oily phase produced by the centrifuge must be further processed to eliminate the tiny amount of water and the few solids that make the oil cloudy and affect its sensory and organoleptic characteristics. For this purpose, a vertical centrifuge is used, which, at the same rpm, can exert a greater separation force [76,77,78,79]. Figure 4 graphically shows the various stages of the virgin (VO) or extra virgin (EVOO) olive oil production process.

Figure 4.

Typical stages of VO or EVOO production process.

The clarified oil goes to downstream operations:

- Weighing.

- Temporary storage in stainless steel barrels.

- Final packaging in glass or metal containers (labelled and ready for marketing).

In the case of low-quality raw material, the downstream operations are more complex as they must foresee some refining process.

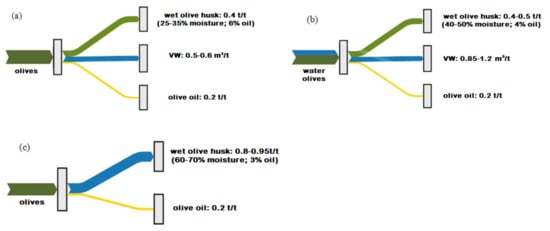

Figure 5 [51] shows the material balance for the traditional batch mill and the two continuous three-phase and two-phase centrifugal systems.

Figure 5.

Material balance for the traditional (a) and for the two continuous three-phase (b) and two-phase (c) centrifugal systems.

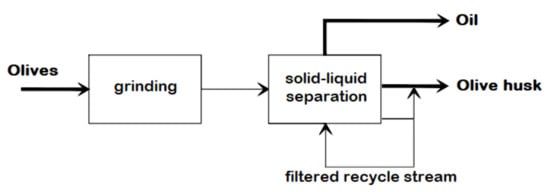

It is worth emphasizing that the two-phase system is based on the observation that the pomace produced by a traditional batch mill can be mixed with the corresponding VW to obtain a single wetted solid phase. For the same reason, the three-phase decanter is easily transformable into a two-phase decanter by recycling the VW stream, as shown in Figure 6. It would also be better to introduce a membrane filtration system (microfiltration of VW and Reverse Osmosis of the permeate) with very high concentration factors (15–20) to recycle a purified solution and recombine the small amount of retentate with the pomace. In this case, the quality of the oil produced would be practically identical to that of the three-phase decanter. However, the cost of reconversion, periodic regeneration of membranes, replacement of filter modules, and energy consumption would increase operating costs in a non-marginal way.

Figure 6.

Conversion of a three-phase system into a two-phase system by recycling VW stream.

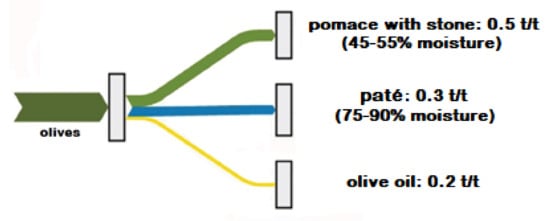

A new decanter, called DMF or Multi-Phase Decanter (MPD), has recently been developed and adopted by some sizeable Italian oil mills. It represents the evolution of the two-phase decanter. MPD does not require any addition of water for the malaxation phase. In addition, the oily phase produces a solid phase, like that obtained with the three-phase decanter and a further pitted solid-phase called paté. The olive paté has a humidity similar to or higher than that of the pomace produced by the two-phase decanter and contains, in significant concentration, numerous substances with high nutritional and functional power to be used as a basis for the preparation of food for human use, with dietary-therapeutic and diet-preventive characteristics [34,80,81]. Figure 7 summarizes the MPD material balance.

Figure 7.

Schematic representation of the MPD with relative material balance.

It is not possible to foresee the commercial development of the MDP and the olive paté. It is not easy to involve Spain and the other countries that have recently adopted the two-phase decanter technology. It is also challenging to think of a simple transformation of the two-phase decanter into MPD. However, should the paté become a widely consumed product, MPD could spread massively. In addition, the pomace produced by MPD has a much higher energy content as it contains all the woody parts of the kernel. The percentage of residual oil tends to decrease with introducing new technologies upstream and downstream of the malaxation process. The recombination of the pomace from the batch mill with the polluting VW was not practiced in the past, for two reasons principally: the environmental regulation was less stringent for VW purification before discharging, and the pomace was further processed by drying followed by solvent extraction, to recover the residual amount of oil (about 5–6%). Some decade ago, the solvent extraction of the olive pomace started to become obsolete in many major olive oil producer countries. For example, in Italy, most olive pomace oil extraction plants were dismissed, and almost the same happened in Spain, where the adoption of the two-phase system was subsidized by public funding. In the USA, there does not exist any olive pomace oil extraction plants [10].

From all the above, it is reasonable to assume that soon the OMW will be made only of SOMW. This significant milestone for the olive oil industry allows to avoid the problem, never solved, related to the VW management, and discourages using pomace to recover residual oil by solvent extraction [32,82,83,84,85,86,87,88]. Unlike in the past, the very wet SOMW is unsuitable as a by-product. Instead, it represents an actual waste to be purified, possibly through energy enhancement or recovery of matter and energy. Furthermore, woody waste from pruning and leaves from the olives pretreatment could be treated along with SOMW in a context in which the oil sector takes on the characteristics of an agro-industrial activity.

In some cases, a precious by-product is a woody material deriving from the pitting of the olives. This material, produced in minimal quantities compared to SOMW and TCW, is typically used to produce high-quality activated carbon, characterized by a very high adsorbing surface (micropores) per unit of mass. Finally, simple membrane filtration operations allow recovering and recycling the olive washing water.

4. Technologies and Practice of Disposal

Previous paragraphs highlighted that the by-products and waste associated with the production of olive oil were many and of different types in the past. Consequently, various waste management technologies and strategies were adopted to meet environmental constraints and economic feasibility. These technologies are synthetically described and critically evaluated along with emerging strategies and technologies. The purpose is to find a sustainable solution applicable to modern olive oil waste management considering that, as already partially mentioned:

- Olive growing is rapidly evolving towards HD and SHD cultivation systems on non-marginal and irrigable land with a size suitable for profitable agro-industrial activity.

- For more than fifty years, traditional mills have been disappearing in favour of continuous centrifugal decanters, having a significantly higher potentiality, consistent with the evolution of olive production systems.

- Since the pomace of the two-phase or similar mills is very wet, the extraction of the residual oil is no longer economically convenient, and the pomace oil extraction plants will become less useful.

- The size and type of new olive groves and cultivation methods must provide for the mechanized harvesting of pruning that will become available to treatment along with the solid waste (SOMW) resulting from modern olive oil production.

The fact remains that for the management of the SOMW, there is still no solution or even a predictable perspective concerning a wide variety of options [43]. A possible classification of the technological options is the one that considers biological and physicochemical treatments alternatively to thermal treatments. In any case, one must change the paradigm according to which the SOMW is not a waste. On the contrary, it is a resource in terms of energy, new materials, or both. A further consideration that may be useful for the search for prevailing options concerns the integration of the process and the overcoming of seasonality for the operational continuity of the plants. A preventive examination of the technologies in the research and technological development phase and of those already used in full scale for the management of SOMW in the last 15 years in different parts of the world can be helpful to identify the most reasonable prospects for the construction of new plants or to replace those existing at the end of their life.

4.1. Anaerobic Digestion

Anaerobic digestion (AD) is a consolidated and widely applied, all around the world, full-scale technology for the disposal of a variety of biomass waste such as the manure produced by livestock farms, excess sludge produced by urban wastewater treatment plants, food and agro-industrial waste, and the wet fraction deriving from the separate collection of municipal solid waste [89,90]. AD occurs in the absence of oxygen and at atmospheric pressure. Depending on the type of microorganisms used, mesophilic or thermophilic, the operating temperature is between 40 and 60 °C, respectively.

AD with mesophilic bacteria is the most used even if it requires longer residence times, 7–30 days depending on the characteristics of the treated material (liquid, semi-solid and solid), the type of reactor (mixing or flow piston), and the type of process (continuous or batch). AD is usually divided into hydrolysis, acidogenesis, acetogenesis, and methanogenesis. AD products are Biogas rich in methane (typically 50–70%), carbon dioxide, and other substances at low concentrations, such as water vapour. Burning Biogas allows producing electrical energy and heat. In large plants (over one hundred thousand t/a of raw material), removing the inert part from the Biogas may be convenient to transform it into renewable methane to be used as a substitute for natural gas in both gaseous and liquid form. The other typical effluents of AD are the digestate sludge, consisting of the wetted solid part of the feed more resistant to attack by microorganisms, and process water. The final disposal of both digestate and wastewater depends on the type of treated material and the plant’s context [91]. The application of AD to olive oil mills waste has been extensively studied since these materials are very rich in organic matter that is mainly biodegradable [92,93,94,95,96,97,98]. However, it does not apply to lignocellulosic residues, such as pruning and olive pits. A further and not marginal problem is the high concentration of aromatic compounds and lipids, which are toxic for methanogenic bacteria. A recently published paper analyzes in detail the problems related with the application of AD to OMW generated by three phase decanters in Saudi Arabia concluding that pretreatment and co-digestion are crucial factor to obtain satisfactory results [99].

AD involves high investment costs and is economically inapplicable when the plant’s potential is less than a few tens of thousands of tons per year [91,100,101]. Waste from oil mills can be treated with this technology only if added in a limited percentage (10–20%) to different substrates for which AD is the preferred solution [102,103]. Alternatively, they require previous pretreatments to eliminate or transform bactericidal substances [94,104,105,106,107]. Further alternatives are the adoption of technology solutions that allow reducing the feed flow rate of the incoming biomass and its stratification, considering that the total input solids are variable during the processing time [108] and the hybridization of AD with pyrolysis [109]. When treating OMW with AD and the manure deriving from animal breeding, the digestate can find application as a soil improver, even if the woody fragments deriving from the crushing of the stone can have negative implications in the medium–long term [27]. The application of AD to the final disposal of SOMW presents several contraindications of both a technical and regulation nature. Co-AD and process integration are more promising. Achieving economic feasibility is not easy.

4.2. Composting

Composting is a term universally used to identify the solid-phase fermentation of biodegradable organic materials in excess of oxygen. Using uncontaminated materials such a treatment is a typical example of waste to a valuable product called compost. Compost has fascinating characteristics for use in the agronomic field, like horticulture, gardening, and ornamental plants for indoor and outdoor use. Otherwise, an off-specification compost is obtained. It is usually landfilled as a stabilized substance that does not produce leachate. The agronomic properties of compost depend on the presence of humic acids and fulvic acids that perform a soil amendment action, supporting the intense stimulation of microbial activity in the soil and the plant’s ability to absorb fertilizing elements present in the soil or added with fertilization. Good conditions for the life of microorganisms require a humidity between 40% and 60%, and optimal C/N ratio between 25 and 30 and must contain both Phosphorus and Potassium. The composting process splits into two phases after adjusting the composition and particle size of the mixture. The first is bio-oxidation, which takes place in about seven days, while the second is maturation which takes a few months. During the first phase, the temperature of the mass of material tends to increase up to 60–70 °C due to exothermic reactions with the consequent killing of pathogenic microorganisms. This phase is carried out in batch or continuous reactors, equipped with ventilation systems and temperature monitoring of the solid mass and filtering systems to prevent the escape of malodorous gaseous substances. The maturation has the purpose of stabilizing and containing compost before packaging and marketing (for compost to specification) or landfilling (for compost out of specification). The application of this technology for the treatment of SOMW has received much attention [110,111,112,113,114,115,116], and there are numerous full-scale applications. Like AD, SOMW composting must account for the presence of bactericidal substances and the need to adjust moisture and nutrient ratios using other biodegradable organic materials through composting. Also, in contrast to AD, SOMW composting does not produce but consumes electricity, primarily for aeration of the solid mass during bio-oxidation. Compared to AD, the size of the composting plants is not limiting. The conduction is more manageable than in AD, and the material obtained is more stabilized. Usually, the compost value does not repay the investment and production costs. A further problem of composting is the one deriving from the production of unrecoverable CO2, being diluted in excess air. Like for AD, the final disposal of SOMW by composting is problematic. Co-composting is mandatory and process integration can give more chances to this widely diffused and easily applicable technology. Economic feasibility is not easily achievable.

4.3. Thermal Treatments

Conventional thermal treatments of waste rich in organic material are torrefaction, pyrolysis, gasification, and combustion. The list is made in ascending order of operating temperature ranging from about 150 °C for torrefaction to over 1000 °C for combustion. Research and technological development activities, including recent ones, on applying heat treatments to SOMW are widely documented [43,50,117,118,119,120,121,122,123,124,125,126,127,128,129,130,131,132,133,134,135,136,137,138]. Heat treatments are all aimed at the disposal of SOMW with the concomitant recovery of the energy contained in them. More specifically, torrefaction and pyrolysis occur at atmospheric pressure and without oxygen. In the former, the material is heated to 150–300 °C using, generally, a part of the product of torrefaction that has the characteristics of solid semi-carbonaceous fuel, devoid of volatile organic substances and with residual humidity tending to zero. Subsequently, the product thus obtained is aggregated into pellets by extrusion or other geometric shapes using, for this purpose, other technologies and compression equipment.

The purpose of aggregation is to eliminate dust formation and increase the density of the solid fuel, thus favouring its use. In addition to the pressure effect, aggregation is favoured by the formation, during treatment, of small quantities of bituminous material that acts as glue. The torrefaction of SOMW is not applied on an industrial scale because it is energetically and environmentally unsustainable; this happens because of the high humidity of the charge and the presence of volatile compounds with high contaminating power in the atmosphere. Pyrolysis or carbonization instead is realized by previously heating the material to a sufficiently high temperature (about 280 °C) to cause the breakage of the heavy organic molecules and trigger a series of exothermic reactions capable of achieving further heating of the mass up to 500–600 °C. Under these conditions, one obtains practically anhydrous coal and high energy density representing the main product. At the same time, a gas is produced that contains all the water initially present in the feed, the volatile organic substances and the less volatile ones resulting from the thermal splitting of the larger molecules into coal, and compounds that at room temperature have a bituminous appearance [139,140]. When the moisture content of the feedstock is not excessively high, the combustion of the gaseous phase may be sufficient to support the endothermic phase of the pyrolysis process. At the same time, it supports the elimination of a gaseous effluent that should be recondensed to avoid atmospheric pollution. Subsequently, it should be separated into an aqueous liquid phase with high contaminating power and an organic phase with rheological characteristics that strongly limit its use as a fuel. In other words, when the moisture content of the feedstock does not exceed 25–35%, the pyrolysis process is energetically self-sufficient, and the pyrolysis product is a valuable solid material mainly used to replace fossil coal. Therefore, pyrolysation of SOMW is not attractive for full-scale applications. In contrast, both torrefaction and pyrolysis can apply well to the energy densification of TCW.

However, pelletization after natural ground drying and shredding is generally preferred. In this regard, it is worth pointing out that wood pellets are the solid fuel with the largest market share in Europe and that pruning’s waste is the preferred raw material for its production [27]. This is due to the size that facilitates its natural moisture reduction and the ease of shredding. At temperatures higher than those used for pyrolysis (600–800 °C) and in a partially oxidizing environment, the thermal treatment of biomass is generally called gasification [141,142] and the product of this operation is called Syngas. It is a mixture of H2 and CO used as a renewable fuel and a fundamental building block for many hydrocarbons. The conversion of Syngas into fuels for power generation or motor fuels and chemicals has been widely described in many scientific papers mentioned earlier and in books [143]. Similar considerations as for pyrolysis apply to the gasification of SOMW and TCW. Direct combustion of biomass for energy production is undoubtedly the most widespread technology applied at full scale. Combustion requires excess oxygen at temperatures between 800 and over 1000 °C, depending on the composition of the feed (moisture content and type of inorganic compounds), size of material, and type of combustor. The application of direct combustion to SOMW is practically impossible due to the moisture content, which is incompatible with the ignition temperature. The chlorine content is another critical contraindication for the direct combustion of SOMW, even in mixtures with other materials [54]. Elevated hydrogen chloride emissions from biomass combustion in utility boilers are a significant issue. They can cause corrosion problems and deposit molten alkali chloride salts on boiler’s water tubes, resulting in further corrosion and the possible formation of very polluting compounds. Pyrolysis is a good pre-treatment for solving this problem [144].

4.4. Hydrothermal Treatments

The hydrothermal technologies allow transforming biomass into solid, liquid, or gaseous fuels in an aqueous environment. If the product is a carbonaceous solid, the familiar name of the process is hydrothermal carbonization (HTC). Similarly, we refer to hydrothermal liquefaction (HTL) if the product is an organic liquid. The most advanced in terms of full-scale application of the two processes is HTC. It takes place in a reactor at temperatures ranging from 180 to 250 °C, under autogenous pressure (approximately the vapour pressure of water at the operating temperature), residence time ranging from 0.5 to 8 h, and optimal weight ratio between water and organic compound in the range between 5 and 10. It is widely agreed that the HTC process imitates the coalification (brown coal formation process) within a few hours, which takes place in nature over enormously longer geological periods of 50,000–50 million years. It was described in 1913 [145] and recently reconsidered by [146,147,148,149]. Multiple reactions occur during the HTC process, namely hydrolysis, dehydration, decarboxylation, and aromatization.

A small quantity of gas, mainly CO2 (about 1% of the dry organic biomass processed), evolves during the HTC treatment. It is discharged into the atmosphere after purification by adsorption or washing. Consequently, both the ratios hydrogen to carbon (H/C) and oxygen to carbon (O/C) decrease, giving rise to a carbon-rich hydrochar separated from the process water by filtration or centrifugation. The overall yield of hydrochar, on a dry basis, varies over a wide range (30–70%) depending on the nature of the biomass processed and the upstream treatments, temperature, residence time, reactor type, the ratio of water to biomass, and pH. HTC is an exothermic process releasing 25–38% of the dry biomass’s energy value, resulting in a significant improvement of the energy balance of the whole process.

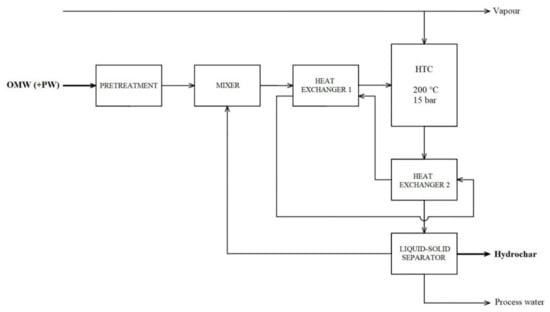

The application of HTC for the disposal and valorization of wet and very wet waste biomass from the agri-food industry, livestock farming, biological purification of urban wastewater, algae and other dedicated crops on non-marginal land has been the subject of research, technological development, modelling, and development of processes and plants at the pilot, pre-industrial and, in some cases, industrial scales by numerous researchers, public and private bodies and entrepreneurs. Recent scientific works made by the authors of this review are a testimony to this and, at the same time, a source of information [148,149,150,151,152,153]. On the other hand, this review reports the most recent works and reviews concerning the research activities on the application of HTC to olive oil production wastes and by-products regarding SOMW produced by the two-phase decanter and TCW and solid mixtures of these and other biomasses [154,155,156,157,158,159,160,161]. In Figure 8, a continuous HTC process with heat recovery for hydrochar (HC) production from wet and very wet waste biomass, including the two-phase decanter SOMW, TCW, and mixtures thereof, is schematically presented.

Figure 8.

Blok diagram of the continuous HTC process of SOMW, TCW or mixtures of them, equipped with a double exchanger for heat recovery. The double heat exchanger aims to prevent the formation of deposits of dirty material on the shell side.

If the material to be processed has a moisture content of 65%, typical for SOMW, at 200 °C, a residence time of one hour and a water/SOMW ratio on a dry basis of 7.5, approximately 27% mechanically dehydrated HC with a residual moisture content of 30% is obtained. The possibility of mechanically dehydrating HC to such low levels depends on the hydrophobic characteristics and the small grain size of the solid material obtained from the treatment. It is worth noting that HC, with all residual moisture, has a mass almost four times lower than SOMW. It is entirely biologically stable as it is sterilized and has solid fuel characteristics in ignition temperature and energy content. The amount of process water remaining from the treatment is comparable to that of the AV produced by traditional olive oil mills. Unlike AV, it is sterilized and has about five times lower COD values as it does not contain carbohydrates, fats, and suspended solids. Compared to AV, the process water from SOMW’s HTC treatment is much more suitable for fertigation, both in odour pollution and for a lower concentration of substances with bactericidal power. Similar but more favourable considerations apply to the HTC treatment of TCW or mixtures of SOMW and TCW. The energy balance and the waste-to-energy value of the HTC treatment of SOMW can derive from the following considerations. 80% of the heat required to bring the feed to reaction temperature is recovered from the process water, while direct contact condensation of steam at 225 °C gives the remaining required heat. Approximately 10% of the energy content of the dry biomass fed to the plant is lost as water-soluble organic compounds, while the remainder remains in the HC. Under the specified operating conditions, about three tons of aqueous suspension must be heated for each ton of feed. The net heat from isothermal reactions and losses, burning no more than 5–10% of the HC, produces the energy required by the HTC process. The remainder can be used for electricity production, heating, as a carbonaceous material with adsorbent properties, for soil improvement, and other applications [162,163]. As already mentioned, a different hydrothermal technology for the treatment and valorization of wet and very wet biomass, such as SOMW, is the liquefaction of the organic fraction under supercritical water conditions [135,164]. The very severe operating conditions of pressure and temperature make these technologies less attractive than HTC for full-scale applications. For the sake of completeness, it is worth adding that supercritical water treatment of biomass, including SOMW, can also be done in an oxidizing atmosphere [43], in contrast to HTL. In this case, the process is called supercritical water oxidation. It has been the subject of much attention at the laboratory and pilot plant research level, mainly to destroy very toxic organic substances dissolved or dispersed in water at low concentrations [165,166,167].

4.5. Process Integration and Biorefinery

Process integration is the interconnection of two or more technologies to minimize energy consumption, limit environmental impact, and diversify the products obtainable from processing raw materials and their by-products and waste. Biorefinery is a different way of indicating process integration. It prefigures the possibility of treating SOMW to obtain, from renewable organic material, a variety of chemicals traditionally produced using raw materials of fossil origin. In the context of the oil sector, this approach has been the subject of intense research and technological development for the treatment of SOMW and TCW. For example, Schievano et al. proposed an integrated biorefinery concept to manage pomace, using SFE for extracting polyphenols and fatty acids, followed by the thermochemical recovery of energy, biofuels, and materials [168]. Plaza et al. proposed the production of Hydroxytyrosol from solid OMW using deep eutectic solvents and then supercritical CO2 [169]. Similarly, other researchers have proposed this approach to produce new materials, with sometimes unpredictable destinations, integrating partly established and partly innovative technologies usually used in other sectors [46,156,162,170,171,172,173,174,175,176,177,178]. However, although attractive, process integration and biorefining involve higher investment costs and organizational and commercial complications. It is necessary to assess the economic feasibility of this approach on a case-by-case basis and define the limits of integration in terms of both technologies and products. Another non-marginal aspect concerns territorial, business, and raw material integration. This aspect of the problem can be better clarified by referring to the treatment of SOMW, TCW and other possible by-products and waste from olive oil production.

A typical example is a pomace oil extraction plant that recovers oil from pomace by solvent extraction. Such plants serve a much larger territory than individual olive groves and receive pomace from numerous mills. Moreover, several pomace oil extraction plants deliver the extracted oil to a refining plant that processes oil extracted from different fruits and seeds. Similarly, the size of the SOMW treatment plant is generally not compatible with the farm size, and a single treatment technology might not be the optimal choice to valorize woody wastes such as TCW, together with SOMW. A process integration that seems interesting could be a hybrid consisting of one section of HTC, one of AD, and one of filtration with semi-permeable membranes. In this case, the HTC pre-treatment of the lignocellulosic material produces HC and contributes to increasing biogas production by the AD. The membrane filtration section could treat all wastewater, including washing water. However, there remains the problem of seasonality that is typical of all processes and plants in the agro-industrial sector. For this reason, there is no generalized solution. However, a hybrid process such as the one briefly described and a census of the biomass availability during the year could significantly contribute to sustainable development, according to the EU Taxonomy [179].

5. Conclusions

This review highlighted that the production of olives and the production and consumption of virgin and extra virgin olive oil are no longer a prerogative of the Mediterranean countries, as they spread at an increasing rate to all continents.

At the same time, the cultivation of the olive tree is irreversibly changing in favour of intensive and super-intensive olive groves managed with cultivation techniques typical of organic and precision farming. The progressive disappearance of traditional olive groves and plants scattered on marginal not irrigable land is a further fact, with possible residual amateur margins. Further modest improvements resulting from the optimization of the shape and size of plants and different management of lignocellulosic residues cannot be excluded.

Production technologies have also undergone an irreversible transformation consistent with new cultivation practices and the evolution of environmental legislation. It is reasonable to foresee that the continuous two-phase decanter will quickly replace most traditional batch mills while the three-phase decanters still in business will probably be converted into two-phase decanters, recycling the aqueous phase. The only residue from the oil industry will be a solid material, SOMW, with humidity higher than 60%, consisting of 80–85% of the processed olives. Moreover, further modest marginal improvements deriving from the possible diffusion of the multi-phase decanter and the purification of the washing water with membrane filtration technologies cannot be excluded in this sector. The fact remains that production technologies have found a practically definitive landing point.

The situation regarding the management technologies of the SOMW is different, poorly suited as they are for the recovery of residual oil, agronomic application, conventional biological treatments (anaerobic digestion and composting), and traditional heat treatments (roasting, pyrolysis, gasification, and combustion). Instead, it is reasonable to predict that hydrothermal carbonization, HTC, could represent the definitive outcome of the long-standing and still unsolved problem of the disposal of SOMW with the simultaneous production of hydrochar, which can be used for different applications. As for the lignocellulosic residues deriving from the pruning of olive groves, TCW, pelletization is undoubtedly very attractive. However, the development and construction of hybrid plants that provide for the anaerobic digestion of different biomasses pretreated with HTC could be attractive for overcoming the seasonality of raw materials and the operational continuity of the plants.

Currently, there are no full-scale hydrothermal carbonization plants of the SOMW and even fewer hybrid anaerobic digestion plants of mixed biomass pretreated with HTC. However, it is reasonable to foresee that such plants could take the place of the traditional pomace oil extraction plants in the short to medium term. The olive sector would finally have found a definitive and sustainable structure if this were to happen.

Author Contributions

Conceptualization, G.D.G.; methodology, G.D.G. and P.R.; investigation, G.D.G. and P.R.; resources, G.D.G. and P.R.; writing—original draft preparation G.D.G.; writing—review and editing, P.R.; supervision, G.D.G.; visualization, P.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors thank the administrative and technical staff of the department of Industrial and Information Engineering and of Economics of the University of L’Aquila for helpful support.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kummu, M.; de Moel, H.; Porkka, M.; Siebert, S.; Varis, O.; Ward, P.J. Lost food, wasted resources: Global food supply chain losses and their impacts on freshwater, cropland, and fertiliser use. Sci. Total Environ. 2012, 438, 477–489. [Google Scholar] [CrossRef] [PubMed]

- Zimon, D.; Madzik, P.; Domingues, P. Development of key processes along the supply chain by implementing the ISO 22000 standard. Sustainability 2020, 12, 6176. [Google Scholar] [CrossRef]

- Papargyropoulou, E.; Lozano, R.; Steinberger, J.; Wright, N.; Ujang, Z. Bin The food waste hierarchy as a framework for the management of food surplus and food waste. J. Clean. Prod. 2014, 76, 106–115. [Google Scholar] [CrossRef]

- Di Giacomo, G.; Gallifuoco, A.; Scimia, F.; Taglieri, L. Food quality, food packaging and food waste reduction. In Proceedings of the 15th International Conference on Food Processing & Technology, Rome, Italy, 27–29 October 2016. [Google Scholar]

- First Circular Economy Action Plan. Available online: https://ec.europa.eu/environment/topics/circular-economy/first-circular-economy-action-plan_en (accessed on 27 December 2021).

- H2020 Project—Ref. Ares(2019)4112037, Grant agreement number 818312. In Unlocking New Value from Urban Bioeaste; European Biomass Industry Association: Brussels, Belgium, 2019.

- EEA Report N°04/2020. In Bio-Waste in Europe-Turning Challenges into Opportunities; Publications Office of the European Union: Luxembourg, 2020.

- Hirst, K.K. ThoughtCo. Available online: https://www.thoughtco.com/k-kris-hirst-166730 (accessed on 22 September 2021).

- Bartolini, G. Classification, Origin, Diffusion and History of the Olive; Food & Agriculture Organization (FAO): Rome, Italy, 2002. [Google Scholar]

- Vossen, P. Olive Oil: History, Production, and Characteristics of the World’s Classic Oils. HortScience 2007, 42, 1093–1100. [Google Scholar] [CrossRef]

- Galili, E.; Langgut, D.; Terral, J.F.; Barazani, O.; Dag, A.; Kolska Horwitz, L.; Ogloblin Ramirez, I.; Rosen, B.; Weinstein-Evron, M.; Chaim, S.; et al. Early production of table olives at a mid-7th millennium BP submerged site off the Carmel coast (Israel). Sci. Rep. 2021, 11, 1–15. [Google Scholar] [CrossRef]

- Sánchez-Martínez, J.D.; Garrido-Almonacid, A. Olive cultivation in the era of globalization. Sci. Technol. Dev. J. Soc. Sci. Humanit. 2019, 2, 60–71. [Google Scholar] [CrossRef]

- Fiorino, P. L’evoluzione globale dell’ovicoltura. In Proceedings of the “L’olivo e il suo olio” Conference, Rome, Italy, 16 December 2008. [Google Scholar]

- L’Arca Olearia. Le Nuove Frontiere Dell’ovicoltura. Available online: https://www.teatronaturale.it/strettamente-tecnico/l-arca-olearia/4888-le-nuove-frontiere-della.htm (accessed on 23 September 2021).

- Tamasi, G.; Bonechi, C.; Belyakova, A.; Pardini, A.; Rossi, C. The olive tree, a source of antioxidant compounds. J. Siena Acad. Sci. 2017, 8, 10–29. [Google Scholar] [CrossRef][Green Version]

- FAO (Food and Agriculture Organization of United Nations). Available online: http://www.fao.org/home/en/?source=tuolamx (accessed on 29 September 2021).

- Pereira Benitez, J.E. International Olive Growing; Fundación Caja Rural de Jaén: La Carolina, Spain, 2018. [Google Scholar]

- Vilar, J.; Pereira, J.E. Informe Caja Rural de jaén Sobre Coyuntura Para la Olivicultura. Available online: https://www.juanvilar.com/informe-caja-rural-jaen-coyuntura-la-olivicultura/ (accessed on 23 September 2021).

- Dawson, D. Global Olive Oil Production Will Reach 4.4M Tons by 2050, Expert Projects. Available online: https://www.oliveoiltimes.com/world/global-olive-oil-production-reach-4-million-tons-by-2050/101131 (accessed on 15 December 2021).

- Ghanbari, R.; Anwar, F.; Alkharfy, K.M.; Gilani, A.H.; Saari, N. Valuable nutrients and functional bioactives in different parts of olive (Olea europaea L.)—A review. Int. J. Mol. Sci. 2012, 13, 3291–3340. [Google Scholar] [CrossRef]

- Difference between Traditional, Intensive and SHD Olive Grove. Available online: https://livitaplus.com/traditional-intensive-olive/?lang=en (accessed on 27 September 2021).

- Russo, C.; Cappelletti, G.M.; Nicoletti, G.M.; Di Noia, A.E.; Michalopoulos, G. Comparison of European olive production systems. Sustainability 2016, 8, 825. [Google Scholar] [CrossRef]

- Olivae 126 English Edition; International Olive Council: Madrid, Spain, 2019.

- Ornek, E.R.; Gündoğdu, M.A.; Seker, M. Comparison of olive oil chemical characteristics of some local olive genotypes. In Proceedings of the 1st International Symposium on Biodiversity Research, Çanakkale, Turkey, 2–4 May 2019; pp. 11–21. [Google Scholar]

- Bianchi, G. Lipids and phenols in table olives. Eur. J. Lipid Sci. Technol. 2003, 105, 229–242. [Google Scholar] [CrossRef]

- Velázquez-Martí, B.; Fernández-González, E.; López-Cortés, I.; Salazar-Hernández, D.M. Quantification of the residual biomass obtained from pruning of trees in Mediterranean olive groves. Biomass Bioenergy 2011, 35, 3208–3217. [Google Scholar] [CrossRef]

- Di Giacomo, G.; Taglieri, L. Renewable energy benefits with conversion of woody residues to pellets. Energy 2009, 34, 724–731. [Google Scholar] [CrossRef]

- Sciubba, F.; Chronopoulou, L.; Pizzichini, D.; Lionetti, V.; Fontana, C.; Aromolo, R.; Socciarelli, S.; Gambelli, L.; Bartolacci, B.; Finotti, E.; et al. Olive mill wastes: A source of bioactive molecules for plant growth and protection against pathogens. Biology 2020, 9, 450. [Google Scholar] [CrossRef]

- Ntougias, S.; Bourtzis, K.; Tsiamis, G. The microbiology of olive mill wastes. Biomed Res. Int. 2013, 2013, 1–16. [Google Scholar] [CrossRef]

- Ruiz, E.; Romero-García, J.M.; Romero, I.; Manzanares, P.; Negro, M.J.; Castro, E. Olive-derived biomass as a source of energy and chemicals. Biofuels Bioprod. Biorefin. 2017, 11, 1077–1094. [Google Scholar] [CrossRef]

- International Olive Council. Available online: https://www.internationaloliveoil.org/ (accessed on 19 September 2021).

- Tamimi, N.; Diehl, D.; Njoum, M.; Marei, A.; Schaumann, G.E. Effects of olive mill wastewater disposal on soil: Interaction mechanisms during different seasons. J. Hydrol. Hydromech. 2016, 64, 176–195. [Google Scholar] [CrossRef]

- Niaounakis, M.; Halvadakis, C.P. Olive Processing Waste Management, 2nd ed.; Pergamon: Oxford, UK, 2006. [Google Scholar]

- Di Giovacchino, L. Tecnologie di Lavorazione Delle Olive in Frantoio. Rese di Estrazione e Qualità dell’olio; Tecniche Nuove: Milano, Italy, 2010. [Google Scholar]

- Martinez, J.M.B. World Olive Encyclopedia; International Olive Counsil, Ed.; World Olive Counci: Madrid, Spain, 1996. [Google Scholar]

- Galanakis, C.M. Olive Mill Waste: Recent Advances for Sustainable Management; Elsevier Science Publishing Co., Inc.: Amsterdam, The Netherlands, 2017. [Google Scholar]

- Alpi, A.; Nanni, P.; Vincenzini, M. Olivo, Olivicoltura, Olio di Oliva. Guardando al Futuro; Polistampa: Firenze, Italy, 2021. [Google Scholar]

- Torrecilla, J.S. The Olive: Its Processing and Waste Management; Nova Science Publishers, Inc.: Hauppauge, NY, USA, 2010. [Google Scholar]

- Blatchly, R.; Delen, Z.; O’Hara, P. The Chemical Story of Olive Oil: From Grove to Table; Royal Society of Chemistry: London, UK, 2017. [Google Scholar]

- Aparicio, R.; Harwood, J. Handbook of Olive Oil: Analysis and Properties; Springer: Berlin, Germany, 2013. [Google Scholar]

- Corrigan, J.D. Olive Oil and Health, 1st ed.; Nova Biomedical: Cheshire, UK, 2010. [Google Scholar]

- Doula, M.K.; Tinivella, F.; Moreno-Ortego, J.L.; Kavvadias, V.; Sarris, A.; Theocharopoulos, S.; Sanchez-Monedero, M.; Elaiopoulos, K. Good Practices for the Agronomic Use of Olive Mill Wastes; Doula, M.K., Ed.; Prosodol: Crete, Greece, 2012. [Google Scholar]

- Khdair, A.; Abu-Rumman, G. Sustainable environmental management and valorization options for olive mill byproducts in the Middle East and North Africa (MENA) region. Processes 2020, 8, 671. [Google Scholar] [CrossRef]

- Azbar, N.; Bayram, A.; Filibeli, A.; Muezzinoglu, A.; Sengul, F.; Ozer, A. A review of waste management options in olive oil production. Crit. Rev. Environ. Sci. Technol. 2004, 34, 209–247. [Google Scholar] [CrossRef]

- Messineo, A.; Maniscalco, M.P.; Volpe, R. Biomethane recovery from olive mill residues through anaerobic digestion: A review of the state of the art technology. Sci. Total Environ. 2020, 703, 135508. [Google Scholar] [CrossRef]

- Medouni-Haroune, L.; Zaidi, F.; Medouni-Adrar, S.; Kecha, M. Olive Pomace: From An Olive Mill Waste To A Resource, An Overview Of The New Treatments. J. Crit. Rev. 2018, 5, 1–6. [Google Scholar] [CrossRef]

- Muktadirul Bari Chowdhury, A.K.M.; Akratos, C.S.; Vayenas, D.V.; Pavlou, S. Olive mill waste composting: A review. Int. Biodeterior. Biodegrad. 2013, 85, 108–119. [Google Scholar] [CrossRef]

- Pardo, T.; Bernal, P.; Clemente, R. Chapter 9—The use of olive mill waste to promote phytoremediation. In Olive Mill Waste; Elsevier Science Publishing Co., Inc.: Amsterdam, The Netherlands, 2017. [Google Scholar]

- Hanifi, S.; El Hadrami, I. Olive mill wastewaters: Diversity of the fatal product in olive oil industry and its valorisation as agronomical amendment of poor soils: A review. J. Agron. 2009, 8, 1–13. [Google Scholar] [CrossRef][Green Version]

- Guida, M.Y.; Hannioui, A. A review on thermochemical treatment of biomass: Pyrolysis of olive mill wastes in comparison with other types of biomass. Prog. Agric. Eng. Sci. 2016, 12, 1–23. [Google Scholar] [CrossRef]

- Christoforou, E.; Fokaides, P.A. A review of olive mill solid wastes to energy utilization techniques. Waste Manag. 2016, 49, 346–363. [Google Scholar] [CrossRef]

- Donner, M.; Radić, I. Innovative circular business models in the olive oil sector for sustainable mediterranean agrifood systems. Sustainability 2021, 13, 2588. [Google Scholar] [CrossRef]

- Zipori, I.; Erel, R.; Yermiyahu, U.; Bengal, A.; Dag, A. Sustainable management of olive orchard nutrition: A review. Agriculture 2020, 10, 11. [Google Scholar] [CrossRef]

- Ouazzane, H.; Laajine, F.; El Yamani, M.; El Hilaly, J.; Rharrabti, Y.; Amarouch, M.Y.; Mazouzi, D. Olive mill solid waste characterization and recycling opportunities: A review. J. Mater. Environ. Sci. 2017, 8, 2632–2650. [Google Scholar]

- Ahmed, P.M.; Fernández, P.M.; de Figueroa, L.I.C.; Pajot, H.F. Exploitation alternatives of olive mill wastewater: Production of value-added compounds useful for industry and agriculture. Biofuel Res. J. 2019, 6, 980–994. [Google Scholar] [CrossRef]

- Taguas, E.V.; Marín-Moreno, V.; Díez, C.M.; Mateos, L.; Barranco, D.; Mesas-Carrascosa, F.J.; Pérez, R.; García-Ferrer, A.; Quero, J.L. Opportunities of super high-density olive orchard to improve soil quality: Management guidelines for application of pruning residues. J. Environ. Manag. 2021, 293, 112785. [Google Scholar] [CrossRef] [PubMed]

- Di Giovacchino, L. Technological aspects. In Handbook of Olive Oil: Analysis and Properties; Springer Science & Business Media: Berlin, Germany, 2013. [Google Scholar]

- Paul, V. Organic Olive Production Manual; Agriculture and Natural Resources, Ed.; UCANR Publications: Davis, CA, USA, 2017. [Google Scholar]

- DeAndreis, P. Modern Olive Growing Starting to Overtake Traditional Methods. Available online: https://www.oliveoiltimes.com/world/modern-olive-growing-starting-to-overtake-traditional-methods/88625 (accessed on 25 September 2021).

- Lo Bianco, R.; Proietti, P.; Regni, L.; Caruso, T. Planting systems for modern olive growing: Strengths and weaknesses. Agriculture 2021, 11, 494. [Google Scholar] [CrossRef]

- Hermoso Fernández, M. Elaboración de aceites de oliva de calidad. Obtención por el sistema de dos fases; Pesca, C.D.A.Y., Ed.; Consejería de Agricultura y Pesca: Seville, Spain, 1998. [Google Scholar]

- Rodis, P.S.; Karathanos, V.T.; Mantzavinou, A. Partitioning of olive oil antioxidants between oil and water phases. J. Agric. Food Chem. 2002, 50, 596–601. [Google Scholar] [CrossRef]

- Servili, M.; Esposto, S.; Taticchi, A.; Urbani, S.; Di Maio, I.; Veneziani, G.; Selvaggini, R. New approaches to virgin olive oil quality, technology, and by-products valorization. Eur. J. Lipid Sci. Technol. 2015, 117, 1882–1892. [Google Scholar] [CrossRef]

- Servili, M.; Taticchi, A.; Esposto, S.; Urbani, S.; Selvaggini, R.; Montedoro, G.F. Effect of olive stoning on the volatile and phenolic composition of virgin olive oil. J. Agric. Food Chem. 2007, 55, 7028–7035. [Google Scholar] [CrossRef]

- Angerosa, F.; Servili, M.; Selvaggini, R.; Taticchi, A.; Esposto, S.; Montedoro, G. Volatile compounds in virgin olive oil: Occurrence and their relationship with the quality. J. Chromatogr. A 2004, 1054, 17–31. [Google Scholar] [CrossRef]

- Tamborrino, A.; Clodoveo, M.L.; Leone, A.; Amirante, P.; Paice, A.G. The Malaxation Process: Influence on Olive Oil Quality and the Effect of the Control of Oxygen Concentration in Virgin Olive Oil. In Olives and Olive Oil in Health and Disease Prevention; Academic Press: Cambridge, MA, USA, 2010. [Google Scholar]

- Amirante, P.; Clodoveo, M.L.; Dugo, G.; Leone, A.; Tamborrino, A. Advance technology in virgin olive oil production from traditional and de-stoned pastes: Influence of the introduction of a heat exchanger on oil quality. Food Chem. 2006, 98, 797–805. [Google Scholar] [CrossRef]

- Di Giovacchino, L.; Sestili, S.; Di Vincenzo, D. Influence of olive processing on virgin olive oil quality. Eur. J. Lipid Sci. Technol. 2002, 104, 587–601. [Google Scholar] [CrossRef]

- Zuccardi, J.M.; Bonino, F.A. Methods and Devices to Extract Oil from Oily Fruits. U.S. Patent N° 20210169097, 13 May 2021. [Google Scholar]

- Alfa Laval Copenhagen A/S. Methods and Devices to Extract Oil from Oily Fruits. A.U. Patent N° 2018335949, 28 March 2019.

- Alba-Mendoza, J. Elaboración de Aceite de Oliva Virgin. El Cultivo del Olivo, 4th ed.; Ediciones MundiPrensa: Madrid, Spain, 2001; pp. 551–587. [Google Scholar]

- Di Giovacchino, L.; Solinas, M.; Brandani, V.; Del Re, G.; Di Giacomo, G. Risultati delle prove preliminari di estrazione dell’ olio dalle olive con CO2 supercritica. Industrie Alimentari 1989, 28, 925–928. [Google Scholar]

- Belbaki, A.; Louaer, W.; Meniai, A.H. Supercritical CO2 extraction of oil from Crushed Algerian olives. J. Supercrit. Fluids 2017, 130, 165–171. [Google Scholar] [CrossRef]

- The Evolution of the System of Olive Oil Extraction from Three Phases to Two Phases. Available online: http://www.frantoiovalleargentata.it/eng/wp-content/uploads/2011/09/Valle-Argentata-Sistema-a-2-Fasi.pdf (accessed on 30 September 2021).

- Kapellakis, I.E.; Tsagarakis, K.P.; Crowther, J.C. Olive oil history, production and by-product management. Rev. Environ. Sci. Biotechnol. 2008, 7, 1–26. [Google Scholar] [CrossRef]

- Masella, P.; Parenti, A.; Spugnoli, P.; Calamai, L. Influence of vertical centrifugation on extra virgin olive oil quality. JAOCS J. Am. Oil Chem. Soc. 2009, 86, 1137–1140. [Google Scholar] [CrossRef]

- Guerrini, L.; Luca Pantani, O.; Parenti, A. The impact of vertical centrifugation on olive oil quality. J. Food Process Eng. 2017, 40, 1–8. [Google Scholar] [CrossRef]

- Vidal, A.M.; Alcalá, S.; De Torres, A.; Moya, M.; Espínola, F. Centrifugation, Storage, and Filtration of Olive Oil in an Oil Mill: Effect on the Quality and Content of Minority Compounds. J. Food Qual. 2019, 2019, 1–7. [Google Scholar] [CrossRef]

- Altieri, G.; Genovese, F.; Matera, A.; Di Renzo, G.C. A comparison among innovative plants for high quality extra-virgin olive oil production. J. Sci. Food Agric. 2020, 100, 5283–5291. [Google Scholar] [CrossRef]

- Lanza, B.; Cellini, M.; Di Marco, S.; D’amico, E.; Simone, N.; Giansante, L.; Pompilio, A.; Di Loreto, G.; Bacceli, M.; Del Re, P.; et al. Olive pâté by multi-phase decanter as potential source of bioactive compounds of both nutraceutical and anticancer effects. Molecules 2020, 25, 5967. [Google Scholar] [CrossRef] [PubMed]

- Grimelli, A. DMF2012: Produrre patè d’olive Direttamente dal Decanter. Available online: https://www.teatronaturale.it/strettamente-tecnico/l-arca-olearia/12879-dmf2012:-produrre-pate-d-olive-direttamente-dal-decanter.htm (accessed on 1 October 2021).

- Vallini, G. Book Review: Olive Processing Waste Management-Literature Review and Patent Survey (Waste Management Series, 5). Waste Manag. Res. J. A Sustain. Circ. Econ. 2006, 24, 402. [Google Scholar] [CrossRef]

- Poerschmann, J.; Baskyr, I.; Kopinke, F.D. Hydrothermal carbonization of olive mill wastewater. Bioresour. Technol. 2013, 133, 581–588. [Google Scholar] [CrossRef] [PubMed]

- Atallah, E.; Kwapinski, W.; Ahmad, M.N.; Leahy, J.J.; Al-Muhtaseb, A.H.; Zeaiter, J. Hydrothermal carbonization of olive mill wastewater: Liquid phase product analysis. J. Environ. Chem. Eng. 2019, 7, 7. [Google Scholar] [CrossRef]

- Piccinno, F.; Hischier, R.; Seeger, S.; Som, C. From laboratory to industrial scale: A scale-up framework for chemical processes in life cycle assessment studies. J. Clean. Prod. 2016, 135, 1085–1097. [Google Scholar] [CrossRef]

- Kipçak, E.; Söǧüt, O.Ö.; Akgün, M. Hydrothermal gasification of olive mill wastewater as a biomass source in supercritical water. J. Supercrit. Fluids 2011, 57, 50–57. [Google Scholar] [CrossRef]

- Zbakh, H.; El Abbassi, A. Potential use of olive mill wastewater in the preparation of functional beverages: A review. J. Funct. Foods 2012, 4, 53–65. [Google Scholar] [CrossRef]

- Takaç, S.; Karakaya, A. Recovery of phenolic antioxidants from olive mill wastewater. Recent Pat. Chem. Eng. 2009, 2, 230–237. [Google Scholar] [CrossRef]

- IEA Bioenergy. Food Waste Digestion—Anaerobic Digestion of Food Waste for a Circular Economy. Available online: https://www.ieabioenergy.com/wp-content/uploads/2018/12/Food-waste_WEB_END.pdf (accessed on 1 October 2021).

- Ge, X.; Xu, F.; Li, Y. Solid-state anaerobic digestion of lignocellulosic biomass: Recent progress and perspectives. Bioresour. Technol. 2016, 205, 239–249. [Google Scholar] [CrossRef]

- Tavoni, T. Adeguamento dell’Autoparco della TE.AM., Previa Verifica di Fattibilità per l’uso di Biometano Aziendale. Master’s Thesis, University of L’Aquila, L’Aquila, Italy, July 2016. [Google Scholar]

- Stoyanova, E.; Lundaa, T.; Bochmann, G.; Fuchs, W. Overcoming the bottlenecks of anaerobic digestion of olive mill solid waste by two-stage fermentation. Environ. Technol. 2017, 38, 394–405. [Google Scholar] [CrossRef]

- Carlini, M.; Castellucci, S.; Cocchi, S. Mesophilic fermentation of SOMW in a micro pilot-scale anaerobic digester. Adv. Mater. Res. 2014, 827, 84–90. [Google Scholar] [CrossRef]

- Maamir, W.; Ouahabi, Y.; Poncin, S.; Li, H.Z.; Bensadok, K. Effect of fenton pretreatment on anaerobic digestion of olive mill wastewater and olive mill solid waste in mesophilic conditions. Int. J. Green Energy 2017, 14, 555–560. [Google Scholar] [CrossRef]

- Bolanos, M.M. Feasibility Study of Anaerobic Digestion of Olive Mill Waste for Energy Production. Case Study Applied to Two Olive Oil Extraction Industries in Spain. Bachelor’s Thesis, Universitat Politècnica de Catalunya, Barcelona, Spain, June 2017; p. 69. [Google Scholar]

- Fernández-Rodríguez, M.J.; de la Lama-Calvente, D.; Jiménez-Rodríguez, A.; Borja, R.; Rincón-Llorente, B. Anaerobic co-digestion of olive mill solid waste and microalga Scenedesmus quadricauda: Effect of different carbon to nitrogen ratios on process performance and kinetics. J. Appl. Phycol. 2019, 31, 3583–3591. [Google Scholar] [CrossRef]

- Blika, P.S.; Stamatelatou, K.; Kornaros, M.; Lyberatos, G. Anaerobic digestion of olive mill wastewater. Glob. Nest J. 2009, 11, 364–372. [Google Scholar] [CrossRef]

- Benalia, S.; Falcone, G.; Stillitano, T.; De Luca, A.I.; Strano, A.; Gulisano, G.; Zimbalatti, G.; Bernardi, B. Increasing the content of olive mill wastewater in biogas reactors for a sustainable recovery: Methane productivity and life cycle analyses of the process. Foods 2021, 10, 1029. [Google Scholar] [CrossRef]

- Uddin, M.A.; Siddiki, S.Y.A.; Ahmed, S.F.; Rony, Z.I.; Chowdhury, M.A.K.; Mofijur, M. Estimation of sustainable bioenergy production from olive mill solid waste. Energies 2021, 14, 7654. [Google Scholar] [CrossRef]

- Carusoni, A. Fattibilità tecnico-economica per la produzione di Biometano da F.O.R.S.U. (organic fraction of municipal solid waste). Bachelor’s Thesis, University of L’Aquila, L’Aquila, Italy, March 2018. [Google Scholar]

- Gadaleta, G.; De Gisi, S.; Notarnicola, M. Feasibility analysis on the adoption of decentralized anaerobic co-digestion for the treatment of municipal organic waste with energy recovery in urban districts of metropolitan areas. Int. J. Environ. Res. Public Health 2021, 18, 1820. [Google Scholar] [CrossRef]

- Fernández-Rodríguez, M.J.; Rincón, B.; Fermoso, F.G.; Jiménez, A.M.; Borja, R. Assessment of two-phase olive mill solid waste and microalgae co-digestion to improve methane production and process kinetics. Bioresour. Technol. 2014, 157, 263–269. [Google Scholar] [CrossRef]

- Carlini, M.; Castellucci, S.; Moneti, M. Anaerobic co-digestion of olive-mill solid waste with cattle manure and cattle slurry: Analysis of bio-methane potential. In Proceedings of the 69th Conference of the Italian Thermal Machines Engineering Association, ATI2014, Roma, Italy, 9–11 September 2015; pp. 354–367. [Google Scholar]

- Pellera, F.M.; Santori, S.; Pomi, R.; Polettini, A.; Gidarakos, E. Effect of alkaline pretreatment on anaerobic digestion of olive mill solid waste. Waste Manag. 2016, 58, 160–168. [Google Scholar] [CrossRef]

- Gianico, A.; Braguglia, C.M.; Mescia, D.; Mininni, G. Ultrasonic and thermal pretreatments to enhance the anaerobic bioconversion of olive husks. Bioresour. Technol. 2013, 147, 623–626. [Google Scholar] [CrossRef]

- Gunay, A.; Karadag, D. Recent developments in the anaerobic digestion of olive mill effluents. Process. Biochem. 2015, 50, 1893–1903. [Google Scholar] [CrossRef]

- Rincón, B.; González De Canales, M.; Martín, A.; Borja, R. Impact of microwave pre-Treatment on the batch anaerobic digestion of two-phase olive mill solid residue: A kinetic approach. Grasas y Aceites 2016, 67, 165. [Google Scholar] [CrossRef]

- Tamborrino, A.; Catalano, F.; Leone, A.; Bianchi, B. A real case study of a full-scale anaerobic digestion plant powered by olive by-products. Foods 2021, 10, 1946. [Google Scholar] [CrossRef]

- Pyrodigest: Conversion of Olive Oil Wastes through Combined Pyrolysis and Anaerobic Digestion: Energy, Value Added Products and Eco-Fertilizers Production. Available online: https://umr-iate.cirad.fr/projets/pyrodigest-arimnet2 (accessed on 2 October 2021).

- Raviv, M.; Medina, S.; Krassnovsky, A.; Laor, Y.; Aviani, I. Composting olive mill waste and assessment of its horticultural value. Acta Hortic. 2009, 819, 353–360. [Google Scholar] [CrossRef]

- Tüzel, Y.; Ekinci, K.; Öztekin, G.B.; Erdal, I.; Varol, N.; Merken, Ö. Utilization of olive oil processing waste composts in organic tomato seedling production. Agronomy 2020, 10, 797. [Google Scholar] [CrossRef]

- Toscano, P.; Casacchia, T.; Diacono, M.; Montemurro, F. Composted olive mill by-products: Compost characterization and application on olive orchards. J. Agric. Sci. Technol. 2013, 15, 627–638. [Google Scholar]

- Gmez-Muoz, B.; Hatch, J.D.; Bol, R.; Garca-Ruiz, R. The Compost of Olive Mill Pomace: From a Waste to a Resource—Environmental Benefits of Its Application in Olive Oil Groves. In Sustainable Development—Authoritative and Leading Edge Content for Environmental Management; Intechopen: London, UK, 2012. [Google Scholar]

- Chowdhury, A.K.M.M.B.; Michailides, M.K.; Akratos, C.S.; Tekerlekopoulou, A.G.; Pavlou, S.; Vayenas, D.V. Composting of three phase olive mill solid waste using different bulking agents. Int. Biodeterior. Biodegrad. 2014, 91, 66–73. [Google Scholar] [CrossRef]

- Roig, A.; Cayuela, M.L.; Sánchez-Monedero, M.A. An overview on olive mill wastes and their valorisation methods. Waste Manag. 2006, 26, 960–969. [Google Scholar] [CrossRef] [PubMed]

- Barje, F.; El Fels, L.; El Hajjouji, H.; Amir, S.; Winterton, P.; Hafidi, M. Molecular behaviour of humic acid-like substances during co-composting of olive mill waste and the organic part of municipal solid waste. Int. Biodeterior. Biodegrad. 2012, 74, 17–23. [Google Scholar] [CrossRef]

- Caputo, A.C.; Scacchia, F.; Pelagagge, P.M. Disposal of by-products in olive oil industry: Waste-to-energy solutions. Appl. Therm. Eng. 2003, 23, 197–241. [Google Scholar] [CrossRef]

- Nunes, L.J.R.; Loureiro, L.M.E.F.; Sá, L.C.R.; Silva, H.F.C. Evaluation of the potential for energy recovery from olive oil industry waste: Thermochemical conversion technologies as fuel improvement methods. Fuel 2020, 279, 118536. [Google Scholar] [CrossRef]

- Frostinone, L.; Li, Y.; Liu, X.; Misic, M.; Paterakis, C.; Phadtare, M.; Venkat, K.; Wuennenberg, L. Olive Mill Waste Case Study Analysis. Available online: https://es.slideshare.net/krithivenkat50/olive-mill-waste-case-study-analysis (accessed on 30 September 2021).

- Ducom, G.; Gautier, M.; Pietraccini, M.; Tagutchou, J.P.; Lebouil, D.; Gourdon, R. Comparative analyses of three olive mill solid residues from different countries and processes for energy recovery by gasification. Renew. Energy 2020, 145, 180–189. [Google Scholar] [CrossRef]

- Mami, M.A.; Mätzing, H.; Gehrmann, H.J.; Stapf, D.; Bolduan, R.; Lajili, M. Investigation of the olive mill solid wastes pellets combustion in a counter-current fixed bed reactor. Energies 2018, 11, 1965. [Google Scholar] [CrossRef]

- Caballero, B.M.; López-Urionabarrenechea, A.; Pérez, B.; Solar, J.; Acha, E.; de Marco, I. Potentiality of “orujillo” (olive oil solid waste) to produce hydrogen by means of pyrolysis. Int. J. Hydrogen Energy 2020, 45, 20549–20557. [Google Scholar] [CrossRef]

- Tabaja, N.; Kassas, A.; Hamieh, S.; Haidar, R.; Foddis, M.-L.; Toufaily, J.; Daou, T.J.; Hamieh, T. High Quality Bio-Oil Obtained from Catalyzed Pyrolysis of Olive Mill Solid Wastes in a Bi-Functional Reactor. Mater. Sci. Appl. 2021, 12, 52–77. [Google Scholar] [CrossRef]

- Guida, M.Y.; Bouaik, H.; Tabal, A.; Hannioui, A.; Solhy, A.; Barakat, A.; Aboulkas, A.; El Harfi, K. Thermochemical treatment of olive mill solid waste and olive mill wastewater: Pyrolysis kinetics. J. Therm. Anal. Calorim. 2016, 123, 1657–1666. [Google Scholar] [CrossRef]

- Lajili, M.; Guizani, C.; Escudero Sanz, F.J.; Jeguirim, M. Fast pyrolysis and steam gasification of pellets prepared from olive oil mill residues. Energy 2018, 150, 61–68. [Google Scholar] [CrossRef]

- García, G.B.; Calero De Hoces, M.; Martínez García, C.; Cotes Palomino, M.T.; Gálvez, A.R.; Martín-Lara, M.Á. Characterization and modeling of pyrolysis of the two-phase olive mill solid waste. Fuel Process. Technol. 2014, 126, 104–111. [Google Scholar] [CrossRef]

- Marks, E.A.N.; Kinigopoulou, V.; Akrout, H.; Azzaz, A.A.; Doulgeris, C.; Jellali, S.; Rad, C.; Zulueta, P.S.; Tziritis, E.; El-Bassi, L.; et al. Potential for production of biochar-based fertilizers from olive millwaste in mediterranean basin countries: An initial assessment for Spain, Tunisia, and Greece. Sustainability 2020, 12, 6081. [Google Scholar] [CrossRef]

- Nunes, L.J.R.; Loureiro, L.M.E.F.; Sá, L.C.R.; Silva, H.F.C. Thermochemical conversion of olive oil industry waste: Circular economy through energy recovery. Recycling 2020, 5, 12. [Google Scholar] [CrossRef]