Performance Analysis of the Coupled Heating System of the Air-Source Heat Pump, the Energy Accumulator and the Water-Source Heat Pump

Abstract

1. Introduction

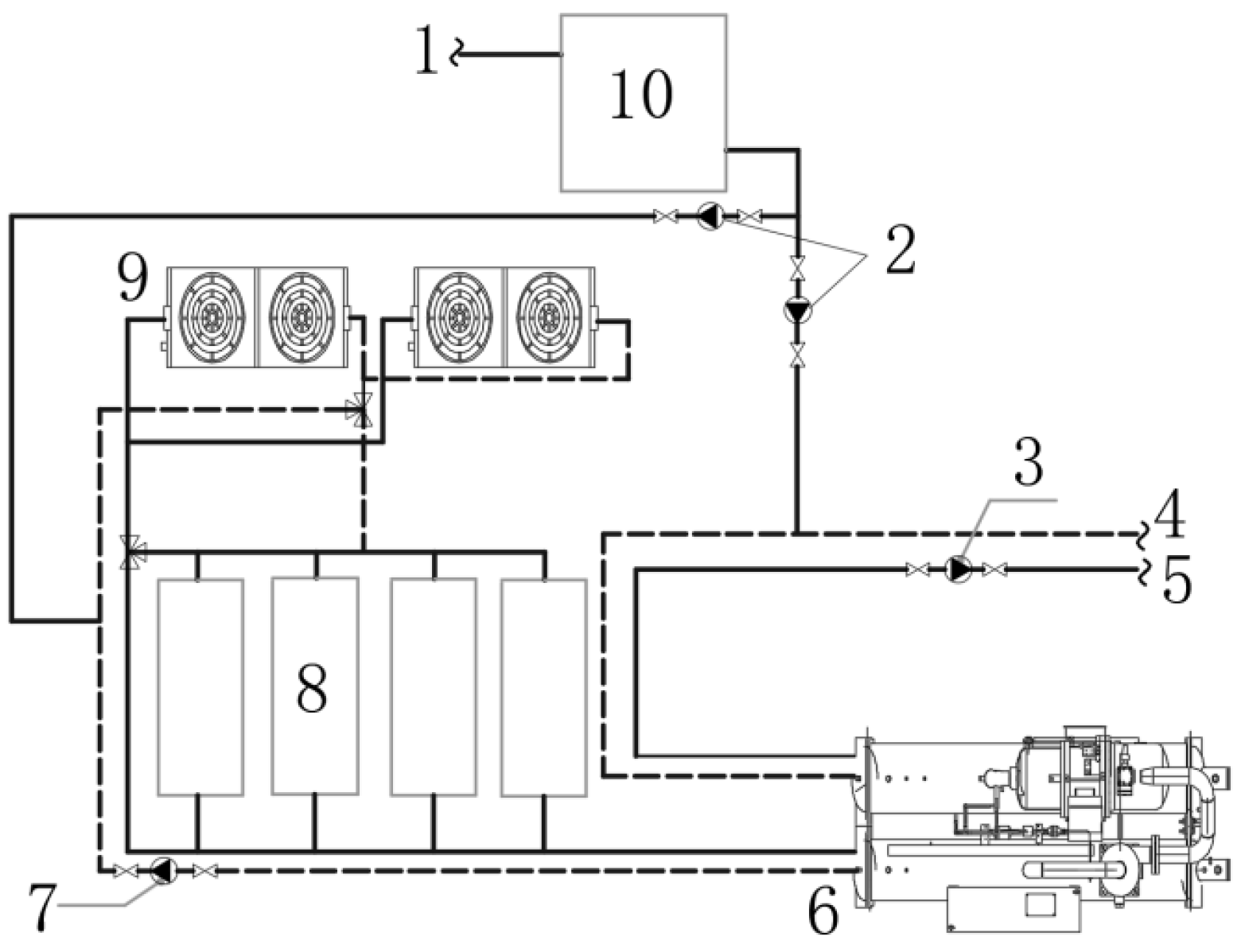

2. The Project Background

3. Simulation Analysis

3.1. Evaluation Index

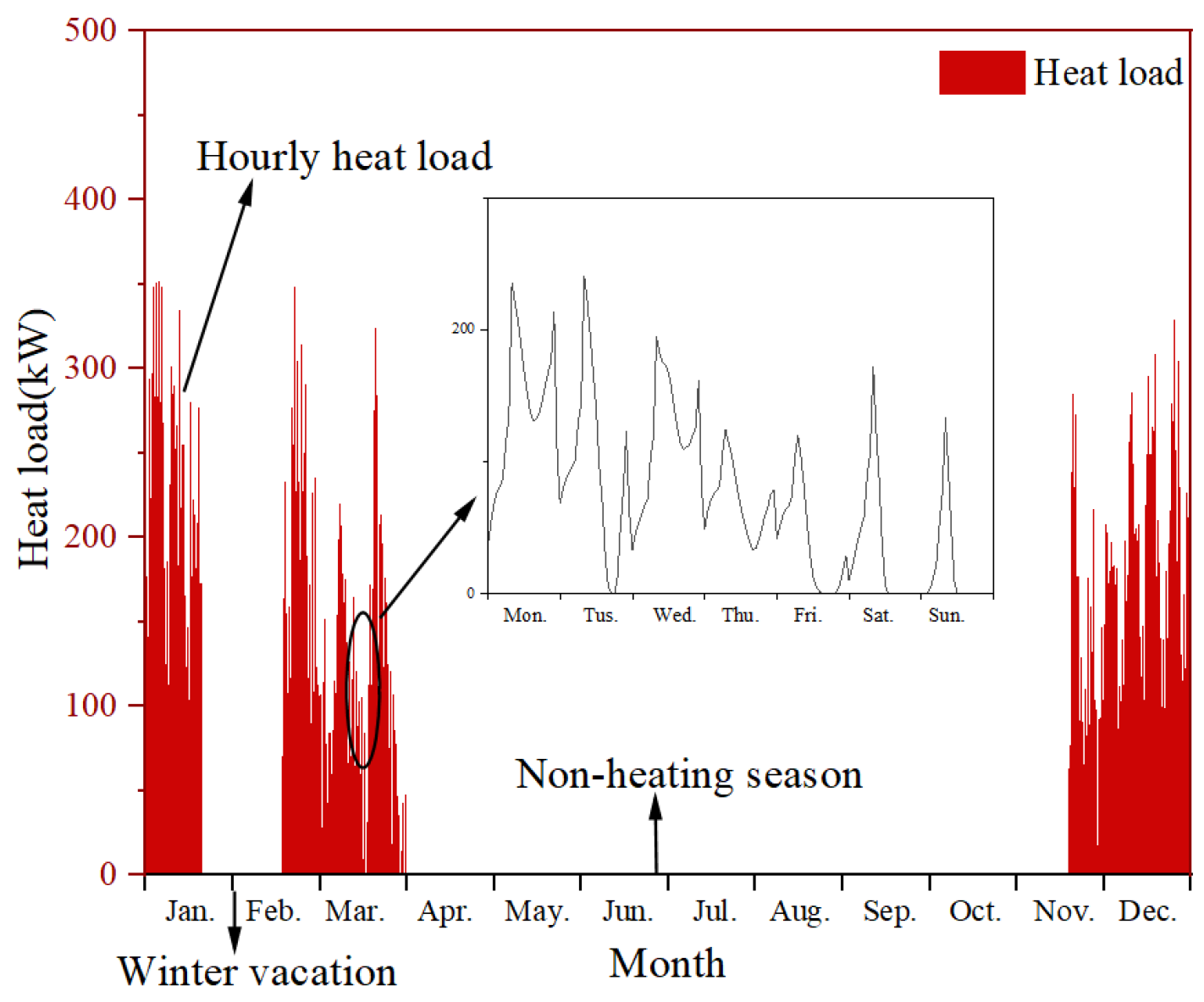

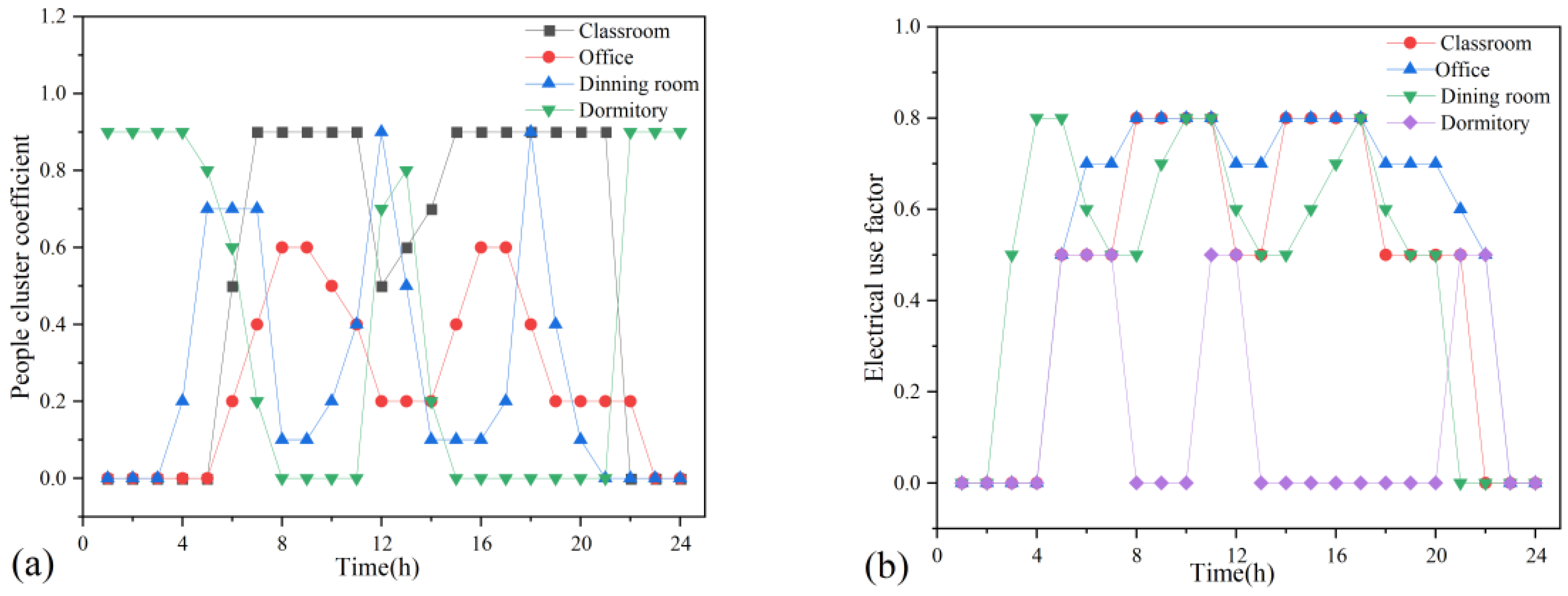

3.2. Heating Load and Component Capacity

3.3. System Simulation Model

3.4. Numerical Results and Analysis

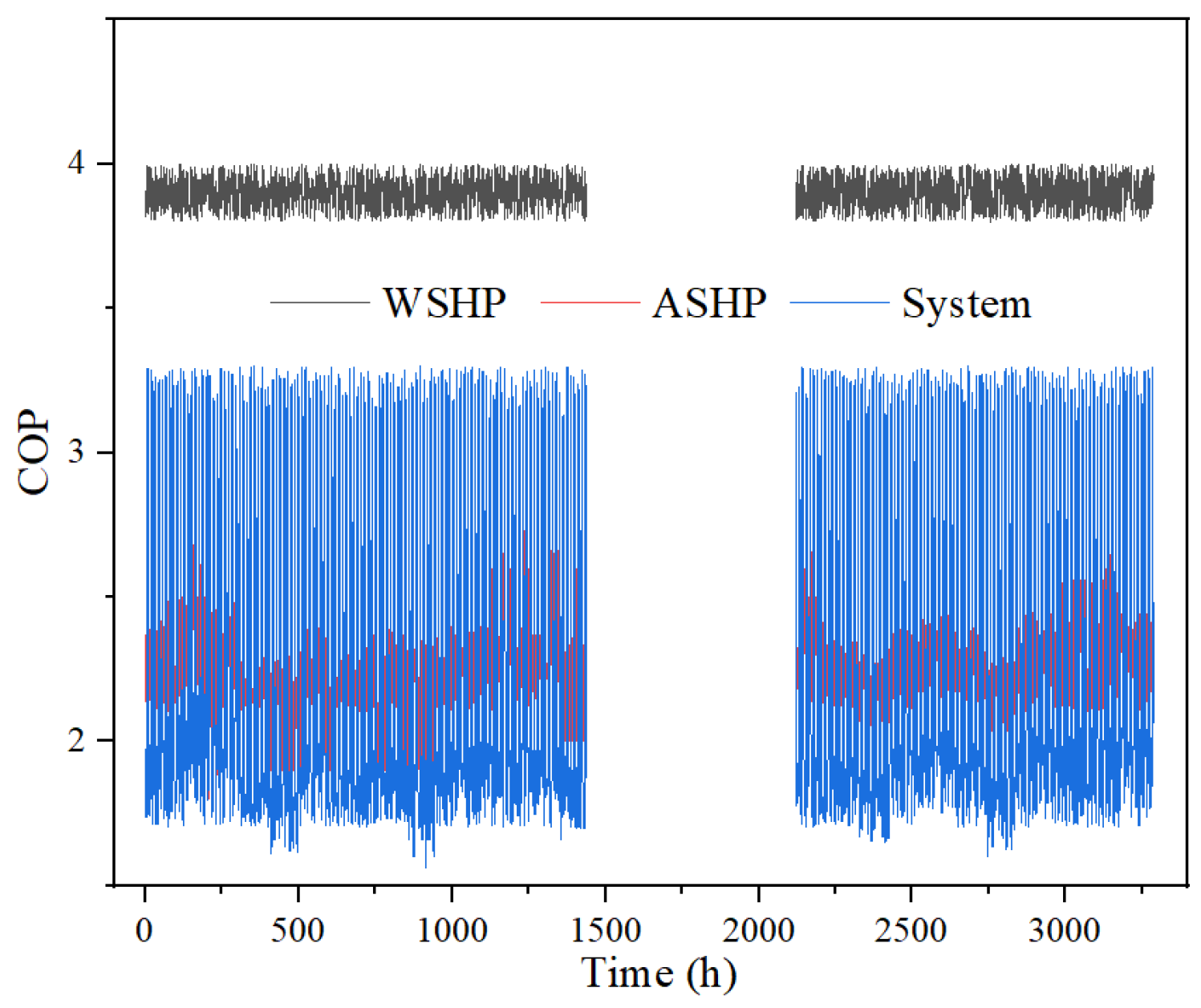

3.4.1. COPs Simulated in the Heating Period

3.4.2. Benefit Predict

4. The Project

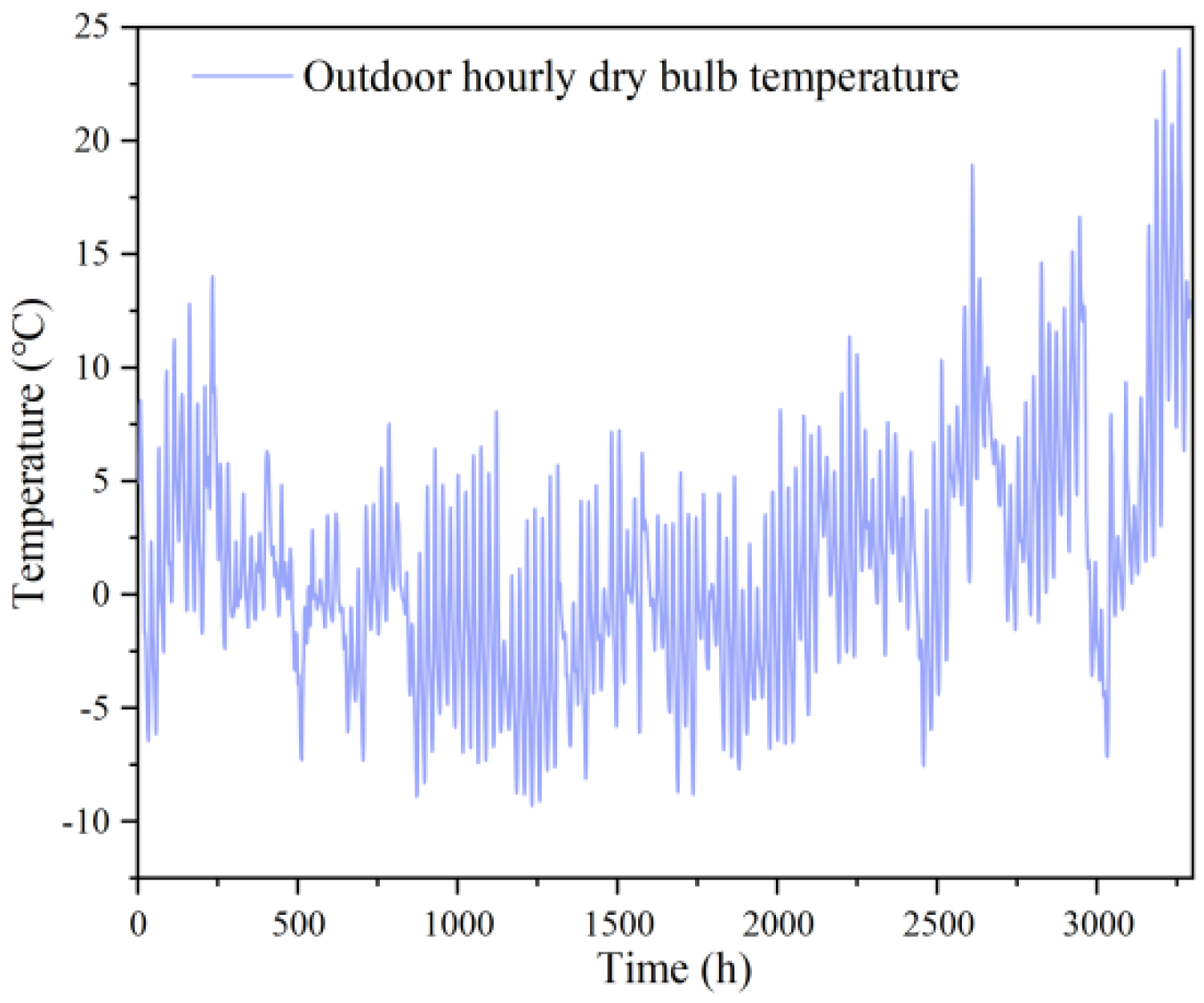

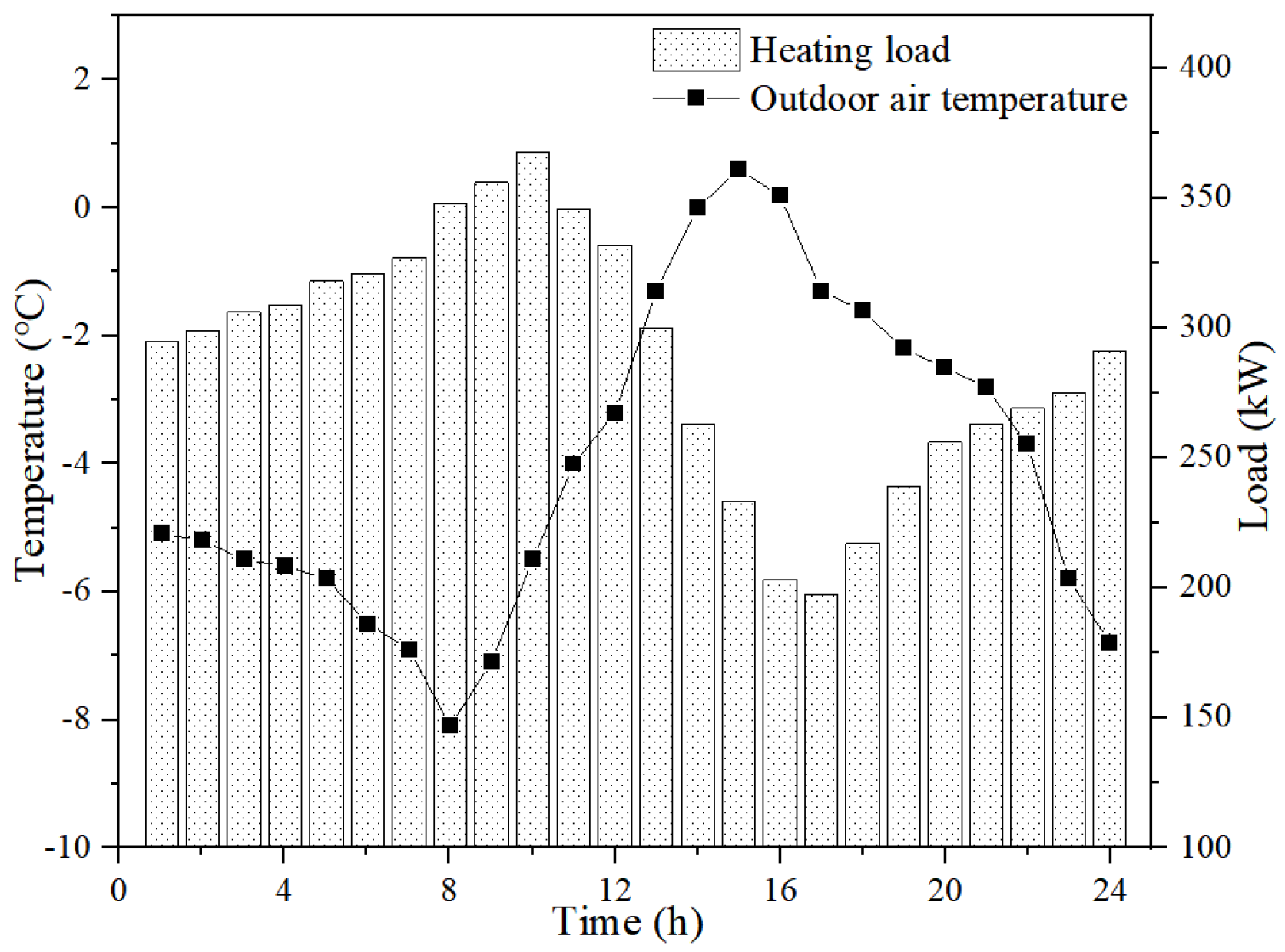

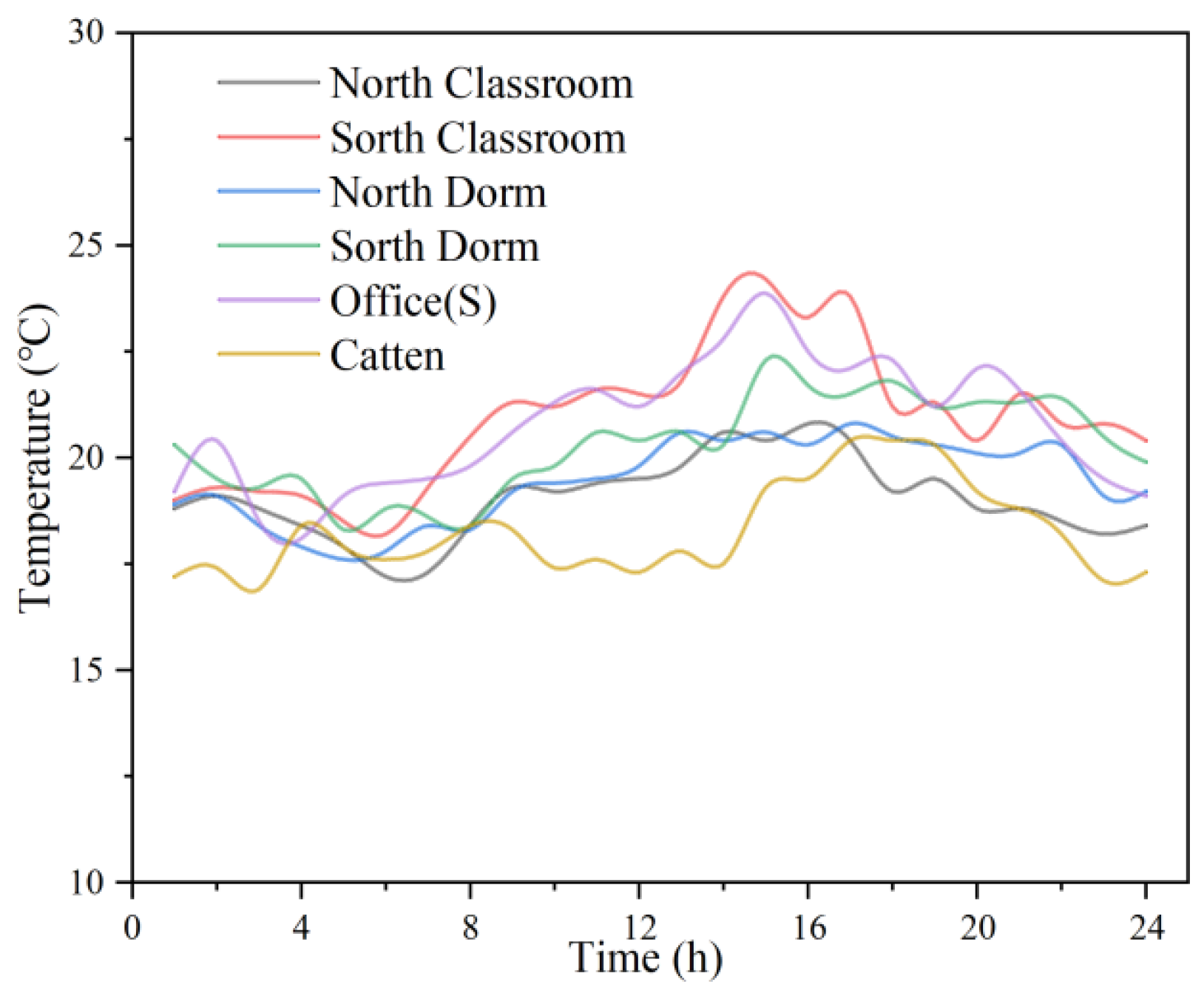

4.1. Outdoor Temperature and Heating Load

4.2. Water Temperature at Each Node

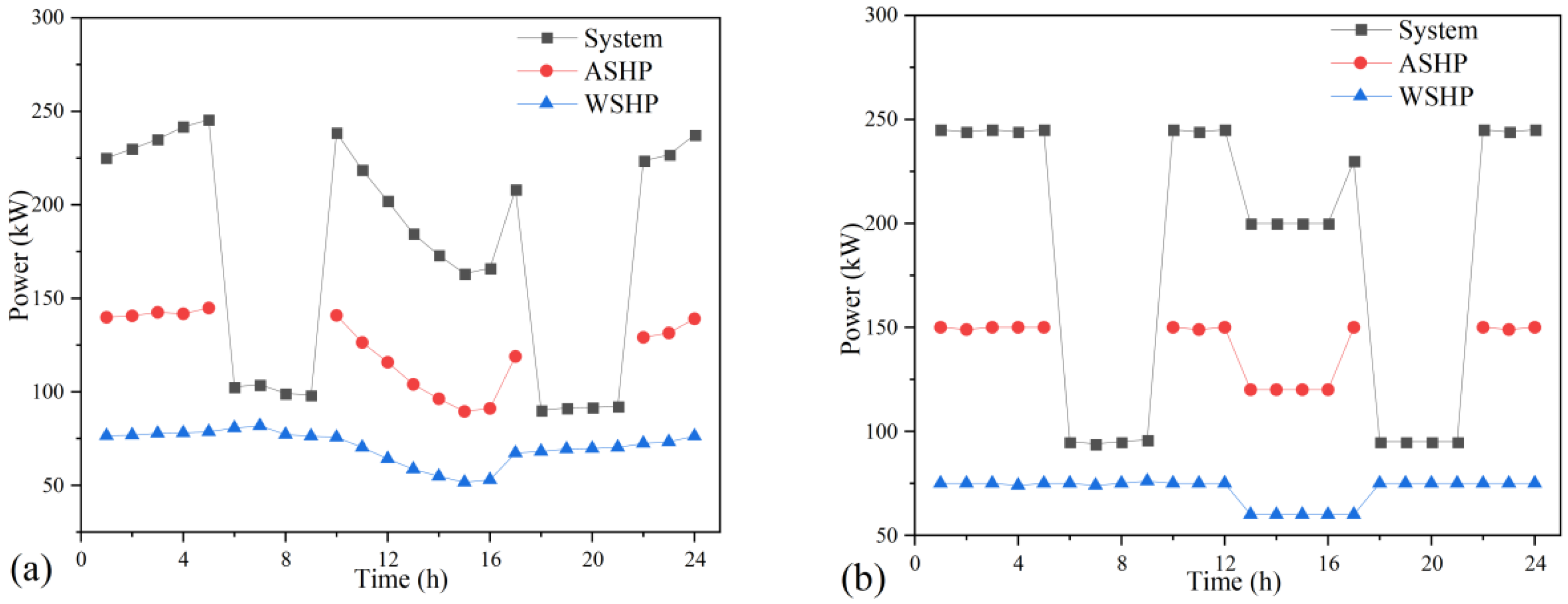

4.3. Power Consumed

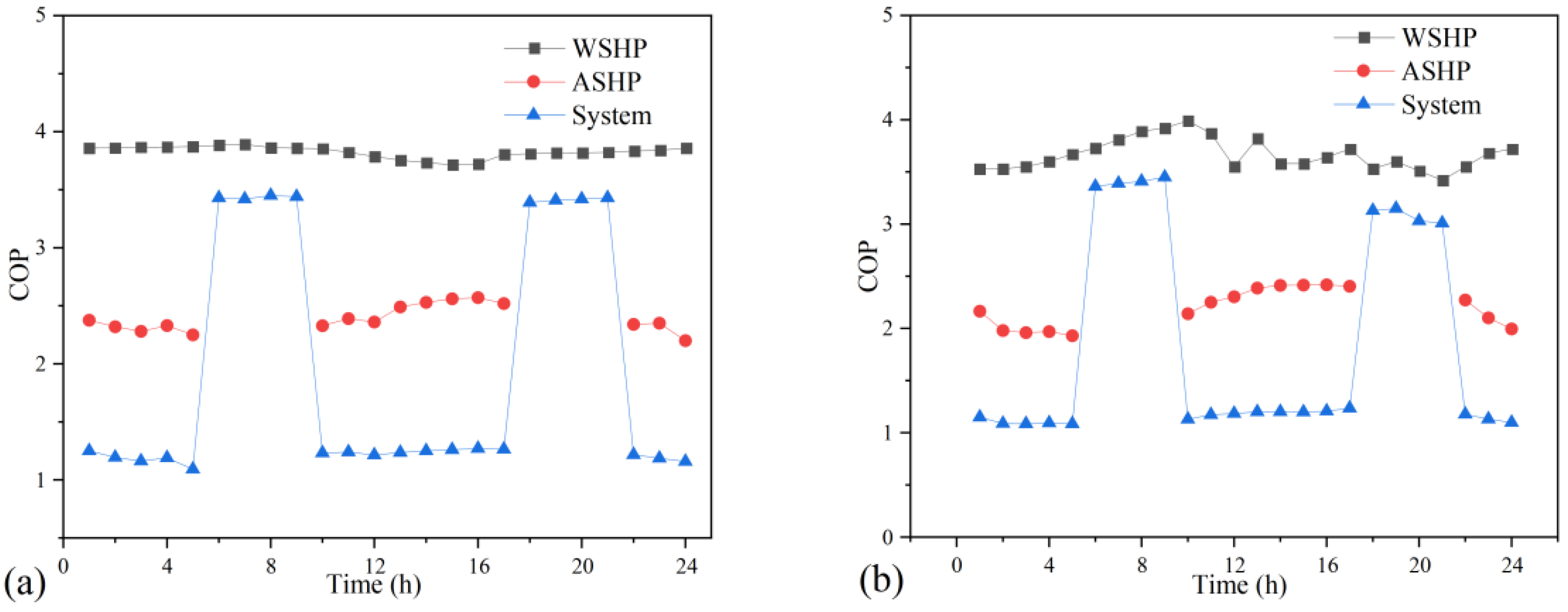

4.4. COPs

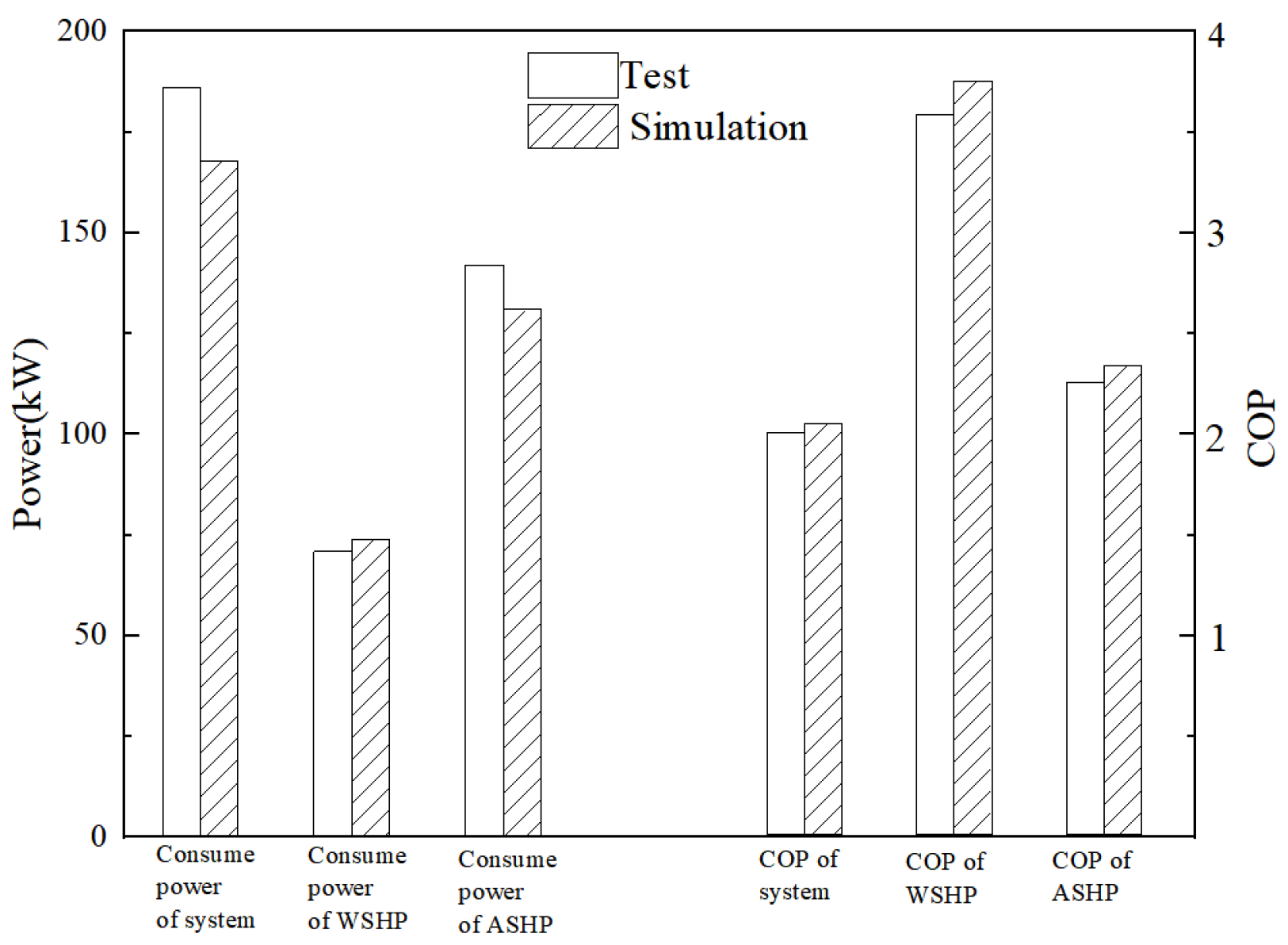

4.5. Comparison between Numerical Results with Test

5. Conclusions

- (1)

- The numerical model and method developed in TRANSYS is practical and validated to calculate the performance of the heating system, even the coupled heat pump system.

- (2)

- Compared to the ASHP and WSHP system, the initial investment, energy and running cost saving effect of the coupled heating system is significantly improved by the introduced accumulator.

- (3)

- The heating system provided would be the promising one to cater to the clean transformation demand for some users such as the middle school mentioned in this paper.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Abduljalil, A.; Al, A.; Mat, S.B.; Sopian, K.; Sulaiman, M.Y.; Lim, C.H.; Abdulrahman, T. Review of thermal energy storage for air conditioning systems. Renew Sust. Energ. Rev. 2012, 16, 5802–5819. [Google Scholar]

- Wu, Y.F. Investigation and analysis of the status quo and trend of building energy efficiency in China. Low Carbon World 2017, 17, 151–152. [Google Scholar]

- Chua, K.J.; Chou, S.K.; Yang, W.M.; Yan, J. Achieving better energy-efficient air conditioning–A review of technologies and strategies. Appl Energ. 2013, 104, 87–104. [Google Scholar] [CrossRef]

- Jiang, Y. China Building Energy Research Report 2020. Build. Energy Effic. 2021, 49, 1–6. [Google Scholar]

- Chua, K.J.; Chou, S.K.; Yang, W.M. Field test investigation of a double-stage coupled heat pumps heating system for cold regions. Int. J. Refrig. 2005, 28, 672–679. [Google Scholar]

- Ozgener, O.; Hepbasli, A. A review on the energy and exergy analysis of solar assisted heat pump systems. Renew Sustain. Energy Rev. 2007, 11, 482–496. [Google Scholar] [CrossRef]

- Ma, J.F.; Qian, Q.K.; Visscher, H.; Song, K. Homeowners’ Participation in Energy Efficient Renovation Projects in China’s Northern Heating Region. Sustainability 2021, 13, 9037. [Google Scholar] [CrossRef]

- Wu, Y.; Meng, Q.; Li, L.; Mu, J.Y. Interaction between Sound and Thermal Influences on Patient Comfort in the Hospitals of China’s Northern Heating Region. Appl. Sci. 2019, 9, 5551. [Google Scholar] [CrossRef]

- Zheng, Z.H.; Zhou, J.; Xu, F.; Zhang, R.; Guang, D. Integrated operation of PV assisted ground source heat pump and air source heat pump system: Performance analysis and economic optimization. Energy Convers. Manag. 2022, 269, 116091. [Google Scholar] [CrossRef]

- Chen, Q.; Li, N. Energy, emissions, economic analysis of air-source heat pump with radiant heating system in hot-summer and cold-winter zone in China. Energy Sustain. Dev. 2022, 70, 10–22. [Google Scholar] [CrossRef]

- Ermel, C.; Bianchi, M.V.A.; Cardoso, A.P.; Schneider, P.S. Thermal storage integrated into air-source heat pumps to leverage building electrification: A systematic literature review. Appl. Therm. Eng. 2022, 215, 118975. [Google Scholar] [CrossRef]

- Lu, S.L.; Feng, W.; Kong, X.F.; Wu, Y. Analysis and case studies of residential heat metering and energy-efficiency retrofits in China’s northern heating region. Renew Sust. Energy Rev. 2014, 38, 765–774. [Google Scholar] [CrossRef]

- Li, S.Y.; Lu, J.; Li, W.Y.; Zhang, Y.Q.; Huang, S.; Tian, L.; Lv, Y.F.; Hu, Y.F.; Zeng, Y.J. Thermodynamic analyses of a novel ejector enhanced dual-temperature air source heat pump cycle with self-defrosting. Appl. Therm. Eng. 2022, 215, 118944. [Google Scholar] [CrossRef]

- Gao, B.; Xiao, Y.Z.; Xiao, J.Y.; Yan, P.Y.; Nan, Y.Y.; Ji, N. Operation performance test and energy efficiency analysis of ground-source heat pump systems. J. Build. Eng. 2021, 41, 102446. [Google Scholar] [CrossRef]

- Shi, F.H. ASHP Technology and Application. HVAC 2019, 49, 86–95. [Google Scholar]

- Xu, W.; Liu, C.P.; Li, A.G.; Li, J.; Qiao, B. Feasibility and performance study on hybrid air source heat pump system for ultra-low energy building in severe cold region of China. Renew. Energy 2020, 146, 2124–2133. [Google Scholar] [CrossRef]

- Ling, J.H.; Tong, H.; Xing, J.C.; Zhao, Y.X. Simulation and optimization of the operation strategy of ASHP heating system: A case study in Tianjin. Energy Build. 2020, 226, 110349. [Google Scholar] [CrossRef]

- Li, X.Y. The Theory and Application of Compressor Intermediate Air-supplement Heat Pump Technology for Heating in Severe Cold Regions of Inner Mongolia. J. Beijing Jiaotong Univ. 2018, 42, 131–136. [Google Scholar]

- Meng, Y.; Sheng, L.; Xue, J.Z.; Yang, Z. Techno-economic analysis of air source heat pump combined with latent thermal energy storage applied for space heating in China. Appl. Therm. Eng. 2021, 185, 116434. [Google Scholar]

- Xu, Z.W.; Zhao, W.Y.; Shao, S.Q.; Wang, Z.C.; Xu, W.; Li, H.; Wang, Y.C.; Wang, W.; Yang, Q.; Xu, C. Analysis on key influence factors of air source heat pumps with field monitored data in Beijing. Sustain. Energy Technol. 2021, 48, 101642. [Google Scholar] [CrossRef]

- Sandra, R.L.C.; José, L.B.A. Phase change materials and energy efficiency of buildings: A review of knowledge. J. Energy Storage 2020, 27, 101083. [Google Scholar]

- Mohanrajab, M.; Karthicka, L.; Dhivagar, R. Performance and economic analysis of a heat pump water heater assisted regenerative solar still using latent heat storage. Appl. Therm. Eng. 2021, 196, 117263. [Google Scholar] [CrossRef]

- Badescu, V. Model of a thermal energy storage device integrated into a solar assisted heat pump system for space heating. Energy Convers. Manag. 2003, 44, 1589–1604. [Google Scholar] [CrossRef]

- Lizana, J.; Friedrich, D.; Renaldi, R.; Chacartegui, R. Energy flexible building through smart demand-side management and latent heat storage. Appl. Energy 2018, 230, 471–485. [Google Scholar] [CrossRef]

- Chu, S.; Wei, J.H.; Liu, Q.M. Scheme design and economic analysis of ground-source heat pump composite water storage system with buried pipes. Build. Energy Effic. 2020, 48, 58–67. [Google Scholar]

- Tang, R.; Wang, F.; Wang, Z.H.; Yang, W.W. Division of Frosting Type and Frosting Degree of the Air Source Heat Pump for Heating in China. Front. Energy Res. 2021, 9, 708478. [Google Scholar] [CrossRef]

- Li, Z.Y.; Wang, W.; Sun, Y.Y.; Wang, S.Q.; Shiming, D.; Yao, L. Applying image recognition to frost built-up detection in air source heat pumps. Energy 2021, 2022, 121004. [Google Scholar] [CrossRef]

- Xu, L.F.; Li, E.T.; Xu, Y.J.; Mao, N.; Shen, X.; Wang, X.L. An experimental energy performance investigation and economic analysis on a cascade heat pump for high-temperature water in cold region. Renew. Energy 2020, 152, 674–683. [Google Scholar] [CrossRef]

- Lin, Y.; Fan, Y.B.; Yu, M.; Jiang, L.; Zhang, X.J. Performance investigation on an air source heat pump system with latent heat thermal energy storage. Energy 2022, 239, 121898. [Google Scholar] [CrossRef]

- Qu, D.H. Research on Characteristics of Solar-Assisted ASHP Energy Storage System. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2017. [Google Scholar]

- Redón, A.; Navarro-Peris, E.; Pitarch, M.; Gonzálvez-Macia, J.; Corberán, J.M. Analysis and optimization of subcritical two-stage vapor injection heat pump systems. Appl. Energy 2014, 124, 231–240. [Google Scholar] [CrossRef]

- Chen, X.; Yang, H. Performance analysis of a proposed solar assisted ground coupled heat pump system. Appl. Energy 2012, 97, 888–896. [Google Scholar] [CrossRef]

- Zhang, J.M.; Yang, H.; Luo, D.W. The operation strategy of the combined system of ground-source heat pump and water storage is redesigned. Gas Heat 2019, 39, 15–25. [Google Scholar]

- Seevers, J.P.; Schlosser, F. Integration of heat pump storage systems in manufacturing systems via data farming and Monte Carlo simulation. Chem. Eng. Trans. 2019, 76, 373–378. [Google Scholar]

- Hirmiz, R.; Teamah, H.M.; Lightstone, M.F.; Cotton, J.S. Performance of heat pump integrated phase change material thermal storage for electric load shifting in building demand side management. Energy Build. 2019, 190, 103–118. [Google Scholar] [CrossRef]

- Chen, H.F.; Li, G.Q.; Ling, Y.Y.; Fu, J.; Wang, Y.J.; Yang, J.; Jiang, L.Y.; Badiei, A.; Zhang, Y. Experimental Analysis of a Solar Energy Storage Heat Pump System. J. Therm. Sci. 2021, 30, 1491–1502. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhao, Y.; Li, N.; Feng, F.; Shi, P.F. A novel solar photovoltaic/thermal assisted gas engine driven energy storage heat pump system (SESGEHPs) and its performance analysis. Energy Convers. Manag. 2019, 184, 301–314. [Google Scholar] [CrossRef]

- Christoph, Z.; Bernd, W.; Michael, L.; Gerwin, D.S. Thomas Leitgeb. Development of an Energy Efficient Extrusion Factory employing a latent heat storage and a high temperature heat pump. Appl. Energy 2020, 259, 114114. [Google Scholar]

- American Society of Heating; Refrigerating and Air-Conditioning Engineers; US Green Building Council; National Association of Home Builders of the United States. National Green Building Standard: ANSI/ASHRAE/NAHB/ICC Standard ICC/ASHRAE 700-2015; National Association of Home Builders of the United States: Washington, DC, USA, 2016; pp. 1–76. [Google Scholar]

- Wang, Y.B.; Quan, Z.H.; Jing, H.R.; Wang, L.C.; Zhao, Y.H. Performance and operation strategy optimization of a new dual-source building energy supply system with heat pumps and energy storage. Energy Convers. Manag. 2021, 239, 114204. [Google Scholar] [CrossRef]

| Model | ASHP | Accumulator | WSHP | Period |

|---|---|---|---|---|

| 1 | working | Heat recharge | working | 10:00 a.m.–6:00 p.m. |

| 2 | stop | Heat release | working | 6:00 p.m.–10:00 p.m. |

| 3 | working | Heat recharge | working | 10:00 p.m.–6:00 a.m. |

| 4 | stop | Heat release | working | 6:00 a.m.–10:00 a.m. |

| No. | Device Name | Parameter | Quantity |

|---|---|---|---|

| 1 | WSHP | max heating capacity: 390 kW, max input power: 80 kW | 1 |

| 2 | ASHP 1 | max heating capacity: 300 kW, max input power: 120 kW | 1 |

| 3 | ASHP 2 | max heating capacity: 150 kW, max input power: 60 kW | 1 |

| 4 | circulating pump of ASHP | rated input power: 10 kW | 2 |

| 5 | circulating pump of WSHP | rated input power: 10 kW | 2 |

| 6 | accumulator | capacity: 293 kW | 4 |

| Parameters | Instruments | Types | Accuracy | Quantity |

|---|---|---|---|---|

| Outdoor temperature | Thermometer | LGR-WD01u | ±0.2–0.5 °C | 1 |

| Thermal resistance sensor | WZP-230 | PT100, Level A | 1 | |

| Indoor temperature | Thermometer | LGR-WD01u | ±0.2–0.5 °C | 6 |

| Flow rate and water temperature | Ultrasound calorimeter (temperature probe and flow probe) | TDS-100 | 2–3% | 6 |

| TDS-100 | 2–3% | |||

| Power consumption | Smarter meter | CHTK900E-3S4 | 1 W | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, W.; Wang, B.; Wang, M.; Chen, Y. Performance Analysis of the Coupled Heating System of the Air-Source Heat Pump, the Energy Accumulator and the Water-Source Heat Pump. Energies 2022, 15, 7305. https://doi.org/10.3390/en15197305

Zhou W, Wang B, Wang M, Chen Y. Performance Analysis of the Coupled Heating System of the Air-Source Heat Pump, the Energy Accumulator and the Water-Source Heat Pump. Energies. 2022; 15(19):7305. https://doi.org/10.3390/en15197305

Chicago/Turabian StyleZhou, Wenhe, Bin Wang, Meng Wang, and Yuying Chen. 2022. "Performance Analysis of the Coupled Heating System of the Air-Source Heat Pump, the Energy Accumulator and the Water-Source Heat Pump" Energies 15, no. 19: 7305. https://doi.org/10.3390/en15197305

APA StyleZhou, W., Wang, B., Wang, M., & Chen, Y. (2022). Performance Analysis of the Coupled Heating System of the Air-Source Heat Pump, the Energy Accumulator and the Water-Source Heat Pump. Energies, 15(19), 7305. https://doi.org/10.3390/en15197305